general NISSAN TERRANO 2002 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 1215 of 1767

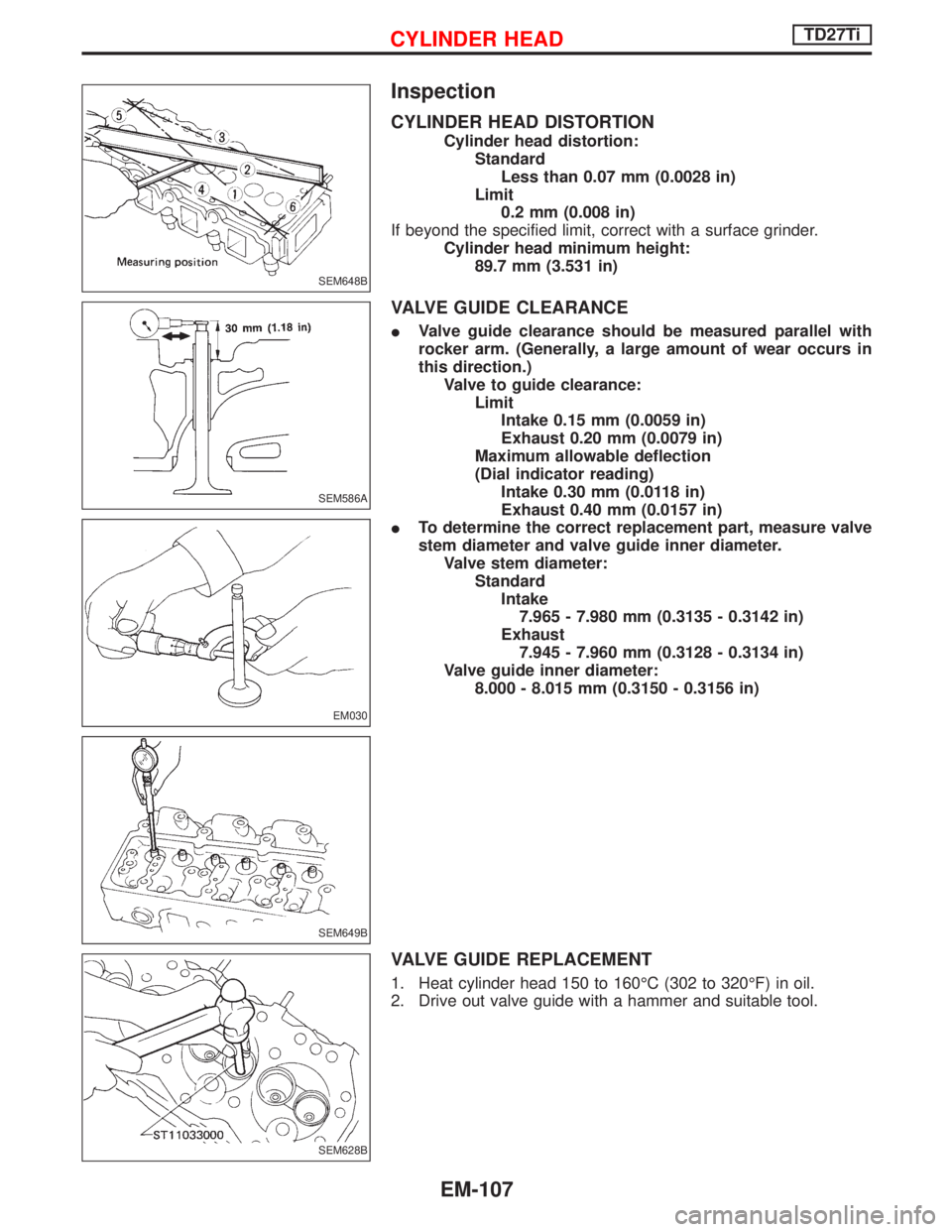

Inspection

CYLINDER HEAD DISTORTION

Cylinder head distortion:

Standard

Less than 0.07 mm (0.0028 in)

Limit

0.2 mm (0.008 in)

If beyond the specified limit, correct with a surface grinder.

Cylinder head minimum height:

89.7 mm (3.531 in)

VALVE GUIDE CLEARANCE

IValve guide clearance should be measured parallel with

rocker arm. (Generally, a large amount of wear occurs in

this direction.)

Valve to guide clearance:

Limit

Intake 0.15 mm (0.0059 in)

Exhaust 0.20 mm (0.0079 in)

Maximum allowable deflection

(Dial indicator reading)

Intake 0.30 mm (0.0118 in)

Exhaust 0.40 mm (0.0157 in)

ITo determine the correct replacement part, measure valve

stem diameter and valve guide inner diameter.

Valve stem diameter:

Standard

Intake

7.965 - 7.980 mm (0.3135 - 0.3142 in)

Exhaust

7.945 - 7.960 mm (0.3128 - 0.3134 in)

Valve guide inner diameter:

8.000 - 8.015 mm (0.3150 - 0.3156 in)

VALVE GUIDE REPLACEMENT

1. Heat cylinder head 150 to 160ÉC (302 to 320ÉF) in oil.

2. Drive out valve guide with a hammer and suitable tool.

SEM648B

SEM586A

EM030

SEM649B

SEM628B

CYLINDER HEADTD27Ti

EM-107

Page 1251 of 1767

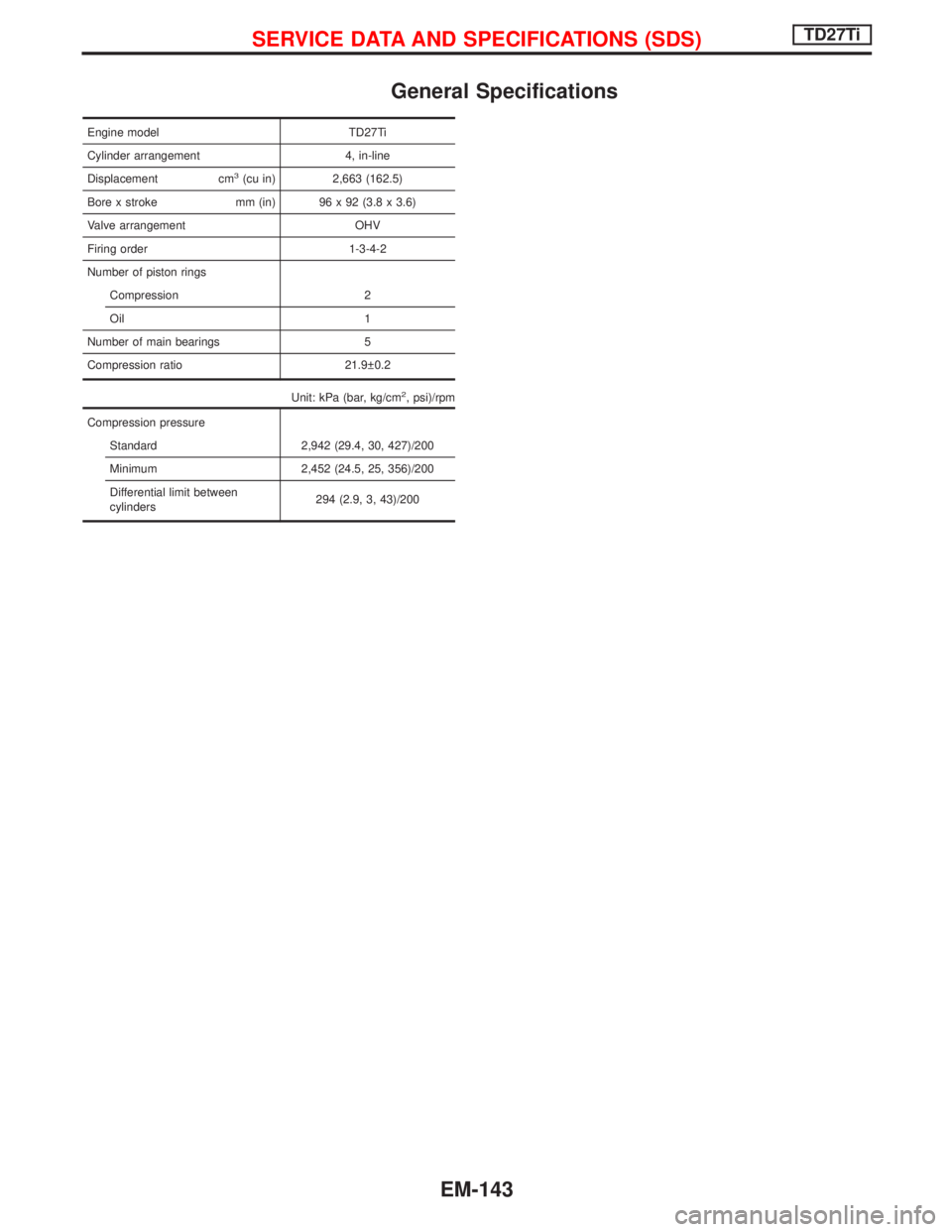

General Specifications

Engine model TD27Ti

Cylinder arrangement 4, in-line

Displacement cm

3(cu in) 2,663 (162.5)

Bore x stroke mm (in) 96 x 92 (3.8 x 3.6)

Valve arrangement OHV

Firing order 1-3-4-2

Number of piston rings

Compression 2

Oil 1

Number of main bearings 5

Compression ratio 21.9 0.2

Unit: kPa (bar, kg/cm

2, psi)/rpm

Compression pressure

Standard 2,942 (29.4, 30, 427)/200

Minimum 2,452 (24.5, 25, 356)/200

Differential limit between

cylinders294 (2.9, 3, 43)/200

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

EM-143

Page 1259 of 1767

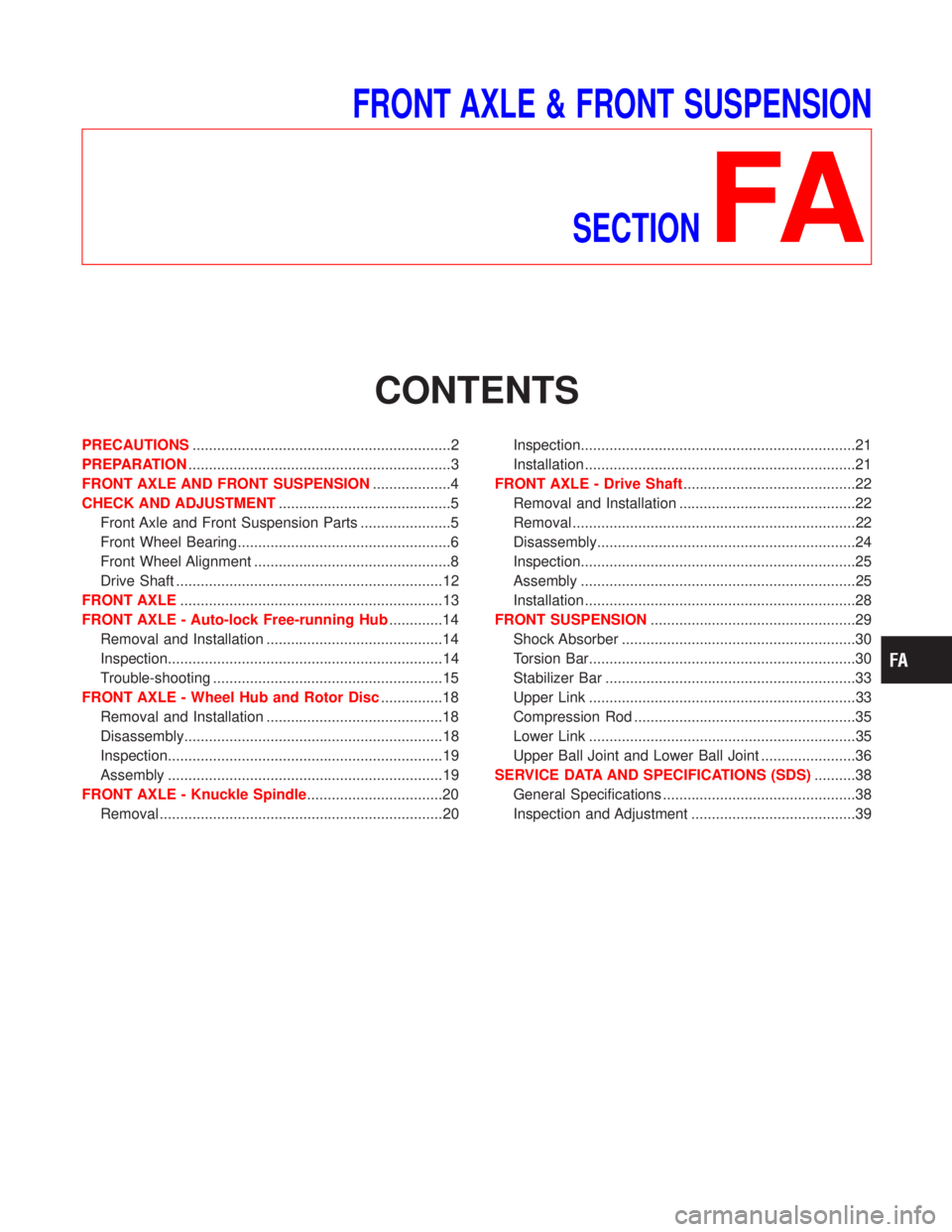

FRONT AXLE & FRONT SUSPENSION

SECTION

FA

CONTENTS

PRECAUTIONS...............................................................2

PREPARATION................................................................3

FRONT AXLE AND FRONT SUSPENSION...................4

CHECK AND ADJUSTMENT..........................................5

Front Axle and Front Suspension Parts ......................5

Front Wheel Bearing....................................................6

Front Wheel Alignment ................................................8

Drive Shaft .................................................................12

FRONT AXLE................................................................13

FRONT AXLE - Auto-lock Free-running Hub.............14

Removal and Installation ...........................................14

Inspection...................................................................14

Trouble-shooting ........................................................15

FRONT AXLE - Wheel Hub and Rotor Disc...............18

Removal and Installation ...........................................18

Disassembly...............................................................18

Inspection...................................................................19

Assembly ...................................................................19

FRONT AXLE - Knuckle Spindle.................................20

Removal .....................................................................20Inspection...................................................................21

Installation ..................................................................21

FRONT AXLE - Drive Shaft..........................................22

Removal and Installation ...........................................22

Removal .....................................................................22

Disassembly...............................................................24

Inspection...................................................................25

Assembly ...................................................................25

Installation ..................................................................28

FRONT SUSPENSION..................................................29

Shock Absorber .........................................................30

Torsion Bar.................................................................30

Stabilizer Bar .............................................................33

Upper Link .................................................................33

Compression Rod ......................................................35

Lower Link .................................................................35

Upper Ball Joint and Lower Ball Joint .......................36

SERVICE DATA AND SPECIFICATIONS (SDS)..........38

General Specifications ...............................................38

Inspection and Adjustment ........................................39

Page 1296 of 1767

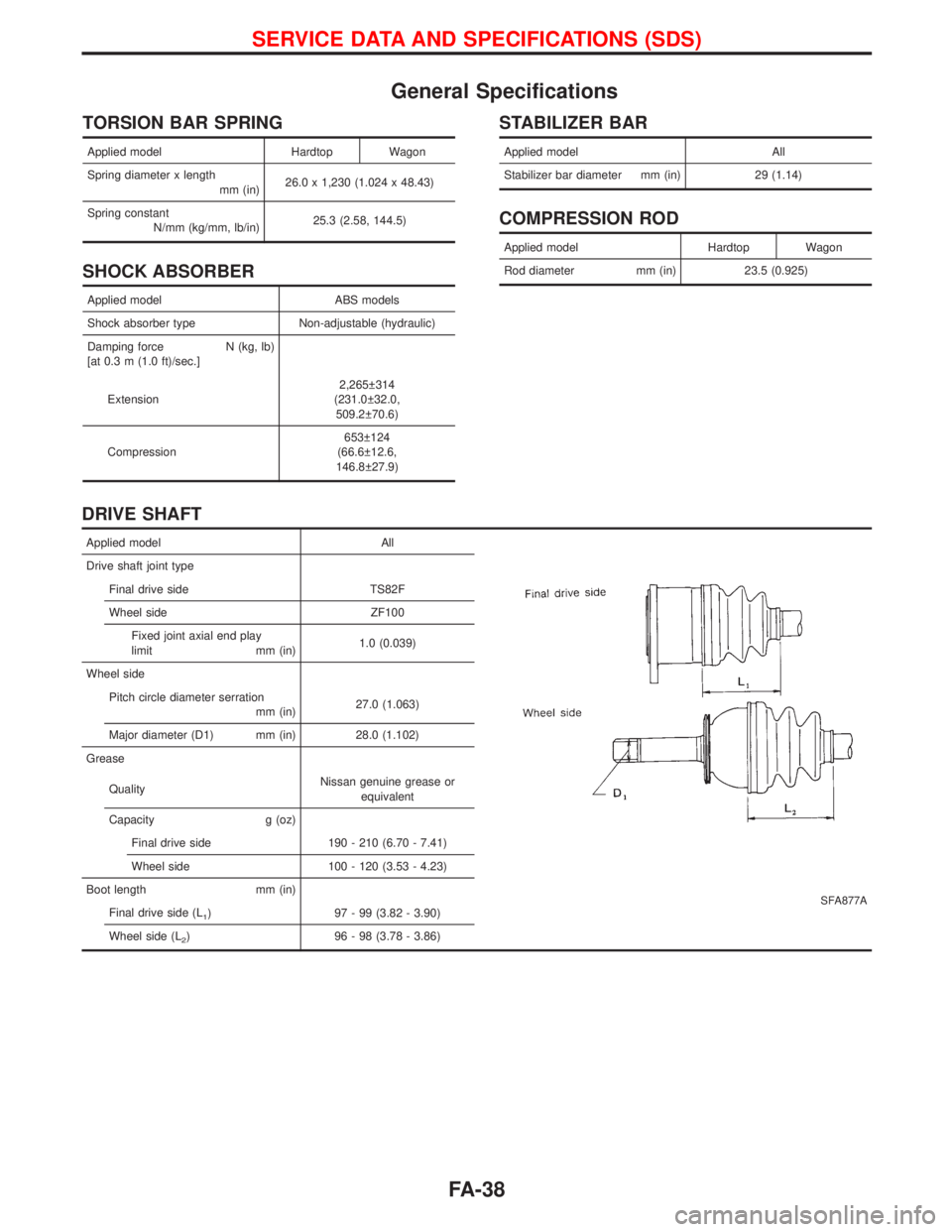

General Specifications

TORSION BAR SPRING

Applied model Hardtop Wagon

Spring diameter x length

mm (in)26.0 x 1,230 (1.024 x 48.43)

Spring constant

N/mm (kg/mm, lb/in)25.3 (2.58, 144.5)

SHOCK ABSORBER

Applied model ABS models

Shock absorber type Non-adjustable (hydraulic)

Damping force N (kg, lb)

[at 0.3 m (1.0 ft)/sec.]

Extension2,265 314

(231.0 32.0,

509.2 70.6)

Compression653 124

(66.6 12.6,

146.8 27.9)

STABILIZER BAR

Applied model All

Stabilizer bar diameter mm (in) 29 (1.14)

COMPRESSION ROD

Applied model Hardtop Wagon

Rod diameter mm (in) 23.5 (0.925)

DRIVE SHAFT

Applied model All

SFA877A

Drive shaft joint type

Final drive side TS82F

Wheel side ZF100

Fixed joint axial end play

limit mm (in)1.0 (0.039)

Wheel side

Pitch circle diameter serration

mm (in)27.0 (1.063)

Major diameter (D1) mm (in) 28.0 (1.102)

Grease

QualityNissan genuine grease or

equivalent

Capacity g (oz)

Final drive side 190 - 210 (6.70 - 7.41)

Wheel side 100 - 120 (3.53 - 4.23)

Boot length mm (in)

Final drive side (L

1) 97 - 99 (3.82 - 3.90)

Wheel side (L

2) 96 - 98 (3.78 - 3.86)

SERVICE DATA AND SPECIFICATIONS (SDS)

FA-38

Page 1316 of 1767

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²

(Dual Air Bag System) .................................................3

Precautions for NATS ..................................................4

Precautions for Multiport Fuel Injection System

or Engine Control System ...........................................5

Precautions for Catalyst ..............................................5

Precautions for Turbocharger ......................................5

Precautions for Fuel ....................................................6

Precautions for Engine Oils .........................................6

HOW TO USE THIS MANUAL........................................8

HOW TO READ WIRING DIAGRAMS..........................10

Sample/Wiring Diagram - EXAMPL - ........................10

Description .................................................................12

HOW TO CHECK TERMINAL.......................................19

How to Probe Connectors .........................................19

How to Check Enlarged Contact Spring of

Terminal .....................................................................20

Waterproof Connector Inspection ..............................21

Terminal Lock Inspection ...........................................21

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT........................................22Work Flow ..................................................................22

Incident Simulation Tests ...........................................23

HOW TO FOLLOW FLOW CHART IN TROUBLE

DIAGNOSES..................................................................25

CONSULT-II CHECKING SYSTEM...............................26

General ......................................................................26

Function and System Application ..............................26

Nickel Metal Hydride Battery Replacement...............27

Checking Equipment..................................................27

IDENTIFICATION INFORMATION.................................28

Model Variation ..........................................................28

Identification Number .................................................29

Dimensions ................................................................31

Wheels and Tires .......................................................31

LIFTING POINTS AND TOW TRUCK TOWING...........32

Garage Jack and Safety Stand .................................32

Screw Jack ................................................................32

4-pole Lift ...................................................................33

Tow Truck Towing ......................................................33

ISO 15031-2 TERMINOLOGY LIST..............................35

ISO 15031-2 Terminology List ...................................35

TIGHTENING TORQUE OF STANDARD BOLTS........38

Page 1341 of 1767

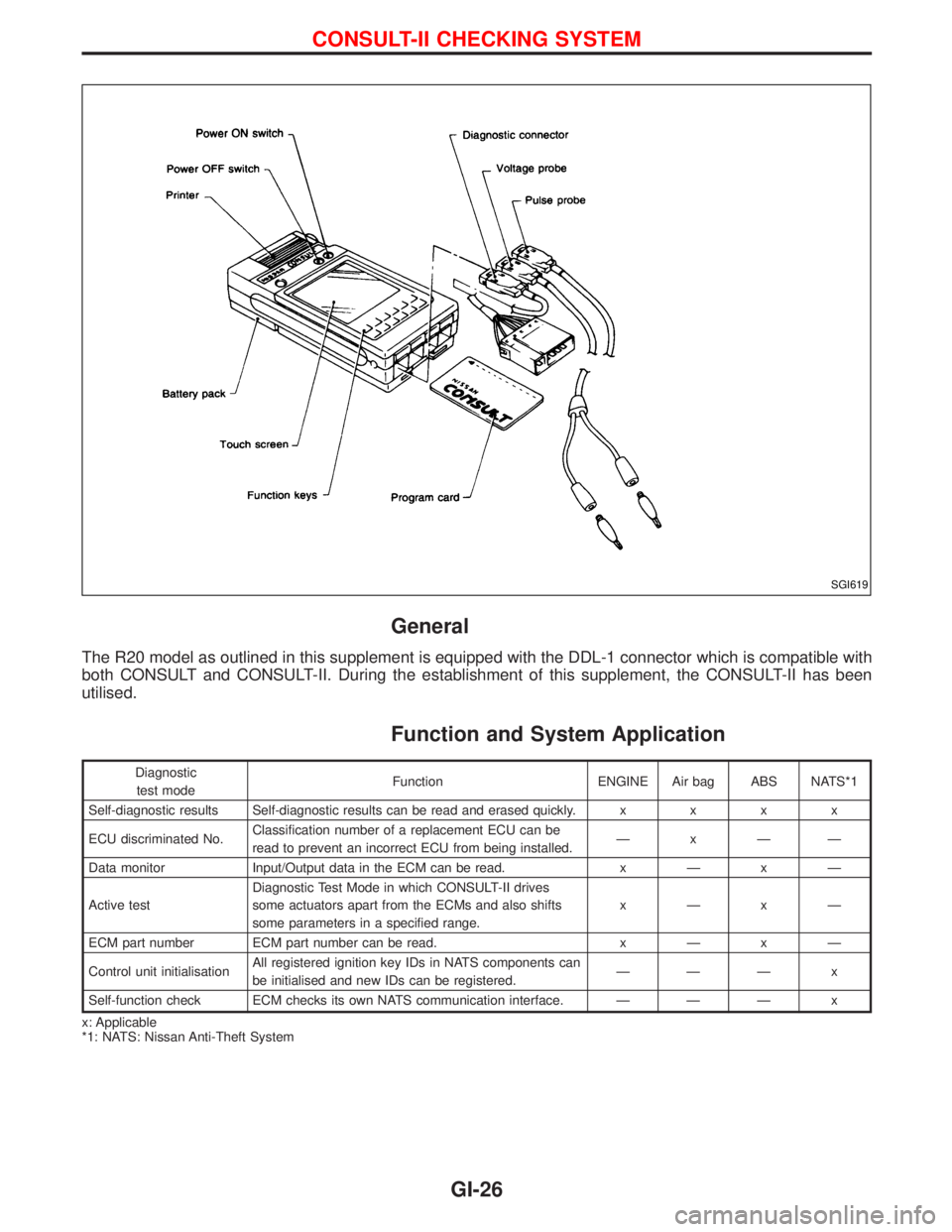

General

The R20 model as outlined in this supplement is equipped with the DDL-1 connector which is compatible with

both CONSULT and CONSULT-II. During the establishment of this supplement, the CONSULT-II has been

utilised.

Function and System Application

Diagnostic

test modeFunction ENGINE Air bag ABS NATS*1

Self-diagnostic results Self-diagnostic results can be read and erased quickly.xxxx

ECU discriminated No.Classification number of a replacement ECU can be

read to prevent an incorrect ECU from being installed.ÐxÐÐ

Data monitor Input/Output data in the ECM can be read.xÐxÐ

Active testDiagnostic Test Mode in which CONSULT-II drives

some actuators apart from the ECMs and also shifts

some parameters in a specified range.xÐxÐ

ECM part number ECM part number can be read.xÐxÐ

Control unit initialisationAll registered ignition key IDs in NATS components can

be initialised and new IDs can be registered.ÐÐÐ x

Self-function check ECM checks its own NATS communication interface. Ð Ð Ð x

x: Applicable

*1: NATS: Nissan Anti-Theft System

SGI619

CONSULT-II CHECKING SYSTEM

GI-26

Page 1354 of 1767

HEATER & AIR CONDITIONER

SECTION

HA

CONTENTS

PRECAUTIONS...............................................................2

Introduction ..................................................................2

Identification .................................................................2

Precautions for Working with HFC-134a (R-134a) .....3

General Refrigerant Precautions .................................3

Precautions for Refrigerant Connection ......................4

Precautions for Servicing Compressor ........................5

DESCRIPTION - Overall System...................................6

Control Operation ........................................................6

Component Layout ......................................................7

Air Flow ........................................................................8

DESCRIPTION - Refrigeration System.........................9

Refrigeration Cycle ......................................................9

PREPARATION..............................................................10

Special Service Tools ................................................10

HFC-134a (R-134a) Service Tools and

Equipment .................................................................. 11

Precautions for Service Equipment ...........................13

SERVICE PROCEDURES.............................................15

HFC-134a (R-134a) Service Procedure ....................15

Refrigerant Lines .......................................................17

Compressor Mounting ...............................................21

Belt Tension ...............................................................21

LUBRICATION OIL - Checking and Adjusting...........22

Lubrication Oil ............................................................22Maintenance of Oil Quantity in Compressor .............22

Checking and Adjusting .............................................22

COMPRESSOR - Model DKV-14C (ZEXEL make)......24

Compressor Clutch ....................................................24

DIAGNOSES - Overall System....................................27

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................27

Operation Check ........................................................28

Performance Chart ....................................................30

Performance Test Diagnoses ....................................31

TROUBLE DIAGNOSES...............................................36

Symptom Chart ..........................................................36

Preliminary Check......................................................37

Harness Layout for A/C System ................................39

Wiring Diagram - Heater............................................41

Wiring Diagram ..........................................................43

Main Power Supply and Ground Circuit Check ........51

Diagnostic Procedure 1 .............................................52

Diagnostic Procedure 2 .............................................54

Diagnostic Procedure 3 .............................................59

Electrical Components Inspection .............................60

Control Linkage Adjustment.......................................61

SERVICE DATA AND SPECIFICATIONS (SDS)..........64

General Specifications ...............................................64

Inspection and Adjustment ........................................64

When you read wiring diagrams:

IRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

ISee EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSESº.

Page 1356 of 1767

Precautions for Working with HFC-134a

(R-134a)

WARNING:

ICFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant must never be mixed, even in the

smallest amounts, as they are incompatible with each other. If the refrigerants are mixed, com-

pressor failure is likely to occur.

IUse only specified lubrication oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a)

components. If lubrication oil other than that specified is used, compressor failure is likely to

occur.

IThe specified HFC-134a (R-134a) lubrication oil absorbs moisture from the atmosphere at a rapid

rate, therefore the following handling precautions must be observed:

a: When removing refrigerant components from a vehicle, immediately cap (seal) the component

to minimize the entry of moisture from the atmosphere.

b: When installing refrigerant components to a vehicle, do not remove the caps (unseal) until

just before connecting the components. Also, complete the connection of all refrigerant loop

components as quickly as possible to minimize the entry of moisture into the system.

c: Use the specified lubrication oil from a sealed container only. Containers must be re-sealed

immediately after dispensing the lubrication oil. Lubrication oil in containers which are not

properly sealed will become moisture saturated, and such lubrication oil is no longer suitable

for use and should be properly disposed of.

d: Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose

and throat. Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a)

system. If accidental system discharge occurs, ventilate work area before resuming service.

Additional health and safety information may be obtained from refrigerant and lubricant

manufacturers.

e: Do not allow lubrication oil (Nissan A/C System Oil Type S or Type R) to come in contact with

styrofoam parts. Damage may result.

General Refrigerant Precautions

WARNING:

IDo not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

IAlways wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

IDo not store or heat refrigerant containers above 52ÉC (125ÉF).

IDo not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

IDo not drop, puncture, or incinerate refrigerant containers.

IKeep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

IRefrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent

suffocation.

IDo not introduce compressed air to any refrigerant container or refrigerant component.

PRECAUTIONS

HA-3

Page 1367 of 1767

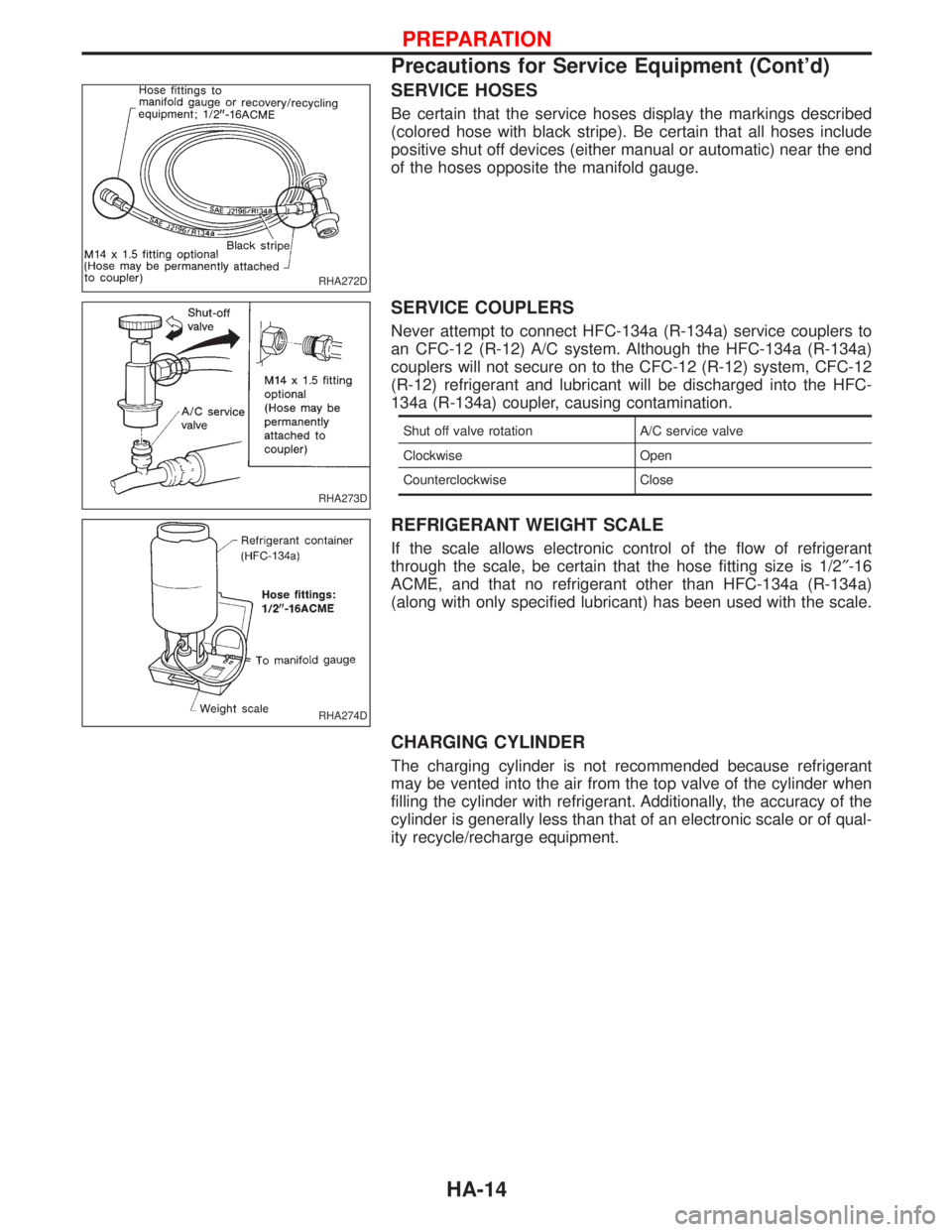

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). Be certain that all hoses include

positive shut off devices (either manual or automatic) near the end

of the hoses opposite the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to

an CFC-12 (R-12) A/C system. Although the HFC-134a (R-134a)

couplers will not secure on to the CFC-12 (R-12) system, CFC-12

(R-12) refrigerant and lubricant will be discharged into the HFC-

134a (R-134a) coupler, causing contamination.

Shut off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

REFRIGERANT WEIGHT SCALE

If the scale allows electronic control of the flow of refrigerant

through the scale, be certain that the hose fitting size is 1/2²-16

ACME, and that no refrigerant other than HFC-134a (R-134a)

(along with only specified lubricant) has been used with the scale.

CHARGING CYLINDER

The charging cylinder is not recommended because refrigerant

may be vented into the air from the top valve of the cylinder when

filling the cylinder with refrigerant. Additionally, the accuracy of the

cylinder is generally less than that of an electronic scale or of qual-

ity recycle/recharge equipment.

RHA272D

RHA273D

RHA274D

PREPARATION

Precautions for Service Equipment (Cont'd)

HA-14

Page 1417 of 1767

General Specifications

COMPRESSOR

Model DKV-14C

Type Vane rotary

Displacement cm

3(cu in)/Rev 140 (8.54)

Direction of rotationClockwise

(Viewed from drive end)

Drive belt A type

LUBRICATION OIL

ModelZEXEL make

DKV-14C

NameNissan A/C System Oil

Type R

Part number KLH00-PAGR0

Capacity m(Imp fl oz)

Total in system 200 (7.0)

Compressor (Service parts)

charging amount200 (7.0)

REFRIGERANT

Type R134a

Capacity kg (lb) 0.70 - 0.80 (1.54 - 1.76)

Inspection and Adjustment

ENGINE IDLING SPEED

When A/C is ON

Refer to EF & EC section.

BELT TENSION

Refer to Checking Drive Belts (MA section).

COMPRESSOR

Model DKV-14C

Clutch disc-to-pulley clearance

mm (in)0.3 - 0.6

(0.012 - 0.024)

SERVICE DATA AND SPECIFICATIONS (SDS)

HA-64