ecu NISSAN TERRANO 2004 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 122 of 1833

3. Remove injection tube and injection nozzle assembly. Refer toEC section, ªInjection Tube and Injection Nozzleº in ªBASIC

SERVICE PROCEDUREº.

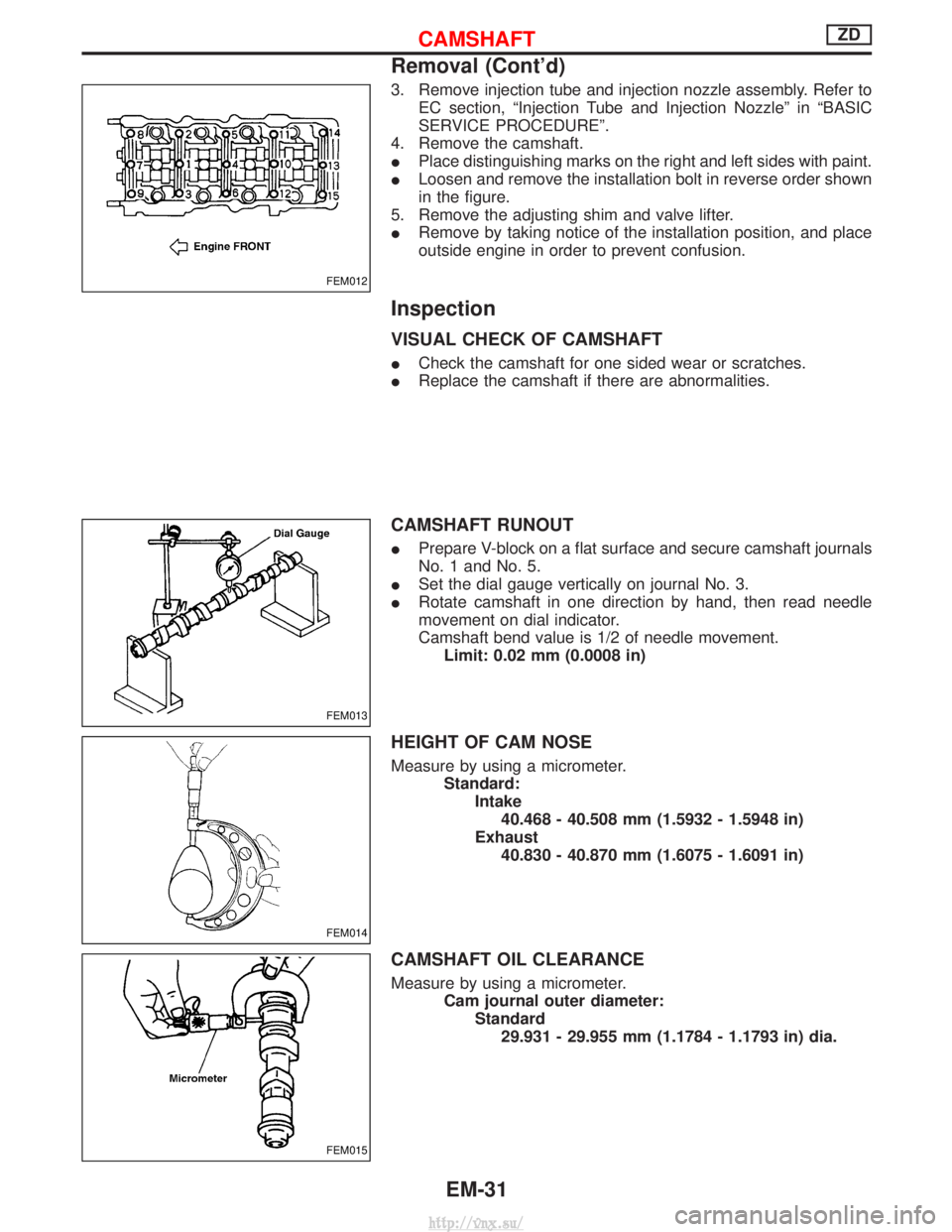

4. Remove the camshaft.

I Place distinguishing marks on the right and left sides with paint.

I Loosen and remove the installation bolt in reverse order shown

in the figure.

5. Remove the adjusting shim and valve lifter.

I Remove by taking notice of the installation position, and place

outside engine in order to prevent confusion.

Inspection

VISUAL CHECK OF CAMSHAFT

ICheck the camshaft for one sided wear or scratches.

I Replace the camshaft if there are abnormalities.

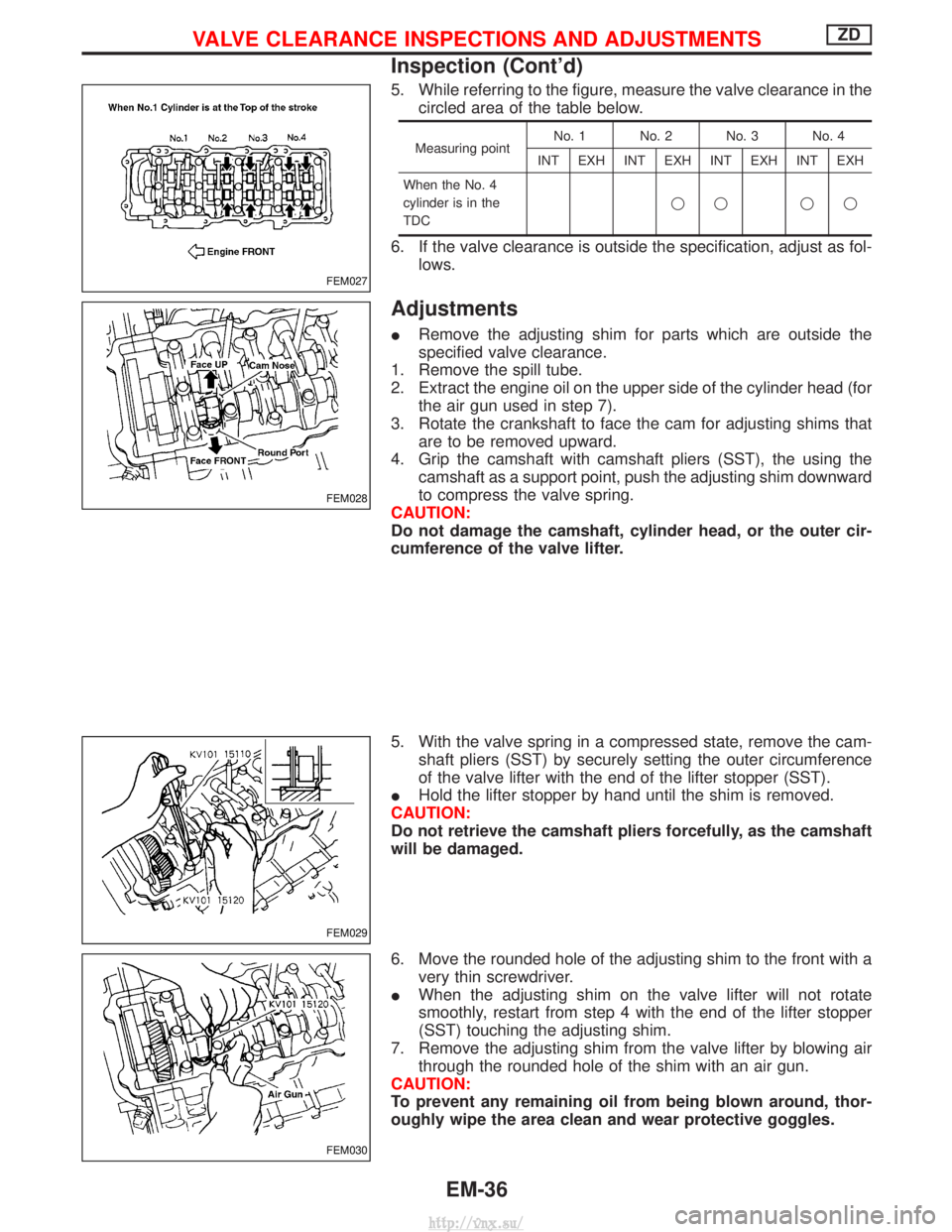

CAMSHAFT RUNOUT

IPrepare V-block on a flat surface and secure camshaft journals

No. 1 and No. 5.

I Set the dial gauge vertically on journal No. 3.

I Rotate camshaft in one direction by hand, then read needle

movement on dial indicator.

Camshaft bend value is 1/2 of needle movement.

Limit: 0.02 mm (0.0008 in)

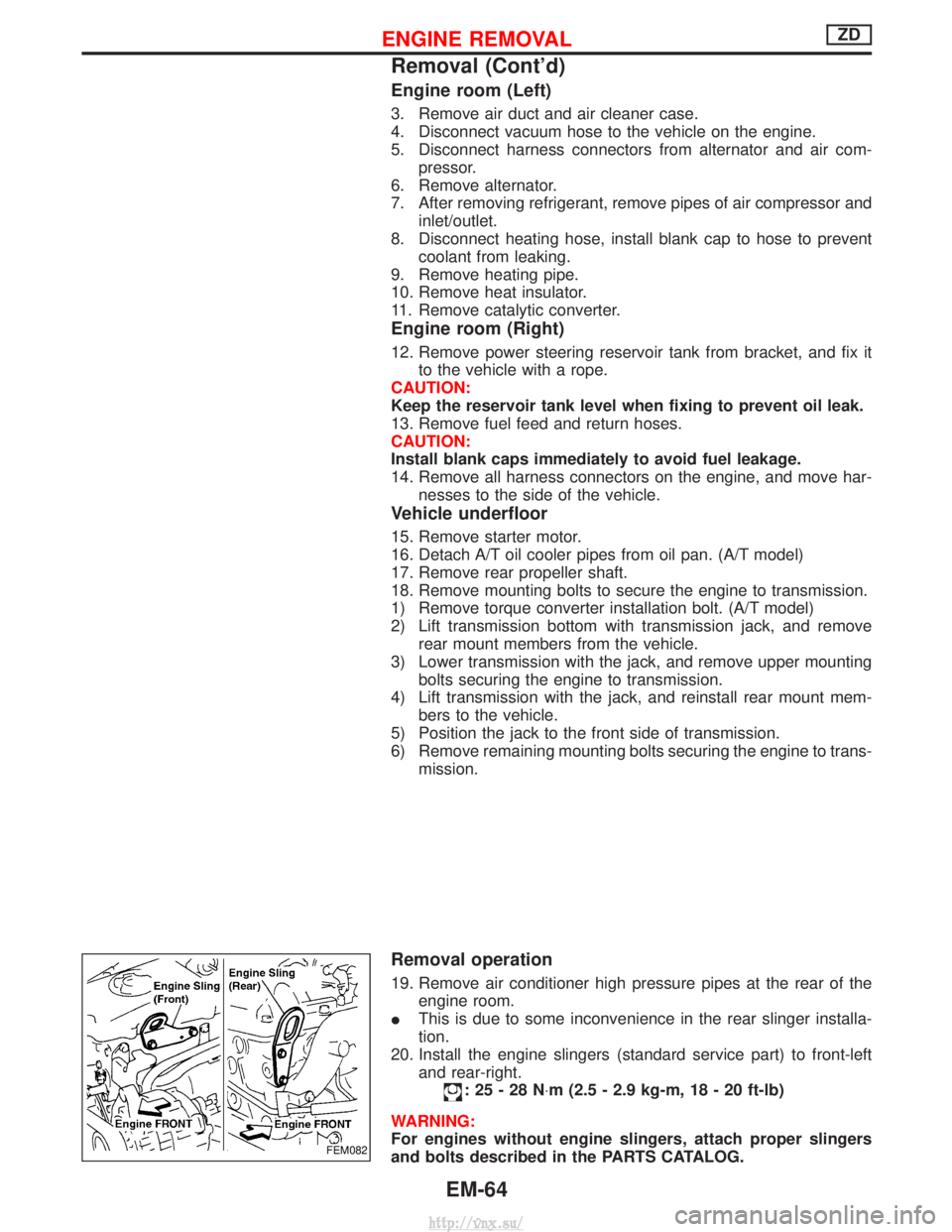

HEIGHT OF CAM NOSE

Measure by using a micrometer. Standard:Intake40.468 - 40.508 mm (1.5932 - 1.5948 in)

Exhaust 40.830 - 40.870 mm (1.6075 - 1.6091 in)

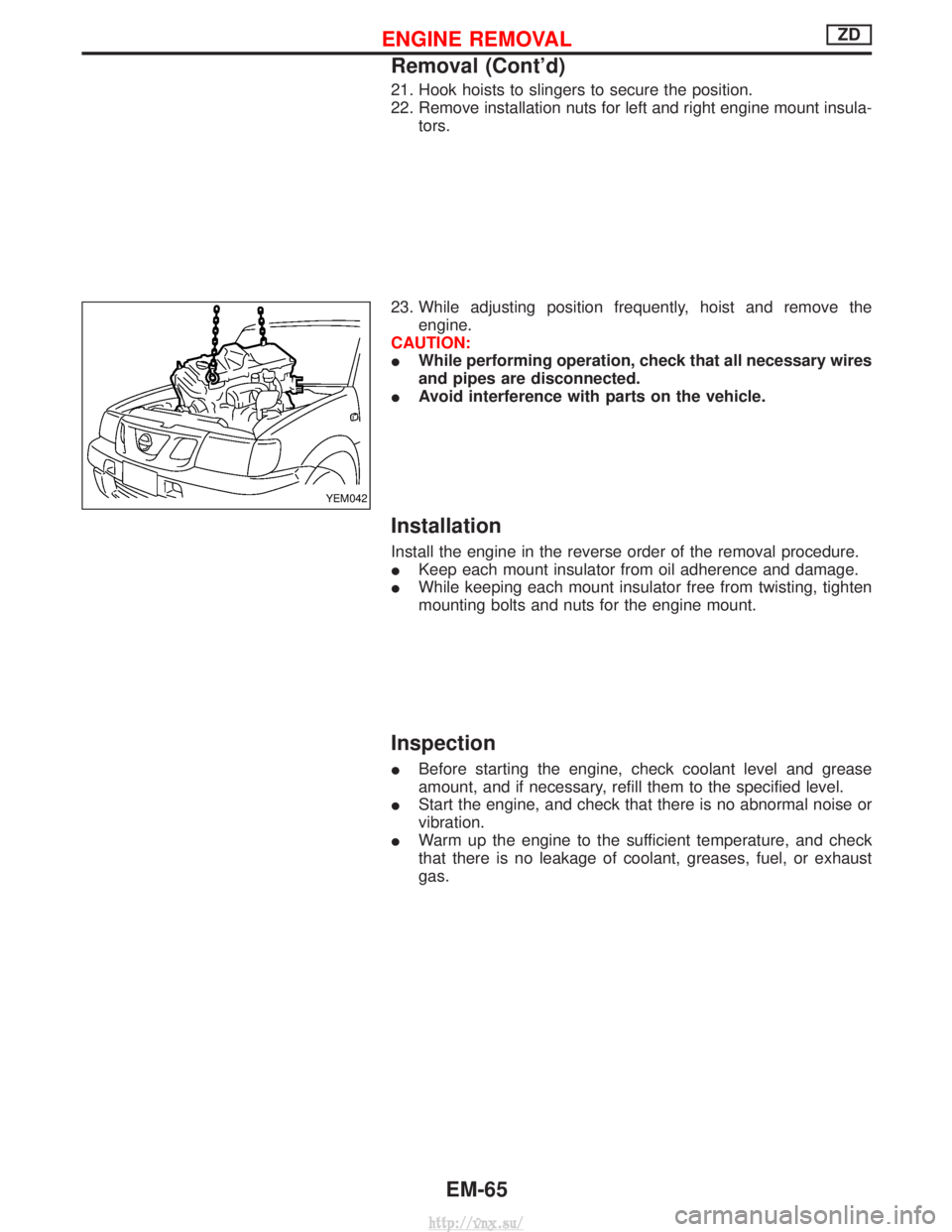

CAMSHAFT OIL CLEARANCE

Measure by using a micrometer. Cam journal outer diameter:Standard29.931 - 29.955 mm (1.1784 - 1.1793 in) dia.

FEM012

FEM013

FEM014

FEM015

CAMSHAFTZD

Removal (Cont'd)

EM-31

http://vnx.su/

Page 127 of 1833

5. While referring to the figure, measure the valve clearance in thecircled area of the table below.

Measuring point No. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 4

cylinder is in the

TDC qq qq

6. If the valve clearance is outside the specification, adjust as fol-

lows.

Adjustments

IRemove the adjusting shim for parts which are outside the

specified valve clearance.

1. Remove the spill tube.

2. Extract the engine oil on the upper side of the cylinder head (for the air gun used in step 7).

3. Rotate the crankshaft to face the cam for adjusting shims that are to be removed upward.

4. Grip the camshaft with camshaft pliers (SST), the using the camshaft as a support point, push the adjusting shim downward

to compress the valve spring.

CAUTION:

Do not damage the camshaft, cylinder head, or the outer cir-

cumference of the valve lifter.

5. With the valve spring in a compressed state, remove the cam- shaft pliers (SST) by securely setting the outer circumference

of the valve lifter with the end of the lifter stopper (SST).

I Hold the lifter stopper by hand until the shim is removed.

CAUTION:

Do not retrieve the camshaft pliers forcefully, as the camshaft

will be damaged.

6. Move the rounded hole of the adjusting shim to the front with a very thin screwdriver.

I When the adjusting shim on the valve lifter will not rotate

smoothly, restart from step 4 with the end of the lifter stopper

(SST) touching the adjusting shim.

7. Remove the adjusting shim from the valve lifter by blowing air through the rounded hole of the shim with an air gun.

CAUTION:

To prevent any remaining oil from being blown around, thor-

oughly wipe the area clean and wear protective goggles.

FEM027

FEM028

FEM029

FEM030

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

Inspection (Cont'd)

EM-36

http://vnx.su/

Page 155 of 1833

Engine room (Left)

3. Remove air duct and air cleaner case.

4. Disconnect vacuum hose to the vehicle on the engine.

5. Disconnect harness connectors from alternator and air com-pressor.

6. Remove alternator.

7. After removing refrigerant, remove pipes of air compressor and inlet/outlet.

8. Disconnect heating hose, install blank cap to hose to prevent coolant from leaking.

9. Remove heating pipe.

10. Remove heat insulator.

11. Remove catalytic converter.

Engine room (Right)

12. Remove power steering reservoir tank from bracket, and fix it to the vehicle with a rope.

CAUTION:

Keep the reservoir tank level when fixing to prevent oil leak.

13. Remove fuel feed and return hoses.

CAUTION:

Install blank caps immediately to avoid fuel leakage.

14. Remove all harness connectors on the engine, and move har- nesses to the side of the vehicle.

Vehicle underfloor

15. Remove starter motor.

16. Detach A/T oil cooler pipes from oil pan. (A/T model)

17. Remove rear propeller shaft.

18. Remove mounting bolts to secure the engine to transmission.

1) Remove torque converter installation bolt. (A/T model)

2) Lift transmission bottom with transmission jack, and removerear mount members from the vehicle.

3) Lower transmission with the jack, and remove upper mounting bolts securing the engine to transmission.

4) Lift transmission with the jack, and reinstall rear mount mem- bers to the vehicle.

5) Position the jack to the front side of transmission.

6) Remove remaining mounting bolts securing the engine to trans- mission.

Removal operation

19. Remove air conditioner high pressure pipes at the rear of theengine room.

I This is due to some inconvenience in the rear slinger installa-

tion.

20. Install the engine slingers (standard service part) to front-left and rear-right.

:25-28N ×m (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

WARNING:

For engines without engine slingers, attach proper slingers

and bolts described in the PARTS CATALOG.

FEM082

ENGINE REMOVALZD

Removal (Cont'd)

EM-64

http://vnx.su/

Page 156 of 1833

21. Hook hoists to slingers to secure the position.

22. Remove installation nuts for left and right engine mount insula-tors.

23. While adjusting position frequently, hoist and remove the engine.

CAUTION:

I While performing operation, check that all necessary wires

and pipes are disconnected.

I Avoid interference with parts on the vehicle.

Installation

Install the engine in the reverse order of the removal procedure.

IKeep each mount insulator from oil adherence and damage.

I While keeping each mount insulator free from twisting, tighten

mounting bolts and nuts for the engine mount.

Inspection

IBefore starting the engine, check coolant level and grease

amount, and if necessary, refill them to the specified level.

I Start the engine, and check that there is no abnormal noise or

vibration.

I Warm up the engine to the sufficient temperature, and check

that there is no leakage of coolant, greases, fuel, or exhaust

gas.

YEM042

ENGINE REMOVALZD

Removal (Cont'd)

EM-65

http://vnx.su/

Page 158 of 1833

Selection Procedure for Selective Part

Combination

LocationSelective part combination ItemMethod

Cylinder block - piston Piston and piston assembly

(Part No. is given to a piston and piston pin as a set.) Piston grade (Piston outer

diameter) Refer to ªSelective combination

chartº.

IIdentification grade stamped on each part represents initial

dimension of new part. This grade will not be applied to a

reused part.

I Measure correct dimensions of a reused or modified part, then

refer to ªSelective combination chartº in this manual to identify

the grade.

I Refer to the applicable pages for measurement method for

each part, standards for reuse, and selecting method for selec-

tive part combination.

Disassembly

1. Remove engine assembly from vehicle.

Refer to EM-63, ªENGINE REMOVALº.

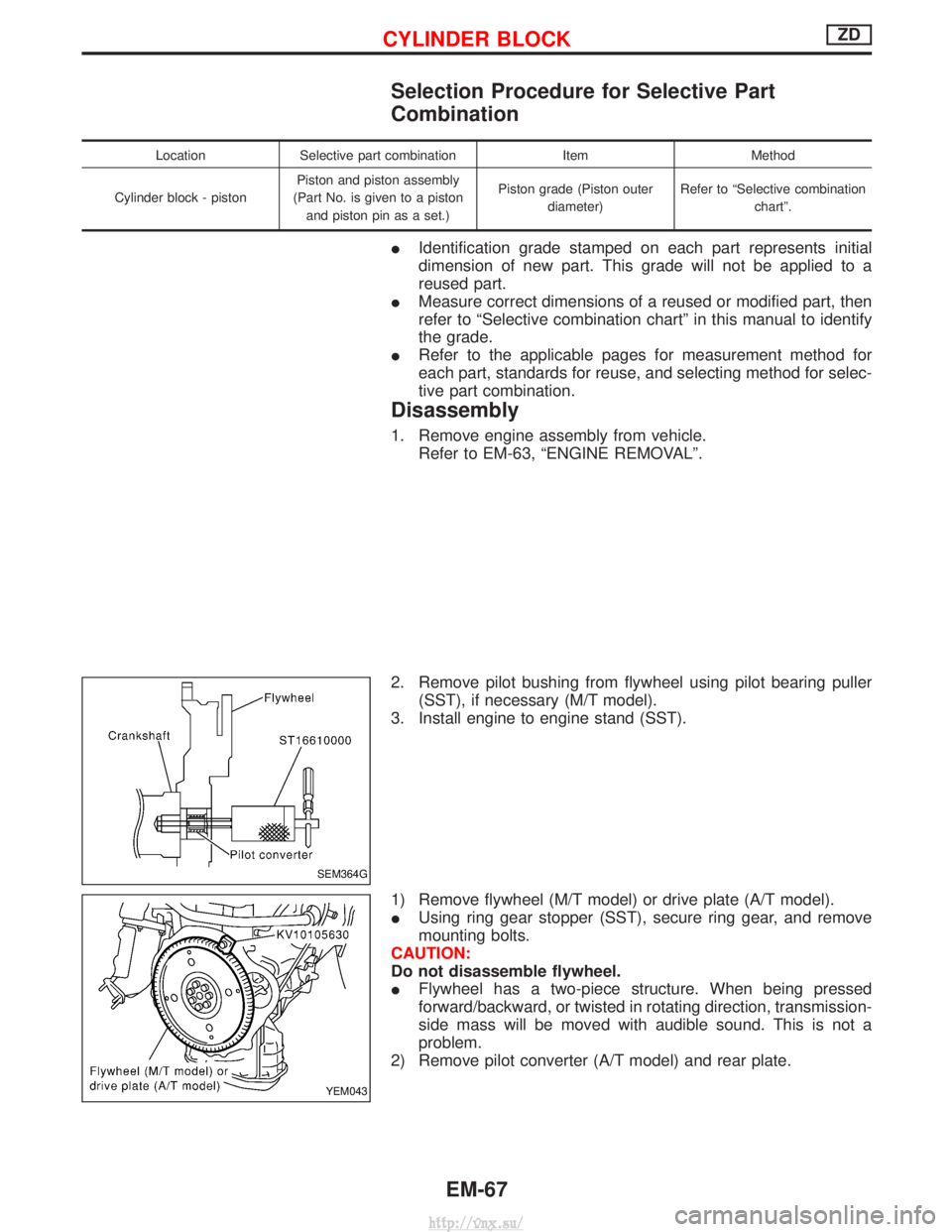

2. Remove pilot bushing from flywheel using pilot bearing puller (SST), if necessary (M/T model).

3. Install engine to engine stand (SST).

1) Remove flywheel (M/T model) or drive plate (A/T model).

I Using ring gear stopper (SST), secure ring gear, and remove

mounting bolts.

CAUTION:

Do not disassemble flywheel.

I Flywheel has a two-piece structure. When being pressed

forward/backward, or twisted in rotating direction, transmission-

side mass will be moved with audible sound. This is not a

problem.

2) Remove pilot converter (A/T model) and rear plate.

SEM364G

YEM043

CYLINDER BLOCKZD

EM-67

http://vnx.su/

Page 171 of 1833

Assembly

1. Blow air sufficiently to inside coolant passage, oil passage,crankcase, and cylinder bore to remove foreign matter.

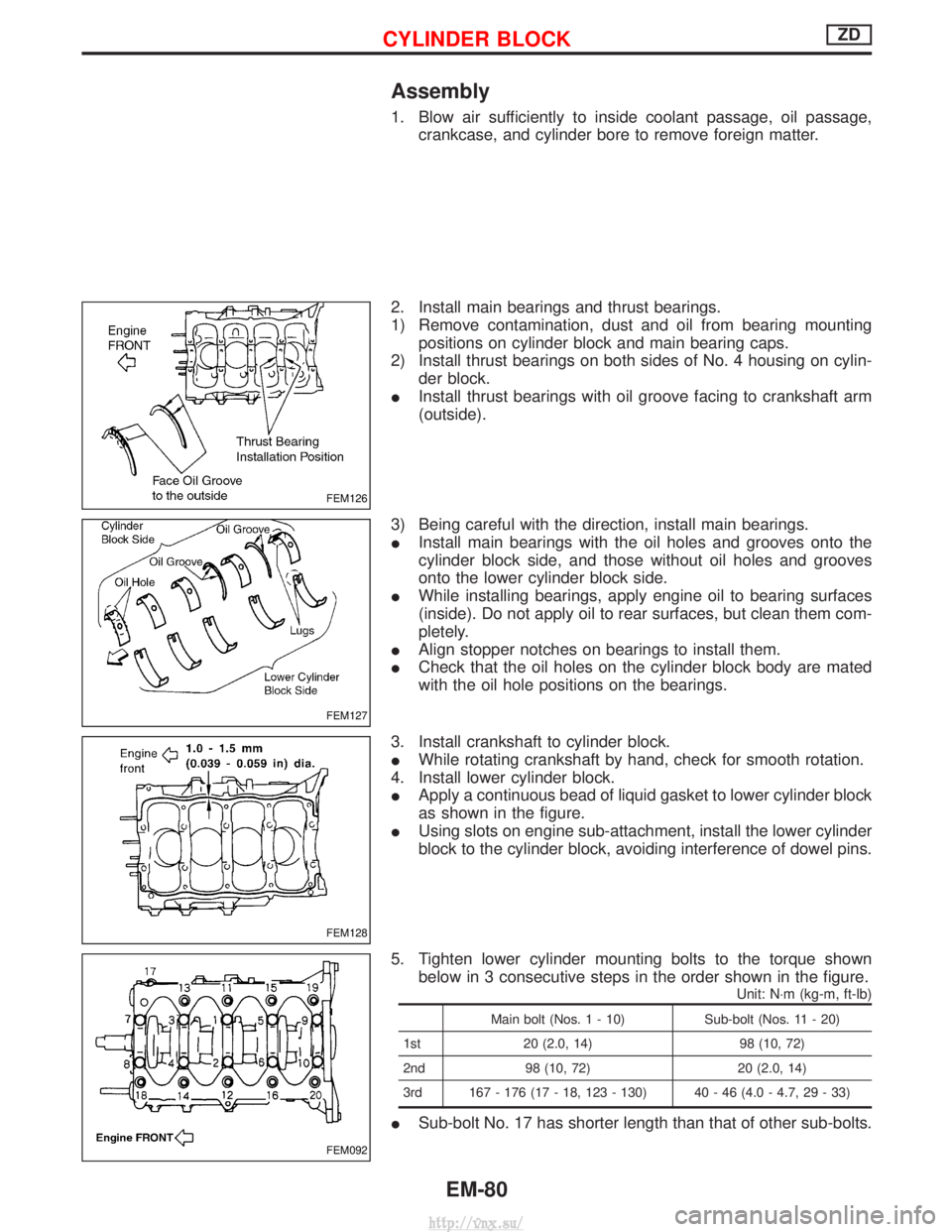

2. Install main bearings and thrust bearings.

1) Remove contamination, dust and oil from bearing mounting positions on cylinder block and main bearing caps.

2) Install thrust bearings on both sides of No. 4 housing on cylin- der block.

I Install thrust bearings with oil groove facing to crankshaft arm

(outside).

3) Being careful with the direction, install main bearings.

I Install main bearings with the oil holes and grooves onto the

cylinder block side, and those without oil holes and grooves

onto the lower cylinder block side.

I While installing bearings, apply engine oil to bearing surfaces

(inside). Do not apply oil to rear surfaces, but clean them com-

pletely.

I Align stopper notches on bearings to install them.

I Check that the oil holes on the cylinder block body are mated

with the oil hole positions on the bearings.

3. Install crankshaft to cylinder block.

I While rotating crankshaft by hand, check for smooth rotation.

4. Install lower cylinder block.

I Apply a continuous bead of liquid gasket to lower cylinder block

as shown in the figure.

I Using slots on engine sub-attachment, install the lower cylinder

block to the cylinder block, avoiding interference of dowel pins.

5. Tighten lower cylinder mounting bolts to the torque shown below in 3 consecutive steps in the order shown in the figure.

Unit: N ×m (kg-m, ft-lb)

Main bolt (Nos. 1 - 10) Sub-bolt (Nos. 11 - 20)

1st 20 (2.0, 14) 98 (10, 72)

2nd 98 (10, 72) 20 (2.0, 14)

3rd 167 - 176 (17 - 18, 123 - 130) 40 - 46 (4.0 - 4.7, 29 - 33)

I Sub-bolt No. 17 has shorter length than that of other sub-bolts.

FEM126

FEM127

FEM128

FEM092

CYLINDER BLOCKZD

EM-80

http://vnx.su/

Page 174 of 1833

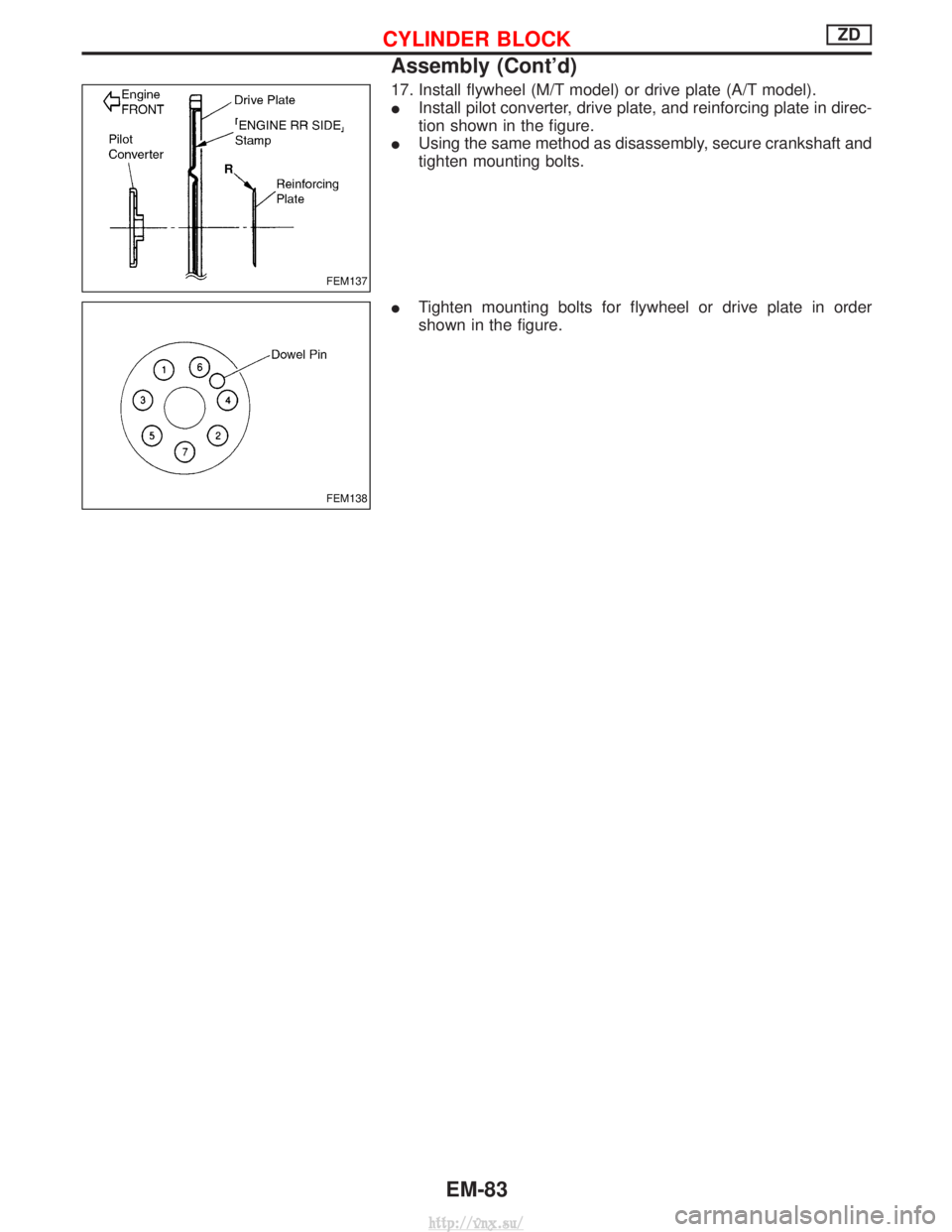

17. Install flywheel (M/T model) or drive plate (A/T model).

IInstall pilot converter, drive plate, and reinforcing plate in direc-

tion shown in the figure.

I Using the same method as disassembly, secure crankshaft and

tighten mounting bolts.

I Tighten mounting bolts for flywheel or drive plate in order

shown in the figure.

FEM137

FEM138

CYLINDER BLOCKZD

Assembly (Cont'd)

EM-83

http://vnx.su/

Page 252 of 1833

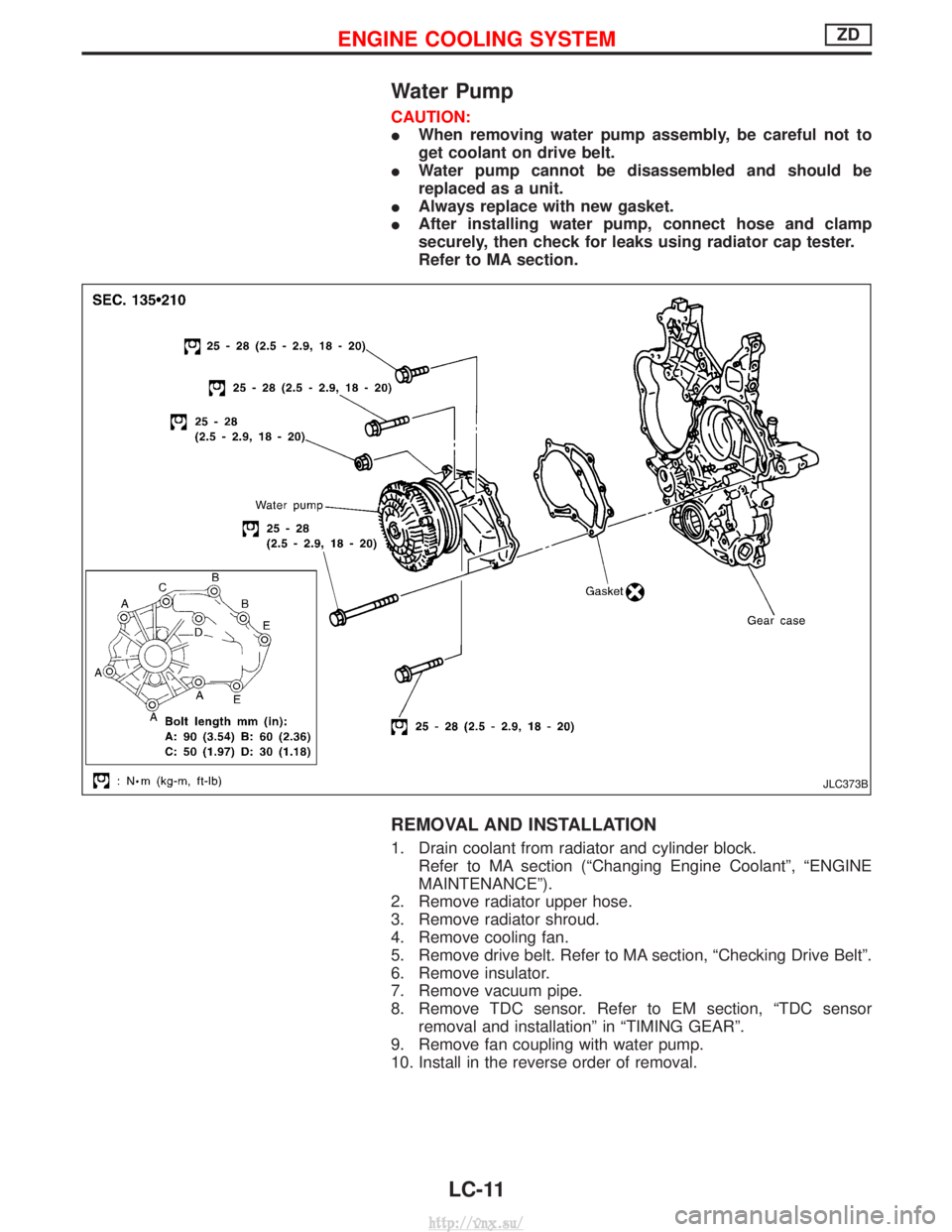

Water Pump

CAUTION:

IWhen removing water pump assembly, be careful not to

get coolant on drive belt.

I Water pump cannot be disassembled and should be

replaced as a unit.

I Always replace with new gasket.

I After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

Refer to MA section.

REMOVAL AND INSTALLATION

1. Drain coolant from radiator and cylinder block.

Refer to MA section (ªChanging Engine Coolantº, ªENGINE

MAINTENANCEº).

2. Remove radiator upper hose.

3. Remove radiator shroud.

4. Remove cooling fan.

5. Remove drive belt. Refer to MA section, ªChecking Drive Beltº.

6. Remove insulator.

7. Remove vacuum pipe.

8. Remove TDC sensor. Refer to EM section, ªTDC sensor removal and installationº in ªTIMING GEARº.

9. Remove fan coupling with water pump.

10. Install in the reverse order of removal.

JLC373B

ENGINE COOLING SYSTEMZD

LC-11

http://vnx.su/

Page 270 of 1833

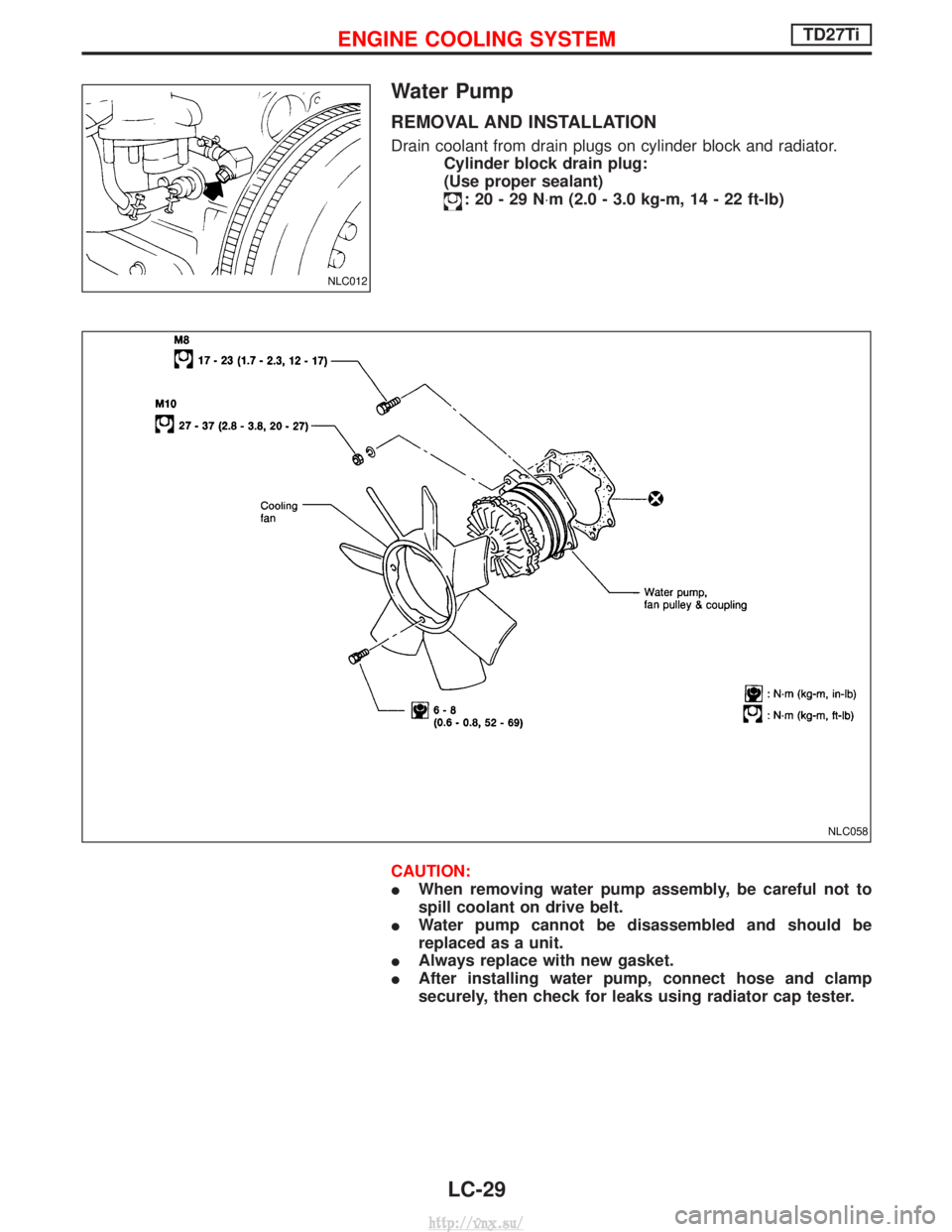

Water Pump

REMOVAL AND INSTALLATION

Drain coolant from drain plugs on cylinder block and radiator.Cylinder block drain plug:

(Use proper sealant)

:20-29N ×m (2.0 - 3.0 kg-m, 14 - 22 ft-lb)

CAUTION:

I When removing water pump assembly, be careful not to

spill coolant on drive belt.

I Water pump cannot be disassembled and should be

replaced as a unit.

I Always replace with new gasket.

I After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

NLC012

NLC058

ENGINE COOLING SYSTEMTD27Ti

LC-29

http://vnx.su/

Page 284 of 1833

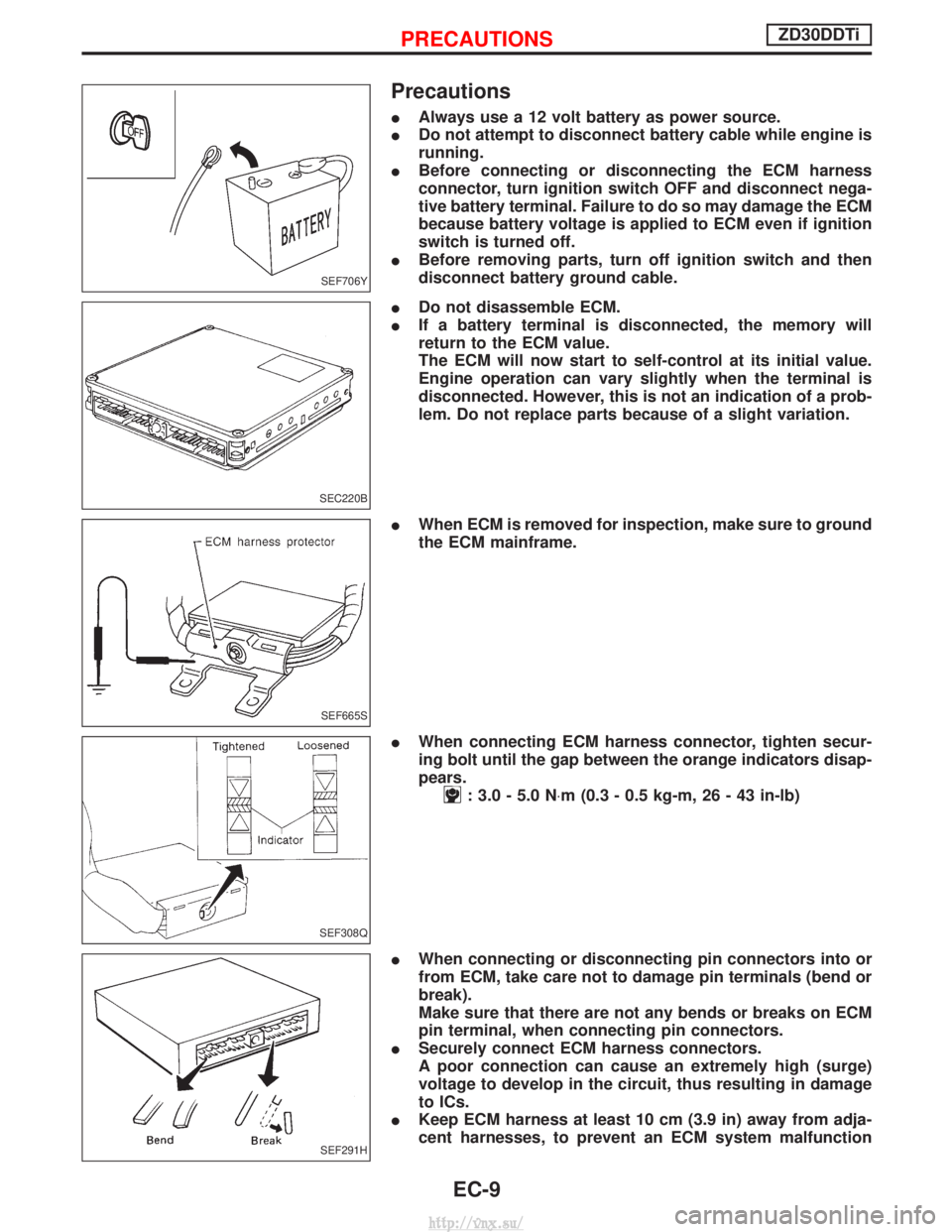

Precautions

IAlways use a 12 volt battery as power source.

I Do not attempt to disconnect battery cable while engine is

running.

I Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

I Before removing parts, turn off ignition switch and then

disconnect battery ground cable.

I Do not disassemble ECM.

I If a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a prob-

lem. Do not replace parts because of a slight variation.

I When ECM is removed for inspection, make sure to ground

the ECM mainframe.

I When connecting ECM harness connector, tighten secur-

ing bolt until the gap between the orange indicators disap-

pears.

: 3.0 - 5.0 N ×m (0.3 - 0.5 kg-m, 26 - 43 in-lb)

I When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

I Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in the circuit, thus resulting in damage

to ICs.

I Keep ECM harness at least 10 cm (3.9 in) away from adja-

cent harnesses, to prevent an ECM system malfunction

SEF706Y

SEC220B

SEF665S

SEF308Q

SEF291H

PRECAUTIONSZD30DDTi

EC-9

http://vnx.su/