oil NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1495 of 1833

Oil Pressure Switch Check ...................................... 110

Wiring Diagram - CHIME - ...................................... 111

WIPER AND WASHER ................................................ 112

Wiring Diagram - WIPER - ...................................... 112

Wiring Diagram - WIP/R -........................................ 114

Installation ................................................................ 116

Washer Nozzle Adjustment ..................................... 117

Check Valve ............................................................. 117

Wiring Diagram - HLC - ........................................... 118

HORN, CIGARETTE LIGHTER AND CLOCK ............122

Wiring Diagram - HORN - .......................................122

Wiring Diagram - CIGAR -.......................................123

Wiring Diagram - CLOCK -......................................124

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER .................................................125

System Description ..................................................125

Wiring Diagram - DEF - ...........................................126

Trouble Diagnoses...................................................128

Filament Check ........................................................132

Filament Repair .......................................................133

AUDIO ........................................................................\

..134

System Description ..................................................134

Schematic ................................................................136

Wiring Diagram - AUDIO - .......................................138

Wiring Diagram - REMOTE -...................................145

Trouble Diagnoses...................................................147

Inspection.................................................................149

Location of Roof Mounted Antenna .........................150

HEATED SEAT ............................................................151

Wiring Diagram - HSEAT - ......................................151

SUNROOF ....................................................................153

Wiring Diagram - SROOF - .....................................153

DOOR MIRROR ...........................................................154

Wiring Diagram - MIRROR - ...................................154

POWER WINDOW .......................................................156

System Description ..................................................156

Schematic ................................................................158

Wiring Diagram - WINDOW - ..................................159

Trouble Diagnoses...................................................162

POWER DOOR LOCK .................................................163

System Description ..................................................163

Schematic ................................................................164

Wiring Diagram - D/LOCK -.....................................166

Trouble Diagnoses...................................................171

POWER DOOR LOCK - SUPER LOCK - ...................179

Component Parts Location ......................................179

System Description ..................................................180

Schematic ................................................................182 Wiring Diagram - S/LOCK - .....................................184

Trouble Diagnoses...................................................192

MULTI-REMOTE CONTROL SYSTEM .......................202

System Description ..................................................202

Schematic ................................................................204

Wiring Diagram - MULTI - .......................................205

Trouble Diagnoses...................................................213

ID Code Entry Procedure ........................................215

TIME CONTROL UNIT (TCU) .....................................216

System Description ..................................................216

Trouble Diagnosis ....................................................218

Schematic ................................................................220

NATS (Nissan Anti-Theft System) .............................222

System Description ..................................................222

System Composition ................................................223

Component Parts Location ......................................224

Wiring Diagram - NATS -.........................................225

CONSULT-II .............................................................229

Trouble Diagnoses...................................................231

How to Replace NATS IMMU ..................................242

THEFT WARNING SYSTEM .......................................243

Components Parts and Harness Connector

Location ...................................................................243

System Description ..................................................244

Theft Warning System/Schematic ...........................247

Wiring Diagram - THEFT -.......................................248

Trouble Diagnoses...................................................264

LOCATION OF ELECTRICAL UNITS .........................275

Engine Compartment ...............................................275

Passenger Compartment/LHD Models ....................276

Passenger Compartment/RHD Models ...................278

HARNESS LAYOUT ....................................................280

How to Read Harness Layout .................................280

Outline......................................................................281

Main Harness...........................................................282

EFC Harness ...........................................................298

Engine Harness .......................................................310

Body Harness ..........................................................312

Chassis Harness......................................................320

Room Lamp Harness...............................................321

Tailgate Harness ......................................................322

Door Harness (LH side)...........................................323

Door Harness (RH side) ..........................................324

BULB SPECIFICATIONS ............................................325

Headlamps ...............................................................325

Exterior Lamps.........................................................325

Interior Lamps ..........................................................325

WIRING DIAGRAM CODES (CELL CODES) .............326

CONTENTS(Cont'd)

EL-2

http://vnx.su/

Page 1540 of 1833

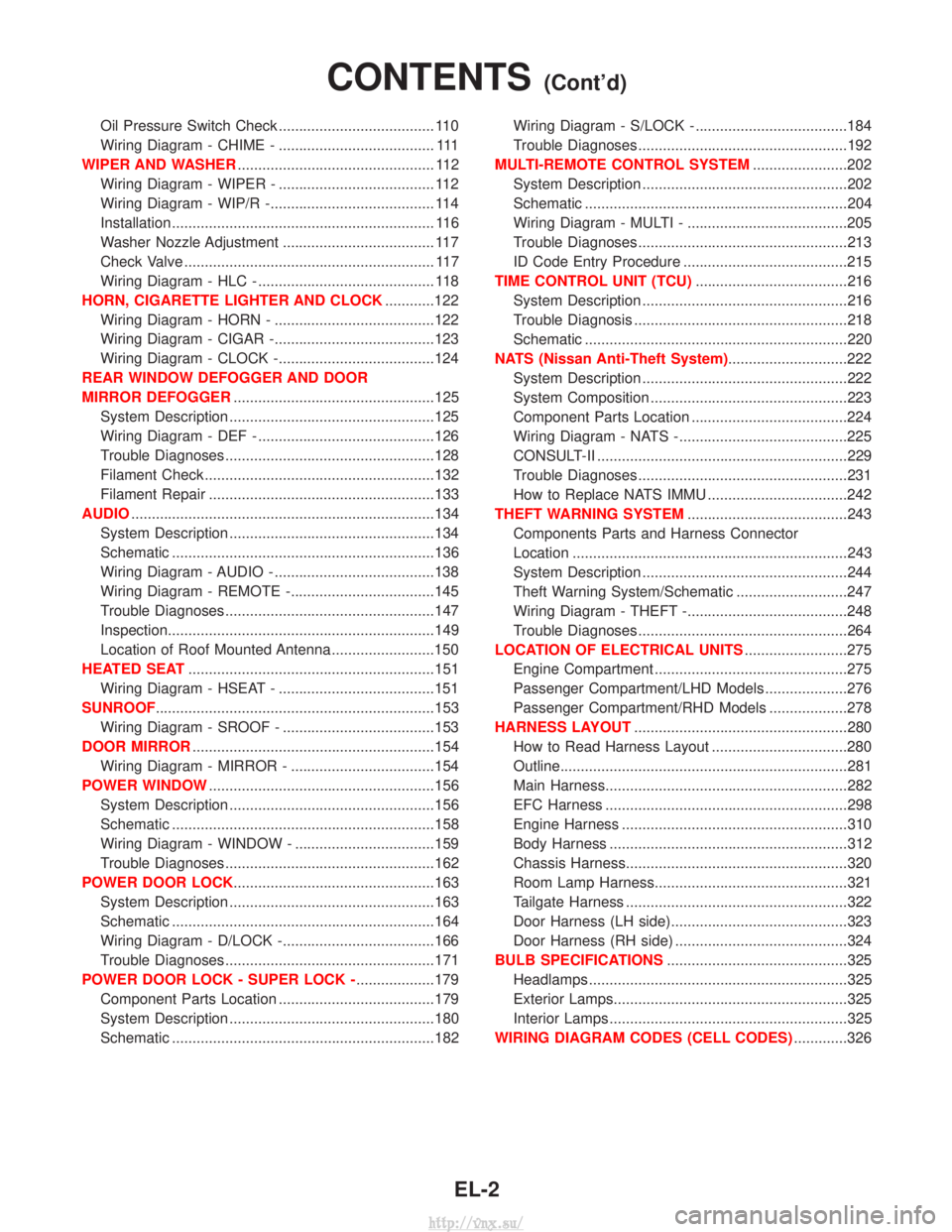

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replacable

halogen bulb. The bulb can be replaced from the engine compart-

ment side without removing the headlamp body.

IGrasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the bulb.

3. Pull off the rubber cap.

4. Press end of the retaining pin together to release bulb.

5. Remove the headlamp bulb. Do not shake or rotate the bulb when removing it.

6. Install the new bulb in reverse order of removal.

CAUTION:

I Do not leave headlamp reflector without bulb for a long

period of time as dust, moisture, smoke, etc. may enter the

headlamp body and affect the performance of the head-

lamp. Thus, the headlamp bulb should not be removed

from the headlamp reflector until just before a replacement

bulb is to be installed.

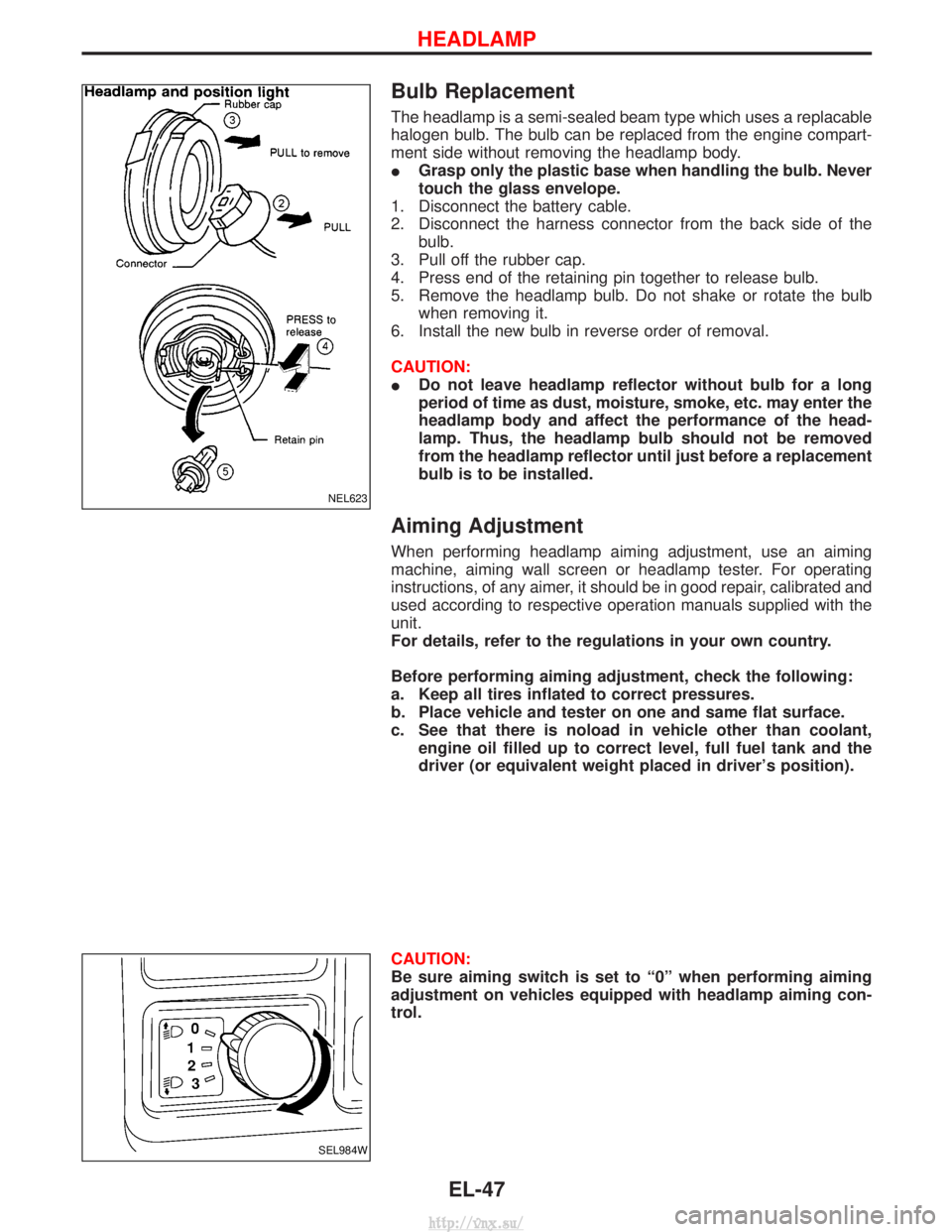

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. For operating

instructions, of any aimer, it should be in good repair, calibrated and

used according to respective operation manuals supplied with the

unit.

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following:

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is noload in vehicle other than coolant,

engine oil filled up to correct level, full fuel tank and the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ª0º when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

NEL623

SEL984W

HEADLAMP

EL-47

http://vnx.su/

Page 1550 of 1833

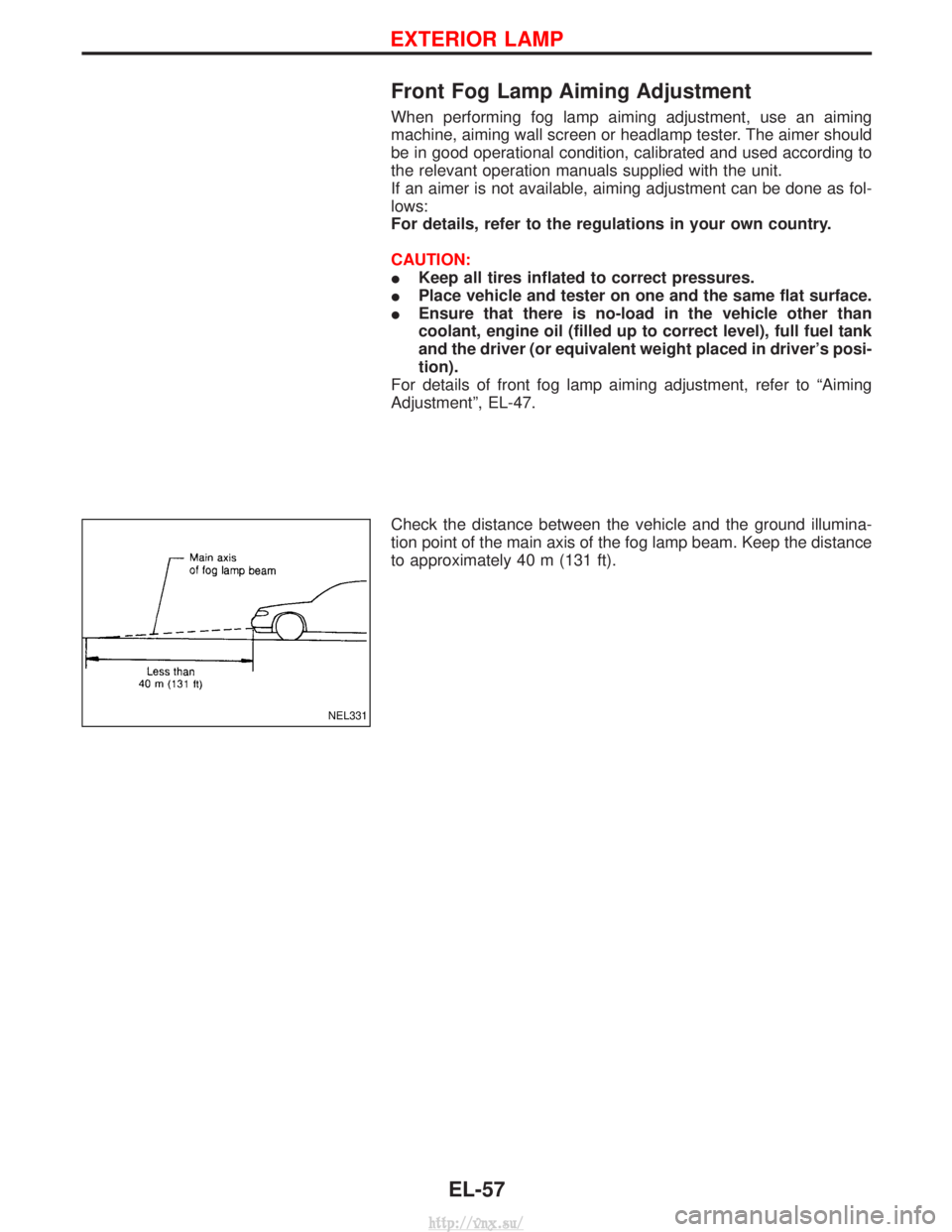

Front Fog Lamp Aiming Adjustment

When performing fog lamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. The aimer should

be in good operational condition, calibrated and used according to

the relevant operation manuals supplied with the unit.

If an aimer is not available, aiming adjustment can be done as fol-

lows:

For details, refer to the regulations in your own country.

CAUTION:

IKeep all tires inflated to correct pressures.

I Place vehicle and tester on one and the same flat surface.

I Ensure that there is no-load in the vehicle other than

coolant, engine oil (filled up to correct level), full fuel tank

and the driver (or equivalent weight placed in driver's posi-

tion).

For details of front fog lamp aiming adjustment, refer to ªAiming

Adjustmentº, EL-47.

Check the distance between the vehicle and the ground illumina-

tion point of the main axis of the fog lamp beam. Keep the distance

to approximately 40 m (131 ft).

NEL331

EXTERIOR LAMP

EL-57

http://vnx.su/

Page 1603 of 1833

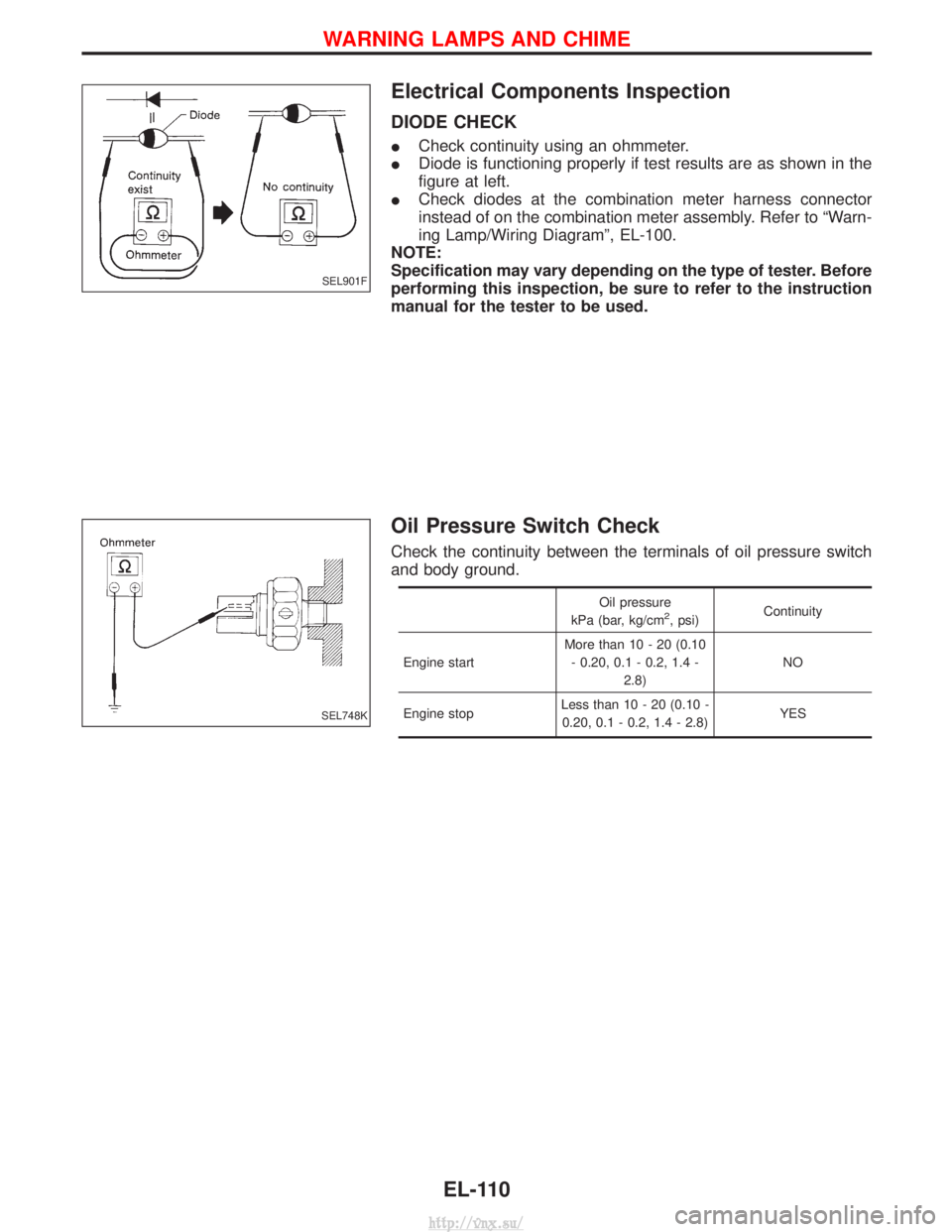

Electrical Components Inspection

DIODE CHECK

ICheck continuity using an ohmmeter.

I Diode is functioning properly if test results are as shown in the

figure at left.

I Check diodes at the combination meter harness connector

instead of on the combination meter assembly. Refer to ªWarn-

ing Lamp/Wiring Diagramº, EL-100.

NOTE:

Specification may vary depending on the type of tester. Before

performing this inspection, be sure to refer to the instruction

manual for the tester to be used.

Oil Pressure Switch Check

Check the continuity between the terminals of oil pressure switch

and body ground.

Oil pressure

kPa (bar, kg/cm2, psi) Continuity

Engine start More than 10 - 20 (0.10

- 0.20, 0.1 - 0.2, 1.4 - 2.8) NO

Engine stop Less than 10 - 20 (0.10 -

0.20, 0.1 - 0.2, 1.4 - 2.8) YES

SEL901F

SEL748K

WARNING LAMPS AND CHIME

EL-110

http://vnx.su/

Page 1618 of 1833

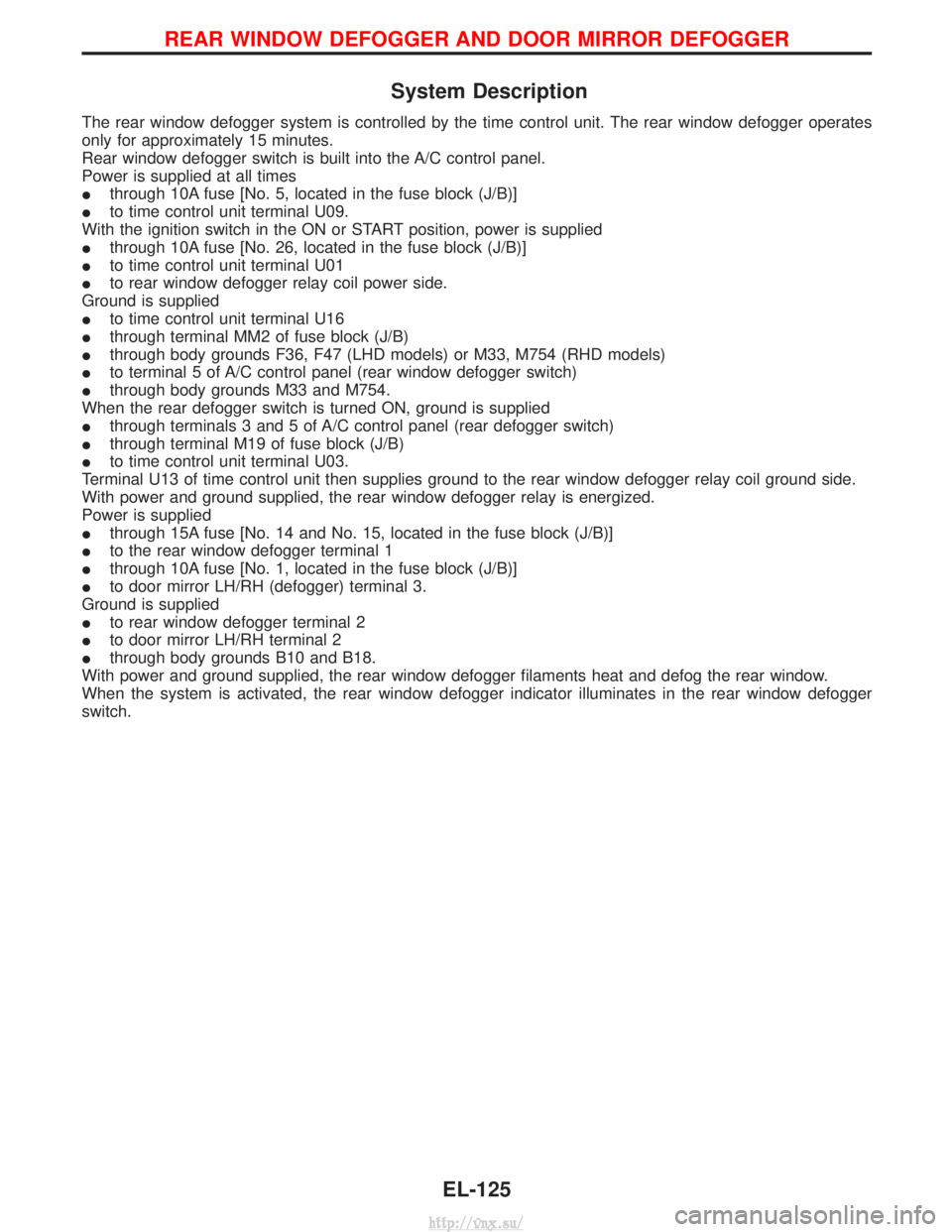

System Description

The rear window defogger system is controlled by the time control unit. The rear window defogger operates

only for approximately 15 minutes.

Rear window defogger switch is built into the A/C control panel.

Power is supplied at all times

Ithrough 10A fuse [No. 5, located in the fuse block (J/B)]

I to time control unit terminal U09.

With the ignition switch in the ON or START position, power is supplied

I through 10A fuse [No. 26, located in the fuse block (J/B)]

I to time control unit terminal U01

I to rear window defogger relay coil power side.

Ground is supplied

I to time control unit terminal U16

I through terminal MM2 of fuse block (J/B)

I through body grounds F36, F47 (LHD models) or M33, M754 (RHD models)

I to terminal 5 of A/C control panel (rear window defogger switch)

I through body grounds M33 and M754.

When the rear defogger switch is turned ON, ground is supplied

I through terminals 3 and 5 of A/C control panel (rear defogger switch)

I through terminal M19 of fuse block (J/B)

I to time control unit terminal U03.

Terminal U13 of time control unit then supplies ground to the rear window defogger relay coil ground side.

With power and ground supplied, the rear window defogger relay is energized.

Power is supplied

I through 15A fuse [No. 14 and No. 15, located in the fuse block (J/B)]

I to the rear window defogger terminal 1

I through 10A fuse [No. 1, located in the fuse block (J/B)]

I to door mirror LH/RH (defogger) terminal 3.

Ground is supplied

I to rear window defogger terminal 2

I to door mirror LH/RH terminal 2

I through body grounds B10 and B18.

With power and ground supplied, the rear window defogger filaments heat and defog the rear window.

When the system is activated, the rear window defogger indicator illuminates in the rear window defogger

switch.

REAR WINDOW DEFOGGER AND DOOR MIRROR DEFOGGER

EL-125

http://vnx.su/

Page 1625 of 1833

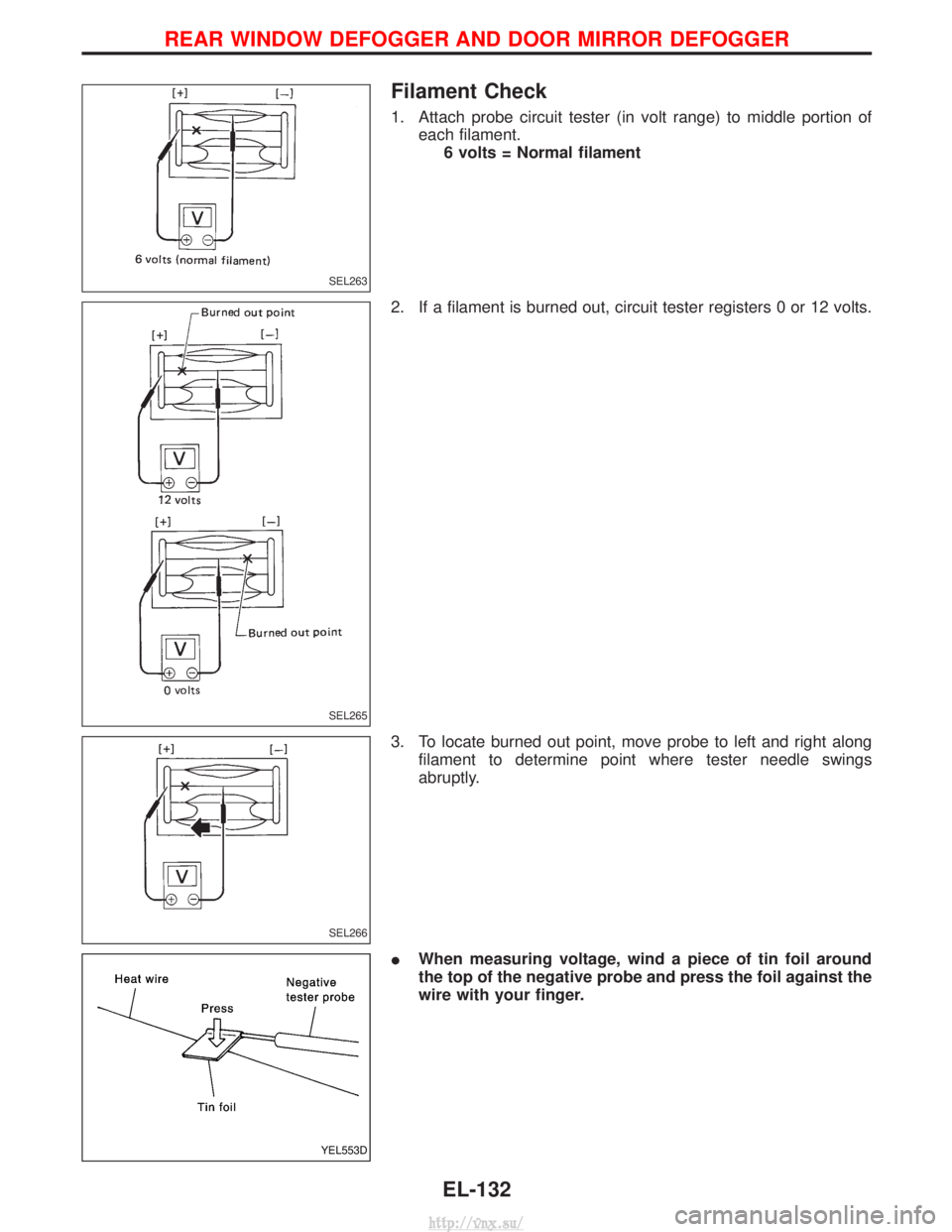

Filament Check

1. Attach probe circuit tester (in volt range) to middle portion ofeach filament.6 volts = Normal filament

2. If a filament is burned out, circuit tester registers 0 or 12 volts.

3. To locate burned out point, move probe to left and right along filament to determine point where tester needle swings

abruptly.

I When measuring voltage, wind a piece of tin foil around

the top of the negative probe and press the foil against the

wire with your finger.

SEL263

SEL265

SEL266

YEL553D

REAR WINDOW DEFOGGER AND DOOR MIRROR DEFOGGER

EL-132

http://vnx.su/

Page 1640 of 1833

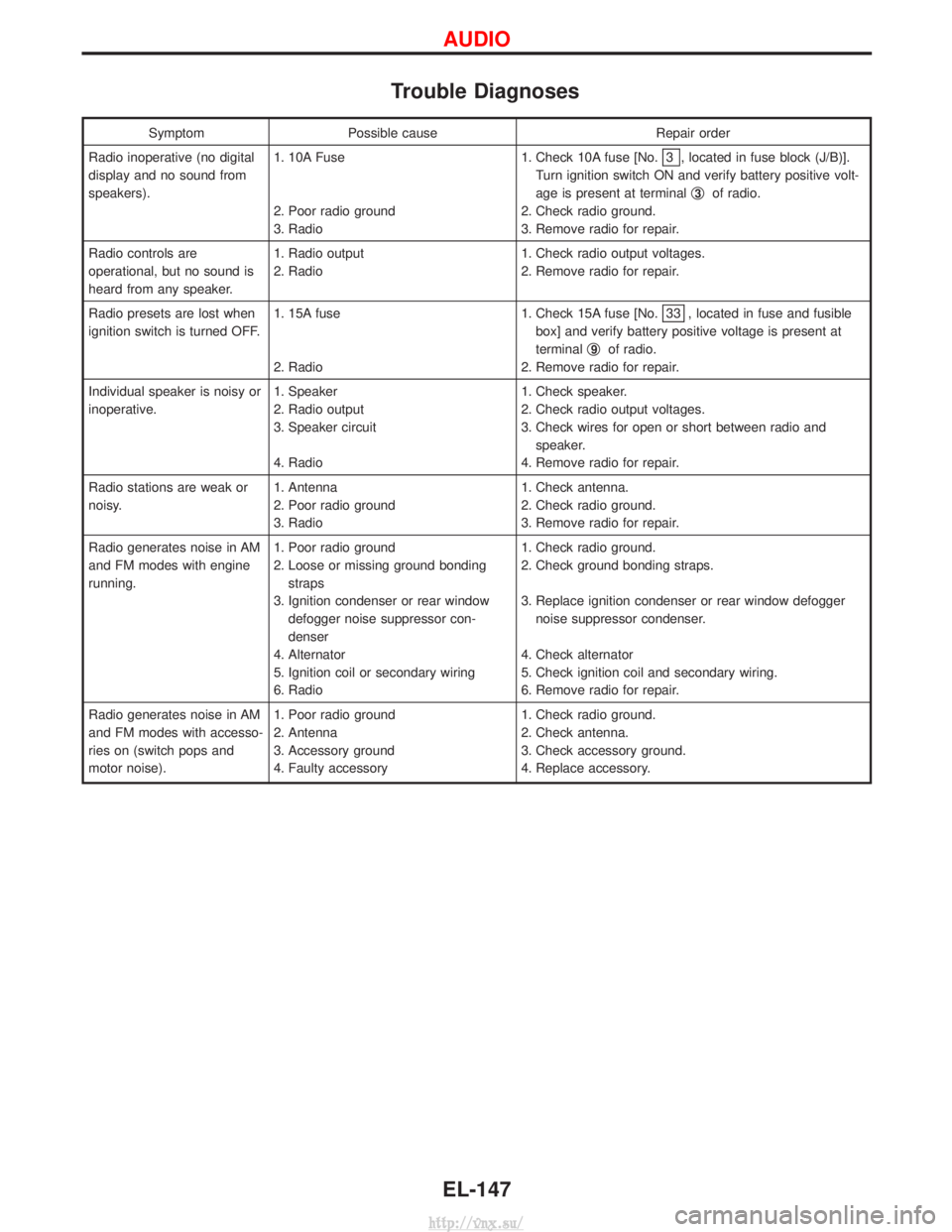

Trouble Diagnoses

SymptomPossible cause Repair order

Radio inoperative (no digital

display and no sound from

speakers). 1. 10A Fuse

2. Poor radio ground

3. Radio 1. Check 10A fuse [No.

3 , located in fuse block (J/B)].

Turn ignition switch ON and verify battery positive volt-

age is present at terminal q

3of radio.

2. Check radio ground.

3. Remove radio for repair.

Radio controls are

operational, but no sound is

heard from any speaker. 1. Radio output

2. Radio

1. Check radio output voltages.

2. Remove radio for repair.

Radio presets are lost when

ignition switch is turned OFF. 1. 15A fuse

2. Radio 1. Check 15A fuse [No.

33 , located in fuse and fusible

box] and verify battery positive voltage is present at

terminal q

9of radio.

2. Remove radio for repair.

Individual speaker is noisy or

inoperative. 1. Speaker

2. Radio output

3. Speaker circuit

4. Radio 1. Check speaker.

2. Check radio output voltages.

3. Check wires for open or short between radio and

speaker.

4. Remove radio for repair.

Radio stations are weak or

noisy. 1. Antenna

2. Poor radio ground

3. Radio 1. Check antenna.

2. Check radio ground.

3. Remove radio for repair.

Radio generates noise in AM

and FM modes with engine

running. 1. Poor radio ground

2. Loose or missing ground bonding

straps

3. Ignition condenser or rear window defogger noise suppressor con-

denser

4. Alternator

5. Ignition coil or secondary wiring

6. Radio 1. Check radio ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger

noise suppressor condenser.

4. Check alternator

5. Check ignition coil and secondary wiring.

6. Remove radio for repair.

Radio generates noise in AM

and FM modes with accesso-

ries on (switch pops and

motor noise). 1. Poor radio ground

2. Antenna

3. Accessory ground

4. Faulty accessory 1. Check radio ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

AUDIO

EL-147

http://vnx.su/

Page 1641 of 1833

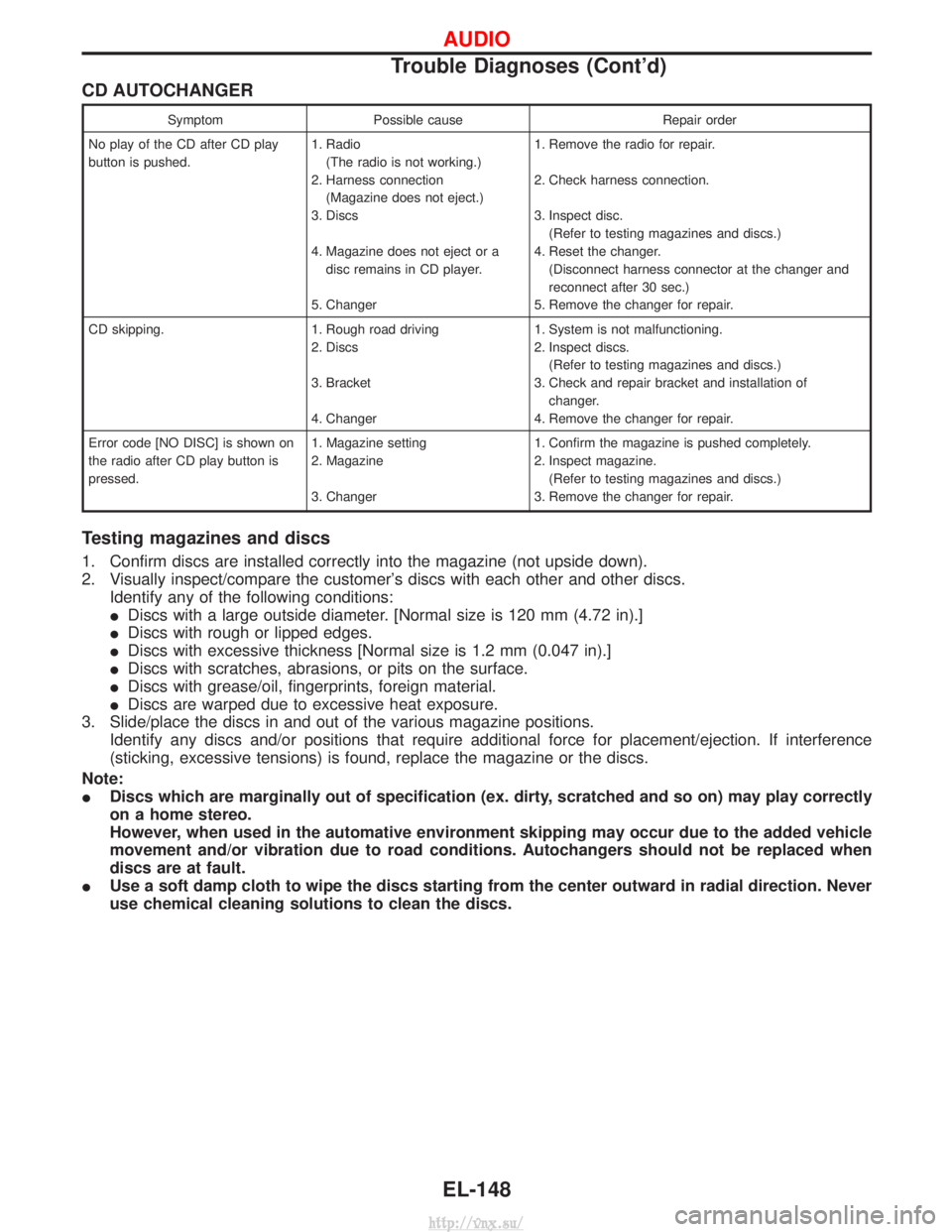

CD AUTOCHANGER

SymptomPossible cause Repair order

No play of the CD after CD play

button is pushed. 1. Radio

(The radio is not working.)

2. Harness connection (Magazine does not eject.)

3. Discs

4. Magazine does not eject or a disc remains in CD player.

5. Changer 1. Remove the radio for repair.

2. Check harness connection.

3. Inspect disc.

(Refer to testing magazines and discs.)

4. Reset the changer. (Disconnect harness connector at the changer and

reconnect after 30 sec.)

5. Remove the changer for repair.

CD skipping. 1. Rough road driving 2. Discs

3. Bracket

4. Changer1. System is not malfunctioning.

2. Inspect discs.

(Refer to testing magazines and discs.)

3. Check and repair bracket and installation of changer.

4. Remove the changer for repair.

Error code [NO DISC] is shown on

the radio after CD play button is

pressed. 1. Magazine setting

2. Magazine

3. Changer1. Confirm the magazine is pushed completely.

2. Inspect magazine.

(Refer to testing magazines and discs.)

3. Remove the changer for repair.

Testing magazines and discs

1. Confirm discs are installed correctly into the magazine (not upside down).

2. Visually inspect/compare the customer's discs with each other and other discs. Identify any of the following conditions:

IDiscs with a large outside diameter. [Normal size is 120 mm (4.72 in).]

I Discs with rough or lipped edges.

I Discs with excessive thickness [Normal size is 1.2 mm (0.047 in).]

I Discs with scratches, abrasions, or pits on the surface.

I Discs with grease/oil, fingerprints, foreign material.

I Discs are warped due to excessive heat exposure.

3. Slide/place the discs in and out of the various magazine positions. Identify any discs and/or positions that require additional force for placement/ejection. If interference

(sticking, excessive tensions) is found, replace the magazine or the discs.

Note:

I Discs which are marginally out of specification (ex. dirty, scratched and so on) may play correctly

on a home stereo.

However, when used in the automative environment skipping may occur due to the added vehicle

movement and/or vibration due to road conditions. Autochangers should not be replaced when

discs are at fault.

I Use a soft damp cloth to wipe the discs starting from the center outward in radial direction. Never

use chemical cleaning solutions to clean the discs.

AUDIO

Trouble Diagnoses (Cont'd)

EL-148

http://vnx.su/

Page 1819 of 1833

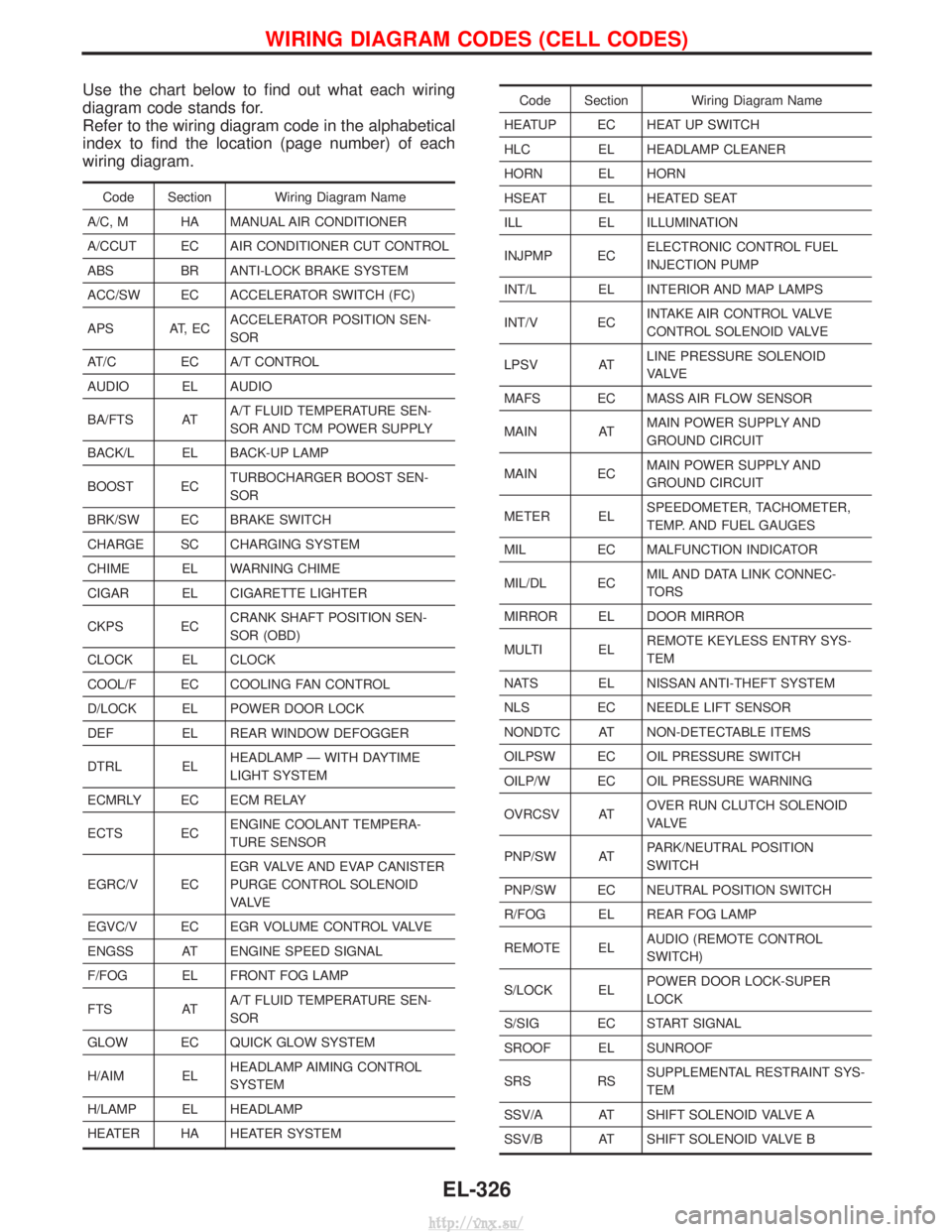

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

A/C, M HA MANUAL AIR CONDITIONER

A/CCUT EC AIR CONDITIONER CUT CONTROL

ABS BR ANTI-LOCK BRAKE SYSTEM

ACC/SW EC ACCELERATOR SWITCH (FC)

APS AT, EC ACCELERATOR POSITION SEN-

SOR

AT/C EC A/T CONTROL

AUDIO EL AUDIO

BA/FTS AT A/T FLUID TEMPERATURE SEN-

SOR AND TCM POWER SUPPLY

BACK/L EL BACK-UP LAMP

BOOST EC TURBOCHARGER BOOST SEN-

SOR

BRK/SW EC BRAKE SWITCH

CHARGE SC CHARGING SYSTEM

CHIME EL WARNING CHIME

CIGAR EL CIGARETTE LIGHTER

CKPS EC CRANK SHAFT POSITION SEN-

SOR (OBD)

CLOCK EL CLOCK

COOL/F EC COOLING FAN CONTROL

D/LOCK EL POWER DOOR LOCK

DEF EL REAR WINDOW DEFOGGER

DTRL EL HEADLAMP Ð WITH DAYTIME

LIGHT SYSTEM

ECMRLY EC ECM RELAY

ECTS EC ENGINE COOLANT TEMPERA-

TURE SENSOR

EGRC/V EC EGR VALVE AND EVAP CANISTER

PURGE CONTROL SOLENOID

VA LV E

EGVC/V EC EGR VOLUME CONTROL VALVE

ENGSS AT ENGINE SPEED SIGNAL

F/FOG EL FRONT FOG LAMP

FTS AT A/T FLUID TEMPERATURE SEN-

SOR

GLOW EC QUICK GLOW SYSTEM

H/AIM EL HEADLAMP AIMING CONTROL

SYSTEM

H/LAMP EL HEADLAMP

HEATER HA HEATER SYSTEM

Code Section Wiring Diagram Name

HEATUP EC HEAT UP SWITCH

HLC EL HEADLAMP CLEANER

HORN EL HORN

HSEAT EL HEATED SEAT

ILL EL ILLUMINATION

INJPMP EC ELECTRONIC CONTROL FUEL

INJECTION PUMP

INT/L EL INTERIOR AND MAP LAMPS

INT/V EC INTAKE AIR CONTROL VALVE

CONTROL SOLENOID VALVE

LPSV AT LINE PRESSURE SOLENOID

VA LV E

MAFS EC MASS AIR FLOW SENSOR

MAIN AT MAIN POWER SUPPLY AND

GROUND CIRCUIT

MAIN EC MAIN POWER SUPPLY AND

GROUND CIRCUIT

METER EL SPEEDOMETER, TACHOMETER,

TEMP. AND FUEL GAUGES

MIL EC MALFUNCTION INDICATOR

MIL/DL EC MIL AND DATA LINK CONNEC-

TORS

MIRROR EL DOOR MIRROR

MULTI EL REMOTE KEYLESS ENTRY SYS-

TEM

NATS EL NISSAN ANTI-THEFT SYSTEM

NLS EC NEEDLE LIFT SENSOR

NONDTC AT NON-DETECTABLE ITEMS

OILPSW EC OIL PRESSURE SWITCH

OILP/W EC OIL PRESSURE WARNING

OVRCSV AT OVER RUN CLUTCH SOLENOID

VA LV E

PNP/SW AT PARK/NEUTRAL POSITION

SWITCH

PNP/SW EC NEUTRAL POSITION SWITCH

R/FOG EL REAR FOG LAMP

REMOTE EL AUDIO (REMOTE CONTROL

SWITCH)

S/LOCK EL POWER DOOR LOCK-SUPER

LOCK

S/SIG EC START SIGNAL

SROOF EL SUNROOF

SRS RS SUPPLEMENTAL RESTRAINT SYS-

TEM

SSV/A AT SHIFT SOLENOID VALVE A

SSV/B AT SHIFT SOLENOID VALVE B

WIRING DIAGRAM CODES (CELL CODES)

EL-326

http://vnx.su/

Page 1828 of 1833

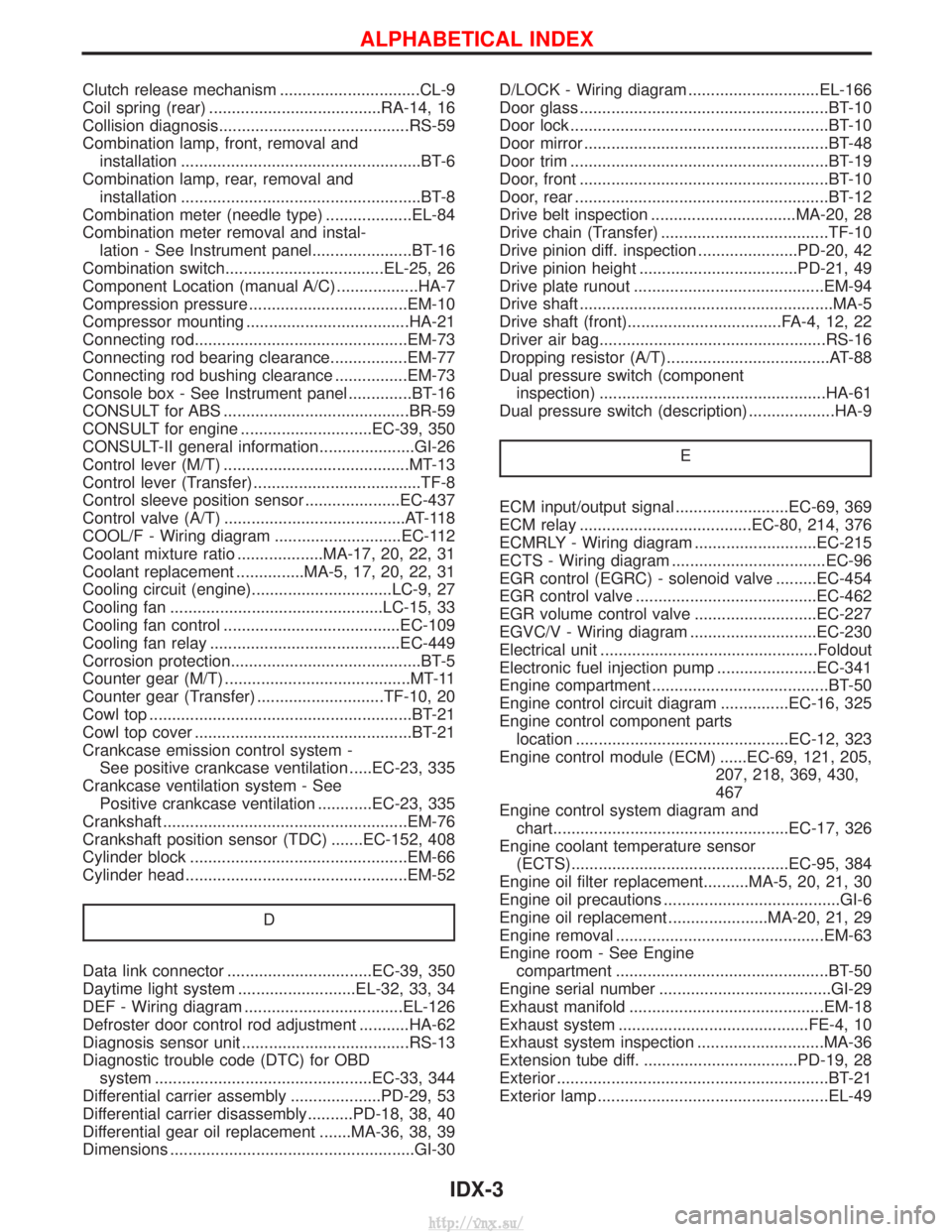

Clutch release mechanism ...............................CL-9

Coil spring (rear) ......................................RA-14, 16

Collision diagnosis..........................................RS-59

Combination lamp, front, removal andinstallation .....................................................BT-6

Combination lamp, rear, removal and installation .....................................................BT-8

Combination meter (needle type) ...................EL-84

Combination meter removal and instal- lation - See Instrument panel......................BT-16

Combination switch...................................EL-25, 26

Component Location (manual A/C) ..................HA-7

Compression pressure ...................................EM-10

Compressor mounting ....................................HA-21

Connecting rod...............................................EM-73

Connecting rod bearing clearance.................EM-77

Connecting rod bushing clearance ................EM-73

Console box - See Instrument panel ..............BT-16

CONSULT for ABS .........................................BR-59

CONSULT for engine .............................EC-39, 350

CONSULT-II general information.....................GI-26

Control lever (M/T) .........................................MT-13

Control lever (Transfer) .....................................TF-8

Control sleeve position sensor .....................EC-437

Control valve (A/T) ........................................AT-118

COOL/F - Wiring diagram ............................EC-112

Coolant mixture ratio ...................MA-17, 20, 22, 31

Coolant replacement ...............MA-5, 17, 20, 22, 31

Cooling circuit (engine)...............................LC-9, 27

Cooling fan ...............................................LC-15, 33

Cooling fan control .......................................EC-109

Cooling fan relay ..........................................EC-449

Corrosion protection..........................................BT-5

Counter gear (M/T) .........................................MT-11

Counter gear (Transfer) ............................TF-10, 20

Cowl top ..........................................................BT-21

Cowl top cover ................................................BT-21

Crankcase emission control system - See positive crankcase ventilation .....EC-23, 335

Crankcase ventilation system - See Positive crankcase ventilation ............EC-23, 335

Crankshaft ......................................................EM-76

Crankshaft position sensor (TDC) .......EC-152, 408

Cylinder block ................................................EM-66

Cylinder head .................................................EM-52

D

Data link connector ................................EC-39, 350

Daytime light system ..........................EL-32, 33, 34

DEF - Wiring diagram ...................................EL-126

Defroster door control rod adjustment ...........HA-62

Diagnosis sensor unit .....................................RS-13

Diagnostic trouble code (DTC) for OBDsystem ................................................EC-33, 344

Differential carrier assembly ....................PD-29, 53

Differential carrier disassembly..........PD-18, 38, 40

Differential gear oil replacement .......MA-36, 38, 39

Dimensions ......................................................GI-30 D/LOCK - Wiring diagram .............................EL-166

Door glass .......................................................BT-10

Door lock .........................................................BT-10

Door mirror ......................................................BT-48

Door trim .........................................................BT-19

Door, front .......................................................BT-10

Door, rear ........................................................BT-12

Drive belt inspection ................................MA-20, 28

Drive chain (Transfer) .....................................TF-10

Drive pinion diff. inspection ......................PD-20, 42

Drive pinion height ...................................PD-21, 49

Drive plate runout ..........................................EM-94

Drive shaft ........................................................MA-5

Drive shaft (front)..................................FA-4, 12, 22

Driver air bag..................................................RS-16

Dropping resistor (A/T)....................................AT-88

Dual pressure switch (component

inspection) ..................................................HA-61

Dual pressure switch (description) ...................HA-9

E

ECM input/output signal .........................EC-69, 369

ECM relay ......................................EC-80, 214, 376

ECMRLY - Wiring diagram ...........................EC-215

ECTS - Wiring diagram ..................................EC-96

EGR control (EGRC) - solenoid valve .........EC-454

EGR control valve ........................................EC-462

EGR volume control valve ...........................EC-227

EGVC/V - Wiring diagram ............................EC-230

Electrical unit ................................................Foldout

Electronic fuel injection pump ......................EC-341

Engine compartment .......................................BT-50

Engine control circuit diagram ...............EC-16, 325

Engine control component partslocation ...............................................EC-12, 323

Engine control module (ECM) ......EC-69, 121, 205, 207, 218, 369, 430,

467

Engine control system diagram and chart....................................................EC-17, 326

Engine coolant temperature sensor (ECTS)................................................EC-95, 384

Engine oil filter replacement..........MA-5, 20, 21, 30

Engine oil precautions .......................................GI-6

Engine oil replacement ......................MA-20, 21, 29

Engine removal ..............................................EM-63

Engine room - See Engine compartment ...............................................BT-50

Engine serial number ......................................GI-29

Exhaust manifold ...........................................EM-18

Exhaust system ..........................................FE-4, 10

Exhaust system inspection ............................MA-36

Extension tube diff. ..................................PD-19, 28

Exterior ............................................................BT-21

Exterior lamp ...................................................EL-49

ALPHABETICAL INDEX

IDX-3

http://vnx.su/