system NISSAN TERRANO 2004 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 84 of 1833

Changing Brake Fluid

1. Drain brake fluid from each air bleeder valve.

2. Refill until new brake fluid comes out from each air bleedervalve. Use same procedure as in bleeding hydraulic system to

refill brake fluid.

Refer to section BR.

I Refill with recommended brake fluid ªDOT 4º.

I Never reuse drained brake fluid.

I Be careful not to splash brake fluid on painted areas.

Balancing Wheels

Adjust wheel balance using the road wheel center.

Radial runout limit:Steel wheel:0.5 mm (0.020 in)

Aluminum wheel: 0.3 mm (0.012 in)

Lateral runout limit: Steel wheel:0.8 mm (0.031 in)

Aluminum wheel: 0.3 mm (0.012 in)

Tire Rotation

Wheel nuts

: 118 - 147 N ×m (12 - 15 kg-m, 87 - 108 ft-lb)

Checking Steering Gear and Linkage

STEERING GEAR

ICheck gear housing and boots for looseness, damage or

grease leakage.

I Check connection with steering column for looseness.

STEERING LINKAGE

ICheck ball joint, dust cover and other component parts for

looseness, wear damage or grease leakage.

SBR992

EMA039

EMA051

CHASSIS AND BODY MAINTENANCE

MA-43

http://vnx.su/

Page 89 of 1833

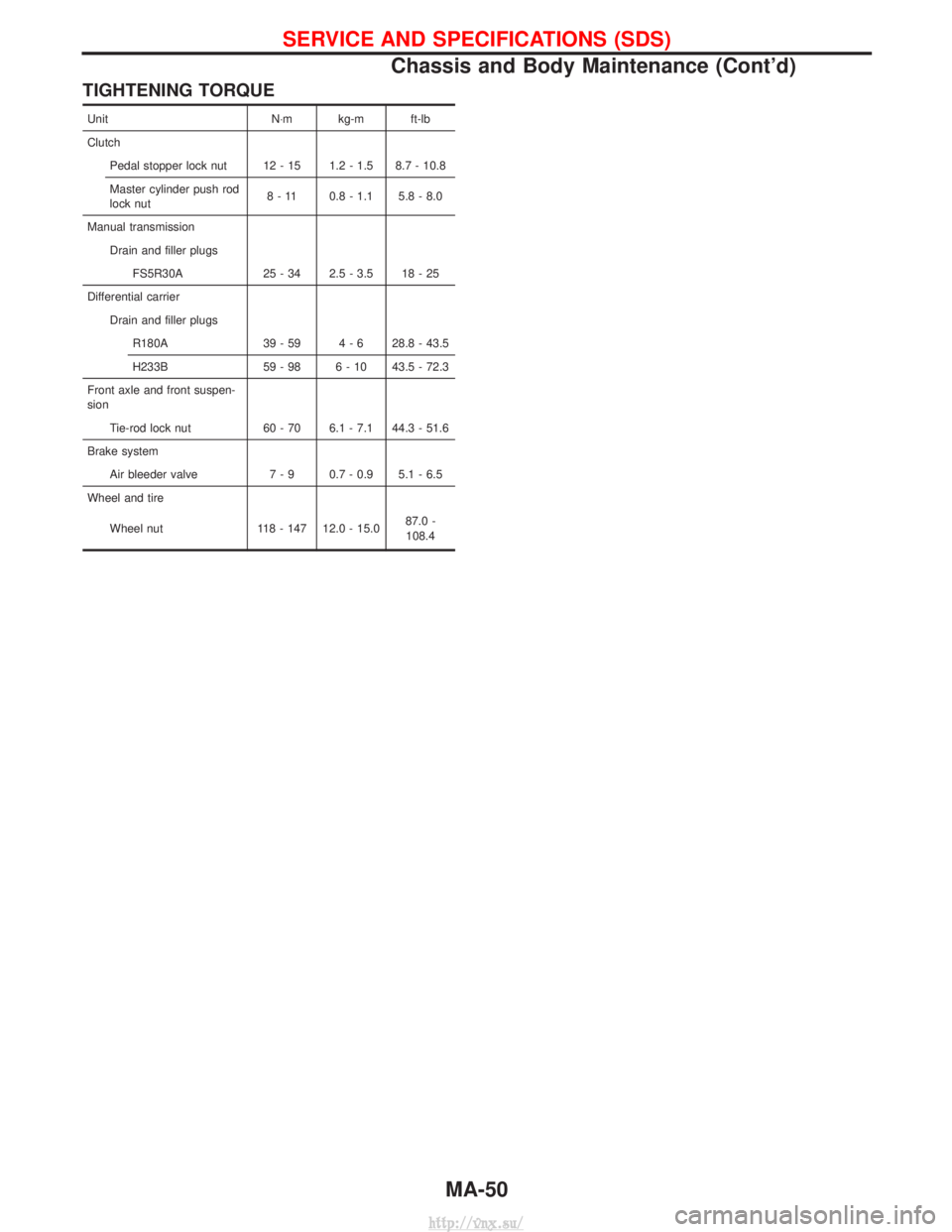

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflectionDeflection of

new belt

Limit Deflection after

adjustment

Engine TD27Ti TD27Ti TD27Ti

Alternator 20

(0.79) 11-13

(0.43 - 0.51) 9-11

(0.35 - 0.43)

Air conditioner 12

(0.47) 6 - 7.5

(0.236 - 0.295) 5 - 6.5

(0.197 - 0.256)

Power steering

oil pump 15

(0.59) 8 - 9.5

(0.315 - 0.374) 7 - 8.5

(0.276 - 0.335)

Applied pushing

force 98 N (10 kg, 22 lb)

Oil capacity (Refill capacity)

TD27Ti engine

Unit:

(Imp qt)

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

ZD30DDTi engine

Unit: (Imp qt)

With oil filter change 6.7 (5-7/8)

Without oil filter change 6.2 (5-1/2)

Cooling system check

TD27Ti engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 78-98

(0.78 - 0.98, 0.8 - 1.0, 11 - 14)

ZD30DDTi engine

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 157 (1.57, 1.6, 23)

Radiator cap relief pressure 108 - 128

(1.08 - 1.28, 1.1 - 1.3, 16 - 18)

Coolant capacity (Refill capacity)

Unit: (Imp qt)

Engine TD27TiZD30DDTi

Without reservoir tank 10 (8-3/4) 10.6 (9-3/8)

Reservoir tank 0.8 (3/4) 0.75 (5/8)

Valve clearance (Hot)

Unit: mm (in)

Engine TD27Ti

Intake 0.25 (0.0098)

Exhaust

Injection nozzle

Unit: kPa (bar, kg/cm2, psi)

Engine TD27Ti

Initial injection pressure

New 12,259 - 12,749 (122.6 - 127.5, 125 -

130, 1,778 - 1,849)

Used 12,749 - 13,730 (127.5 - 137.3, 130 -

140, 1,849 - 1,991)

Idle speed

Unit: rpm

Engine TD27Ti

With A/C 850 50

Without A/C 700 50

SERVICE AND SPECIFICATIONS (SDS)

MA-48

http://vnx.su/

Page 91 of 1833

TIGHTENING TORQUE

UnitN×m kg-m ft-lb

Clutch Pedal stopper lock nut 12 - 15 1.2 - 1.5 8.7 - 10.8

Master cylinder push rod

lock nut 8 - 11 0.8 - 1.1 5.8 - 8.0

Manual transmission Drain and filler plugsFS5R30A 25 - 34 2.5 - 3.5 18 - 25

Differential carrier Drain and filler plugsR180A 39 - 59 4 - 6 28.8 - 43.5

H233B 59 - 98 6 - 10 43.5 - 72.3

Front axle and front suspen-

sion Tie-rod lock nut 60 - 70 6.1 - 7.1 44.3 - 51.6

Brake system Air bleeder valve 7 - 9 0.7 - 0.9 5.1 - 6.5

Wheel and tire

Wheel nut 118 - 147 12.0 - 15.0 87.0 -

108.4

SERVICE AND SPECIFICATIONS (SDS)

Chassis and Body Maintenance (Cont'd)

MA-50

http://vnx.su/

Page 100 of 1833

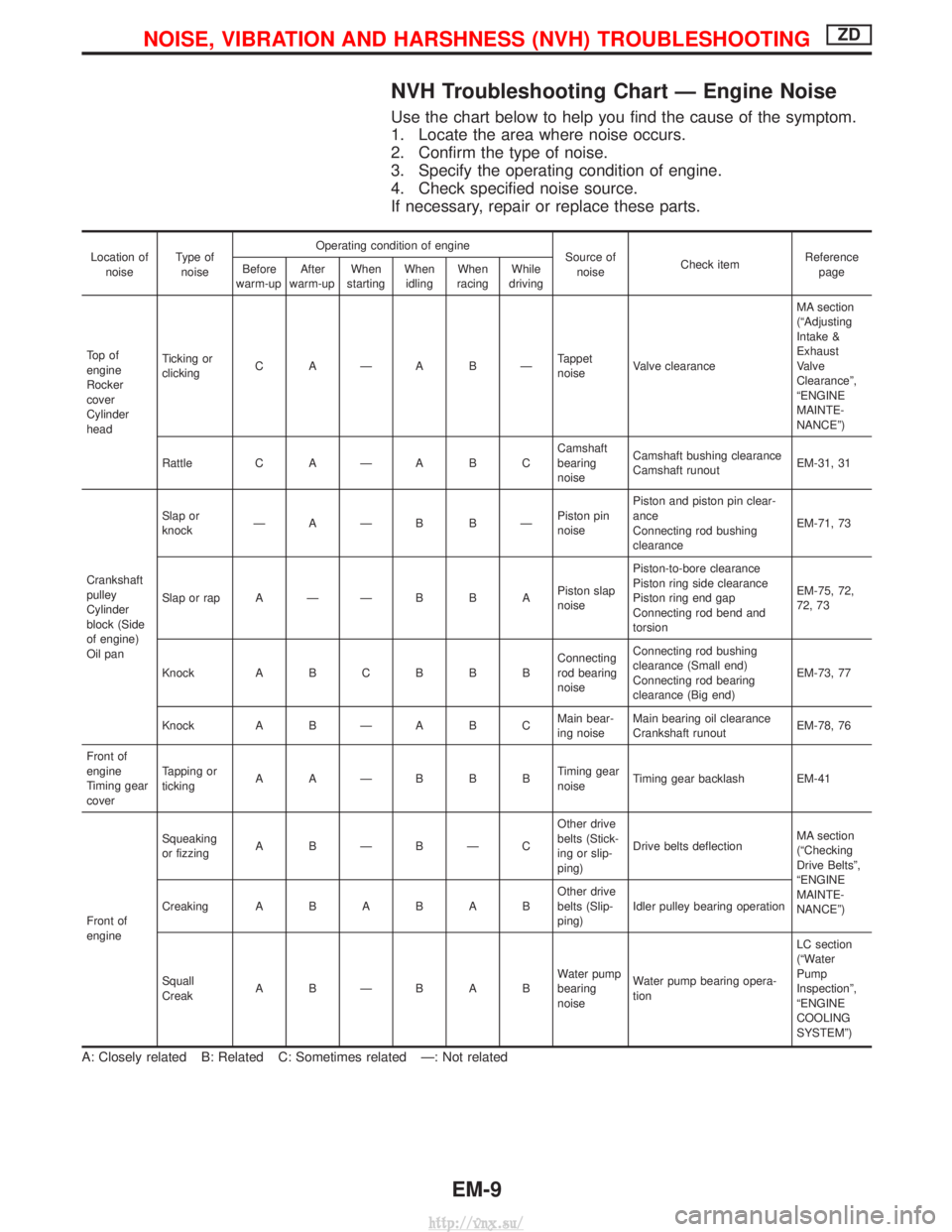

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location ofnoise Type of

noise Operating condition of engine

Source of

noise Check item Reference

page

Before

warm-up After

warm-up When

starting When

idling When

racing While

driving

To p o f

engine

Rocker

cover

Cylinder

head Ticking or

clicking

C AÐA BÐ Tappet

noiseValve clearance MA section

(ªAdjusting

Intake &

Exhaust

Valve

Clearanceº,

ªENGINE

MAINTE-

NANCEº)

Rattle C A Ð A B C Camshaft

bearing

noiseCamshaft bushing clearance

Camshaft runout

EM-31, 31

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil pan Slap or

knock

ÐAÐB BÐ Piston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearance

EM-71, 73

Slap or rap A Ð Ð B B A Piston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsion EM-75, 72,

72, 73

Knock A B C B B B Connecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)

EM-73, 77

Knock A B Ð A B C Main bear-

ing noiseMain bearing oil clearance

Crankshaft runout

EM-78, 76

Front of

engine

Timing gear

cover Tapping or

ticking

AAÐBBB Timing gear

noiseTiming gear backlash EM-41

Front of

engine Squeaking

or fizzing

A BÐBÐC Other drive

belts (Stick-

ing or slip-

ping)Drive belts deflection

MA section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº)

Creaking

ABABAB Other drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

Creak ABÐBAB Water pump

bearing

noiseWater pump bearing opera-

tion LC section

(ªWater

Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGZD

EM-9

http://vnx.su/

Page 105 of 1833

Removal and Installation

REMOVAL

1. Remove the following parts.

IUndercover

I Under guard

I Engine coolant (drain)

Refer to MA section, ªChanging Engine Coolantº.

I Exhaust front tube

Refer to FE section, ªRemoval and Installationº, ªEXHAUST

SYSTEMº.

I Remove wires, harnesses, tubes and pipes.

YEM057

SEM296G

CATALYST AND TURBOCHARGERZD

EM-14

http://vnx.su/

Page 108 of 1833

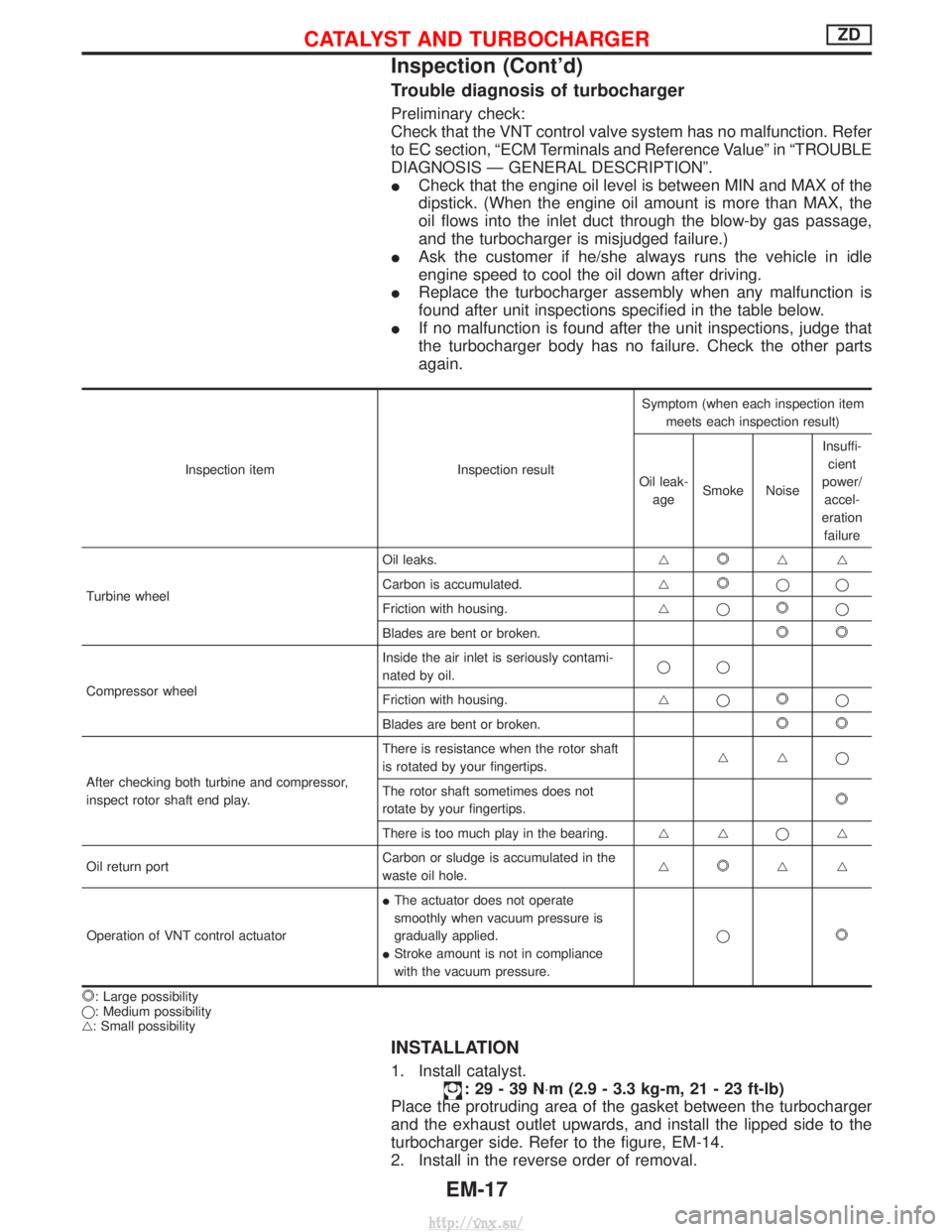

Trouble diagnosis of turbocharger

Preliminary check:

Check that the VNT control valve system has no malfunction. Refer

to EC section, ªECM Terminals and Reference Valueº in ªTROUBLE

DIAGNOSIS Ð GENERAL DESCRIPTIONº.

ICheck that the engine oil level is between MIN and MAX of the

dipstick. (When the engine oil amount is more than MAX, the

oil flows into the inlet duct through the blow-by gas passage,

and the turbocharger is misjudged failure.)

I Ask the customer if he/she always runs the vehicle in idle

engine speed to cool the oil down after driving.

I Replace the turbocharger assembly when any malfunction is

found after unit inspections specified in the table below.

I If no malfunction is found after the unit inspections, judge that

the turbocharger body has no failure. Check the other parts

again.

Inspection item Inspection resultSymptom (when each inspection item

meets each inspection result)

Oil leak- age Smoke Noise Insuffi-

cient

power/ accel-

eration failure

Turbine wheel Oil leaks.

g

gg

Carbon is accumulated. g

qq

Friction with housing. gq

q

Blades are bent or broken.

Compressor wheel Inside the air inlet is seriously contami-

nated by oil.

qq

Friction with housing. gqq

Blades are bent or broken.

After checking both turbine and compressor,

inspect rotor shaft end play. There is resistance when the rotor shaft

is rotated by your fingertips.

ggq

The rotor shaft sometimes does not

rotate by your fingertips.

There is too much play in the bearing. g gqg

Oil return port Carbon or sludge is accumulated in the

waste oil hole.g

gg

Operation of VNT control actuator I

The actuator does not operate

smoothly when vacuum pressure is

gradually applied.

I Stroke amount is not in compliance

with the vacuum pressure. q

: Large possibility

q: Medium possibility

g: Small possibility

INSTALLATION

1. Install catalyst.

:29-39N ×m (2.9 - 3.3 kg-m, 21 - 23 ft-lb)

Place the protruding area of the gasket between the turbocharger

and the exhaust outlet upwards, and install the lipped side to the

turbocharger side. Refer to the figure, EM-14.

2. Install in the reverse order of removal.

CATALYST AND TURBOCHARGERZD

Inspection (Cont'd)

EM-17

http://vnx.su/

Page 154 of 1833

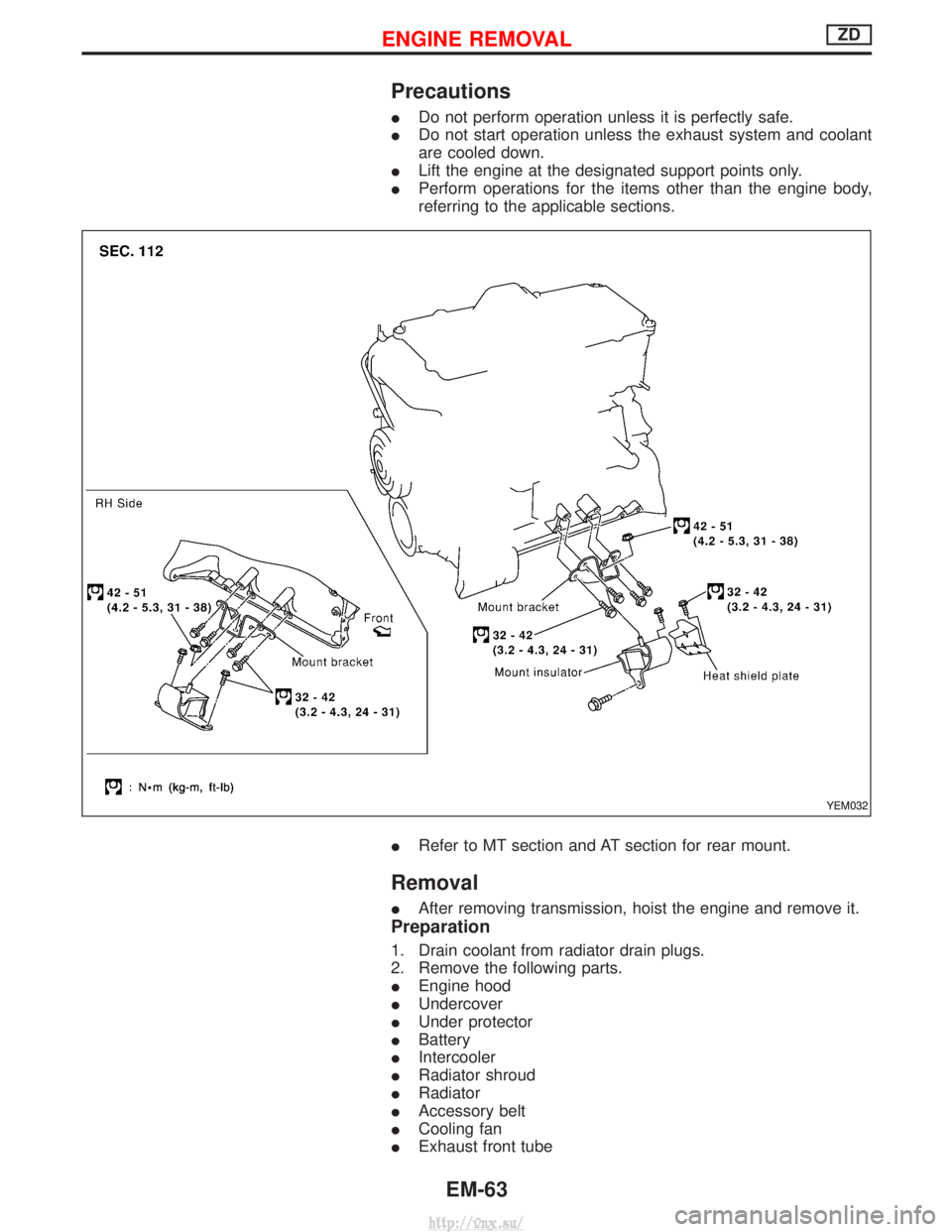

Precautions

IDo not perform operation unless it is perfectly safe.

I Do not start operation unless the exhaust system and coolant

are cooled down.

I Lift the engine at the designated support points only.

I Perform operations for the items other than the engine body,

referring to the applicable sections.

I Refer to MT section and AT section for rear mount.

Removal

IAfter removing transmission, hoist the engine and remove it.

Preparation

1. Drain coolant from radiator drain plugs.

2. Remove the following parts.

IEngine hood

I Undercover

I Under protector

I Battery

I Intercooler

I Radiator shroud

I Radiator

I Accessory belt

I Cooling fan

I Exhaust front tube

YEM032

ENGINE REMOVALZD

EM-63

http://vnx.su/

Page 215 of 1833

WARNING:

a. Situate vehicle on a flat and solid surface.

b. Place chocks at front and back of rear wheels.

c. Do not remove engine until exhaust system has completelycooled off.

d. For safety during subsequent steps, the tension of wires should be slackened against the engine.

e. Be sure to hoist engine in a safe manner.

f. For engines not equipped with engine slingers, attach proper slingers and bolts described in PARTS CATALOG.

CAUTION:

I When lifting engine, be careful not to strike adjacent parts,

especially, brake lines and brake master cylinder.

I In hoisting the engine, always use engine slingers in a safe

manner.

ENGINE REMOVALTD27Ti

EM-124

http://vnx.su/

Page 242 of 1833

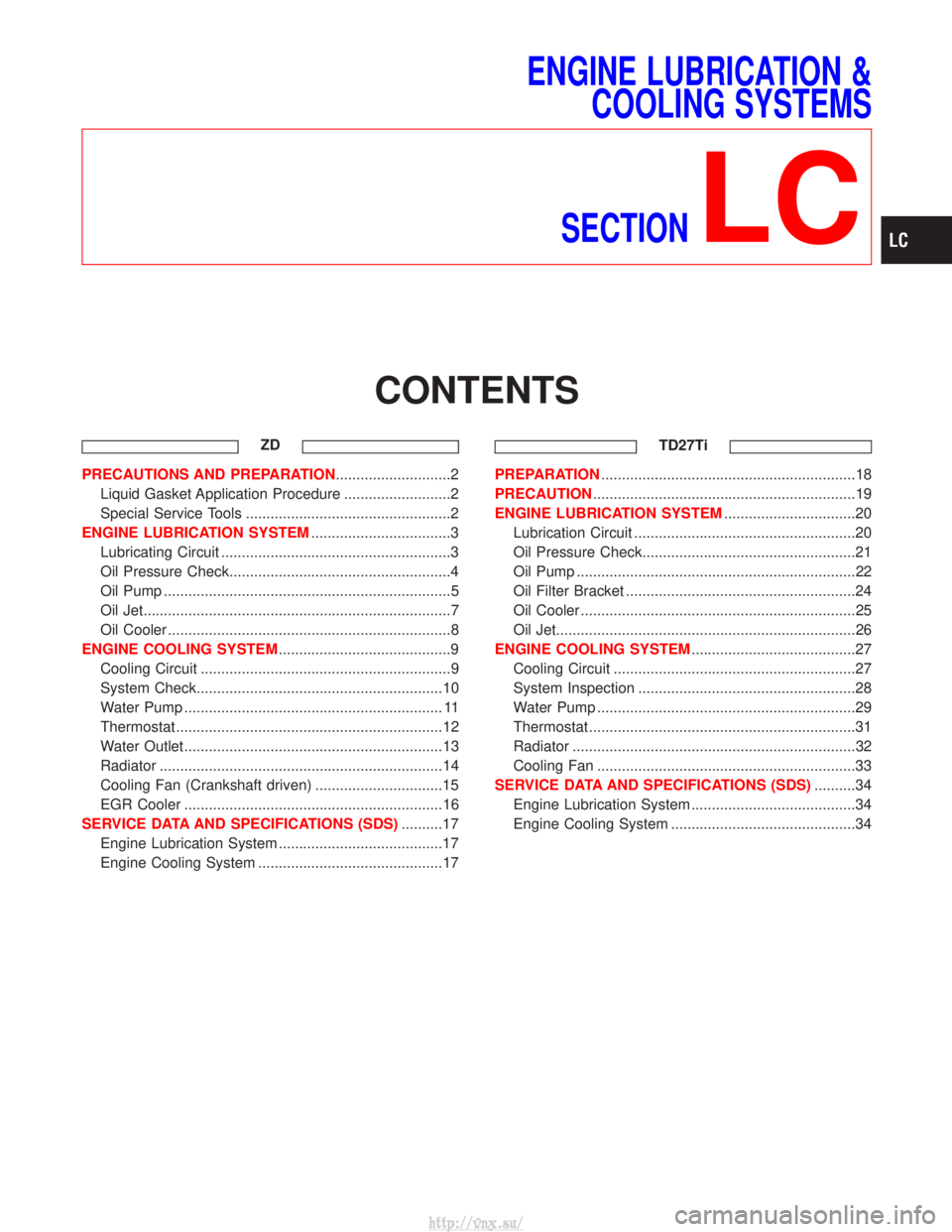

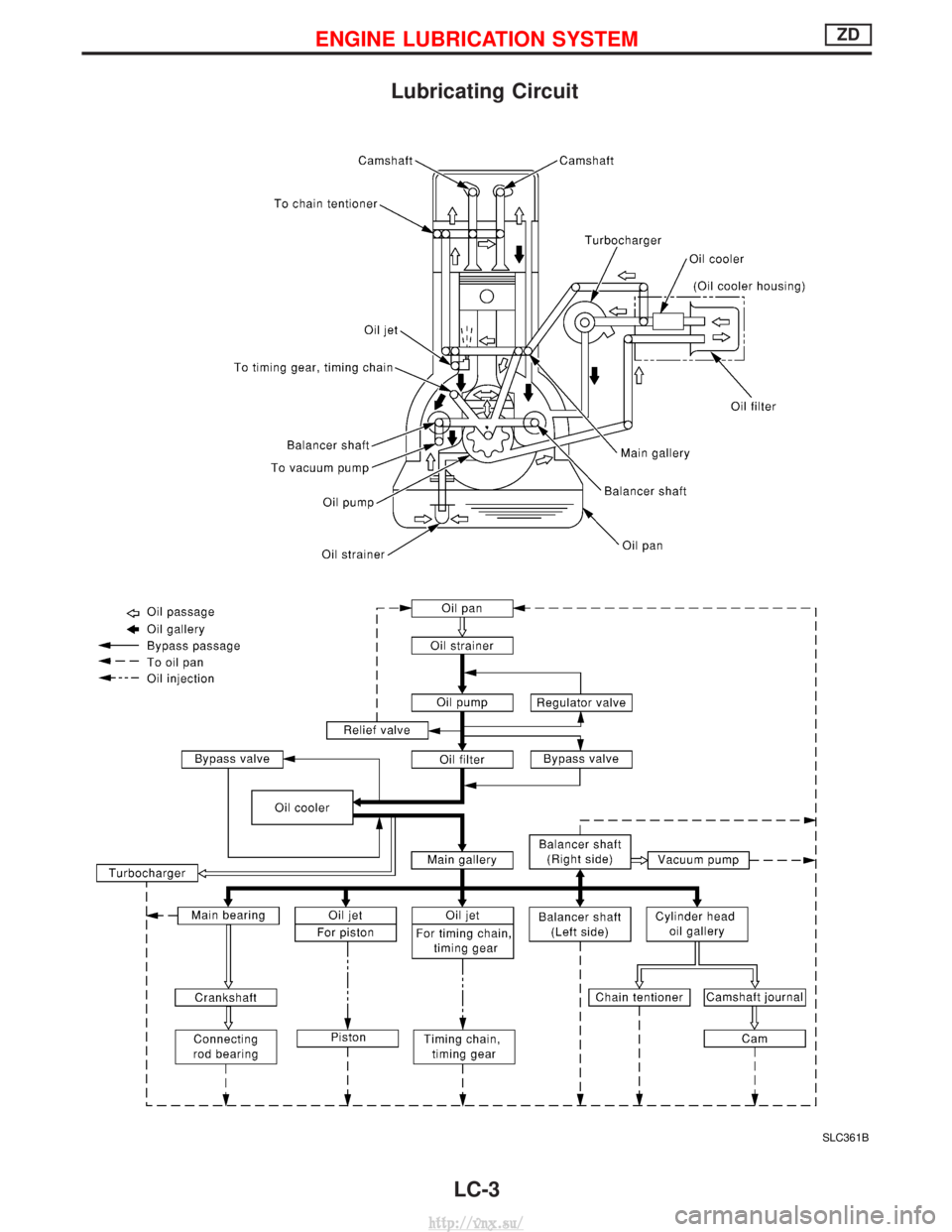

ENGINE LUBRICATION &COOLING SYSTEMS

SECTION

LC

CONTENTS

ZD

PRECAUTIONS AND PREPARATION ............................2

Liquid Gasket Application Procedure ..........................2

Special Service Tools ..................................................2

ENGINE LUBRICATION SYSTEM ..................................3

Lubricating Circuit ........................................................3

Oil Pressure Check......................................................4

Oil Pump ......................................................................5

Oil Jet........................................................................\

...7

Oil Cooler .....................................................................8

ENGINE COOLING SYSTEM ..........................................9

Cooling Circuit .............................................................9

System Check............................................................10

Water Pump ............................................................... 11

Thermostat .................................................................12

Water Outlet ...............................................................13

Radiator .....................................................................14

Cooling Fan (Crankshaft driven) ...............................15

EGR Cooler ...............................................................16

SERVICE DATA AND SPECIFICATIONS (SDS) ..........17

Engine Lubrication System ........................................17

Engine Cooling System .............................................17 TD27TiPREPARATION

..............................................................18

PRECAUTION ................................................................19

ENGINE LUBRICATION SYSTEM ................................20

Lubrication Circuit ......................................................20

Oil Pressure Check....................................................21

Oil Pump ....................................................................22

Oil Filter Bracket ........................................................24

Oil Cooler ...................................................................25

Oil Jet........................................................................\

.26

ENGINE COOLING SYSTEM ........................................27

Cooling Circuit ...........................................................27

System Inspection .....................................................28

Water Pump ...............................................................29

Thermostat .................................................................31

Radiator .....................................................................32

Cooling Fan ...............................................................33

SERVICE DATA AND SPECIFICATIONS (SDS) ..........34

Engine Lubrication System ........................................34

Engine Cooling System .............................................34

http://vnx.su/

Page 244 of 1833

Lubricating Circuit

SLC361B

ENGINE LUBRICATION SYSTEMZD

LC-3

http://vnx.su/