system NISSAN TERRANO 2004 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 25 of 1833

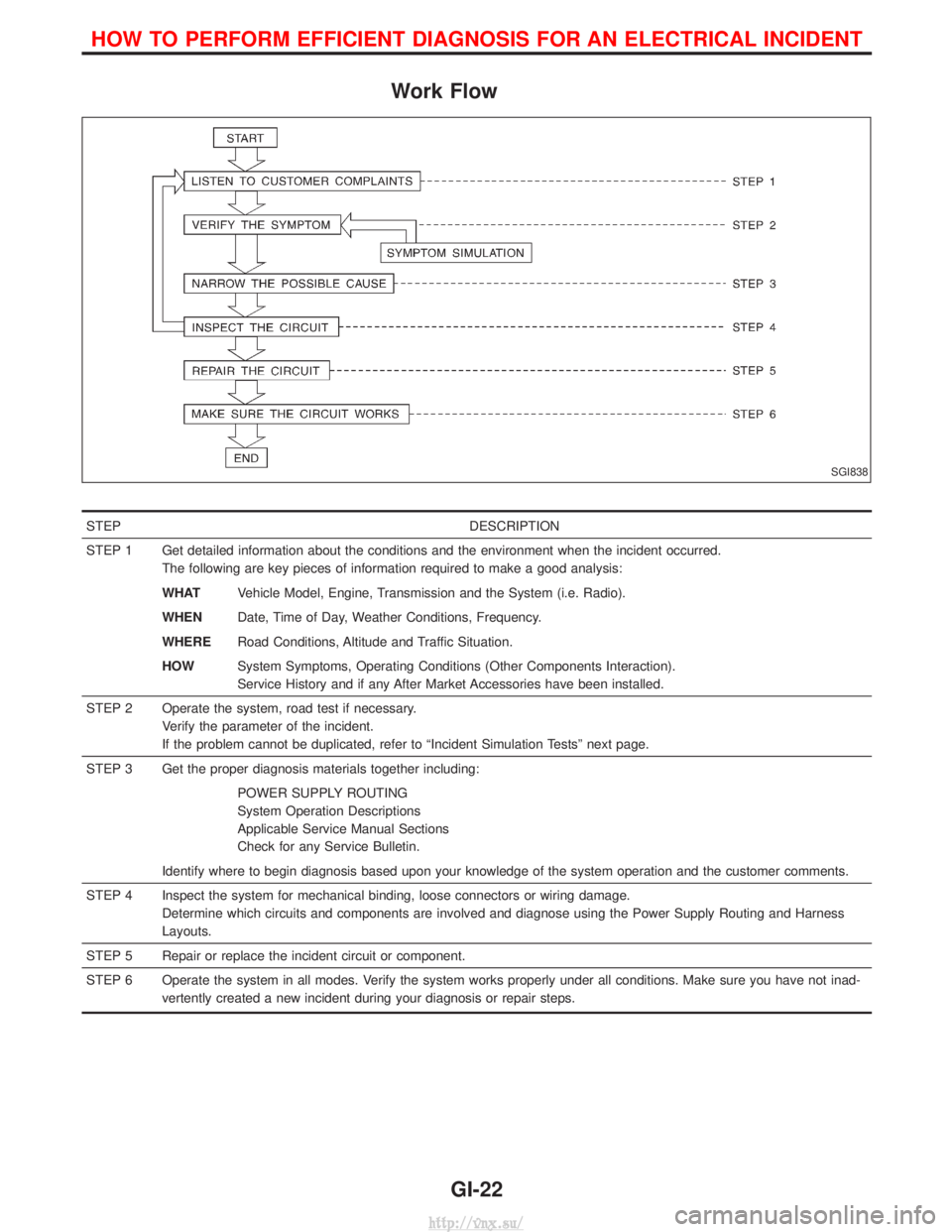

Work Flow

STEPDESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred. The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission and the System (i.e. Radio).

WHEN Date, Time of Day, Weather Conditions, Frequency.

WHERE Road Conditions, Altitude and Traffic Situation.

HOW System Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary. Verify the parameter of the incident.

If the problem cannot be duplicated, refer to ªIncident Simulation Testsº next page.

STEP 3 Get the proper diagnosis materials together including: POWER SUPPLY ROUTING

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletin.

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage. Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad- vertently created a new incident during your diagnosis or repair steps.

SGI838

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-22

http://vnx.su/

Page 26 of 1833

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

IVehicle vibration

I Heat sensitive

I Freezing

I Water intrusion

I Electrical load

I Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

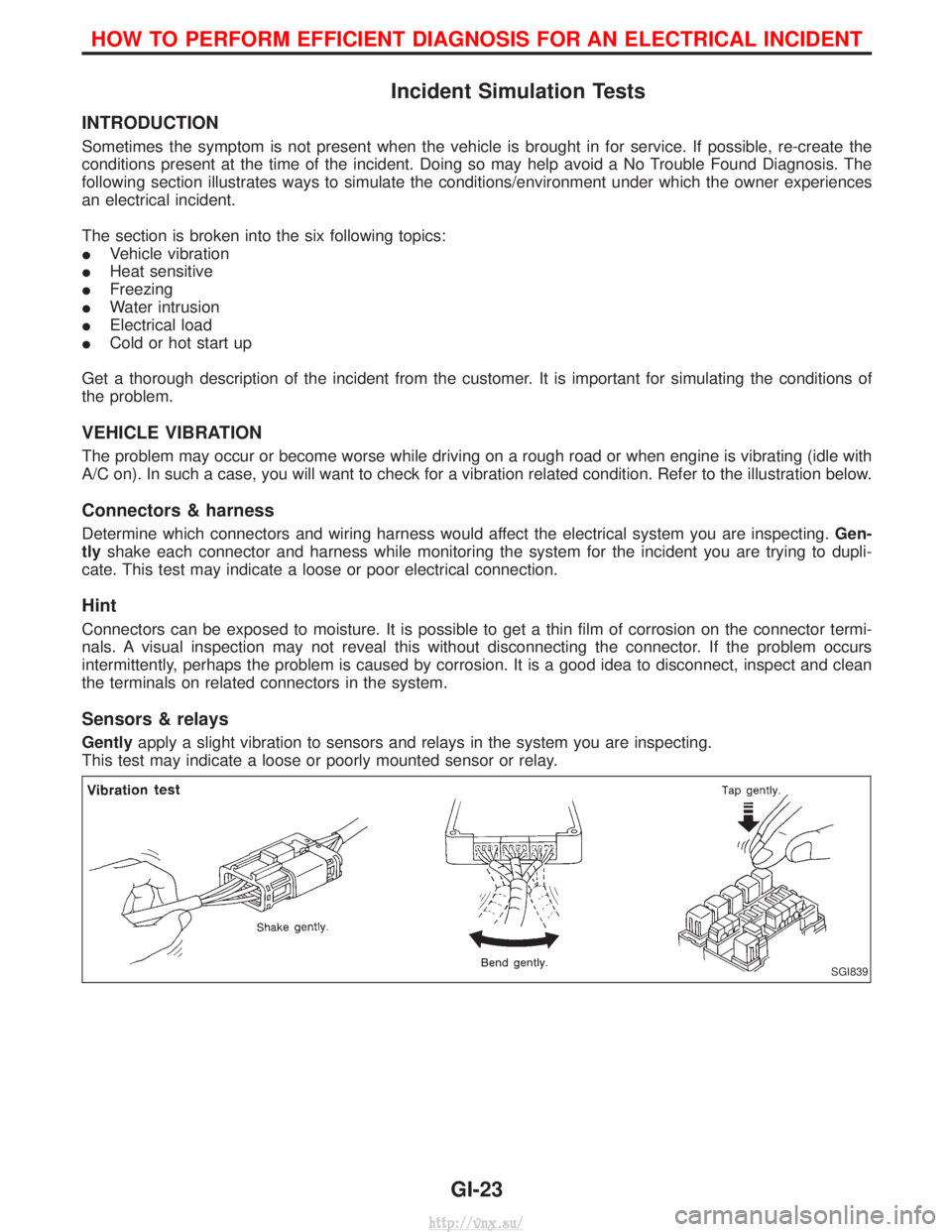

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gen-

tly shake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-23

http://vnx.su/

Page 27 of 1833

Engine compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for are:

IConnectors not fully seated.

I Wiring harness not long enough and is being stressed due to

engine vibrations or rocking.

I Wires laying across brackets or moving components.

I Loose, dirty or corroded ground wires.

I Wires routed too close to hot components.

To inspect components under the hood, start by verifying the integ-

rity of ground connections. (Refer to GROUND INSPECTION

described later.) First check that the system is properly grounded.

Then check for loose connection by gently shakingthe wiring or

components as previously explained. Using the wiring diagrams

inspect the wiring for continuity.

Behind the instrument panel

An improperly routed or improperly clamped harness can become

pinched during accessory installation. Vehicle vibration can aggra-

vate a harness which is routed along a bracket or near a screw.

Under seating areas

An unclamped or loose harness can cause wiring to be pinched by

seat components (such as slide guides) during vehicle vibration. If

the wiring runs under seating areas, inspect wire routing for pos-

sible damage or pinching.

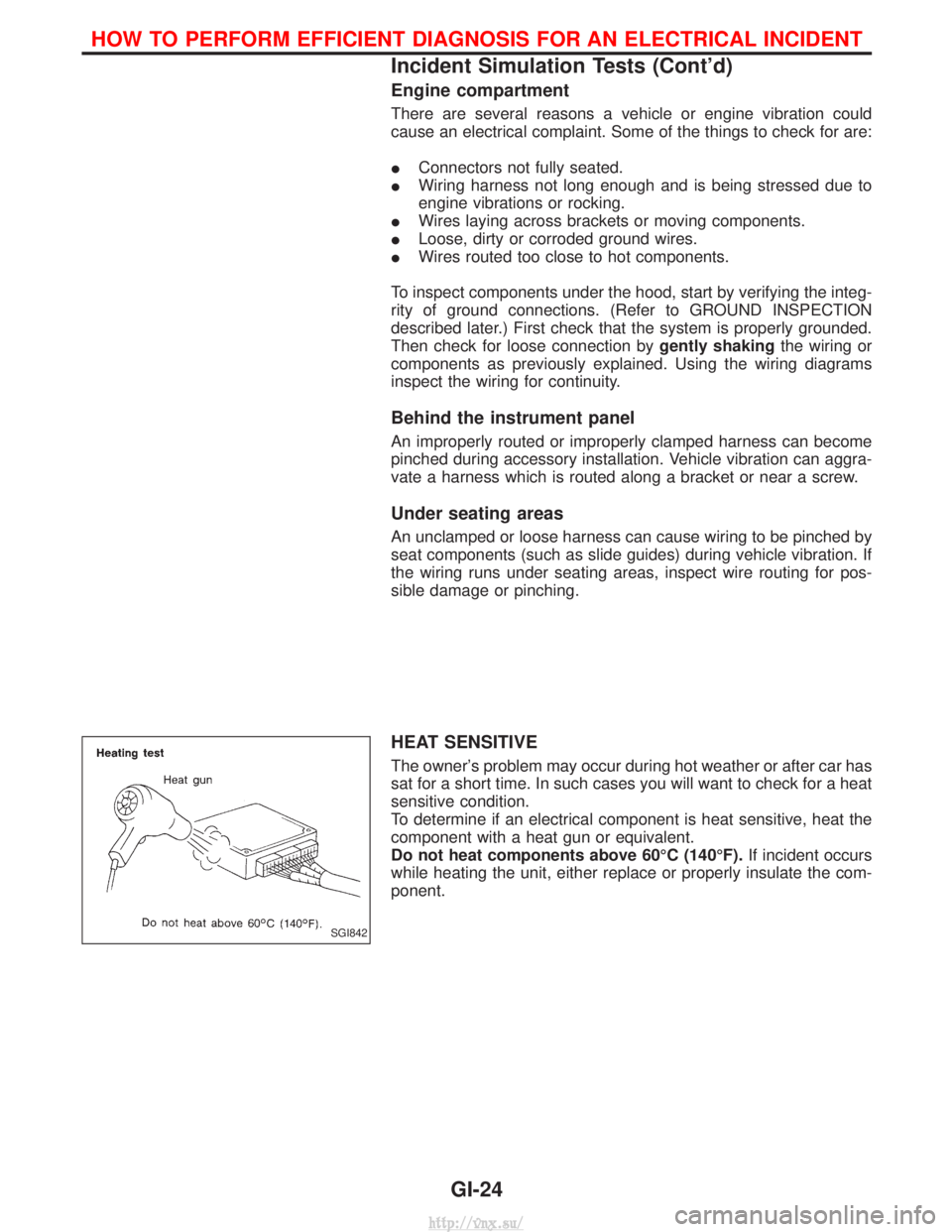

HEAT SENSITIVE

The owner's problem may occur during hot weather or after car has

sat for a short time. In such cases you will want to check for a heat

sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60ÉC (140ÉF). If incident occurs

while heating the unit, either replace or properly insulate the com-

ponent.

SGI842

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-24

http://vnx.su/

Page 29 of 1833

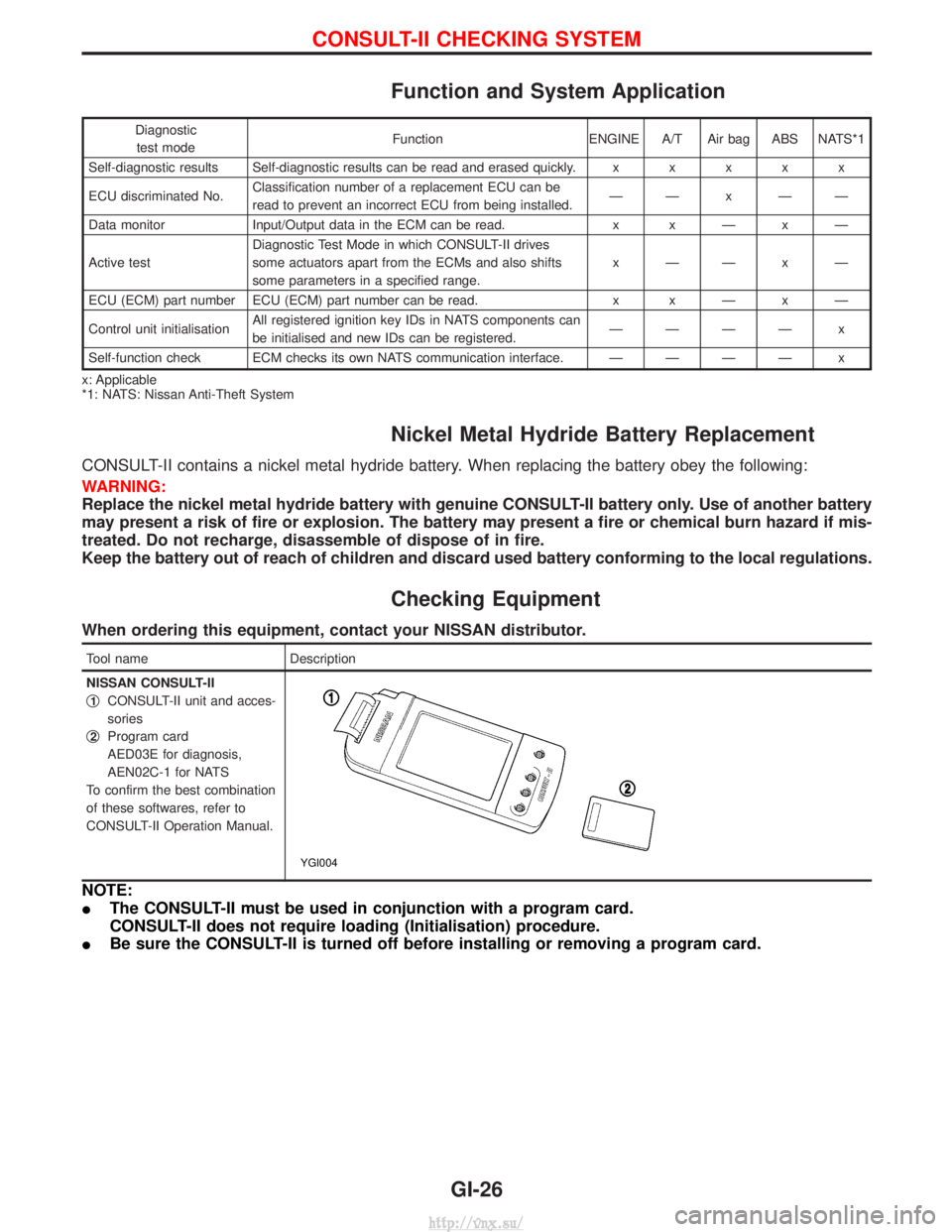

Function and System Application

Diagnostictest mode Function ENGINE A/T Air bag ABS NATS*1

Self-diagnostic results Self-diagnostic results can be read and erased quickly. xxxxx

ECU discriminated No. Classification number of a replacement ECU can be

read to prevent an incorrect ECU from being installed. ÐÐxÐÐ

Data monitor Input/Output data in the ECM can be read. x xÐxÐ

Active test Diagnostic Test Mode in which CONSULT-II drives

some actuators apart from the ECMs and also shifts

some parameters in a specified range. xÐÐxÐ

ECU (ECM) part number ECU (ECM) part number can be read. x xÐxÐ

Control unit initialisation All registered ignition key IDs in NATS components can

be initialised and new IDs can be registered. ÐÐÐÐ x

Self-function check ECM checks its own NATS communication interface. ÐÐÐÐ x

x: Applicable

*1: NATS: Nissan Anti-Theft System

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with genuine CONSULT-II battery only. Use of another battery

may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard if mis-

treated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

Checking Equipment

When ordering this equipment, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT-II

q

1CONSULT-II unit and acces-

sories

q

2Program card

AED03E for diagnosis,

AEN02C-1 for NATS

To confirm the best combination

of these softwares, refer to

CONSULT-II Operation Manual.

YGI004

NOTE:

I The CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialisation) procedure.

I Be sure the CONSULT-II is turned off before installing or removing a program card.

CONSULT-II CHECKING SYSTEM

GI-26

http://vnx.su/

Page 35 of 1833

4-pole Lift

WARNING:

Do not use a 2-pole lift.

Due to weight balance of the vehicle and shape of underbody,

lift arms can not be attached in a safe way. Therefore it is rec-

ommended to use a 4-pole lift only.

Tow Truck Towing

CAUTION:

IAll applicable local laws regarding the towing operation

must be obeyed.

I It is necessary to use proper towing equipment to avoid

possible damage to the vehicle during a towing operation.

I Attach safety chains for all towing.

I When towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, a dolly must be used.

I When towing with the front wheels on the ground:

Move both the gearshift and transfer levers to neutral (ªNº

position).

Turn the ignition key to the ªOFFº position and secure the

steering wheel in a straightahead position with a rope or

similar device. Never place the ignition key in the ªLOCKº

position. This will result in damage to the steering lock

mechanism.

I When towing with the rear wheels on the ground, release

the parking brake and move both the gearshift and trans-

fer levers to neutral (ªNº position).

I Never tow vehicle from the rear (i.e., backward) with four

wheels on the ground as this may cause serious and

expensive damage to the transmission.

LIFTING POINTS AND TOW TRUCK TOWING

GI-32

http://vnx.su/

Page 37 of 1833

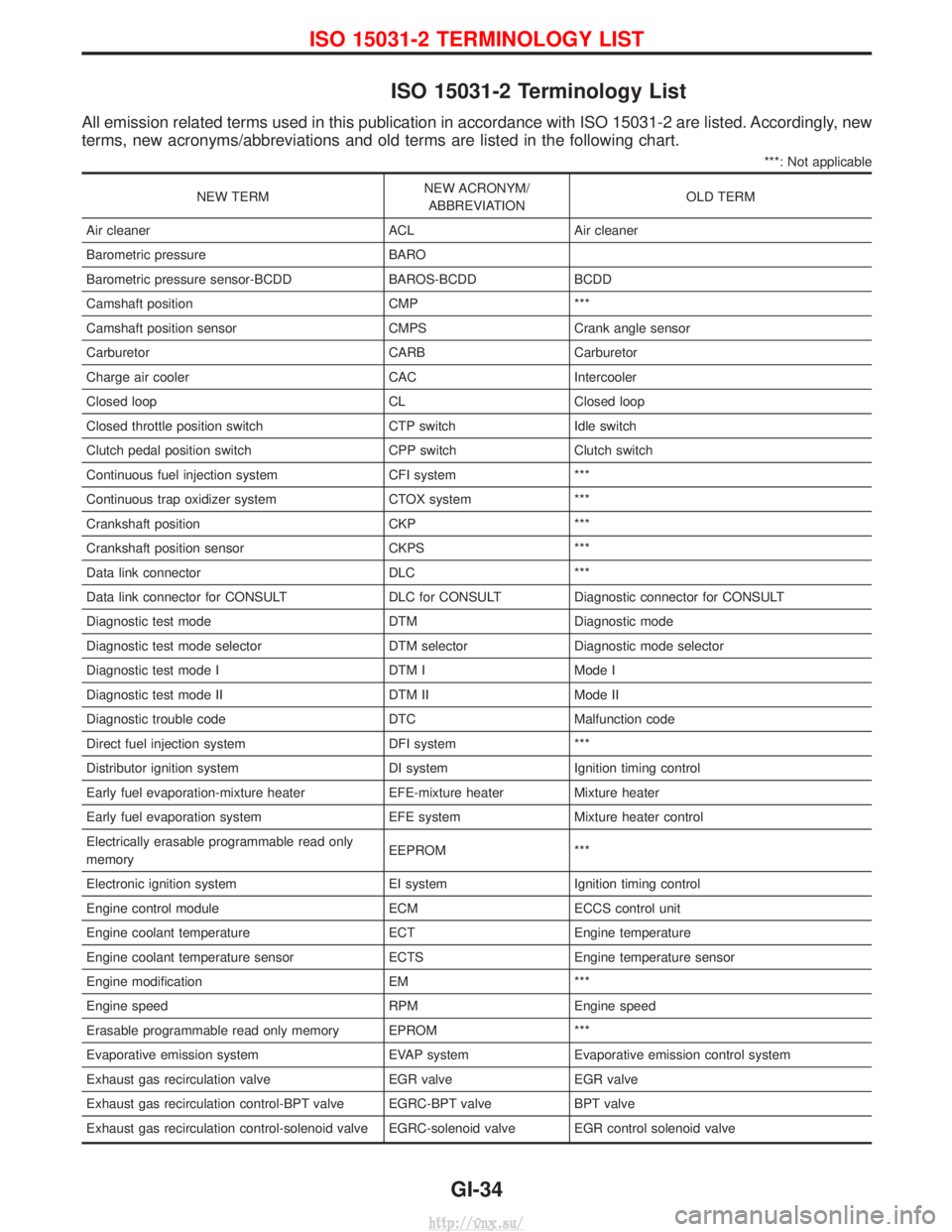

ISO 15031-2 Terminology List

All emission related terms used in this publication in accordance with ISO 15031-2 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

***: Not applicable

NEW TERMNEW ACRONYM/

ABBREVIATION OLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONSULT DLC for CONSULT Diagnostic connector for CONSULT

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read only

memory EEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid valve EGRC-solenoid valve EGR control solenoid valve

ISO 15031-2 TERMINOLOGY LIST

GI-34

http://vnx.su/

Page 38 of 1833

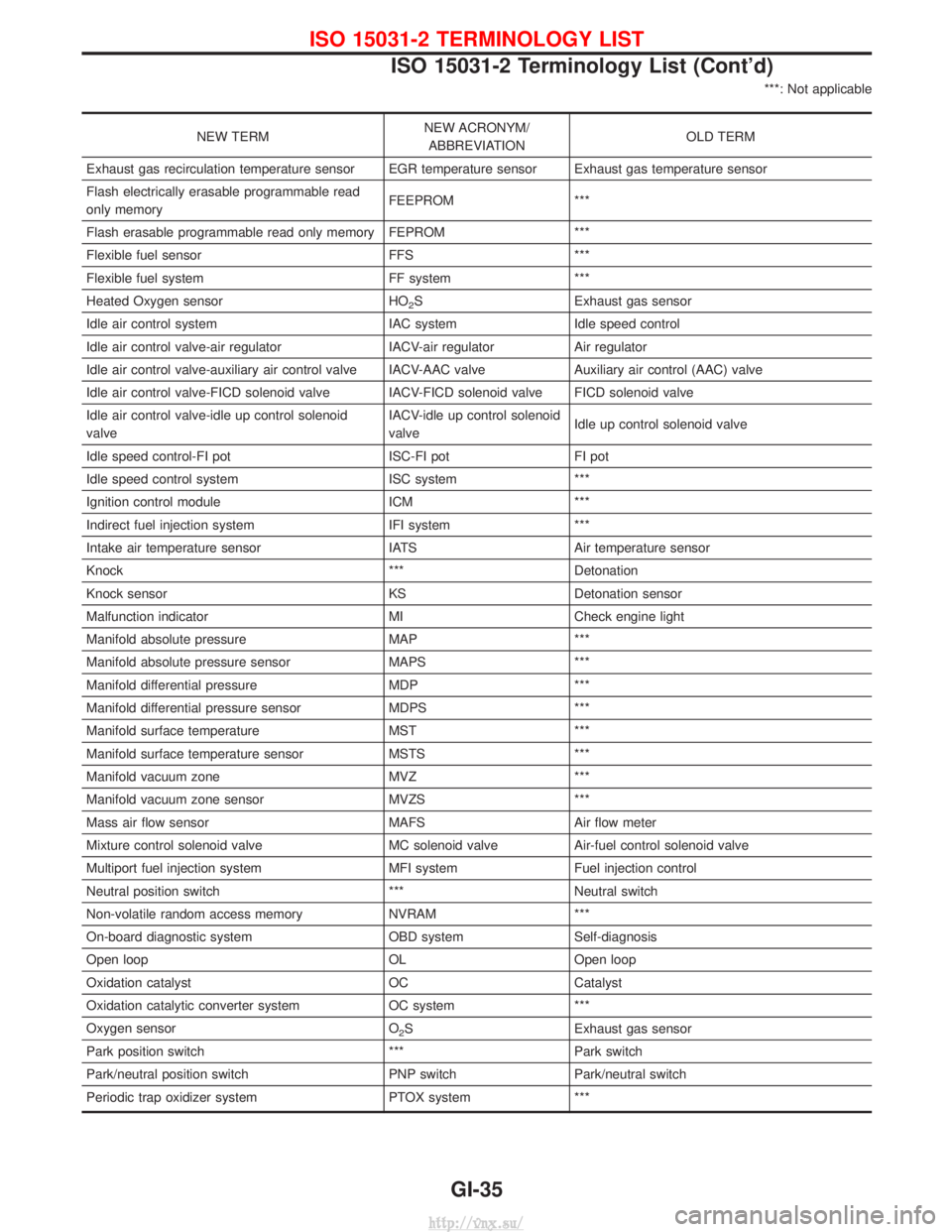

***: Not applicable

NEW TERMNEW ACRONYM/

ABBREVIATION OLD TERM

Exhaust gas recirculation temperature sensor EGR temperature sensor Exhaust gas temperature sensor

Flash electrically erasable programmable read

only memory FEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Heated Oxygen sensor HO

2S Exhaust gas sensor

Idle air control system IAC systemIdle speed control

Idle air control valve-air regulator IACV-air regulatorAir regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valve IACV-idle up control solenoid

valve

Idle up control solenoid valve

Idle speed control-FI pot ISC-FI potFI pot

Idle speed control system ISC system***

Ignition control module ICM***

Indirect fuel injection system IFI system***

Intake air temperature sensor IATS Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Neutral position switch *** Neutral switch

Non-volatile random access memory NVRAM ***

On-board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O

2S Exhaust gas sensor

Park position switch ***Park switch

Park/neutral position switch PNP switch Park/neutral switch

Periodic trap oxidizer system PTOX system ***

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 Terminology List (Cont'd)

GI-35

http://vnx.su/

Page 39 of 1833

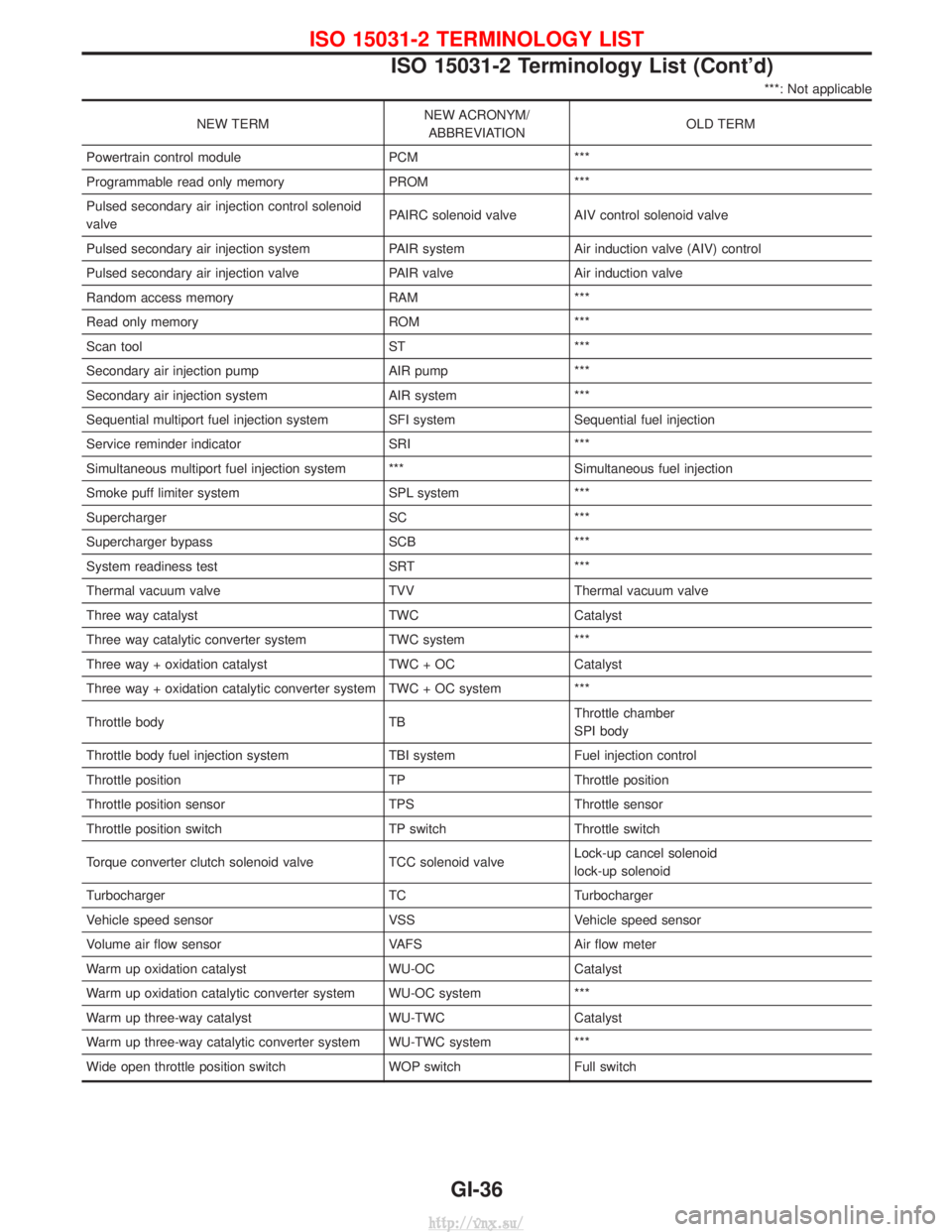

***: Not applicable

NEW TERMNEW ACRONYM/

ABBREVIATION OLD TERM

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control solenoid

valve PAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

Simultaneous multiport fuel injection system *** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter system TWC + OC system ***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancel solenoid

lock-up solenoid

Turbocharger TC Turbocharger

Vehicle speed sensor VSS Vehicle speed sensor

Volume air flow sensor VAFS Air flow meter

Warm up oxidation catalyst WU-OC Catalyst

Warm up oxidation catalytic converter system WU-OC system ***

Warm up three-way catalyst WU-TWC Catalyst

Warm up three-way catalytic converter system WU-TWC system ***

Wide open throttle position switch WOP switch Full switch

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 Terminology List (Cont'd)

GI-36

http://vnx.su/

Page 42 of 1833

MAINTENANCE

SECTION

MA

CONTENTS

PRE-DELIVERY INSPECTION ITEMS ............................3

GENERAL MAINTENANCE ............................................4

PERIODIC MAINTENANCE ............................................5

Maintenance Schedule for Diesel Engine Models

(annual mileage < 30,000 km/year) ............................5

Maintenance Schedule for Diesel Engine Models

(annual mileage > 30,000 km/year) ............................8

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year) .......................... 11

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year) ..........................14

RECOMMENDED FLUIDS AND LUBRICANTS ...........17

Fluids and Lubricants ................................................17

SAE Viscosity Number ..............................................18

Engine Coolant Mixture Ratio....................................19

TD

ENGINE MAINTENANCE ..............................................20

Retightening Manifold Bolts and Nuts .......................20

Adjusting Intake and Exhaust Valve Clearance ........20

Drive Belt Inspection..................................................20

Changing Engine Oil..................................................21

Changing Oil Filter .....................................................21

Changing Engine Coolant..........................................22

Checking Cooling System .........................................23

Checking and Replacing fuel filter and Draining

Water ........................................................................\

.23

Cleaning and Replacing Air Cleaner Filter (Dry

paper type).................................................................24

Checking Injection Nozzle .........................................25

Checking Idle Speed .................................................26

ZD

ENGINE MAINTENANCE ..............................................28

Checking Tightening Torque ......................................28

Adjusting Intake and Exhaust Valve Clearance ........28

Checking Drive Belt ...................................................28

Removal .....................................................................29 Installation ..................................................................29

Changing Engine Oil..................................................29

Changing Engine Oil Filter ........................................30

Changing Engine Coolant..........................................31

Checking Cooling System .........................................32

Checking and Replacing Fuel Filter and Draining

Water ........................................................................\

.33

Checking Fuel Lines ..................................................34

Cleaning and Replacing Air Cleaner Filter ................35

CHASSIS AND BODY MAINTENANCE .......................36

Checking Exhaust System.........................................36

Checking Clutch Operation........................................36

Checking Clutch Fluid Level and Leaks ....................36

Checking Clutch System ...........................................36

Checking M/T Oil .......................................................36

Changing M/T Oil.......................................................37

Checking Water Entry ................................................37

Checking Transfer Oil ................................................37

Changing Transfer Oil................................................38

Checking Propeller Shaft ...........................................38

Checking Differential Gear Oil ...................................38

Changing Differential Gear Oil ..................................39

Checking Front Wheel Bearing Grease ....................39

Repacking Front Wheel Bearing Grease ..................39

Checking Free-running Hub Grease .........................40

Checking Brake Fluid Level and Leaks.....................40

Checking Brake System ............................................40

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve ..................................40

Checking Disc Brake .................................................40

Checking Drum Brake ...............................................41

Checking Foot Brake Pedal Operation......................42

Checking Parking Brake ............................................42

Changing Brake Fluid ................................................43

Balancing Wheels ......................................................43

Tire Rotation ..............................................................43

Checking Steering Gear and Linkage .......................43

Checking Fluid Level and Leaks (Power steering) ...44

http://vnx.su/

Page 45 of 1833

General maintenance includes those items which should be checked during normal day-to-day operation of

the vehicle. They are essential if the vehicle is to continue functioning correctly. Owners can perform the

checks and inspections themselves, or they can be carried out by a NISSAN dealer.

ItemReference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be checked periodically, unless otherwise specified.

Tires Check the pressure with a gauge weekly when at a service station, including the spare,

and adjust to the specified pressure if necessary. Check carefully for damage, cuts or excessive

wear. Ð

Windshield wiper blades Check for cracks or wear if not functioning correctly. Ð

Doors and engine hood Check that all doors, the engine hood, the trunk lid and back door

function correctly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch prevents the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication more

often. MA-45

Tire rotation Tires should be rotated every 5,000 km (3,000 miles). MA-43

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle etc.

Lights Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating correctly and installed securely. Also check headlight aim. Ð

Warning lights and buzzers/chimes Make sure that all warning lights and buzzers/chimes are

functioning correctly. Ð

Steering wheel Check that it has the specified play. Check for changes in the steering

operation, such as excessive free play, hard steering or strange noises. Free play: Less than 35 mm (1.38 in) Ð

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear of damage. MA-46

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer fluid Check that there is adequate fluid in the tank.

Engine coolant level Check the coolant level when the engine is cold. MA-22

Engine oil level Check the level after parking the vehicle (on level ground) and turning off the

engine. MA-21

Brake and clutch fluid level Make sure that the brake fluid level is between the ªMAXº and

ªMINº lines on the reservoir. MA-36/MA-40

Battery Check the fluid level in each cell. It should be between the ªMAXº and ªMINº lines. Ð

GENERAL MAINTENANCE

MA-4

http://vnx.su/