Ignition NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 486 of 1833

Diagnostic Procedure

1 CHECK STOP LAMP SWITCH CIRCUIT

1. Turn ignition switch ªONº.

2. Check the stop lamp when depressing and releasing the stop lamp switch.

MTBL0443

OK or NG

OK EGO TO 4.

NG EGO TO 2.

2 CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

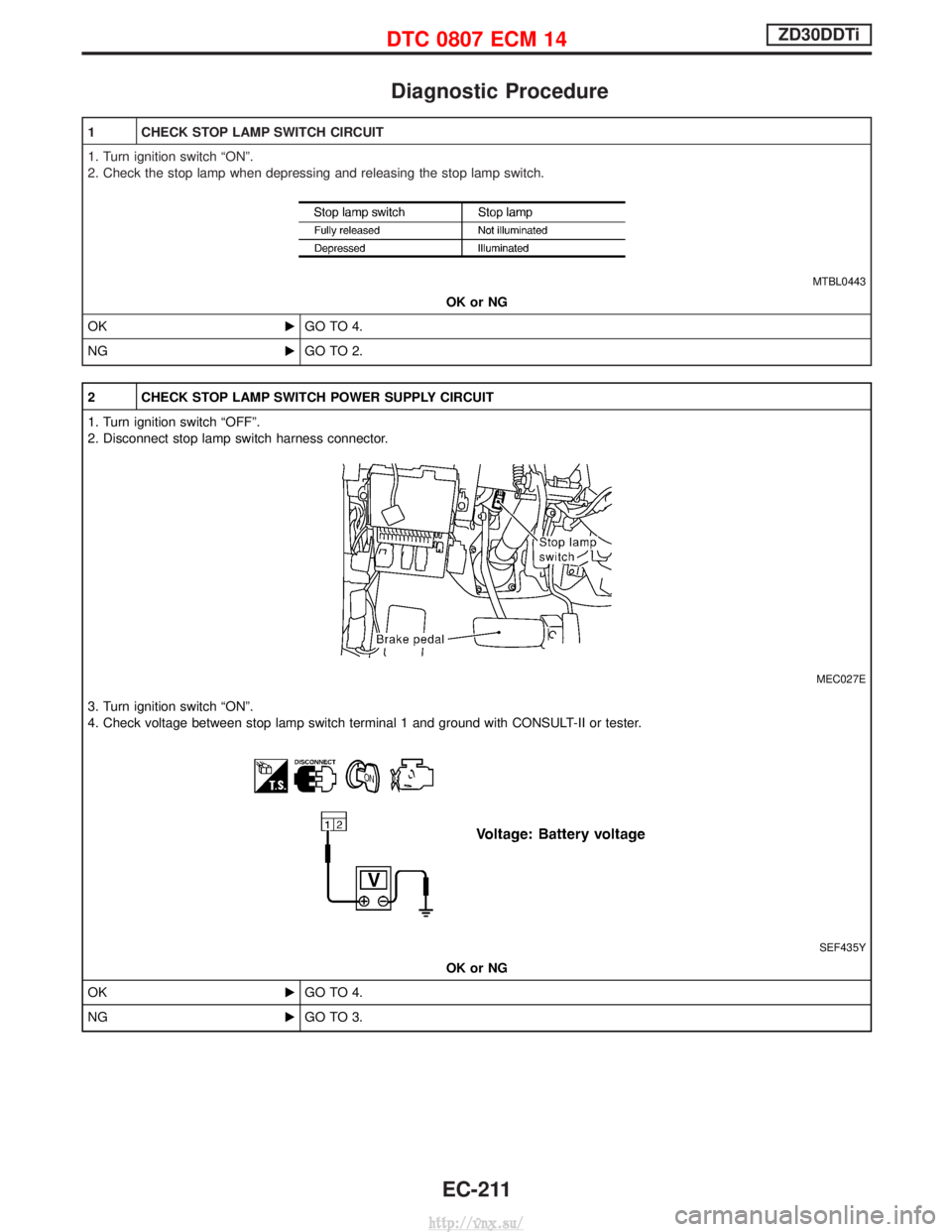

2. Disconnect stop lamp switch harness connector.

MEC027E

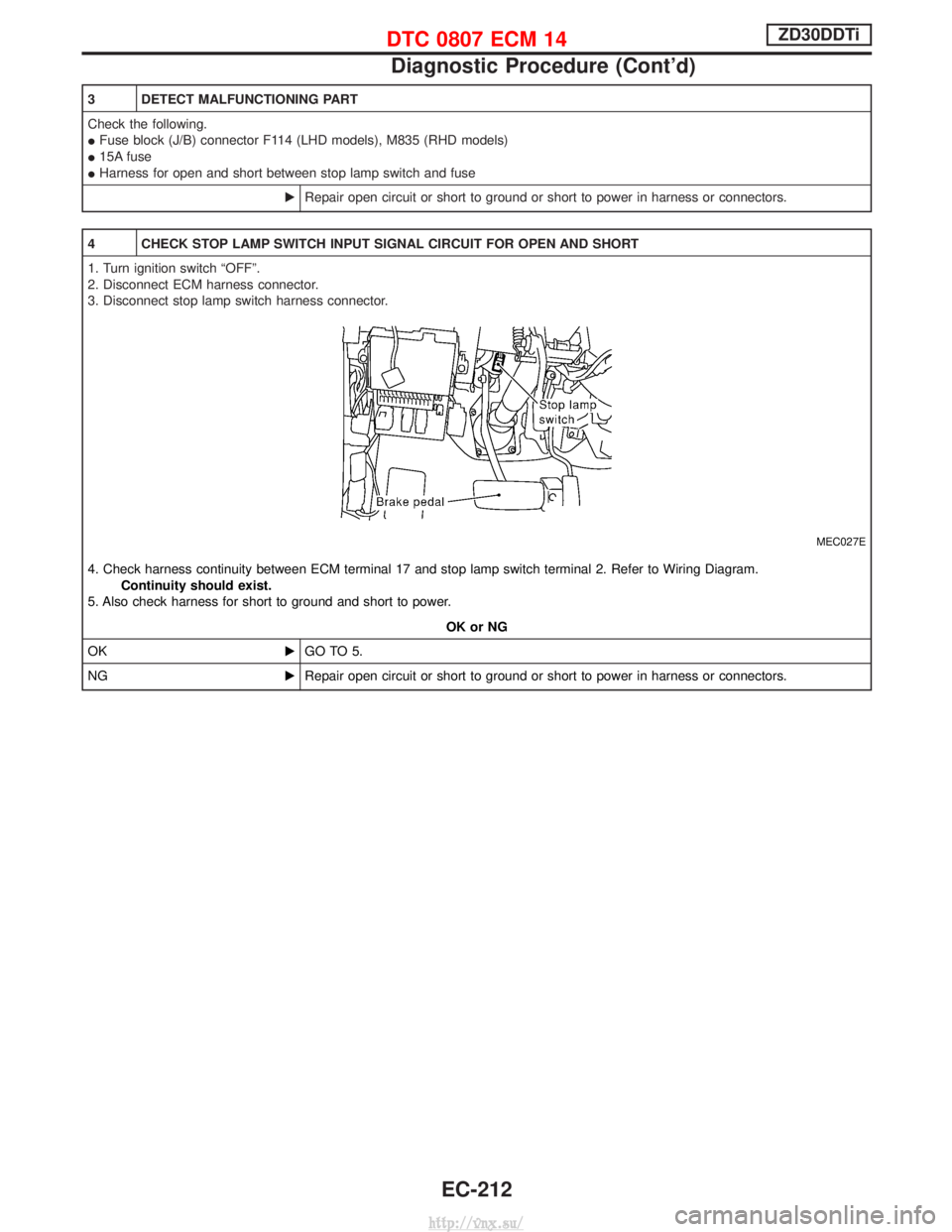

3. Turn ignition switch ªONº.

4. Check voltage between stop lamp switch terminal 1 and ground with CONSULT-II or tester.

SEF435Y

OK or NG

OK EGO TO 4.

NG EGO TO 3.

DTC 0807 ECM 14ZD30DDTi

EC-211

http://vnx.su/

Page 487 of 1833

3 DETECT MALFUNCTIONING PART

Check the following.

IFuse block (J/B) connector F114 (LHD models), M835 (RHD models)

I 15A fuse

I Harness for open and short between stop lamp switch and fuse

ERepair open circuit or short to ground or short to power in harness or connectors.

4 CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Disconnect stop lamp switch harness connector.

MEC027E

4. Check harness continuity between ECM terminal 17 and stop lamp switch terminal 2. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG ERepair open circuit or short to ground or short to power in harness or connectors.

DTC 0807 ECM 14ZD30DDTi

Diagnostic Procedure (Cont'd)

EC-212

http://vnx.su/

Page 489 of 1833

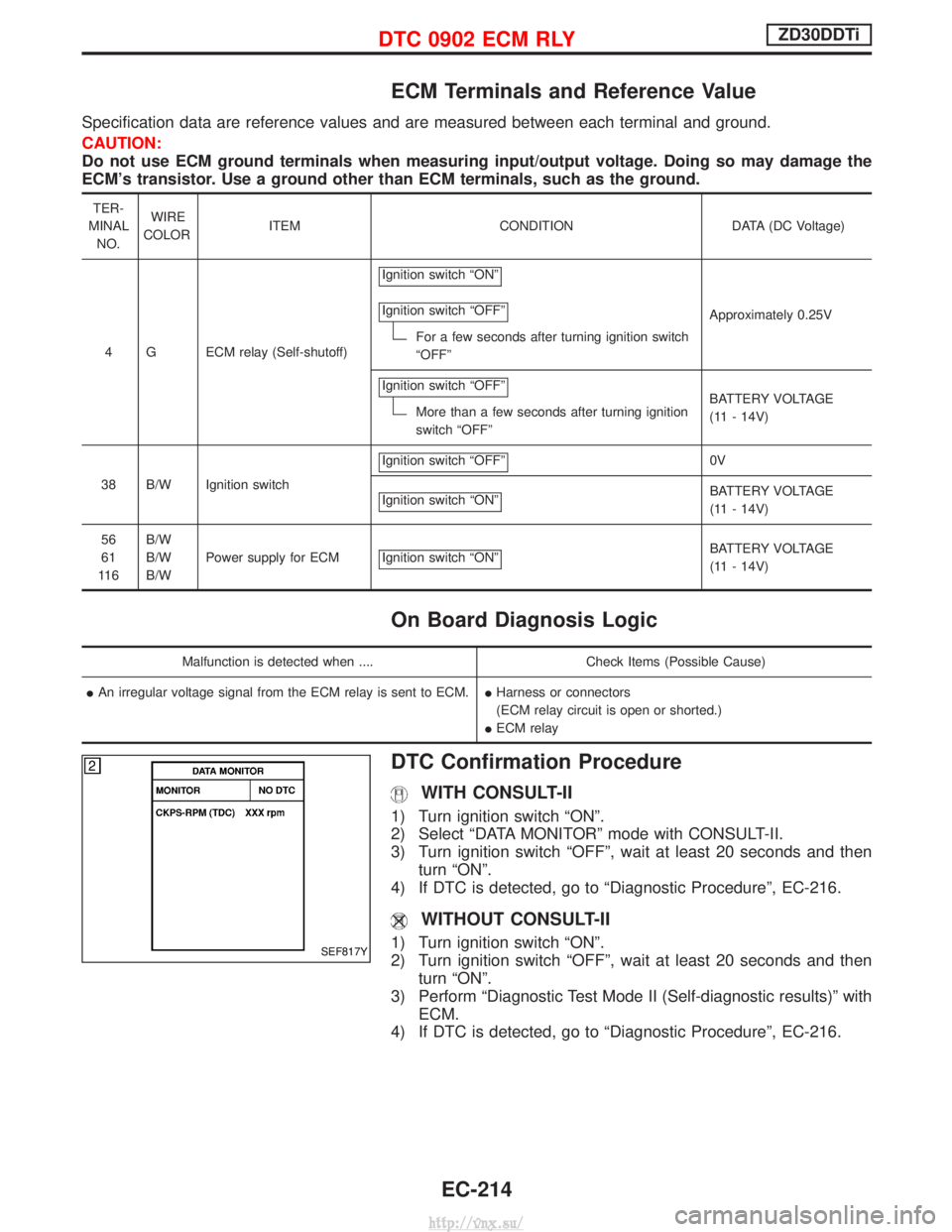

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION DATA (DC Voltage)

4 G ECM relay (Self-shutoff) Ignition switch ªONº

Ignition switch ªOFFº

For a few seconds after turning ignition switch

ªOFFº

Approximately 0.25V

Ignition switch ªOFFº

More than a few seconds after turning ignition

switch ªOFFº BATTERY VOLTAGE

(11 - 14V)

38 B/W Ignition switch Ignition switch ªOFFº

0V

Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

56

61

11 6 B/W

B/W

B/W

Power supply for ECM Ignition switch ªONº

BATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis Logic

Malfunction is detected when ....

Check Items (Possible Cause)

I An irregular voltage signal from the ECM relay is sent to ECM. IHarness or connectors

(ECM relay circuit is open or shorted.)

I ECM relay

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Turn ignition switch ªOFFº, wait at least 20 seconds and then

turn ªONº.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-216.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº.

2) Turn ignition switch ªOFFº, wait at least 20 seconds and then turn ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-216.SEF817Y

DTC 0902 ECM RLYZD30DDTi

EC-214

http://vnx.su/

Page 491 of 1833

Diagnostic Procedure

1 CHECK ECM POWER SUPPLY CIRCUIT

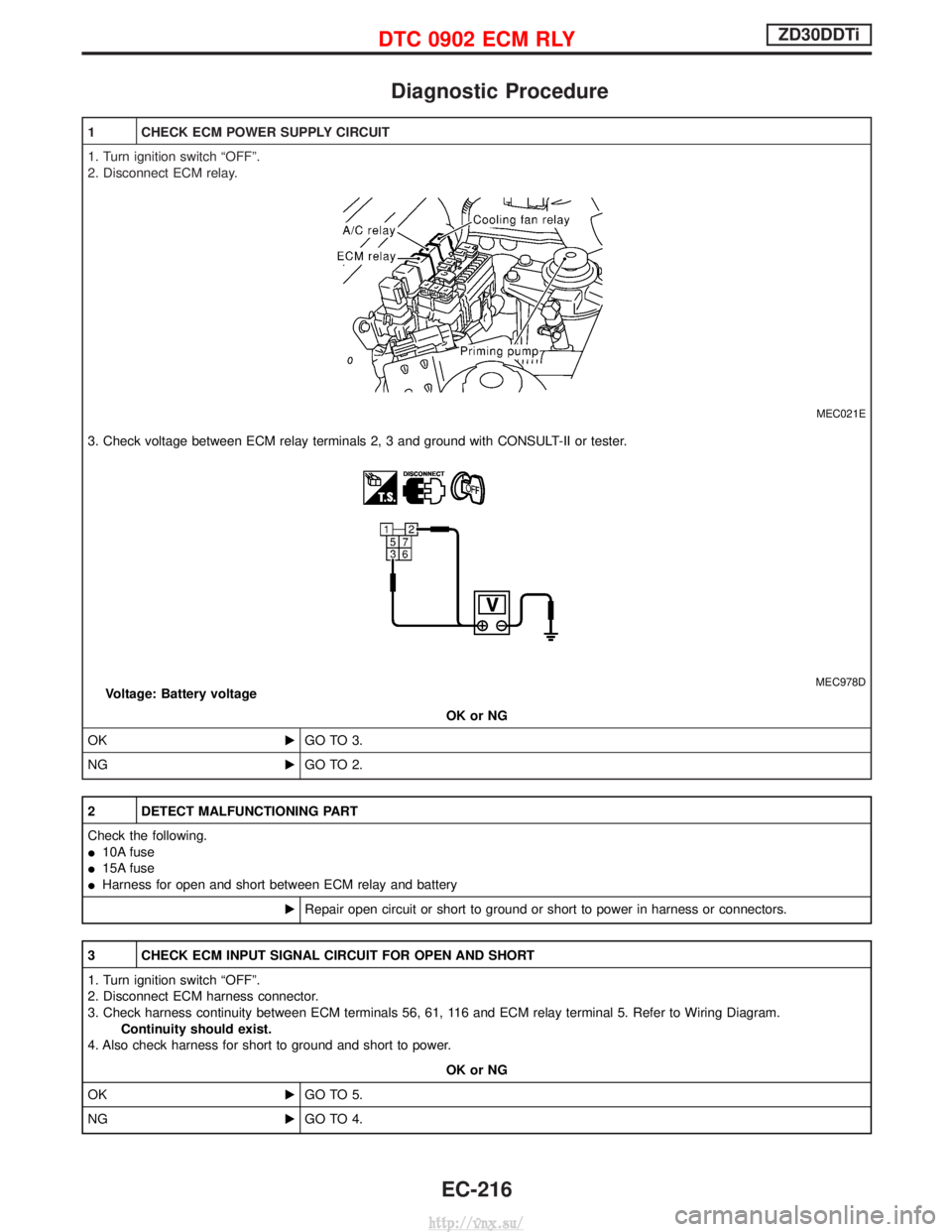

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay.

MEC021E

3. Check voltage between ECM relay terminals 2, 3 and ground with CONSULT-II or tester.

MEC978DVoltage: Battery voltageOK or NG

OK EGO TO 3.

NG EGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

I10A fuse

I 15A fuse

I Harness for open and short between ECM relay and battery

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ECM INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 56, 61, 116 and ECM relay terminal 5. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG EGO TO 4.

DTC 0902 ECM RLYZD30DDTi

EC-216

http://vnx.su/

Page 493 of 1833

Description

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis Logic

Malfunction is detected when ...Check Items (Possible Cause)

I ECM input signal processing function is malfunctioning. IECM

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Turn ignition switch ªOFFº, wait at least 20 seconds and then

turn ªONº.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-219.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Turn ignition switch ªOFFº, wait at least 20 seconds and then turn ªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-219.

SEC220B

SEF817Y

DTC 0903 ECM 15ZD30DDTi

EC-218

http://vnx.su/

Page 494 of 1833

Diagnostic Procedure

1 INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº, EC-218, again.

5. Is the malfunction displayed again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº, EC-218, again.

4. Perform ªDiagnostic Test Mode II (Self-diagnostic results)º.

5. Is the DTC 0903 displayed again?

YesorNo

Ye s EReplace ECM.

No EINSPECTION END

DTC 0903 ECM 15ZD30DDTi

EC-219

http://vnx.su/

Page 496 of 1833

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 1 second.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-224.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 1 second.

2) Turn ignition switch ªOFFº, wait at least 5 seconds and then turnªONº.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-224.

SEF817Y

DTC 0905 TURBO PRESSUREZD30DDTi

EC-221

http://vnx.su/

Page 499 of 1833

Diagnostic Procedure

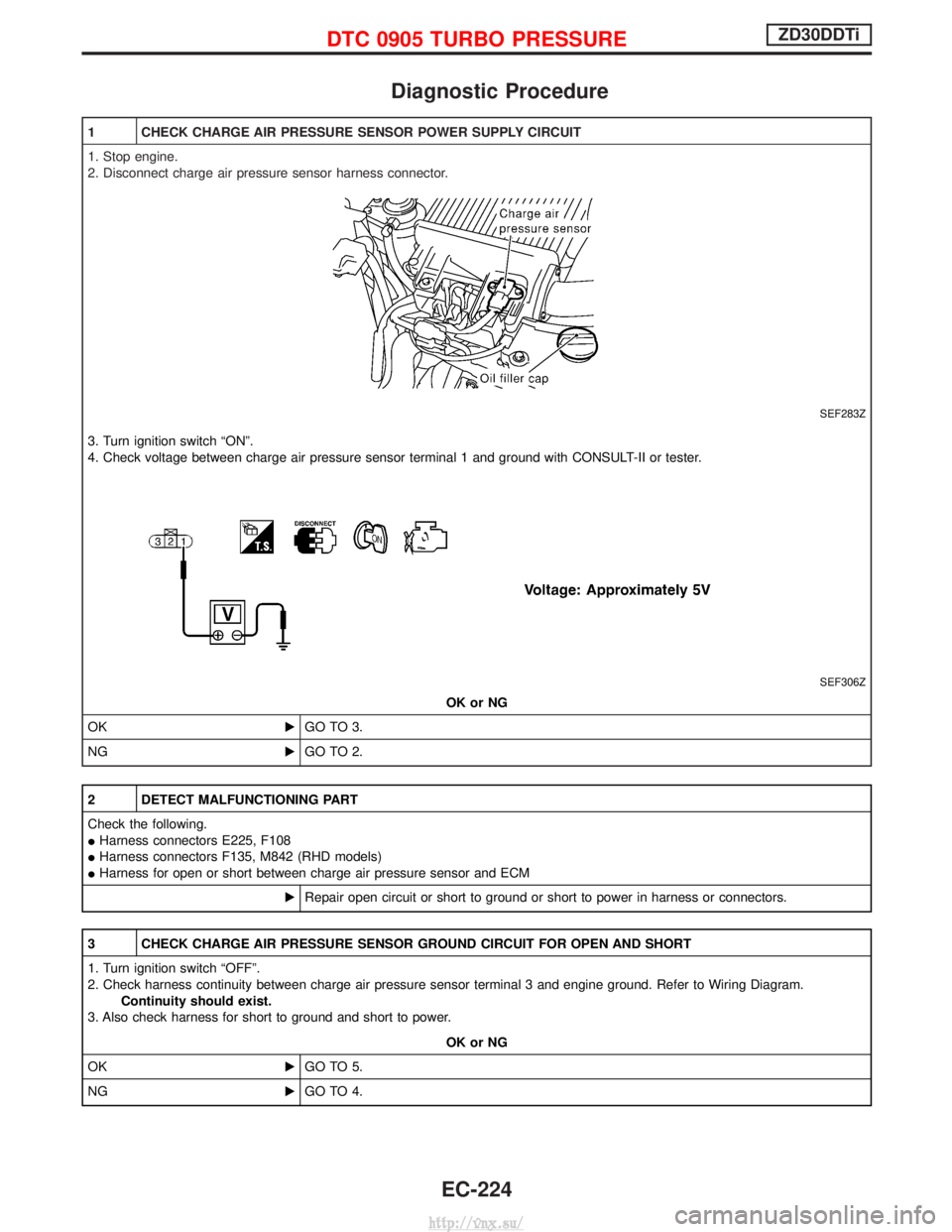

1 CHECK CHARGE AIR PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Stop engine.

2. Disconnect charge air pressure sensor harness connector.

SEF283Z

3. Turn ignition switch ªONº.

4. Check voltage between charge air pressure sensor terminal 1 and ground with CONSULT-II or tester.

SEF306Z

OK or NG

OK EGO TO 3.

NG EGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

I Harness connectors F135, M842 (RHD models)

I Harness for open or short between charge air pressure sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK CHARGE AIR PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between charge air pressure sensor terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 5.

NG EGO TO 4.

DTC 0905 TURBO PRESSUREZD30DDTi

EC-224

http://vnx.su/

Page 500 of 1833

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

I Harness connectors F135, M852 (RHD models)

I Harness for open or short between ECM and charge air pressure sensor

ERepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK CHARGE AIR PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 46 and charge air pressure sensor terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK EGO TO 7.

NG EGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E225, F108

I Harness connectors F135, M842 (RHD models)

I Harness for open or short between charge air pressure sensor and ECM

ERepair open circuit or short to ground or short to power in harness or connectors.

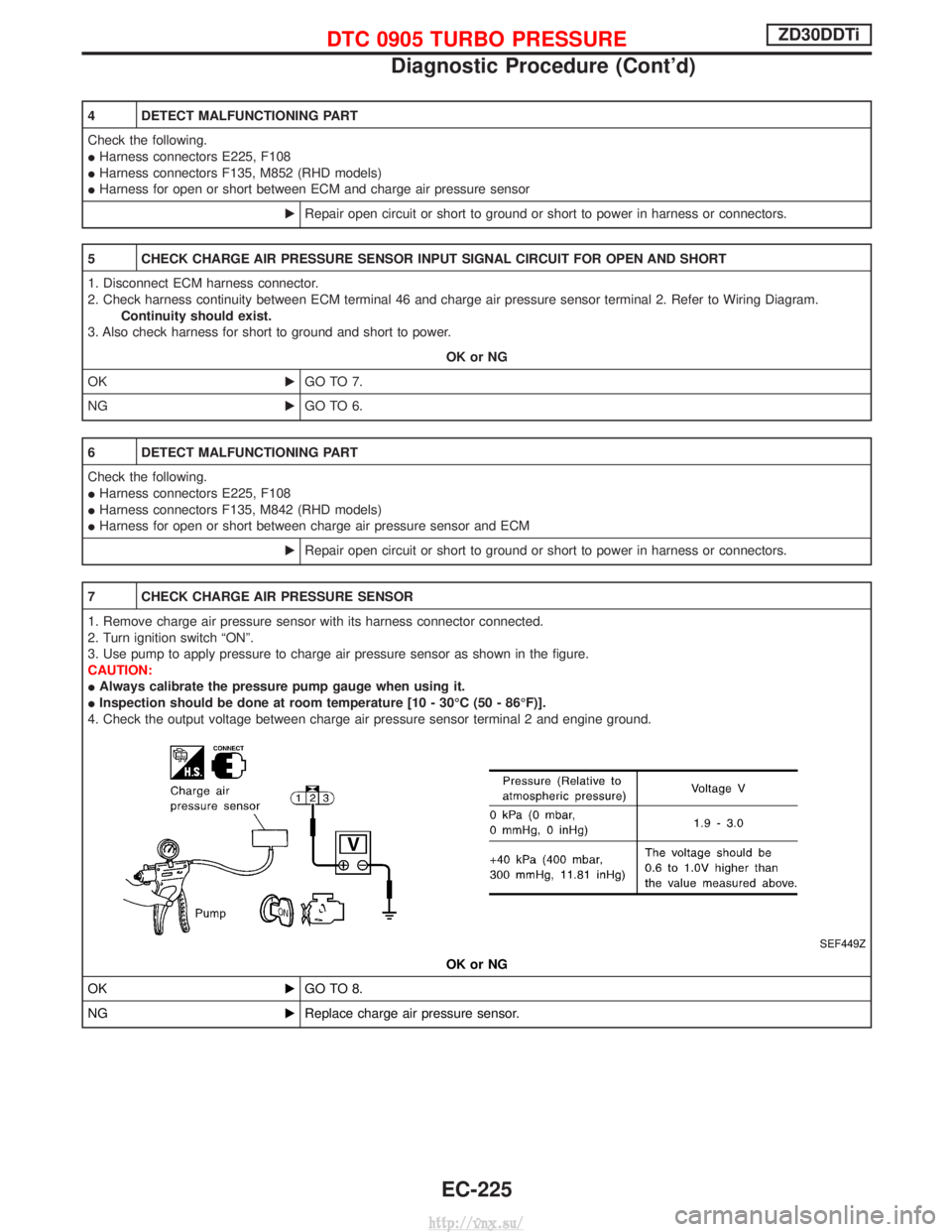

7 CHECK CHARGE AIR PRESSURE SENSOR

1. Remove charge air pressure sensor with its harness connector connected.

2. Turn ignition switch ªONº.

3. Use pump to apply pressure to charge air pressure sensor as shown in the figure.

CAUTION:

IAlways calibrate the pressure pump gauge when using it.

I Inspection should be done at room temperature [10 - 30ÉC (50 - 86ÉF)].

4. Check the output voltage between charge air pressure sensor terminal 2 and engine ground.

SEF449Z

OK or NG

OK EGO TO 8.

NG EReplace charge air pressure sensor.

DTC 0905 TURBO PRESSUREZD30DDTi

Diagnostic Procedure (Cont'd)

EC-225

http://vnx.su/

Page 502 of 1833

Description

SYSTEM DESCRIPTION

SensorInput Signal to ECMECM FunctionActuator

Electronic controlled fuel injection pump Fuel injection signal

EGR volume

controlEGR volume control valve

Crankshaft position sensor (TDC) Engine speed

Vehicle speed sensor

Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Battery Battery voltage

Mass air flow sensor Amount of intake air

Air conditioner switch Air conditioner operation

Electrical load Electrical load signal

PNP switch Park/Neutral position signal

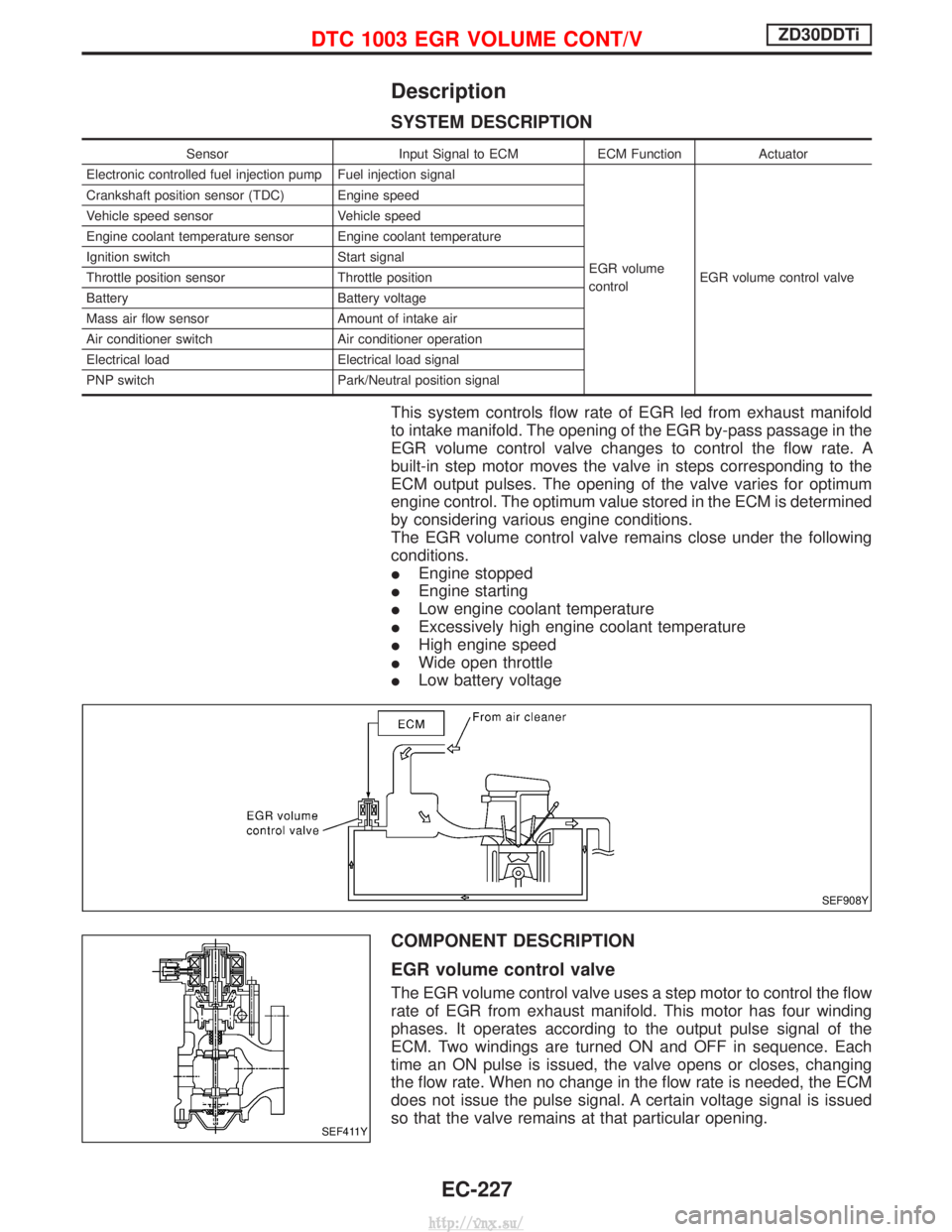

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions.

The EGR volume control valve remains close under the following

conditions.

IEngine stopped

I Engine starting

I Low engine coolant temperature

I Excessively high engine coolant temperature

I High engine speed

I Wide open throttle

I Low battery voltage

COMPONENT DESCRIPTION

EGR volume control valve

The EGR volume control valve uses a step motor to control the flow

rate of EGR from exhaust manifold. This motor has four winding

phases. It operates according to the output pulse signal of the

ECM. Two windings are turned ON and OFF in sequence. Each

time an ON pulse is issued, the valve opens or closes, changing

the flow rate. When no change in the flow rate is needed, the ECM

does not issue the pulse signal. A certain voltage signal is issued

so that the valve remains at that particular opening.

SEF908Y

SEF411Y

DTC 1003 EGR VOLUME CONT/VZD30DDTi

EC-227

http://vnx.su/