glow plug NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 98 of 1833

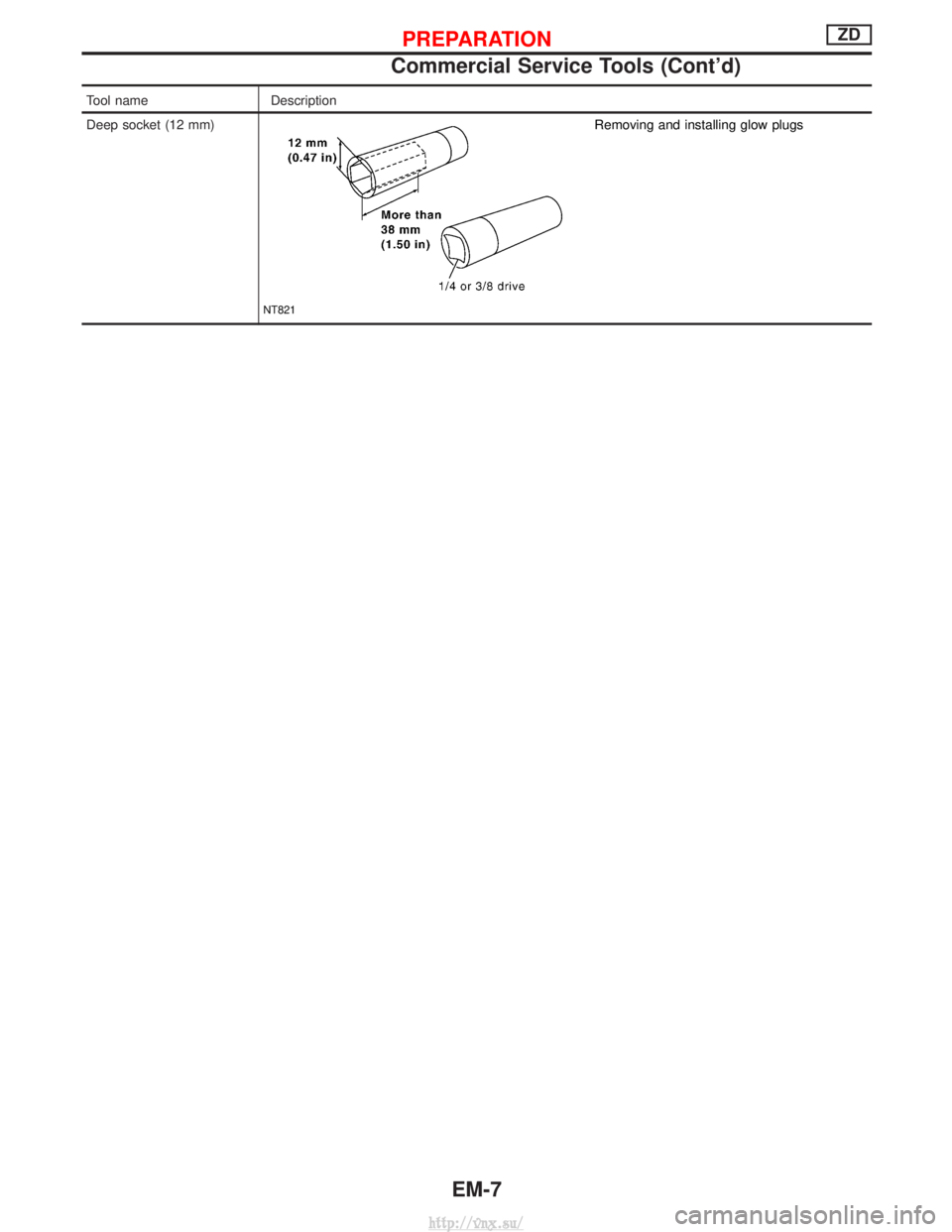

Tool nameDescription

Deep socket (12 mm)

NT821

Removing and installing glow plugs

PREPARATIONZD

Commercial Service Tools (Cont'd)

EM-7

http://vnx.su/

Page 101 of 1833

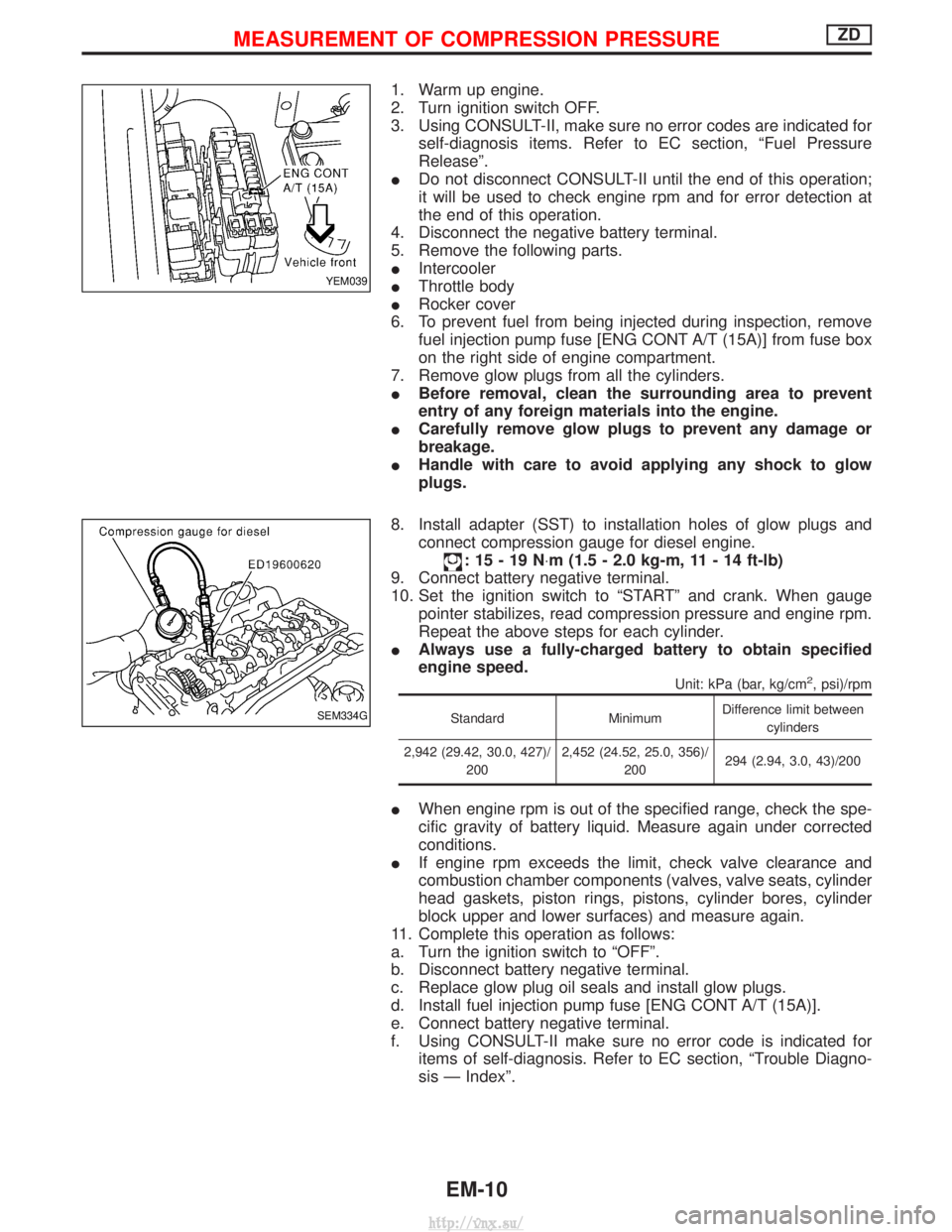

1. Warm up engine.

2. Turn ignition switch OFF.

3. Using CONSULT-II, make sure no error codes are indicated forself-diagnosis items. Refer to EC section, ªFuel Pressure

Releaseº.

I Do not disconnect CONSULT-II until the end of this operation;

it will be used to check engine rpm and for error detection at

the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

I Intercooler

I Throttle body

I Rocker cover

6. To prevent fuel from being injected during inspection, remove fuel injection pump fuse [ENG CONT A/T (15A)] from fuse box

on the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

I Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

I Carefully remove glow plugs to prevent any damage or

breakage.

I Handle with care to avoid applying any shock to glow

plugs.

8. Install adapter (SST) to installation holes of glow plugs and connect compression gauge for diesel engine.

:15-19N ×m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to ªSTARTº and crank. When gauge pointer stabilizes, read compression pressure and engine rpm.

Repeat the above steps for each cylinder.

I Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

2,942 (29.42, 30.0, 427)/ 200 2,452 (24.52, 25.0, 356)/

200 294 (2.94, 3.0, 43)/200

I

When engine rpm is out of the specified range, check the spe-

cific gravity of battery liquid. Measure again under corrected

conditions.

I If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cylinder

head gaskets, piston rings, pistons, cylinder bores, cylinder

block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT A/T (15A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for items of self-diagnosis. Refer to EC section, ªTrouble Diagno-

sis Ð Indexº.

YEM039

SEM334G

MEASUREMENT OF COMPRESSION PRESSUREZD

EM-10

http://vnx.su/

Page 111 of 1833

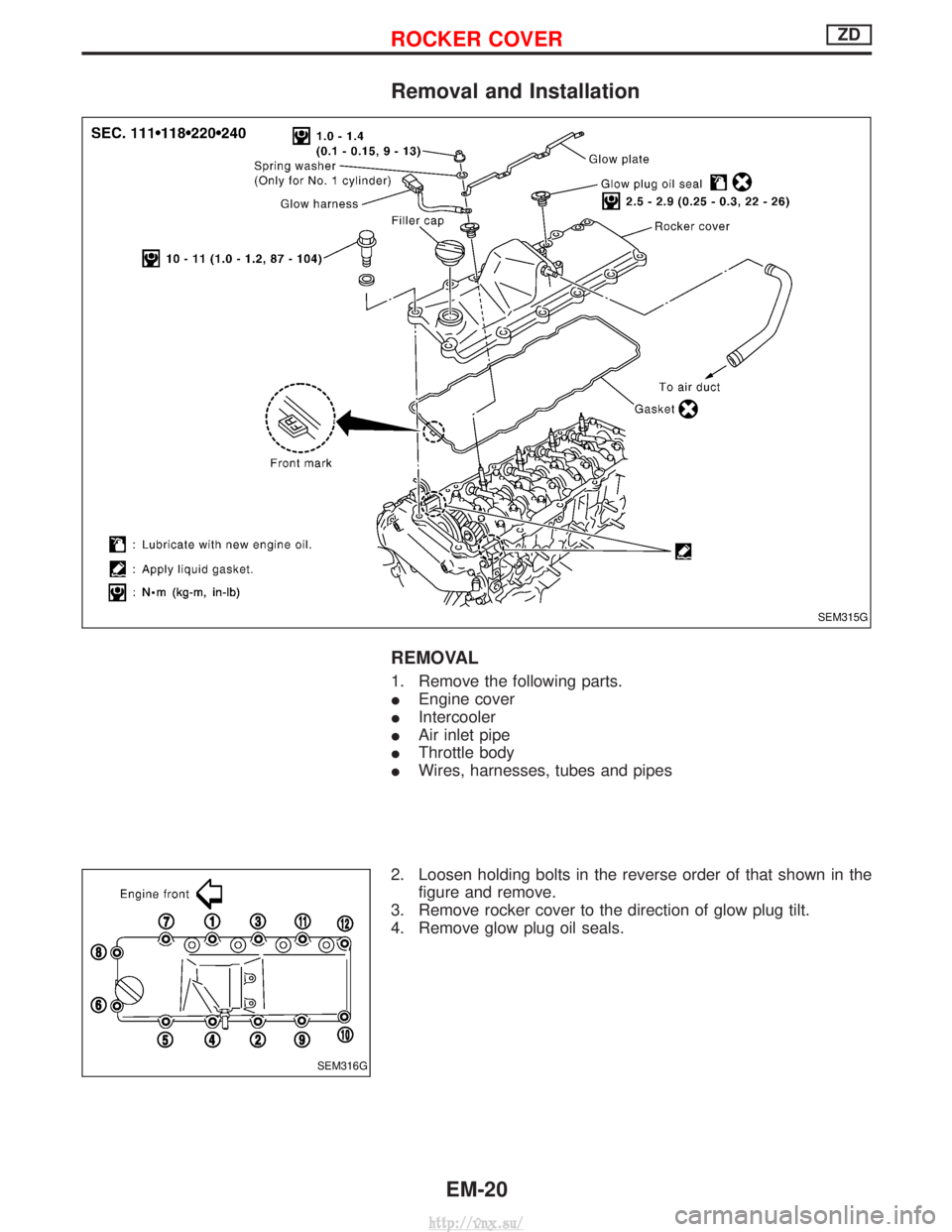

Removal and Installation

REMOVAL

1. Remove the following parts.

IEngine cover

I Intercooler

I Air inlet pipe

I Throttle body

I Wires, harnesses, tubes and pipes

2. Loosen holding bolts in the reverse order of that shown in the figure and remove.

3. Remove rocker cover to the direction of glow plug tilt.

4. Remove glow plug oil seals.

SEM315G

SEM316G

ROCKER COVERZD

EM-20

http://vnx.su/

Page 112 of 1833

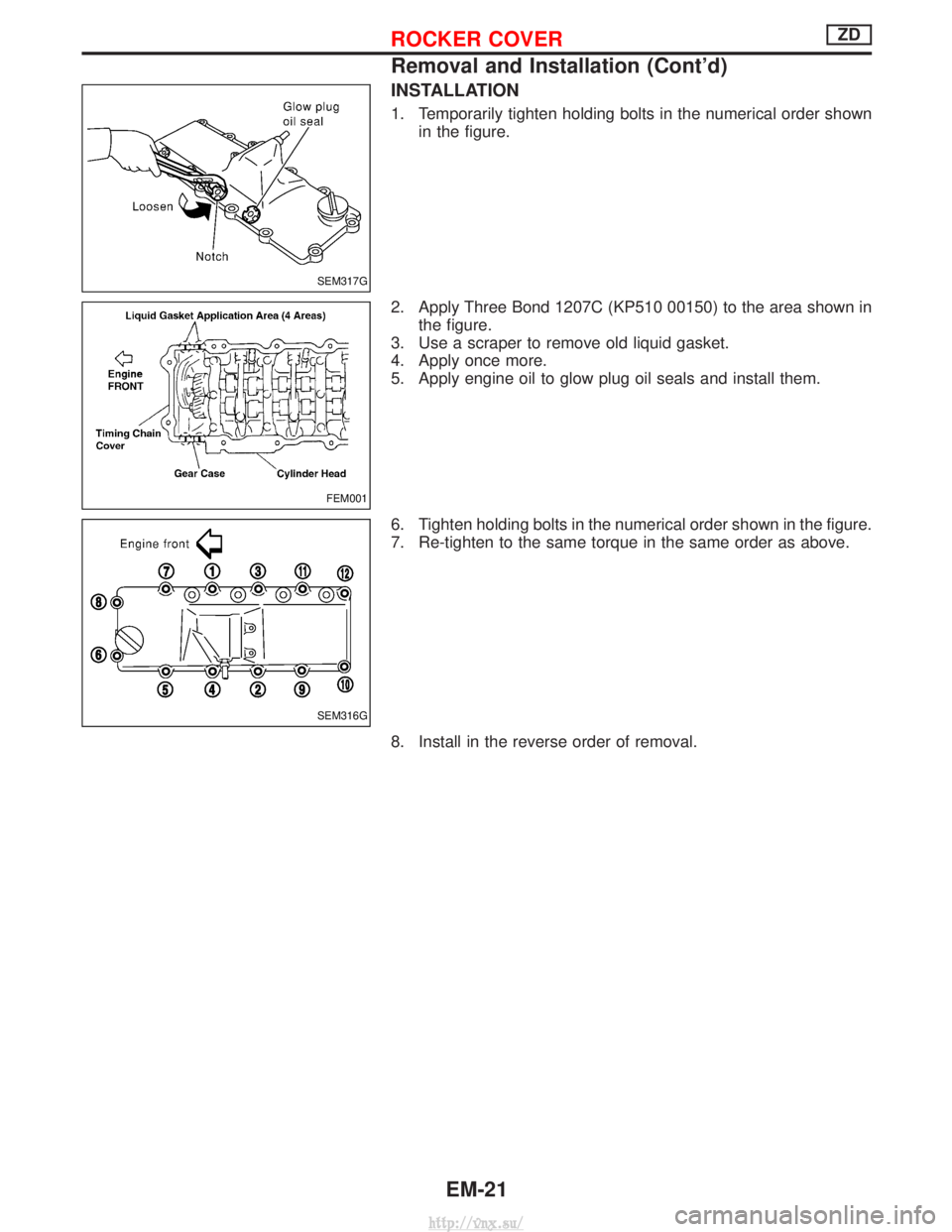

INSTALLATION

1. Temporarily tighten holding bolts in the numerical order shownin the figure.

2. Apply Three Bond 1207C (KP510 00150) to the area shown in the figure.

3. Use a scraper to remove old liquid gasket.

4. Apply once more.

5. Apply engine oil to glow plug oil seals and install them.

6. Tighten holding bolts in the numerical order shown in the figure.

7. Re-tighten to the same torque in the same order as above.

8. Install in the reverse order of removal.

SEM317G

FEM001

SEM316G

ROCKER COVERZD

Removal and Installation (Cont'd)

EM-21

http://vnx.su/

Page 144 of 1833

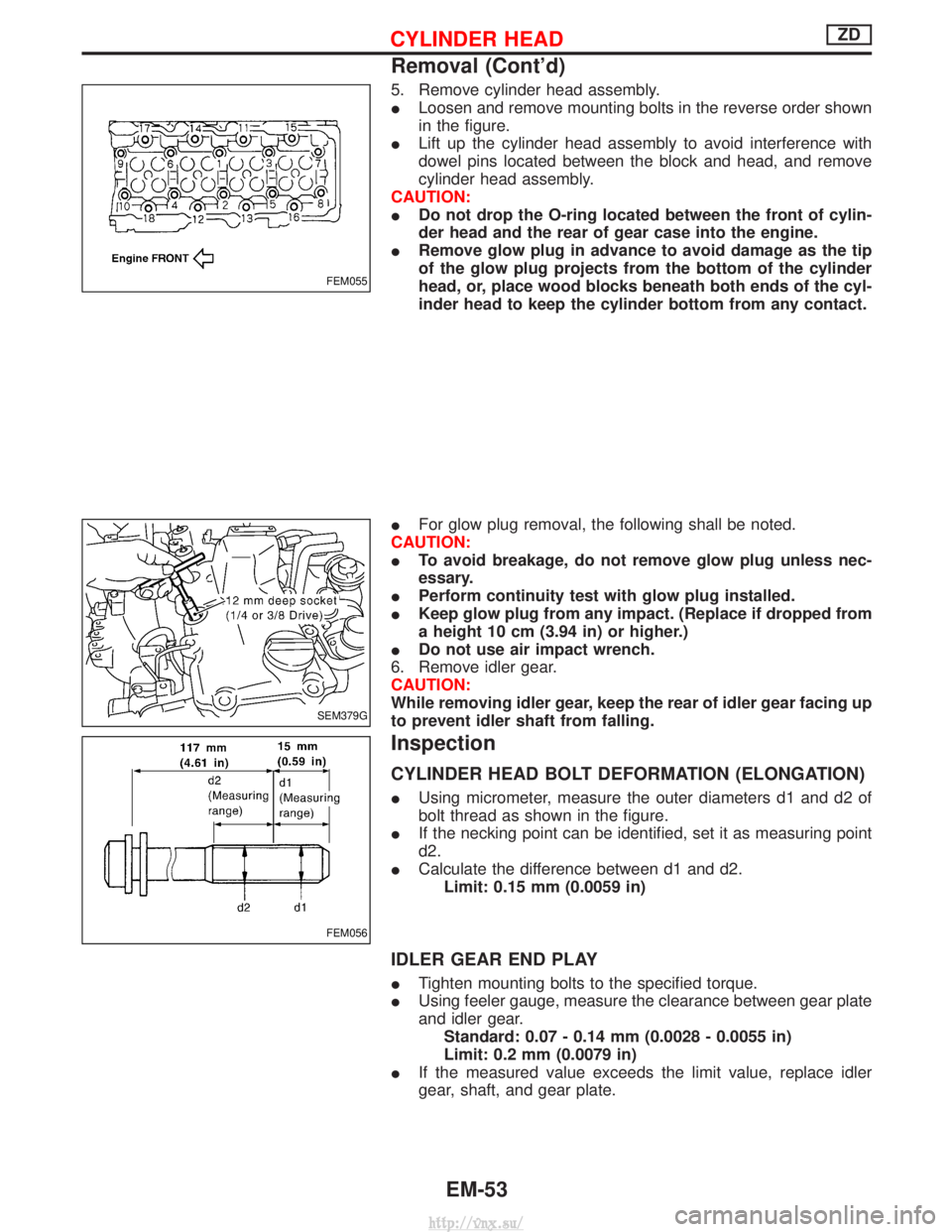

5. Remove cylinder head assembly.

ILoosen and remove mounting bolts in the reverse order shown

in the figure.

I Lift up the cylinder head assembly to avoid interference with

dowel pins located between the block and head, and remove

cylinder head assembly.

CAUTION:

I Do not drop the O-ring located between the front of cylin-

der head and the rear of gear case into the engine.

I Remove glow plug in advance to avoid damage as the tip

of the glow plug projects from the bottom of the cylinder

head, or, place wood blocks beneath both ends of the cyl-

inder head to keep the cylinder bottom from any contact.

I For glow plug removal, the following shall be noted.

CAUTION:

I To avoid breakage, do not remove glow plug unless nec-

essary.

I Perform continuity test with glow plug installed.

I Keep glow plug from any impact. (Replace if dropped from

a height 10 cm (3.94 in) or higher.)

I Do not use air impact wrench.

6. Remove idler gear.

CAUTION:

While removing idler gear, keep the rear of idler gear facing up

to prevent idler shaft from falling.

Inspection

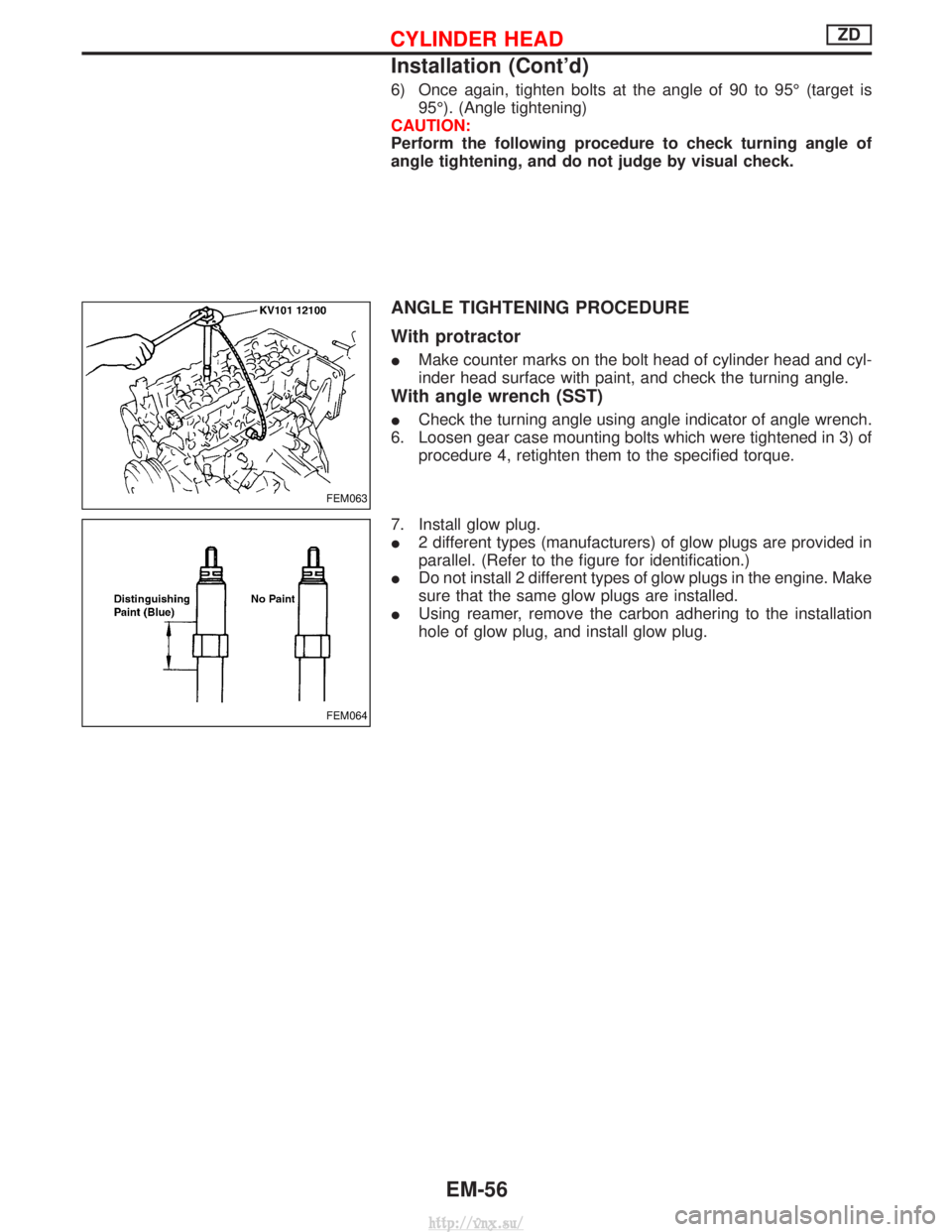

CYLINDER HEAD BOLT DEFORMATION (ELONGATION)

I Using micrometer, measure the outer diameters d1 and d2 of

bolt thread as shown in the figure.

I If the necking point can be identified, set it as measuring point

d2.

I Calculate the difference between d1 and d2.

Limit: 0.15 mm (0.0059 in)

IDLER GEAR END PLAY

I Tighten mounting bolts to the specified torque.

I Using feeler gauge, measure the clearance between gear plate

and idler gear.

Standard: 0.07 - 0.14 mm (0.0028 - 0.0055 in)

Limit: 0.2 mm (0.0079 in)

I If the measured value exceeds the limit value, replace idler

gear, shaft, and gear plate.

FEM055

SEM379G

FEM056

CYLINDER HEADZD

Removal (Cont'd)

EM-53

http://vnx.su/

Page 147 of 1833

6) Once again, tighten bolts at the angle of 90 to 95É (target is95É). (Angle tightening)

CAUTION:

Perform the following procedure to check turning angle of

angle tightening, and do not judge by visual check.

ANGLE TIGHTENING PROCEDURE

With protractor

I Make counter marks on the bolt head of cylinder head and cyl-

inder head surface with paint, and check the turning angle.

With angle wrench (SST)

ICheck the turning angle using angle indicator of angle wrench.

6. Loosen gear case mounting bolts which were tightened in 3) of procedure 4, retighten them to the specified torque.

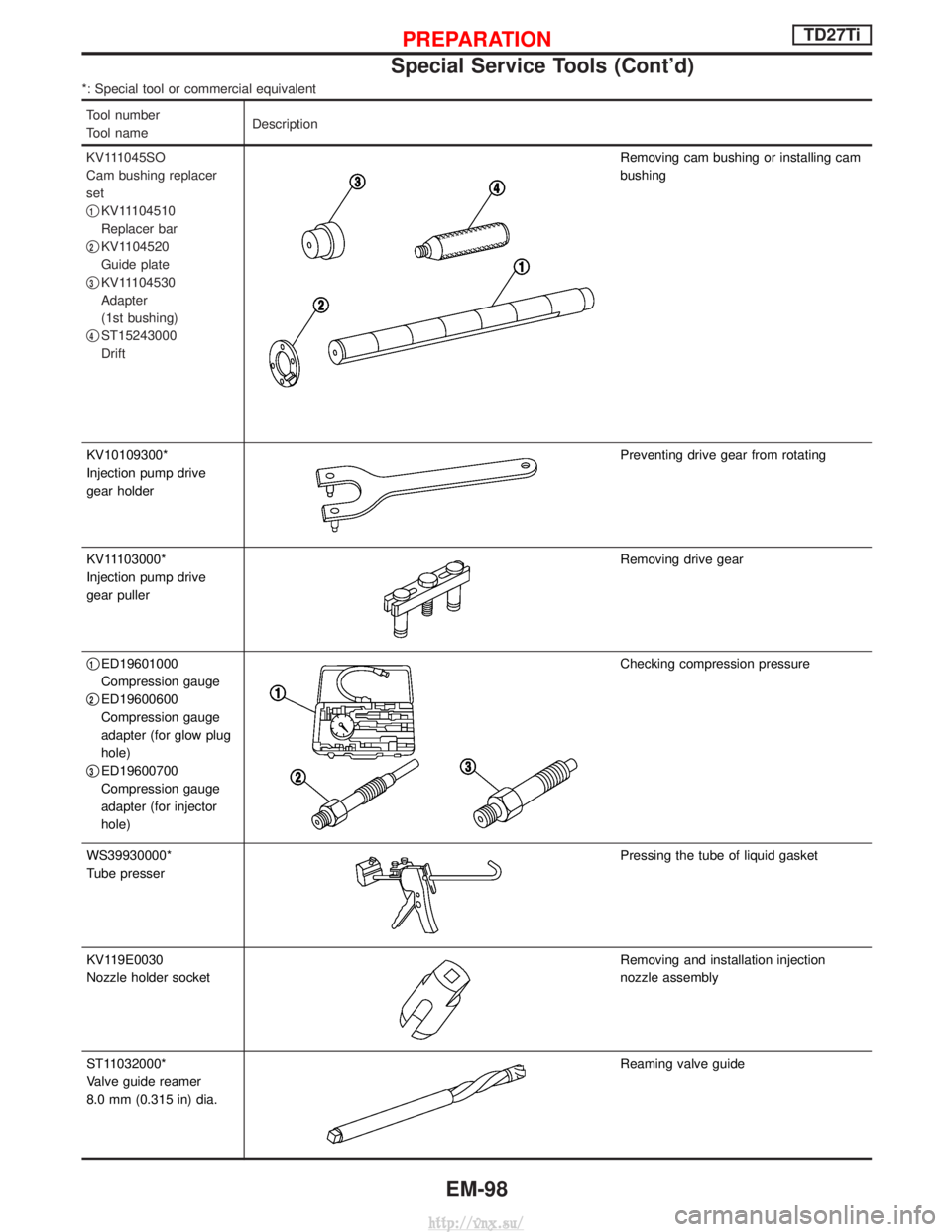

7. Install glow plug.

I 2 different types (manufacturers) of glow plugs are provided in

parallel. (Refer to the figure for identification.)

I Do not install 2 different types of glow plugs in the engine. Make

sure that the same glow plugs are installed.

I Using reamer, remove the carbon adhering to the installation

hole of glow plug, and install glow plug.

FEM063

FEM064

CYLINDER HEADZD

Installation (Cont'd)

EM-56

http://vnx.su/

Page 189 of 1833

*: Special tool or commercial equivalent

Tool number

Tool nameDescription

KV111045SO

Cam bushing replacer

set

q

1KV11104510

Replacer bar

q

2KV1104520

Guide plate

q

3KV11104530

Adapter

(1st bushing)

q

4ST15243000

Drift

Removing cam bushing or installing cam

bushing

KV10109300*

Injection pump drive

gear holder

Preventing drive gear from rotating

KV11103000*

Injection pump drive

gear puller

Removing drive gear

q

1ED19601000

Compression gauge

q

2ED19600600

Compression gauge

adapter (for glow plug

hole)

q

3ED19600700

Compression gauge

adapter (for injector

hole)

Checking compression pressure

WS39930000*

Tube presser

Pressing the tube of liquid gasket

KV119E0030

Nozzle holder socket

Removing and installation injection

nozzle assembly

ST11032000*

Valve guide reamer

8.0 mm (0.315 in) dia.

Reaming valve guide

PREPARATIONTD27Ti

Special Service Tools (Cont'd)

EM-98

http://vnx.su/

Page 194 of 1833

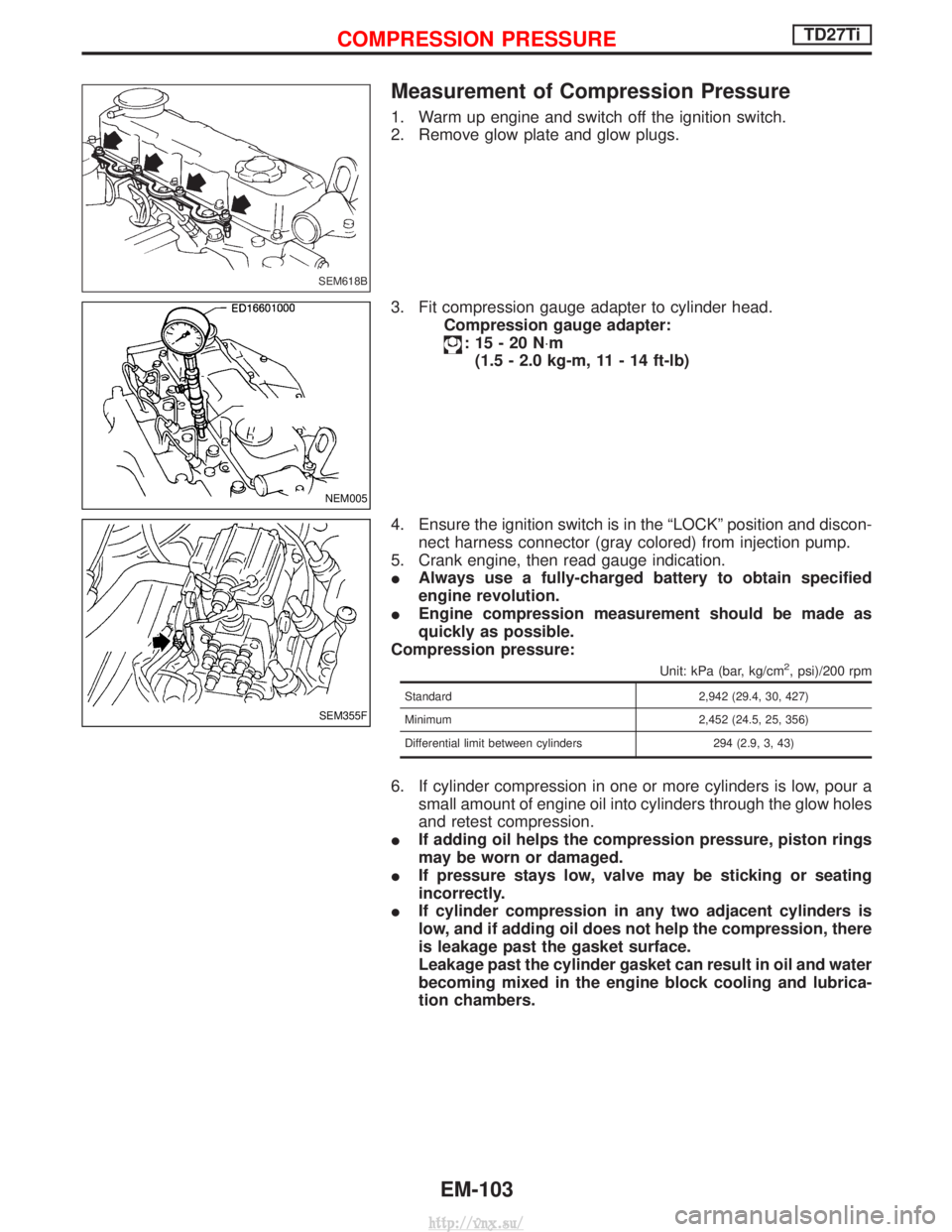

Measurement of Compression Pressure

1. Warm up engine and switch off the ignition switch.

2. Remove glow plate and glow plugs.

3. Fit compression gauge adapter to cylinder head.Compression gauge adapter:

:15-20N ×m

(1.5 - 2.0 kg-m, 11 - 14 ft-lb)

4. Ensure the ignition switch is in the ªLOCKº position and discon- nect harness connector (gray colored) from injection pump.

5. Crank engine, then read gauge indication.

I Always use a fully-charged battery to obtain specified

engine revolution.

I Engine compression measurement should be made as

quickly as possible.

Compression pressure:

Unit: kPa (bar, kg/cm2, psi)/200 rpm

Standard 2,942 (29.4, 30, 427)

Minimum 2,452 (24.5, 25, 356)

Differential limit between cylinders 294 (2.9, 3, 43)

6. If cylinder compression in one or more cylinders is low, pour a small amount of engine oil into cylinders through the glow holes

and retest compression.

I If adding oil helps the compression pressure, piston rings

may be worn or damaged.

I If pressure stays low, valve may be sticking or seating

incorrectly.

I If cylinder compression in any two adjacent cylinders is

low, and if adding oil does not help the compression, there

is leakage past the gasket surface.

Leakage past the cylinder gasket can result in oil and water

becoming mixed in the engine block cooling and lubrica-

tion chambers.

SEM618B

NEM005

SEM355F

COMPRESSION PRESSURETD27Ti

EM-103

http://vnx.su/

Page 195 of 1833

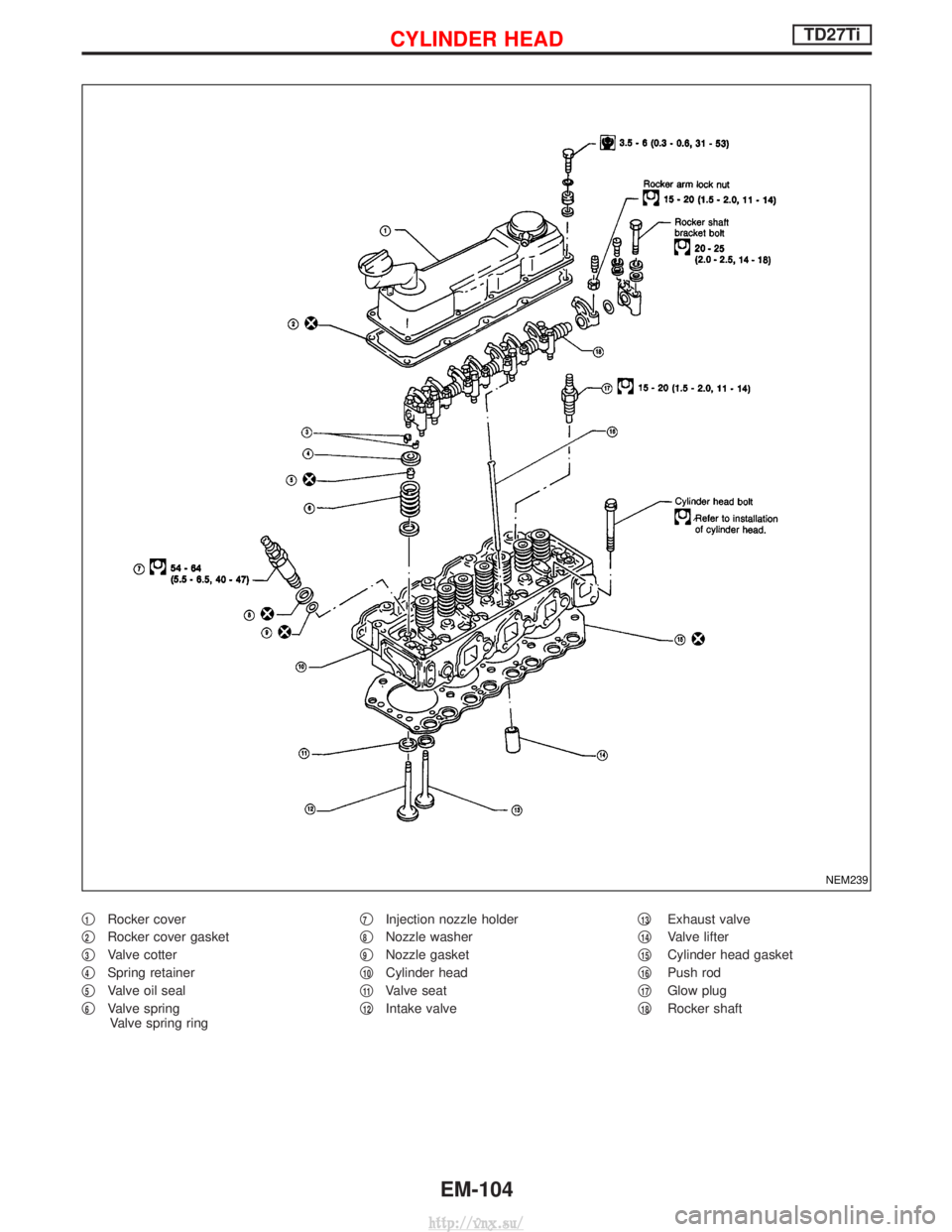

q1Rocker cover

q

2Rocker cover gasket

q

3Valve cotter

q

4Spring retainer

q

5Valve oil seal

q

6Valve spring Valve spring ring q

7Injection nozzle holder

q

8Nozzle washer

q

9Nozzle gasket

q

10Cylinder head

q

11Valve seat

q

12Intake valve q

13Exhaust valve

q

14Valve lifter

q

15Cylinder head gasket

q

16Push rod

q

17Glow plug

q

18Rocker shaft

NEM239

CYLINDER HEADTD27Ti

EM-104

http://vnx.su/

Page 197 of 1833

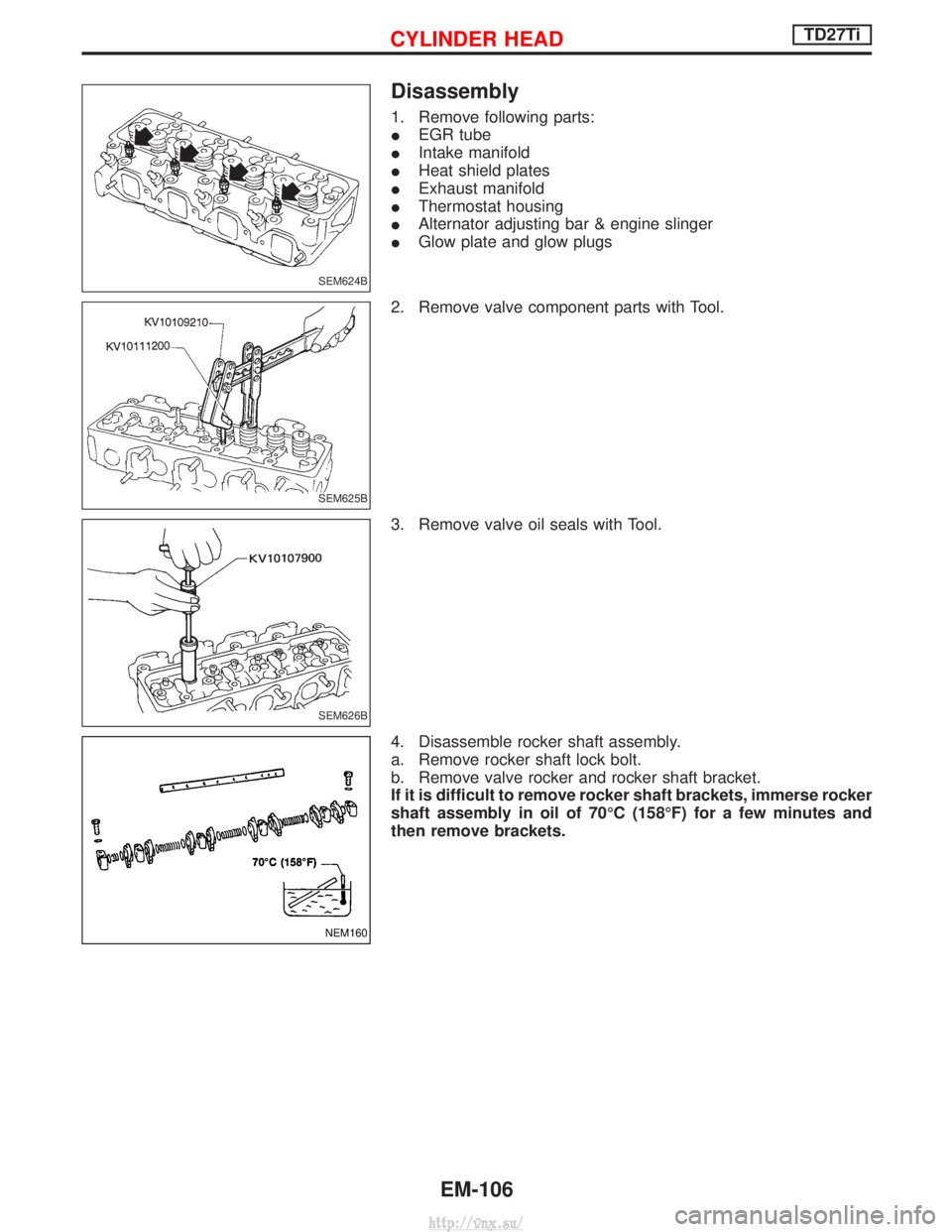

Disassembly

1. Remove following parts:

IEGR tube

I Intake manifold

I Heat shield plates

I Exhaust manifold

I Thermostat housing

I Alternator adjusting bar & engine slinger

I Glow plate and glow plugs

2. Remove valve component parts with Tool.

3. Remove valve oil seals with Tool.

4. Disassemble rocker shaft assembly.

a. Remove rocker shaft lock bolt.

b. Remove valve rocker and rocker shaft bracket.

If it is difficult to remove rocker shaft brackets, immerse rocker

shaft assembly in oil of 70ÉC (158ÉF) for a few minutes and

then remove brackets.

SEM624B

SEM625B

SEM626B

NEM160

CYLINDER HEADTD27Ti

EM-106

http://vnx.su/