oil temperature NISSAN TERRANO 2004 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 8 of 1833

Precautions for Multiport Fuel Injection System

or Engine Control System

1. Before connecting or disconnecting any harness connector forthe multiport fuel injection system or ECM (Engine Control

Module):

Turn ignition switch to ªOFFº position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

2. Before disconnecting pressurized fuel line from fuel pump to injectors, be sure to release fuel pressure to eliminate danger.

3. Be careful not to jar components such as control unit and air flow meter.

Precautions for Catalyst

If a large amount of unburned fuel enters the converter, the con-

verter temperature will rise to excessively high values. To prevent

this, follow the procedure below:

1. Use unleaded gasoline only. Leaded gasoline will seriouslydamage the catalytic converter.

2. When checking for ignition spark or measuring engine compression, perform tests quickly and only when necessary.

3. Do not run engine when the fuel tank level is low, as a result the engine may misfire causing damage to the converter.

4. Do not place the vehicle on inflammable material. Keep inflam- mable material off the exhaust pipe.

Precautions for Turbocharger

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean

supply of oil flowing through the turbocharger and to follow all

required maintenance instructions and operating procedures.

For proper operation of the system, follow the procedure below:

1. Always use the recommended oil. Follow the instructions forproper time to change the oil and proper oil level.

2. Avoid accelerating engine to a high rpm immediately after start- ing.

3. If engine had been operating at high rpm for an extended period of time, let it idle for a few minutes prior to shutting it off.

SGI787

SGI290

SGI292

PRECAUTIONS

GI-5

http://vnx.su/

Page 9 of 1833

Precautions for Fuel

DIESEL ENGINE*:

Diesel fuel of at least 50 cetane for ZD30DDTi engine.

* If two types of diesel fuel are available, use summer or winterfuel properly according to the following temperature conditions.

I Above þ7ÉC (20ÉF) ... Summer type diesel fuel.

I Below þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

I Do not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

I Do not use summer fuel at temperature below þ7ÉC (20ÉF).

The cold temperature will cause wax to form in the fuel. As

a result, it may prevent the engine from running smoothly.

I Do not add gasoline or other alternate fuels to diesel fuel.

Precautions for Engine Oils

Prolonged and repeated contact with mineral oil will result in the

removal of natural fats from the skin, leading to dryness, irritation

and dermatitis. In addition, used engine oil contains potentially

harmful contaminants which may cause skin cancer. Adequate

means of skin protection and washing facilities must be provided.

HEALTH PROTECTION PRECAUTIONS

1. Avoid prolonged and repeated contact with oils, particularly

used engine oils.

2. Wear protective clothing, including impervious gloves where practicable.

3. Do not put oily rags in pockets.

4. Avoid contaminating clothes, particularly underwear, with oil.

5. Heavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regularly.

6. First Aid treatment should be obtained immediately for open cuts and wounds.

7. Use barrier creams, applying them before each work period, to help the removal of oil from the skin.

8. Wash with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). Preparations containing

lanolin replace the natural skin oils which have been removed.

9. Do not use petrol, kerosine, diesel fuel, gas oil, thinners or sol- vents for cleaning skin.

10. If skin disorders develop, obtain medical advice without delay.

11. Where practicable, degrease components prior to handling.

12. Where there is a risk of eye contact, eye protection should be worn, for example, chemical goggles or face shields; in addition

an eye wash facility should be provided.

(For the United Kingdom, see also HSE Cautionary Notice SHW

397 ªEffects of Mineral Oil on the Skinº.)

ENVIRONMENTAL PROTECTION PRECAUTIONS

Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating sys-

tem must meet the requirements of HM Inspectorate of Pollution for

small burners of less than 0.4 MW. If in doubt check with the

appropriate local authority and/or manufacturer of the approved

appliance.

PRECAUTIONS

GI-6

http://vnx.su/

Page 52 of 1833

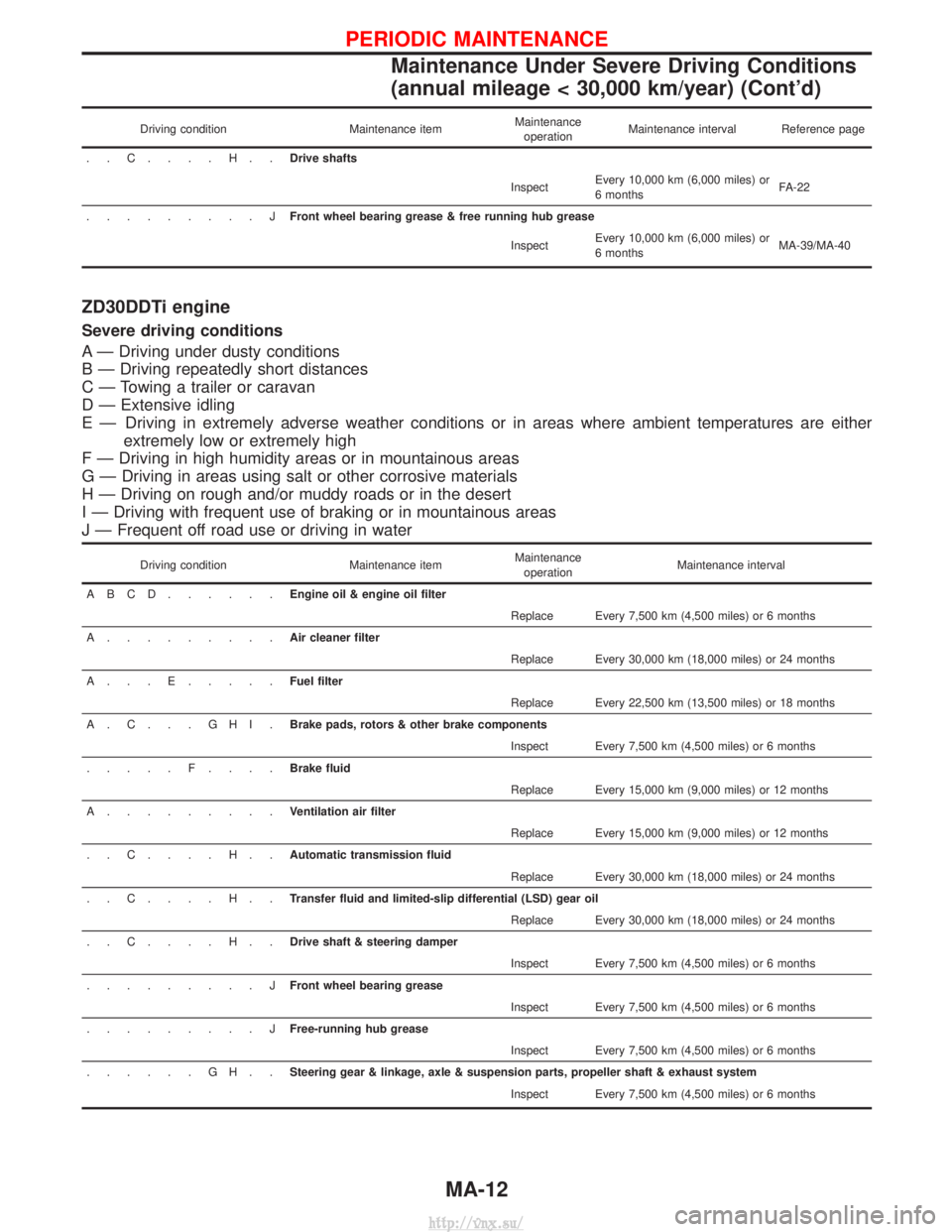

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

TD27Ti engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperature is eitherextremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of brakes or in mountainous areas

J Ð Frequent driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval Reference page

ABCD......Engine oil & engine oil filter ReplaceEvery 5,000 km (3,000 miles) or

3 months MA-21

A.........Air cleaner filter (dry paper type) CleanEvery 10,000 km (6,000 miles) or

6 months

MA-24

Replace Every 20,000 km (12,000 miles)

or 12 months

A...E.....Fuel filter

ReplaceEvery 20,000 km (12,000 miles)

or 12 months MA-23

A....F....Ventilation air filter ReplaceEvery 20,000 km (12,000 miles)

or 12 months MA-44

.....F....Brake fluid ReplaceEvery 20,000 km (12,000 miles)

or 12 months MA-43

..C....H..Limited-slip differential (L.S.D.) gear oil ReplaceEvery 30,000 km (18,000 miles)

or 18 months MA-38

..C....H..Transfer & standard differential gear oil ReplaceEvery 60,000 km (36,000 miles)

or 24 months MA-36/MA-37/

MA-38

A.C...GHI.Brake pads/linings, discs/drums & other brake system components

InspectEvery 10,000 km (6,000 miles) or

6 months MA-40/MA-41

......GH.J Greasing points of steering linkage, propeller shafts and suspension

LubricateEvery 10,000 km (6,000 miles) or

6 months MA-44/MA-38

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system

InspectEvery 10,000 km (6,000 miles) or

6 months MA-43/FA-4/

RA-4/MA-38/

MA-36

PERIODIC MAINTENANCE

MA-11

http://vnx.su/

Page 53 of 1833

Driving conditionMaintenance itemMaintenance

operation Maintenance interval Reference page

..C....H..Drive shafts InspectEvery 10,000 km (6,000 miles) or

6 months FA-22

.........J Front wheel bearing grease & free running hub grease

InspectEvery 10,000 km (6,000 miles) or

6 months MA-39/MA-40

ZD30DDTi engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval

ABCD......Engine oil & engine oil filter Replace Every 7,500 km (4,500 miles) or 6 months

A.........Air cleaner filter Replace Every 30,000 km (18,000 miles) or 24 months

A...E.....Fuel filter Replace Every 22,500 km (13,500 miles) or 18 months

A.C...GHI.Brake pads, rotors & other brake components Inspect Every 7,500 km (4,500 miles) or 6 months

.....F....Brake fluid Replace Every 15,000 km (9,000 miles) or 12 months

A.........Ventilation air filter Replace Every 15,000 km (9,000 miles) or 12 months

..C....H..Automatic transmission fluid Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Transfer fluid and limited-slip differential (LSD) gear oil Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Drive shaft & steering damper Inspect Every 7,500 km (4,500 miles) or 6 months

.........J Front wheel bearing grease

Inspect Every 7,500 km (4,500 miles) or 6 months

.........J Free-running hub grease

Inspect Every 7,500 km (4,500 miles) or 6 months

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system Inspect Every 7,500 km (4,500 miles) or 6 months

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions

(annual mileage < 30,000 km/year) (Cont'd)

MA-12

http://vnx.su/

Page 55 of 1833

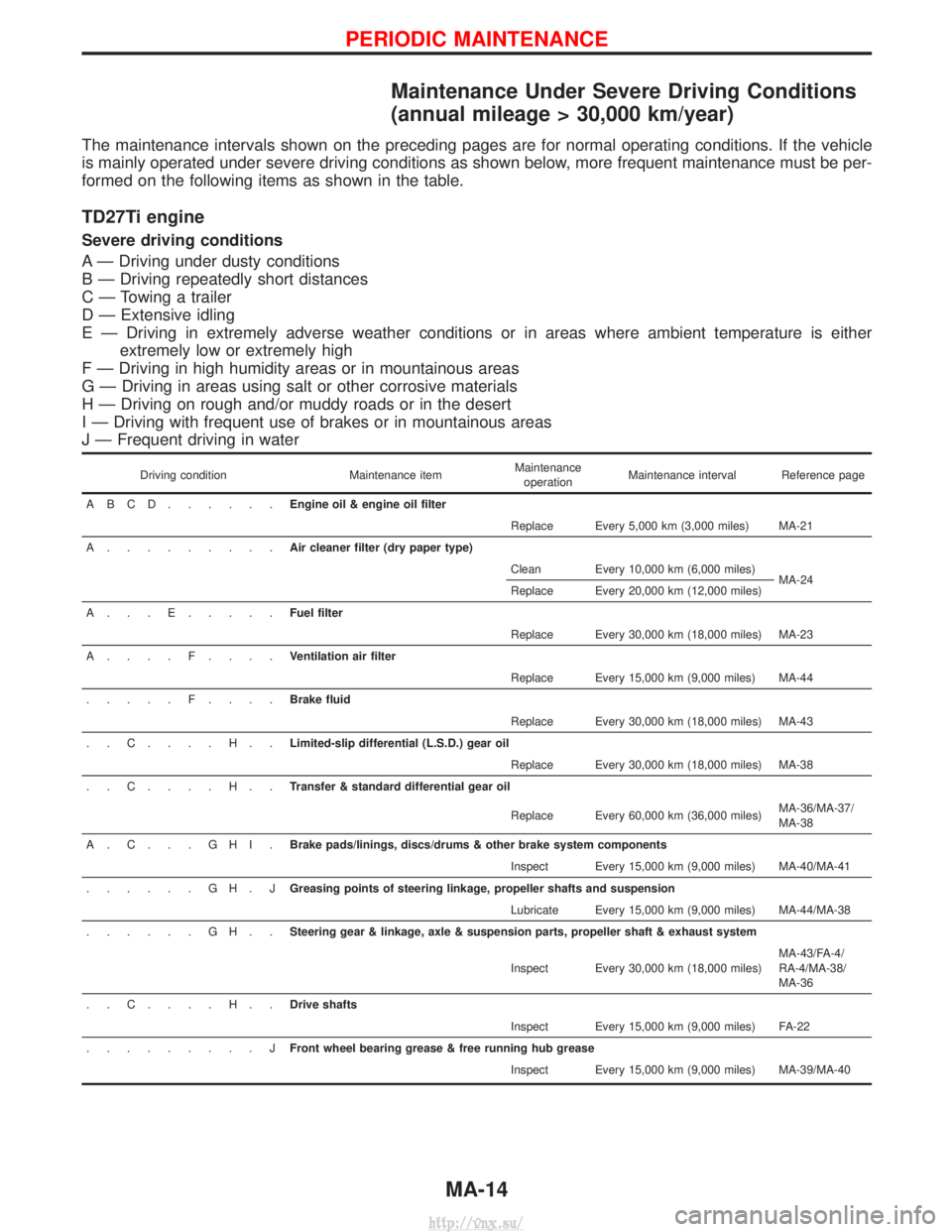

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

TD27Ti engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperature is eitherextremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of brakes or in mountainous areas

J Ð Frequent driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval Reference page

ABCD......Engine oil & engine oil filter Replace Every 5,000 km (3,000 miles) MA-21

A.........Air cleaner filter (dry paper type) Clean Every 10,000 km (6,000 miles)MA-24

Replace Every 20,000 km (12,000 miles)

A...E.....Fuel filter Replace Every 30,000 km (18,000 miles) MA-23

A....F....Ventilation air filter Replace Every 15,000 km (9,000 miles) MA-44

.....F....Brake fluid Replace Every 30,000 km (18,000 miles) MA-43

..C....H..Limited-slip differential (L.S.D.) gear oil Replace Every 30,000 km (18,000 miles) MA-38

..C....H..Transfer & standard differential gear oil

Replace Every 60,000 km (36,000 miles)MA-36/MA-37/

MA-38

A.C...GHI.Brake pads/linings, discs/drums & other brake system components Inspect Every 15,000 km (9,000 miles) MA-40/MA-41

......GH.J Greasing points of steering linkage, propeller shafts and suspension

Lubricate Every 15,000 km (9,000 miles) MA-44/MA-38

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system

Inspect Every 30,000 km (18,000 miles)MA-43/FA-4/

RA-4/MA-38/

MA-36

..C....H..Drive shafts Inspect Every 15,000 km (9,000 miles) FA-22

.........J Front wheel bearing grease & free running hub grease

Inspect Every 15,000 km (9,000 miles) MA-39/MA-40

PERIODIC MAINTENANCE

MA-14

http://vnx.su/

Page 56 of 1833

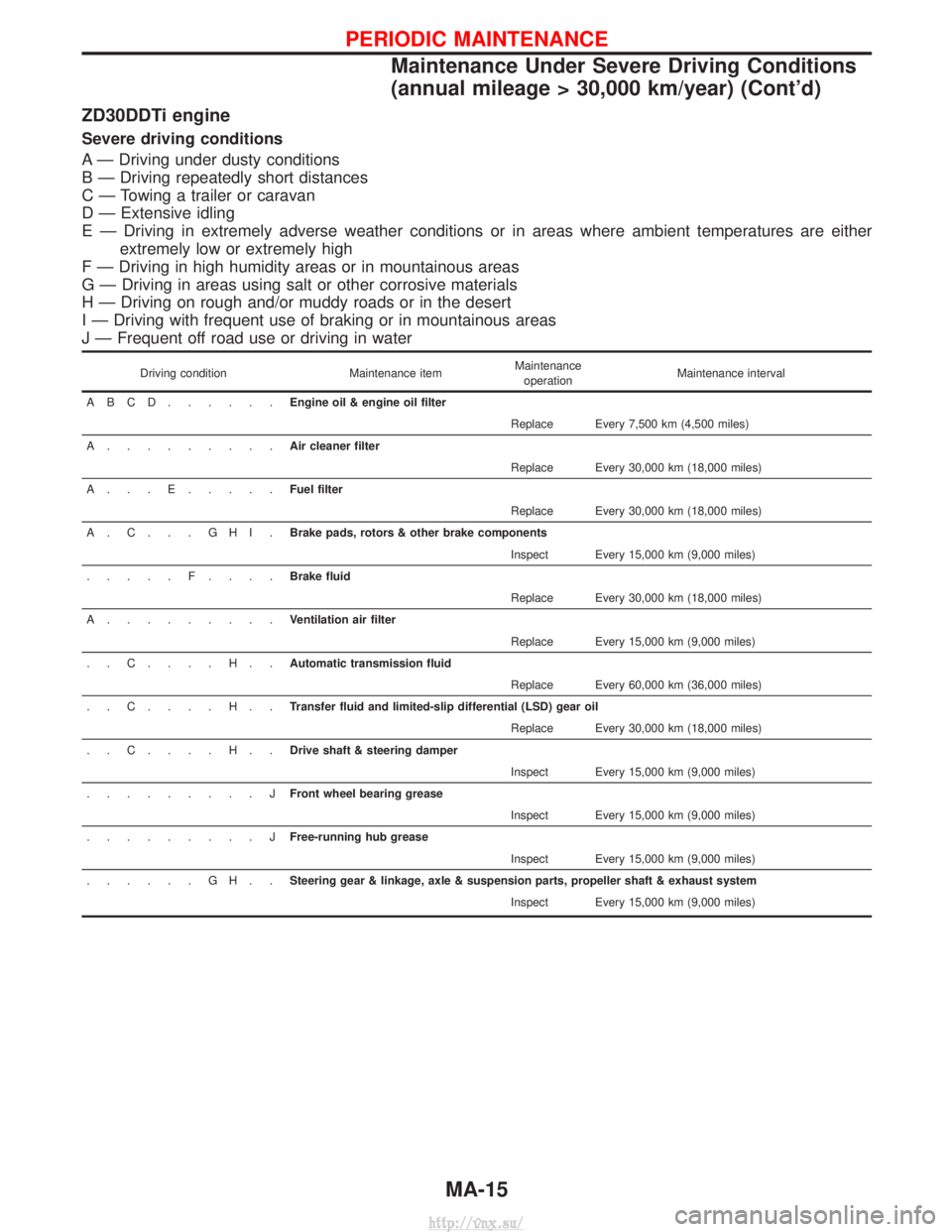

ZD30DDTi engine

Severe driving conditions

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather conditions or in areas where ambient temperatures are eitherextremely low or extremely high

F Ð Driving in high humidity areas or in mountainous areas

G Ð Driving in areas using salt or other corrosive materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operation Maintenance interval

ABCD......Engine oil & engine oil filter Replace Every 7,500 km (4,500 miles)

A.........Air cleaner filter Replace Every 30,000 km (18,000 miles)

A...E.....Fuel filter Replace Every 30,000 km (18,000 miles)

A.C...GHI.Brake pads, rotors & other brake components Inspect Every 15,000 km (9,000 miles)

.....F....Brake fluid Replace Every 30,000 km (18,000 miles)

A.........Ventilation air filter Replace Every 15,000 km (9,000 miles)

..C....H..Automatic transmission fluid Replace Every 60,000 km (36,000 miles)

..C....H..Transfer fluid and limited-slip differential (LSD) gear oil Replace Every 30,000 km (18,000 miles)

..C....H..Drive shaft & steering damper Inspect Every 15,000 km (9,000 miles)

.........J Front wheel bearing grease

Inspect Every 15,000 km (9,000 miles)

.........J Free-running hub grease

Inspect Every 15,000 km (9,000 miles)

......GH..Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust system Inspect Every 15,000 km (9,000 miles)

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions

(annual mileage > 30,000 km/year) (Cont'd)

MA-15

http://vnx.su/

Page 58 of 1833

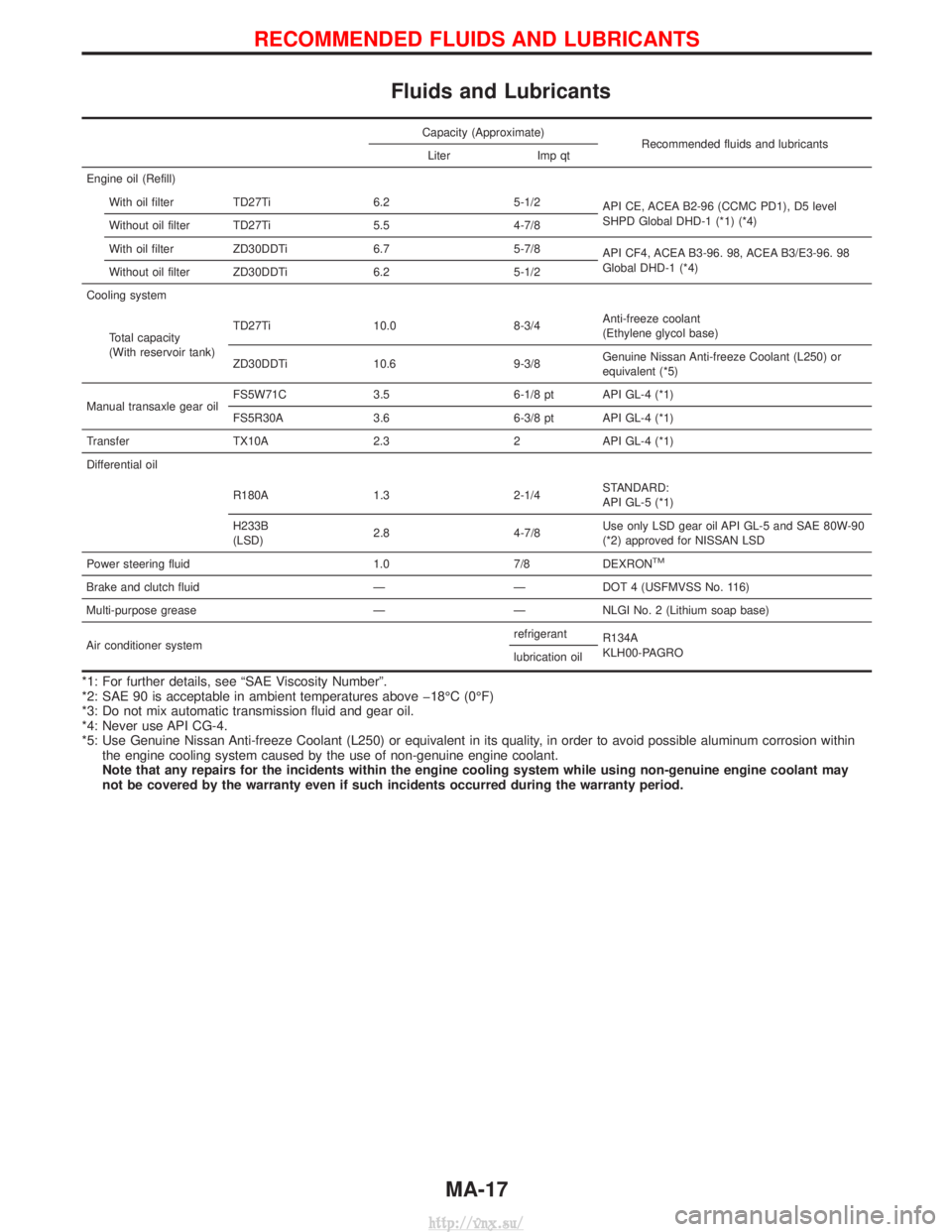

Fluids and Lubricants

Capacity (Approximate)Recommended fluids and lubricants

Liter Imp qt

Engine oil (Refill) With oil filter TD27Ti 6.2 5-1/2 API CE, ACEA B2-96 (CCMC PD1), D5 level

SHPD Global DHD-1 (*1) (*4)

Without oil filter TD27Ti 5.5 4-7/8

With oil filter ZD30DDTi 6.7 5-7/8 API CF4, ACEA B3-96. 98, ACEA B3/E3-96. 98

Global DHD-1 (*4)

Without oil filter ZD30DDTi 6.2 5-1/2

Cooling system

Total capacity

(With reservoir tank) TD27Ti 10.0 8-3/4

Anti-freeze coolant

(Ethylene glycol base)

ZD30DDTi 10.6 9-3/8 Genuine Nissan Anti-freeze Coolant (L250) or

equivalent (*5)

Manual transaxle gear oil FS5W71C 3.5 6-1/8 pt API GL-4 (*1)

FS5R30A 3.6 6-3/8 pt API GL-4 (*1)

Transfer TX10A 2.3 2 API GL-4 (*1)

Differential oil

R180A 1.3 2-1/4 STANDARD:

API GL-5 (*1)

H233B

(LSD) 2.8 4-7/8 Use only LSD gear oil API GL-5 and SAE 80W-90

(*2) approved for NISSAN LSD

Power steering fluid 1.0 7/8 DEXRON

TM

Brake and clutch fluid ÐÐDOT 4 (USFMVSS No. 116)

Multi-purpose grease Ð Ð NLGI No. 2 (Lithium soap base)

Air conditioner system refrigerant

R134A

KLH00-PAGRO

lubrication oil

*1: For further details, see ªSAE Viscosity Numberº.

*2: SAE 90 is acceptable in ambient temperatures above þ18ÉC (0ÉF)

*3: Do not mix automatic transmission fluid and gear oil.

*4: Never use API CG-4.

*5: Use Genuine Nissan Anti-freeze Coolant (L250) or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may

not be covered by the warranty even if such incidents occurred during the warranty period.

RECOMMENDED FLUIDS AND LUBRICANTS

MA-17

http://vnx.su/

Page 62 of 1833

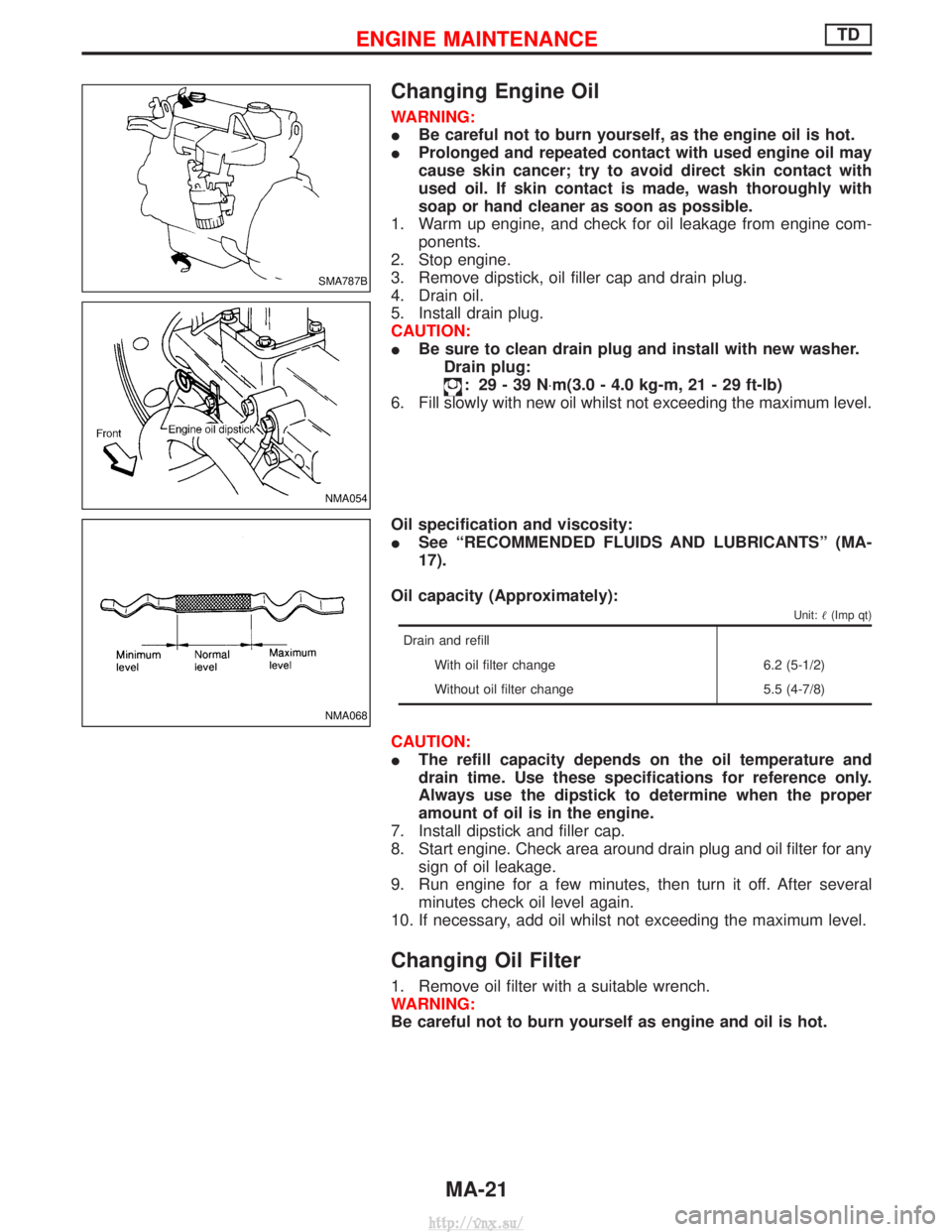

Changing Engine Oil

WARNING:

IBe careful not to burn yourself, as the engine oil is hot.

I Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com- ponents.

2. Stop engine.

3. Remove dipstick, oil filler cap and drain plug.

4. Drain oil.

5. Install drain plug.

CAUTION:

I Be sure to clean drain plug and install with new washer.

Drain plug:

: 29-39N ×m(3.0 - 4.0 kg-m, 21 - 29 ft-lb)

6. Fill slowly with new oil whilst not exceeding the maximum level.

Oil specification and viscosity:

I See ªRECOMMENDED FLUIDS AND LUBRICANTSº (MA-

17).

Oil capacity (Approximately):

Unit: (Imp qt)

Drain and refill

With oil filter change 6.2 (5-1/2)

Without oil filter change 5.5 (4-7/8)

CAUTION:

IThe refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

7. Install dipstick and filler cap.

8. Start engine. Check area around drain plug and oil filter for any sign of oil leakage.

9. Run engine for a few minutes, then turn it off. After several minutes check oil level again.

10. If necessary, add oil whilst not exceeding the maximum level.

Changing Oil Filter

1. Remove oil filter with a suitable wrench.

WARNING:

Be careful not to burn yourself as engine and oil is hot.

SMA787B

NMA054

NMA068

ENGINE MAINTENANCETD

MA-21

http://vnx.su/

Page 67 of 1833

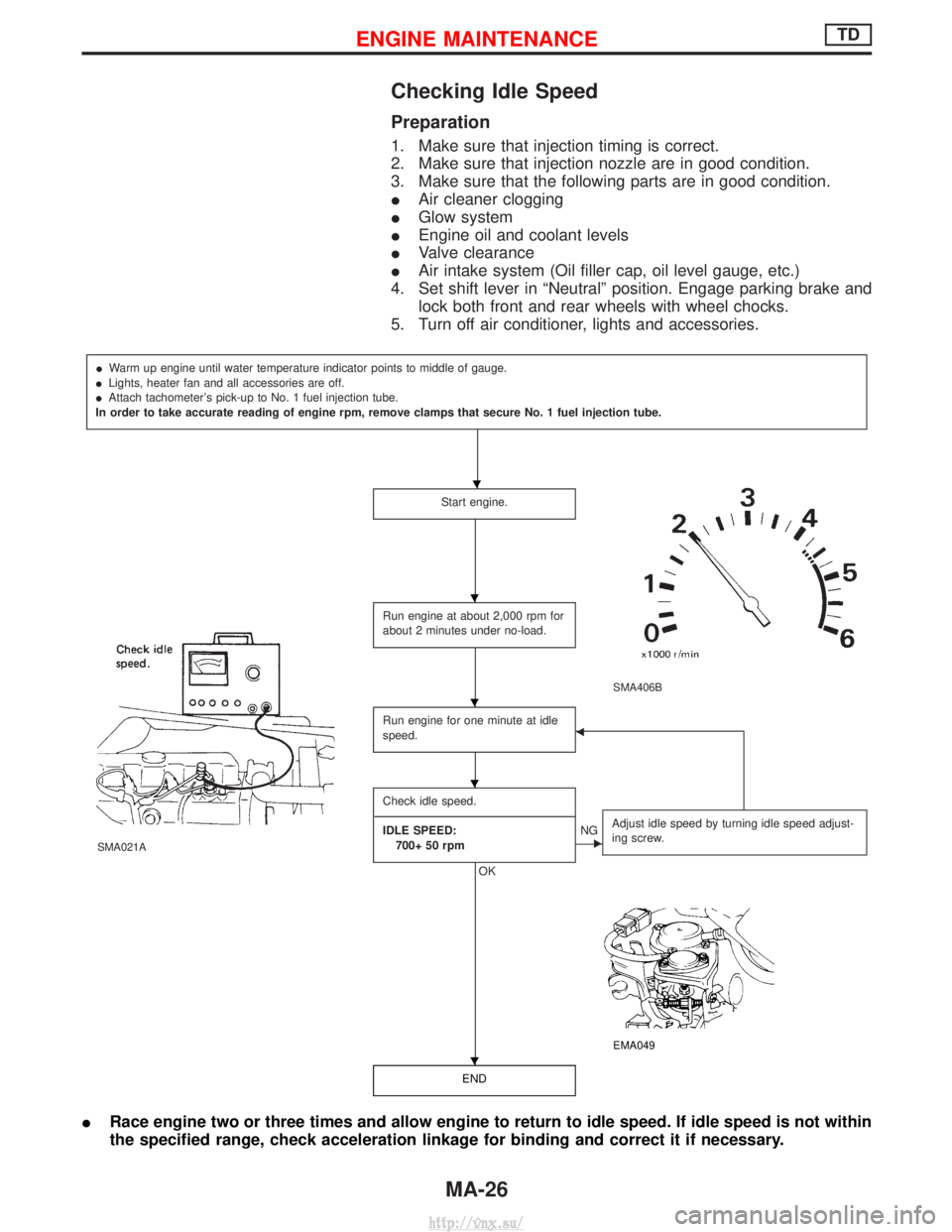

Checking Idle Speed

Preparation

1. Make sure that injection timing is correct.

2. Make sure that injection nozzle are in good condition.

3. Make sure that the following parts are in good condition.

IAir cleaner clogging

I Glow system

I Engine oil and coolant levels

I Valve clearance

I Air intake system (Oil filler cap, oil level gauge, etc.)

4. Set shift lever in ªNeutralº position. Engage parking brake and lock both front and rear wheels with wheel chocks.

5. Turn off air conditioner, lights and accessories.

I Warm up engine until water temperature indicator points to middle of gauge.

I Lights, heater fan and all accessories are off.

I Attach tachometer's pick-up to No. 1 fuel injection tube.

In order to take accurate reading of engine rpm, remove clamps that secure No. 1 fuel injection tube.

Start engine.

SMA406B

SMA021A

Run engine at about 2,000 rpm for

about 2 minutes under no-load.

Run engine for one minute at idle

speed.F

Check idle speed.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- IDLE SPEED: 700+ 50 rpm

OK

ENG Adjust idle speed by turning idle speed adjust-

ing screw.

EMA049

END

I

Race engine two or three times and allow engine to return to idle speed. If idle speed is not within

the specified range, check acceleration linkage for binding and correct it if necessary.

H

H

H

H

H

ENGINE MAINTENANCETD

MA-26

http://vnx.su/

Page 156 of 1833

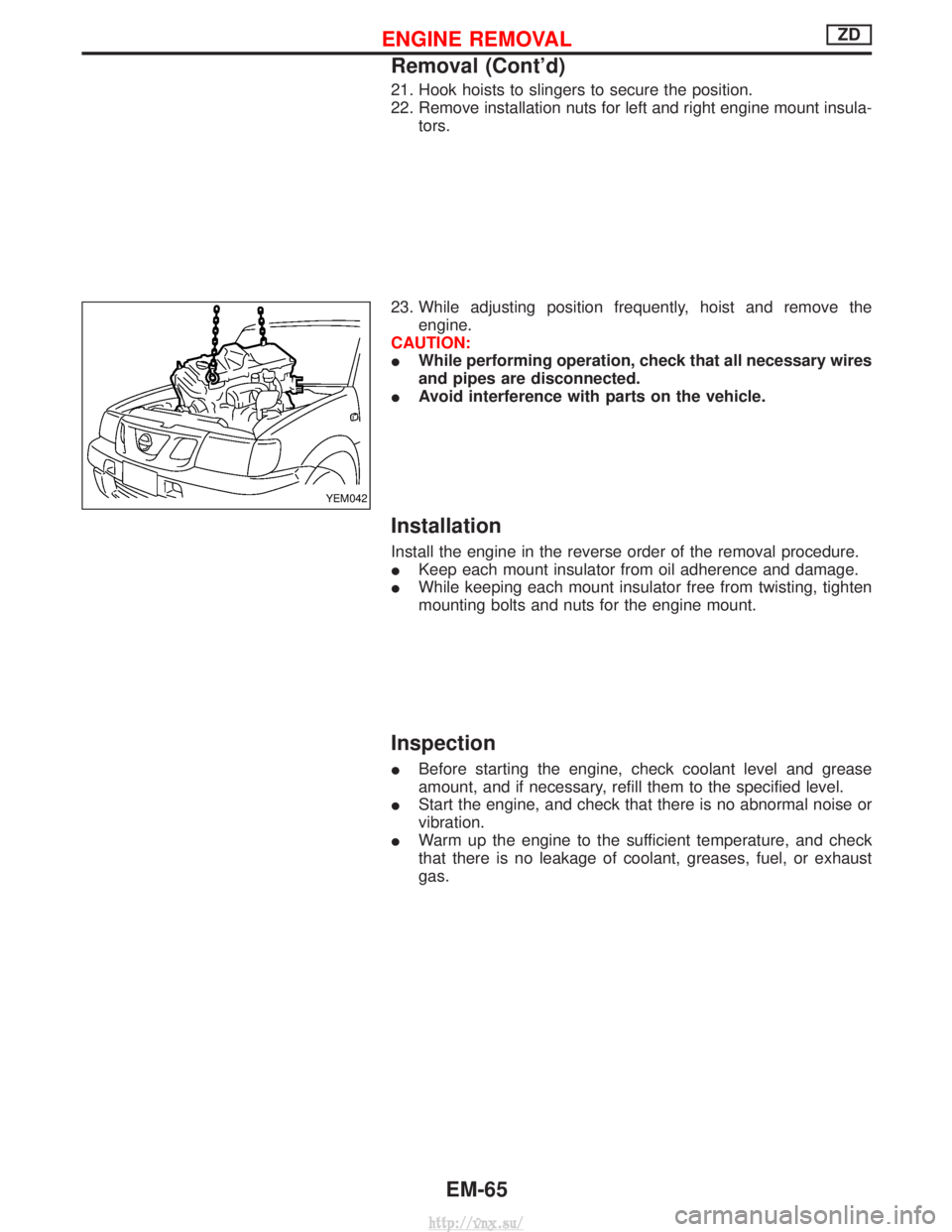

21. Hook hoists to slingers to secure the position.

22. Remove installation nuts for left and right engine mount insula-tors.

23. While adjusting position frequently, hoist and remove the engine.

CAUTION:

I While performing operation, check that all necessary wires

and pipes are disconnected.

I Avoid interference with parts on the vehicle.

Installation

Install the engine in the reverse order of the removal procedure.

IKeep each mount insulator from oil adherence and damage.

I While keeping each mount insulator free from twisting, tighten

mounting bolts and nuts for the engine mount.

Inspection

IBefore starting the engine, check coolant level and grease

amount, and if necessary, refill them to the specified level.

I Start the engine, and check that there is no abnormal noise or

vibration.

I Warm up the engine to the sufficient temperature, and check

that there is no leakage of coolant, greases, fuel, or exhaust

gas.

YEM042

ENGINE REMOVALZD

Removal (Cont'd)

EM-65

http://vnx.su/