engine NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3612 of 5883

![NISSAN TIIDA 2007 Service Repair Manual AIR CONDITIONER CONTROL

HAC-279

< ECU DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

ECU DIAGNOSIS

AIR CONDITIONER CONTROL

Front Air Control Terminals Reference ValuesINFO NISSAN TIIDA 2007 Service Repair Manual AIR CONDITIONER CONTROL

HAC-279

< ECU DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

ECU DIAGNOSIS

AIR CONDITIONER CONTROL

Front Air Control Terminals Reference ValuesINFO](/img/5/57395/w960_57395-3611.png)

AIR CONDITIONER CONTROL

HAC-279

< ECU DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

ECU DIAGNOSIS

AIR CONDITIONER CONTROL

Front Air Control Terminals Reference ValuesINFOID:0000000001547371

Measure voltage between each terminal and ground by following ter-

minals and reference value for front air control

A/C FRONT AIR CONTROL HARNESS CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUE FOR FRONT AIR CONTROL

SJIA0739E

AWIIA0564ZZ

Te r m i n a l

No.Wire

colorItemIgnition

switchConditionVo l ta g e

(V)

1R Gas sensor

Power supply for intake

door PBR (5V output)ON - Approx. 5

2RRear window defogger feed-

back signalON Rear window defogger: ON Approx. 12

3 SB Ambient sensor - - -

4 LG In-vehicle sensor - - -

5 P Sunload sensor - - -

6 O Intake sensor - - -

9 B Illumination Ground ON - Approx. 0

10 BR Sensor ground ON - Approx. 0

11 R Power supply for IGN 2 ON - Battery voltage

12 BREngine coolant temperature

sensor signalONAt idle (after warming up, ap-

prox. 80°C)

CAUTION:

The waveforms vary depend-

ing on coolant temperature.

14 SBIntake door motor feedback

signalONREC position Approx. 5

FRE position Approx. 0

SKIB3651J

Page 3633 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-300

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

>> GO TO 9.

9.CHECK REFRIGERANT PURITY

1. Connect recovery/recycling equipment to vehicle.

2. Confirm refrigerant puri NISSAN TIIDA 2007 Service Repair Manual HAC-300

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

>> GO TO 9.

9.CHECK REFRIGERANT PURITY

1. Connect recovery/recycling equipment to vehicle.

2. Confirm refrigerant puri](/img/5/57395/w960_57395-3632.png)

HAC-300

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

>> GO TO 9.

9.CHECK REFRIGERANT PURITY

1. Connect recovery/recycling equipment to vehicle.

2. Confirm refrigerant purity in supply tank using recovery/recycling and refrigerant identifier.

Is the inspection result normal?

YES >> GO TO 10.

NO >> Check contaminated refrigerant. Refer to HA-21, "

HFC-134a (R-134a) Service Procedure".

10.CHECK FOR EVAPORATOR FREEZE UP

Start engine and run A/C. Check for evaporator freeze up.

Does evaporator freeze up?

YES >> Perform performance test diagnoses. Refer to HAC-300, "Performance Test Diagnoses".

NO >> GO TO 11.

11 .CHECK REFRIGERANT PRESSURE

Check refrigerant pressure with manifold gauge connected. Refer to HAC-303, "

Test Reading".

Is the inspection result normal?

YES >> Perform performance test diagnoses. Refer to HAC-300, "Performance Test Diagnoses".

NO >> GO TO 12.

12.CHECK AIR DUCTS

Check ducts for air leaks.

Is the inspection result normal?

YES >> System OK.

NO >> Repair air leaks.

Performance Test DiagnosesINFOID:0000000001547375

PERFORMANCE TEST DIAGNOSIS

Page 3636 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-303

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

Testing must be performed as follows:

Test ReadingINFOID:0000000001547377

TEST READIN NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT COOLING

HAC-303

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

Testing must be performed as follows:

Test ReadingINFOID:0000000001547377

TEST READIN](/img/5/57395/w960_57395-3635.png)

INSUFFICIENT COOLING

HAC-303

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

Testing must be performed as follows:

Test ReadingINFOID:0000000001547377

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

*1: In the blower motor low-speed control

*2: In the blower motor high-speed control

Trouble Diagnoses for Unusual PressureINFOID:0000000001547378

TROUBLE DIAGNOSIS FOR UNUSUAL PRESSURE

Vehicle condition Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode control dial

(Ventilation) set

Intake switch

(Recirculation) set

Blower speedMax. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C (°F) Relative humidity

%Air temperature

°C (°F)

50 - 6020 (68) 7.2 - 9.1 (45 - 48)

25 (77) 11.4 - 13.8 (53 - 57)

30 (86) 15.5 - 18.4 (60 - 65)

35 (95) 20.3 - 23.7 (69 - 75)

60 - 7020 (68) 9.1 - 10.9 (48 - 52)

25 (77) 13.8 - 16.2 (57 - 61)

30 (86) 18.4 - 21.3 (65 - 70)

35 (95) 23.7 - 27.1 (75 - 81)

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2, psi)Low-pressure (Suction side)

kPa (bar, kg/cm2, psi) Relative humidity

%Air temperature

°C (°F)

50 - 7020 (68)843 - 1,036 *1

(11.08 - 13.63, 8.6 - 10.6, 122 - 150)159.0 - 194.0

(1.59 - 1.94, 1.62 - 1.98, 23.1 - 28.1)

25 (77)1,094 - 1,338 *1

(10.94 - 13.38, 11.2 - 13.6, 159 - 194)196.3 - 240.0

(1.96 - 2.40, 2.00 - 2.45, 28.5 - 34.8)

30 (86)1,298 - 1,590 *1

(12.98 - 15.90, 13.2 - 16.2, 188 - 231)248.0 - 302.7

(2.48 - 3.03, 2.53 - 3.09, 36.0 - 43.9)

35 (95)1,383 - 1,688 *2

(13.83 - 16.88, 14.1 - 17.2, 201 - 245)308.8 - 377.4

(3.09 - 3.77, 3.15 - 3.85, 44.8 - 54.7)

40 (104)1,628 - 1,988 *2

(16.28 - 19.88, 16.6 - 20.3, 236 - 288)377.4 - 461.2

(3.77 - 4.61, 3.85 - 4.70, 54.7 - 66.8)

Page 3637 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-304

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above NISSAN TIIDA 2007 Service Repair Manual HAC-304

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above](/img/5/57395/w960_57395-3636.png)

HAC-304

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT COOLING

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table).

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure

sides are too high.Pressure is reduced soon af-

ter water is splashed on con-

denser.Excessive refrigerant charge in refrig-

eration cycle.Reduce refrigerant until

specified pressure is ob-

tained.

Air suction by cooling fan is in-

sufficient.Insufficient condenser cooling perfor-

mance.

↓

1. Condenser fins are clogged.

2. Improper fan rotation of cooling

fan. Clean condenser.

Check and repair cooling

fan if necessary.

Low-pressure pipe is not

cold.

When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (1.96 bar, 2

kg/cm

2, 28 psi). It then de-

creases gradually thereaf-

ter.Poor heat exchange in condenser

(After compressor operation stops,

high-pressure decreases too slowly.).

↓

Air in refrigeration cycle.Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems malfunction.Check and repair each en-

gine cooling system.

An area of the low-pressure

pipe is colder than areas

near the evaporator outlet.

Plates are sometimes cov-

ered with frost. Excessive liquid refrigerant on low-

pressure side.

Excessive refrigerant discharge

flow.

Expansion valve is open a little

compared with the specification.

↓

Improper expansion valve adjust-

ment.Replace expansion valve.

AC359A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high

and low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts located

between compressor and condenser

are clogged or crushed. Check and repair or re-

place malfunctioning

parts.

Check oil for contami-

nation.

AC360A

Page 3640 of 5883

![NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT HEATING

HAC-307

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547379

SYMPTOM: Insuffi NISSAN TIIDA 2007 Service Repair Manual INSUFFICIENT HEATING

HAC-307

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547379

SYMPTOM: Insuffi](/img/5/57395/w960_57395-3639.png)

INSUFFICIENT HEATING

HAC-307

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547379

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - TEMPERATURE INCREASE

1. Press the AUTO switch.

2. Turn the temperature control dial (driver) clockwise until 32° C (90° F) is displayed.

3. Check for hot air at discharge air outlets.

Can this symptom be duplicated?

YES >> GO TO 2.

NO >> Perform complete system operational check. Refer to HAC-202, "

Operational Check".

2.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

3.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to HAC-213, "

Front Air Control Self-Diagnosis".

Is the inspection results normal?

YES >> GO TO 4.

NO >> Refer to HAC-218, "

Front Air Control Self-Diagnosis Code Chart".

4.CHECK ENGINE COOLING SYSTEM

1. Check for proper engine coolant level. Refer to CO-11, "

Inspection" (HR16DE) or CO-35, "Inspection"

(HR18DE) or CO-58, "Inspection" (K9K).

2. Check hoses for leaks or kinks.

3. Check radiator cap. Refer to CO-14, "

Checking Radiator Cap" (HR16DE) CO-38, "Checking Radiator

Cap" or (HR18DE) or CO-60, "Checking Radiator Cap" (K9K).

4. Check for air in cooling system.

>> GO TO 5.

5.CHECK AIR MIX DOOR OPERATION

Check the operation of the air mix door. Refer to HAC-225, "

Air Mix Door Motor Component Function Check".

Is the inspection result normal?

YES >> GO TO 6.

NO >> Check the air mix door motor circuit. Refer to HAC-226, "

Air Mix Door Motor Diagnosis Proce-

dure".

6.CHECK AIR DUCTS

Check for disconnected or leaking air ducts.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair all disconnected or leaking air ducts.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

Is the inspection result normal?

YES >> Hot inlet hose and a warm outlet hose: GO TO 8.

NO >> Inlet hose cold: GO TO 11.

Both hoses warm: GO TO 9.

Page 3641 of 5883

![NISSAN TIIDA 2007 Service Repair Manual HAC-308

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT HEATING

8.CHECK ENGINE COOLANT SYSTEM

Check engine control temperature sensor. Refer to XX-XX, "*****"

HR16DE WITH EURO-OBD NISSAN TIIDA 2007 Service Repair Manual HAC-308

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT HEATING

8.CHECK ENGINE COOLANT SYSTEM

Check engine control temperature sensor. Refer to XX-XX, "*****"

HR16DE WITH EURO-OBD](/img/5/57395/w960_57395-3640.png)

HAC-308

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

INSUFFICIENT HEATING

8.CHECK ENGINE COOLANT SYSTEM

Check engine control temperature sensor. Refer to XX-XX, "*****"

HR16DE WITH EURO-OBD or XX-XX,

"*****" HR16DE WITHOUT EURO-OBD or EC-808, "Component Inspection" MRDE or EC-1133, "Component

Inspection" K9K.

Is the inspection result normal?

YES >> System OK.

NO >> Repair or replace as necessary. Retest.

9.CHECK HEATER HOSES

Check heater hoses for proper installation.

Is the inspection result normal?

YES >> System OK.

NO >> 1. Back flush heater core.

2. Drain the water from the system.

3. Refill system with new engine coolant. Refer to CO-11, "

Changing Engine Coolant" HR16DE

CO-35, "

Changing Engine Coolant" HR18DE or CO-58, "Inspection" K9K.

4. GO TO 10 to retest.

10.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

Is the inspection result normal?

YES >> System OK.

NO >> Replace heater core. Refer to XXXX.

Page 3659 of 5883

INL-8

< FUNCTION DIAGNOSIS >

ILLUMINATION CONTROL SYSTEM

ILLUMINATION CONTROL SYSTEM

System DiagramINFOID:0000000001730918

System DescriptionINFOID:0000000001730919

The illumination lamps operation is dependent upon the position of the lighting switch (combination switch).

When the lighting switch is placed in the 1ST or 2ND position (or if the auto light system is activated) the BCM

(body control module) receives input requesting the parking lamps to illuminate. This input is communicated to

the IPDM E/R (intelligent power distribution module engine room) via the CAN communication lines. The CPU

(central processing unit) of the IPDM E/R controls the tail lamp relay coil. When energized, this relay directs

power to the parking and illumination lamps, which then illuminate.

BATTERY SAVER CONTROL

When the lighting switch (combination switch) is in the 1ST or 2ND position and the ignition switch is turned

from ON or ACC to OFF, the battery saver control feature is activated. Under this condition, the illumination

lamps remain illuminated for 30 minutes unless the lighting switch position is changed. If the lighting switch

position is changed, then the illumination lamps are turned off after a 30 second delay. When the lighting

switch is turned from OFF to 1ST or 2ND position (or if auto light system is activated) after illumination lamps

have been turned off by the battery saver control, the illumination lamps illuminate again.

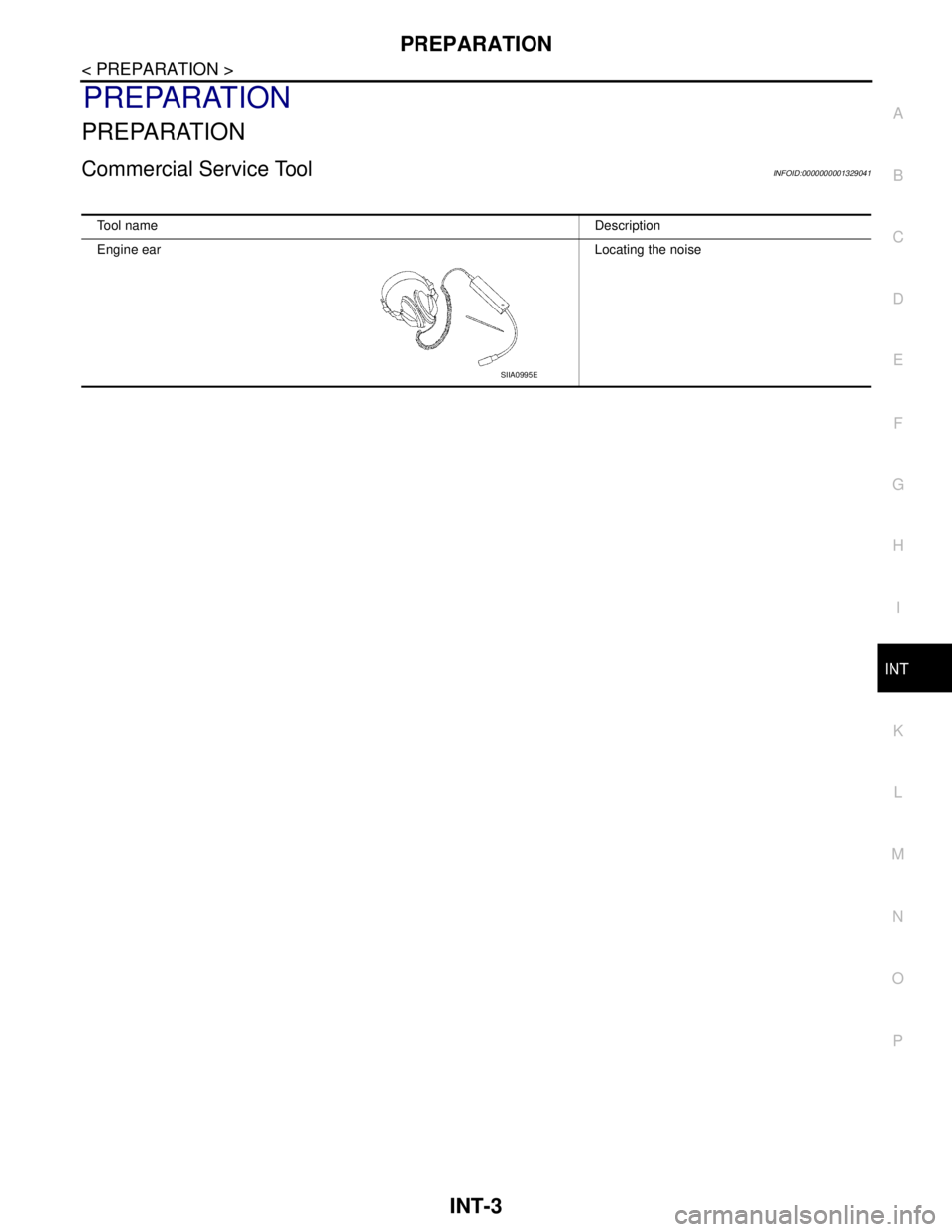

Component Parts LocationINFOID:0000000001730920

ALNIA0894GB

WKIA5674E

Page 3682 of 5883

PREPARATION

INT-3

< PREPARATION >

C

D

E

F

G

H

I

K

L

MA

B

INT

N

O

P

PREPARATION

PREPARATION

Commercial Service ToolINFOID:0000000001329041

Tool nameDescription

Engine earLocating the noise

SIIA0995E

Page 3687 of 5883

INT-8

< PREPARATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

Close a door.

Tap or push/pull around the area where the noise appears to be coming from.

Rev the engine.

Use a floor jack to recreate vehicle “twist”.

At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners

can be broken or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be elimi-

nated only temporarily.

Feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing

the noise.

Placing a piece of paper between components that you suspect are causing the noise.

Looking for loose components and contact marks.

Refer to INT-9, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 x 135 mm (3.94 x 5.31 in)/76884-71L01: 60 x 85 mm (2.36 x 3.35 in)/76884-71L02: 15 x 25

mm (0.59 x 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 x 50 mm (1.97 x 1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50 x 50

mm (1.97 x 1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 x 50 mm (1.18 x 1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 x 25 mm (0.59 x 0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

Page 3689 of 5883

INT-10

< PREPARATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.