headlamp NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 5852 of 5883

WW-50

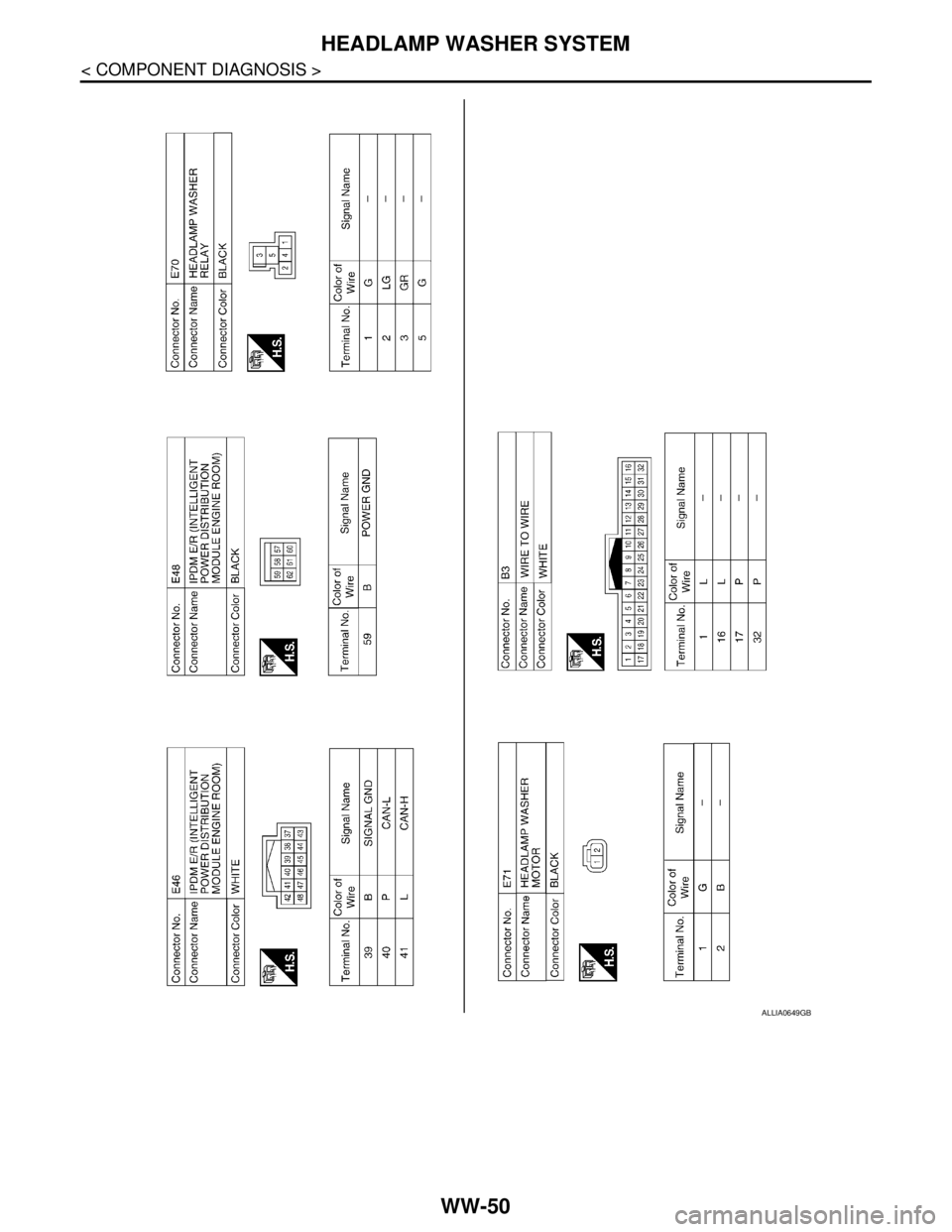

< COMPONENT DIAGNOSIS >

HEADLAMP WASHER SYSTEM

ALLIA0649GB

Page 5854 of 5883

WW-52

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

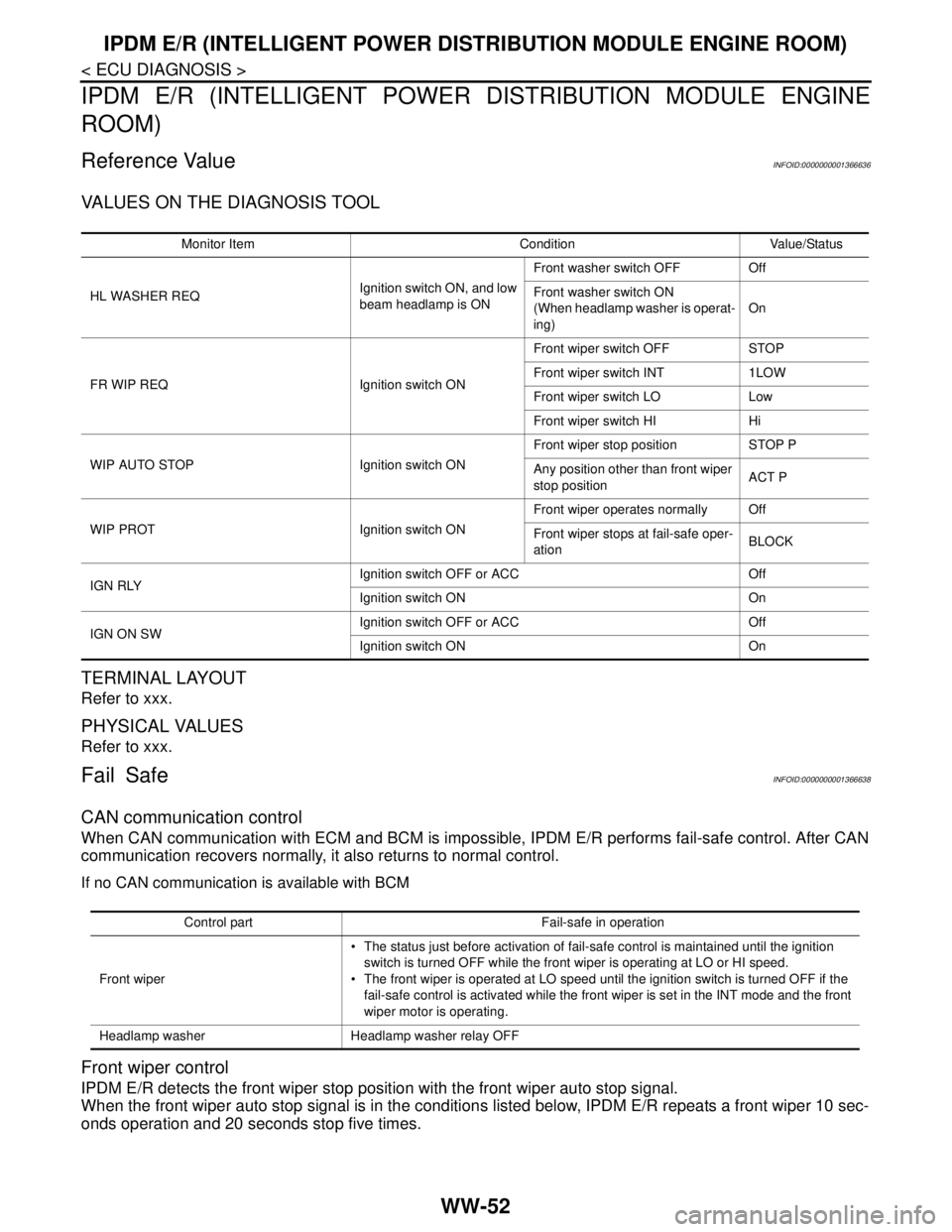

Reference ValueINFOID:0000000001366636

VALUES ON THE DIAGNOSIS TOOL

TERMINAL LAYOUT

Refer to xxx.

PHYSICAL VALUES

Refer to xxx.

Fail SafeINFOID:0000000001366638

CAN communication control

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If no CAN communication is available with BCM

Front wiper control

IPDM E/R detects the front wiper stop position with the front wiper auto stop signal.

When the front wiper auto stop signal is in the conditions listed below, IPDM E/R repeats a front wiper 10 sec-

onds operation and 20 seconds stop five times.

Monitor Item Condition Value/Status

HL WASHER REQIgnition switch ON, and low

beam headlamp is ONFront washer switch OFF Off

Front washer switch ON

(When headlamp washer is operat-

ing)On

FR WIP REQ Ignition switch ONFront wiper switch OFF STOP

Front wiper switch INT 1LOW

Front wiper switch LO Low

Front wiper switch HI Hi

WIP AUTO STOP Ignition switch ONFront wiper stop position STOP P

Any position other than front wiper

stop positionACT P

WIP PROT Ignition switch ONFront wiper operates normally Off

Front wiper stops at fail-safe oper-

ationBLOCK

IGN RLYIgnition switch OFF or ACC Off

Ignition switch ON On

IGN ON SWIgnition switch OFF or ACC Off

Ignition switch ON On

Control part Fail-safe in operation

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The front wiper is operated at LO speed until the ignition switch is turned OFF if the

fail-safe control is activated while the front wiper is set in the INT mode and the front

wiper motor is operating.

Headlamp washer Headlamp washer relay OFF

Page 5858 of 5883

WW-56

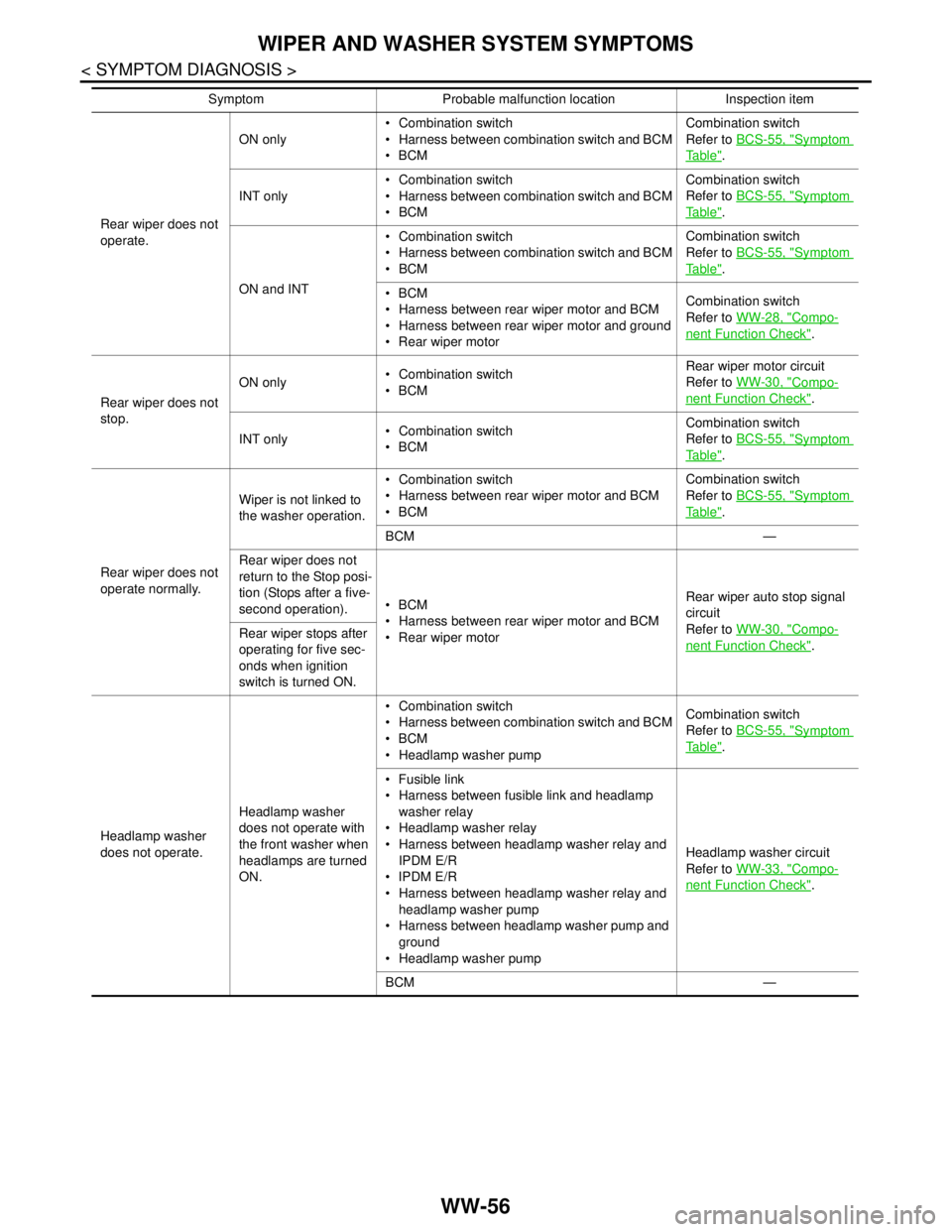

< SYMPTOM DIAGNOSIS >

WIPER AND WASHER SYSTEM SYMPTOMS

Rear wiper does not

operate.ON only Combination switch

Harness between combination switch and BCM

BCMCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

INT only Combination switch

Harness between combination switch and BCM

BCMCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

ON and INT Combination switch

Harness between combination switch and BCM

BCMCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

BCM

Harness between rear wiper motor and BCM

Harness between rear wiper motor and ground

Rear wiper motorCombination switch

Refer to WW-28, "

Compo-

nent Function Check".

Rear wiper does not

stop.ON only Combination switch

BCMRear wiper motor circuit

Refer to WW-30, "

Compo-

nent Function Check".

INT only Combination switch

BCMCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

Rear wiper does not

operate normally.Wiper is not linked to

the washer operation. Combination switch

Harness between rear wiper motor and BCM

BCMCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

BCM —

Rear wiper does not

return to the Stop posi-

tion (Stops after a five-

second operation).BCM

Harness between rear wiper motor and BCM

Rear wiper motorRear wiper auto stop signal

circuit

Refer to WW-30, "

Compo-

nent Function Check". Rear wiper stops after

operating for five sec-

onds when ignition

switch is turned ON.

Headlamp washer

does not operate.Headlamp washer

does not operate with

the front washer when

headlamps are turned

ON. Combination switch

Harness between combination switch and BCM

BCM

Headlamp washer pumpCombination switch

Refer to BCS-55, "

Symptom

Ta b l e".

Fusible link

Harness between fusible link and headlamp

washer relay

Headlamp washer relay

Harness between headlamp washer relay and

IPDM E/R

IPDM E/R

Harness between headlamp washer relay and

headlamp washer pump

Harness between headlamp washer pump and

ground

Headlamp washer pumpHeadlamp washer circuit

Refer to WW-33, "

Compo-

nent Function Check".

BCM — Symptom Probable malfunction location Inspection item

Page 5862 of 5883

WW-60

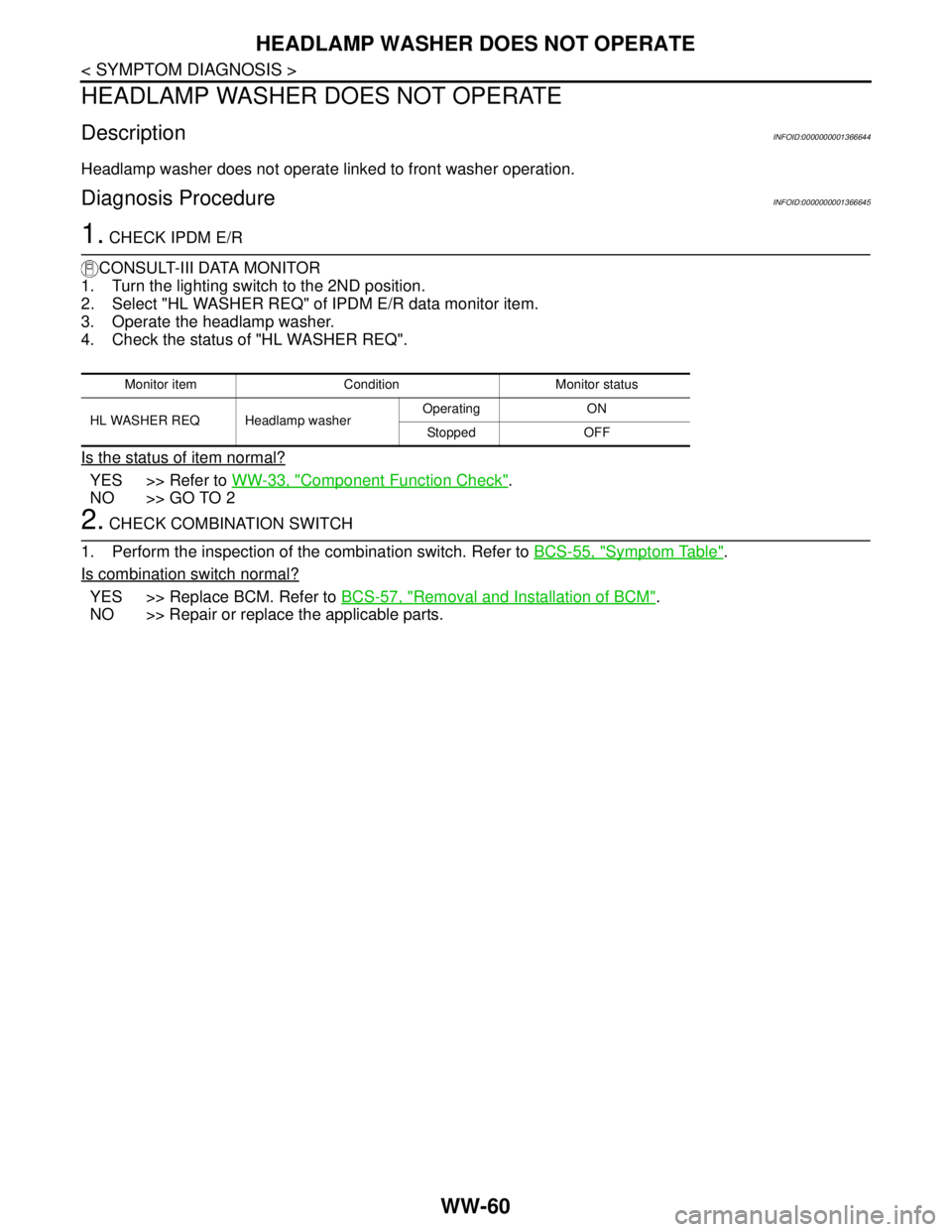

< SYMPTOM DIAGNOSIS >

HEADLAMP WASHER DOES NOT OPERATE

HEADLAMP WASHER DOES NOT OPERATE

DescriptionINFOID:0000000001366644

Headlamp washer does not operate linked to front washer operation.

Diagnosis ProcedureINFOID:0000000001366645

1. CHECK IPDM E/R

CONSULT-III DATA MONITOR

1. Turn the lighting switch to the 2ND position.

2. Select "HL WASHER REQ" of IPDM E/R data monitor item.

3. Operate the headlamp washer.

4. Check the status of "HL WASHER REQ".

Is the status of item normal?

YES >> Refer to WW-33, "Component Function Check".

NO >> GO TO 2

2. CHECK COMBINATION SWITCH

1. Perform the inspection of the combination switch. Refer to BCS-55, "

Symptom Table".

Is combination switch normal?

YES >> Replace BCM. Refer to BCS-57, "Removal and Installation of BCM".

NO >> Repair or replace the applicable parts.

Monitor item Condition Monitor status

HL WASHER REQ Headlamp washer Operating ON

Stopped OFF

Page 5864 of 5883

WW-62

< ON-VEHICLE REPAIR >

HEADLAMP WASHER NOZZLE AND TUBE

ON-VEHICLE REPAIR

HEADLAMP WASHER NOZZLE AND TUBE

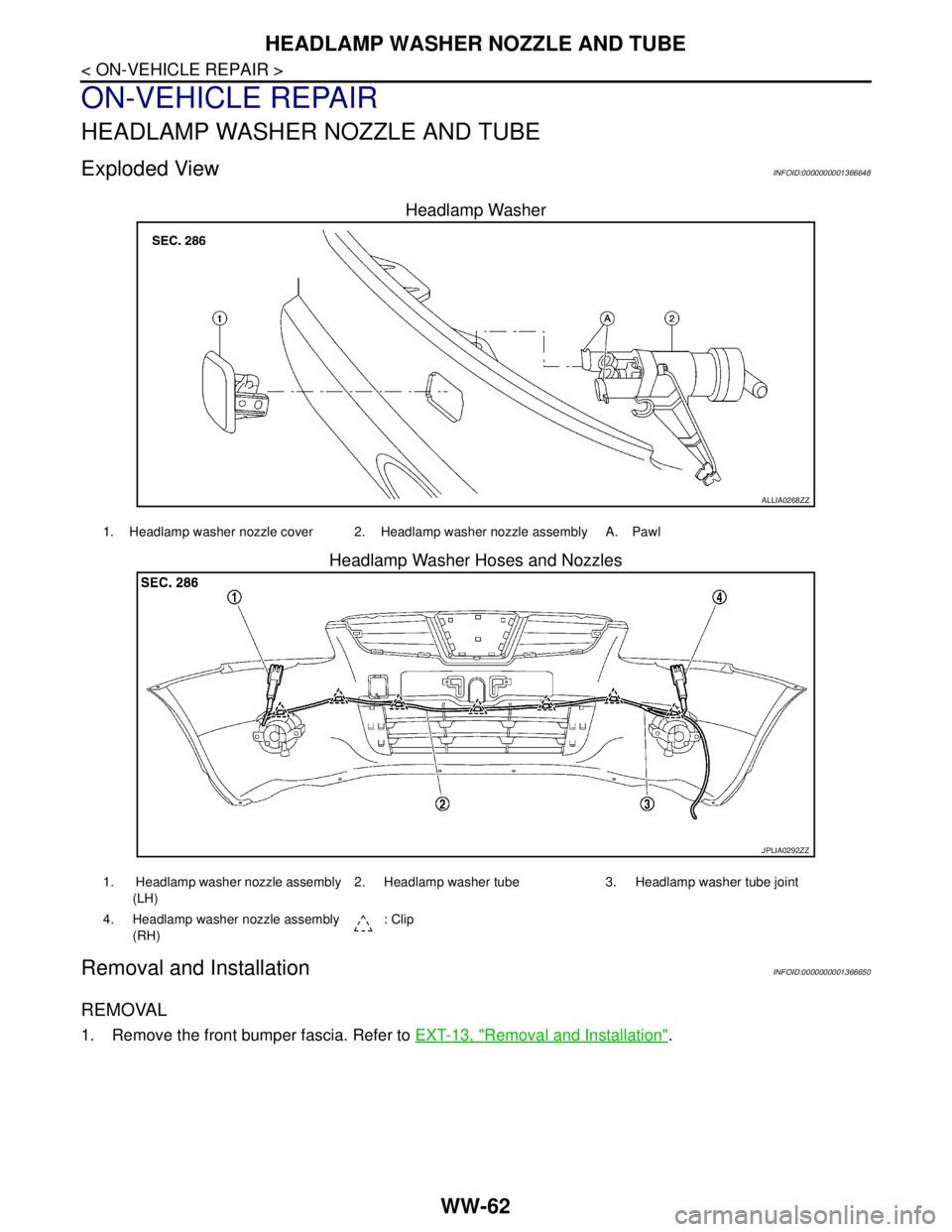

Exploded ViewINFOID:0000000001366648

Headlamp Washer

Headlamp Washer Hoses and Nozzles

Removal and InstallationINFOID:0000000001366650

REMOVAL

1. Remove the front bumper fascia. Refer to EXT-13, "Removal and Installation".

ALLIA0268ZZ

1. Headlamp washer nozzle cover 2. Headlamp washer nozzle assembly A. Pawl

JPLIA0292ZZ

1. Headlamp washer nozzle assembly

(LH)2. Headlamp washer tube 3. Headlamp washer tube joint

4. Headlamp washer nozzle assembly

(RH): Clip

Page 5865 of 5883

HEADLAMP WASHER NOZZLE AND TUBE

WW-63

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

2. Remove headlamp washer tube from headlamp washer nozzle

assembly (2).

3. Detach headlamp washer nozzle cover pawl (A), and remove

headlamp washer nozzle cover (1).

4. Push pawl, and remove headlamp washer nozzle assembly (2)

from the front bumper fascia.

:Front

INSTALLATION

Installation is in the reverse order of removal.

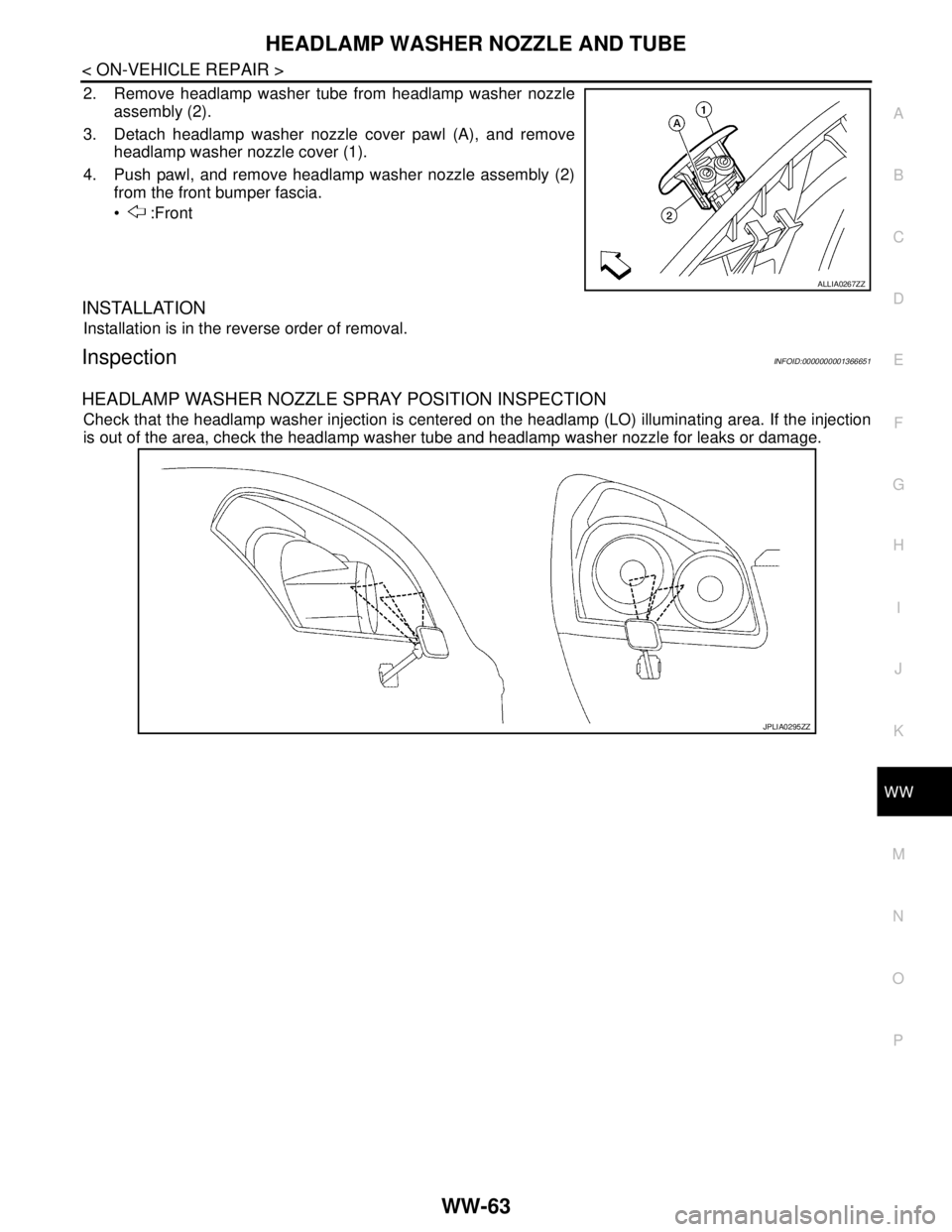

InspectionINFOID:0000000001366651

HEADLAMP WASHER NOZZLE SPRAY POSITION INSPECTION

Check that the headlamp washer injection is centered on the headlamp (LO) illuminating area. If the injection

is out of the area, check the headlamp washer tube and headlamp washer nozzle for leaks or damage.

ALLIA0267ZZ

JPLIA0295ZZ

Page 5866 of 5883

WW-64

< ON-VEHICLE REPAIR >

WASHER TANK

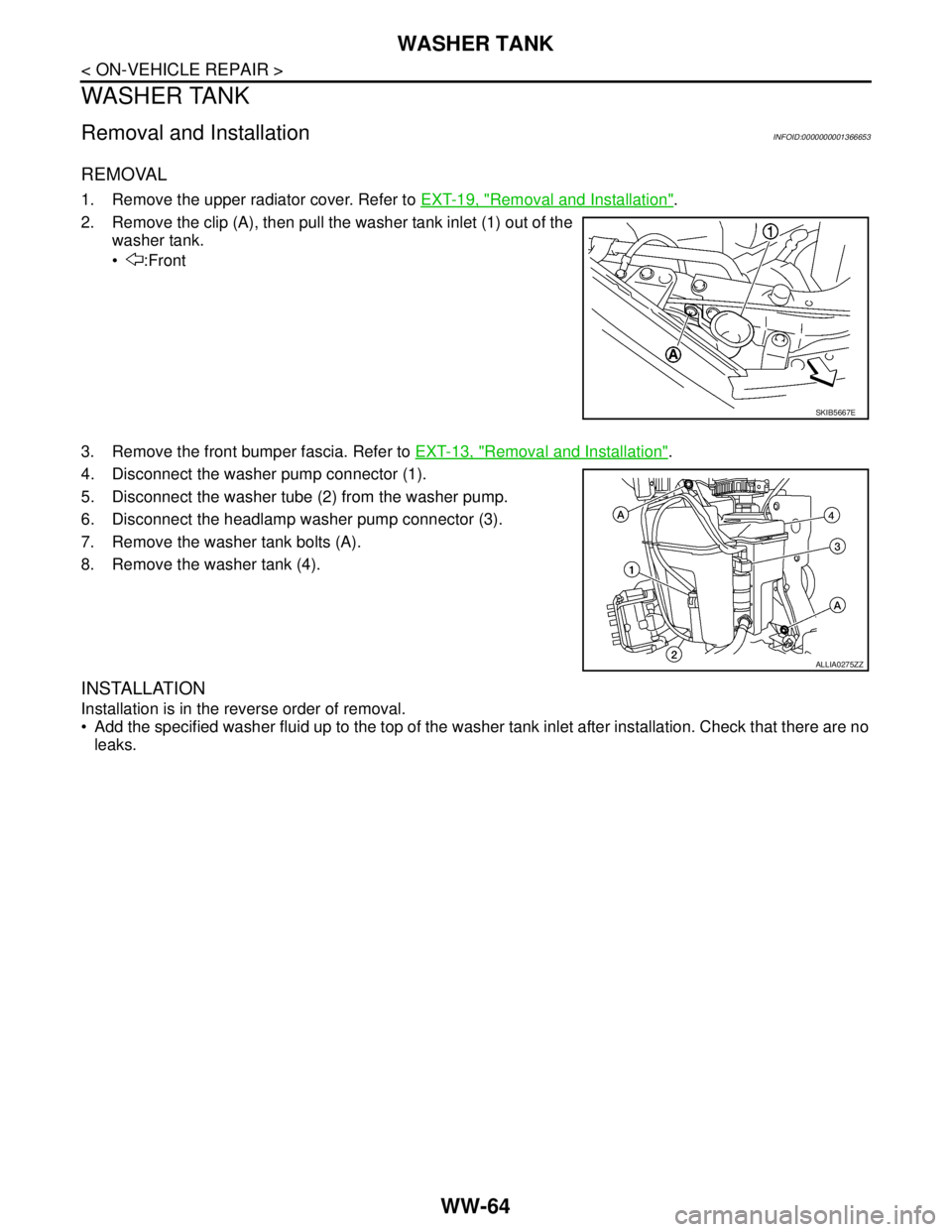

WASHER TANK

Removal and InstallationINFOID:0000000001366653

REMOVAL

1. Remove the upper radiator cover. Refer to EXT-19, "Removal and Installation".

2. Remove the clip (A), then pull the washer tank inlet (1) out of the

washer tank.

:Front

3. Remove the front bumper fascia. Refer to EXT-13, "

Removal and Installation".

4. Disconnect the washer pump connector (1).

5. Disconnect the washer tube (2) from the washer pump.

6. Disconnect the headlamp washer pump connector (3).

7. Remove the washer tank bolts (A).

8. Remove the washer tank (4).

INSTALLATION

Installation is in the reverse order of removal.

Add the specified washer fluid up to the top of the washer tank inlet after installation. Check that there are no

leaks.

SKIB5667E

ALLIA0275ZZ

Page 5868 of 5883

WW-66

< ON-VEHICLE REPAIR >

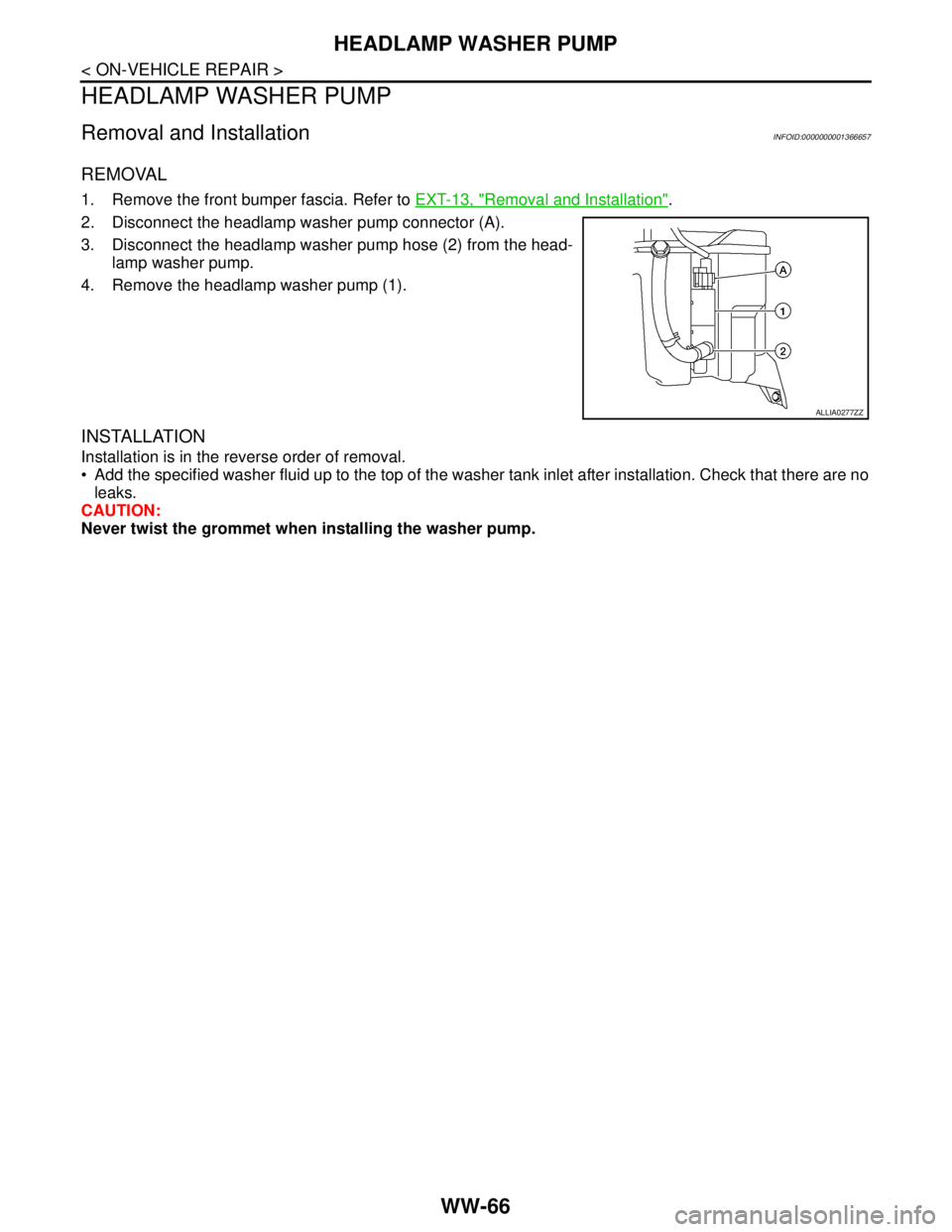

HEADLAMP WASHER PUMP

HEADLAMP WASHER PUMP

Removal and InstallationINFOID:0000000001366657

REMOVAL

1. Remove the front bumper fascia. Refer to EXT-13, "Removal and Installation".

2. Disconnect the headlamp washer pump connector (A).

3. Disconnect the headlamp washer pump hose (2) from the head-

lamp washer pump.

4. Remove the headlamp washer pump (1).

INSTALLATION

Installation is in the reverse order of removal.

Add the specified washer fluid up to the top of the washer tank inlet after installation. Check that there are no

leaks.

CAUTION:

Never twist the grommet when installing the washer pump.

ALLIA0277ZZ