clock NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 45 of 5883

![NISSAN TIIDA 2007 Service Repair Manual AV-40

< FUNCTION DIAGNOSIS >[AUDIO WITH NAVIGATION]

DIAGNOSIS SYSTEM (NAVI CONTROL UNIT)

3. Turn the volume control dial clockwise or counterclockwise for

40 clicks or more while pushing the “SETTIN NISSAN TIIDA 2007 Service Repair Manual AV-40

< FUNCTION DIAGNOSIS >[AUDIO WITH NAVIGATION]

DIAGNOSIS SYSTEM (NAVI CONTROL UNIT)

3. Turn the volume control dial clockwise or counterclockwise for

40 clicks or more while pushing the “SETTIN](/img/5/57395/w960_57395-44.png)

AV-40

< FUNCTION DIAGNOSIS >[AUDIO WITH NAVIGATION]

DIAGNOSIS SYSTEM (NAVI CONTROL UNIT)

3. Turn the volume control dial clockwise or counterclockwise for

40 clicks or more while pushing the “SETTING” button. (A short

beep will be heard when the self-diagnosis mode is started.)

Shifting from current screen to previous screen is performed

by pushing “BACK” button.

4. The trouble diagnosis initial screen is displayed, and then the

items of “Self Diagnosis” and “Confirmation / Adjustment” can be

selected.

Self-diagnosis mode

1. Start the self-diagnosis function. Then select “Self Diagnosis”.

- Self-diagnosis subdivision screen is displayed, and the self-

diagnosis mode starts.

- The bar graph visible on the center of the self-diagnosis subdivi-

sion screen indicates progress of the trouble diagnosis.

2. Diagnosis results are displayed after the self-diagnosis is com-

pleted. The unit names and the connection lines are color-coded

according to the diagnostic results.

NOTE:

Only the control unit (NAVI control unit) is displayed in red.

- The screen switch colors are determined according to the following order of priority: red > yellow > gray if

multiple errors occur at the same time for a single unit.

JPNIA0173GB

SKIB3961E

SKIB3657E

Diagnosis results Unit Connection

line

Normal Green Green

Connection malfunction Gray Yellow

DVD drive undiagnosed Gray Green

DVD-ROM and DVD-ROM

drive malfunctionYellow Green

Unit malfunction

NoteRed Green

ALNIA0883GB

Page 199 of 5883

BRAKE PEDAL

BR-7

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

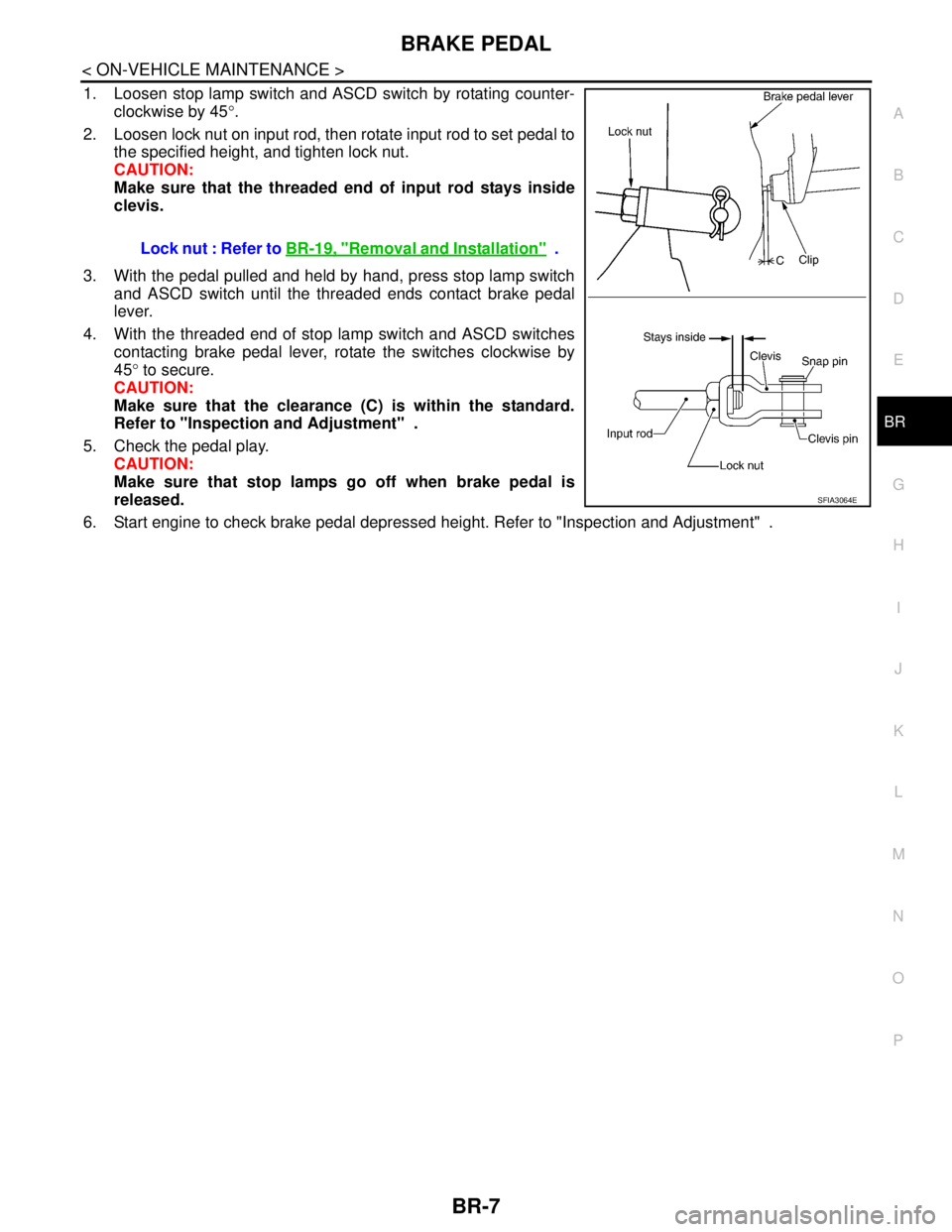

1. Loosen stop lamp switch and ASCD switch by rotating counter-

clockwise by 45°.

2. Loosen lock nut on input rod, then rotate input rod to set pedal to

the specified height, and tighten lock nut.

CAUTION:

Make sure that the threaded end of input rod stays inside

clevis.

3. With the pedal pulled and held by hand, press stop lamp switch

and ASCD switch until the threaded ends contact brake pedal

lever.

4. With the threaded end of stop lamp switch and ASCD switches

contacting brake pedal lever, rotate the switches clockwise by

45° to secure.

CAUTION:

Make sure that the clearance (C) is within the standard.

Refer to "Inspection and Adjustment" .

5. Check the pedal play.

CAUTION:

Make sure that stop lamps go off when brake pedal is

released.

6. Start engine to check brake pedal depressed height. Refer to "Inspection and Adjustment" . Lock nut : Refer to BR-19, "

Removal and Installation" .

SFIA3064E

Page 206 of 5883

BR-14

< ON-VEHICLE REPAIR >

BRAKE TUBE AND HOSE

BRAKE TUBE AND HOSE

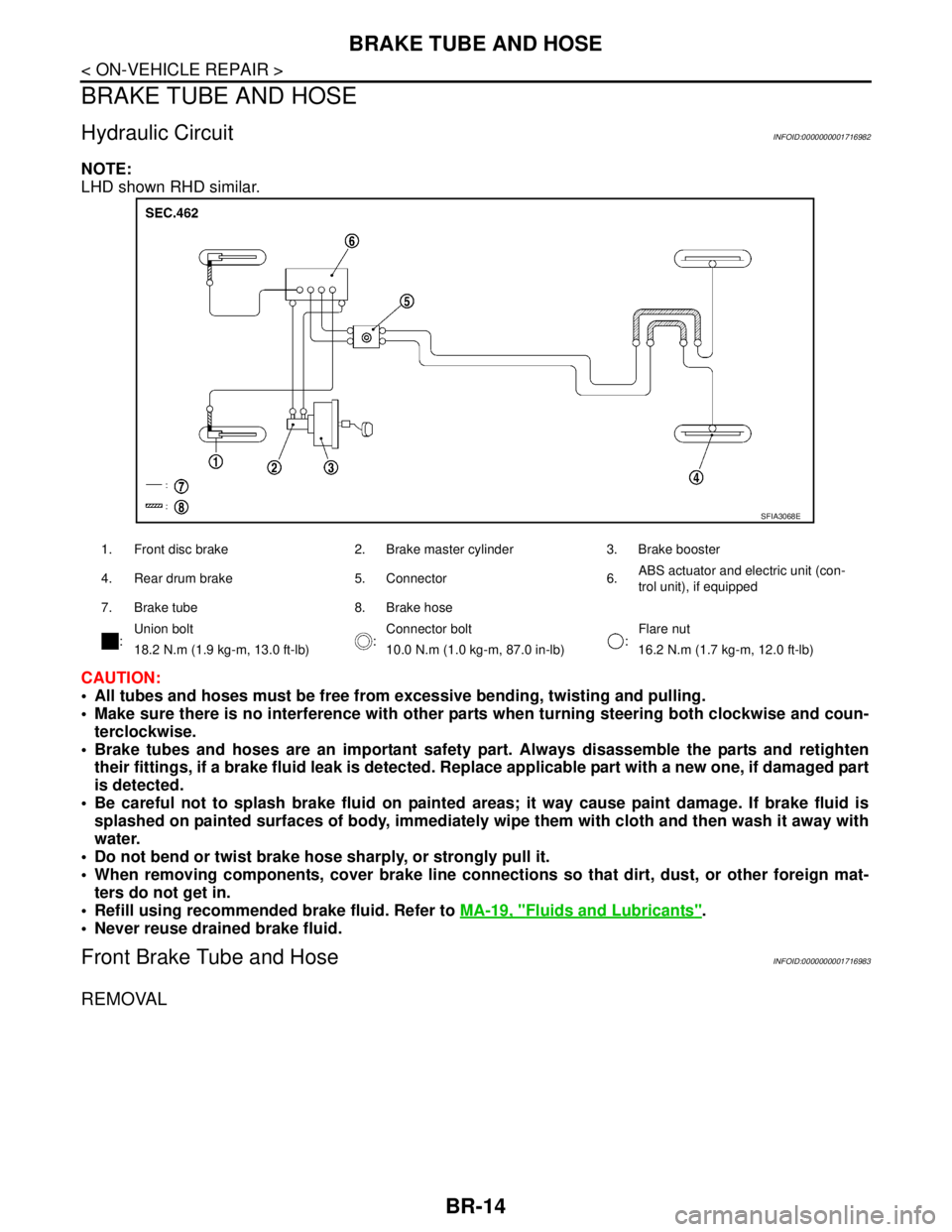

Hydraulic CircuitINFOID:0000000001716982

NOTE:

LHD shown RHD similar.

CAUTION:

All tubes and hoses must be free from excessive bending, twisting and pulling.

Make sure there is no interference with other parts when turning steering both clockwise and coun-

terclockwise.

Brake tubes and hoses are an important safety part. Always disassemble the parts and retighten

their fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part

is detected.

Be careful not to splash brake fluid on painted areas; it way cause paint damage. If brake fluid is

splashed on painted surfaces of body, immediately wipe them with cloth and then wash it away with

water.

Do not bend or twist brake hose sharply, or strongly pull it.

When removing components, cover brake line connections so that dirt, dust, or other foreign mat-

ters do not get in.

Refill using recommended brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Front Brake Tube and HoseINFOID:0000000001716983

REMOVAL

1. Front disc brake 2. Brake master cylinder 3. Brake booster

4. Rear drum brake 5. Connector 6.ABS actuator and electric unit (con-

trol unit), if equipped

7. Brake tube 8. Brake hose

:Union bolt

:Connector bolt

:Flare nut

18.2 N.m (1.9 kg-m, 13.0 ft-lb) 10.0 N.m (1.0 kg-m, 87.0 in-lb) 16.2 N.m (1.7 kg-m, 12.0 ft-lb)

SFIA3068E

Page 474 of 5883

CLUTCH MASTER CYLINDER

CL-9

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

CL

N

O

P

CLUTCH MASTER CYLINDER

Removal and InstallationINFOID:0000000001375296

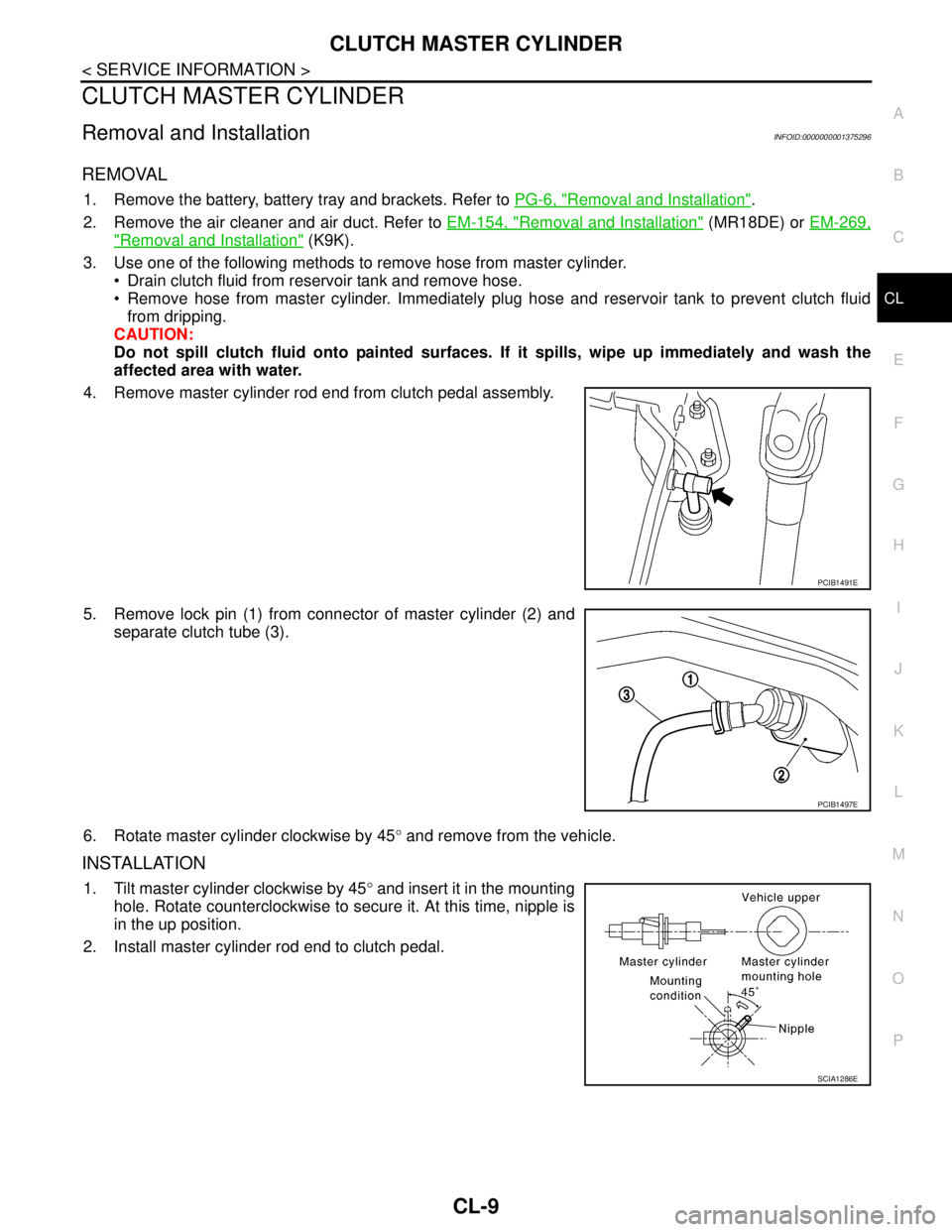

REMOVAL

1. Remove the battery, battery tray and brackets. Refer to PG-6, "Removal and Installation".

2. Remove the air cleaner and air duct. Refer to EM-154, "

Removal and Installation" (MR18DE) or EM-269,

"Removal and Installation" (K9K).

3. Use one of the following methods to remove hose from master cylinder.

Drain clutch fluid from reservoir tank and remove hose.

Remove hose from master cylinder. Immediately plug hose and reservoir tank to prevent clutch fluid

from dripping.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the

affected area with water.

4. Remove master cylinder rod end from clutch pedal assembly.

5. Remove lock pin (1) from connector of master cylinder (2) and

separate clutch tube (3).

6. Rotate master cylinder clockwise by 45° and remove from the vehicle.

INSTALLATION

1. Tilt master cylinder clockwise by 45° and insert it in the mounting

hole. Rotate counterclockwise to secure it. At this time, nipple is

in the up position.

2. Install master cylinder rod end to clutch pedal.

PCIB1491E

PCIB1497E

SCIA1286E

Page 791 of 5883

![NISSAN TIIDA 2007 Service Repair Manual DLK-202

< SYMPTOM DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001396663

CUSTOMER INTERVIEW

Interview the NISSAN TIIDA 2007 Service Repair Manual DLK-202

< SYMPTOM DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001396663

CUSTOMER INTERVIEW

Interview the](/img/5/57395/w960_57395-790.png)

DLK-202

< SYMPTOM DIAGNOSIS >[WITH I-KEY, WITHOUT SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001396663

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any of

the customer's comments; refer to DLK-206, "

Diagnostic Worksheet". This information is necessary to dupli-

cate the conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak – (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping

Creak – (Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

Rattle – (Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

Knock – (Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

Tick – (Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

Buzz – (Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Page 1020 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-431

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001396891

CUSTOME NISSAN TIIDA 2007 Service Repair Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-431

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001396891

CUSTOME](/img/5/57395/w960_57395-1019.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-431

< SYMPTOM DIAGNOSIS >[WITH I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001396891

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any of

the customer's comments; refer to XX-XX, "*****"

. This information is necessary to duplicate the conditions

that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak – (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping

Creak – (Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

Rattle – (Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

Knock – (Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

Tick – (Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

Buzz – (Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Page 1162 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-573

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001397114

CUST NISSAN TIIDA 2007 Service Repair Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-573

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001397114

CUST](/img/5/57395/w960_57395-1161.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-573

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY & SUPER LOCK]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001397114

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any of

the customer's comments; refer to XX-XX, "*****"

. This information is necessary to duplicate the conditions

that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak – (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping

Creak – (Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

Rattle – (Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

Knock – (Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

Tick – (Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

Buzz – (Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Page 1313 of 5883

![NISSAN TIIDA 2007 Service Repair Manual DLK-724

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY, WITH SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001397339

CUSTOMER INTERVIEW

Interview the NISSAN TIIDA 2007 Service Repair Manual DLK-724

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY, WITH SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001397339

CUSTOMER INTERVIEW

Interview the](/img/5/57395/w960_57395-1312.png)

DLK-724

< SYMPTOM DIAGNOSIS >[WITHOUT I-KEY, WITH SUPER LOCK]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000001397339

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any of

the customer's comments; refer to XX-XX, "*****"

. This information is necessary to duplicate the conditions

that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak – (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping

Creak – (Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

Rattle – (Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

Knock – (Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

Tick – (Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

Buzz – (Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Page 1377 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EC-28

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

INSPECTION AND ADJUSTMENT

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT-III

1. Perform Accelerator Pedal Released Position Learning. Refer t NISSAN TIIDA 2007 Service Repair Manual EC-28

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

INSPECTION AND ADJUSTMENT

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT-III

1. Perform Accelerator Pedal Released Position Learning. Refer t](/img/5/57395/w960_57395-1376.png)

EC-28

< BASIC INSPECTION >[HR16DE (WITH EURO-OBD)]

INSPECTION AND ADJUSTMENT

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT-III

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-26, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-27, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

5. Touch “START” and wait 20 seconds.

Is

“CMPLT” displayed on CONSULT-III screen?

YES >> GO TO 4.

NO >> GO TO 5.

3.IDLE AIR VOLUME LEARNING

Without CONSULT-III

NOTE:

It is better to count the time accurately with a clock.

It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-26, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-27, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Confirm that accelerator pedal is fully released, turn ignition switch ON and wait 3 seconds.

6. Repeat the following procedure quickly five times within 5 seconds.

- Fully depress the accelerator pedal.

- Fully release the accelerator pedal.

7. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MI stops

blinking and turned ON.

8. Fully release the accelerator pedal within 3 seconds after the MI turned ON.

9. Start engine and let it idle.

10. Wait 20 seconds.

>> GO TO 4.

4.CHECK IDLE SPEED AND IGNITION TIMING

Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifi-

cations.

For specification, refer to EC-380, "

Idle Speed" and EC-380, "Ignition Timing".

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following

SEC897C

Page 1451 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EC-102

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

How to Switch Diagnostic Test Mode

NOTE:

It is better to count the time accurately with a clock.

It is impossi NISSAN TIIDA 2007 Service Repair Manual EC-102

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

How to Switch Diagnostic Test Mode

NOTE:

It is better to count the time accurately with a clock.

It is impossi](/img/5/57395/w960_57395-1450.png)

EC-102

< FUNCTION DIAGNOSIS >[HR16DE (WITH EURO-OBD)]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

How to Switch Diagnostic Test Mode

NOTE:

It is better to count the time accurately with a clock.

It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

Always ECM returns to Diagnostic Test Mode I after ignition switch is turned OFF.

HOW TO SET DIAGNOSTIC TEST MODE II (SELF-DIAGNOSTIC RESULTS)

1. Confirm that accelerator pedal is fully released, turn ignition switch ON and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

- Fully depress the accelerator pedal.

- Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MI starts

blinking.

NOTE:

Do not release the accelerator pedal for 10 seconds if MI may start blinking on the halfway of this

10 seconds. This blinking is displaying SRT status and is continued for another 10 seconds.

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnostic results).

NOTE:

Wait until the same DTC (or 1st trip DTC) appears to confirm all DTCs certainly.

HOW TO SET DIAGNOSTIC TEST MODE II (HEATE OXYGEN SENSOR 1 MONITOR)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic results).

Refer to “How to Set Diagnostic Test Mode II (Self-diagnostic Results)”.

2. Start Engine.

ECM has entered to Diagnostic Test Mode II (Heated oxygen sensor 1 monitor).

HOW TO ERASE DIAGNOSTIC TEST MODE II (SELF-DIAGNOSTIC RESULTS)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer to “How to Set Diagnostic Test Mode II

(Self-diagnostic Results)”.

2. Fully depress the accelerator pedal and keep it for more than 10 seconds.

The emission-related diagnostic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

The DTC can be erased from the back up memory in the ECM by depressing accelerator pedal. Refer to “How

to Erase Diagnostic Test Mode II (Self-diagnostic Results)”.

If the battery is disconnected, the DTC will be lost from the backup memory within 24 hours.

Be careful not to erase the stored memory before starting trouble diagnoses.

OBD System Operation Chart

Relationship Between MI, 1st Trip DTC, DTC and Detectable Items

When a malfunction is detected for the first time, the 1st trip DTC and the 1st trip freeze frame data are

stored in the ECM memory.

When the same malfunction is detected in two consecutive trips, the DTC and the freeze frame data are

stored in the ECM memory, and the MI will come on.

The MI will go off after the vehicle is driven 3 times (pattern B) with no malfunction. The drive is counted only

when the recorded driving pattern is met (as stored in the ECM). If another malfunction occurs while count-

ing, the counter will reset.

The DTC and the freeze frame data will be stored until the vehicle is driven 40 times (pattern A) without the

same malfunction recurring (except for Misfire and Fuel Injection System). For Misfire and Fuel Injection

System, the DTC and freeze frame data will be stored until the vehicle is driven 80 times (pattern C) without

PBIB0092E