wiring diagram NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 5111 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s](/img/5/57395/w960_57395-5110.png)

PRECAUTIONS

TM-165

< PRECAUTION >[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

After overhaul, refill the A/T with new ATF.

When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

XX-XX, "*****"

, XX-XX, "*****".

Service Notice or PrecautionINFOID:0000000001696268

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

External leaks in the hub weld area.

Converter hub is scored or damaged.

Converter pilot is broken, damaged or fits poorly into crankshaft.

Steel particles are found after flushing the cooler and cooler lines.

Pump is damaged or steel particles are found in the converter.

Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

Converter is contaminated with engine coolant containing antifreeze.

Internal malfunction of stator roller clutch.

Heavy clutch debris due to overheating (blue converter).

Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

The threads in one or more of the converter bolt holes are damaged.

A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD SELF-DIAGNOSIS (FOR TYPE 1 ONLY)

A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on XX-XX, "*****"

for the indicator used to display each self-diagnostic result.

The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on XX-XX, "*****"

to complete the repair and

avoid unnecessary blinking of the MIL.

The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

-PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD, refer to XX-XX, "*****"

.

Wiring Diagram and Trouble DiagnosisINFOID:0000000001696269

When reading wiring diagrams, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

When performing trouble diagnosis, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

Page 5284 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-338

< FUNCTION DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000001714312

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial com NISSAN TIIDA 2007 Service Repair Manual TM-338

< FUNCTION DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000001714312

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial com](/img/5/57395/w960_57395-5283.png)

TM-338

< FUNCTION DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

A/T CONTROL SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000001714312

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-13,

"System Description".

Input/Output Signal of TCMINFOID:0000000001714313

SCIA7112E

Control itemLine

pressure

controlVehicle

speed

controlShift

controlLock-up

controlEngine

brake

controlFail-safe

functionSelf-diag-

nostics

function

InputAccelerator pedal position signal

(*5)XXXXX(*3) XX

Vehicle speed sensor·A/T

(Revolution sensor)XXXX (*3) XX

Vehicle speed sensor·MTR (*1) X (*1) X (*1) X (*1) X X

Closed throttle position signal

(*5)(*2) X (*2) X X (*4) X

Wide open throttle position signal

(*5)(*2) X (*2) X (*4) X

Turbine revolution sensor (Power

train revolution sensor)XXXXX

Engine speed signal X X

PNP switch XXXXX(*3) X(*4) X

Stop lamp switch signal

(*5)XXX(*4) X

A/T fluid temperature sensors X X X X

Overdrive control switch signal

(*5)XXX(*4) X

TCM power supply voltage signal XX

Page 5365 of 5883

![NISSAN TIIDA 2007 Service Repair Manual A/T SHIFT LOCK SYSTEM

TM-419

< COMPONENT DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

A/T SHIFT LOCK SYSTEM

Wiring Diagram - A/T Shift Lock System - INFOID:0000000001731057

Termi NISSAN TIIDA 2007 Service Repair Manual A/T SHIFT LOCK SYSTEM

TM-419

< COMPONENT DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

A/T SHIFT LOCK SYSTEM

Wiring Diagram - A/T Shift Lock System - INFOID:0000000001731057

Termi](/img/5/57395/w960_57395-5364.png)

A/T SHIFT LOCK SYSTEM

TM-419

< COMPONENT DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

A/T SHIFT LOCK SYSTEM

Wiring Diagram - A/T Shift Lock System - INFOID:0000000001731057

Terminals And Reference ValuesINFOID:0000000001731059

SHIFT LOCK CONTROL UNIT INSPECTION TABLE

ALDWA0058GB

Page 5372 of 5883

![NISSAN TIIDA 2007 Service Repair Manual TM-426

< ECU DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

TCM

Wiring Diagram - A/T CONTROL SYSTEM -

INFOID:0000000001714340

Fail-SafeINFOID:0000000001714341

The TCM has an electronic Fail-safe mode. This allows NISSAN TIIDA 2007 Service Repair Manual TM-426

< ECU DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

TCM

Wiring Diagram - A/T CONTROL SYSTEM -

INFOID:0000000001714340

Fail-SafeINFOID:0000000001714341

The TCM has an electronic Fail-safe mode. This allows](/img/5/57395/w960_57395-5371.png)

TM-426

< ECU DIAGNOSIS >[TYPE 2 (4AT: RE4F03B)]

TCM

Wiring Diagram - A/T CONTROL SYSTEM -

INFOID:0000000001714340

Fail-SafeINFOID:0000000001714341

The TCM has an electronic Fail-safe mode. This allows the vehicle to be driven even if a major electrical input/

output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of “1”, “2” or “D”. The cus-

tomer may complain of sluggish or poor acceleration.

Always follow TM-10, "

Work Flow".

ALDWA0057GB

Page 5413 of 5883

![NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-467

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s NISSAN TIIDA 2007 Service Repair Manual PRECAUTIONS

TM-467

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

s](/img/5/57395/w960_57395-5412.png)

PRECAUTIONS

TM-467

< PRECAUTION >[TYPE 2 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

After overhaul, refill the A/T with new ATF.

When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

XX-XX, "*****"

, XX-XX, "*****".

Service Notice or PrecautionINFOID:0000000001723048

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

External leaks in the hub weld area.

Converter hub is scored or damaged.

Converter pilot is broken, damaged or fits poorly into crankshaft.

Steel particles are found after flushing the cooler and cooler lines.

Pump is damaged or steel particles are found in the converter.

Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

Converter is contaminated with engine coolant containing antifreeze.

Internal malfunction of stator roller clutch.

Heavy clutch debris due to overheating (blue converter).

Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

The threads in one or more of the converter bolt holes are damaged.

A/T malfunction did not display evidence of damaged or worn internal parts, steel particles or clutch plate lin-

ing material in unit and inside the fluid filter.

Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such as

taxi, delivery or police use.

OBD SELF-DIAGNOSIS (FOR TYPE 1 ONLY)

A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the OD OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the table

on XX-XX, "*****"

for the indicator used to display each self-diagnostic result.

The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on XX-XX, "*****"

to complete the repair and

avoid unnecessary blinking of the MIL.

The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when the

OD OFF indicator lamp does not indicate any malfunctions.

-PNP switch

- A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of OBD, refer to XX-XX, "*****"

.

Wiring Diagram and Trouble DiagnosisINFOID:0000000001723049

When reading wiring diagrams, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

When performing trouble diagnosis, refer to the following:

XX-XX, "*****"

XX-XX, "*****"

Page 5717 of 5883

WCS-2

BCM (BODY CONTROL MODULE) .........................21

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ...............................................................

21

METER BUZZER CIRCUIT ................................23

Description ..............................................................23

Component Function Check ...................................23

Diagnosis Procedure .............................................23

SEAT BELT BUCKLE SWITCH SIGNAL CIR-

CUIT ...................................................................

24

Description ..............................................................24

Component Function Check .................................24

Diagnosis Procedure .............................................24

Component Inspection ............................................25

KEY SWITCH SIGNAL CIRCUIT (WITH IN-

TELLIGENT KEY) ..............................................

26

Description ..............................................................26

Component Function Check .................................26

Diagnosis Procedure .............................................26

Component Inspection ............................................27

KEY SWITCH SIGNAL CIRCUIT (WITHOUT

INTELLIGENT KEY) ..........................................

28

Description ..............................................................28

Component Function Check .................................28

Diagnosis Procedure .............................................28

Component Inspection ............................................29

PARKING BRAKE SWITCH SIGNAL CIR-

CUIT ...................................................................

30

Description ..............................................................30

Component Function Check ...................................30

Diagnosis Procedure ..............................................30

Component Inspection ............................................30

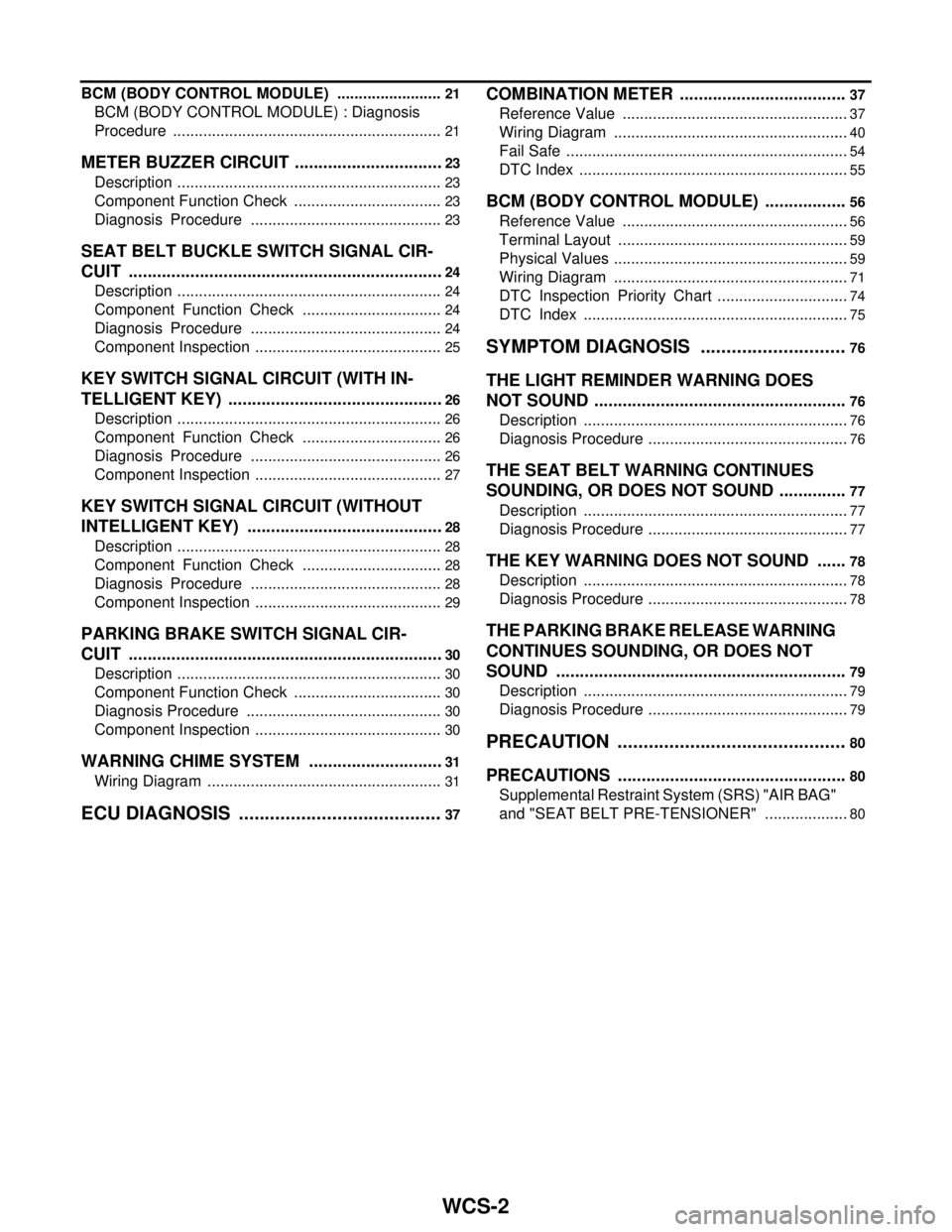

WARNING CHIME SYSTEM .............................31

Wiring Diagram .......................................................31

ECU DIAGNOSIS ........................................37

COMBINATION METER ....................................37

Reference Value .....................................................37

Wiring Diagram .......................................................40

Fail Safe ..................................................................54

DTC Index ...............................................................55

BCM (BODY CONTROL MODULE) ..................56

Reference Value .....................................................56

Terminal Layout ......................................................59

Physical Values .......................................................59

Wiring Diagram .......................................................71

DTC Inspection Priority Chart ...............................74

DTC Index ..............................................................75

SYMPTOM DIAGNOSIS ............................76

THE LIGHT REMINDER WARNING DOES

NOT SOUND ......................................................

76

Description ..............................................................76

Diagnosis Procedure ...............................................76

THE SEAT BELT WARNING CONTINUES

SOUNDING, OR DOES NOT SOUND ...............

77

Description ..............................................................77

Diagnosis Procedure ...............................................77

THE KEY WARNING DOES NOT SOUND .......78

Description ..............................................................78

Diagnosis Procedure ...............................................78

THE PARKING BRAKE RELEASE WARNING

CONTINUES SOUNDING, OR DOES NOT

SOUND ..............................................................

79

Description ..............................................................79

Diagnosis Procedure ...............................................79

PRECAUTION ............................................80

PRECAUTIONS .................................................80

Supplemental Restraint System (SRS) "AIR BAG"

and "SEAT BELT PRE-TENSIONER" ....................

80

Page 5746 of 5883

WCS

WARNING CHIME SYSTEM

WCS-31

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

WARNING CHIME SYSTEM

Wiring DiagramINFOID:0000000001722944

ALNWA0136GB

Page 5755 of 5883

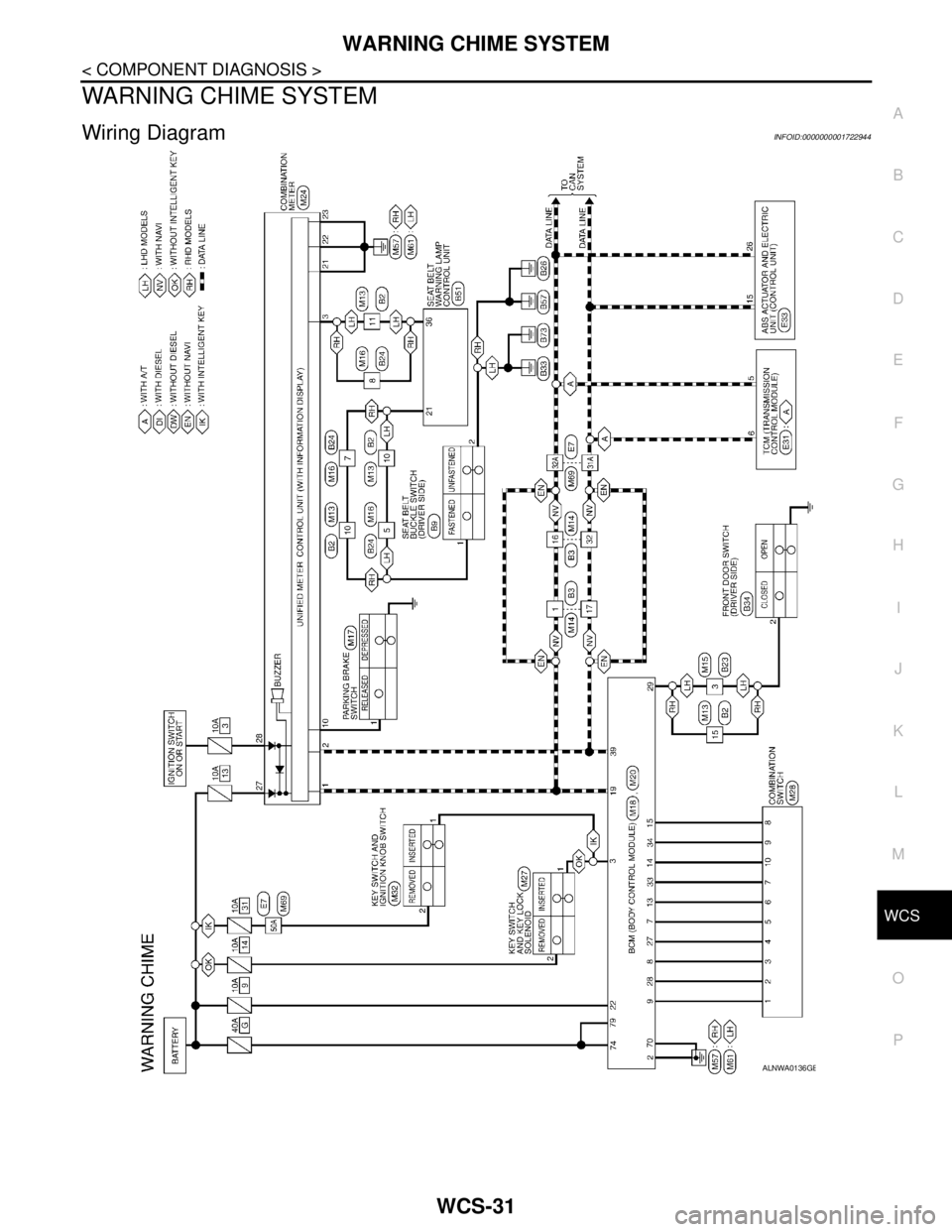

WCS-40

< ECU DIAGNOSIS >

COMBINATION METER

Wiring Diagram

INFOID:0000000001728309

ALNWA0096GB

Page 5786 of 5883

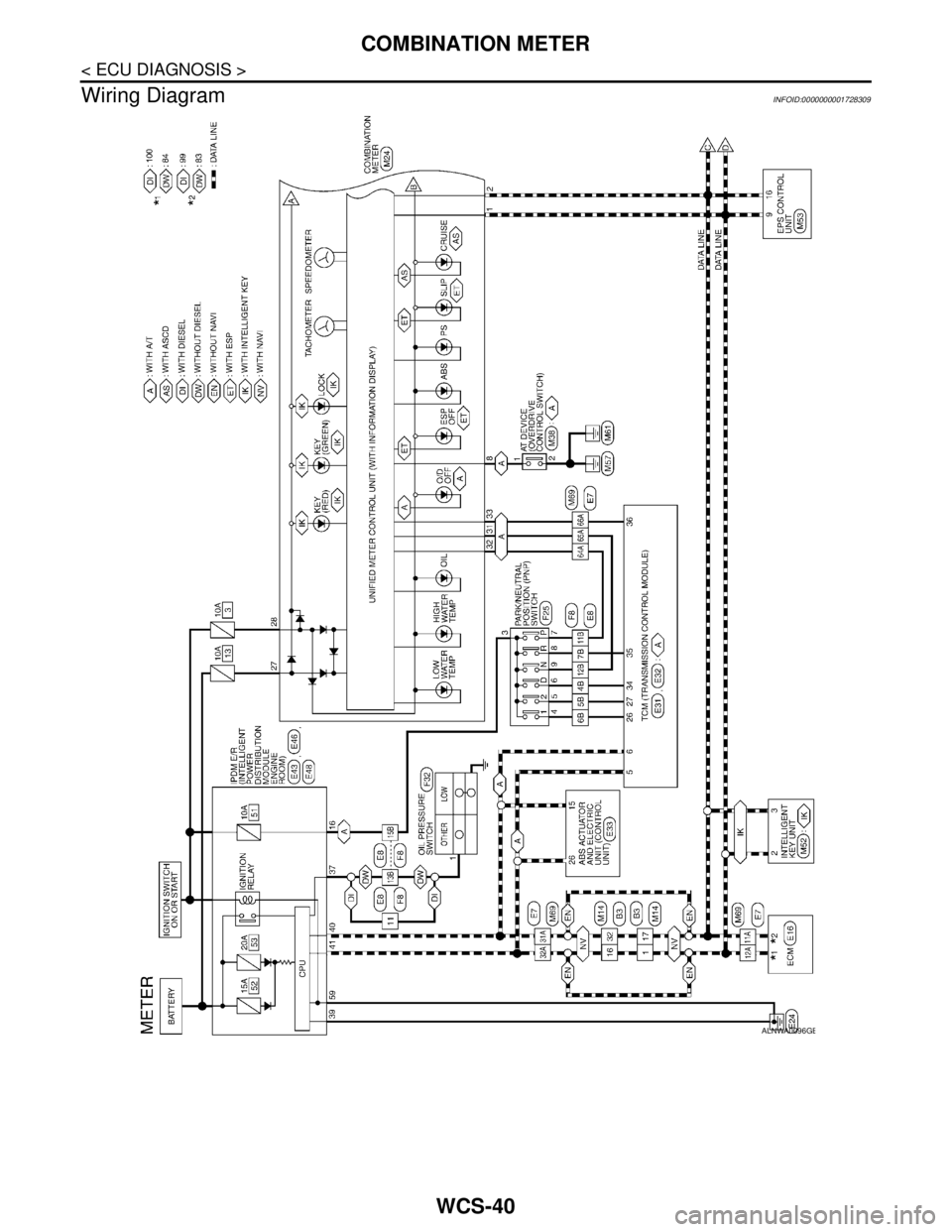

WCS

BCM (BODY CONTROL MODULE)

WCS-71

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

Wiring DiagramINFOID:0000000001728315

ALMWA0067GB

Page 5804 of 5883

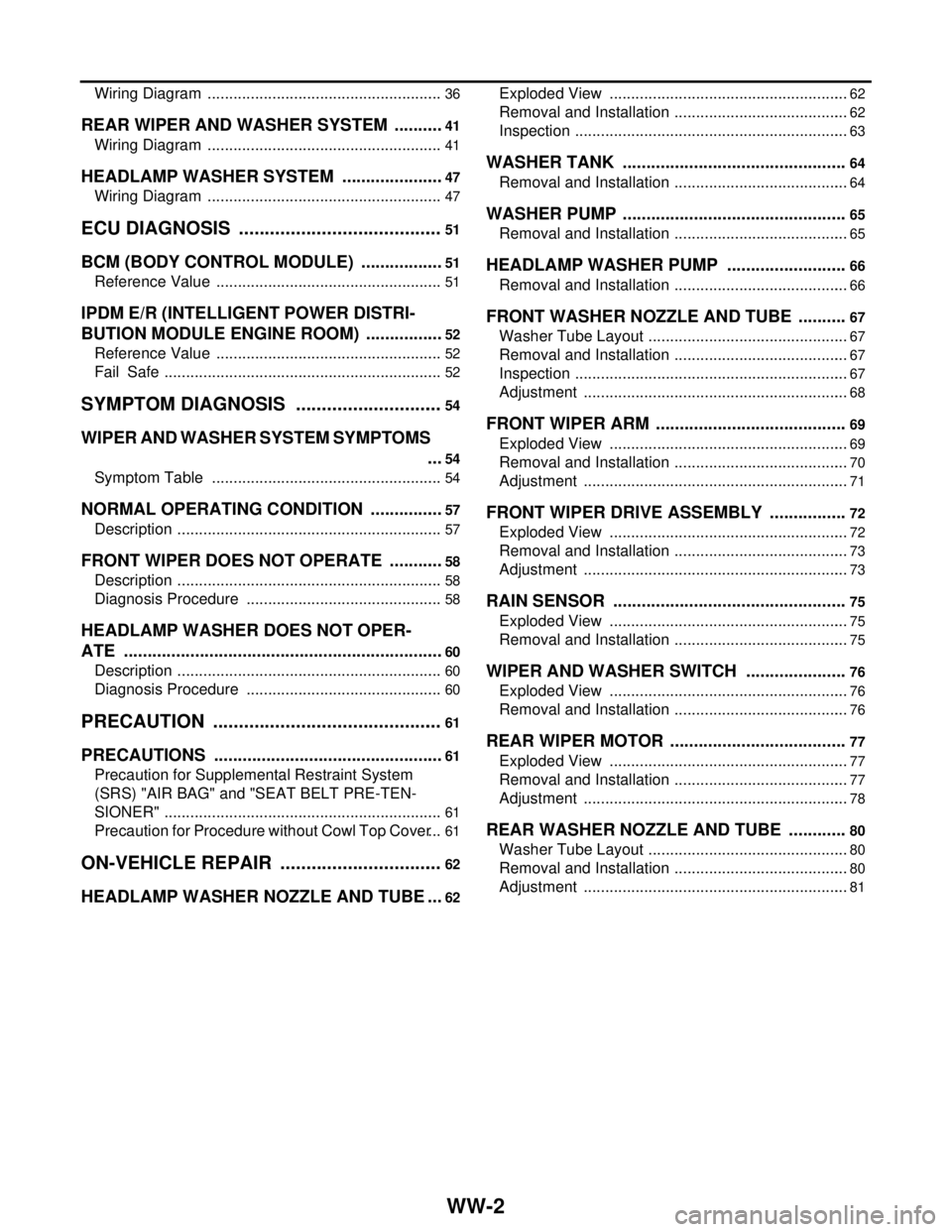

WW-2

Wiring Diagram .......................................................36

REAR WIPER AND WASHER SYSTEM ...........41

Wiring Diagram .......................................................41

HEADLAMP WASHER SYSTEM ......................47

Wiring Diagram .......................................................47

ECU DIAGNOSIS ........................................51

BCM (BODY CONTROL MODULE) ..................51

Reference Value .....................................................51

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

52

Reference Value .....................................................52

Fail Safe .................................................................52

SYMPTOM DIAGNOSIS .............................54

WIPER AND WASHER SYSTEM SYMPTOMS

...

54

Symptom Table ......................................................54

NORMAL OPERATING CONDITION ................57

Description ..............................................................57

FRONT WIPER DOES NOT OPERATE ............58

Description ..............................................................58

Diagnosis Procedure ..............................................58

HEADLAMP WASHER DOES NOT OPER-

ATE ....................................................................

60

Description ..............................................................60

Diagnosis Procedure ..............................................60

PRECAUTION .............................................61

PRECAUTIONS .................................................61

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

61

Precaution for Procedure without Cowl Top Cover ...61

ON-VEHICLE REPAIR ................................62

HEADLAMP WASHER NOZZLE AND TUBE ...62

Exploded View ........................................................62

Removal and Installation .........................................62

Inspection ................................................................63

WASHER TANK ................................................64

Removal and Installation .........................................64

WASHER PUMP ................................................65

Removal and Installation .........................................65

HEADLAMP WASHER PUMP ..........................66

Removal and Installation .........................................66

FRONT WASHER NOZZLE AND TUBE ...........67

Washer Tube Layout ...............................................67

Removal and Installation .........................................67

Inspection ................................................................67

Adjustment ..............................................................68

FRONT WIPER ARM .........................................69

Exploded View ........................................................69

Removal and Installation .........................................70

Adjustment ..............................................................71

FRONT WIPER DRIVE ASSEMBLY .................72

Exploded View ........................................................72

Removal and Installation .........................................73

Adjustment ..............................................................73

RAIN SENSOR ..................................................75

Exploded View ........................................................75

Removal and Installation .........................................75

WIPER AND WASHER SWITCH ......................76

Exploded View ........................................................76

Removal and Installation .........................................76

REAR WIPER MOTOR ......................................77

Exploded View ........................................................77

Removal and Installation .........................................77

Adjustment ..............................................................78

REAR WASHER NOZZLE AND TUBE .............80

Washer Tube Layout ...............................................80

Removal and Installation .........................................80

Adjustment ..............................................................81