engine NISSAN TIIDA 2007 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 161 of 5883

BCS-26

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

*: Each lamp switch is in ON position.

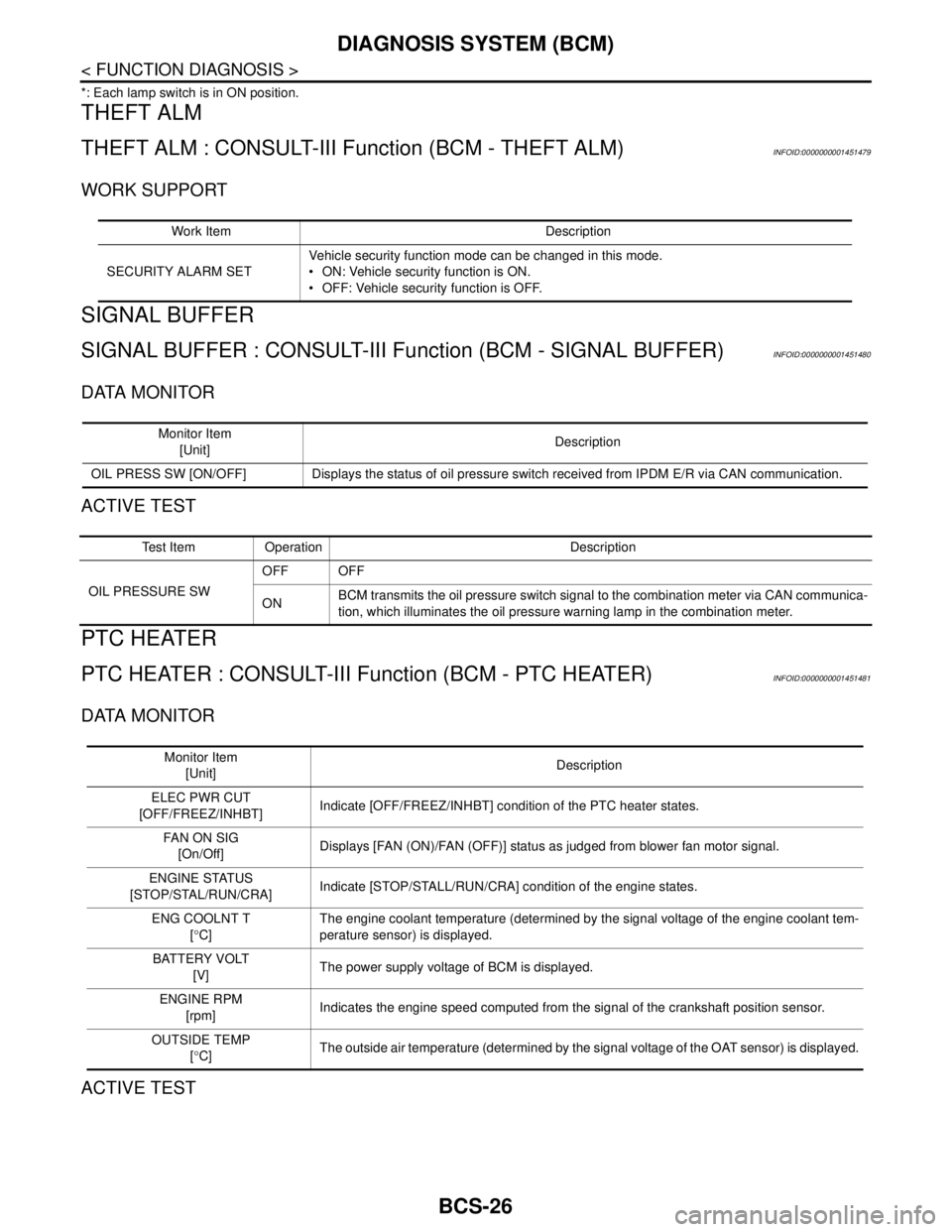

THEFT ALM

THEFT ALM : CONSULT-III Function (BCM - THEFT ALM)INFOID:0000000001451479

WORK SUPPORT

SIGNAL BUFFER

SIGNAL BUFFER : CONSULT-III Function (BCM - SIGNAL BUFFER)INFOID:0000000001451480

DATA MONITOR

ACTIVE TEST

PTC HEATER

PTC HEATER : CONSULT-III Function (BCM - PTC HEATER)INFOID:0000000001451481

DATA MONITOR

ACTIVE TEST

Work Item Description

SECURITY ALARM SETVehicle security function mode can be changed in this mode.

ON: Vehicle security function is ON.

OFF: Vehicle security function is OFF.

Monitor Item

[Unit]Description

OIL PRESS SW [ON/OFF] Displays the status of oil pressure switch received from IPDM E/R via CAN communication.

Test Item Operation Description

OIL PRESSURE SWOFF OFF

ONBCM transmits the oil pressure switch signal to the combination meter via CAN communica-

tion, which illuminates the oil pressure warning lamp in the combination meter.

Monitor Item

[Unit]Description

ELEC PWR CUT

[OFF/FREEZ/INHBT]Indicate [OFF/FREEZ/INHBT] condition of the PTC heater states.

FA N O N S I G

[On/Off]Displays [FAN (ON)/FAN (OFF)] status as judged from blower fan motor signal.

ENGINE STATUS

[STOP/STAL/RUN/CRA]Indicate [STOP/STALL/RUN/CRA] condition of the engine states.

ENG COOLNT T

[°C]The engine coolant temperature (determined by the signal voltage of the engine coolant tem-

perature sensor) is displayed.

BATTERY VOLT

[V]The power supply voltage of BCM is displayed.

ENGINE RPM

[rpm]Indicates the engine speed computed from the signal of the crankshaft position sensor.

OUTSIDE TEMP

[°C]The outside air temperature (determined by the signal voltage of the OAT sensor) is displayed.

Page 170 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-35

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

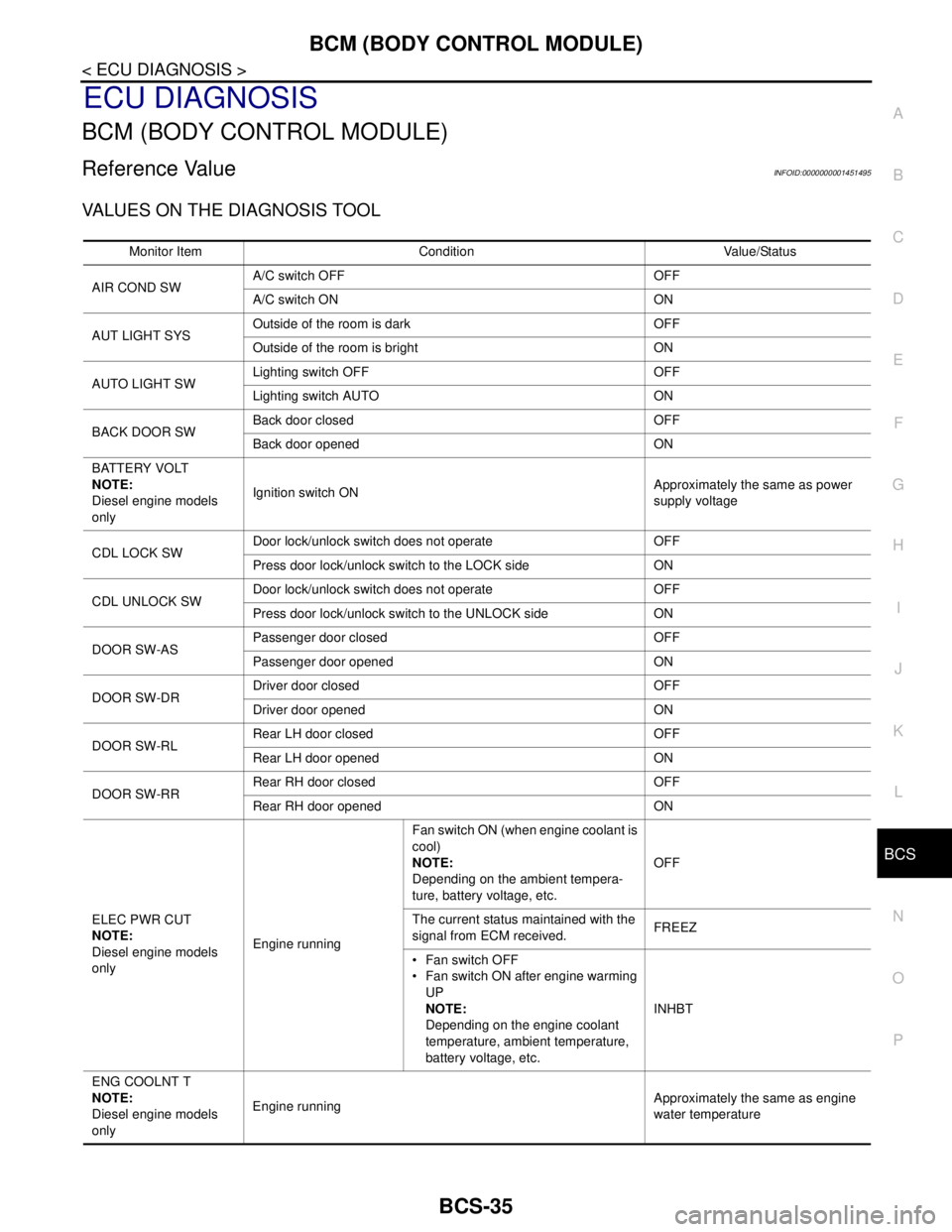

ECU DIAGNOSIS

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000001451495

VALUES ON THE DIAGNOSIS TOOL

Monitor Item Condition Value/Status

AIR COND SWA/C switch OFF OFF

A/C switch ON ON

AUT LIGHT SYSOutside of the room is dark OFF

Outside of the room is bright ON

AUTO LIGHT SWLighting switch OFF OFF

Lighting switch AUTO ON

BACK DOOR SWBack door closed OFF

Back door opened ON

BATTERY VOLT

NOTE:

Diesel engine models

onlyIgnition switch ONApproximately the same as power

supply voltage

CDL LOCK SWDoor lock/unlock switch does not operate OFF

Press door lock/unlock switch to the LOCK side ON

CDL UNLOCK SWDoor lock/unlock switch does not operate OFF

Press door lock/unlock switch to the UNLOCK side ON

DOOR SW-ASPassenger door closed OFF

Passenger door opened ON

DOOR SW-DRDriver door closed OFF

Driver door opened ON

DOOR SW-RLRear LH door closed OFF

Rear LH door opened ON

DOOR SW-RRRear RH door closed OFF

Rear RH door opened ON

ELEC PWR CUT

NOTE:

Diesel engine models

onlyEngine runningFan switch ON (when engine coolant is

cool)

NOTE:

Depending on the ambient tempera-

ture, battery voltage, etc.OFF

The current status maintained with the

signal from ECM received.FREEZ

Fan switch OFF

Fan switch ON after engine warming

UP

NOTE:

Depending on the engine coolant

temperature, ambient temperature,

battery voltage, etc.INHBT

ENG COOLNT T

NOTE:

Diesel engine models

onlyEngine runningApproximately the same as engine

water temperature

Page 171 of 5883

BCS-36

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

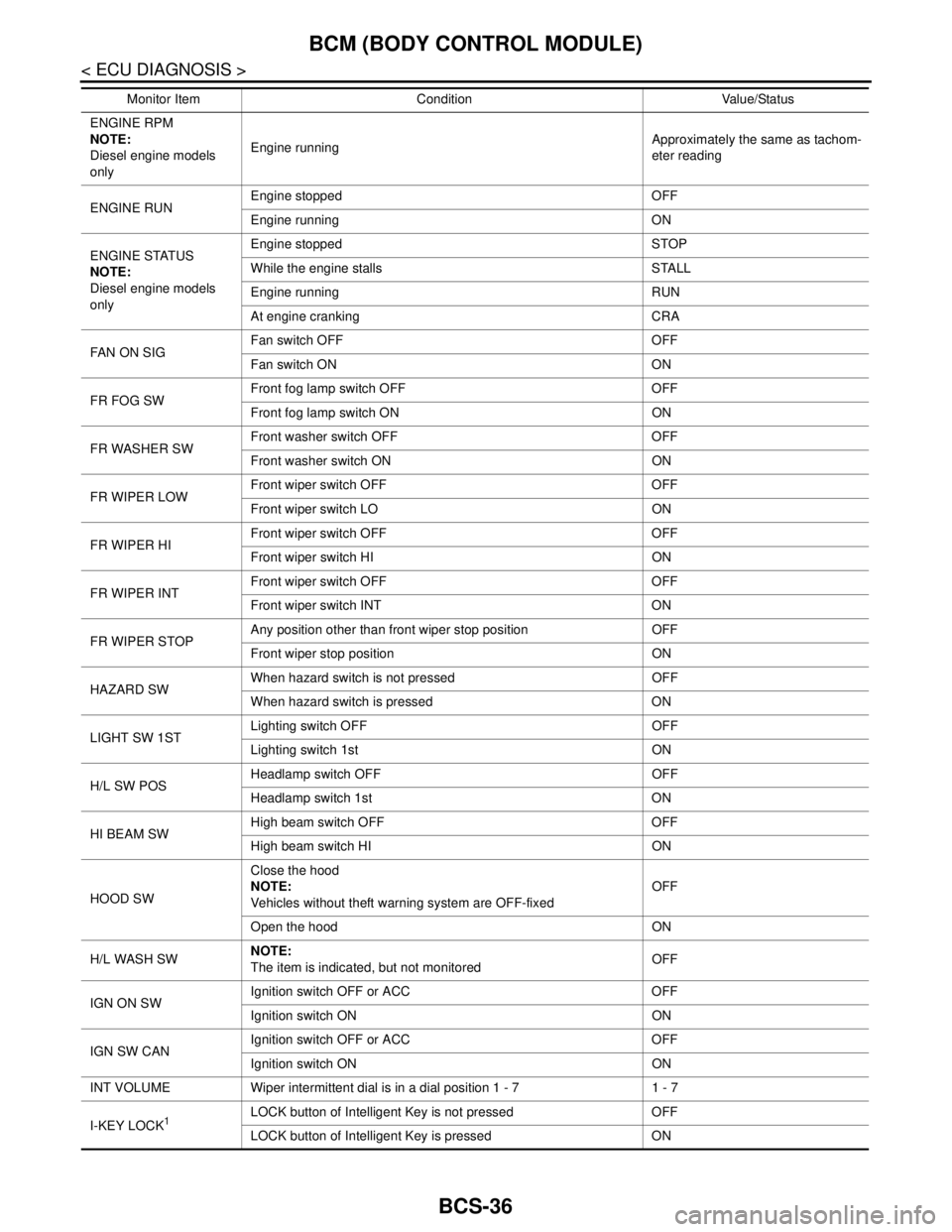

ENGINE RPM

NOTE:

Diesel engine models

onlyEngine runningApproximately the same as tachom-

eter reading

ENGINE RUNEngine stopped OFF

Engine running ON

ENGINE STATUS

NOTE:

Diesel engine models

onlyEngine stopped STOP

While the engine stalls STALL

Engine running RUN

At engine cranking CRA

FA N O N S I GFan switch OFF OFF

Fan switch ON ON

FR FOG SWFront fog lamp switch OFF OFF

Front fog lamp switch ON ON

FR WASHER SWFront washer switch OFF OFF

Front washer switch ON ON

FR WIPER LOWFront wiper switch OFF OFF

Front wiper switch LO ON

FR WIPER HIFront wiper switch OFF OFF

Front wiper switch HI ON

FR WIPER INTFront wiper switch OFF OFF

Front wiper switch INT ON

FR WIPER STOPAny position other than front wiper stop position OFF

Front wiper stop position ON

HAZARD SWWhen hazard switch is not pressed OFF

When hazard switch is pressed ON

LIGHT SW 1STLighting switch OFF OFF

Lighting switch 1st ON

H/L SW POSHeadlamp switch OFF OFF

Headlamp switch 1st ON

HI BEAM SWHigh beam switch OFF OFF

High beam switch HI ON

HOOD SWClose the hood

NOTE:

Vehicles without theft warning system are OFF-fixedOFF

Open the hood ON

H/L WASH SWNOTE:

The item is indicated, but not monitoredOFF

IGN ON SWIgnition switch OFF or ACC OFF

Ignition switch ON ON

IGN SW CANIgnition switch OFF or ACC OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK

1LOCK button of Intelligent Key is not pressed OFF

LOCK button of Intelligent Key is pressed ON Monitor Item Condition Value/Status

Page 172 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-37

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

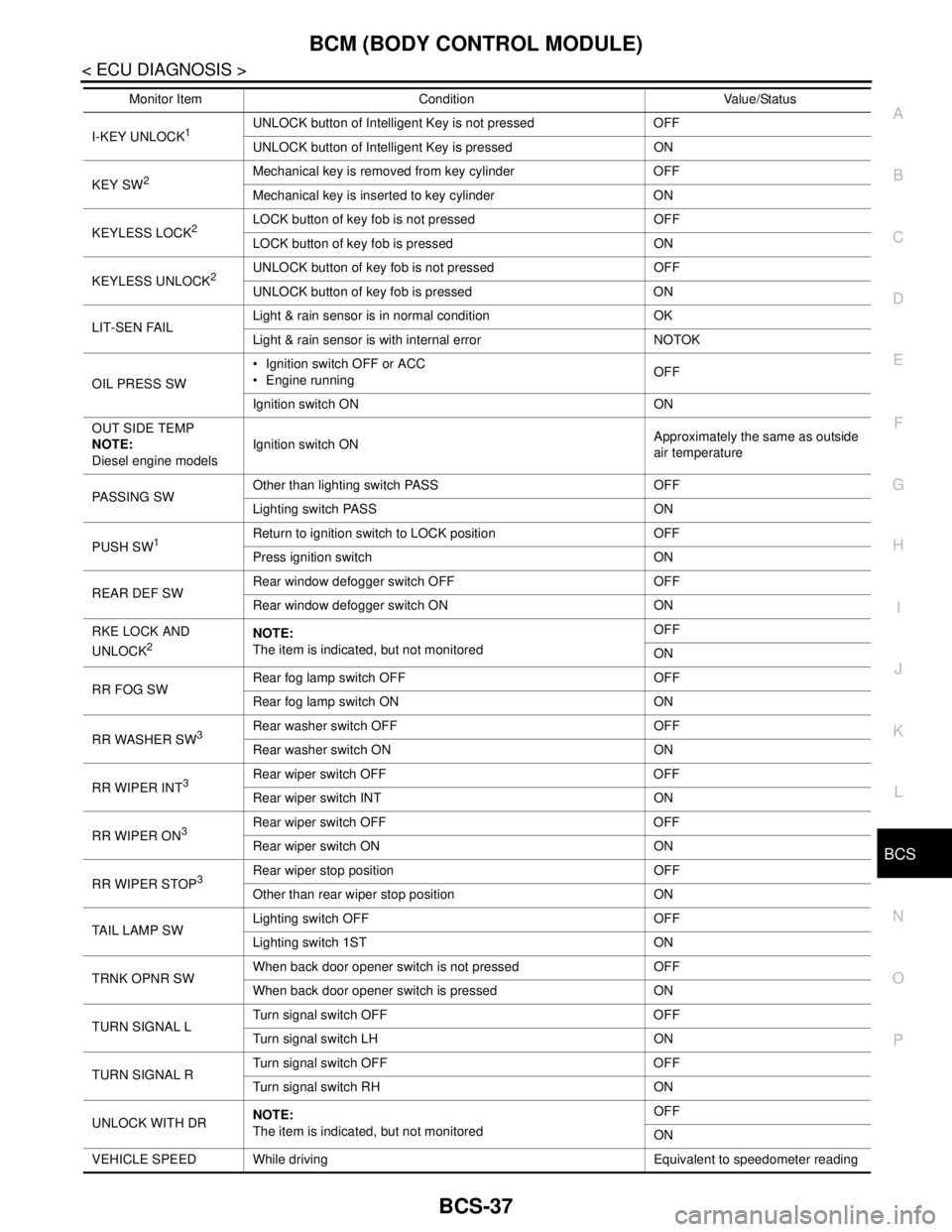

I-KEY UNLOCK1UNLOCK button of Intelligent Key is not pressed OFF

UNLOCK button of Intelligent Key is pressed ON

KEY SW

2Mechanical key is removed from key cylinder OFF

Mechanical key is inserted to key cylinder ON

KEYLESS LOCK

2LOCK button of key fob is not pressed OFF

LOCK button of key fob is pressed ON

KEYLESS UNLOCK

2UNLOCK button of key fob is not pressed OFF

UNLOCK button of key fob is pressed ON

LIT-SEN FAILLight & rain sensor is in normal condition OK

Light & rain sensor is with internal error NOTOK

OIL PRESS SW Ignition switch OFF or ACC

Engine runningOFF

Ignition switch ON ON

OUT SIDE TEMP

NOTE:

Diesel engine modelsIgnition switch ONApproximately the same as outside

air temperature

PASSING SWOther than lighting switch PASS OFF

Lighting switch PASS ON

PUSH SW

1Return to ignition switch to LOCK position OFF

Press ignition switch ON

REAR DEF SWRear window defogger switch OFF OFF

Rear window defogger switch ON ON

RKE LOCK AND

UNLOCK

2NOTE:

The item is indicated, but not monitoredOFF

ON

RR FOG SWRear fog lamp switch OFF OFF

Rear fog lamp switch ON ON

RR WASHER SW

3Rear washer switch OFF OFF

Rear washer switch ON ON

RR WIPER INT

3Rear wiper switch OFF OFF

Rear wiper switch INT ON

RR WIPER ON

3 Rear wiper switch OFF OFF

Rear wiper switch ON ON

RR WIPER STOP

3Rear wiper stop position OFF

Other than rear wiper stop position ON

TAIL LAMP SWLighting switch OFF OFF

Lighting switch 1ST ON

TRNK OPNR SWWhen back door opener switch is not pressed OFF

When back door opener switch is pressed ON

TURN SIGNAL LTurn signal switch OFF OFF

Turn signal switch LH ON

TURN SIGNAL RTurn signal switch OFF OFF

Turn signal switch RH ON

UNLOCK WITH DRNOTE:

The item is indicated, but not monitoredOFF

ON

VEHICLE SPEED While driving Equivalent to speedometer reading Monitor Item Condition Value/Status

Page 198 of 5883

BR-6

< ON-VEHICLE MAINTENANCE >

BRAKE PEDAL

ON-VEHICLE MAINTENANCE

BRAKE PEDAL

Inspection and AdjustmentINFOID:0000000001716917

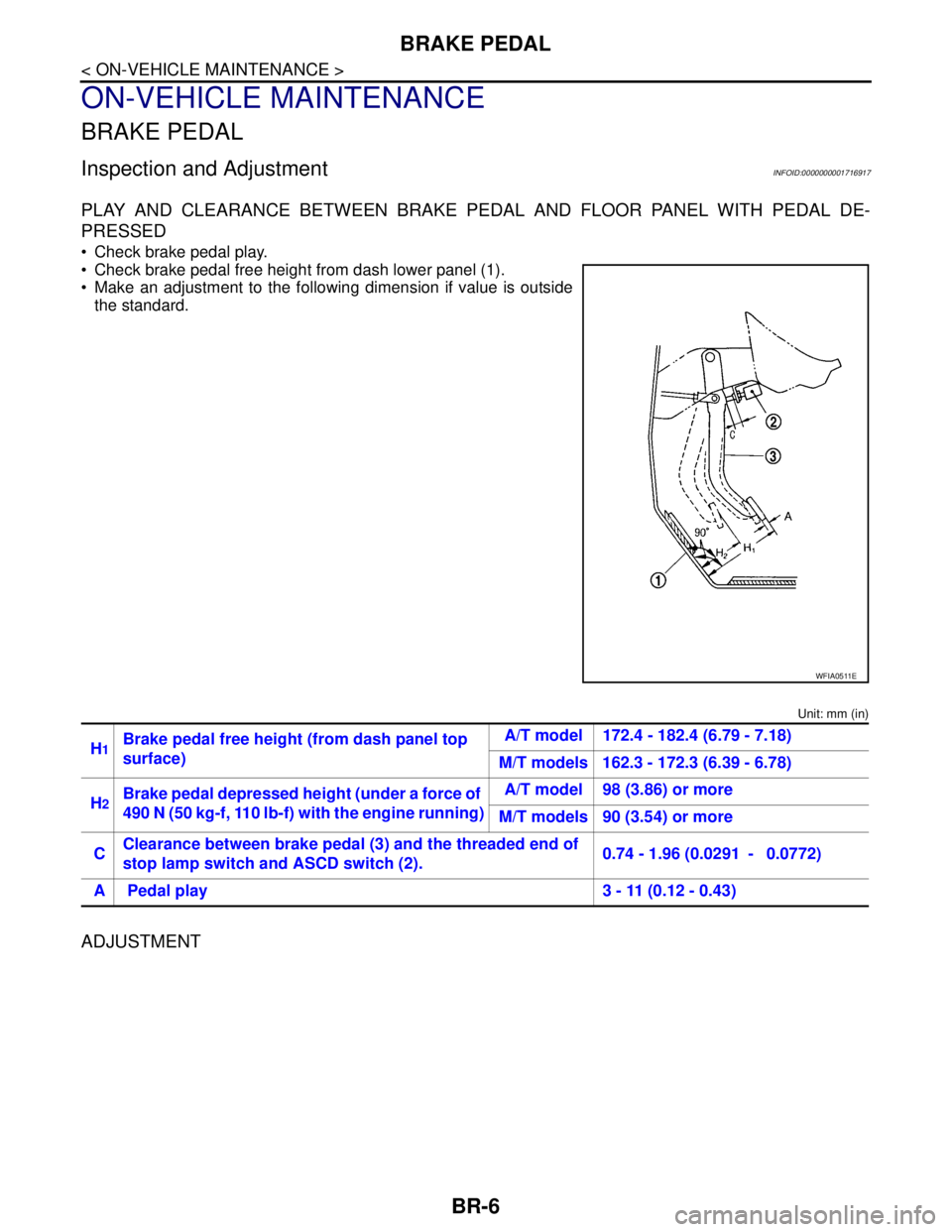

PLAY AND CLEARANCE BETWEEN BRAKE PEDAL AND FLOOR PANEL WITH PEDAL DE-

PRESSED

Check brake pedal play.

Check brake pedal free height from dash lower panel (1).

Make an adjustment to the following dimension if value is outside

the standard.

Unit: mm (in)

ADJUSTMENT

WFIA0511E

H1Brake pedal free height (from dash panel top

surface)A/T model 172.4 - 182.4 (6.79 - 7.18)

M/T models 162.3 - 172.3 (6.39 - 6.78)

H

2Brake pedal depressed height (under a force of

490 N (50 kg-f, 110 lb-f) with the engine running)A/T model 98 (3.86) or more

M/T models 90 (3.54) or more

CClearance between brake pedal (3) and the threaded end of

stop lamp switch and ASCD switch (2).0.74 - 1.96 (0.0291 - 0.0772)

A Pedal play 3 - 11 (0.12 - 0.43)

Page 199 of 5883

BRAKE PEDAL

BR-7

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

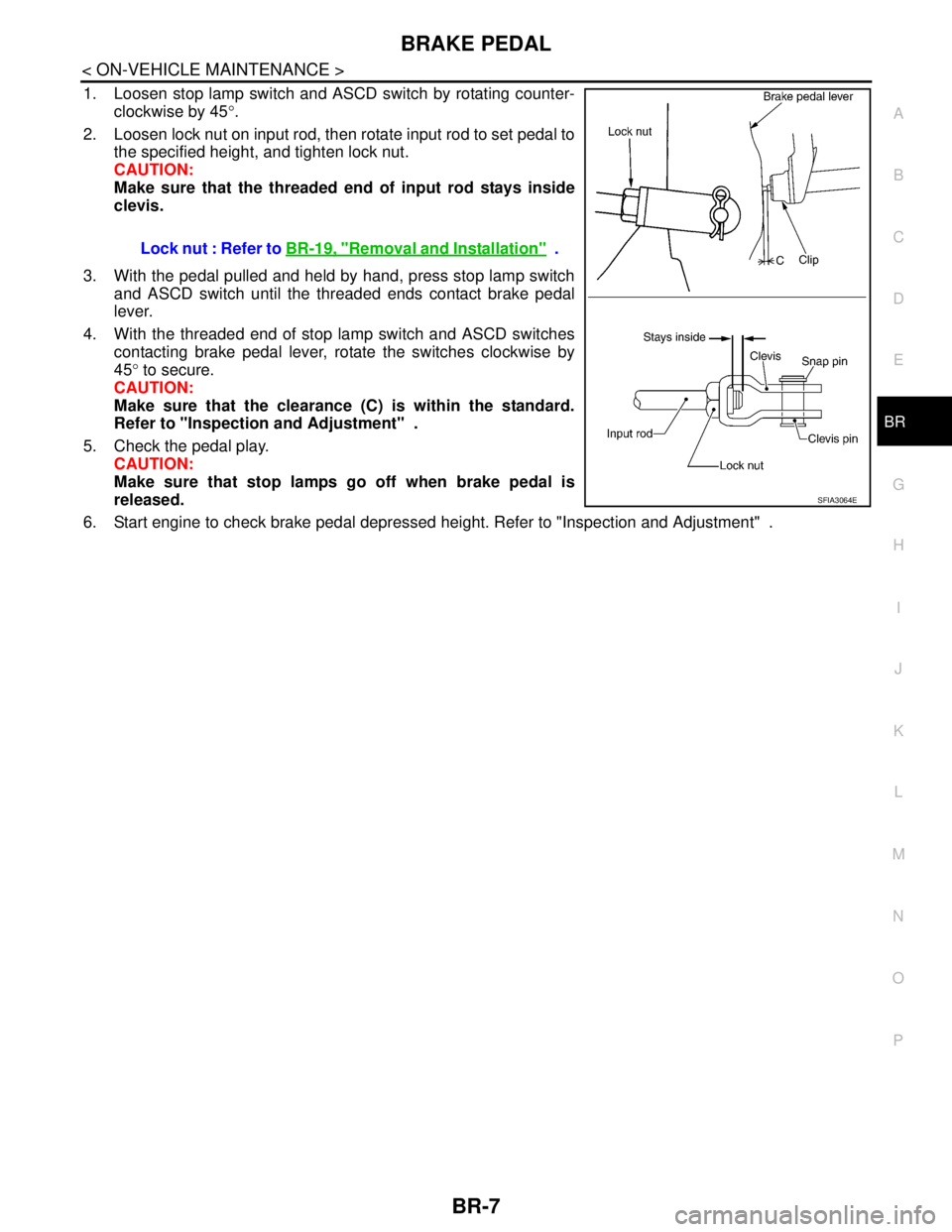

1. Loosen stop lamp switch and ASCD switch by rotating counter-

clockwise by 45°.

2. Loosen lock nut on input rod, then rotate input rod to set pedal to

the specified height, and tighten lock nut.

CAUTION:

Make sure that the threaded end of input rod stays inside

clevis.

3. With the pedal pulled and held by hand, press stop lamp switch

and ASCD switch until the threaded ends contact brake pedal

lever.

4. With the threaded end of stop lamp switch and ASCD switches

contacting brake pedal lever, rotate the switches clockwise by

45° to secure.

CAUTION:

Make sure that the clearance (C) is within the standard.

Refer to "Inspection and Adjustment" .

5. Check the pedal play.

CAUTION:

Make sure that stop lamps go off when brake pedal is

released.

6. Start engine to check brake pedal depressed height. Refer to "Inspection and Adjustment" . Lock nut : Refer to BR-19, "

Removal and Installation" .

SFIA3064E

Page 208 of 5883

BR-16

< ON-VEHICLE REPAIR >

BRAKE TUBE AND HOSE

1. Check brake hose, tube, and connections for fluid leaks, damage, twist, deformation, contact with other

parts, and loose connections.

2. While depressing pedal under a force of 785 N (80 kg-f, 177 lb-f) with the engine running for approxi-

mately 5 seconds, check for fluid leak from each part.

Page 211 of 5883

BRAKE BOOSTER

BR-19

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

BRAKE BOOSTER

On Board InspectionINFOID:0000000001716999

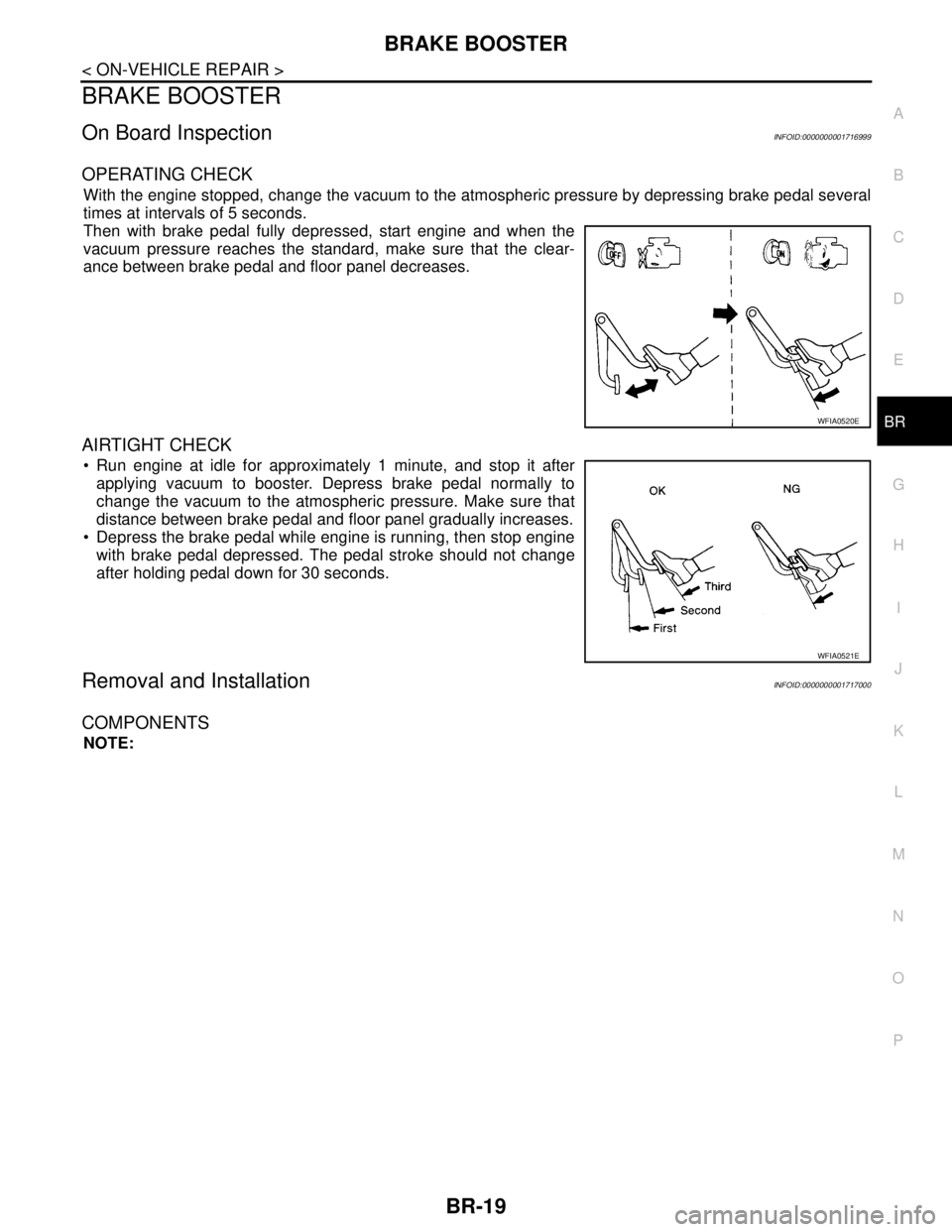

OPERATING CHECK

With the engine stopped, change the vacuum to the atmospheric pressure by depressing brake pedal several

times at intervals of 5 seconds.

Then with brake pedal fully depressed, start engine and when the

vacuum pressure reaches the standard, make sure that the clear-

ance between brake pedal and floor panel decreases.

AIRTIGHT CHECK

Run engine at idle for approximately 1 minute, and stop it after

applying vacuum to booster. Depress brake pedal normally to

change the vacuum to the atmospheric pressure. Make sure that

distance between brake pedal and floor panel gradually increases.

Depress the brake pedal while engine is running, then stop engine

with brake pedal depressed. The pedal stroke should not change

after holding pedal down for 30 seconds.

Removal and InstallationINFOID:0000000001717000

COMPONENTS

NOTE:

WFIA0520E

WFIA0521E

Page 214 of 5883

BR-22

< ON-VEHICLE REPAIR >

VACUUM LINES

VACUUM LINES

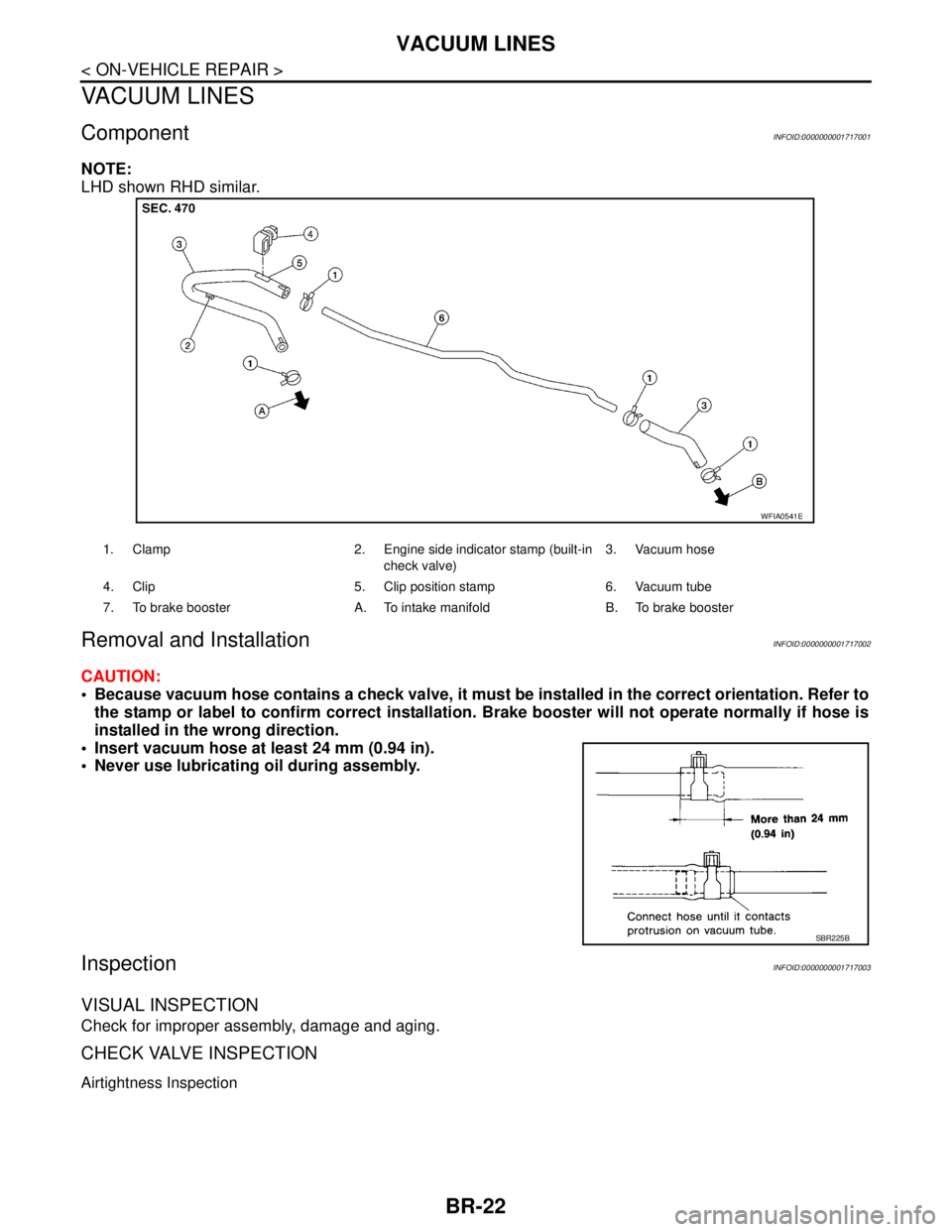

ComponentINFOID:0000000001717001

NOTE:

LHD shown RHD similar.

Removal and InstallationINFOID:0000000001717002

CAUTION:

Because vacuum hose contains a check valve, it must be installed in the correct orientation. Refer to

the stamp or label to confirm correct installation. Brake booster will not operate normally if hose is

installed in the wrong direction.

Insert vacuum hose at least 24 mm (0.94 in).

Never use lubricating oil during assembly.

InspectionINFOID:0000000001717003

VISUAL INSPECTION

Check for improper assembly, damage and aging.

CHECK VALVE INSPECTION

Airtightness Inspection

1. Clamp 2. Engine side indicator stamp (built-in

check valve)3. Vacuum hose

4. Clip 5. Clip position stamp 6. Vacuum tube

7. To brake booster A. To intake manifold B. To brake booster

WFIA0541E

SBR225B

Page 215 of 5883

VACUUM LINES

BR-23

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

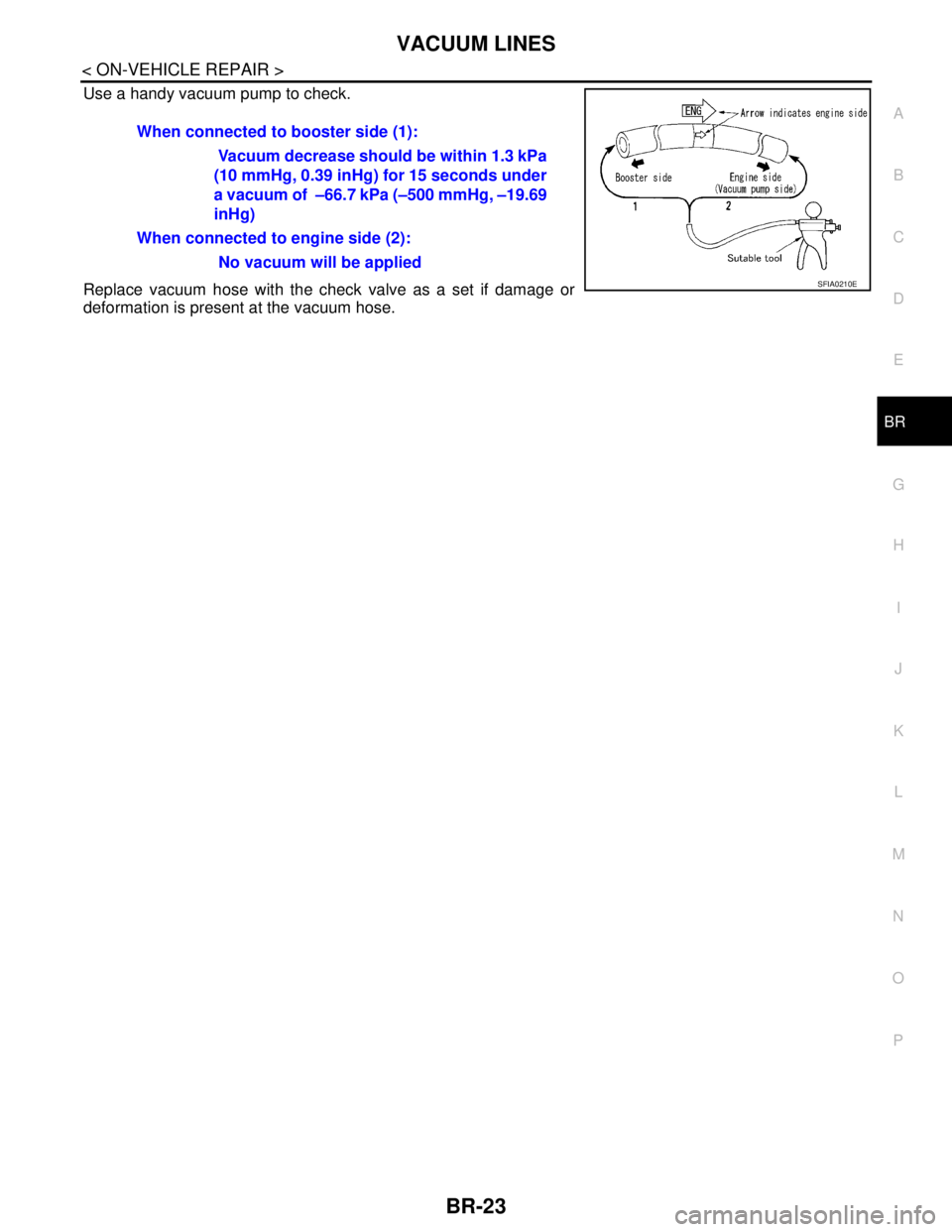

Use a handy vacuum pump to check.

Replace vacuum hose with the check valve as a set if damage or

deformation is present at the vacuum hose.When connected to booster side (1):

Vacuum decrease should be within 1.3 kPa

(10 mmHg, 0.39 inHg) for 15 seconds under

a vacuum of –66.7 kPa (–500 mmHg, –19.69

inHg)

When connected to engine side (2):

No vacuum will be applied

SFIA0210E