instrument cluster NISSAN TIIDA 2007 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3727 of 5883

![NISSAN TIIDA 2007 Service User Guide IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

d NISSAN TIIDA 2007 Service User Guide IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

d](/img/5/57395/w960_57395-3726.png)

IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

degrees while disengaging the instrument finisher E metal clips

and pawl.

Glove box assembly"GLOVE

BOX AS-

SEMBLY"[ 15 ]

Side ventilator assembly (RH)IP-10

[ 16 ] [ 4 ]

Passenger air bag module assemblySR-9

[ 17 ] [ 5 ]

Instrument upper maskIP-10

[ 18 ]

Instrument finisher DIP-10

[ 19 ]

Controller TM-674

[ 20 ]

Instrument upper panel assembly IP-11

[ 21 ]

Console mask"Remov-

al"[ 22 ] [ 1 ]

CVT, A/T console finisherIP-23

[ 23 ] [ 2 ]

M/T console bootIP-23

[ 23 ] [ 2 ]

Console rear finisherIP-23

[ 24 ] [ 3 ]

Console mask cover (with arm rest)IP-23

[ 25 ] [ 4 ]

Rear cup holder (without arm rest)IP-23

[ 25 ] [ 4 ]

Console body assemblyIP-23

[ 26 ] [ 5 ]

Instrument lower cover (LH/RH)"INSTRU-

MENT

LOWER

FINISH-

ER"[ 27 ] [ 6 ]

Center console assembly"CEN-

TER

CON-

SOLE AS-

SEMBLY"[ 28 ] [ 7 ]

Fuse block lidIP-10

[ 29 ]

Lighting and turn signal switchEXL-101

[ 30 ]

Wiper & washer switchWW-76

[ 31 ]

Instrument panel & padIP-10

[ 32 ] PartsReference

pageInstrument

panel and padCluster lid A Cluster lid C Passenger air

bag module

assemblyCenter con-

sole assembly

WIIA1224E

Page 3728 of 5883

INSTRUMENT PANEL ASSEMBLY

IP-13

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

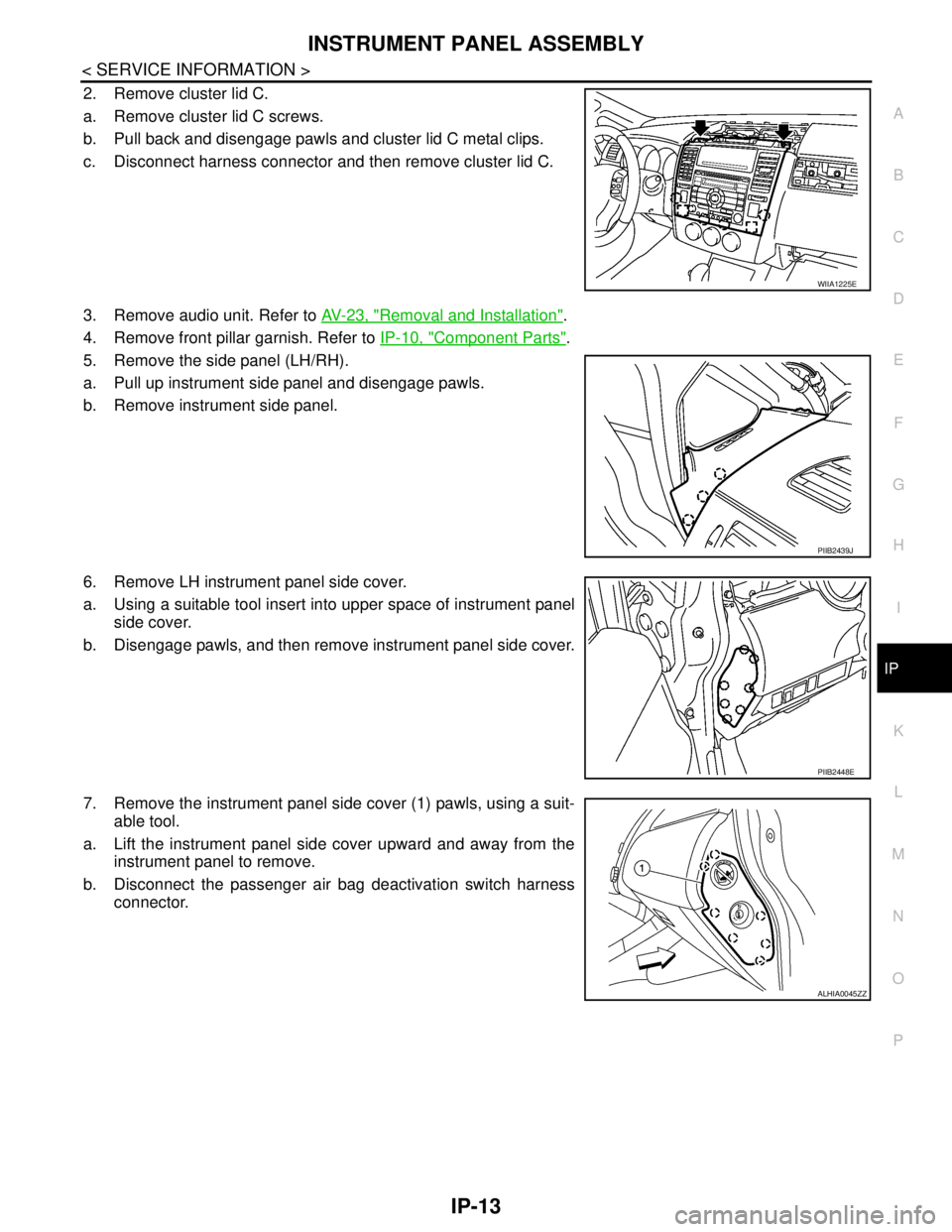

2. Remove cluster lid C.

a. Remove cluster lid C screws.

b. Pull back and disengage pawls and cluster lid C metal clips.

c. Disconnect harness connector and then remove cluster lid C.

3. Remove audio unit. Refer to AV-23, "

Removal and Installation".

4. Remove front pillar garnish. Refer to IP-10, "

Component Parts".

5. Remove the side panel (LH/RH).

a. Pull up instrument side panel and disengage pawls.

b. Remove instrument side panel.

6. Remove LH instrument panel side cover.

a. Using a suitable tool insert into upper space of instrument panel

side cover.

b. Disengage pawls, and then remove instrument panel side cover.

7. Remove the instrument panel side cover (1) pawls, using a suit-

able tool.

a. Lift the instrument panel side cover upward and away from the

instrument panel to remove.

b. Disconnect the passenger air bag deactivation switch harness

connector.

WIIA1225E

PIIB2439J

PIIB2448E

ALHIA0045ZZ

Page 3729 of 5883

IP-14

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

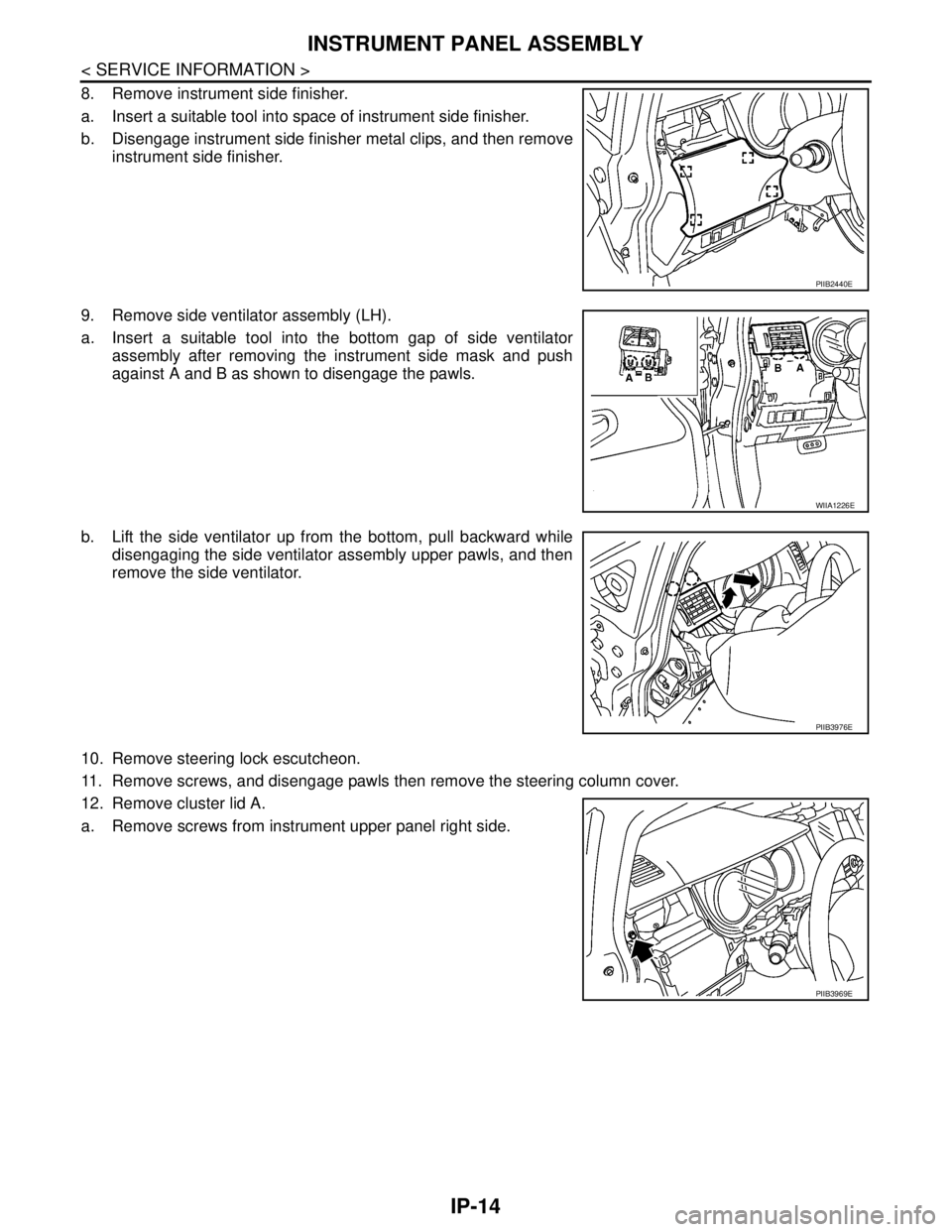

8. Remove instrument side finisher.

a. Insert a suitable tool into space of instrument side finisher.

b. Disengage instrument side finisher metal clips, and then remove

instrument side finisher.

9. Remove side ventilator assembly (LH).

a. Insert a suitable tool into the bottom gap of side ventilator

assembly after removing the instrument side mask and push

against A and B as shown to disengage the pawls.

b. Lift the side ventilator up from the bottom, pull backward while

disengaging the side ventilator assembly upper pawls, and then

remove the side ventilator.

10. Remove steering lock escutcheon.

11. Remove screws, and disengage pawls then remove the steering column cover.

12. Remove cluster lid A.

a. Remove screws from instrument upper panel right side.

PIIB2440E

WIIA1226E

PIIB3976E

PIIB3969E

Page 3730 of 5883

INSTRUMENT PANEL ASSEMBLY

IP-15

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

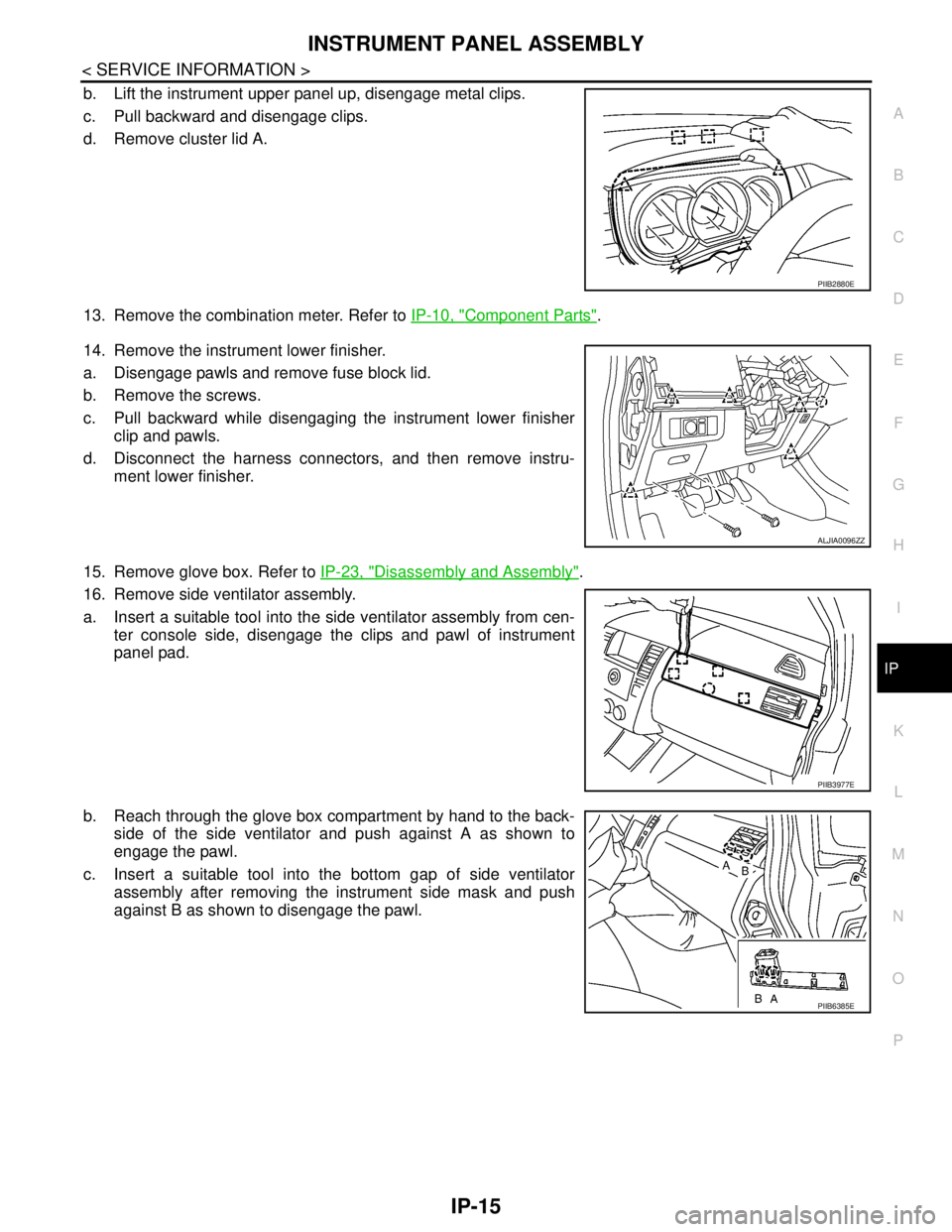

b. Lift the instrument upper panel up, disengage metal clips.

c. Pull backward and disengage clips.

d. Remove cluster lid A.

13. Remove the combination meter. Refer to IP-10, "

Component Parts".

14. Remove the instrument lower finisher.

a. Disengage pawls and remove fuse block lid.

b. Remove the screws.

c. Pull backward while disengaging the instrument lower finisher

clip and pawls.

d. Disconnect the harness connectors, and then remove instru-

ment lower finisher.

15. Remove glove box. Refer to IP-23, "

Disassembly and Assembly".

16. Remove side ventilator assembly.

a. Insert a suitable tool into the side ventilator assembly from cen-

ter console side, disengage the clips and pawl of instrument

panel pad.

b. Reach through the glove box compartment by hand to the back-

side of the side ventilator and push against A as shown to

engage the pawl.

c. Insert a suitable tool into the bottom gap of side ventilator

assembly after removing the instrument side mask and push

against B as shown to disengage the pawl.

PIIB2880E

ALJIA0096ZZ

PIIB3977E

PIIB6385E

Page 3732 of 5883

INSTRUMENT PANEL ASSEMBLY

IP-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

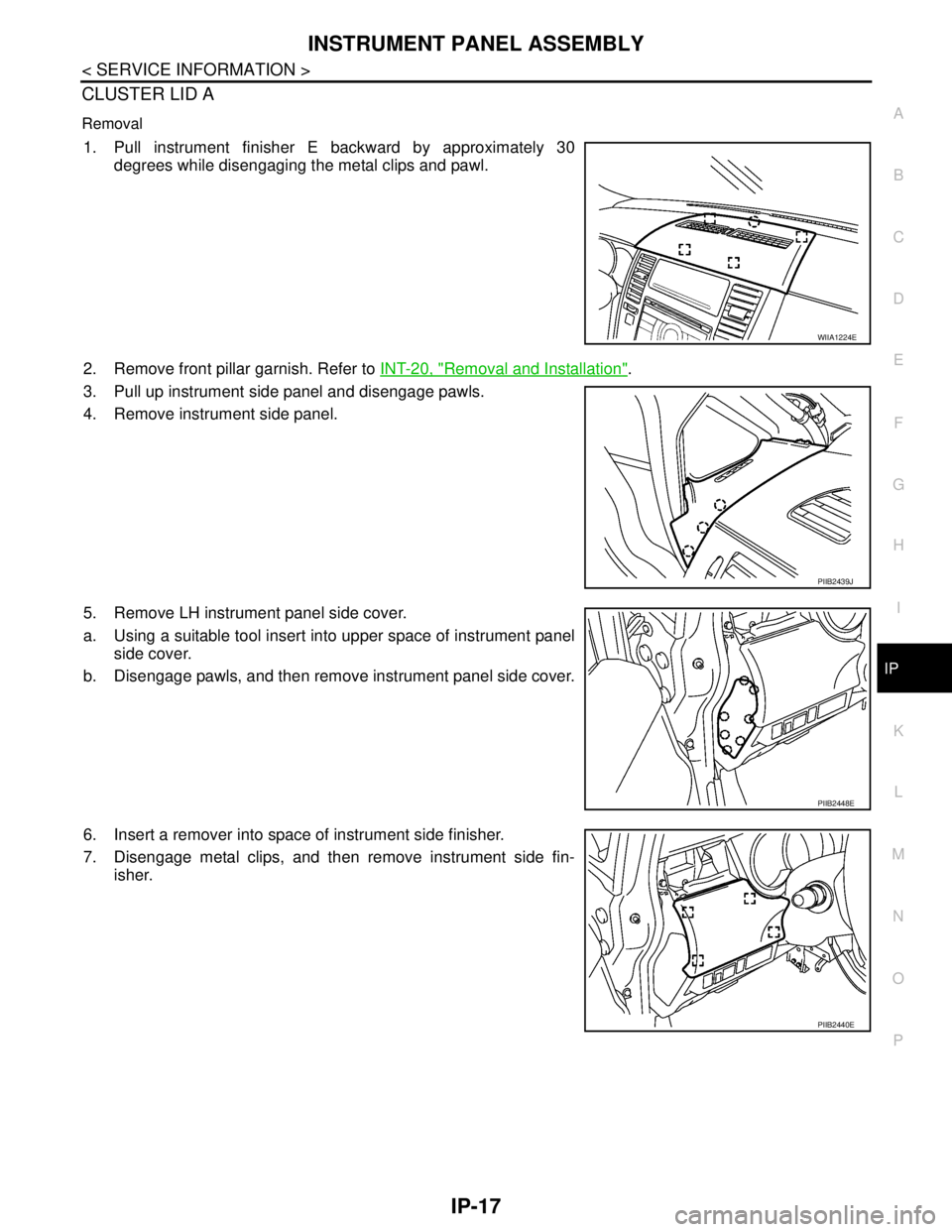

CLUSTER LID A

Removal

1. Pull instrument finisher E backward by approximately 30

degrees while disengaging the metal clips and pawl.

2. Remove front pillar garnish. Refer to INT-20, "

Removal and Installation".

3. Pull up instrument side panel and disengage pawls.

4. Remove instrument side panel.

5. Remove LH instrument panel side cover.

a. Using a suitable tool insert into upper space of instrument panel

side cover.

b. Disengage pawls, and then remove instrument panel side cover.

6. Insert a remover into space of instrument side finisher.

7. Disengage metal clips, and then remove instrument side fin-

isher.

WIIA1224E

PIIB2439J

PIIB2448E

PIIB2440E

Page 3733 of 5883

IP-18

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

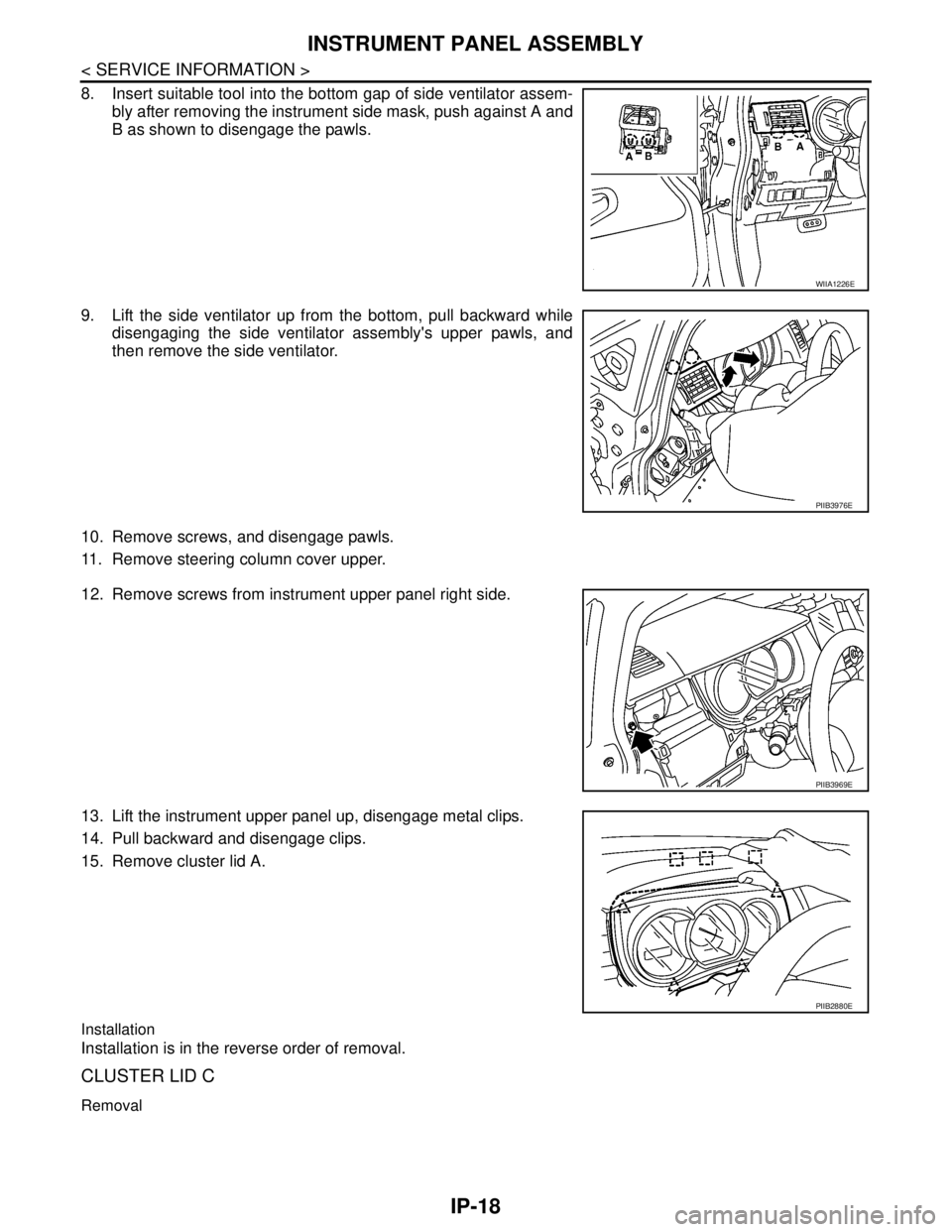

8. Insert suitable tool into the bottom gap of side ventilator assem-

bly after removing the instrument side mask, push against A and

B as shown to disengage the pawls.

9. Lift the side ventilator up from the bottom, pull backward while

disengaging the side ventilator assembly's upper pawls, and

then remove the side ventilator.

10. Remove screws, and disengage pawls.

11. Remove steering column cover upper.

12. Remove screws from instrument upper panel right side.

13. Lift the instrument upper panel up, disengage metal clips.

14. Pull backward and disengage clips.

15. Remove cluster lid A.

Installation

Installation is in the reverse order of removal.

CLUSTER LID C

Removal

WIIA1226E

PIIB3976E

PIIB3969E

PIIB2880E

Page 3734 of 5883

INSTRUMENT PANEL ASSEMBLY

IP-19

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

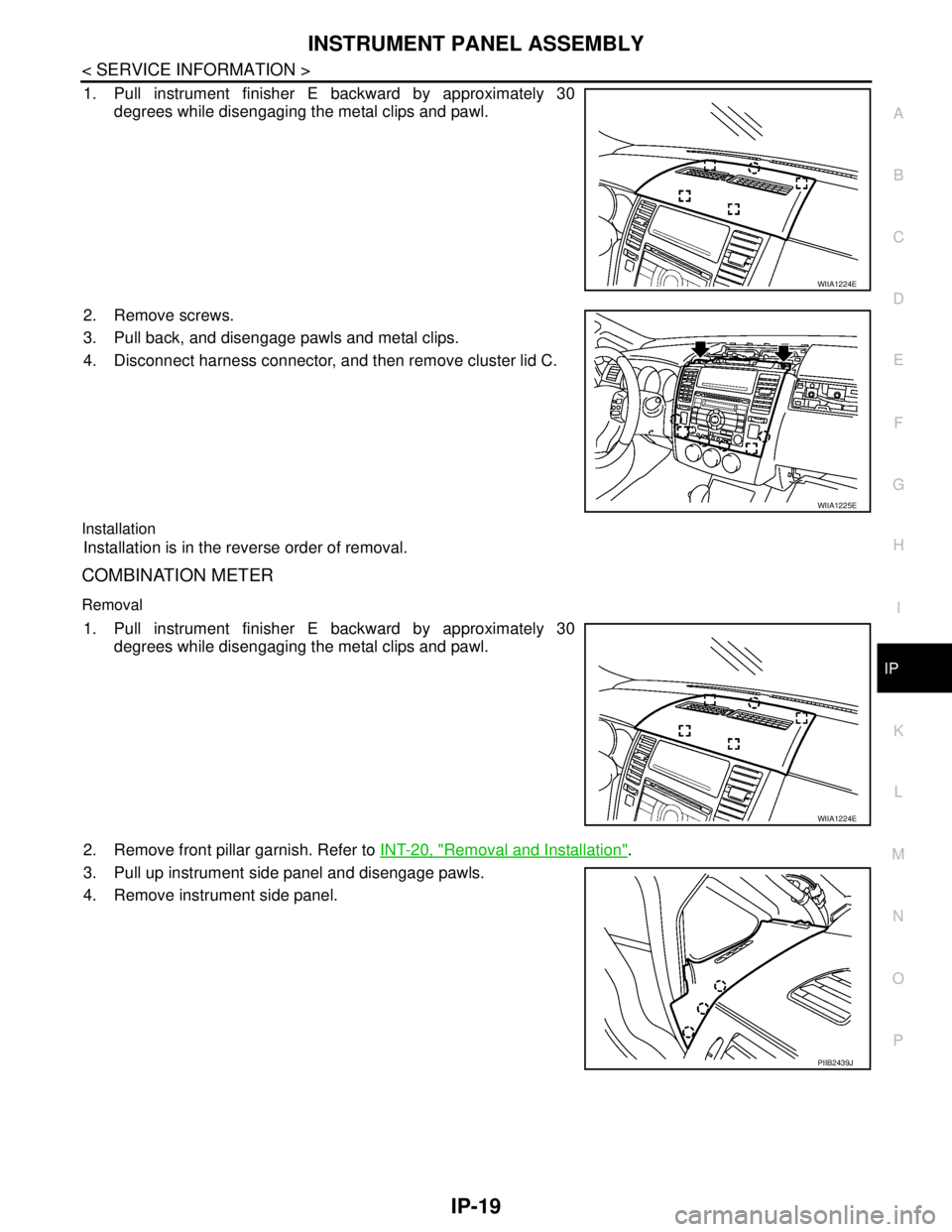

1. Pull instrument finisher E backward by approximately 30

degrees while disengaging the metal clips and pawl.

2. Remove screws.

3. Pull back, and disengage pawls and metal clips.

4. Disconnect harness connector, and then remove cluster lid C.

Installation

Installation is in the reverse order of removal.

COMBINATION METER

Removal

1. Pull instrument finisher E backward by approximately 30

degrees while disengaging the metal clips and pawl.

2. Remove front pillar garnish. Refer to INT-20, "

Removal and Installation".

3. Pull up instrument side panel and disengage pawls.

4. Remove instrument side panel.

WIIA1224E

WIIA1225E

WIIA1224E

PIIB2439J

Page 3736 of 5883

INSTRUMENT PANEL ASSEMBLY

IP-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

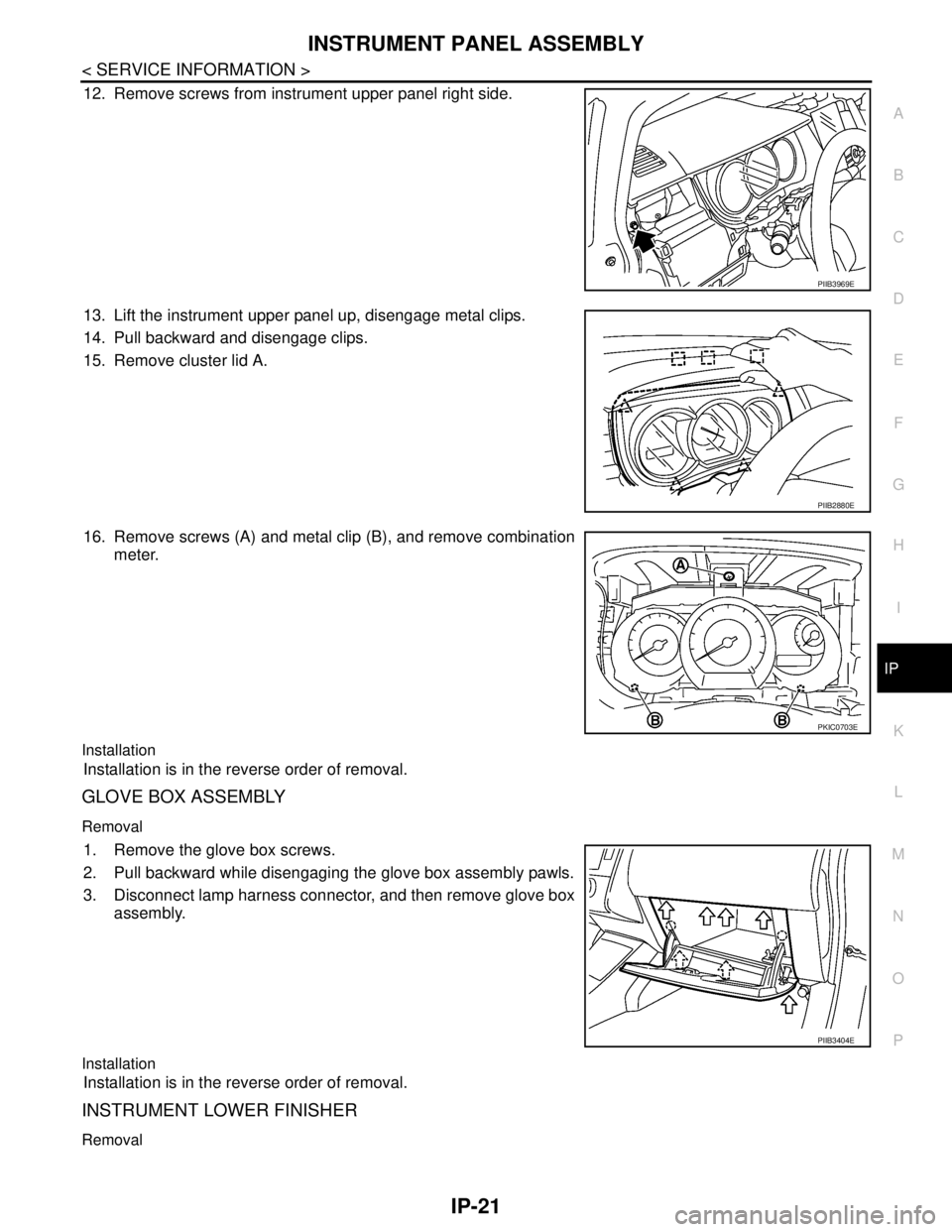

12. Remove screws from instrument upper panel right side.

13. Lift the instrument upper panel up, disengage metal clips.

14. Pull backward and disengage clips.

15. Remove cluster lid A.

16. Remove screws (A) and metal clip (B), and remove combination

meter.

Installation

Installation is in the reverse order of removal.

GLOVE BOX ASSEMBLY

Removal

1. Remove the glove box screws.

2. Pull backward while disengaging the glove box assembly pawls.

3. Disconnect lamp harness connector, and then remove glove box

assembly.

Installation

Installation is in the reverse order of removal.

INSTRUMENT LOWER FINISHER

Removal

PIIB3969E

PIIB2880E

PKIC0703E

PIIB3404E

Page 4402 of 5883

MWI

COMBINATION METER

MWI-95

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

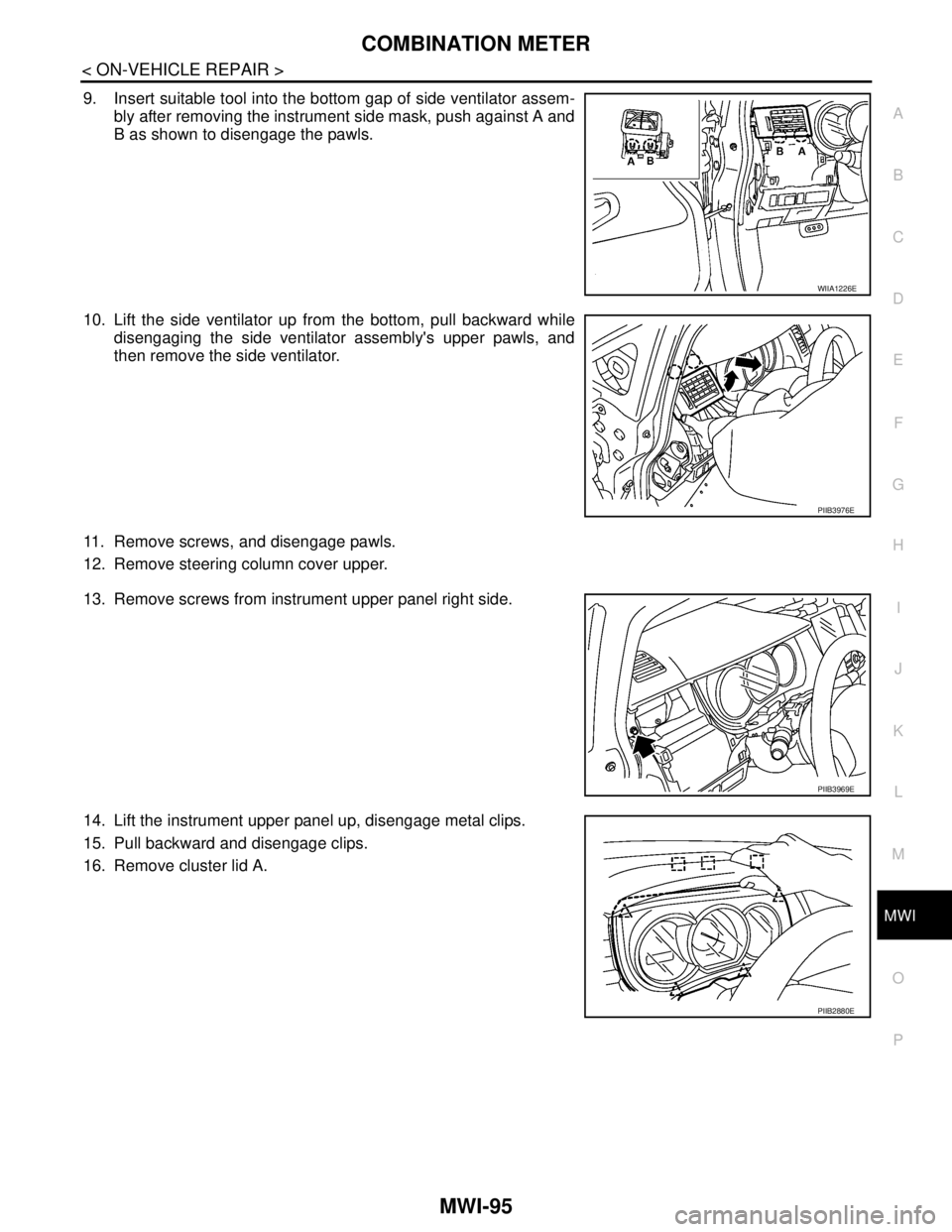

9. Insert suitable tool into the bottom gap of side ventilator assem-

bly after removing the instrument side mask, push against A and

B as shown to disengage the pawls.

10. Lift the side ventilator up from the bottom, pull backward while

disengaging the side ventilator assembly's upper pawls, and

then remove the side ventilator.

11. Remove screws, and disengage pawls.

12. Remove steering column cover upper.

13. Remove screws from instrument upper panel right side.

14. Lift the instrument upper panel up, disengage metal clips.

15. Pull backward and disengage clips.

16. Remove cluster lid A.

WIIA1226E

PIIB3976E

PIIB3969E

PIIB2880E

Page 4560 of 5883

RF-26

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

The following materials, not available through NISSAN Parts Department, can also be used to repair squeaks

and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000001724411

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment