switch NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 458 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CHG

CHARGING SYSTEM PRELIMINARY INSPECTION

CHG-37

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

COMPONENT DIAGNOSIS

CHARGING SYSTEM PRELIMINARY INSPECTION

Inspection ProcedureINFOID:00000 NISSAN TIIDA 2007 Service Repair Manual CHG

CHARGING SYSTEM PRELIMINARY INSPECTION

CHG-37

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

COMPONENT DIAGNOSIS

CHARGING SYSTEM PRELIMINARY INSPECTION

Inspection ProcedureINFOID:00000](/img/5/57395/w960_57395-457.png)

CHG

CHARGING SYSTEM PRELIMINARY INSPECTION

CHG-37

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

COMPONENT DIAGNOSIS

CHARGING SYSTEM PRELIMINARY INSPECTION

Inspection ProcedureINFOID:0000000001724507

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair battery terminals connection.

2.CHECK FUSE

Check for blown fuse and fusible link.

Is the inspection result normal?

YES >> GO TO 3

NO >> Be sure to eliminate cause of malfunction before installing new fuse or fusible link.

3.CHECK GENERATOR CASE GROUND

Verify generator case ground is clean and tight.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair connection.

4.CHECK DRIVE BELT TENSION

Check drive belt tension. Refer to XX-XX, "*****"

.

Is the inspection result normal?

YES >> Inspection end.

NO >> Repair as needed.

Unit Power supply terminals Power source

GeneratorBattery (terminal 3) IPDM E/R

Battery (terminal 1) Fusible Link A

Combination meter Ignition switch ON (terminal 2) Fuse 14

Page 459 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CHG-38

< COMPONENT DIAGNOSIS >[K9K]

B TERMINAL CIRCUIT

B TERMINAL CIRCUIT

DescriptionINFOID:0000000001724509

The terminal “1” (B) circuit supplies power to charge the battery and operate the vehic NISSAN TIIDA 2007 Service Repair Manual CHG-38

< COMPONENT DIAGNOSIS >[K9K]

B TERMINAL CIRCUIT

B TERMINAL CIRCUIT

DescriptionINFOID:0000000001724509

The terminal “1” (B) circuit supplies power to charge the battery and operate the vehic](/img/5/57395/w960_57395-458.png)

CHG-38

< COMPONENT DIAGNOSIS >[K9K]

B TERMINAL CIRCUIT

B TERMINAL CIRCUIT

DescriptionINFOID:0000000001724509

The terminal “1” (B) circuit supplies power to charge the battery and operate the vehicles electrical system.

Diagnosis ProcedureINFOID:0000000001724510

1.CHECK TERMINAL “1” CONNECTION

1. Turn ignition switch OFF.

2. Verify terminal “1” is clean and tight.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair terminal “1” connection. Confirm repair by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

2.CHECK TERMINAL “1” CIRCUIT

Check voltage between generator connector F2 terminal 1 and

ground.

Is voltage reading as specified?

YES >> GO TO 3.

NO >> Check harness for open between generator and fusible

link.

3.CHECK TERMINAL “1” CONNECTION (VOLTAGE DROP TEST)

1. Start engine, then engine running at idle and warm.

2. Check voltage between battery positive terminal and generator

connector F2 terminal 1.

Is the voltage reading as specified?

YES >> Terminal “1” circuit is normal. Refer to CHG-33, "Work

Flow".

NO >> Check harness between battery and generator for high resistance.

(+)

(-) Voltage

Connector Terminal

F2 1 Ground Battery voltage

ALMIA0197ZZ

(+)

(-) Voltage

Connector Terminal

F2 1 Battery positive terminal Less than 0.2V

ALMIA0198ZZ

Page 460 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CHG

L TERMINAL CIRCUIT

CHG-39

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724511

The terminal “2” (L) circuit controls the charge warn NISSAN TIIDA 2007 Service Repair Manual CHG

L TERMINAL CIRCUIT

CHG-39

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724511

The terminal “2” (L) circuit controls the charge warn](/img/5/57395/w960_57395-459.png)

CHG

L TERMINAL CIRCUIT

CHG-39

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724511

The terminal “2” (L) circuit controls the charge warning lamp. The charge warning lamp illuminates when the

ignition switch is set to ON or START. When the generator is providing sufficient voltage with the engine run-

ning, the charge warning lamp will go off. If the charge warning lamp illuminates with the engine running, a

malfunction is indicated.

Diagnosis ProcedureINFOID:0000000001724512

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Verify generator connector F1 terminal 2 is clean and tight.

Is the connection secure?

YES >> GO TO 2

NO >> Repair the connection. Confirm repair by performing complete Starting/Charging system test.

Refer to Technical Service Bulletin.

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector F1.

2. Apply ground to generator harness connector F1 terminal 2 with

the ignition switch in the ON position.

Does the charge lamp illuminate?

YES >> Check generator function. Refer to CHG-33, "Work

Flow".

NO >> GO TO 3

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect the generator connector F1 and combination meter

connector M24.

3. Check continuity between generator harness connector F1 ter-

minal 2 and combination meter harness connector M24 terminal

38.

4. Check continuity between generator harness connector F1 ter-

minal 2 and ground.

Are the continuity results as specified?

YES >> Replace the combination meter. Refer to XX-XX, "*****".

NO >> Repair the harness or connector.Charge lamp should illuminate

ALMIA0328GB

Terminal Terminal

Continuity

Connector Terminal Connector Terminal

F1 2 M24 38 Yes

Te r , m i n a l

—

Continuity

Connector Terminal

F1 2 Ground No

ALMIA0329GB

Page 461 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CHG-40

< COMPONENT DIAGNOSIS >[K9K]

S TERMINAL CIRCUIT

S TERMINAL CIRCUIT

DescriptionINFOID:0000000001724513

The output voltage of the generator is controlled by the IC regulator at terminal “3” ( NISSAN TIIDA 2007 Service Repair Manual CHG-40

< COMPONENT DIAGNOSIS >[K9K]

S TERMINAL CIRCUIT

S TERMINAL CIRCUIT

DescriptionINFOID:0000000001724513

The output voltage of the generator is controlled by the IC regulator at terminal “3” (](/img/5/57395/w960_57395-460.png)

CHG-40

< COMPONENT DIAGNOSIS >[K9K]

S TERMINAL CIRCUIT

S TERMINAL CIRCUIT

DescriptionINFOID:0000000001724513

The output voltage of the generator is controlled by the IC regulator at terminal “3” (S) detecting the input volt-

age. Terminal “3” circuit detects the battery voltage to adjust the generator output voltage with the IC regulator.

Diagnosis ProcedureINFOID:0000000001724514

1.CHECK VOLTAGE REGULATOR CIRCUIT CONNECTION

Check to see if connector F1 terminal 3 is clean and tight.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair terminal connection. Confirm repair by performing complete Starting/Charging system test.

Refer to Technical Service Bulletin.

2.CHECK VOLTAGE REGULATOR CIRCUIT

1. Disconnect generator harness connector F1.

2. Turn ignition switch ON.

3. Check voltage between generator harness connector F1 termi-

nal 3 and ground.

Does battery voltage exist?

YES >> Refer to CHG-33, "Work Flow".

NO >> Check harness for open between generator and fuse.3 - ground Battery voltage

ALMIA0330GB

Page 463 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CHG-42

< SYMPTOM DIAGNOSIS >[K9K]

CHARGING SYSTEM

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

Symptom TableINFOID:0000000001724516

Symptom Reference

Battery discharged

Refer to CHG-33, "

Work Flow". The charge NISSAN TIIDA 2007 Service Repair Manual CHG-42

< SYMPTOM DIAGNOSIS >[K9K]

CHARGING SYSTEM

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

Symptom TableINFOID:0000000001724516

Symptom Reference

Battery discharged

Refer to CHG-33, "

Work Flow". The charge](/img/5/57395/w960_57395-462.png)

CHG-42

< SYMPTOM DIAGNOSIS >[K9K]

CHARGING SYSTEM

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

Symptom TableINFOID:0000000001724516

Symptom Reference

Battery discharged

Refer to CHG-33, "

Work Flow". The charge warning lamp does not illuminate when the ignition

switch is set to ON.

The charge warning lamp does not turn OFF after the engine

starts.

The charging warning lamp turns ON when increasing the engine

speed.

Page 467 of 5883

CL-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001375288

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Service Notice or PrecautionINFOID:0000000001375289

Use recommended brake fluid when adding fluid to the clutch reservoir tank. Refer to MA-19, "Fluids

and Lubricants".

Do not reuse fluid drained from clutch system.

Do not splash brake fluid on painted areas.

Use new brake fluid to clean or wash all parts of master cylinder and operating cylinder.

Do not use mineral oils such as gasoline or kerosene. It will ruin the rubber parts of the hydraulic

system.

If transaxle assembly is removed from the vehicle, always replace CSC (Concentric slave cylinder).

Return CSC to original position to remove transaxle assembly. Dust on clutch disc sliding parts may

damage CSC seal and may cause clutch fluid leakage.

Do not disassemble clutch master cylinder and CSC.

WARNING:

After cleaning clutch disc, clean it with a dust collector. Do not use compressed air.

Page 470 of 5883

CLUTCH PEDAL

CL-5

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

CL

N

O

P

CLUTCH PEDAL

On-vehicle Inspection and AdjustmentINFOID:0000000001375293

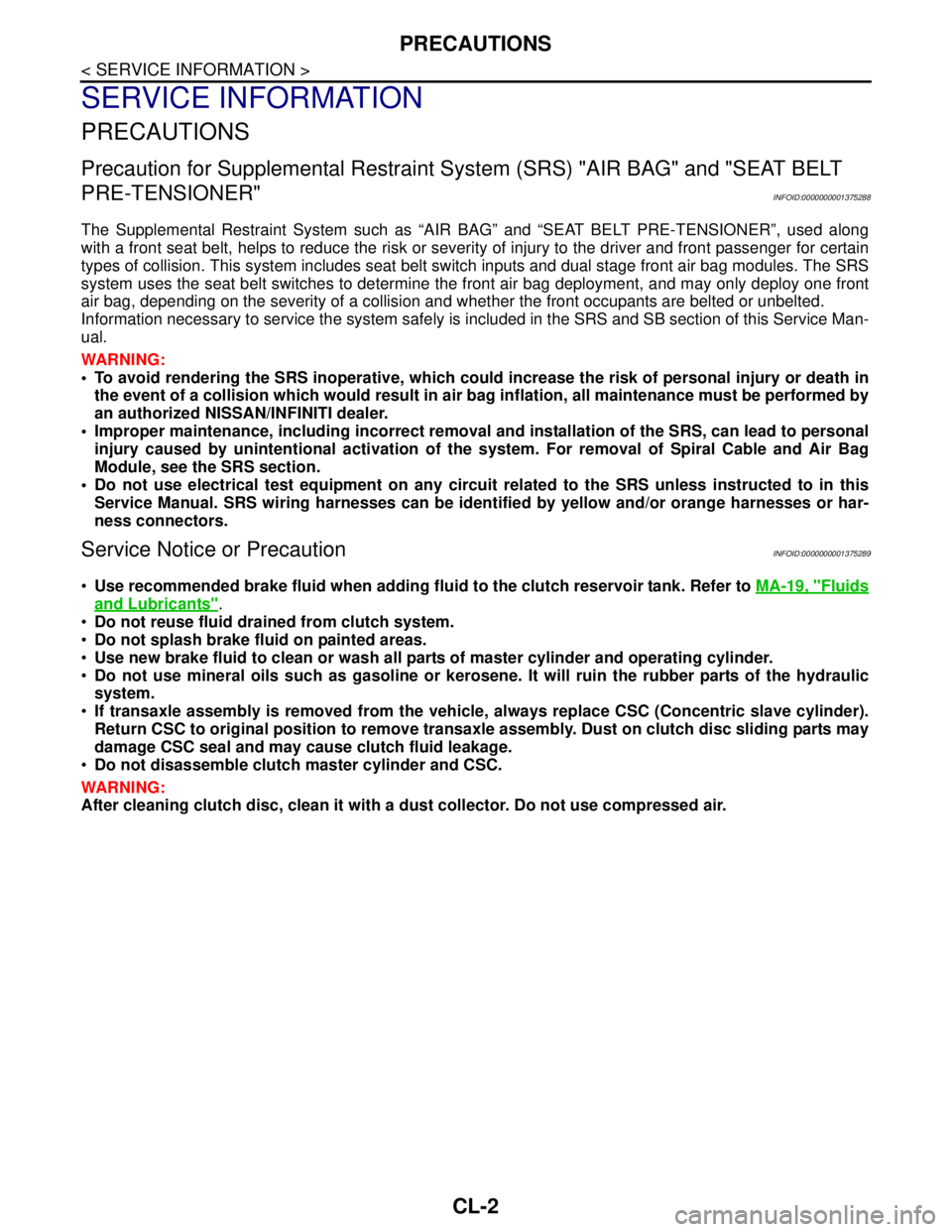

1. Check to see if the master cylinder rod end moves freely. It

should not be bound by the clutch pedal.

a. If the rod end does not move freely, check that the ASCD switch,

if equipped, is not applying pressure to the clutch pedal causing

the rod end to bind. To adjust, disconnect the ASCD switch elec-

trical connector and turn the ASCD switch.

b. Connect the ASCD switch electrical connector, if equipped.

c. Verify that the master cylinder rod end moves freely. It should

not be bound by the clutch pedal.

d. If the rod end does not move freely, remove the rod end and

check for deformation or damage on the rod end. Leave the rod

end removed for step 2.

2. Check the clutch pedal stroke for free range of movement.

a. With the master cylinder rod end removed, manually move the pedal up and down to determine if it moves

freely.

b. If any sticking is noted, replace the clutch pedal assembly. Re-verify that the master cylinder rod end

moves freely.

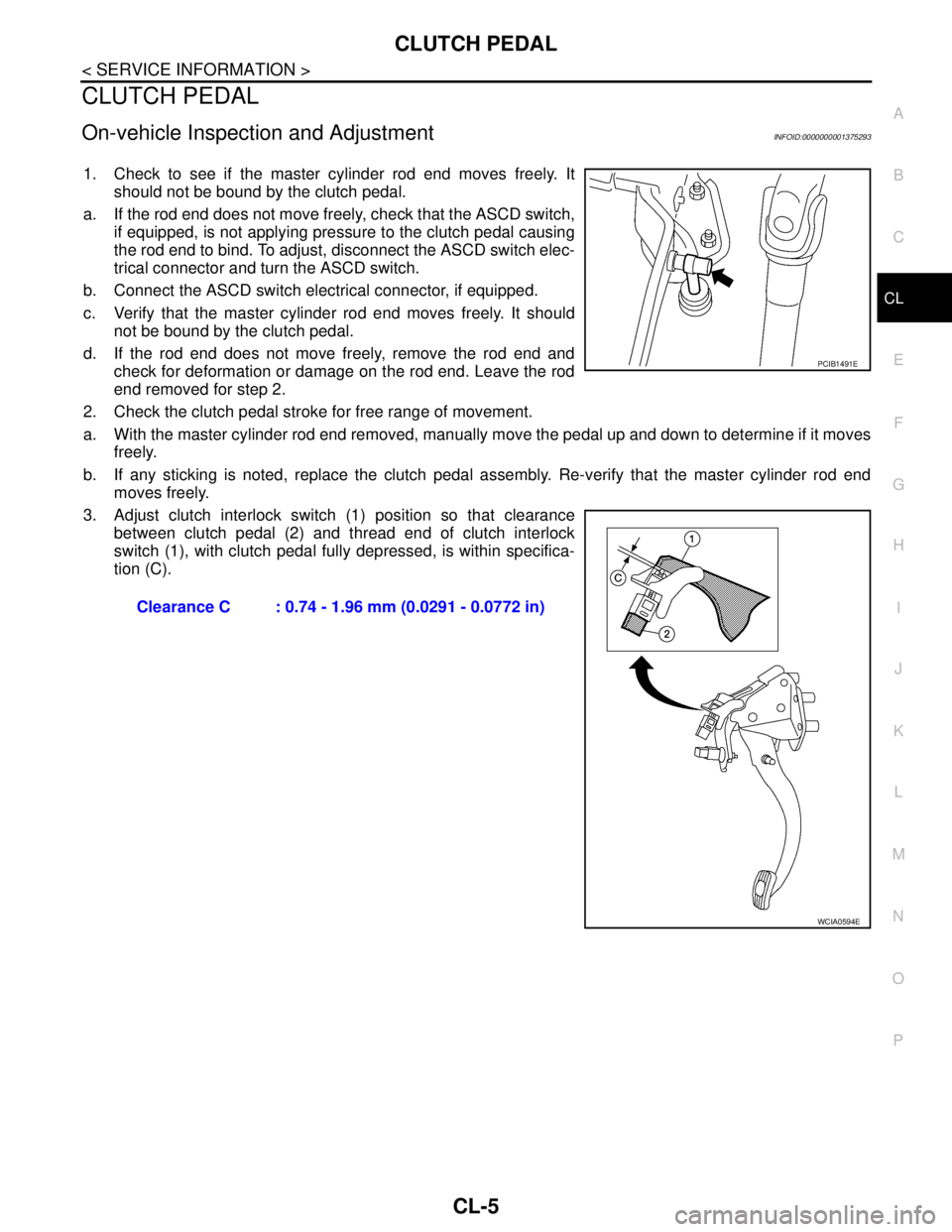

3. Adjust clutch interlock switch (1) position so that clearance

between clutch pedal (2) and thread end of clutch interlock

switch (1), with clutch pedal fully depressed, is within specifica-

tion (C).

Clearance C : 0.74 - 1.96 mm (0.0291 - 0.0772 in)

PCIB1491E

WCIA0594E

Page 471 of 5883

CL-6

< SERVICE INFORMATION >

CLUTCH PEDAL

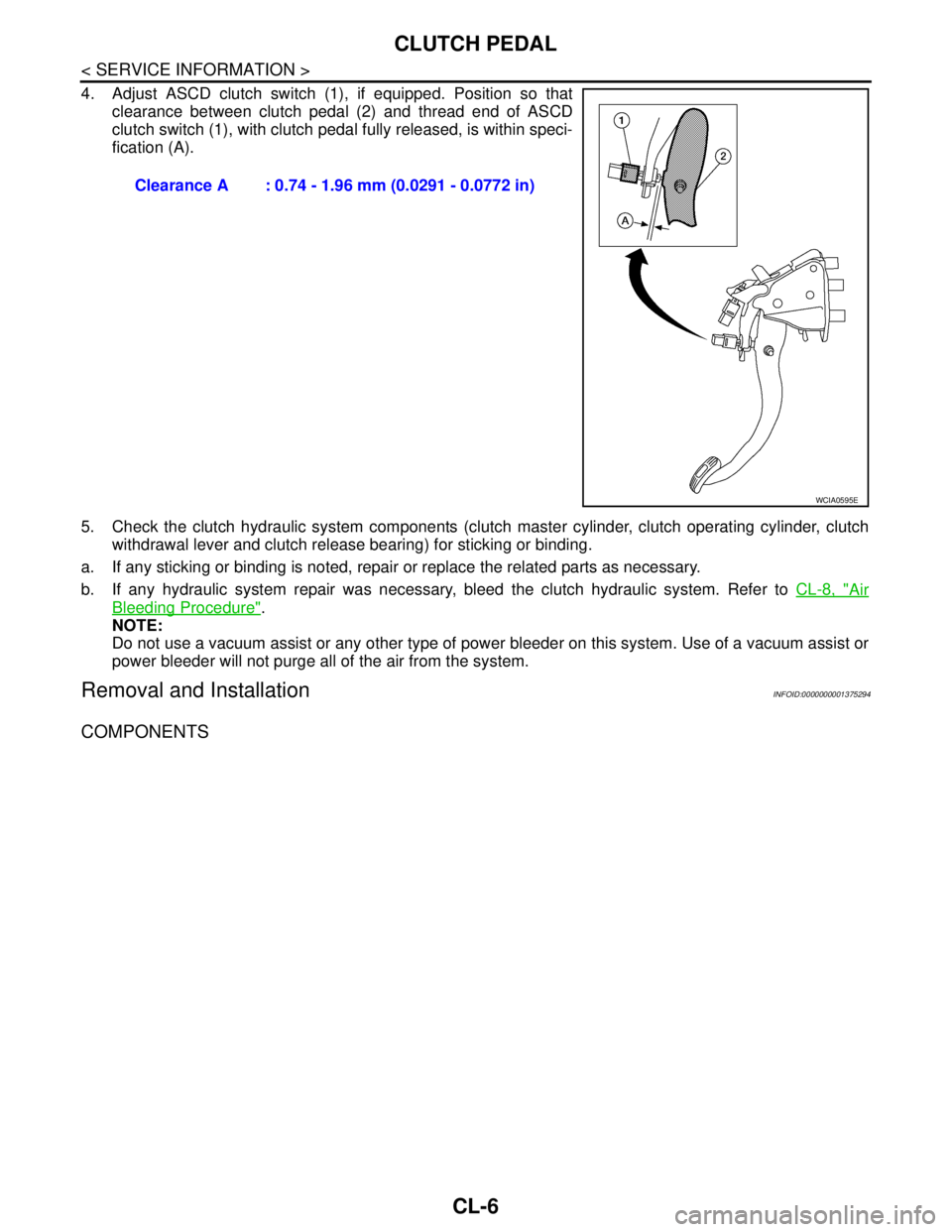

4. Adjust ASCD clutch switch (1), if equipped. Position so that

clearance between clutch pedal (2) and thread end of ASCD

clutch switch (1), with clutch pedal fully released, is within speci-

fication (A).

5. Check the clutch hydraulic system components (clutch master cylinder, clutch operating cylinder, clutch

withdrawal lever and clutch release bearing) for sticking or binding.

a. If any sticking or binding is noted, repair or replace the related parts as necessary.

b. If any hydraulic system repair was necessary, bleed the clutch hydraulic system. Refer to CL-8, "

Air

Bleeding Procedure".

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all of the air from the system.

Removal and InstallationINFOID:0000000001375294

COMPONENTS

Clearance A : 0.74 - 1.96 mm (0.0291 - 0.0772 in)

WCIA0595E

Page 472 of 5883

CLUTCH PEDAL

CL-7

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

CL

N

O

P

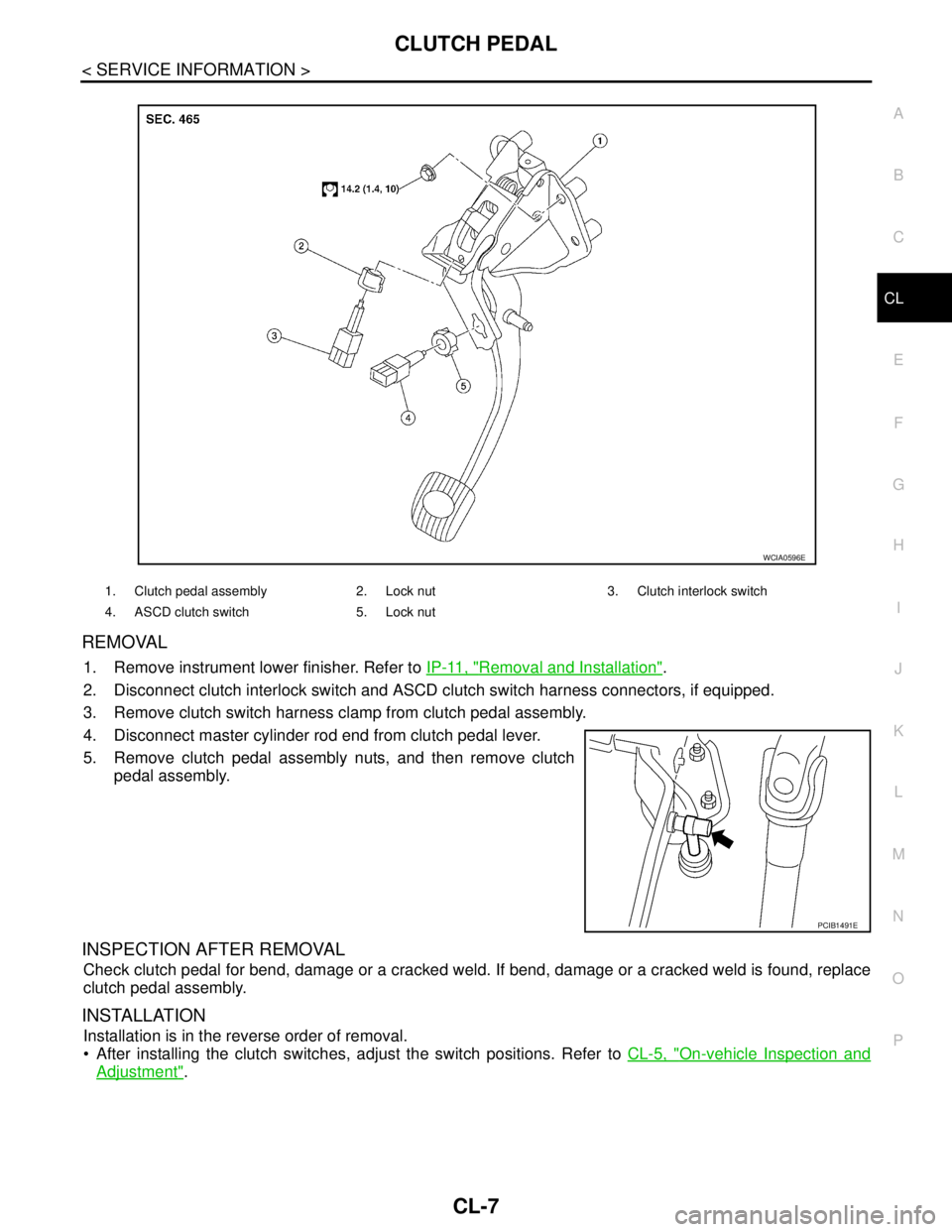

REMOVAL

1. Remove instrument lower finisher. Refer to IP-11, "Removal and Installation".

2. Disconnect clutch interlock switch and ASCD clutch switch harness connectors, if equipped.

3. Remove clutch switch harness clamp from clutch pedal assembly.

4. Disconnect master cylinder rod end from clutch pedal lever.

5. Remove clutch pedal assembly nuts, and then remove clutch

pedal assembly.

INSPECTION AFTER REMOVAL

Check clutch pedal for bend, damage or a cracked weld. If bend, damage or a cracked weld is found, replace

clutch pedal assembly.

INSTALLATION

Installation is in the reverse order of removal.

After installing the clutch switches, adjust the switch positions. Refer to CL-5, "

On-vehicle Inspection and

Adjustment".

1. Clutch pedal assembly 2. Lock nut 3. Clutch interlock switch

4. ASCD clutch switch 5. Lock nut

WCIA0596E

PCIB1491E

Page 481 of 5883

CL-16

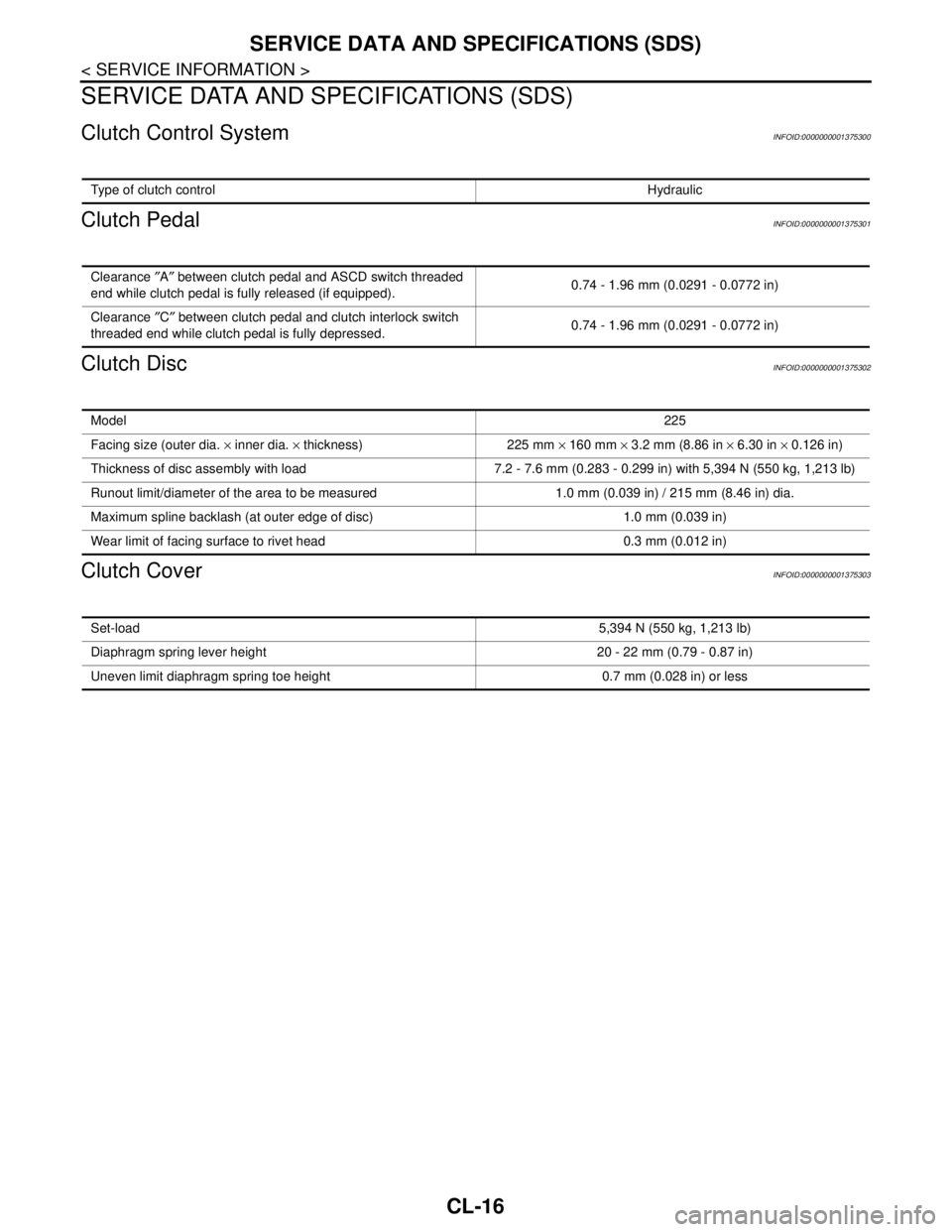

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch Control SystemINFOID:0000000001375300

Clutch PedalINFOID:0000000001375301

Clutch DiscINFOID:0000000001375302

Clutch CoverINFOID:0000000001375303

Type of clutch controlHydraulic

Clearance ″A″ between clutch pedal and ASCD switch threaded

end while clutch pedal is fully released (if equipped). 0.74 - 1.96 mm (0.0291 - 0.0772 in)

Clearance ″C″ between clutch pedal and clutch interlock switch

threaded end while clutch pedal is fully depressed.0.74 - 1.96 mm (0.0291 - 0.0772 in)

Model225

Facing size (outer dia. × inner dia. × thickness) 225 mm × 160 mm × 3.2 mm (8.86 in × 6.30 in × 0.126 in)

Thickness of disc assembly with load 7.2 - 7.6 mm (0.283 - 0.299 in) with 5,394 N (550 kg, 1,213 lb)

Runout limit/diameter of the area to be measured 1.0 mm (0.039 in) / 215 mm (8.46 in) dia.

Maximum spline backlash (at outer edge of disc) 1.0 mm (0.039 in)

Wear limit of facing surface to rivet head 0.3 mm (0.012 in)

Set-load5,394 N (550 kg, 1,213 lb)

Diaphragm spring lever height 20 - 22 mm (0.79 - 0.87 in)

Uneven limit diaphragm spring toe height 0.7 mm (0.028 in) or less