Driver controls NISSAN TIIDA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2367 of 5883

![NISSAN TIIDA 2007 Service Owners Manual EC-1018

< ECU DIAGNOSIS >[MR18DE]

ECM

DTC RELATED ITEM

Engine operating condi-

tion in fail-safe modeDetected items RemarksReference

page

Engine speed will not

rise more than 2,500 rpm

due to the f NISSAN TIIDA 2007 Service Owners Manual EC-1018

< ECU DIAGNOSIS >[MR18DE]

ECM

DTC RELATED ITEM

Engine operating condi-

tion in fail-safe modeDetected items RemarksReference

page

Engine speed will not

rise more than 2,500 rpm

due to the f](/img/5/57395/w960_57395-2366.png)

EC-1018

< ECU DIAGNOSIS >[MR18DE]

ECM

DTC RELATED ITEM

Engine operating condi-

tion in fail-safe modeDetected items RemarksReference

page

Engine speed will not

rise more than 2,500 rpm

due to the fuel cutMalfunction indicator

circuitWhen there is an open circuit on MI circuit, the ECM cannot warn the

driver by lighting up MI when there is malfunction on engine control

system.

Therefore, when electrical controlled throttle and part of ECM related

diagnoses are continuously detected as NG for 5 trips, ECM warns the

driver that engine control system malfunctions and MI circuit is open by

means of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MI

circuit are detected and demands the driver to repair the malfunction.EC-986

DTC No. Detected items Engine operating condition in fail-safe mode

P0011 Intake valve timing control The signal is not energized to the intake valve timing control solenoid valve and the valve

control does not function.

P0102

P0103Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0117

P0118Engine coolant tempera-

ture sensor circuitEngine coolant temperature will be determined by ECM based on the time after following

condition.

CONSULT-III displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided

(CONSULT-III display)

Just as ignition switch is turned ON

or START40°C (104°F)

Approx. 4 minutes after engine

stating80°C (176°F)

Except as shown above40 - 80°C (104 - 176°F)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling

fan operates while engine is running.

P0122

P0123

P0222

P0223

P2135Throttle position sensor The ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

P0500 Vehicle speed sensor When the fail-safe system for vehicle speed sensor is activated, the cooling fan operates

(Highest) while engine is running.

P0605 ECM (When ECM calculation function is malfunctioning:)

ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

ECM deactivates ASCD operation.

P1121 Electric throttle control ac-

tuator(When electric throttle control actuator does not function properly due to the return spring

malfunction:)

ECM controls the electric throttle actuator by regulating the throttle opening around the

idle position. The engine speed will not rise more than 2,000 rpm.

(When throttle valve opening angle in fail-safe mode is not in specified range:)

ECM controls the electric throttle control actuator by regulating the throttle opening to 20

degrees or less.

(When ECM detects the throttle valve is stuck open:)

While the vehicle is driving, it slows down gradually by fuel cut. After the vehicle stops, the

engine stalls.

The engine can restart in Neutral position, and engine speed will not exceed 1,000 rpm or

more.

P1122 Electric throttle control

functionECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

Page 2453 of 5883

![NISSAN TIIDA 2007 Service Owners Manual EC-1104

< FUNCTION DIAGNOSIS >[K9K]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis DescriptionINFOID:0000000001162547

The ECM controls the display on the instrument panel NISSAN TIIDA 2007 Service Owners Manual EC-1104

< FUNCTION DIAGNOSIS >[K9K]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis DescriptionINFOID:0000000001162547

The ECM controls the display on the instrument panel](/img/5/57395/w960_57395-2452.png)

EC-1104

< FUNCTION DIAGNOSIS >[K9K]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis DescriptionINFOID:0000000001162547

The ECM controls the display on the instrument panel of certain information relating to the operation of the

engine.

Four functions are involved here: The OBD malfunction indicator [MI (Yellow)] for the EOBD (European On

Board Diagnostics), the pre/post heating, the engine coolant temperature and engine malfunction [MI (Red)].

These four functions are represented by four lights given out by the ECM

GLOW LAMP

This lamp indicates that the glow control system has been activated.

ENGINE COOLANT TEMPERATURE LIGHT

This light is used as an indicator of engine overheating.

In the event of overheating, it is up to the driver whether to stop the vehicle or not.

MALFUNCTION INDICATOR

The OBD malfunction indicator [MI (Yellow)] is used to alert the driver to the existence of engine control sys-

tem malfunctions involving excessive pollution or if the EOBD system is deactivated.

The ECM makes a request for lighting of the MI (Yellow) only where there is a malfunction present at the end

of three consecutive cycles.

The 3-second visual check upon powering up (automatic test procedure controlled by the IPDM E/R) is per-

formed by the ECM.

In the event of a confirmed OBD malfunction by lighting of the MI, no flashing of the light must be observed fol-

lowing the lighting test.

DTCs Causing MI to Light

ENGINE WARNING LIGHT

In the event of an engine malfunction, the ECM may request the display of an engine warning light [MI (Red)].

HOW TO ERASE DTC, 1ST TRIP DTC AND 2ND TRIP DTC

With CONSULT-III

The emission related diagnostic information in the ECM can be erased by selecting “ALL ERASE” in the

“Description” of “FINAL CHECK” mode with CONSULT-III.

MI OPERATION CHART

Some malfunction must switch on MI to warn driver, that his engine emissions exceed OBD thresholds (Euro 3

x 2.5).

The rule is to switch on MI after 3 consecutive driving cycles (engine start + engine stop + power latch) with a

present OBD malfunction.

To switch off the MI (without CONSULT-III), vehicle has to drive 3 consecutive cycles without present OBD

malfunction.

Ignition switch OFF → ON transition, MI remains switched on in pre-drive check mode until engine start.If MI

does not switch off whereas engine is running, there is at least one present OBD malfunction.

DTC Description Reference page

P0201 Cylinder 1 fuel injector control circuitEC-1142

P0202 Cylinder 2 fuel injector control circuitEC-1142

P0203 Cylinder 3 fuel injector control circuitEC-1142

P0204 Cylinder 4 fuel injector control circuitEC-1142

P0409 EGR Volume control valve control position sensor circuitEC-1158

P0606 ECMEC-1178

P2413 EGR volume control valveEC-1202

Page 3002 of 5883

EXL-1

DRIVER CONTROLS

C

D

E

F

G

H

I

J

K

M

SECTION EXL

A

B

EXL

N

O

P

CONTENTS

EXTERIOR LIGHTING SYSTEM

BASIC INSPECTION ....................................5

DIAGNOSIS AND REPAIR WORKFLOW ..........5

Work Flow .................................................................5

FUNCTION DIAGNOSIS ...............................8

HEADLAMP (HALOGEN) ...................................8

System Diagram ........................................................8

System Description ...................................................8

Component Parts Location ........................................8

Component Description .............................................8

HEADLAMP (XENON) .......................................10

System Diagram ......................................................10

System Description .................................................10

Component Parts Location ......................................10

Component Description ..........................................11

AUTO LIGHT SYSTEM ......................................12

System Diagram ......................................................12

System Description .................................................12

Component Parts Location ......................................12

Component Description ...........................................13

HEADLAMP AIMING SYSTEM (MANUAL) .......14

System Diagram ......................................................14

System Description .................................................14

Component Parts Location ......................................14

Component Description ...........................................14

HEADLAMP AIMING SYSTEM (AUTOMAT-

IC) .......................................................................

15

System Diagram ......................................................15

System Description .................................................15

Component Parts Location ......................................15

Component Description ...........................................15

DAYTIME LIGHT SYSTEM ................................17

System Diagram ......................................................17

System Description .................................................17

Component Parts Location ......................................17

Component Description ..........................................18

FRONT FOG LAMP ..........................................19

System Diagram ......................................................19

System Description ..................................................19

Component Parts Location ......................................19

Component Description ...........................................20

REAR FOG LAMP .............................................21

System Diagram ......................................................21

System Description ..................................................21

Component Parts Location ......................................21

Component Description ..........................................21

TURN SIGNAL AND HAZARD WARNING

LAMPS ..............................................................

22

System Diagram ......................................................22

System Description ..................................................22

Component Parts Location ......................................22

Component Description ...........................................23

PARKING, LICENSE PLATE AND TAIL

LAMPS ..............................................................

24

System Diagram ......................................................24

System Description ..................................................24

Component Parts Location ......................................25

Component Description ...........................................25

DIAGNOSIS SYSTEM (BCM) ...........................26

COMMON ITEM .........................................................26

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

26

BCM ...........................................................................26

BCM : CONSULT-III Function (BCM - BCM) ...........26

HEADLAMP ...............................................................26

HEADLAMP : CONSULT-III Function (BCM -

HEAD LAMP) ...........................................................

26

FLASHER ...................................................................27

Page 3648 of 5883

HRN-1

DRIVER CONTROLS

C

D

E

F

G

H

I

J

K

M

SECTION HRN

A

B

HRN

N

O

P

CONTENTS

HORN

PRECAUTION ...............................................2

PRECAUTION .....................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

COMPONENT DIAGNOSIS ..........................3

HORN .................................................................3

Wiring Diagram .........................................................3

ON-VEHICLE REPAIR ..................................4

HORN .................................................................4

Removal and Installation ..........................................4

Page 3652 of 5883

INL-1

DRIVER CONTROLS

C

D

E

F

G

H

I

J

K

M

SECTION INL

A

B

INL

N

O

P

CONTENTS

INTERIOR LIGHTING SYSTEM

BASIC INSPECTION ....................................2

DIAGNOSIS AND REPAIR WORKFLOW ..........2

Work Flow .................................................................2

FUNCTION DIAGNOSIS ...............................5

INTERIOR ROOM LAMP CONTROL SYSTEM

.....

5

System Diagram ........................................................5

System Description ...................................................5

Component Parts Location ........................................6

Component Description ............................................6

ILLUMINATION CONTROL SYSTEM .................8

System Diagram ........................................................8

System Description ...................................................8

Component Parts Location ........................................8

Component Description .............................................9

DIAGNOSIS SYSTEM (BCM) ............................10

COMMON ITEM .........................................................10

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

10

INT LAMP ..................................................................10

INT LAMP : CONSULT-III Function (BCM - INT

LAMP) .....................................................................

10

BATTERY SAVER .....................................................12

BATTERY SAVER : CONSULT-III Function (BCM

- BATTERY SAVER) ...............................................

12

COMPONENT DIAGNOSIS .........................14

POWER SUPPLY AND GROUND CIRCUIT ......14

BCM ...........................................................................14

BCM : Diagnosis Procedure ....................................14

INTERIOR ROOM LAMP POWER SUPPLY

CIRCUIT ............................................................

15

Description ...............................................................15

Component Function Check ....................................15

Diagnosis Procedure ...............................................15

INTERIOR ROOM LAMP CONTROL SYSTEM

...

17

Wiring Diagram - INTERIOR ROOM LAMP - ..........17

ILLUMINATION .................................................20

Wiring Diagram - ILLUMINATION - .........................20

ECU DIAGNOSIS .........................................22

BCM (BODY CONTROL MODULE) .................22

Description ...............................................................22

SYMPTOM DIAGNOSIS ..............................23

INTERIOR LIGHTING SYSTEM SYMPTOMS ...23

Symptom Table .......................................................23

PRECAUTION ..............................................24

PRECAUTIONS .................................................24

Supplemental Restraint System (SRS) "AIR BAG"

and "SEAT BELT PRE-TENSIONER" .....................

24

General precautions for service operations .............24

ON-VEHICLE REPAIR .................................25

INTERIOR ROOM LAMP ..................................25

Removal and Installation .........................................25

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................

28

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

28

Bulb Specifications ..................................................28

Page 3657 of 5883

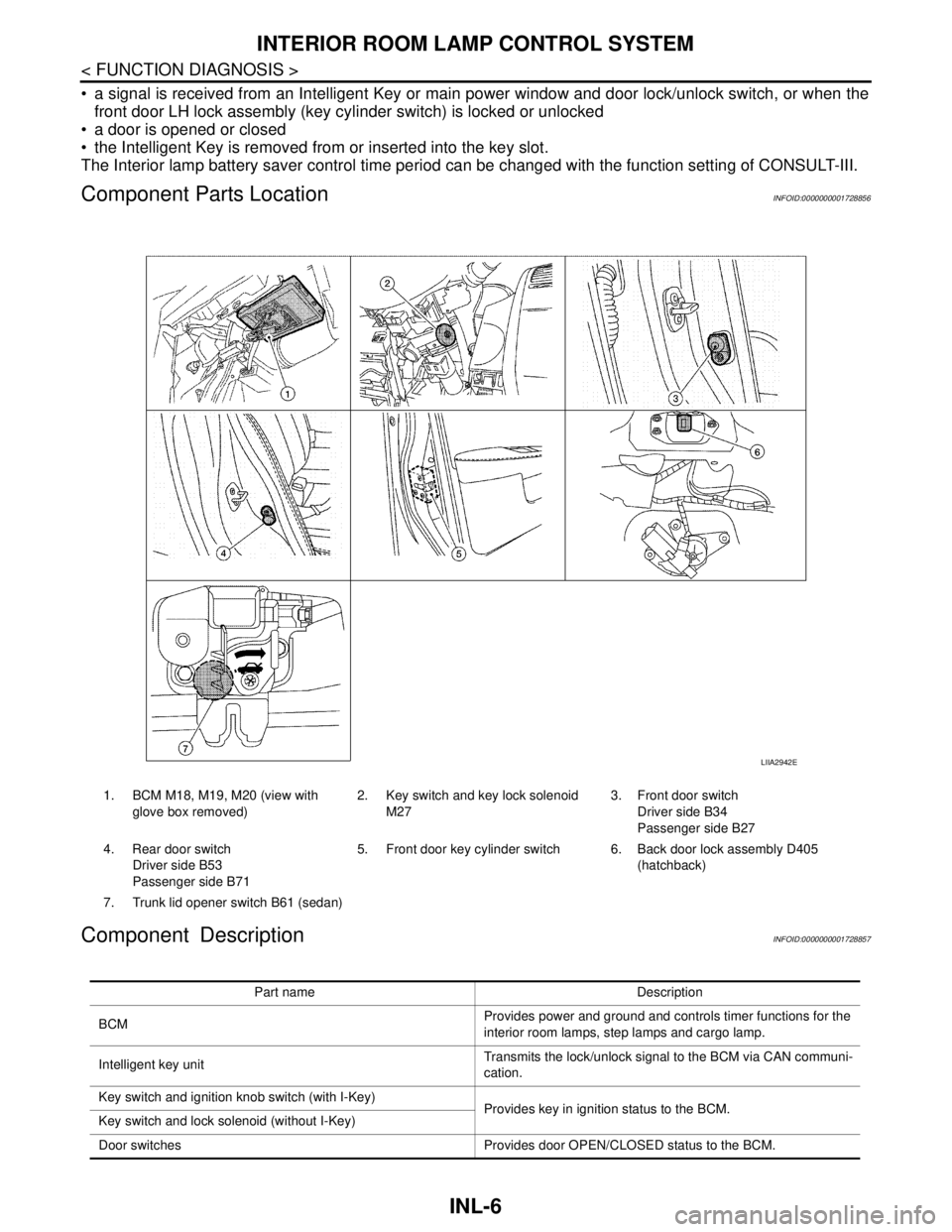

INL-6

< FUNCTION DIAGNOSIS >

INTERIOR ROOM LAMP CONTROL SYSTEM

a signal is received from an Intelligent Key or main power window and door lock/unlock switch, or when the

front door LH lock assembly (key cylinder switch) is locked or unlocked

a door is opened or closed

the Intelligent Key is removed from or inserted into the key slot.

The Interior lamp battery saver control time period can be changed with the function setting of CONSULT-III.

Component Parts LocationINFOID:0000000001728856

Component DescriptionINFOID:0000000001728857

1. BCM M18, M19, M20 (view with

glove box removed)2. Key switch and key lock solenoid

M273. Front door switch

Driver side B34

Passenger side B27

4. Rear door switch

Driver side B53

Passenger side B715. Front door key cylinder switch 6. Back door lock assembly D405

(hatchback)

7. Trunk lid opener switch B61 (sedan)

LIIA2942E

Part name Description

BCMProvides power and ground and controls timer functions for the

interior room lamps, step lamps and cargo lamp.

Intelligent key unitTransmits the lock/unlock signal to the BCM via CAN communi-

cation.

Key switch and ignition knob switch (with I-Key)

Provides key in ignition status to the BCM.

Key switch and lock solenoid (without I-Key)

Door switches Provides door OPEN/CLOSED status to the BCM.

Page 4299 of 5883

MIR-1

DRIVER CONTROLS

C

D

E

F

G

H

I

J

K

M

SECTION MIR

A

B

MIR

N

O

P

CONTENTS

MIRRORS

PRECAUTION ...............................................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

COMPONENT DIAGNOSIS ..........................3

DOOR MIRROR ...................................................3

Wiring Diagram — Position Adjustment (LHD) — ......3

Wiring Diagram — Position Adjustment (RHD) — ......4

Wiring Diagram — Power Fold System (LHD) — .....5

Wiring Diagram — Power Fold System (RHD) — .....6

REMOVAL AND INSTALLATION ................7

DOOR MIRROR .................................................7

Removal and Installation ..........................................7

Disassembly and Assembly ......................................8

INSIDE MIRROR ................................................9

Removal and Installation ..........................................9

Page 4468 of 5883

POWER WINDOW SYSTEM

PWC-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

PWC

N

O

P

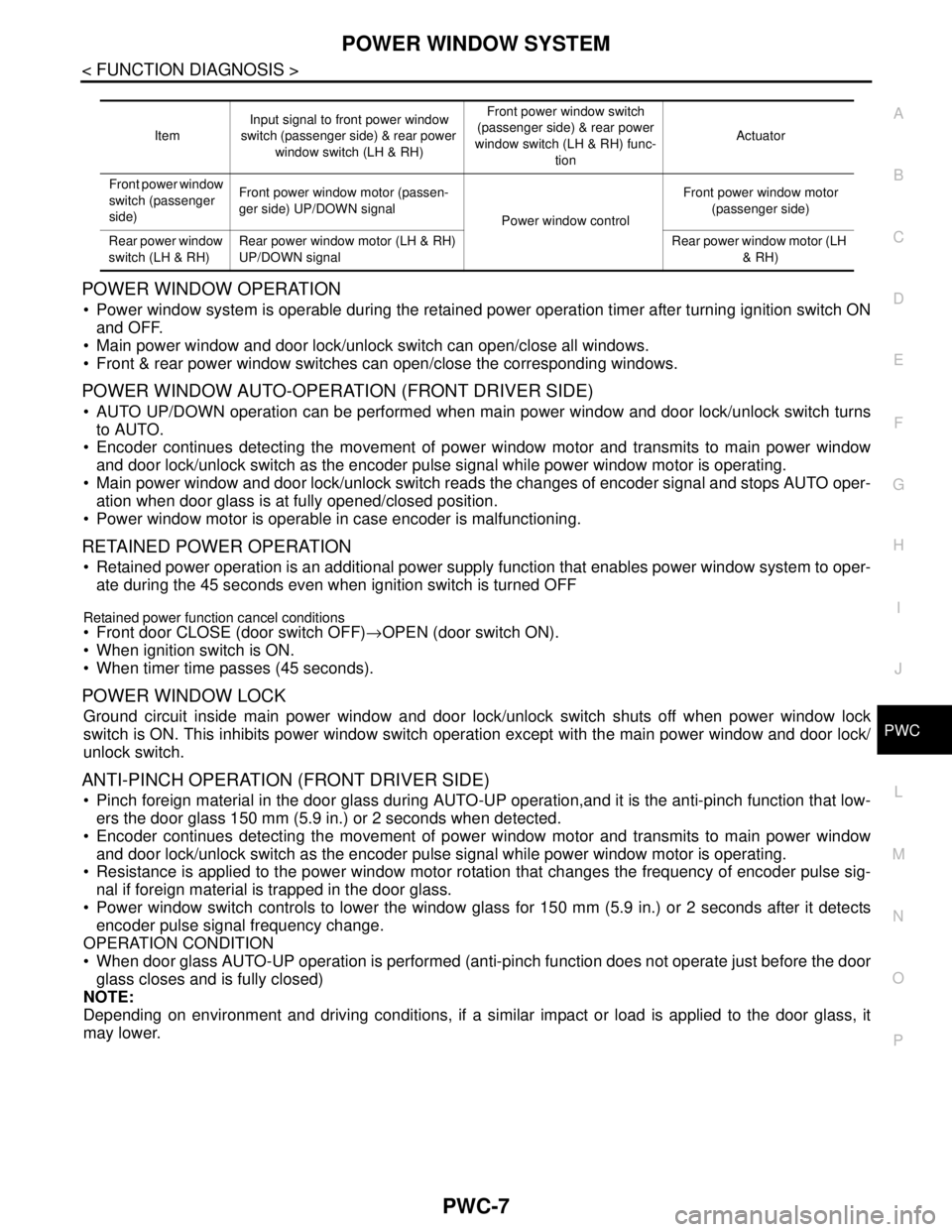

POWER WINDOW OPERATION

Power window system is operable during the retained power operation timer after turning ignition switch ON

and OFF.

Main power window and door lock/unlock switch can open/close all windows.

Front & rear power window switches can open/close the corresponding windows.

POWER WINDOW AUTO-OPERATION (FRONT DRIVER SIDE)

AUTO UP/DOWN operation can be performed when main power window and door lock/unlock switch turns

to AUTO.

Encoder continues detecting the movement of power window motor and transmits to main power window

and door lock/unlock switch as the encoder pulse signal while power window motor is operating.

Main power window and door lock/unlock switch reads the changes of encoder signal and stops AUTO oper-

ation when door glass is at fully opened/closed position.

Power window motor is operable in case encoder is malfunctioning.

RETAINED POWER OPERATION

Retained power operation is an additional power supply function that enables power window system to oper-

ate during the 45 seconds even when ignition switch is turned OFF

Retained power function cancel conditions Front door CLOSE (door switch OFF)→OPEN (door switch ON).

When ignition switch is ON.

When timer time passes (45 seconds).

POWER WINDOW LOCK

Ground circuit inside main power window and door lock/unlock switch shuts off when power window lock

switch is ON. This inhibits power window switch operation except with the main power window and door lock/

unlock switch.

ANTI-PINCH OPERATION (FRONT DRIVER SIDE)

Pinch foreign material in the door glass during AUTO-UP operation,and it is the anti-pinch function that low-

ers the door glass 150 mm (5.9 in.) or 2 seconds when detected.

Encoder continues detecting the movement of power window motor and transmits to main power window

and door lock/unlock switch as the encoder pulse signal while power window motor is operating.

Resistance is applied to the power window motor rotation that changes the frequency of encoder pulse sig-

nal if foreign material is trapped in the door glass.

Power window switch controls to lower the window glass for 150 mm (5.9 in.) or 2 seconds after it detects

encoder pulse signal frequency change.

OPERATION CONDITION

When door glass AUTO-UP operation is performed (anti-pinch function does not operate just before the door

glass closes and is fully closed)

NOTE:

Depending on environment and driving conditions, if a similar impact or load is applied to the door glass, it

may lower.

Item Input signal to front power window

switch (passenger side) & rear power

window switch (LH & RH)Front power window switch

(passenger side) & rear power

window switch (LH & RH) func-

tionActuator

Front power window

switch (passenger

side)Front power window motor (passen-

ger side) UP/DOWN signal

Power window controlFront power window motor

(passenger side)

Rear power window

switch (LH & RH)Rear power window motor (LH & RH)

UP/DOWN signalRear power window motor (LH

& RH)

Page 4469 of 5883

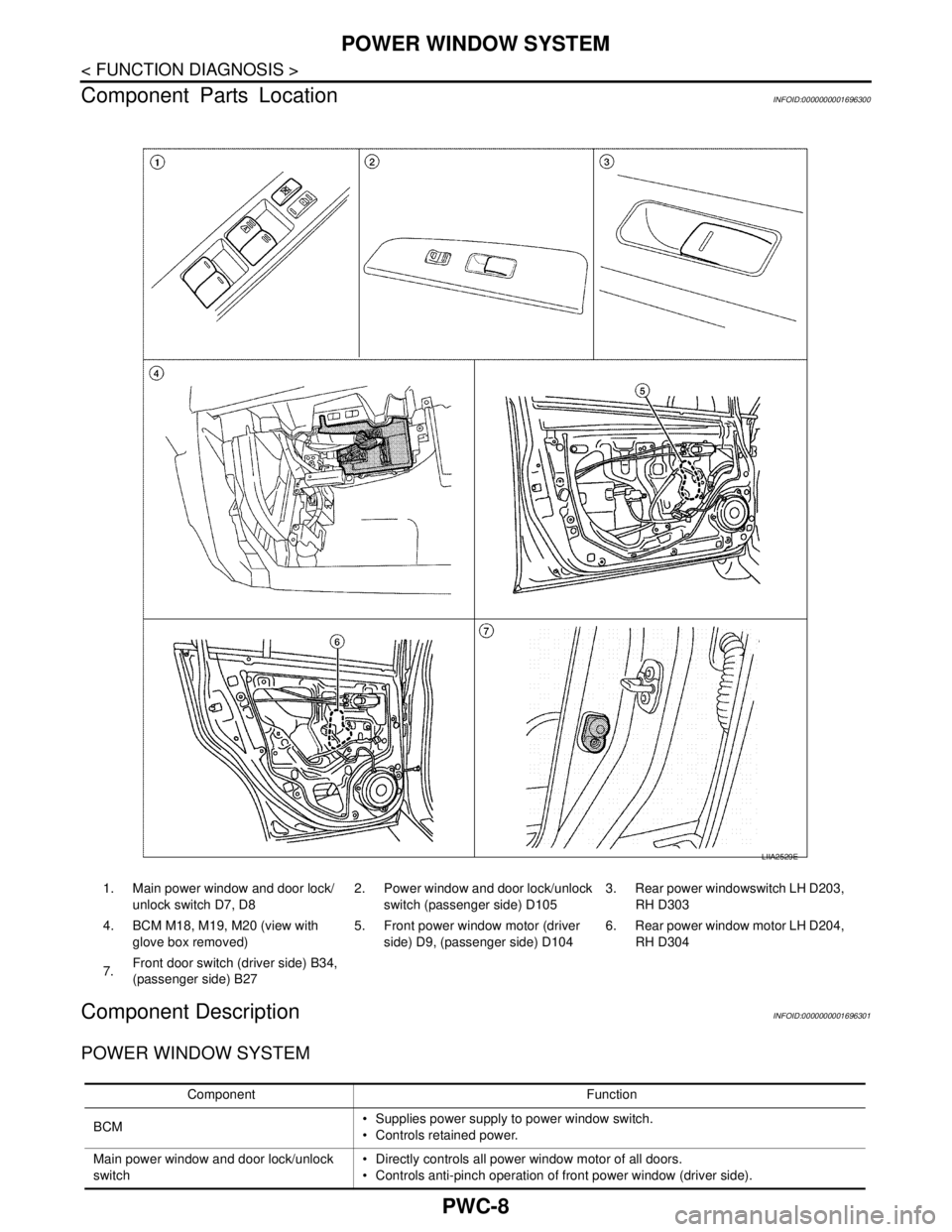

PWC-8

< FUNCTION DIAGNOSIS >

POWER WINDOW SYSTEM

Component Parts Location

INFOID:0000000001696300

Component DescriptionINFOID:0000000001696301

POWER WINDOW SYSTEM

LIIA2529E

1. Main power window and door lock/

unlock switch D7, D82. Power window and door lock/unlock

switch (passenger side) D1053. Rear power windowswitch LH D203,

RH D303

4. BCM M18, M19, M20 (view with

glove box removed)5. Front power window motor (driver

side) D9, (passenger side) D1046. Rear power window motor LH D204,

RH D304

7.Front door switch (driver side) B34,

(passenger side) B27

Component Function

BCM Supplies power supply to power window switch.

Controls retained power.

Main power window and door lock/unlock

switch Directly controls all power window motor of all doors.

Controls anti-pinch operation of front power window (driver side).

Page 4470 of 5883

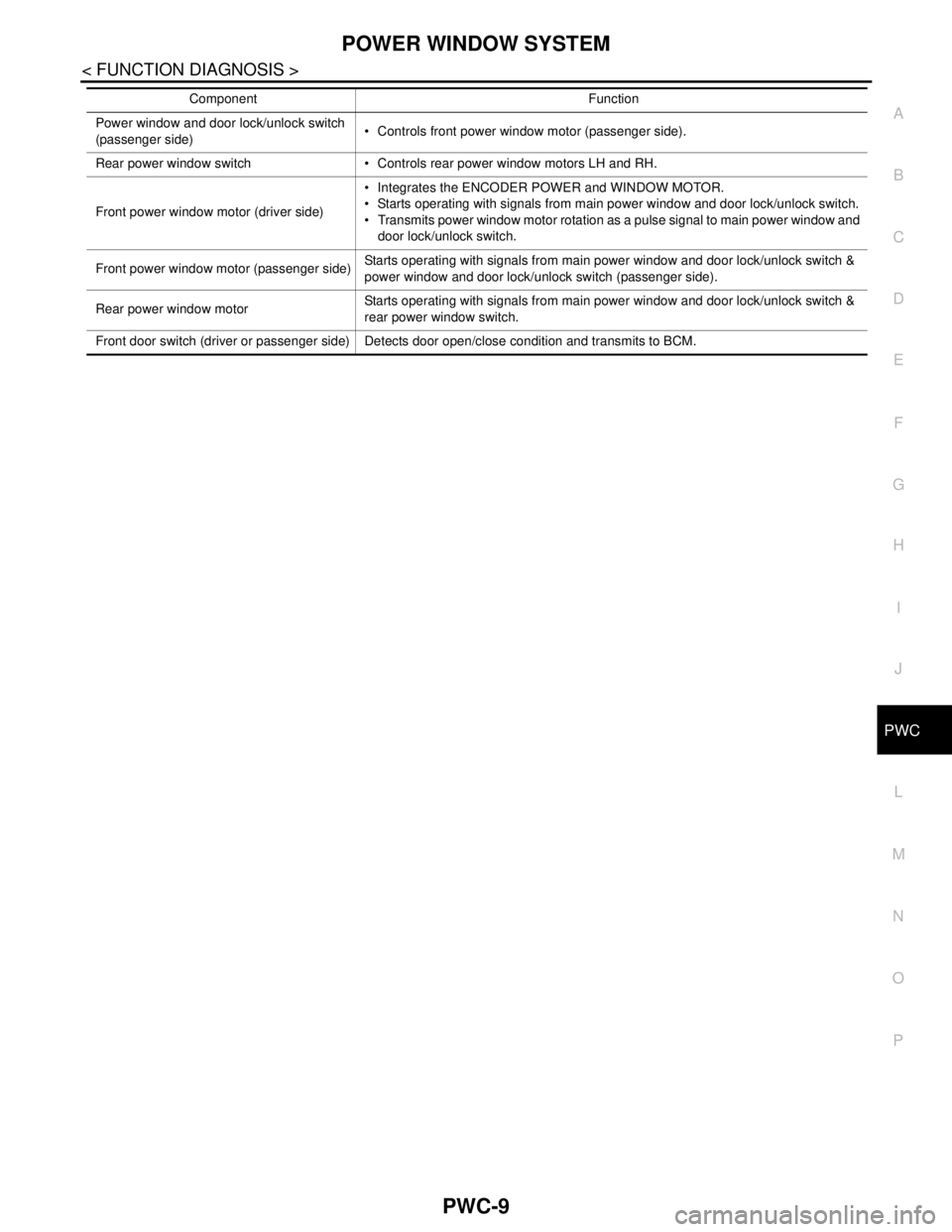

POWER WINDOW SYSTEM

PWC-9

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

PWC

N

O

P

Power window and door lock/unlock switch

(passenger side) Controls front power window motor (passenger side).

Rear power window switch Controls rear power window motors LH and RH.

Front power window motor (driver side) Integrates the ENCODER POWER and WINDOW MOTOR.

Starts operating with signals from main power window and door lock/unlock switch.

Transmits power window motor rotation as a pulse signal to main power window and

door lock/unlock switch.

Front power window motor (passenger side)Starts operating with signals from main power window and door lock/unlock switch &

power window and door lock/unlock switch (passenger side).

Rear power window motorStarts operating with signals from main power window and door lock/unlock switch &

rear power window switch.

Front door switch (driver or passenger side) Detects door open/close condition and transmits to BCM.Component Function