EC Engine Control System NISSAN TIIDA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 402 of 5883

![NISSAN TIIDA 2007 Service Owners Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-169

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

In case of an electrical malfunction with the ABS, the ABS warning lamp, VDC OFF i NISSAN TIIDA 2007 Service Owners Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-169

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

In case of an electrical malfunction with the ABS, the ABS warning lamp, VDC OFF i](/img/5/57395/w960_57395-401.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-169

< ECU DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

In case of an electrical malfunction with the ABS, the ABS warning lamp, VDC OFF indicator lamp and SLIP

indicator lamp will turn on. In case of an electrical malfunction with the EBD system, the BRAKE warning lamp,

ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp will turn on.

The system will revert to one of the following conditions of the Fail-Safe function.

1. For ABS malfunction, only the EBD is operative and the condition of the vehicle is the same condition of

vehicles without ABS/TCS/VDC system.

2. For EBD malfunction, the EBD and ABS become inoperative, and the condition of the vehicle is the same

as the condition of vehicles without ABS/TCS/VDC or EBD system.

VDC/TCS SYSTEM

In case of TCS/VDC system malfunction, the VDC OFF indicator lamp and SLIP indicator lamp are turned on

and the condition of the vehicle is the same as the condition of vehicles without TCS/VDC system. In case of

an electrical malfunction with the TCS/VDC system, the ABS control continues to operate normally without

TCS/VDC control.

DTC No. IndexINFOID:0000000001731199

DTC Items (CONSULT screen terms) Reference

C1101 RR RH SENSOR-1

BRC-30, "

Description"C1102 RR LH SENSOR-1

C1103 FR RH SENSOR-1

C1104 FR LH SENSOR-1

C1105 RR RH SENSOR-2

BRC-33, "

Description"C1106 RR LH SENSOR-2

C1107 FR RH SENSOR-2

C1108 FR LH SENSOR-2

C1109 BATTERY VOLTAGE [ABNORMAL]BRC-36, "

Description"

C1110 CONTROLLER FAILUREBRC-38, "DTC Logic"

C 1111 P U M P M O T O RBRC-39, "Description"

C1113 G-SENSORXX-XX, "*****"

C1115 ABS SENSOR [ABNORMAL SIGNAL]BRC-41, "Description"

C1116 STOP LAMP SWBRC-44, "Description"

C1120 FR LH IN ABS SOLBRC-46, "Description"

C1121 FR LH OUT ABS SOLBRC-49, "Description"

C1122 FR RH IN ABS SOLBRC-46, "Description"

C1123 FR RH OUT ABS SOLBRC-49, "Description"

C1124 RR LH IN ABS SOLBRC-46, "Description"

C1125 RR LH OUT ABS SOLBRC-49, "Description"

C1126 RR RH IN ABS SOLBRC-46, "Description"

C1127 RR RH OUT ABS SOLBRC-49, "Description"

C1130 ENGINE SIGNAL 1

BRC-52, "

Description"

C1131 ENGINE SIGNAL 2

C1132 ENGINE SIGNAL 3

C1133 ENGINE SIGNAL 4

C1136 ENGINE SIGNAL 6

C1140 ACTUATOR RLYBRC-54, "

Description"

C1142 PRESS SEN CIRCUITXX-XX, "*****"

C1143 ST ANG SEN CIRCUIT

XX-XX, "*****"

C1144 ST ANG SEN SIGNAL

Page 404 of 5883

![NISSAN TIIDA 2007 Service Owners Manual VDC/TCS/ABS

BRC-171

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SYMPTOM DIAGNOSIS

VDC/TCS/ABS

Symptom TableINFOID:0000000001731200

If ABS warning lamp, VDC OFF indicator lamp a NISSAN TIIDA 2007 Service Owners Manual VDC/TCS/ABS

BRC-171

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SYMPTOM DIAGNOSIS

VDC/TCS/ABS

Symptom TableINFOID:0000000001731200

If ABS warning lamp, VDC OFF indicator lamp a](/img/5/57395/w960_57395-403.png)

VDC/TCS/ABS

BRC-171

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SYMPTOM DIAGNOSIS

VDC/TCS/ABS

Symptom TableINFOID:0000000001731200

If ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp turn ON, perform self-diagnosis.

NOTE:

1: The ABS does not operate when the speed is 10 km/h (6 MPH) or less.

2: Under the following conditions, ABS is activated and vibration is felt when brake pedal is lightly depressed. However, this is normal.

- When shifting gears

- When driving on slippery road

- During cornering at high speed

- When passing over bumps or grooves [at approximately 50 mm (1.97 in) or more]

- When pulling away just after starting engine [at approximately 10 km/h (6 MPH) or higher]Symptom Check item Reference

Excessive ABS function operation fre-

quencyBrake force distribution

BRC-74, "

Diagno-

sis Procedure"Looseness of front and rear axle

Wheel sensor and rotor system

Unexpected pedal reactionBrake pedal stroke

BRC-75, "

Diagno-

sis Procedure"Make sure the braking force is sufficient when the ABS is not operating.

The braking distance is long Check stopping distance when the ABS is not operating.BRC-76, "

Diagno-

sis Procedure"

ABS function does not operate (Note 1) ABS actuator and electric unit (control unit)BRC-77, "Diagno-

sis Procedure"

Pedal vibration or ABS operation sound

occurs (Note 2)Brake pedal

BRC-78, "Diagno-

sis Procedure"ABS actuator and electric unit (control unit)

Vehicle jerks during VDC/TCS/ABS con-

trolABS actuator and electric unit (control unit)

XX-XX, "*****"

TCM

ECM

Page 412 of 5883

![NISSAN TIIDA 2007 Service Owners Manual PRECAUTIONS

BRC-179

< PRECAUTION >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO NISSAN TIIDA 2007 Service Owners Manual PRECAUTIONS

BRC-179

< PRECAUTION >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO](/img/5/57395/w960_57395-411.png)

PRECAUTIONS

BRC-179

< PRECAUTION >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001691411

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000001691412

Recommended fluid is Genuine NISSAN Fluid, DOT 3 or DOT 4 (US FMVSS No. 116).

Do not reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas such as body. If brake fluid is splashed, wipe it off and

flush area with water immediately.

Do not use mineral oils such as gasoline or kerosene to clean. They will ruin rubber parts and cause

improper operation.

Using a flare nut torque wrench, securely tighten brake tube flare

nuts.

Brake system is an important safety part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Before working, turn ignition switch OFF and disconnect electrical

connectors of ABS actuator and electric unit (control unit) or bat-

tery negative terminals.

When installing brake piping, be sure to check torque.

After removing/installing any hydraulic parts of the brake or ESP

system (such as actuator and piping parts, etc), bleed air from the

system.

Precaution for Brake ControlINFOID:0000000001691413

During ESP/TCS/ABS operation, brake pedal lightly vibrates and a mechanical noise may be heard. This is

normal.

When starting engine, or just after starting vehicle, brake pedal may vibrate or motor operating noise may be

heard from engine room. This is a normal status of operation check.

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

When an error is indicated by ABS or another warning lamp, collect all necessary information from the cus-

tomer (what symptoms are present under what conditions) and check for simple causes before starting diag-

nostic servicing. Besides the electrical system inspection, check booster operation, brake fluid level, and

fluid leaks.

If tire size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

If there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, ESP/TCS/ABS

function may have a malfunction or error.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR820BA

Page 427 of 5883

![NISSAN TIIDA 2007 Service Owners Manual CHG-6

< BASIC INSPECTION >[HR16DE]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to NISSAN TIIDA 2007 Service Owners Manual CHG-6

< BASIC INSPECTION >[HR16DE]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to](/img/5/57395/w960_57395-426.png)

CHG-6

< BASIC INSPECTION >[HR16DE]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to finish.

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-37, "

Inspection Procedure".

>> GO TO 2

2.DISABLE THE POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Disable the power generation voltage variable control with either of the following procedures.

After selecting “ENGINE” on the “SELECT SYSTEM” screen of CONSULT-III, set the “ALTERNATOR DUTY”

value to 0 % by selecting “ALTERNATOR DUTY” with “Active Test”. Continue “Active Test” until the end of

inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the

characteristic of the IC regulator of the generator.)

Turn the ignition switch OFF, disconnect the battery current sensor connector and leave it disconnected dur-

ing the course of the test.

NOTE:

Running the engine with the battery current sensor disconnected will cause DTC's (P1550-P1554) to set.

After finishing the inspection, connect the battery current sensor connector and erase the self-diagnostic

results history of the engine using CONSULT-III.

>> GO TO 3

3.DIAGNOSIS WITH STARTING/CHARGING SYSTEM TESTER

Perform the charging system test using Starting/Charging System Tester (J-44373). For details and operating

instructions, refer to Technical Service Bulletin.

Te s t r e s u l t

CHARGING SYSTEM NOMAL>>Charging system is normal and will also show “DIODE RIPPLE” test result.

NO CHARGING VOLTAGE>>GO TO 4

LOW CHARGING VOLTAGE>>GO TO 12

HIGH CHARGING VOLTAGE>>GO TO 14

DIODE RIPPLE NORMAL>>Diode ripple is OK and will also show “CHARGING VOLTAGE” test result.

EXCESS RIPPLE DETECTED>>Replace the generator. Perform “DIODE RIPPLE” test again using Starting/

Charging System Tester (J-44373) to confirm repair.

DIODE RIPPLE NOT DETECTED>>GO TO 4

4.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate?

YES >> GO TO 6

NO >> GO TO 5

5.TERMINAL“2” (OPEN) CIRCUIT INSPECTION

Check terminal “2” circuit for open circuits. Refer to CHG-39, "

Diagnosis Procedure".

Is the terminal

“2” circuit normal?

YES >> Replace generator.

NO >> Repair as needed.

6.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF?

YES >> GO TO 9

NO >> GO TO 7

7.TERMINAL “2”(SHORT) CIRCUIT INSPECTION

Check terminal “2” circuit for short to ground. Refer to CHG-39, "

Diagnosis Procedure".

Is the terminal

“2” circuit normal?

Page 432 of 5883

![NISSAN TIIDA 2007 Service Owners Manual CHG

L TERMINAL CIRCUIT

CHG-11

< COMPONENT DIAGNOSIS >[HR16DE]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724477

The terminal “2” (L) circuit controls the charge w NISSAN TIIDA 2007 Service Owners Manual CHG

L TERMINAL CIRCUIT

CHG-11

< COMPONENT DIAGNOSIS >[HR16DE]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724477

The terminal “2” (L) circuit controls the charge w](/img/5/57395/w960_57395-431.png)

CHG

L TERMINAL CIRCUIT

CHG-11

< COMPONENT DIAGNOSIS >[HR16DE]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724477

The terminal “2” (L) circuit controls the charge warning lamp. The charge warning lamp illuminates when the

ignition switch is set to ON or START. When the generator is providing sufficient voltage with the engine run-

ning, the charge warning lamp will go off. If the charge warning lamp illuminates with the engine running, a

malfunction is indicated.

Diagnosis ProcedureINFOID:0000000001724478

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Verify generator connector F2 terminal 2 is clean and tight.

Is the connection secure?

YES >> GO TO 2

NO >> Repair the connection. Confirm repair by performing complete Starting/Charging system test.

Refer to Technical Service Bulletin.

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector F2.

2. Apply ground to generator harness connector F2 terminal 2 with

the ignition switch in the ON position.

Does the charge lamp illuminate?

YES >> Check generator function. Refer to CHG-33, "Work

Flow".

NO >> GO TO 3

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect the generator connector F2 and combination meter

connector M24.

3. Check continuity between generator harness connector F2 (A)

terminal 2 and combination meter harness connector M24 (B)

terminal 38.

4. Check continuity between generator harness connector F2 ter-

minal 2 and ground.

Are the continuity results as specified?

YES >> Replace the combination meter. Refer to XX-XX, "*****".

NO >> Repair the harness or connector.Charge lamp should illuminate

ALMIA0200ZZ

AB

Continuity

Connector Terminal Connector Terminal

F2 2 M24 38 Yes

A

—

Continuity

Connector Terminal

F2 2 Ground No

ALMIA0326GB

Page 441 of 5883

![NISSAN TIIDA 2007 Service Owners Manual CHG-20

< BASIC INSPECTION >[MR18DE]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start t NISSAN TIIDA 2007 Service Owners Manual CHG-20

< BASIC INSPECTION >[MR18DE]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start t](/img/5/57395/w960_57395-440.png)

CHG-20

< BASIC INSPECTION >[MR18DE]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to finish.

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-37, "

Inspection Procedure".

>> GO TO 2

2.DISABLE THE POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Disable the power generation voltage variable control with either of the following procedures.

After selecting “ENGINE” on the “SELECT SYSTEM” screen of CONSULT-III, set the “ALTERNATOR DUTY”

value to 0 % by selecting “ALTERNATOR DUTY” with “Active Test”. Continue “Active Test” until the end of

inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the

characteristic of the IC regulator of the generator.)

Turn the ignition switch OFF, disconnect the battery current sensor connector and leave it disconnected dur-

ing the course of the test.

NOTE:

Running the engine with the battery current sensor disconnected will cause DTC's (P1550-P1554) to set.

After finishing the inspection, connect the battery current sensor connector and erase the self-diagnostic

results history of the engine using CONSULT-III.

>> GO TO 3

3.DIAGNOSIS WITH STARTING/CHARGING SYSTEM TESTER

Perform the charging system test using Starting/Charging System Tester (J-44373). For details and operating

instructions, refer to Technical Service Bulletin.

Te s t r e s u l t

CHARGING SYSTEM NOMAL>>Charging system is normal and will also show “DIODE RIPPLE” test result.

NO CHARGING VOLTAGE>>GO TO 4

LOW CHARGING VOLTAGE>>GO TO 12

HIGH CHARGING VOLTAGE>>GO TO 14

DIODE RIPPLE NORMAL>>Diode ripple is OK and will also show “CHARGING VOLTAGE” test result.

EXCESS RIPPLE DETECTED>>Replace the generator. Perform “DIODE RIPPLE” test again using Starting/

Charging System Tester (J-44373) to confirm repair.

DIODE RIPPLE NOT DETECTED>>GO TO 4

4.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate?

YES >> GO TO 6

NO >> GO TO 5

5.TERMINAL“2” (OPEN) CIRCUIT INSPECTION

Check terminal “2” circuit for open circuits. Refer to CHG-39, "

Diagnosis Procedure".

Is the terminal

“2” circuit normal?

YES >> Replace generator.

NO >> Repair as needed.

6.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF?

YES >> GO TO 9

NO >> GO TO 7

7.TERMINAL “2”(SHORT) CIRCUIT INSPECTION

Check terminal “2” circuit for short to ground. Refer to CHG-39, "

Diagnosis Procedure".

Is the terminal

“2” circuit normal?

Page 446 of 5883

![NISSAN TIIDA 2007 Service Owners Manual CHG

L TERMINAL CIRCUIT

CHG-25

< COMPONENT DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724528

The terminal “2” (L) circuit controls the charge w NISSAN TIIDA 2007 Service Owners Manual CHG

L TERMINAL CIRCUIT

CHG-25

< COMPONENT DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724528

The terminal “2” (L) circuit controls the charge w](/img/5/57395/w960_57395-445.png)

CHG

L TERMINAL CIRCUIT

CHG-25

< COMPONENT DIAGNOSIS >[MR18DE]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724528

The terminal “2” (L) circuit controls the charge warning lamp. The charge warning lamp illuminates when the

ignition switch is set to ON or START. When the generator is providing sufficient voltage with the engine run-

ning, the charge warning lamp will go off. If the charge warning lamp illuminates with the engine running, a

malfunction is indicated.

Diagnosis ProcedureINFOID:0000000001724529

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Verify generator connector F2 terminal 2 is clean and tight.

Is the connection secure?

YES >> GO TO 2

NO >> Repair the connection. Confirm repair by performing complete Starting/Charging system test.

Refer to Technical Service Bulletin.

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector F2.

2. Apply ground to generator harness connector F2 terminal 2 with

the ignition switch in the ON position.

Does the charge lamp illuminate?

YES >> Check generator function. Refer to CHG-33, "Work

Flow".

NO >> GO TO 3

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect the generator connector F2 and combination meter

connector M24.

3. Check continuity between generator harness connector F2 (A)

terminal 2 and combination meter harness connector M24 (B)

terminal 38.

4. Check continuity between generator harness connector F2 ter-

minal 2 and ground.

Are the continuity results as specified?

YES >> Replace the combination meter. Refer to XX-XX, "*****".

NO >> Repair the harness or connector.Charge lamp should illuminate

ALMIA0200ZZ

AB

Continuity

Connector Terminal Connector Terminal

F2 2 M24 38 Yes

A

—

Continuity

Connector Terminal

F2 2 Ground No

ALMIA0326GB

Page 455 of 5883

![NISSAN TIIDA 2007 Service Owners Manual CHG-34

< BASIC INSPECTION >[K9K]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to f NISSAN TIIDA 2007 Service Owners Manual CHG-34

< BASIC INSPECTION >[K9K]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to f](/img/5/57395/w960_57395-454.png)

CHG-34

< BASIC INSPECTION >[K9K]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to finish.

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-37, "

Inspection Procedure".

>> GO TO 2

2.DISABLE THE POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Disable the power generation voltage variable control with either of the following procedures.

After selecting “ENGINE” on the “SELECT SYSTEM” screen of CONSULT-III, set the “ALTERNATOR DUTY”

value to 0 % by selecting “ALTERNATOR DUTY” with “Active Test”. Continue “Active Test” until the end of

inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the

characteristic of the IC regulator of the generator.)

Turn the ignition switch OFF, disconnect the battery current sensor connector and leave it disconnected dur-

ing the course of the test.

NOTE:

Running the engine with the battery current sensor disconnected will cause DTC's (P1550-P1554) to set.

After finishing the inspection, connect the battery current sensor connector and erase the self-diagnostic

results history of the engine using CONSULT-III.

>> GO TO 3

3.DIAGNOSIS WITH STARTING/CHARGING SYSTEM TESTER

Perform the charging system test using Starting/Charging System Tester (J-44373). For details and operating

instructions, refer to Technical Service Bulletin.

Te s t r e s u l t

CHARGING SYSTEM NOMAL>>Charging system is normal and will also show “DIODE RIPPLE” test result.

NO CHARGING VOLTAGE>>GO TO 4

LOW CHARGING VOLTAGE>>GO TO 12

HIGH CHARGING VOLTAGE>>GO TO 14

DIODE RIPPLE NORMAL>>Diode ripple is OK and will also show “CHARGING VOLTAGE” test result.

EXCESS RIPPLE DETECTED>>Replace the generator. Perform “DIODE RIPPLE” test again using Starting/

Charging System Tester (J-44373) to confirm repair.

DIODE RIPPLE NOT DETECTED>>GO TO 4

4.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate?

YES >> GO TO 6

NO >> GO TO 5

5.TERMINAL“2” (OPEN) CIRCUIT INSPECTION

Check terminal “2” circuit for open circuits. Refer to CHG-39, "

Diagnosis Procedure".

Is the terminal

“2” circuit normal?

YES >> Replace generator.

NO >> Repair as needed.

6.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF?

YES >> GO TO 9

NO >> GO TO 7

7.TERMINAL “2”(SHORT) CIRCUIT INSPECTION

Check terminal “2” circuit for short to ground. Refer to CHG-39, "

Diagnosis Procedure".

Is the terminal

“2” circuit normal?

Page 460 of 5883

![NISSAN TIIDA 2007 Service Owners Manual CHG

L TERMINAL CIRCUIT

CHG-39

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724511

The terminal “2” (L) circuit controls the charge warn NISSAN TIIDA 2007 Service Owners Manual CHG

L TERMINAL CIRCUIT

CHG-39

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724511

The terminal “2” (L) circuit controls the charge warn](/img/5/57395/w960_57395-459.png)

CHG

L TERMINAL CIRCUIT

CHG-39

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724511

The terminal “2” (L) circuit controls the charge warning lamp. The charge warning lamp illuminates when the

ignition switch is set to ON or START. When the generator is providing sufficient voltage with the engine run-

ning, the charge warning lamp will go off. If the charge warning lamp illuminates with the engine running, a

malfunction is indicated.

Diagnosis ProcedureINFOID:0000000001724512

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Verify generator connector F1 terminal 2 is clean and tight.

Is the connection secure?

YES >> GO TO 2

NO >> Repair the connection. Confirm repair by performing complete Starting/Charging system test.

Refer to Technical Service Bulletin.

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector F1.

2. Apply ground to generator harness connector F1 terminal 2 with

the ignition switch in the ON position.

Does the charge lamp illuminate?

YES >> Check generator function. Refer to CHG-33, "Work

Flow".

NO >> GO TO 3

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect the generator connector F1 and combination meter

connector M24.

3. Check continuity between generator harness connector F1 ter-

minal 2 and combination meter harness connector M24 terminal

38.

4. Check continuity between generator harness connector F1 ter-

minal 2 and ground.

Are the continuity results as specified?

YES >> Replace the combination meter. Refer to XX-XX, "*****".

NO >> Repair the harness or connector.Charge lamp should illuminate

ALMIA0328GB

Terminal Terminal

Continuity

Connector Terminal Connector Terminal

F1 2 M24 38 Yes

Te r , m i n a l

—

Continuity

Connector Terminal

F1 2 Ground No

ALMIA0329GB

Page 483 of 5883

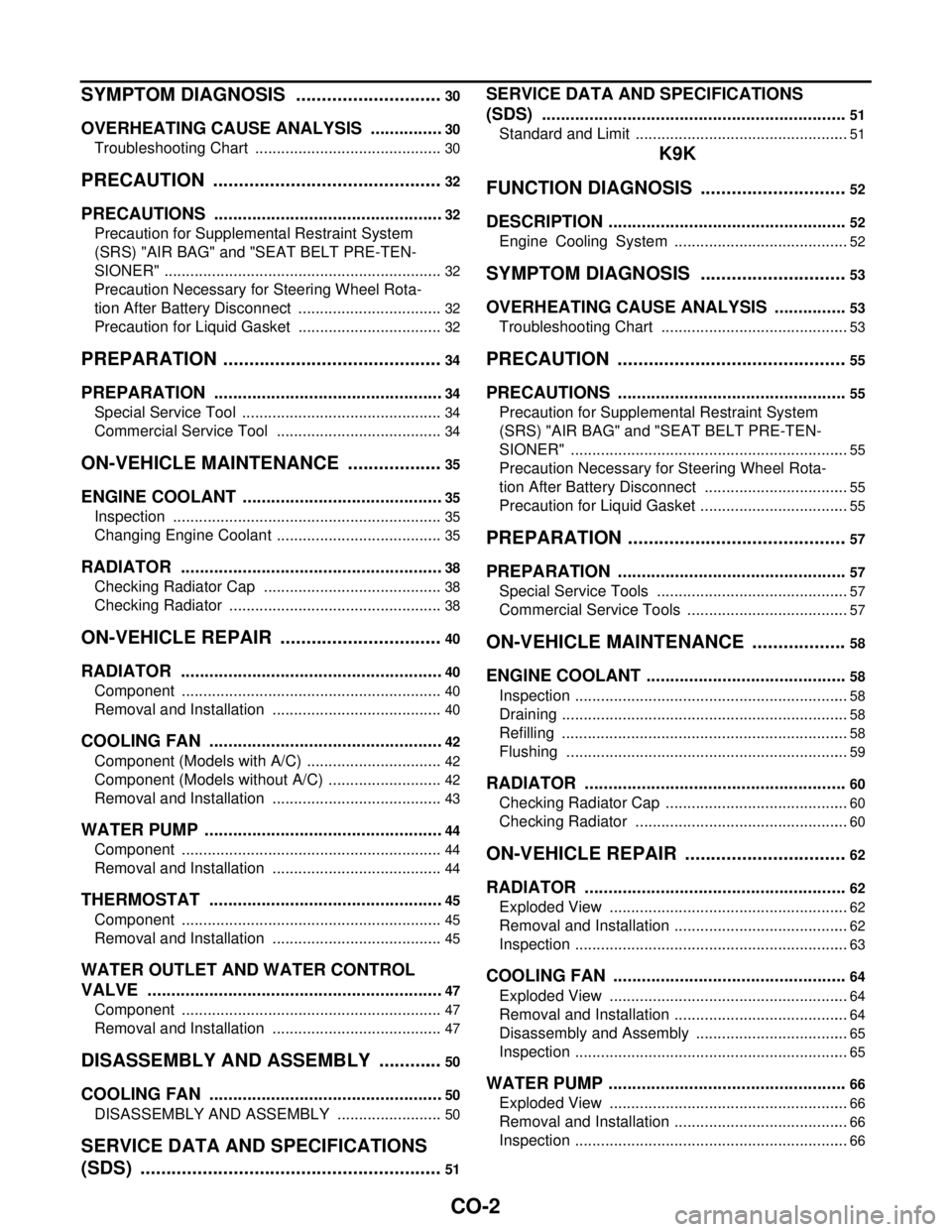

CO-2

SYMPTOM DIAGNOSIS .............................30

OVERHEATING CAUSE ANALYSIS ................30

Troubleshooting Chart ............................................30

PRECAUTION .............................................32

PRECAUTIONS .................................................32

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

32

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

32

Precaution for Liquid Gasket ..................................32

PREPARATION ...........................................34

PREPARATION .................................................34

Special Service Tool ...............................................34

Commercial Service Tool .......................................34

ON-VEHICLE MAINTENANCE ...................35

ENGINE COOLANT ...........................................35

Inspection ...............................................................35

Changing Engine Coolant .......................................35

RADIATOR ........................................................38

Checking Radiator Cap ..........................................38

Checking Radiator ..................................................38

ON-VEHICLE REPAIR ................................40

RADIATOR ........................................................40

Component .............................................................40

Removal and Installation ........................................40

COOLING FAN ..................................................42

Component (Models with A/C) ................................42

Component (Models without A/C) ...........................42

Removal and Installation ........................................43

WATER PUMP ...................................................44

Component .............................................................44

Removal and Installation ........................................44

THERMOSTAT ..................................................45

Component .............................................................45

Removal and Installation ........................................45

WATER OUTLET AND WATER CONTROL

VALVE ...............................................................

47

Component .............................................................47

Removal and Installation ........................................47

DISASSEMBLY AND ASSEMBLY .............50

COOLING FAN ..................................................50

DISASSEMBLY AND ASSEMBLY .........................50

SERVICE DATA AND SPECIFICATIONS

(SDS) ...........................................................

51

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

51

Standard and Limit ..................................................51

K9K

FUNCTION DIAGNOSIS ............................

52

DESCRIPTION ...................................................52

Engine Cooling System .........................................52

SYMPTOM DIAGNOSIS ............................53

OVERHEATING CAUSE ANALYSIS ................53

Troubleshooting Chart ............................................53

PRECAUTION ............................................55

PRECAUTIONS .................................................55

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

55

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

55

Precaution for Liquid Gasket ...................................55

PREPARATION ..........................................57

PREPARATION .................................................57

Special Service Tools .............................................57

Commercial Service Tools ......................................57

ON-VEHICLE MAINTENANCE ..................58

ENGINE COOLANT ...........................................58

Inspection ................................................................58

Draining ...................................................................58

Refilling ...................................................................58

Flushing ..................................................................59

RADIATOR ........................................................60

Checking Radiator Cap ...........................................60

Checking Radiator ..................................................60

ON-VEHICLE REPAIR ...............................62

RADIATOR ........................................................62

Exploded View ........................................................62

Removal and Installation .........................................62

Inspection ................................................................63

COOLING FAN ..................................................64

Exploded View ........................................................64

Removal and Installation .........................................64

Disassembly and Assembly ....................................65

Inspection ................................................................65

WATER PUMP ...................................................66

Exploded View ........................................................66

Removal and Installation .........................................66

Inspection ................................................................66