boot NISSAN TIIDA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3157 of 5883

FRONT DRIVE SHAFT

FAX-23

< DISASSEMBLY AND ASSEMBLY >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

2. Pull and tighten the boot band using suitable tool until both

pawls of boot band are secured in the boot band grooves.

CAUTION:

Do not reuse boot band.

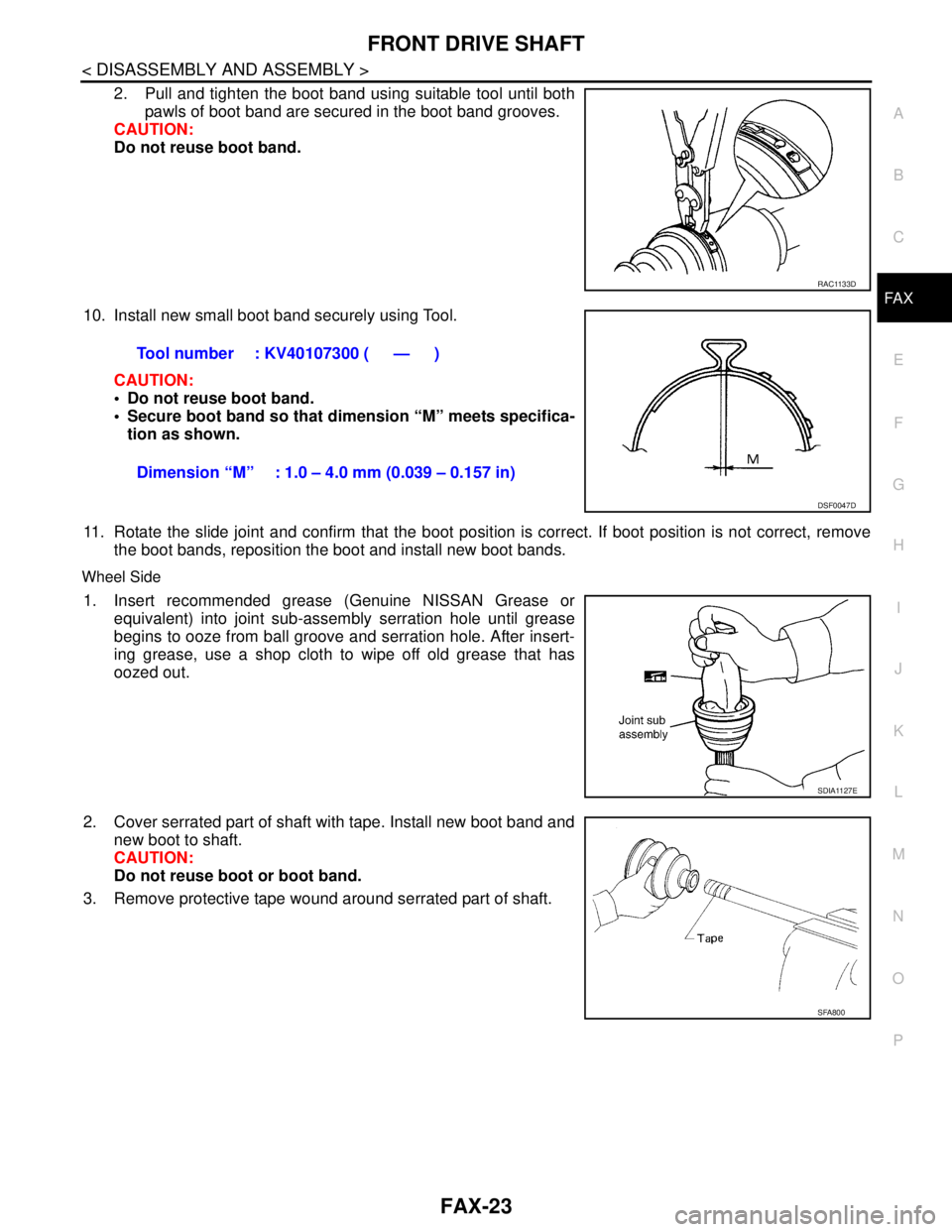

10. Install new small boot band securely using Tool.

CAUTION:

Do not reuse boot band.

Secure boot band so that dimension “M” meets specifica-

tion as shown.

11. Rotate the slide joint and confirm that the boot position is correct. If boot position is not correct, remove

the boot bands, reposition the boot and install new boot bands.

Wheel Side

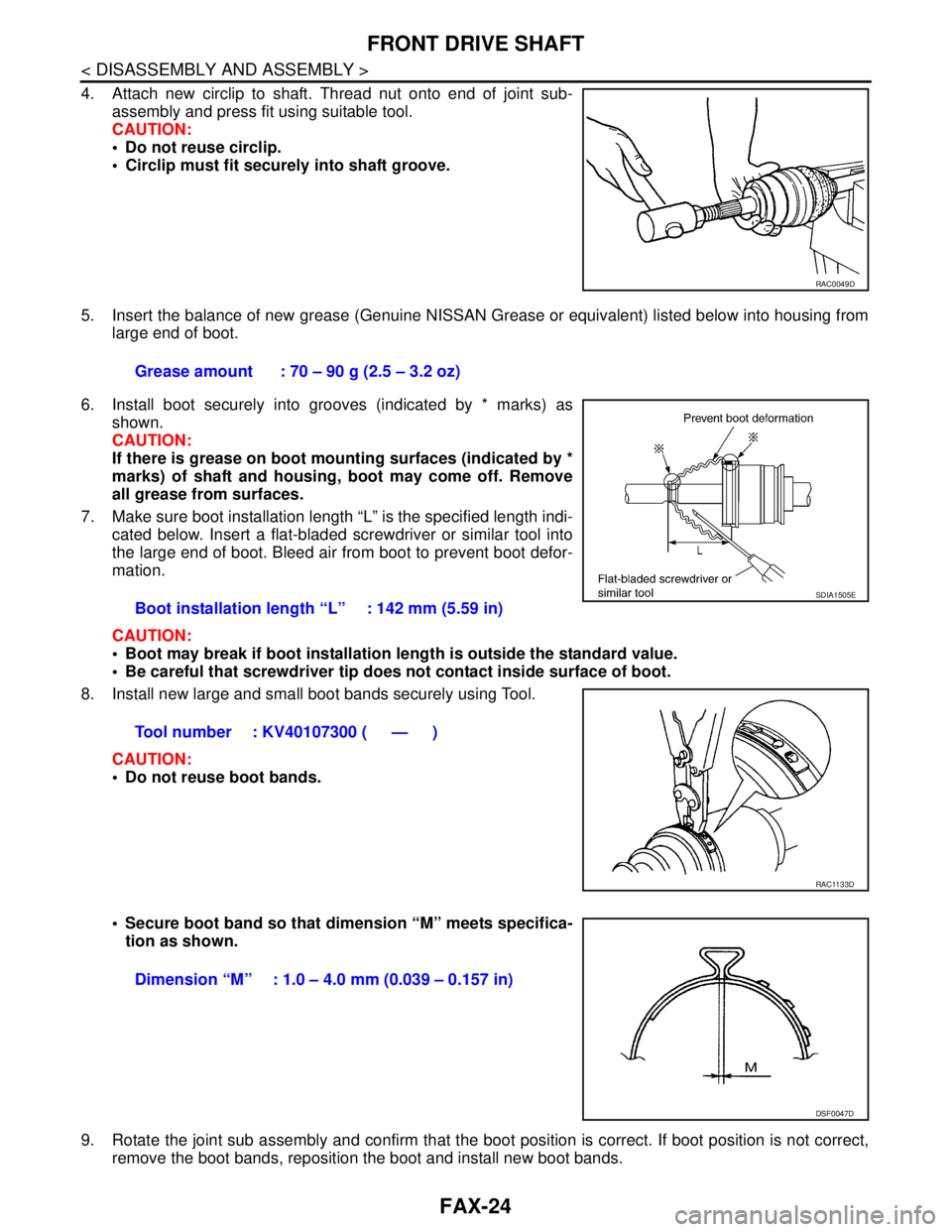

1. Insert recommended grease (Genuine NISSAN Grease or

equivalent) into joint sub-assembly serration hole until grease

begins to ooze from ball groove and serration hole. After insert-

ing grease, use a shop cloth to wipe off old grease that has

oozed out.

2. Cover serrated part of shaft with tape. Install new boot band and

new boot to shaft.

CAUTION:

Do not reuse boot or boot band.

3. Remove protective tape wound around serrated part of shaft.

RAC1133D

Tool number : KV40107300 ( — )

Dimension “M” : 1.0 – 4.0 mm (0.039 – 0.157 in)

DSF0047D

SDIA1127E

SFA800

Page 3158 of 5883

FAX-24

< DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

4. Attach new circlip to shaft. Thread nut onto end of joint sub-

assembly and press fit using suitable tool.

CAUTION:

Do not reuse circlip.

Circlip must fit securely into shaft groove.

5. Insert the balance of new grease (Genuine NISSAN Grease or equivalent) listed below into housing from

large end of boot.

6. Install boot securely into grooves (indicated by * marks) as

shown.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of shaft and housing, boot may come off. Remove

all grease from surfaces.

7. Make sure boot installation length “L” is the specified length indi-

cated below. Insert a flat-bladed screwdriver or similar tool into

the large end of boot. Bleed air from boot to prevent boot defor-

mation.

CAUTION:

Boot may break if boot installation length is outside the standard value.

Be careful that screwdriver tip does not contact inside surface of boot.

8. Install new large and small boot bands securely using Tool.

CAUTION:

Do not reuse boot bands.

Secure boot band so that dimension “M” meets specifica-

tion as shown.

9. Rotate the joint sub assembly and confirm that the boot position is correct. If boot position is not correct,

remove the boot bands, reposition the boot and install new boot bands.

RAC0049D

Grease amount : 70 – 90 g (2.5 – 3.2 oz)

Boot installation length “L” : 142 mm (5.59 in)

Tool number : KV40107300 ( — )

SDIA1505E

RAC1133D

Dimension “M” : 1.0 – 4.0 mm (0.039 – 0.157 in)

DSF0047D

Page 3160 of 5883

FAX-26

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

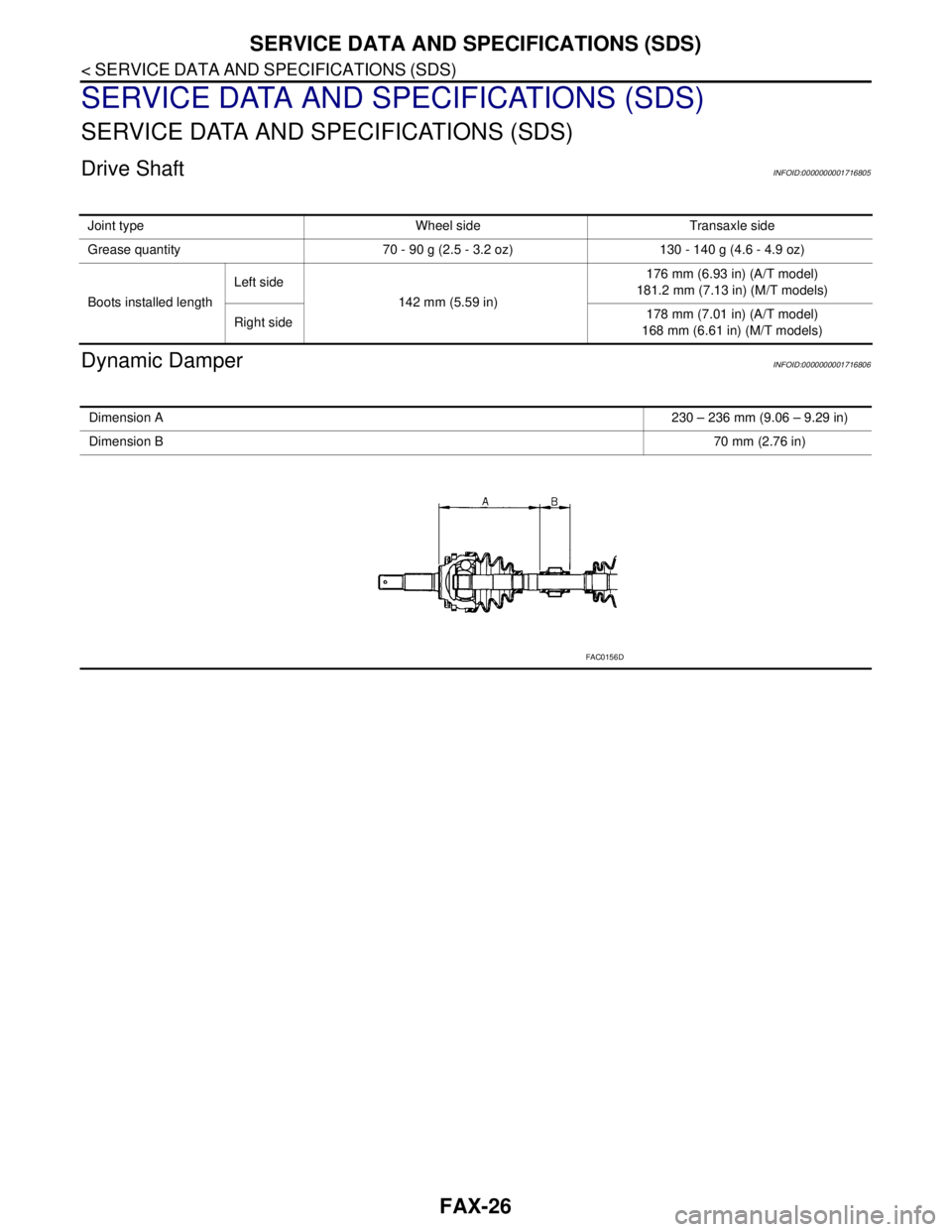

Drive ShaftINFOID:0000000001716805

Dynamic DamperINFOID:0000000001716806

Joint type Wheel side Transaxle side

Grease quantity 70 - 90 g (2.5 - 3.2 oz) 130 - 140 g (4.6 - 4.9 oz)

Boots installed lengthLeft side

142 mm (5.59 in)176 mm (6.93 in) (A/T model)

181.2 mm (7.13 in) (M/T models)

Right side178 mm (7.01 in) (A/T model)

168 mm (6.61 in) (M/T models)

Dimension A230 – 236 mm (9.06 – 9.29 in)

Dimension B70 mm (2.76 in)

FAC0156D

Page 3182 of 5883

FSU-6

< ON-VEHICLE MAINTENANCE >

FRONT SUSPENSION ASSEMBLY

ON-VEHICLE MAINTENANCE

FRONT SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000001716890

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

INSPECTION OF LOWER BALL JOINT END PLAY

1. Set front wheels in a straight-ahead position. Do not depress brake pedal.

2. Place an iron bar or similar tool between transverse link and steering knuckle.

3. Measure axial end play by prying it up and down.

CAUTION:

Be careful not to damage ball joint boot. Do not damage the installation position by applying

excessive force.

STRUT INSPECTION

Check for oil leakage, damage and replace as necessary.

Wheel Alignment InspectionINFOID:0000000001716891

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-5, "

Inspection" .

4. Check the wheel bearing axial end play. Refer to FA X - 5 , "

On-Vehicle Inspection and Service" .

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-18, "

Wheelarch Height (Unladen*)" .

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

This type of alignment is recommended for any NISSAN vehicle.

The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

The alignment machine itself should be capable of accepting any NISSAN vehicle.

The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated.

Your alignment machine should be regularly calibrated in order to give correct information.

Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-17, "Wheel

Alignment (Unladen*)" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators. Axial end play : 0 mm (0 in)

Page 3187 of 5883

FRONT SUSPENSION ASSEMBLY

FSU-11

< REMOVAL AND INSTALLATION >

C

D

F

G

H

I

J

K

L

MA

B

FSU

N

O

P

REMOVAL AND INSTALLATION

FRONT SUSPENSION ASSEMBLY

Removal and InstallationINFOID:0000000001716901

REMOVAL

1. Separate intermediate shaft from steering gear pinion shaft. Refer to ST-9, "Removal and Installation".

2. Remove front tires from vehicle using a power tool.

3. Remove wheel sensor from steering knuckle. Refer to BRC-182, "

Removal and Installation".

CAUTION:

Do not pull on wheel sensor harness.

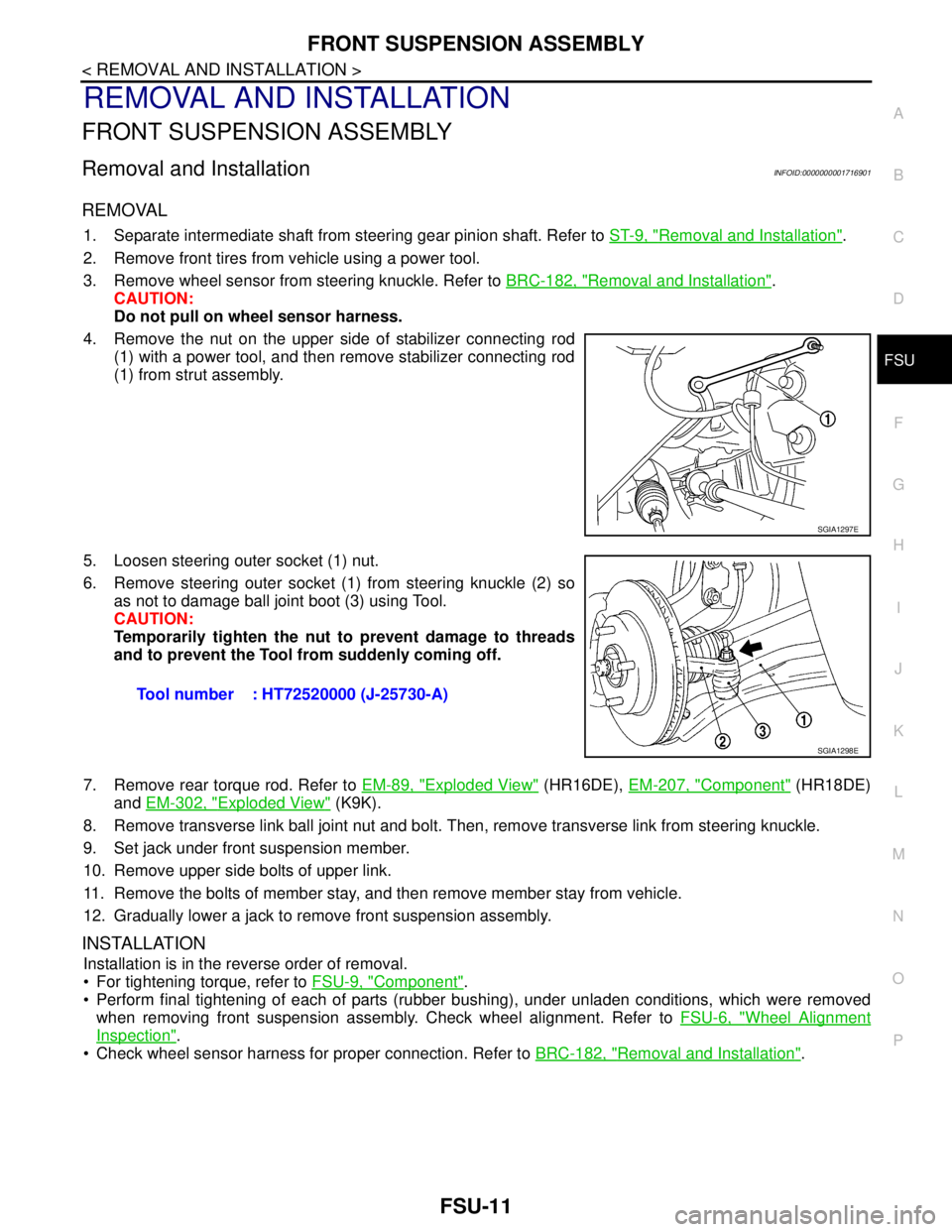

4. Remove the nut on the upper side of stabilizer connecting rod

(1) with a power tool, and then remove stabilizer connecting rod

(1) from strut assembly.

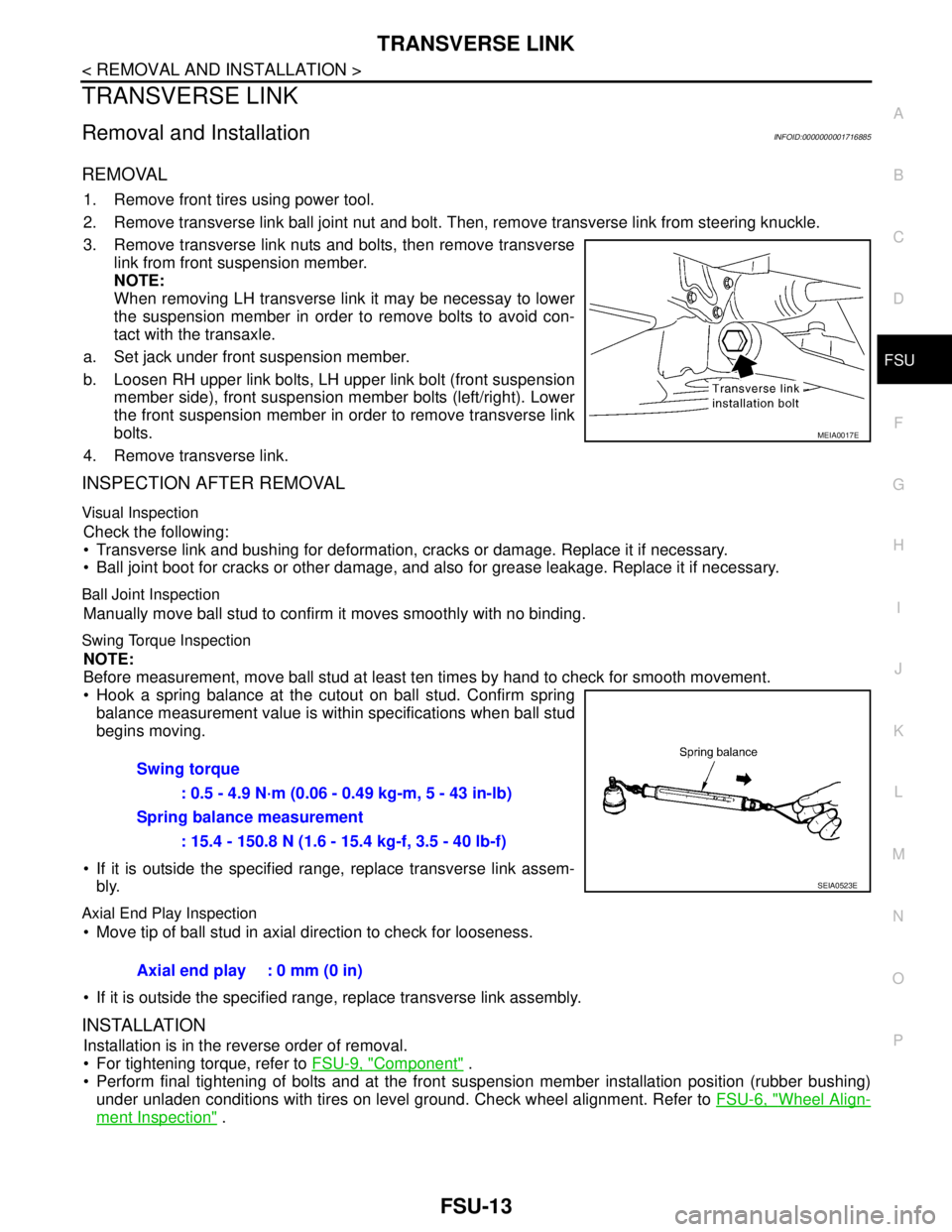

5. Loosen steering outer socket (1) nut.

6. Remove steering outer socket (1) from steering knuckle (2) so

as not to damage ball joint boot (3) using Tool.

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the Tool from suddenly coming off.

7. Remove rear torque rod. Refer to EM-89, "

Exploded View" (HR16DE), EM-207, "Component" (HR18DE)

and EM-302, "

Exploded View" (K9K).

8. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

9. Set jack under front suspension member.

10. Remove upper side bolts of upper link.

11. Remove the bolts of member stay, and then remove member stay from vehicle.

12. Gradually lower a jack to remove front suspension assembly.

INSTALLATION

Installation is in the reverse order of removal.

For tightening torque, refer to FSU-9, "

Component".

Perform final tightening of each of parts (rubber bushing), under unladen conditions, which were removed

when removing front suspension assembly. Check wheel alignment. Refer to FSU-6, "

Wheel Alignment

Inspection".

Check wheel sensor harness for proper connection. Refer to BRC-182, "

Removal and Installation".

SGIA1297E

Tool number : HT72520000 (J-25730-A)

SGIA1298E

Page 3189 of 5883

TRANSVERSE LINK

FSU-13

< REMOVAL AND INSTALLATION >

C

D

F

G

H

I

J

K

L

MA

B

FSU

N

O

P

TRANSVERSE LINK

Removal and InstallationINFOID:0000000001716885

REMOVAL

1. Remove front tires using power tool.

2. Remove transverse link ball joint nut and bolt. Then, remove transverse link from steering knuckle.

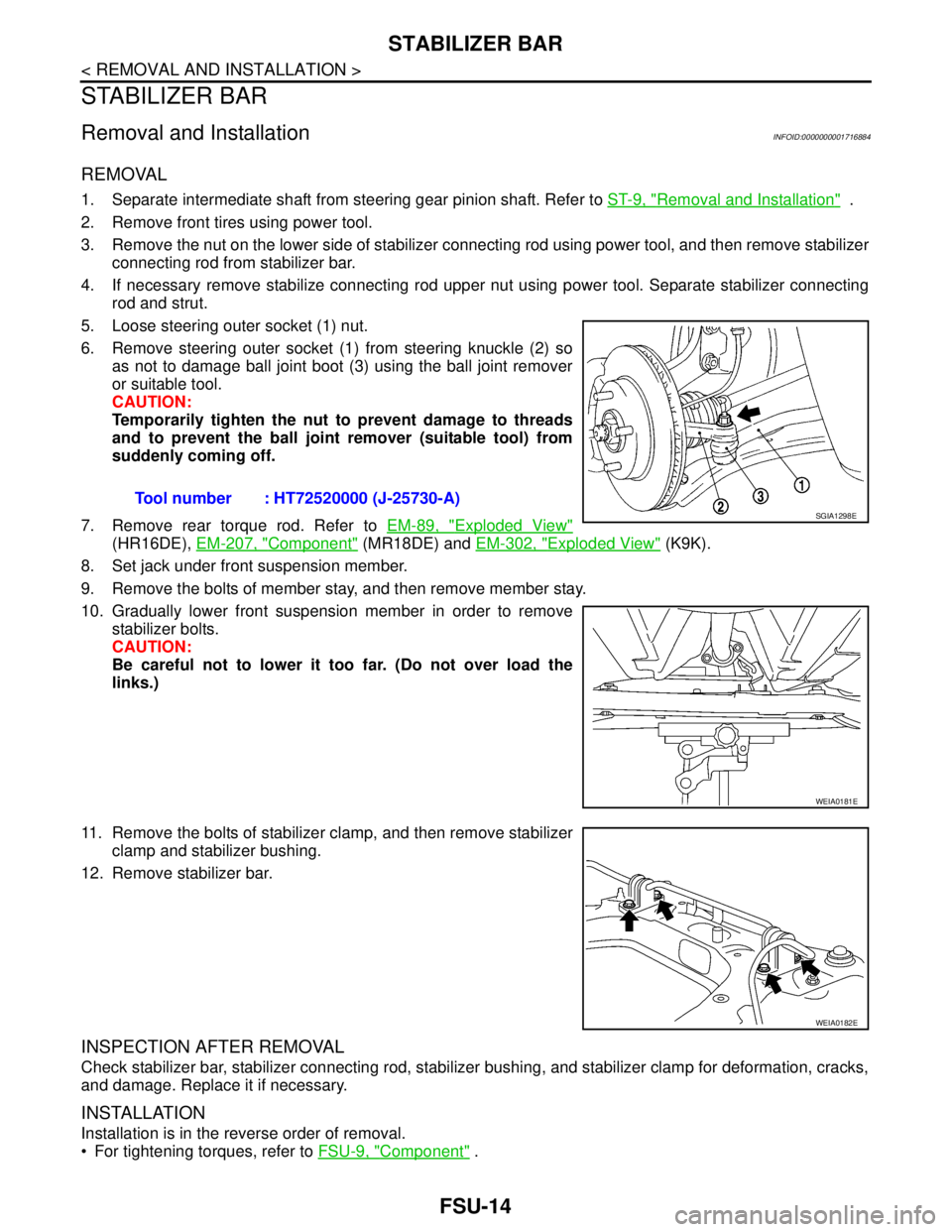

3. Remove transverse link nuts and bolts, then remove transverse

link from front suspension member.

NOTE:

When removing LH transverse link it may be necessay to lower

the suspension member in order to remove bolts to avoid con-

tact with the transaxle.

a. Set jack under front suspension member.

b. Loosen RH upper link bolts, LH upper link bolt (front suspension

member side), front suspension member bolts (left/right). Lower

the front suspension member in order to remove transverse link

bolts.

4. Remove transverse link.

INSPECTION AFTER REMOVAL

Visual Inspection

Check the following:

Transverse link and bushing for deformation, cracks or damage. Replace it if necessary.

Ball joint boot for cracks or other damage, and also for grease leakage. Replace it if necessary.

Ball Joint Inspection

Manually move ball stud to confirm it moves smoothly with no binding.

Swing Torque Inspection

NOTE:

Before measurement, move ball stud at least ten times by hand to check for smooth movement.

Hook a spring balance at the cutout on ball stud. Confirm spring

balance measurement value is within specifications when ball stud

begins moving.

If it is outside the specified range, replace transverse link assem-

bly.

Axial End Play Inspection

Move tip of ball stud in axial direction to check for looseness.

If it is outside the specified range, replace transverse link assembly.

INSTALLATION

Installation is in the reverse order of removal.

For tightening torque, refer to FSU-9, "

Component" .

Perform final tightening of bolts and at the front suspension member installation position (rubber bushing)

under unladen conditions with tires on level ground. Check wheel alignment. Refer to FSU-6, "

Wheel Align-

ment Inspection" .

MEIA0017E

Swing torque

: 0.5 - 4.9 N·m (0.06 - 0.49 kg-m, 5 - 43 in-lb)

Spring balance measurement

: 15.4 - 150.8 N (1.6 - 15.4 kg-f, 3.5 - 40 lb-f)

SEIA0523E

Axial end play : 0 mm (0 in)

Page 3190 of 5883

FSU-14

< REMOVAL AND INSTALLATION >

STABILIZER BAR

STABILIZER BAR

Removal and InstallationINFOID:0000000001716884

REMOVAL

1. Separate intermediate shaft from steering gear pinion shaft. Refer to ST-9, "Removal and Installation" .

2. Remove front tires using power tool.

3. Remove the nut on the lower side of stabilizer connecting rod using power tool, and then remove stabilizer

connecting rod from stabilizer bar.

4. If necessary remove stabilize connecting rod upper nut using power tool. Separate stabilizer connecting

rod and strut.

5. Loose steering outer socket (1) nut.

6. Remove steering outer socket (1) from steering knuckle (2) so

as not to damage ball joint boot (3) using the ball joint remover

or suitable tool.

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

7. Remove rear torque rod. Refer to EM-89, "

Exploded View"

(HR16DE), EM-207, "Component" (MR18DE) and EM-302, "Exploded View" (K9K).

8. Set jack under front suspension member.

9. Remove the bolts of member stay, and then remove member stay.

10. Gradually lower front suspension member in order to remove

stabilizer bolts.

CAUTION:

Be careful not to lower it too far. (Do not over load the

links.)

11. Remove the bolts of stabilizer clamp, and then remove stabilizer

clamp and stabilizer bushing.

12. Remove stabilizer bar.

INSPECTION AFTER REMOVAL

Check stabilizer bar, stabilizer connecting rod, stabilizer bushing, and stabilizer clamp for deformation, cracks,

and damage. Replace it if necessary.

INSTALLATION

Installation is in the reverse order of removal.

For tightening torques, refer to FSU-9, "

Component" . Tool number : HT72520000 (J-25730-A)

SGIA1298E

WEIA0181E

WEIA0182E

Page 3199 of 5883

HOW TO USE THIS MANUAL

GI-5

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

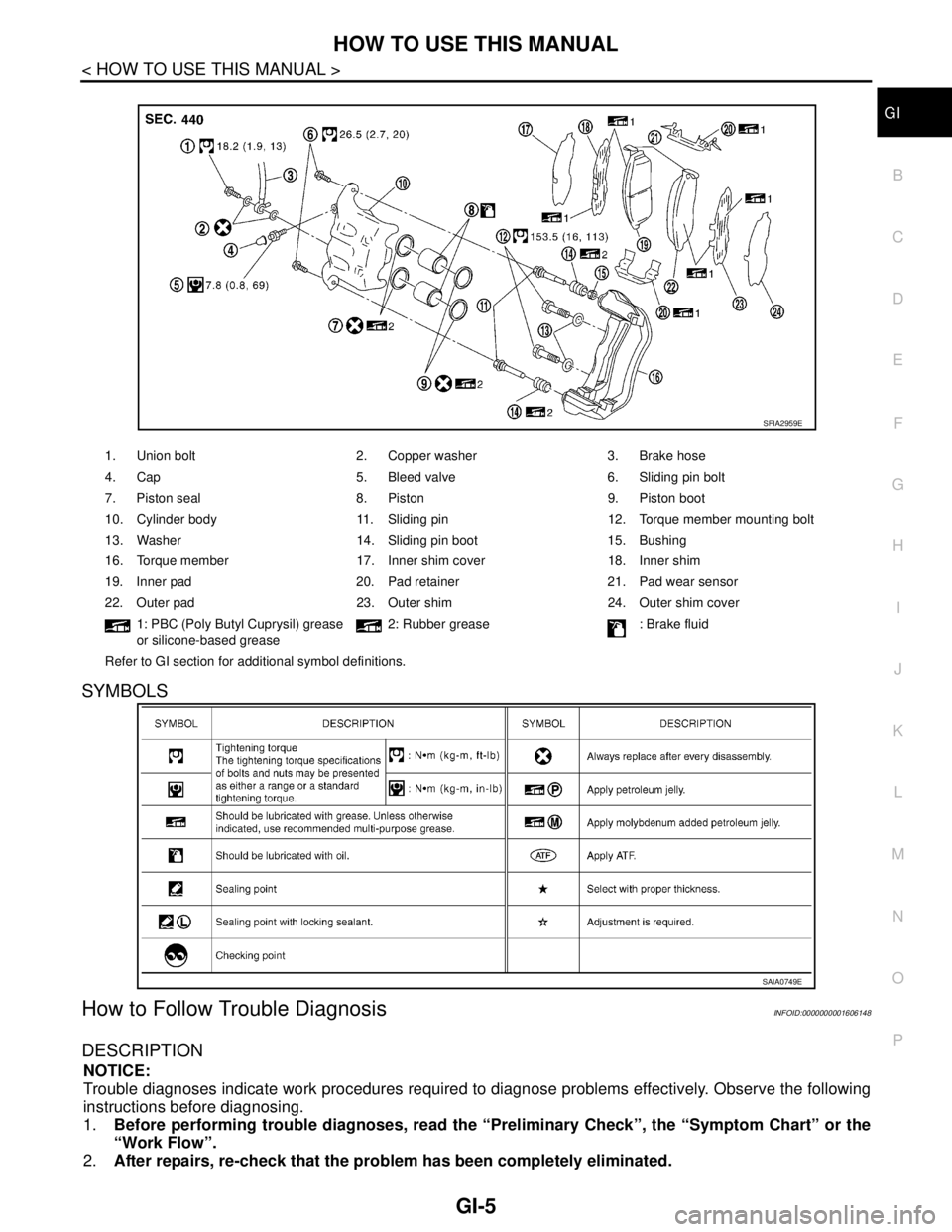

SYMBOLS

How to Follow Trouble DiagnosisINFOID:0000000001606148

DESCRIPTION

NOTICE:

Trouble diagnoses indicate work procedures required to diagnose problems effectively. Observe the following

instructions before diagnosing.

1.Before performing trouble diagnoses, read the “Preliminary Check”, the “Symptom Chart” or the

“Work Flow”.

2.After repairs, re-check that the problem has been completely eliminated.

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Outer shim 24. Outer shim cover

1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease2: Rubber grease : Brake fluid

Refer to GI section for additional symbol definitions.

SFIA2959E

SAIA0749E

Page 3726 of 5883

INSTRUMENT PANEL ASSEMBLY

IP-11

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

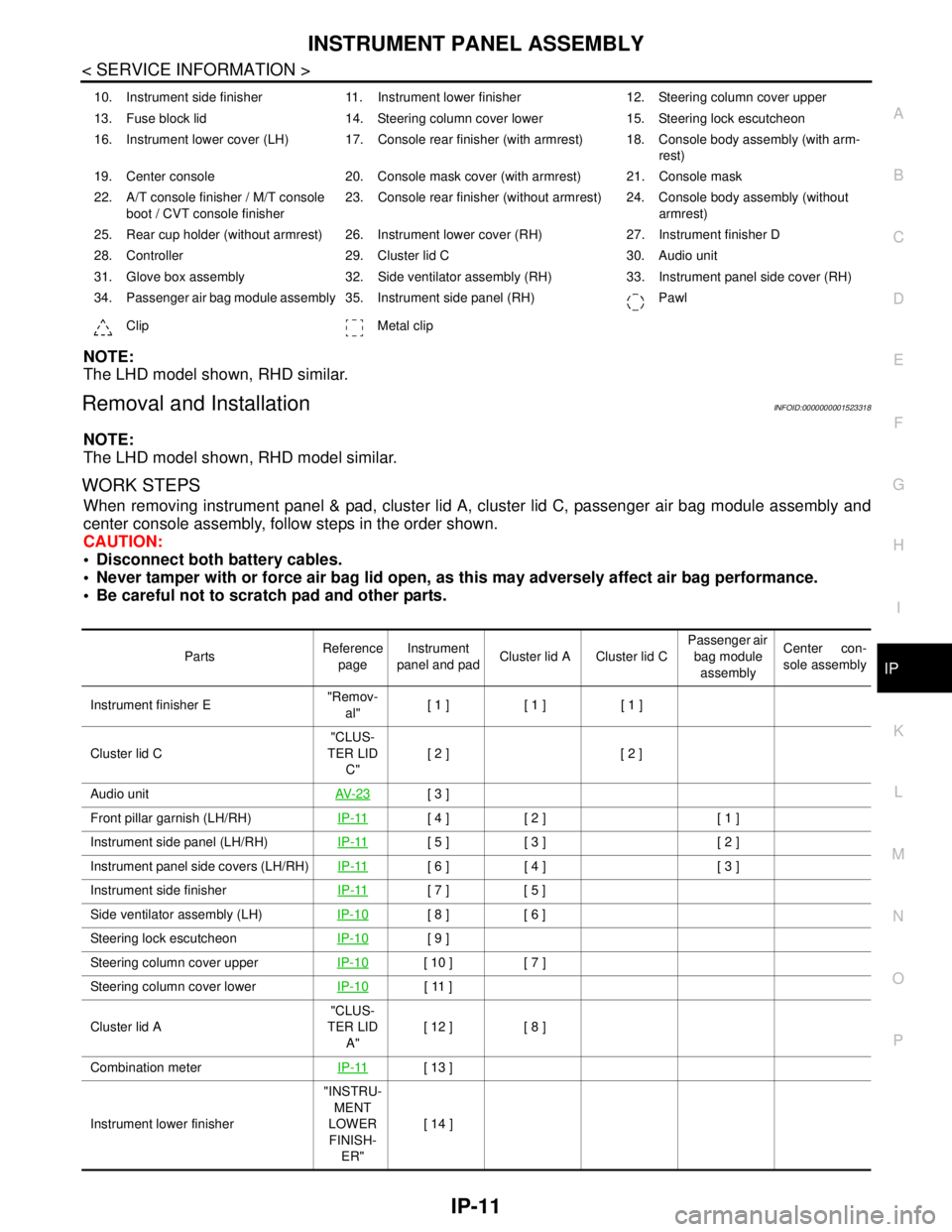

NOTE:

The LHD model shown, RHD similar.

Removal and InstallationINFOID:0000000001523318

NOTE:

The LHD model shown, RHD model similar.

WORK STEPS

When removing instrument panel & pad, cluster lid A, cluster lid C, passenger air bag module assembly and

center console assembly, follow steps in the order shown.

CAUTION:

Disconnect both battery cables.

Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

Be careful not to scratch pad and other parts.

10. Instrument side finisher 11. Instrument lower finisher 12. Steering column cover upper

13. Fuse block lid 14. Steering column cover lower 15. Steering lock escutcheon

16. Instrument lower cover (LH) 17. Console rear finisher (with armrest) 18. Console body assembly (with arm-

rest)

19. Center console 20. Console mask cover (with armrest) 21. Console mask

22. A/T console finisher / M/T console

boot / CVT console finisher23. Console rear finisher (without armrest) 24. Console body assembly (without

armrest)

25. Rear cup holder (without armrest) 26. Instrument lower cover (RH) 27. Instrument finisher D

28. Controller 29. Cluster lid C 30. Audio unit

31. Glove box assembly 32. Side ventilator assembly (RH) 33. Instrument panel side cover (RH)

34. Passenger air bag module assembly 35. Instrument side panel (RH) Pawl

Clip Metal clip

PartsReference

pageInstrument

panel and padCluster lid A Cluster lid C Passenger air

bag module

assemblyCenter con-

sole assembly

Instrument finisher E"Remov-

al"[ 1 ] [ 1 ] [ 1 ]

Cluster lid C"CLUS-

TER LID

C"[ 2 ] [ 2 ]

Audio unitAV- 2 3

[ 3 ]

Front pillar garnish (LH/RH)IP-11

[ 4 ] [ 2 ] [ 1 ]

Instrument side panel (LH/RH)IP-11

[ 5 ] [ 3 ] [ 2 ]

Instrument panel side covers (LH/RH)IP-11

[ 6 ] [ 4 ] [ 3 ]

Instrument side finisherIP-11

[ 7 ] [ 5 ]

Side ventilator assembly (LH)IP-10

[ 8 ] [ 6 ]

Steering lock escutcheonIP-10

[ 9 ]

Steering column cover upperIP-10

[ 10 ] [ 7 ]

Steering column cover lowerIP-10

[ 11 ]

Cluster lid A"CLUS-

TER LID

A"[ 12 ] [ 8 ]

Combination meterIP-11

[ 13 ]

Instrument lower finisher"INSTRU-

MENT

LOWER

FINISH-

ER"[ 14 ]

Page 3727 of 5883

![NISSAN TIIDA 2007 Service Owners Manual IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

d NISSAN TIIDA 2007 Service Owners Manual IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

d](/img/5/57395/w960_57395-3726.png)

IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

degrees while disengaging the instrument finisher E metal clips

and pawl.

Glove box assembly"GLOVE

BOX AS-

SEMBLY"[ 15 ]

Side ventilator assembly (RH)IP-10

[ 16 ] [ 4 ]

Passenger air bag module assemblySR-9

[ 17 ] [ 5 ]

Instrument upper maskIP-10

[ 18 ]

Instrument finisher DIP-10

[ 19 ]

Controller TM-674

[ 20 ]

Instrument upper panel assembly IP-11

[ 21 ]

Console mask"Remov-

al"[ 22 ] [ 1 ]

CVT, A/T console finisherIP-23

[ 23 ] [ 2 ]

M/T console bootIP-23

[ 23 ] [ 2 ]

Console rear finisherIP-23

[ 24 ] [ 3 ]

Console mask cover (with arm rest)IP-23

[ 25 ] [ 4 ]

Rear cup holder (without arm rest)IP-23

[ 25 ] [ 4 ]

Console body assemblyIP-23

[ 26 ] [ 5 ]

Instrument lower cover (LH/RH)"INSTRU-

MENT

LOWER

FINISH-

ER"[ 27 ] [ 6 ]

Center console assembly"CEN-

TER

CON-

SOLE AS-

SEMBLY"[ 28 ] [ 7 ]

Fuse block lidIP-10

[ 29 ]

Lighting and turn signal switchEXL-101

[ 30 ]

Wiper & washer switchWW-76

[ 31 ]

Instrument panel & padIP-10

[ 32 ] PartsReference

pageInstrument

panel and padCluster lid A Cluster lid C Passenger air

bag module

assemblyCenter con-

sole assembly

WIIA1224E