boot NISSAN TIIDA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3737 of 5883

IP-22

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

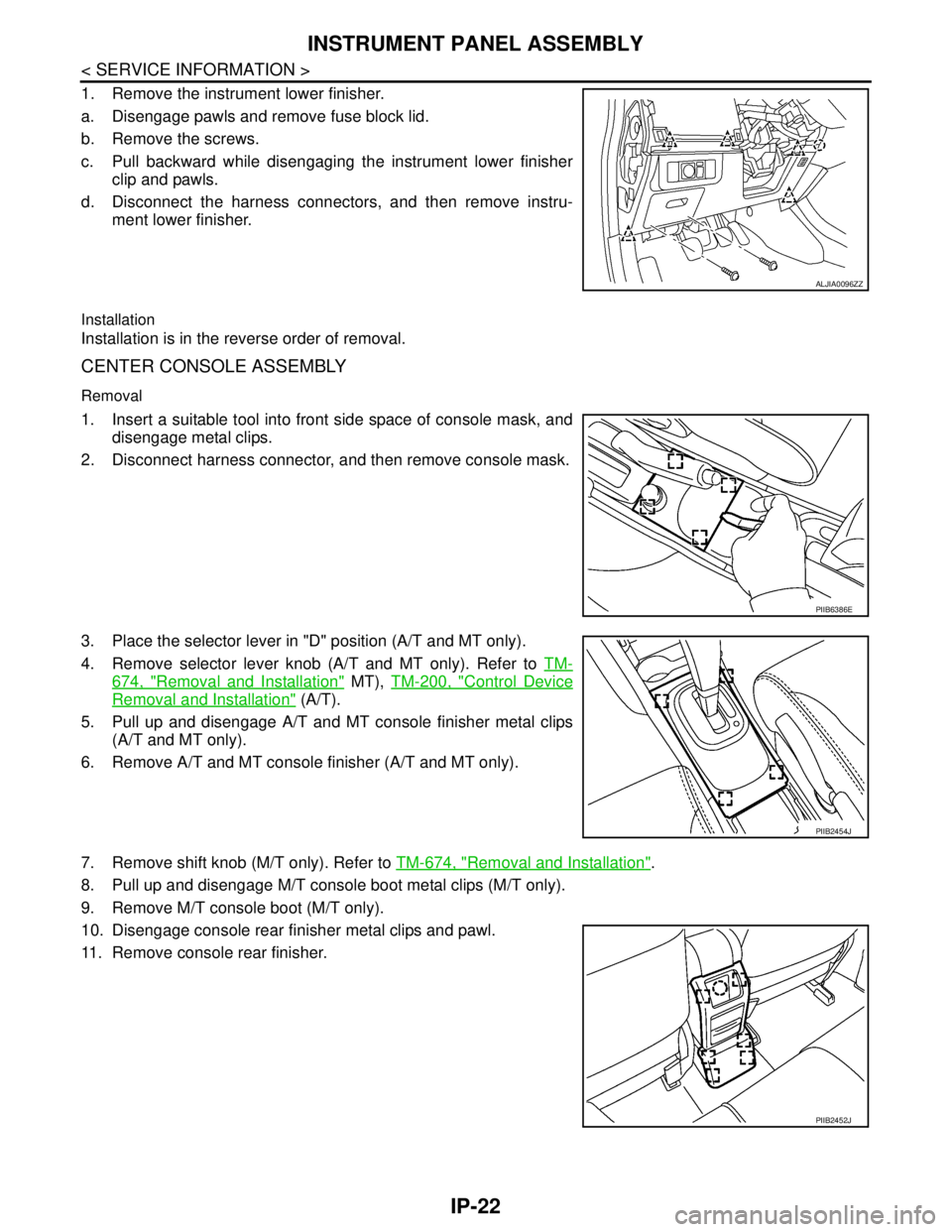

1. Remove the instrument lower finisher.

a. Disengage pawls and remove fuse block lid.

b. Remove the screws.

c. Pull backward while disengaging the instrument lower finisher

clip and pawls.

d. Disconnect the harness connectors, and then remove instru-

ment lower finisher.

Installation

Installation is in the reverse order of removal.

CENTER CONSOLE ASSEMBLY

Removal

1. Insert a suitable tool into front side space of console mask, and

disengage metal clips.

2. Disconnect harness connector, and then remove console mask.

3. Place the selector lever in "D" position (A/T and MT only).

4. Remove selector lever knob (A/T and MT only). Refer to TM-

674, "Removal and Installation" MT), TM-200, "Control Device

Removal and Installation" (A/T).

5. Pull up and disengage A/T and MT console finisher metal clips

(A/T and MT only).

6. Remove A/T and MT console finisher (A/T and MT only).

7. Remove shift knob (M/T only). Refer to TM-674, "

Removal and Installation".

8. Pull up and disengage M/T console boot metal clips (M/T only).

9. Remove M/T console boot (M/T only).

10. Disengage console rear finisher metal clips and pawl.

11. Remove console rear finisher.

ALJIA0096ZZ

PIIB6386E

PIIB2454J

PIIB2452J

Page 4296 of 5883

MA-56

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

Check the brake pads for wear or damage. Refer to BR-24,

"Removal and Installation of Brake Pad" .

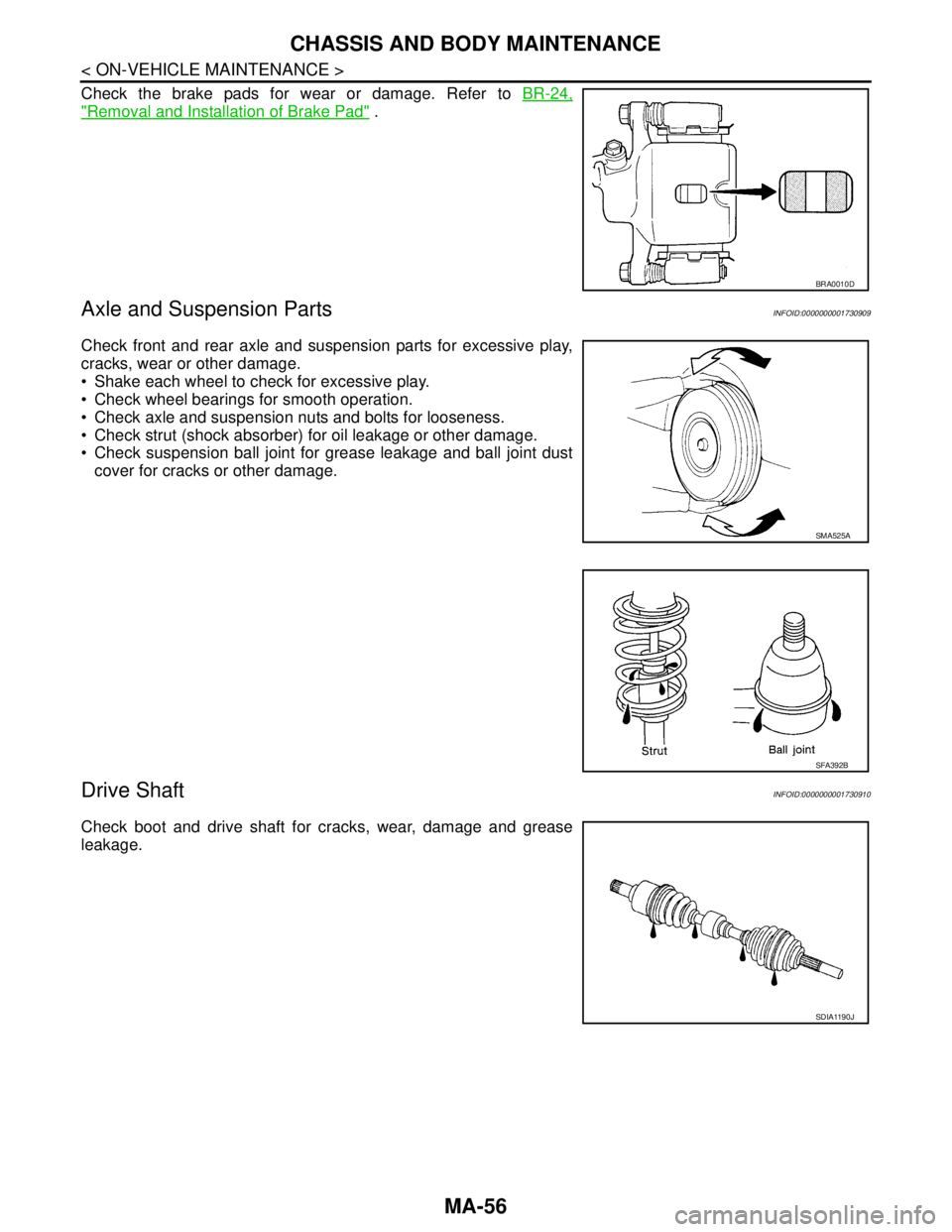

Axle and Suspension PartsINFOID:0000000001730909

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

Shake each wheel to check for excessive play.

Check wheel bearings for smooth operation.

Check axle and suspension nuts and bolts for looseness.

Check strut (shock absorber) for oil leakage or other damage.

Check suspension ball joint for grease leakage and ball joint dust

cover for cracks or other damage.

Drive ShaftINFOID:0000000001730910

Check boot and drive shaft for cracks, wear, damage and grease

leakage.

BRA0010D

SMA525A

SFA392B

SDIA1190J

Page 4859 of 5883

ST-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

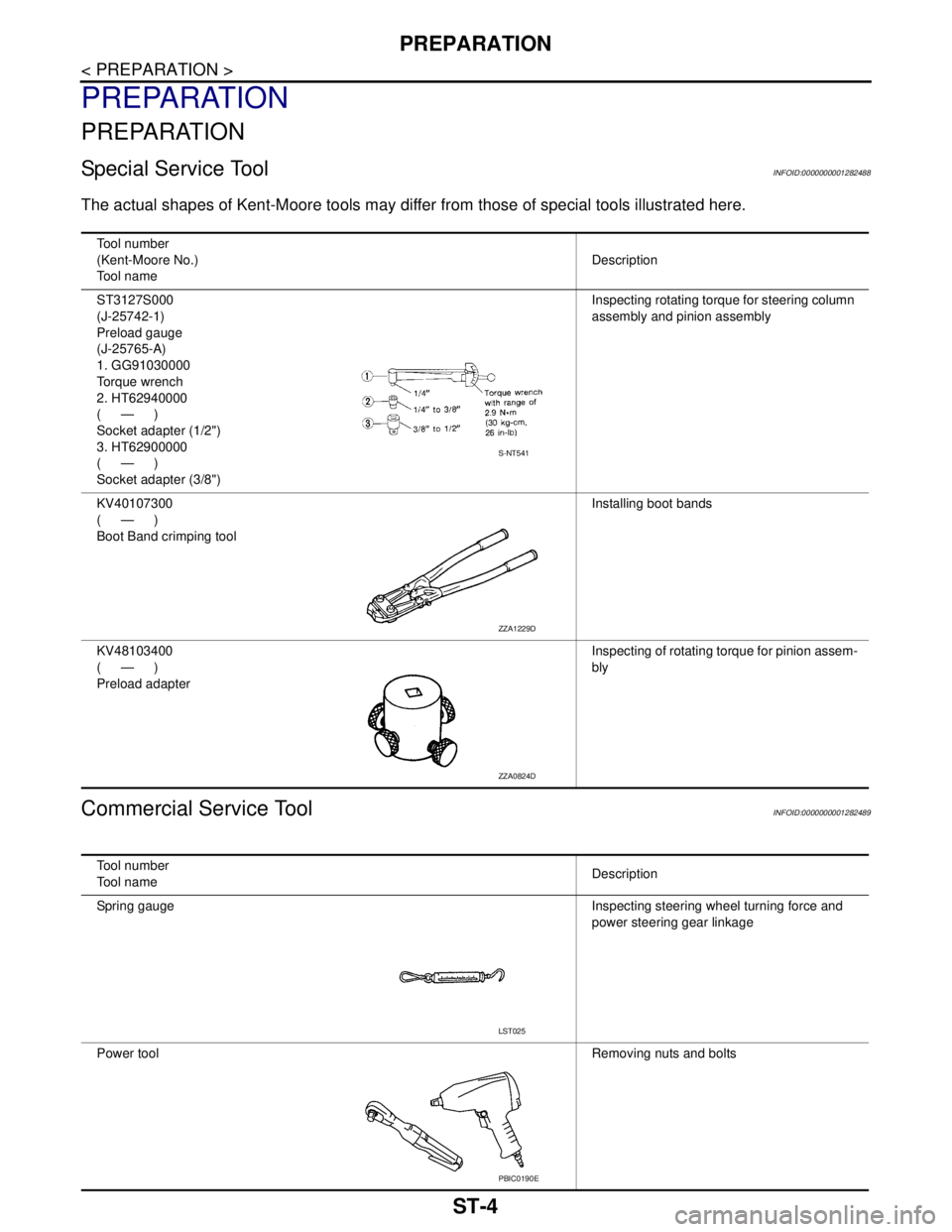

Special Service ToolINFOID:0000000001282488

The actual shapes of Kent-Moore tools may differ from those of special tools illustrated here.

Commercial Service ToolINFOID:0000000001282489

Tool number

(Kent-Moore No.)

Tool nameDescription

ST3127S000

(J-25742-1)

Preload gauge

(J-25765-A)

1. GG91030000

Torque wrench

2. HT62940000

(—)

Socket adapter (1/2")

3. HT62900000

(—)

Socket adapter (3/8")Inspecting rotating torque for steering column

assembly and pinion assembly

KV40107300

(—)

Boot Band crimping toolInstalling boot bands

KV48103400

(—)

Preload adapterInspecting of rotating torque for pinion assem-

bly

S-NT541

ZZA1229D

ZZA0824D

Tool number

Tool nameDescription

Spring gauge Inspecting steering wheel turning force and

power steering gear linkage

Power toolRemoving nuts and bolts

LST025

PBIC0190E

Page 4867 of 5883

ST-12

< ON-VEHICLE REPAIR >

STEERING GEAR

STEERING GEAR

Removal and InstallationINFOID:0000000001282501

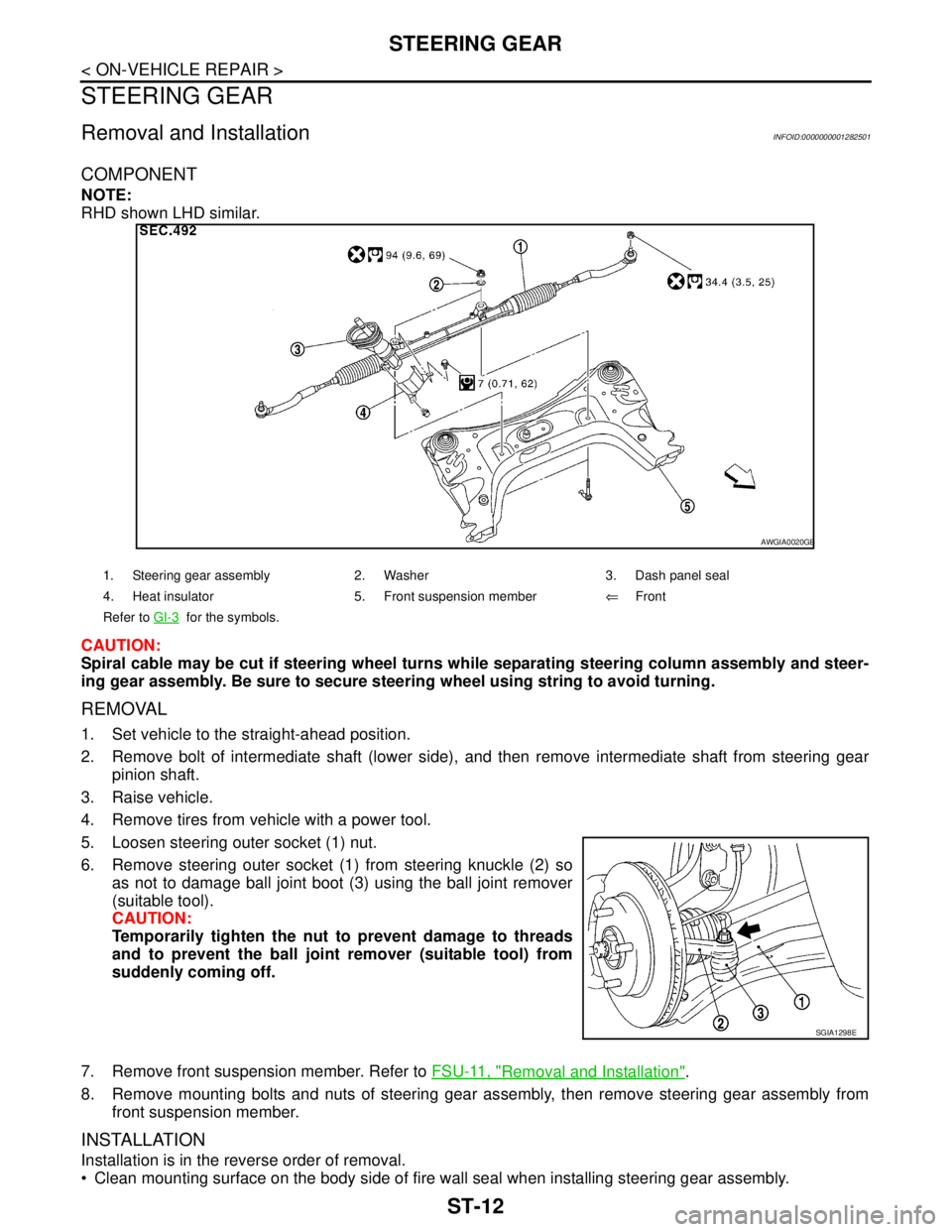

COMPONENT

NOTE:

RHD shown LHD similar.

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steering wheel using string to avoid turning.

REMOVAL

1. Set vehicle to the straight-ahead position.

2. Remove bolt of intermediate shaft (lower side), and then remove intermediate shaft from steering gear

pinion shaft.

3. Raise vehicle.

4. Remove tires from vehicle with a power tool.

5. Loosen steering outer socket (1) nut.

6. Remove steering outer socket (1) from steering knuckle (2) so

as not to damage ball joint boot (3) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

7. Remove front suspension member. Refer to FSU-11, "

Removal and Installation".

8. Remove mounting bolts and nuts of steering gear assembly, then remove steering gear assembly from

front suspension member.

INSTALLATION

Installation is in the reverse order of removal.

Clean mounting surface on the body side of fire wall seal when installing steering gear assembly.

1. Steering gear assembly 2. Washer 3. Dash panel seal

4. Heat insulator 5. Front suspension member⇐Front

Refer to GI-3

for the symbols.

AWGIA0020GB

SGIA1298E

Page 4869 of 5883

ST-14

< DISASSEMBLY AND ASSEMBLY >

STEERING GEAR

DISASSEMBLY AND ASSEMBLY

STEERING GEAR

Disassembly and AssemblyINFOID:0000000001282504

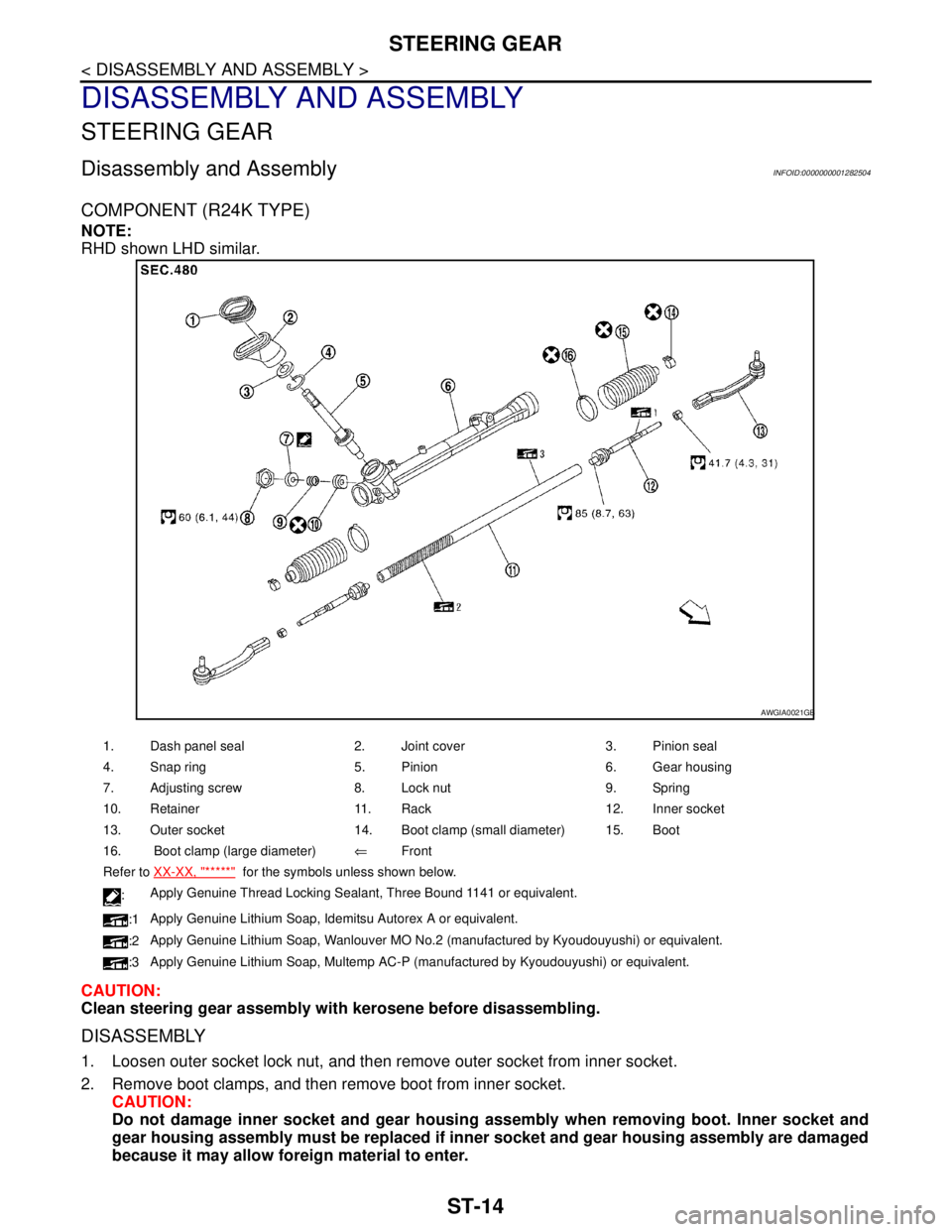

COMPONENT (R24K TYPE)

NOTE:

RHD shown LHD similar.

CAUTION:

Clean steering gear assembly with kerosene before disassembling.

DISASSEMBLY

1. Loosen outer socket lock nut, and then remove outer socket from inner socket.

2. Remove boot clamps, and then remove boot from inner socket.

CAUTION:

Do not damage inner socket and gear housing assembly when removing boot. Inner socket and

gear housing assembly must be replaced if inner socket and gear housing assembly are damaged

because it may allow foreign material to enter.

1. Dash panel seal 2. Joint cover 3. Pinion seal

4. Snap ring 5. Pinion 6. Gear housing

7. Adjusting screw 8. Lock nut 9. Spring

10. Retainer 11. Rack 12. Inner socket

13. Outer socket 14. Boot clamp (small diameter) 15. Boot

16. Boot clamp (large diameter)⇐Front

Refer to XX-XX, "*****"

for the symbols unless shown below.

:Apply Genuine Thread Locking Sealant, Three Bound 1141 or equivalent.

:1Apply Genuine Lithium Soap, Idemitsu Autorex A or equivalent.

:2Apply Genuine Lithium Soap, Wanlouver MO No.2 (manufactured by Kyoudouyushi) or equivalent.

:3Apply Genuine Lithium Soap, Multemp AC-P (manufactured by Kyoudouyushi) or equivalent.

AWGIA0021GB

Page 4872 of 5883

STEERING GEAR

ST-17

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

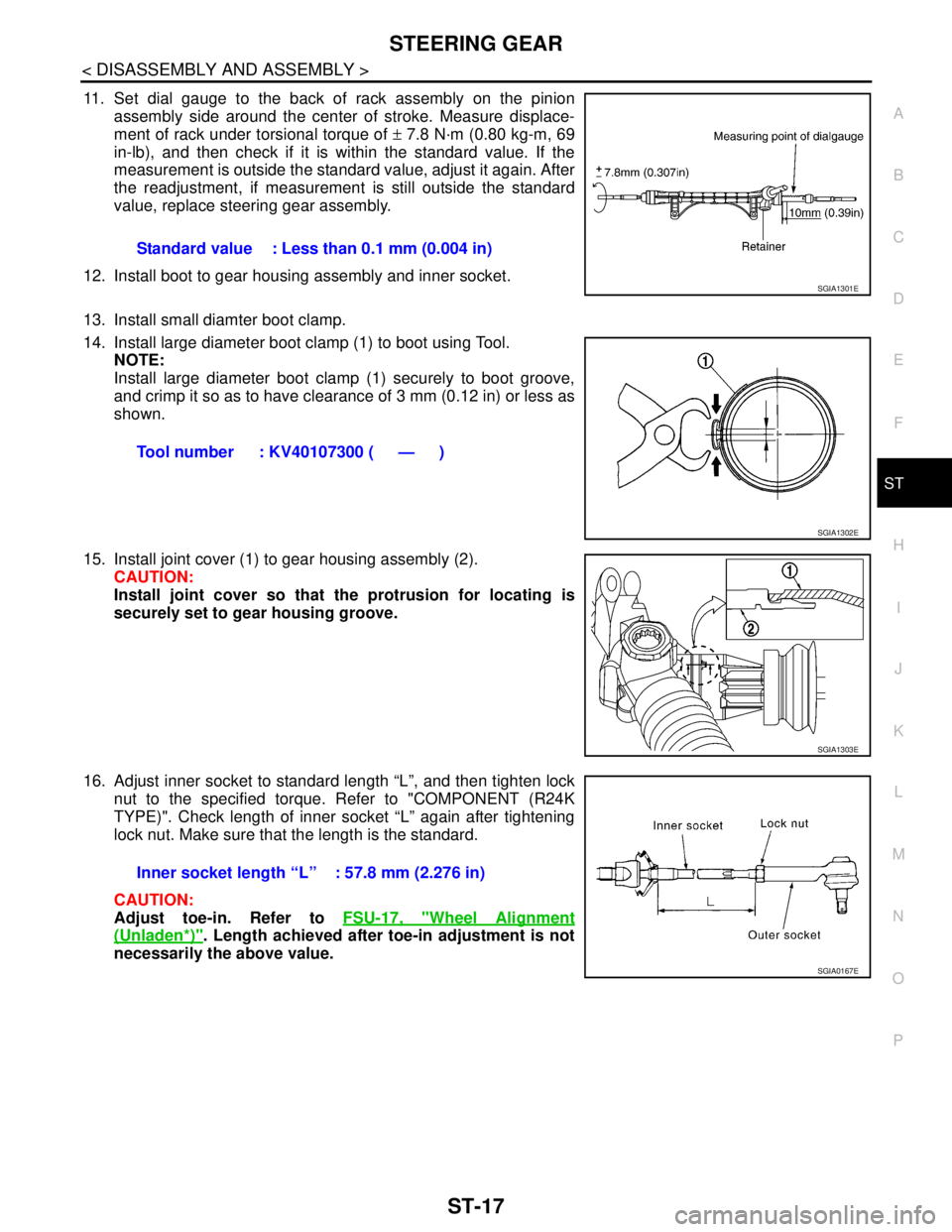

11. Set dial gauge to the back of rack assembly on the pinion

assembly side around the center of stroke. Measure displace-

ment of rack under torsional torque of ± 7.8 N·m (0.80 kg-m, 69

in-lb), and then check if it is within the standard value. If the

measurement is outside the standard value, adjust it again. After

the readjustment, if measurement is still outside the standard

value, replace steering gear assembly.

12. Install boot to gear housing assembly and inner socket.

13. Install small diamter boot clamp.

14. Install large diameter boot clamp (1) to boot using Tool.

NOTE:

Install large diameter boot clamp (1) securely to boot groove,

and crimp it so as to have clearance of 3 mm (0.12 in) or less as

shown.

15. Install joint cover (1) to gear housing assembly (2).

CAUTION:

Install joint cover so that the protrusion for locating is

securely set to gear housing groove.

16. Adjust inner socket to standard length “L”, and then tighten lock

nut to the specified torque. Refer to "COMPONENT (R24K

TYPE)". Check length of inner socket “L” again after tightening

lock nut. Make sure that the length is the standard.

CAUTION:

Adjust toe-in. Refer to FSU-17, "

Wheel Alignment

(Unladen*)". Length achieved after toe-in adjustment is not

necessarily the above value.Standard value : Less than 0.1 mm (0.004 in)

SGIA1301E

Tool number : KV40107300 ( — )

SGIA1302E

SGIA1303E

Inner socket length “L” : 57.8 mm (2.276 in)

SGIA0167E

Page 4911 of 5883

![NISSAN TIIDA 2007 Service Owners Guide PRECAUTIONS

STC-37

< PRECAUTION >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

Check if the connection of steering column assembly and steering gear assembly is proper (there is

not looseness of mounting b NISSAN TIIDA 2007 Service Owners Guide PRECAUTIONS

STC-37

< PRECAUTION >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

Check if the connection of steering column assembly and steering gear assembly is proper (there is

not looseness of mounting b](/img/5/57395/w960_57395-4910.png)

PRECAUTIONS

STC-37

< PRECAUTION >[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

Check if the connection of steering column assembly and steering gear assembly is proper (there is

not looseness of mounting bolts, damage of rods, boots or sealants, and leakage of grease, etc).

Check if the wheel alignment is adjusted properly.

Check if there is any damage or modification to suspension or body resulting in increased weight or

altered ground clearance.

Check if installation conditions of each link and suspension are proper.

Check if the battery voltage is proper

Check connection conditions of each connector are proper.

Before connecting or disconnecting the EPS control unit har-

ness connector, turn ignition switch “OFF” and disconnect

battery ground cable. Because battery voltage is applied to

EPS control unit even if ignition switch is turned “OFF”.

When connecting or disconnecting pin connectors into or

from EPS control unit, take care not to damage pin terminals

(bend or break).

When connecting pin connectors, make sure that there are no

bends or breaks on EPS control unit pin terminal.

Before replacing EPS control unit, perform EPS control unit

input/output signal inspection and make sure whether EPS

control unit functions properly or not. Refer to STC-22, "

EPS

Control Unit Input/Output Signal Reference Value".

SEF289H

SEF291H

SDIA1848E

Page 5577 of 5883

![NISSAN TIIDA 2007 Service Owners Guide CONTROL LINKAGE

TM-631

< ON-VEHICLE REPAIR >[5MT: RS5F91R]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Securely assemble each cable and lever of control shaft.

Be careful about the installation direction, and NISSAN TIIDA 2007 Service Owners Guide CONTROL LINKAGE

TM-631

< ON-VEHICLE REPAIR >[5MT: RS5F91R]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Securely assemble each cable and lever of control shaft.

Be careful about the installation direction, and](/img/5/57395/w960_57395-5576.png)

CONTROL LINKAGE

TM-631

< ON-VEHICLE REPAIR >[5MT: RS5F91R]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Securely assemble each cable and lever of control shaft.

Be careful about the installation direction, and push control lever

knob into control lever.

-⇐: Front

Make sure that the front/rear claws (1) of control device assembly

are in contact with flange of the floor (2).

InspectionINFOID:0000000001381689

Inspect the following items:

When control lever is selected to 1st-2nd side and 5th-reverse side, confirm control lever returns to neutral

position smoothly.

When control lever is shifted to each position, make sure there is no binding or disconnection in each boot.

PCIB1509E

PCIB1510E

Page 5623 of 5883

![NISSAN TIIDA 2007 Service Owners Guide CONTROL LINKAGE

TM-677

< ON-VEHICLE REPAIR >[6MT: RS6F94R]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

7. With the stopper (1) of the select cable pressed into all the way,

slide lock (2) of the select cable all NISSAN TIIDA 2007 Service Owners Guide CONTROL LINKAGE

TM-677

< ON-VEHICLE REPAIR >[6MT: RS6F94R]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

7. With the stopper (1) of the select cable pressed into all the way,

slide lock (2) of the select cable all](/img/5/57395/w960_57395-5622.png)

CONTROL LINKAGE

TM-677

< ON-VEHICLE REPAIR >[6MT: RS6F94R]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

7. With the stopper (1) of the select cable pressed into all the way,

slide lock (2) of the select cable all the way in the direction of the

arrow.

8. Remove the lever stopper pin or a pin [3 mm (0.12 in) dia.] from

the control device assembly.

9. Shift the control lever to each gear position to check that there is

no binding. If any, repeat step 3.

InspectionINFOID:0000000001381640

After installing, confirm the following items:

When the control lever is shifted to 1st-2nd side and 5th-6th side, confirm the control lever returns to neutral

position smoothly.

When the control lever is shifted to each position, make sure there is no binding or disconnection in each

boot.

JPDIC0065ZZ