engine oil type NISSAN TIIDA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2885 of 5883

![NISSAN TIIDA 2007 Service Owners Manual EM-238

< SERVICE DATA AND SPECIFICATIONS (SDS) [MR18DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:00000 NISSAN TIIDA 2007 Service Owners Manual EM-238

< SERVICE DATA AND SPECIFICATIONS (SDS) [MR18DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:00000](/img/5/57395/w960_57395-2884.png)

EM-238

< SERVICE DATA AND SPECIFICATIONS (SDS) [MR18DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000001337815

GENERAL SPECIFICATIONS

DRIVE BELT

WATER CONTROL VALVE

EXHAUST MANIFOLD

Unit: mm (in)

THERMOSTAT

SPARK PLUG

Unit: mm (in)

CYLINDER HEAD

Engine typeMR18DE

Cylinder arrangementIn-line 4

Displacement

cm

3 (cu in)1,798 (109.71)

Bore and stroke mm (in) 84.0 x 81.1 (3.307 x 3.192)

Valve arrangementDOHC

Firing order1-3-4-2

Number of piston ringsCompression 2

Oil 1

Compression ratio9.9

Compression pressure

kPa (bar, kg/cm

2 , psi) / 250 rpmStandard 1,500 (15.0, 15.3, 217.6)

Minimum 1,200 (12.0, 12.2, 174)

Differential limit between cylinders 100 (1.0, 1.0, 15)

Tension of drive belt Auto adjustment by auto-tensioner

Valve opening temperature 93.5 - 96.5°C (200 - 206°F)

Maximum valve lift 8 mm/ 108°C (0.315 in/ 226°F)

Valve closing temperature More than 90°C (194°F)

Items Limit

Surface distortionEach exhaust port 0.3 (0.012)

Entire part 0.7 (0.028)

Valve opening temperature 80.5 - 83.5°C (177 - 182°F)

Maximum valve lift 8 mm/ 95°C (0.315 in/ 203°F)

Valve closing temperature More than 77°C (171°F)

Plug typePlatinum-tipped TYPE

MakeNGK

Standard typePLZKAR6A-11

Spark plug gapNominal: 1.1 (0.043)

Page 2897 of 5883

![NISSAN TIIDA 2007 Service Owners Manual EM-250

< SYMPTOM DIAGNOSIS >[K9K]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000001381449

1. Locate the area where no NISSAN TIIDA 2007 Service Owners Manual EM-250

< SYMPTOM DIAGNOSIS >[K9K]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000001381449

1. Locate the area where no](/img/5/57395/w960_57395-2896.png)

EM-250

< SYMPTOM DIAGNOSIS >[K9K]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000001381449

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related B: Related C: Sometimes related —: Not relatedLocation

of noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemRefer-

ence page Before

warm-

upAfter

warm-

upWhen

start-

ingWhen

idlingWhen

racingWhile

driving

Top of en-

gine

Rocker

cover

Cylinder

headTicking or

clickingCA—AB—Tappet

noiseValve clearanceEM-266

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil panSlap or

rapA——B B APiston

slap noisePiston ring end gapEM-330

Front of

engine

Timing

belt coverTapping or

tickingAA—BBBTiming

belt ten-

sioner

noiseTiming belt tensioner

operationEM-291

Front of

engineSqueak-

ing or fizz-

ingAB—B—CDrive belts

(Sticking

or slip-

ping)Drive belts deflectionEM-263

Squall

CreakAB—BABWater

pump

noiseWater pump operationCO-66

Page 3011 of 5883

EXL-10

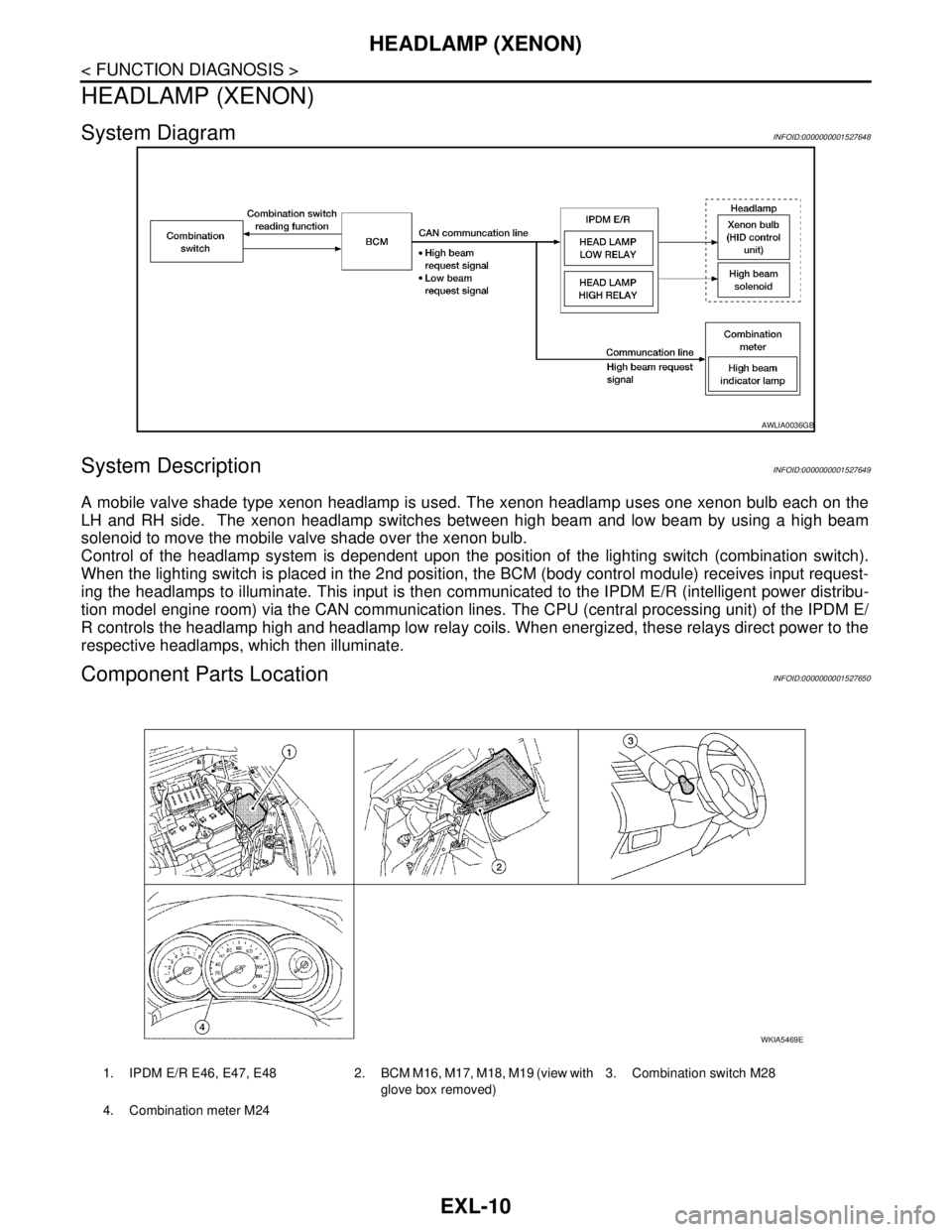

< FUNCTION DIAGNOSIS >

HEADLAMP (XENON)

HEADLAMP (XENON)

System DiagramINFOID:0000000001527648

System DescriptionINFOID:0000000001527649

A mobile valve shade type xenon headlamp is used. The xenon headlamp uses one xenon bulb each on the

LH and RH side. The xenon headlamp switches between high beam and low beam by using a high beam

solenoid to move the mobile valve shade over the xenon bulb.

Control of the headlamp system is dependent upon the position of the lighting switch (combination switch).

When the lighting switch is placed in the 2nd position, the BCM (body control module) receives input request-

ing the headlamps to illuminate. This input is then communicated to the IPDM E/R (intelligent power distribu-

tion model engine room) via the CAN communication lines. The CPU (central processing unit) of the IPDM E/

R controls the headlamp high and headlamp low relay coils. When energized, these relays direct power to the

respective headlamps, which then illuminate.

Component Parts LocationINFOID:0000000001527650

AWLIA0036GB

1. IPDM E/R E46, E47, E48 2. BCM M16, M17, M18, M19 (view with

glove box removed)3. Combination switch M28

4. Combination meter M24

WKIA5469E

Page 3084 of 5883

FRONT FOG LAMP

EXL-83

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

FRONT FOG LAMP

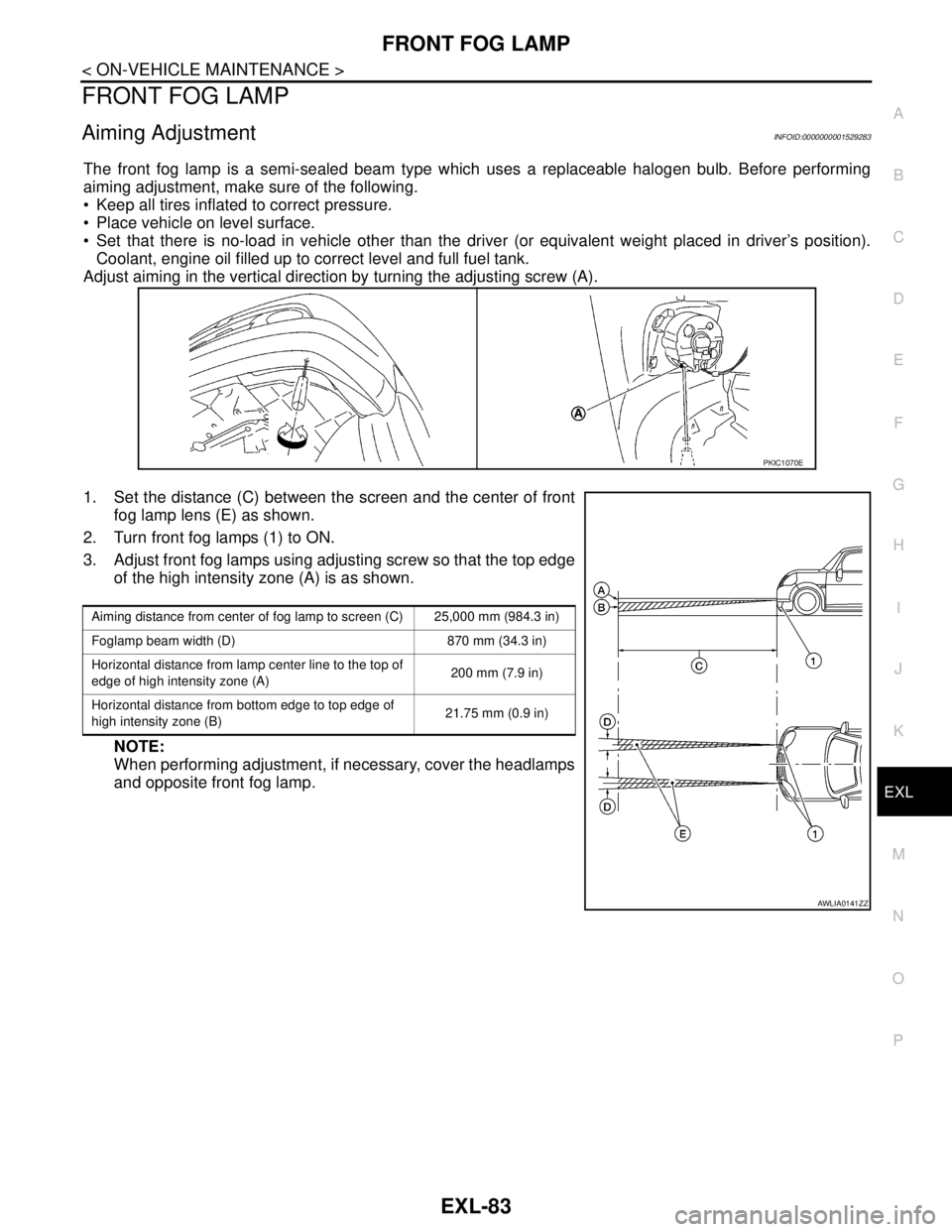

Aiming AdjustmentINFOID:0000000001529283

The front fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing

aiming adjustment, make sure of the following.

Keep all tires inflated to correct pressure.

Place vehicle on level surface.

Set that there is no-load in vehicle other than the driver (or equivalent weight placed in driver’s position).

Coolant, engine oil filled up to correct level and full fuel tank.

Adjust aiming in the vertical direction by turning the adjusting screw (A).

1. Set the distance (C) between the screen and the center of front

fog lamp lens (E) as shown.

2. Turn front fog lamps (1) to ON.

3. Adjust front fog lamps using adjusting screw so that the top edge

of the high intensity zone (A) is as shown.

NOTE:

When performing adjustment, if necessary, cover the headlamps

and opposite front fog lamp.

PKIC1070E

Aiming distance from center of fog lamp to screen (C) 25,000 mm (984.3 in)

Foglamp beam width (D) 870 mm (34.3 in)

Horizontal distance from lamp center line to the top of

edge of high intensity zone (A)200 mm (7.9 in)

Horizontal distance from bottom edge to top edge of

high intensity zone (B)21.75 mm (0.9 in)

AWLIA0141ZZ

Page 3178 of 5883

FSU-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001716875

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Procedure without Cowl Top CoverINFOID:0000000001716876

When performing the procedure after removing cowl top cover, cover

the lower end of windshield.

CautionsINFOID:0000000001716877

When installing rubber bushings, the final tightening must be carried out under unladen conditions with tires

on ground. Oil might shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

After servicing suspension parts, be sure to check wheel alignment.

Self-lock nuts are not reusable. Always use new ones when installing.

WEIA0178E

Page 3332 of 5883

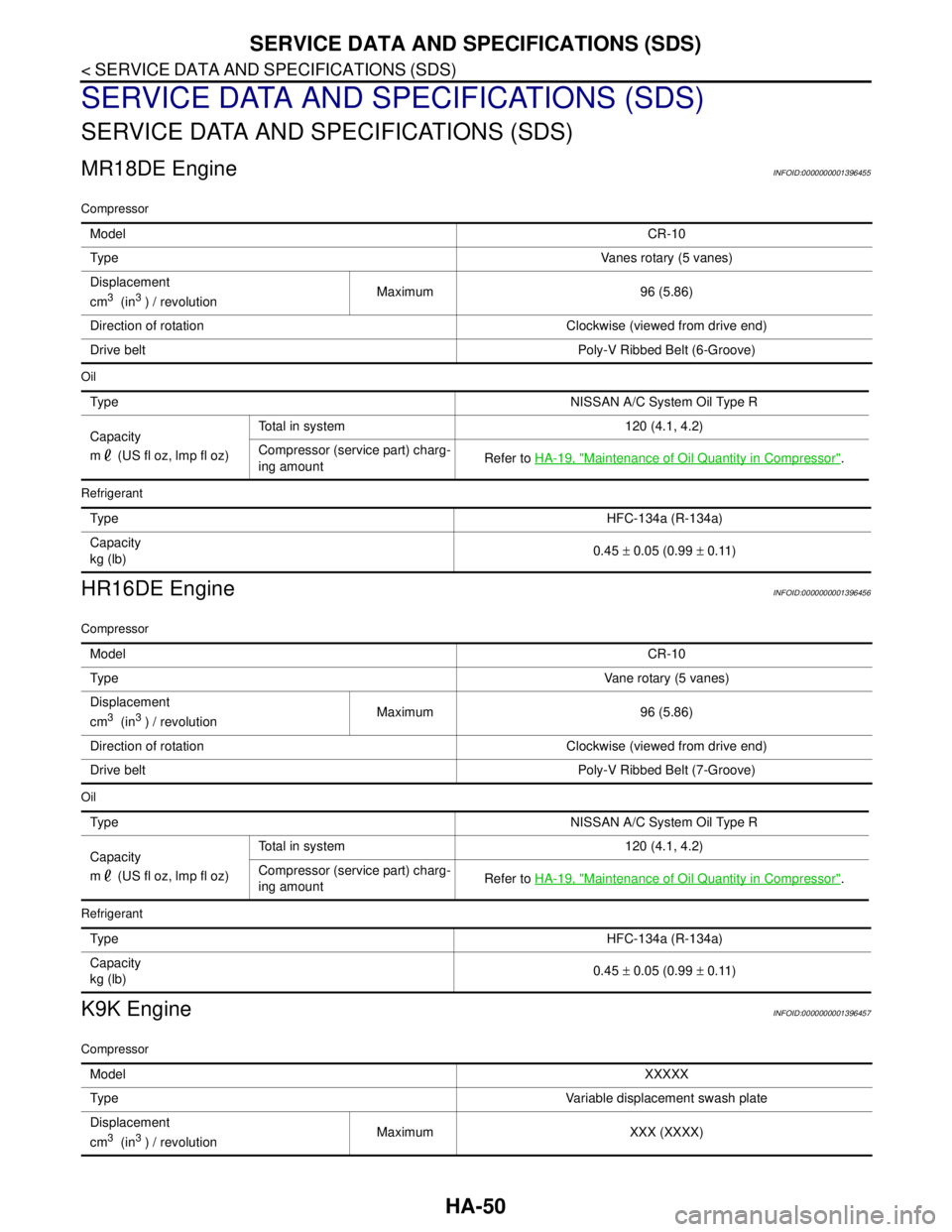

HA-50

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

MR18DE EngineINFOID:0000000001396455

Compressor

Oil

Refrigerant

HR16DE EngineINFOID:0000000001396456

Compressor

Oil

Refrigerant

K9K EngineINFOID:0000000001396457

Compressor

ModelCR-10

Ty p eVanes rotary (5 vanes)

Displacement

cm

3 (in3 ) / revolutionMaximum 96 (5.86)

Direction of rotation Clockwise (viewed from drive end)

Drive beltPoly-V Ribbed Belt (6-Groove)

Ty p eNISSAN A/C System Oil Type R

Capacity

m (US fl oz, lmp fl oz)Total in system 120 (4.1, 4.2)

Compressor (service part) charg-

ing amountRefer to HA-19, "

Maintenance of Oil Quantity in Compressor".

Ty p eHFC-134a (R-134a)

Capacity

kg (lb)0.45 ± 0.05 (0.99 ± 0.11)

ModelCR-10

Ty p eVane rotary (5 vanes)

Displacement

cm

3 (in3 ) / revolutionMaximum 96 (5.86)

Direction of rotation Clockwise (viewed from drive end)

Drive beltPoly-V Ribbed Belt (7-Groove)

Ty p eNISSAN A/C System Oil Type R

Capacity

m (US fl oz, lmp fl oz)Total in system 120 (4.1, 4.2)

Compressor (service part) charg-

ing amountRefer to HA-19, "

Maintenance of Oil Quantity in Compressor".

Ty p eHFC-134a (R-134a)

Capacity

kg (lb)0.45 ± 0.05 (0.99 ± 0.11)

ModelXXXXX

Ty p eVariable displacement swash plate

Displacement

cm

3 (in3 ) / revolutionMaximum XXX (XXXX)

Page 4211 of 5883

![NISSAN TIIDA 2007 Service Owners Manual LU-4

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001516581

The Supplemental Rest NISSAN TIIDA 2007 Service Owners Manual LU-4

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001516581

The Supplemental Rest](/img/5/57395/w960_57395-4210.png)

LU-4

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001516581

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Liquid GasketINFOID:0000000001381524

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

Remove liquid gasket completely from the liquid gasket application surface, mounting bolts, and bolt

holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating

use) to remove adhering moisture, grease and foreign materials.

3. Apply liquid gasket to the liquid gasket application surface.

Use Genuine liquid gasket or equivalent.

Within five minutes of liquid gasket application, install the mating component.

If liquid gasket protrudes, wipe it off immediately.

Do not retighten mounting bolts or nuts after the installation.

After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

Page 4219 of 5883

![NISSAN TIIDA 2007 Service Owners Manual LU-12

< PRECAUTION >[MR18DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001532084

The Supplemental Res NISSAN TIIDA 2007 Service Owners Manual LU-12

< PRECAUTION >[MR18DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001532084

The Supplemental Res](/img/5/57395/w960_57395-4218.png)

LU-12

< PRECAUTION >[MR18DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001532084

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Liquid GasketINFOID:0000000001337823

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

Remove liquid gasket completely from the liquid gasket application surface, bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating

use) to remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the Tool.

Use Genuine Silicone RTV Sealant or equivalent. Refer to

GI-27, "

Recommended Chemical Products and Sealants".

Within 5 minutes of liquid gasket application, install the mating

component.

If liquid gasket protrudes, wipe it off immediately.

Do not retighten bolts or nuts after the installation.

Wait 30 minutes or more after installation before refilling

engine oil and engine coolant.Tool number :WS39930000 ( — )

PBIC2160E

Page 4247 of 5883

PERIODIC MAINTENANCE

MA-7

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

PERIODIC MAINTENANCE

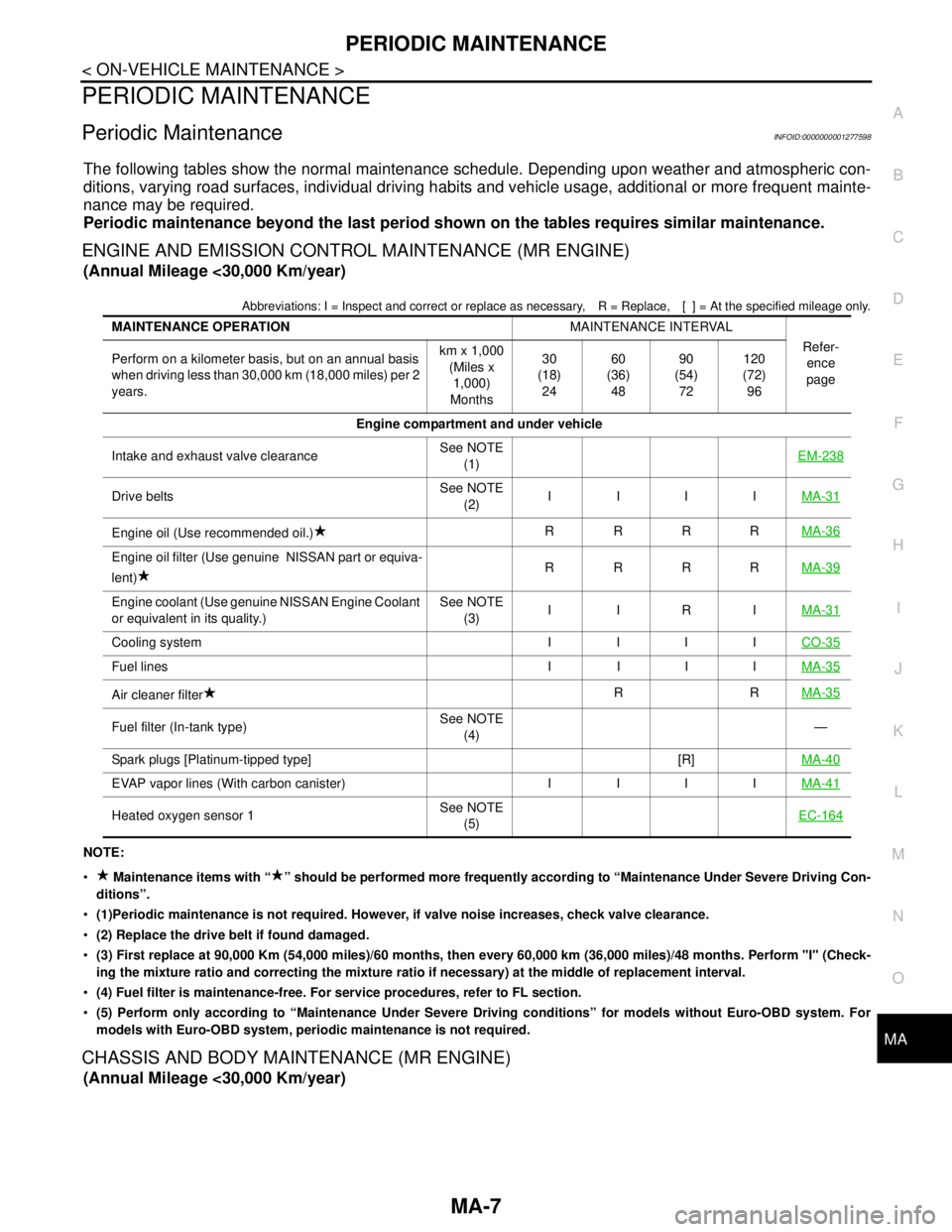

Periodic MaintenanceINFOID:0000000001277598

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

ENGINE AND EMISSION CONTROL MAINTENANCE (MR ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, [ ] = At the specified mileage only.

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged.

(3) First replace at 90,000 Km (54,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform "I" (Check-

ing the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Perform only according to “Maintenance Under Severe Driving conditions” for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (MR ENGINE)

(Annual Mileage <30,000 Km/year)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on an annual basis

when driving less than 30,000 km (18,000 miles) per 2

years.km x 1,000

(Miles x

1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Engine compartment and under vehicle

Intake and exhaust valve clearanceSee NOTE

(1)EM-238

Drive beltsSee NOTE

(2)IIIIMA-31

Engine oil (Use recommended oil.)RRRRMA-36

Engine oil filter (Use genuine NISSAN part or equiva-

lent)RRRRMA-39

Engine coolant (Use genuine NISSAN Engine Coolant

or equivalent in its quality.)See NOTE

(3)IIRIMA-31

Cooling system I I I ICO-35

Fuel lines I I I IMA-35

Air cleaner filterRRMA-35

Fuel filter (In-tank type)See NOTE

(4)—

Spark plugs [Platinum-tipped type] [R]MA-40

EVAP vapor lines (With carbon canister) I I I IMA-41

Heated oxygen sensor 1See NOTE

(5)EC-164

Page 4249 of 5883

PERIODIC MAINTENANCE

MA-9

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

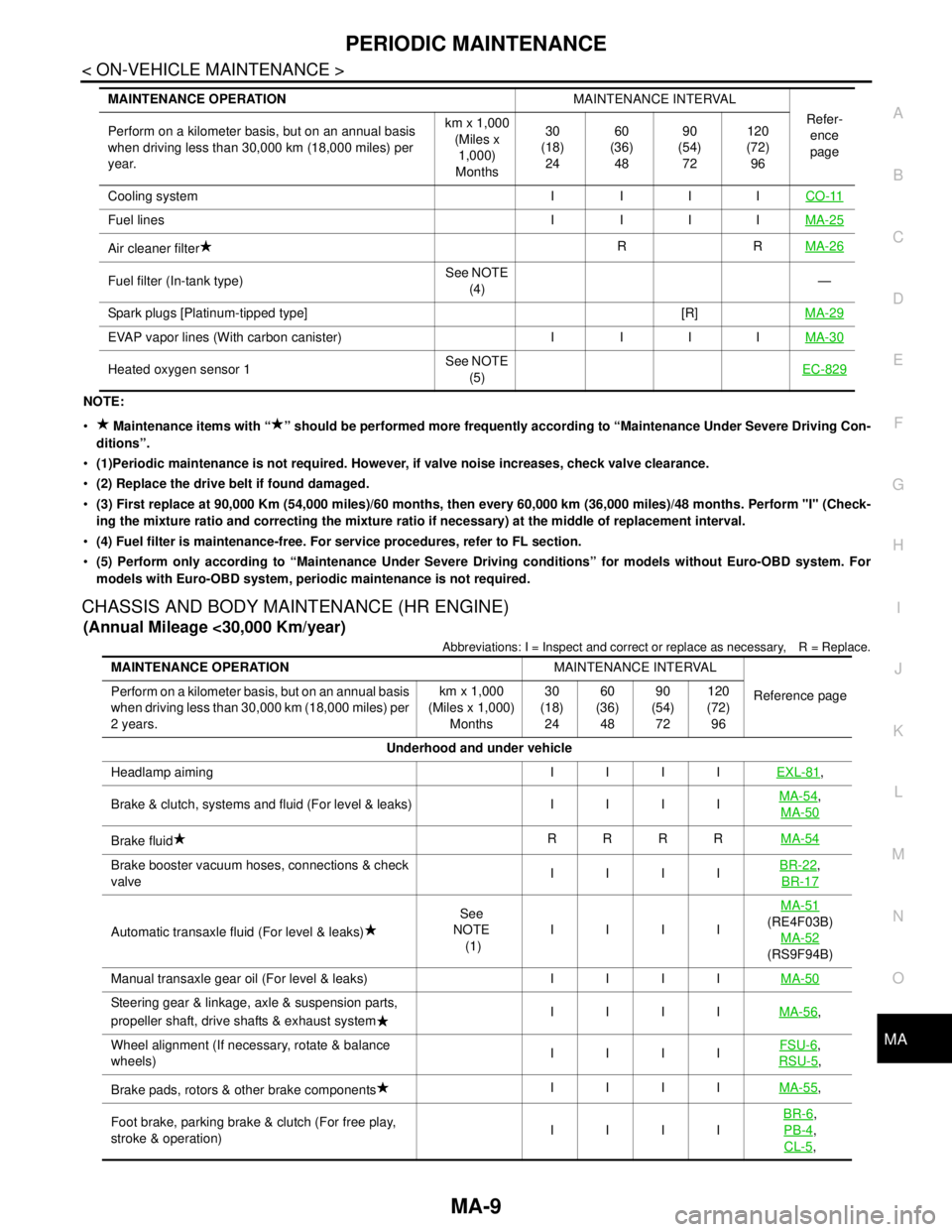

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged.

(3) First replace at 90,000 Km (54,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform "I" (Check-

ing the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Perform only according to “Maintenance Under Severe Driving conditions” for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (HR ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace.

Cooling system I I I ICO-11

Fuel lines I I I IMA-25

Air cleaner filterRRMA-26

Fuel filter (In-tank type)See NOTE

(4)—

Spark plugs [Platinum-tipped type] [R]MA-29

EVAP vapor lines (With carbon canister) I I I IMA-30

Heated oxygen sensor 1See NOTE

(5)EC-829

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on an annual basis

when driving less than 30,000 km (18,000 miles) per

year.km x 1,000

(Miles x

1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page Perform on a kilometer basis, but on an annual basis

when driving less than 30,000 km (18,000 miles) per

2 years.km x 1,000

(Miles x 1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Underhood and under vehicle

Headlamp aiming IIIIEXL-81

,

Brake & clutch, systems and fluid (For level & leaks) IIIIMA-54

,

MA-50

Brake fluidRRRRMA-54

Brake booster vacuum hoses, connections & check

valveIIIIBR-22,

BR-17

Automatic transaxle fluid (For level & leaks)See

NOTE

(1)IIIIMA-51(RE4F03B)

MA-52

(RS9F94B)

Manual transaxle gear oil (For level & leaks) IIIIMA-50

Steering gear & linkage, axle & suspension parts,

propeller shaft, drive shafts & exhaust systemIIIIMA-56,

Wheel alignment (If necessary, rotate & balance

wheels)IIIIFSU-6

,

RSU-5

,

Brake pads, rotors & other brake componentsIIIIMA-55

,

Foot brake, parking brake & clutch (For free play,

stroke & operation)IIIIBR-6

,

PB-4

,

CL-5

,