steering NISSAN TIIDA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 206 of 5883

BR-14

< ON-VEHICLE REPAIR >

BRAKE TUBE AND HOSE

BRAKE TUBE AND HOSE

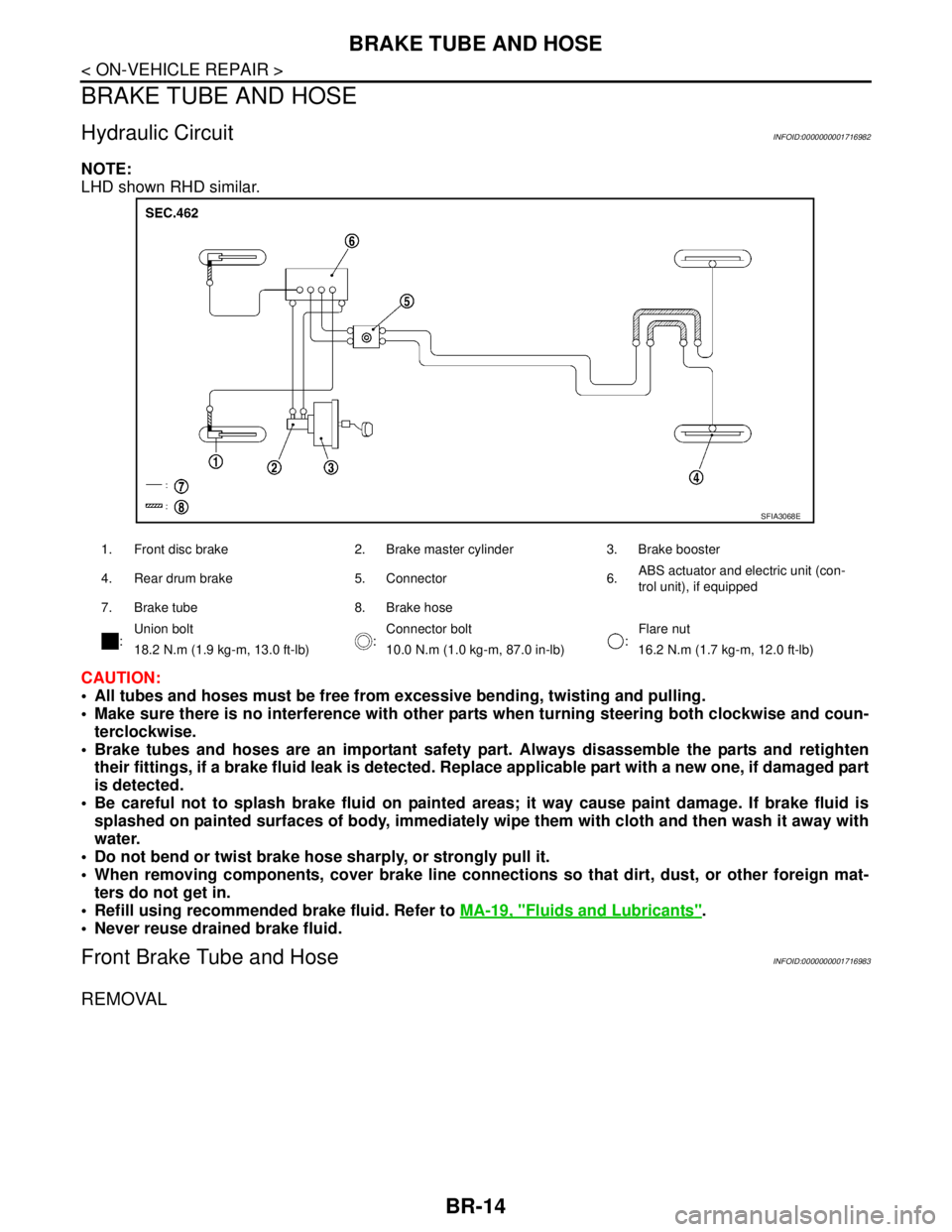

Hydraulic CircuitINFOID:0000000001716982

NOTE:

LHD shown RHD similar.

CAUTION:

All tubes and hoses must be free from excessive bending, twisting and pulling.

Make sure there is no interference with other parts when turning steering both clockwise and coun-

terclockwise.

Brake tubes and hoses are an important safety part. Always disassemble the parts and retighten

their fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part

is detected.

Be careful not to splash brake fluid on painted areas; it way cause paint damage. If brake fluid is

splashed on painted surfaces of body, immediately wipe them with cloth and then wash it away with

water.

Do not bend or twist brake hose sharply, or strongly pull it.

When removing components, cover brake line connections so that dirt, dust, or other foreign mat-

ters do not get in.

Refill using recommended brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Front Brake Tube and HoseINFOID:0000000001716983

REMOVAL

1. Front disc brake 2. Brake master cylinder 3. Brake booster

4. Rear drum brake 5. Connector 6.ABS actuator and electric unit (con-

trol unit), if equipped

7. Brake tube 8. Brake hose

:Union bolt

:Connector bolt

:Flare nut

18.2 N.m (1.9 kg-m, 13.0 ft-lb) 10.0 N.m (1.0 kg-m, 87.0 in-lb) 16.2 N.m (1.7 kg-m, 12.0 ft-lb)

SFIA3068E

Page 218 of 5883

BR-26

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

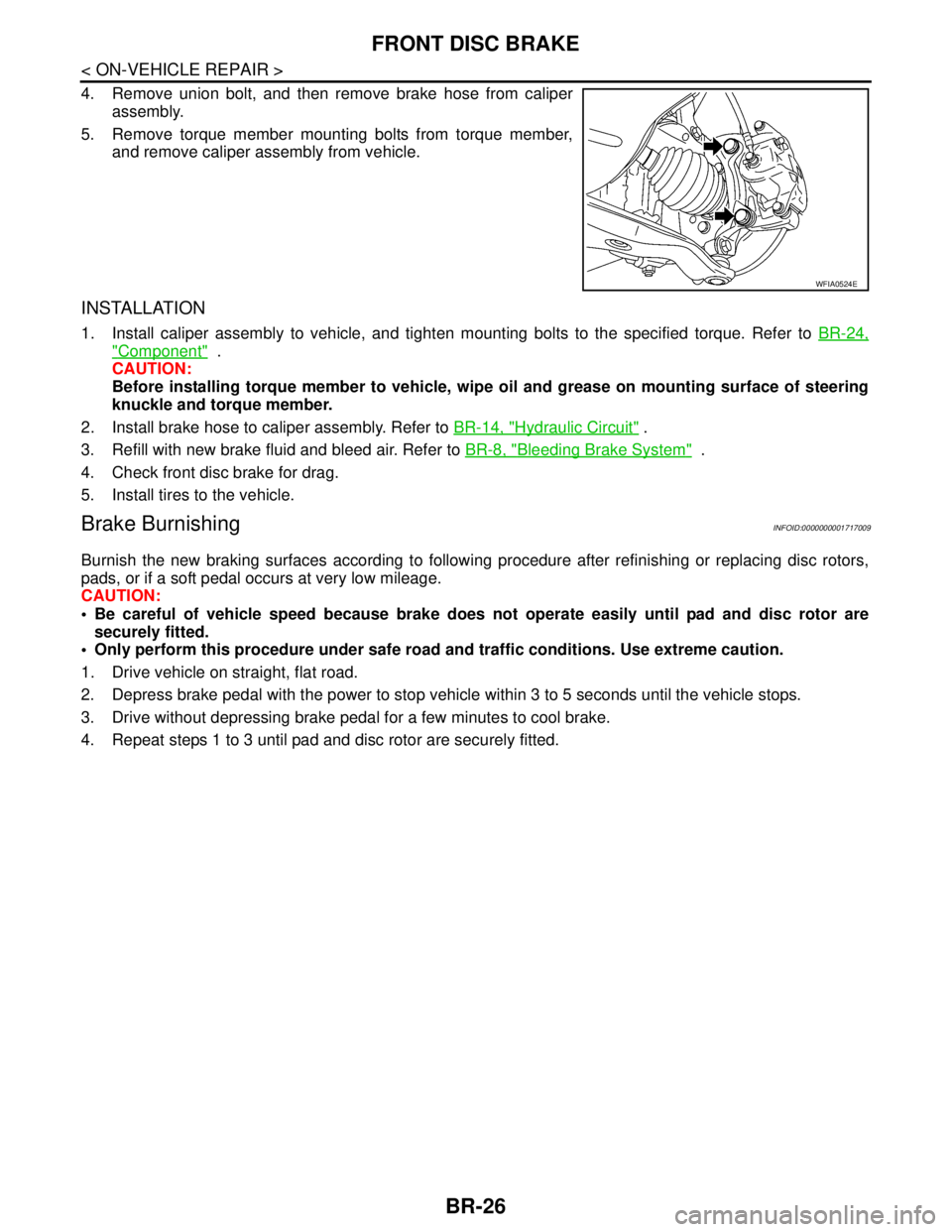

4. Remove union bolt, and then remove brake hose from caliper

assembly.

5. Remove torque member mounting bolts from torque member,

and remove caliper assembly from vehicle.

INSTALLATION

1. Install caliper assembly to vehicle, and tighten mounting bolts to the specified torque. Refer to BR-24,

"Component" .

CAUTION:

Before installing torque member to vehicle, wipe oil and grease on mounting surface of steering

knuckle and torque member.

2. Install brake hose to caliper assembly. Refer to BR-14, "

Hydraulic Circuit" .

3. Refill with new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System" .

4. Check front disc brake for drag.

5. Install tires to the vehicle.

Brake BurnishingINFOID:0000000001717009

Burnish the new braking surfaces according to following procedure after refinishing or replacing disc rotors,

pads, or if a soft pedal occurs at very low mileage.

CAUTION:

Be careful of vehicle speed because brake does not operate easily until pad and disc rotor are

securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake pedal for a few minutes to cool brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

WFIA0524E

Page 234 of 5883

BRC-1

BRAKES

C

D

E

G

H

I

J

K

L

M

SECTION BRC

A

B

BRC

N

O

P

CONTENTS

BRAKE CONTROL SYSTEM

ABS

BASIC INSPECTION ....................................

6

DIAGNOSIS AND REPAIR WORKFLOW ..........6

Work Flow .................................................................6

Diagnostic Work Sheet ..............................................9

INSPECTION AND ADJUSTMENT ....................10

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ........................................................

10

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

10

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

10

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION ................................................

10

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Description ........................

10

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Special Repair Require-

ment ........................................................................

10

CALIBRATION OF DECEL G SENSOR ...................11

CALIBRATION OF DECEL G SENSOR : Descrip-

tion ..........................................................................

11

CALIBRATION OF DECEL G SENSOR : Special

Repair Requirement ................................................

12

FUNCTION DIAGNOSIS ..............................13

VDC ....................................................................13

System Diagram ......................................................13

System Description .................................................13

Component Parts Location ......................................14

Component Description ...........................................15

TCS .....................................................................16

System Diagram ......................................................16

System Description .................................................16

Component Parts Location ......................................17

Component Description ...........................................18

ABS ...................................................................19

System Diagram ......................................................19

System Description ..................................................19

Component Parts Location ......................................20

Component Description ...........................................21

EBD ...................................................................22

System Diagram ......................................................22

System Description ..................................................22

Component Parts Location ......................................23

Component Description ...........................................24

DIAGNOSIS SYSTEM [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)] .......

25

CONSULT-III Function (ABS) ..................................25

COMPONENT DIAGNOSIS .........................30

C1101, C1102, C1103, C1104 WHEEL SEN-

SOR-1 ................................................................

30

Description ...............................................................30

DTC Logic ................................................................30

Diagnosis Procedure ...............................................30

Component Inspection .............................................32

Special Repair Requirement ....................................32

C1105, C1106, C1107, C1108 WHEEL SEN-

SOR-2 ................................................................

33

Description ...............................................................33

DTC Logic ................................................................33

Diagnosis Procedure ...............................................33

Component Inspection .............................................35

Special Repair Requirement ....................................35

C1109 POWER AND GROUND SYSTEM ........36

Description ...............................................................36

DTC Logic ................................................................36

Diagnosis Procedure ...............................................36

Special Repair Requirement ....................................37

Page 236 of 5883

BRC-3

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

PREPARATION ...........................................82

PREPARATION ..................................................82

Special Service Tool ...............................................82

REMOVAL AND INSTALLATION ...............83

WHEEL SENSORS ............................................83

Removal and Installation .........................................83

SENSOR ROTOR ...............................................84

Removal and Installation .........................................84

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ....................................................................

85

Removal and Installation .........................................85

ESP/TCS/ABS

BASIC INSPECTION ...................................

86

DIAGNOSIS AND REPAIR WORKFLOW .........86

Work Flow ...............................................................86

Diagnostic Work Sheet ............................................89

INSPECTION AND ADJUSTMENT ....................90

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ........................................................

90

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

90

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

90

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION ................................................

90

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Description ........................

90

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Special Repair Require-

ment ........................................................................

90

CALIBRATION OF DECEL G SENSOR ...................91

CALIBRATION OF DECEL G SENSOR : Descrip-

tion ..........................................................................

91

CALIBRATION OF DECEL G SENSOR : Special

Repair Requirement ................................................

92

FUNCTION DIAGNOSIS ..............................93

VDC ....................................................................93

System Diagram ......................................................93

System Description .................................................93

Component Parts Location ......................................94

Component Description ...........................................95

TCS .....................................................................96

System Diagram ......................................................96

System Description .................................................96

Component Parts Location ......................................97

Component Description ...........................................98

ABS ....................................................................99

System Diagram ......................................................99

System Description ..................................................99

Component Parts Location ....................................100

Component Description .........................................101

EBD .................................................................102

System Diagram ....................................................102

System Description ................................................102

Component Parts Location ....................................103

Component Description .........................................104

DIAGNOSIS SYSTEM [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)] .....

105

CONSULT-III Function (ABS) ................................105

COMPONENT DIAGNOSIS .......................110

C1101, C1102, C1103, C1104 WHEEL SEN-

SOR-1 ..............................................................

110

Description .............................................................110

DTC Logic ..............................................................110

Diagnosis Procedure .............................................110

Component Inspection ...........................................112

Special Repair Requirement ..................................112

C1105, C1106, C1107, C1108 WHEEL SEN-

SOR-2 ..............................................................

113

Description .............................................................113

DTC Logic ..............................................................113

Diagnosis Procedure .............................................113

Component Inspection ...........................................115

Special Repair Requirement ..................................115

C1109 POWER AND GROUND SYSTEM ......116

Description .............................................................116

DTC Logic ..............................................................116

Diagnosis Procedure .............................................116

Special Repair Requirement ..................................117

C1110, C1170 ABS ACTUATOR AND ELEC-

TRIC UNIT (CONTROL UNIT) ........................

118

DTC Logic ..............................................................118

Diagnosis Procedure .............................................118

Special Repair Requirement ..................................118

C1111 ABS MOTOR, MOTOR RELAY SYS-

TEM .................................................................

119

Description .............................................................119

DTC Logic ..............................................................119

Diagnosis Procedure .............................................119

Component Inspection ...........................................120

Special Repair Requirement ..................................120

C1113, C1145, C1146 YAW RATE/SIDE/DE-

CEL G SENSOR ..............................................

121

Description .............................................................121

DTC Logic ..............................................................121

Diagnosis Procedure .............................................121

Component Inspection ...........................................122

Special Repair Requirement ..................................122

Page 237 of 5883

BRC-4

C1115 WHEEL SENSOR .................................124

Description .............................................................124

DTC Logic ..............................................................124

Diagnosis Procedure .............................................124

Component Inspection ...........................................125

Special Repair Requirement ..................................126

C1116 STOP LAMP SWITCH ..........................127

Description .............................................................127

DTC Logic ..............................................................127

Diagnosis Procedure .............................................127

Special Repair Requirement ..................................128

C1120, C1122, C1124, C1126 IN ABS SOL ...129

Description .............................................................129

DTC Logic ..............................................................129

Diagnosis Procedure .............................................129

Component Inspection ...........................................130

Special Repair Requirement ..................................131

C1121, C1123, C1125, C1127 OUT ABS SOL .132

Description .............................................................132

DTC Logic ..............................................................132

Diagnosis Procedure .............................................132

Component Inspection ...........................................133

Special Repair Requirement ..................................134

C1130, C1131, C1132, C1133, C1136 EN-

GINE SIGNAL ..................................................

135

Description .............................................................135

DTC Logic ..............................................................135

Diagnosis Procedure .............................................135

Special Repair Requirement ..................................135

C1140 ACTUATOR RLY .................................137

Description .............................................................137

DTC Logic ..............................................................137

Diagnosis Procedure .............................................137

Component Inspection ...........................................138

Special Repair Requirement ..................................138

C1142 PRESS SENSOR .................................139

Description .............................................................139

DTC Logic ..............................................................139

Diagnosis Procedure .............................................139

Component Inspection ...........................................141

Special Repair Requirement ..................................141

C1143, C1144 STEERING ANGLE SENSOR .142

Description .............................................................142

DTC Logic ..............................................................142

Diagnosis Procedure .............................................142

Component Inspection ...........................................143

Special Repair Requirement ..................................143

C1155 BRAKE FLUID LEVEL SWITCH ..........145

Description .............................................................145

DTC Logic ..............................................................145

Diagnosis Procedure .............................................145

Component Inspection ...........................................146

Special Repair Requirement ..................................146

C1156 ST ANG SEN COM CIR ........................148

Description ............................................................148

DTC Logic .............................................................148

Diagnosis Procedure .............................................148

C1160 DECEL G SEN SET ..............................149

Description ............................................................149

DTC Logic .............................................................149

Diagnosis Procedure .............................................149

C1163 ST ANGLE SEN SAFE .........................150

Description ............................................................150

DTC Logic .............................................................150

Diagnosis Procedure .............................................150

C1179 ABS DELTA S SEN NG ........................151

Description ............................................................151

DTC Logic .............................................................151

Diagnosis Procedure .............................................151

Component Inspection ..........................................152

Special Repair Requirement .................................152

U1000 CAN COMM CIRCUIT ...........................153

Description ............................................................153

DTC Logic .............................................................153

Diagnosis Procedure .............................................153

Special Repair Requirement .................................153

VDC OFF SWITCH ...........................................154

Description ............................................................154

Component Function Check .................................154

Diagnosis Procedure .............................................154

Component Inspection ..........................................155

ABS WARNING LAMP .....................................156

Description ............................................................156

Component Function Check .................................156

Diagnosis Procedure .............................................156

BRAKE WARNING LAMP ................................157

Description ............................................................157

Component Function Check .................................157

Diagnosis Procedure .............................................157

VDC OFF INDICATOR LAMP ..........................158

Description ............................................................158

Component Function Check .................................158

Diagnosis Procedure .............................................158

SLIP INDICATOR LAMP ..................................159

Description ............................................................159

Component Function Check .................................159

Diagnosis Procedure .............................................159

ECU DIAGNOSIS ......................................160

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .............................................

160

Reference Value ...................................................160

Wiring Diagram - LHD ...........................................165

Wiring Diagram - RHD ..........................................167

Page 238 of 5883

BRC-5

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P Fail-Safe ................................................................

168

DTC No. Index ......................................................169

SYMPTOM DIAGNOSIS ............................171

VDC/TCS/ABS ..................................................171

Symptom Table .....................................................171

EXCESSIVE ABS FUNCTION OPERATION

FREQUENCY ...................................................

172

Diagnosis Procedure .............................................172

UNEXPECTED PEDAL REACTION ................173

Diagnosis Procedure .............................................173

THE BRAKING DISTANCE IS LONG ..............174

Diagnosis Procedure .............................................174

ABS FUNCTION DOES NOT OPERATE .........175

Diagnosis Procedure .............................................175

PEDAL VIBRATION OR ABS OPERATION

SOUND OCCURS ............................................

176

Diagnosis Procedure .............................................176

VEHICLE JERKS DURING VDC/TCS/ABS

CONTROL ........................................................

177

Diagnosis Procedure .............................................177

NORMAL OPERATING CONDITION ...............178

Description ............................................................178

PRECAUTION ............................................179

PRECAUTIONS ...............................................179

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

179

Precaution for Brake System .................................179

Precaution for Brake Control .................................179

Diagnosis Precaution .............................................180

Precaution for Harness Repair ..............................180

PREPARATION .........................................181

PREPARATION ...............................................181

Special Service Tool ..............................................181

REMOVAL AND INSTALLATION .............182

WHEEL SENSORS .........................................182

Removal and Installation .......................................182

SENSOR ROTOR ............................................183

Removal and Installation .......................................183

ACTUATOR AND ELECTRIC UNIT (ASSEM-

BLY) ................................................................

184

Removal and Installation .......................................184

YAW RATE/SIDE G SENSOR ........................185

Removal and Installation .......................................185

STEERING ANGLE SENSOR .........................186

Removal and Installation .......................................186

Page 239 of 5883

![NISSAN TIIDA 2007 Service Owners Guide BRC-6

< BASIC INSPECTION >[ABS]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001731351

PRECAUTIONS FOR DIAGNOSIS

If steering angle sensor, steeri NISSAN TIIDA 2007 Service Owners Guide BRC-6

< BASIC INSPECTION >[ABS]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001731351

PRECAUTIONS FOR DIAGNOSIS

If steering angle sensor, steeri](/img/5/57395/w960_57395-238.png)

BRC-6

< BASIC INSPECTION >[ABS]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001731351

PRECAUTIONS FOR DIAGNOSIS

If steering angle sensor, steering system parts, suspension system parts, ABS actuator and electric unit (con-

trol unit) or tires have been replaced, or if wheel alignment has been adjusted, be sure to adjust neutral posi-

tion of steering angle sensor before driving. Refer to BRC-90, "

ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION : Description".

Page 243 of 5883

![NISSAN TIIDA 2007 Service Owners Guide BRC-10

< BASIC INSPECTION >[ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID: NISSAN TIIDA 2007 Service Owners Guide BRC-10

< BASIC INSPECTION >[ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID:](/img/5/57395/w960_57395-242.png)

BRC-10

< BASIC INSPECTION >[ABS]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID:0000000001731353

After replacing the ABS actuator and electric unit (control unit), perform the following procedures:

Neutral position adjustment for the steering angle sensor

Calibration of the decel G sensor

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000001731354

1.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

Perform the neutral position adjustment for the steering angle sensor.

>> Refer to BRC-90, "

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Spe-

cial Repair Requirement", GO TO 2

2.PERFORM CALIBRATION OF THE DECEL G SENSOR

Perform calibration of the decel G sensor.

>> Refer to BRC-92, "

CALIBRATION OF DECEL G SENSOR : Special Repair Requirement".

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Description

INFOID:0000000001731355

Refer to the table below to determine if adjustment of steering angle sensor neutral position is required.

×: Required –: Not required

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Special Re-

pair Requirement

INFOID:0000000001731356

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

CAUTION:

To adjust neutral position of steering angle sensor, make sure to use CONSULT-III

(Adjustment cannot be done without CONSULT-III)

1.ALIGN THE VEHICLE STATUS

Stop vehicle with front wheels in straight-ahead position.

Situation Adjustment of steering angle sensor neutral position

Removing/Installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit)×

Removing/Installing steering angle sensor×

Replacing steering angle sensor×

Removing/Installing steering components×

Replacing steering components×

Removing/Installing suspension components×

Replacing suspension components×

Change tires to new ones—

Tire rotation—

Adjusting wheel alignment×

Page 244 of 5883

![NISSAN TIIDA 2007 Service Owners Guide INSPECTION AND ADJUSTMENT

BRC-11

< BASIC INSPECTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT-III scr NISSAN TIIDA 2007 Service Owners Guide INSPECTION AND ADJUSTMENT

BRC-11

< BASIC INSPECTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT-III scr](/img/5/57395/w960_57395-243.png)

INSPECTION AND ADJUSTMENT

BRC-11

< BASIC INSPECTION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUSTMENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT-III screen, touch “WORK SUPPORT” and “ST ANG SEN ADJUSTMENT” in order.

2. Touch “START”.

CAUTION:

Do not touch steering wheel while adjusting steering angle sensor.

3. After approximately 10 seconds, touch “END”.

NOTE:

After approximately 60 seconds, it ends automatically.

4. Turn ignition switch OFF, then turn it ON again.

CAUTION:

Be sure to perform above operation.

>> GO TO 3

3.CHECK DATA MONITOR

1. Run vehicle with front wheels in straight-ahead position, then stop.

2. Select “DATA MONITOR”. Then make sure “STR ANGLE SIG” is within 0±2.5°.

Is the steering angle within the specified range?

YES >> GO TO 4

NO >> Perform the neutral position adjustment for the steering angle sensor again, GO TO 1

4.ERASE THE SELF-DIAGNOSIS MEMORY

Erase the self-diagnosis memory of the ABS actuator and electric unit (control unit) and ECM.

ABS actuator and electric unit (control unit): Refer to BRC-25, "

CONSULT-III Function (ABS)".

ECM, refer to:

-EC-107, "

CONSULT-III Function" (HR16DE with EURO-OBD)

-EC-462, "

CONSULT-III Function" (HR16DE without EURO-OBD)

-EC-772, "

CONSULT-III Function" (MR18DE)

-EC-1104, "

Diagnosis Description" (K9K)

Are the memories erased?

YES >> INSPECTION END

NO >> Check the items indicated by the self-diagnosis.

CALIBRATION OF DECEL G SENSOR

CALIBRATION OF DECEL G SENSOR : DescriptionINFOID:0000000001731357

Refer to the table below to determine if calibration of the decel G sensor is required.

×: Required –: Not required

Situation Calibration of decel G sensor

Removing/Installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit)×

Removing/Installing steering angle sensor×

Replacing steering angle sensor×

Removing/Installing steering components×

Replacing steering components×

Removing/Installing suspension components×

Replacing suspension components×

Change tires to new ones—

Tire rotation—

Adjusting wheel alignment×

Page 246 of 5883

![NISSAN TIIDA 2007 Service Owners Guide VDC

BRC-13

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

FUNCTION DIAGNOSIS

VDC

System DiagramINFOID:0000000001731208

System DescriptionINFOID:0000000001731209

Vehicle Dynamics Contro NISSAN TIIDA 2007 Service Owners Guide VDC

BRC-13

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

FUNCTION DIAGNOSIS

VDC

System DiagramINFOID:0000000001731208

System DescriptionINFOID:0000000001731209

Vehicle Dynamics Contro](/img/5/57395/w960_57395-245.png)

VDC

BRC-13

< FUNCTION DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

FUNCTION DIAGNOSIS

VDC

System DiagramINFOID:0000000001731208

System DescriptionINFOID:0000000001731209

Vehicle Dynamics Control system detects driver′s steering operation amount and brake pedal travel from

steering angle sensor and pressure sensors. Using information from yaw rate/side/decel G sensor and

wheel sensor, VDC judges driving condition (conditions of under steer and over steer) to improve vehicle

driving stability by controlling brake application to 4 wheels and engine output.

During VDC operation, it informs driver of system operation by flashing SLIP indicator lamp.

Electrical system diagnosis by CONSULT-III is available.

AWFIA0012GB