ECU NISSAN TIIDA 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 188 of 5883

BCS

BCM (BODY CONTROL MODULE)

BCS-53

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

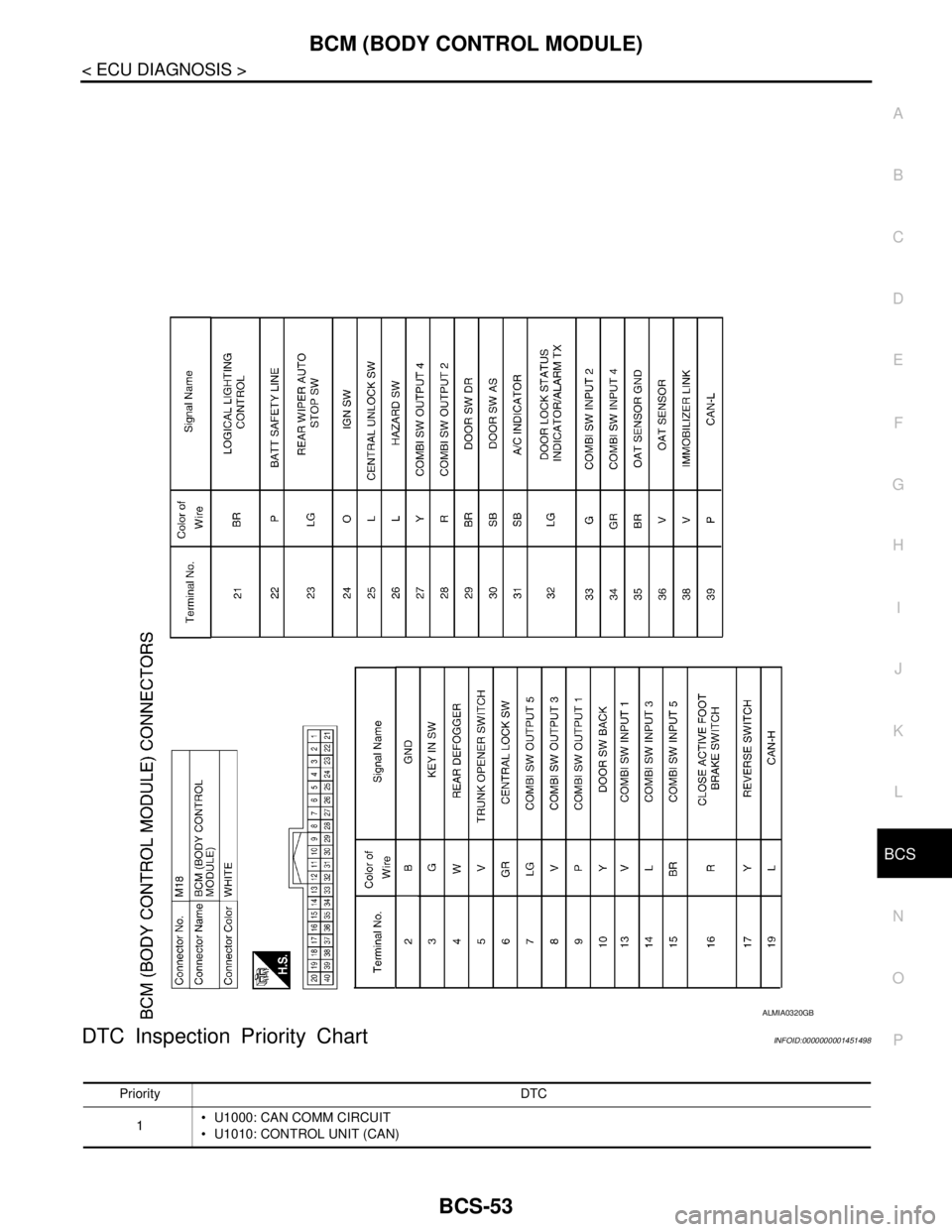

DTC Inspection Priority ChartINFOID:0000000001451498

ALMIA0320GB

Priority DTC

1 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

Page 189 of 5883

BCS-54

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

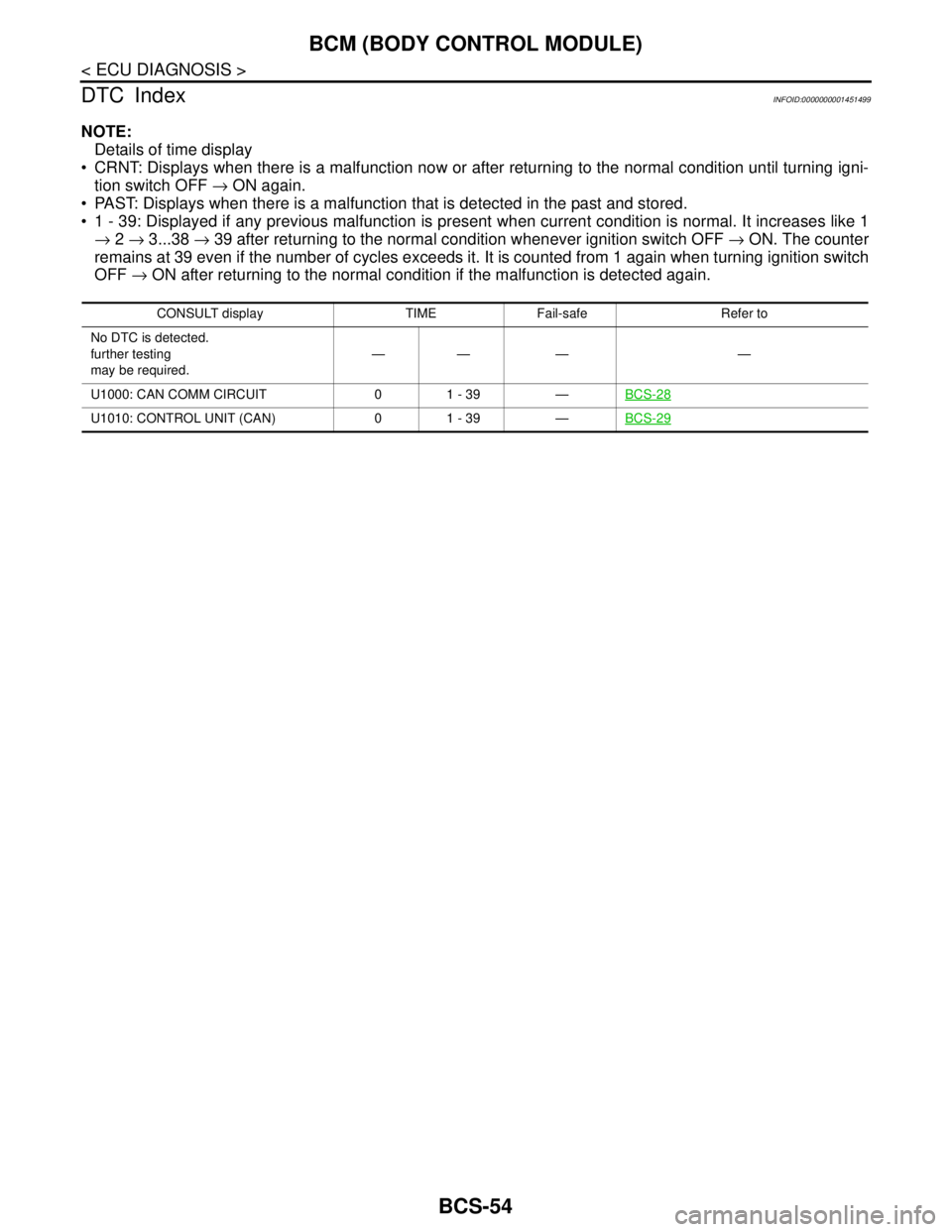

DTC Index

INFOID:0000000001451499

NOTE:

Details of time display

CRNT: Displays when there is a malfunction now or after returning to the normal condition until turning igni-

tion switch OFF → ON again.

PAST: Displays when there is a malfunction that is detected in the past and stored.

1 - 39: Displayed if any previous malfunction is present when current condition is normal. It increases like 1

→ 2 → 3...38 → 39 after returning to the normal condition whenever ignition switch OFF → ON. The counter

remains at 39 even if the number of cycles exceeds it. It is counted from 1 again when turning ignition switch

OFF → ON after returning to the normal condition if the malfunction is detected again.

CONSULT display TIME Fail-safe Refer to

No DTC is detected.

further testing

may be required.—— — —

U1000: CAN COMM CIRCUIT 0 1 - 39 —BCS-28

U1010: CONTROL UNIT (CAN) 0 1 - 39 —BCS-29

Page 199 of 5883

BRAKE PEDAL

BR-7

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

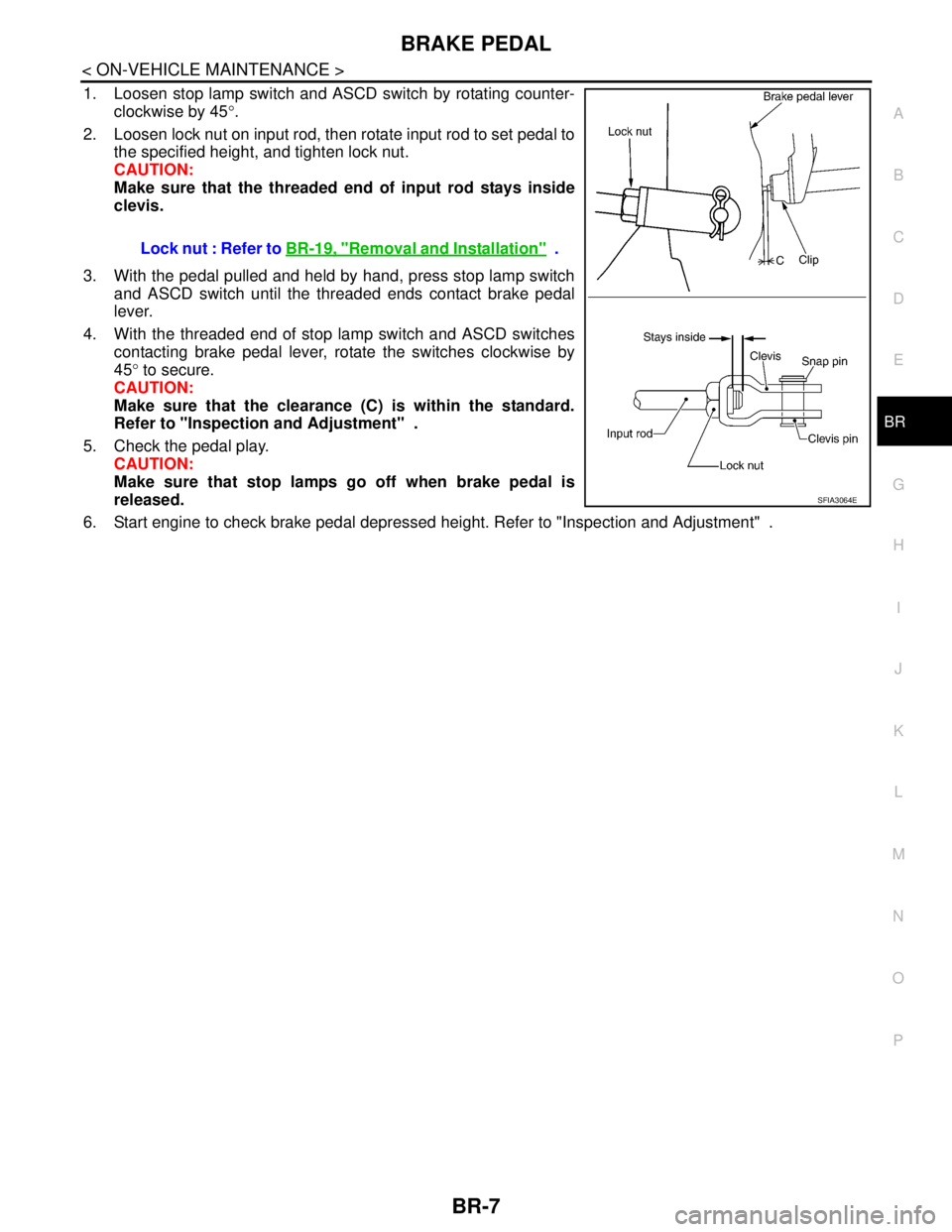

1. Loosen stop lamp switch and ASCD switch by rotating counter-

clockwise by 45°.

2. Loosen lock nut on input rod, then rotate input rod to set pedal to

the specified height, and tighten lock nut.

CAUTION:

Make sure that the threaded end of input rod stays inside

clevis.

3. With the pedal pulled and held by hand, press stop lamp switch

and ASCD switch until the threaded ends contact brake pedal

lever.

4. With the threaded end of stop lamp switch and ASCD switches

contacting brake pedal lever, rotate the switches clockwise by

45° to secure.

CAUTION:

Make sure that the clearance (C) is within the standard.

Refer to "Inspection and Adjustment" .

5. Check the pedal play.

CAUTION:

Make sure that stop lamps go off when brake pedal is

released.

6. Start engine to check brake pedal depressed height. Refer to "Inspection and Adjustment" . Lock nut : Refer to BR-19, "

Removal and Installation" .

SFIA3064E

Page 207 of 5883

BRAKE TUBE AND HOSE

BR-15

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

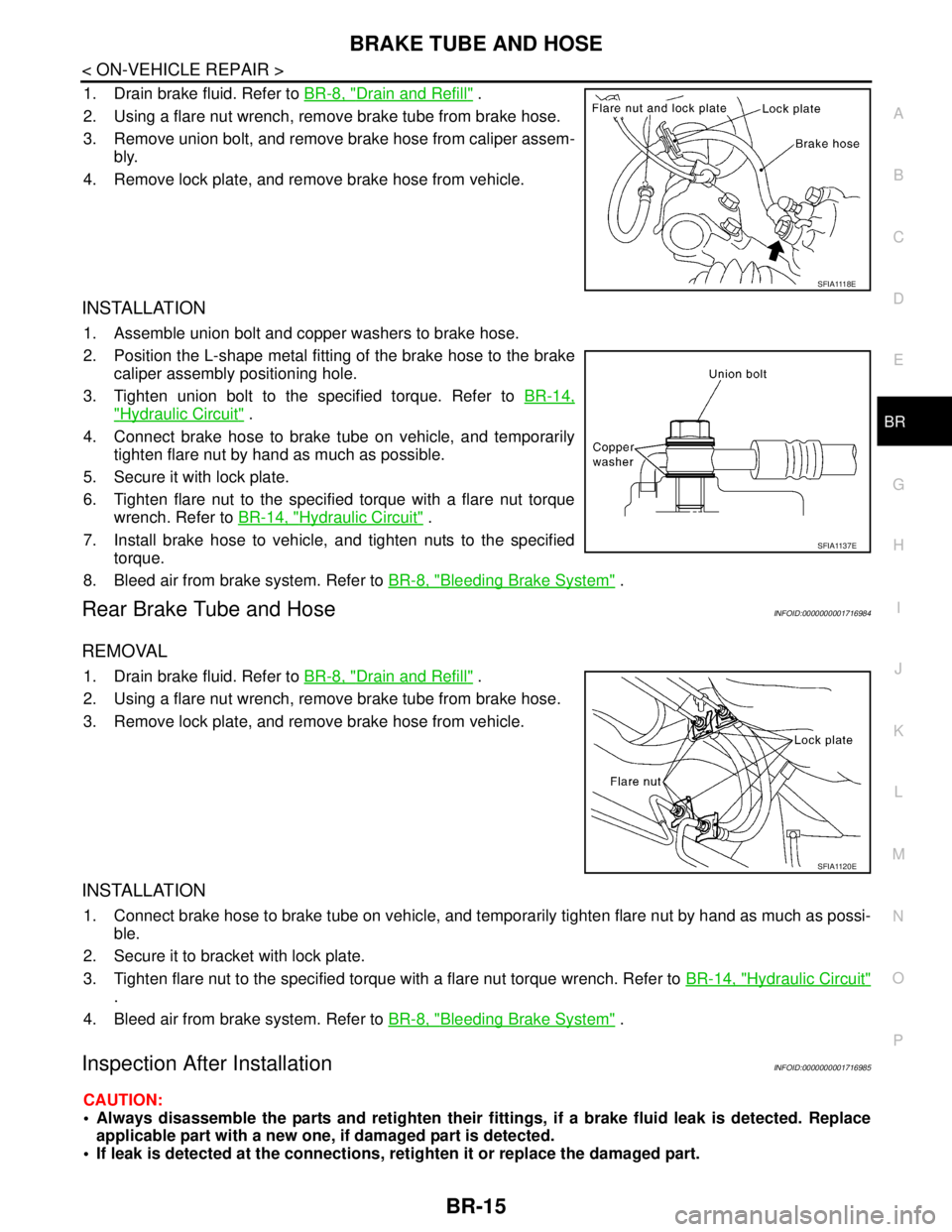

1. Drain brake fluid. Refer to BR-8, "Drain and Refill" .

2. Using a flare nut wrench, remove brake tube from brake hose.

3. Remove union bolt, and remove brake hose from caliper assem-

bly.

4. Remove lock plate, and remove brake hose from vehicle.

INSTALLATION

1. Assemble union bolt and copper washers to brake hose.

2. Position the L-shape metal fitting of the brake hose to the brake

caliper assembly positioning hole.

3. Tighten union bolt to the specified torque. Refer to BR-14,

"Hydraulic Circuit" .

4. Connect brake hose to brake tube on vehicle, and temporarily

tighten flare nut by hand as much as possible.

5. Secure it with lock plate.

6. Tighten flare nut to the specified torque with a flare nut torque

wrench. Refer to BR-14, "

Hydraulic Circuit" .

7. Install brake hose to vehicle, and tighten nuts to the specified

torque.

8. Bleed air from brake system. Refer to BR-8, "

Bleeding Brake System" .

Rear Brake Tube and HoseINFOID:0000000001716984

REMOVAL

1. Drain brake fluid. Refer to BR-8, "Drain and Refill" .

2. Using a flare nut wrench, remove brake tube from brake hose.

3. Remove lock plate, and remove brake hose from vehicle.

INSTALLATION

1. Connect brake hose to brake tube on vehicle, and temporarily tighten flare nut by hand as much as possi-

ble.

2. Secure it to bracket with lock plate.

3. Tighten flare nut to the specified torque with a flare nut torque wrench. Refer to BR-14, "

Hydraulic Circuit"

.

4. Bleed air from brake system. Refer to BR-8, "

Bleeding Brake System" .

Inspection After InstallationINFOID:0000000001716985

CAUTION:

Always disassemble the parts and retighten their fittings, if a brake fluid leak is detected. Replace

applicable part with a new one, if damaged part is detected.

If leak is detected at the connections, retighten it or replace the damaged part.

S F I A 111 8 E

SFIA1137E

SFIA1120E

Page 217 of 5883

FRONT DISC BRAKE

BR-25

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

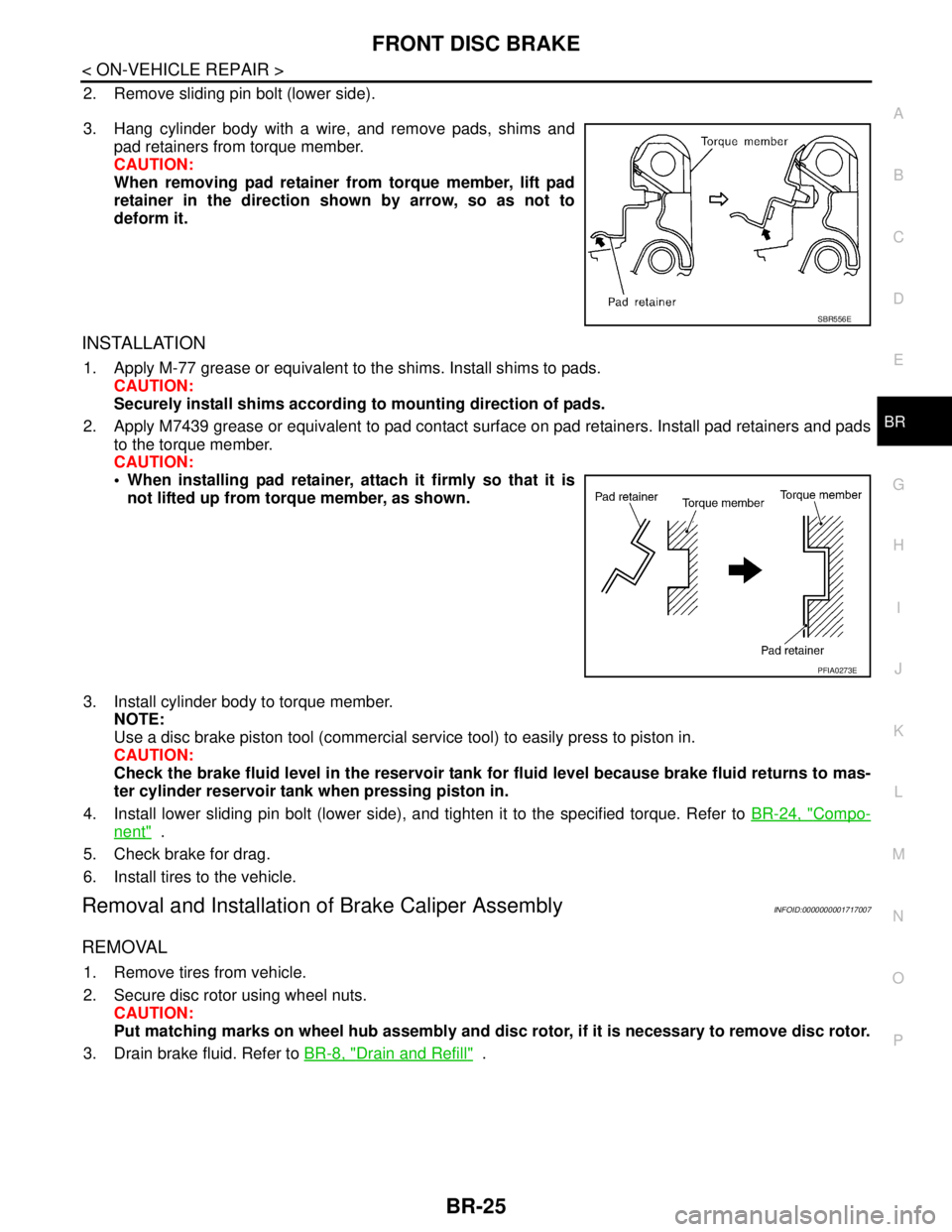

2. Remove sliding pin bolt (lower side).

3. Hang cylinder body with a wire, and remove pads, shims and

pad retainers from torque member.

CAUTION:

When removing pad retainer from torque member, lift pad

retainer in the direction shown by arrow, so as not to

deform it.

INSTALLATION

1. Apply M-77 grease or equivalent to the shims. Install shims to pads.

CAUTION:

Securely install shims according to mounting direction of pads.

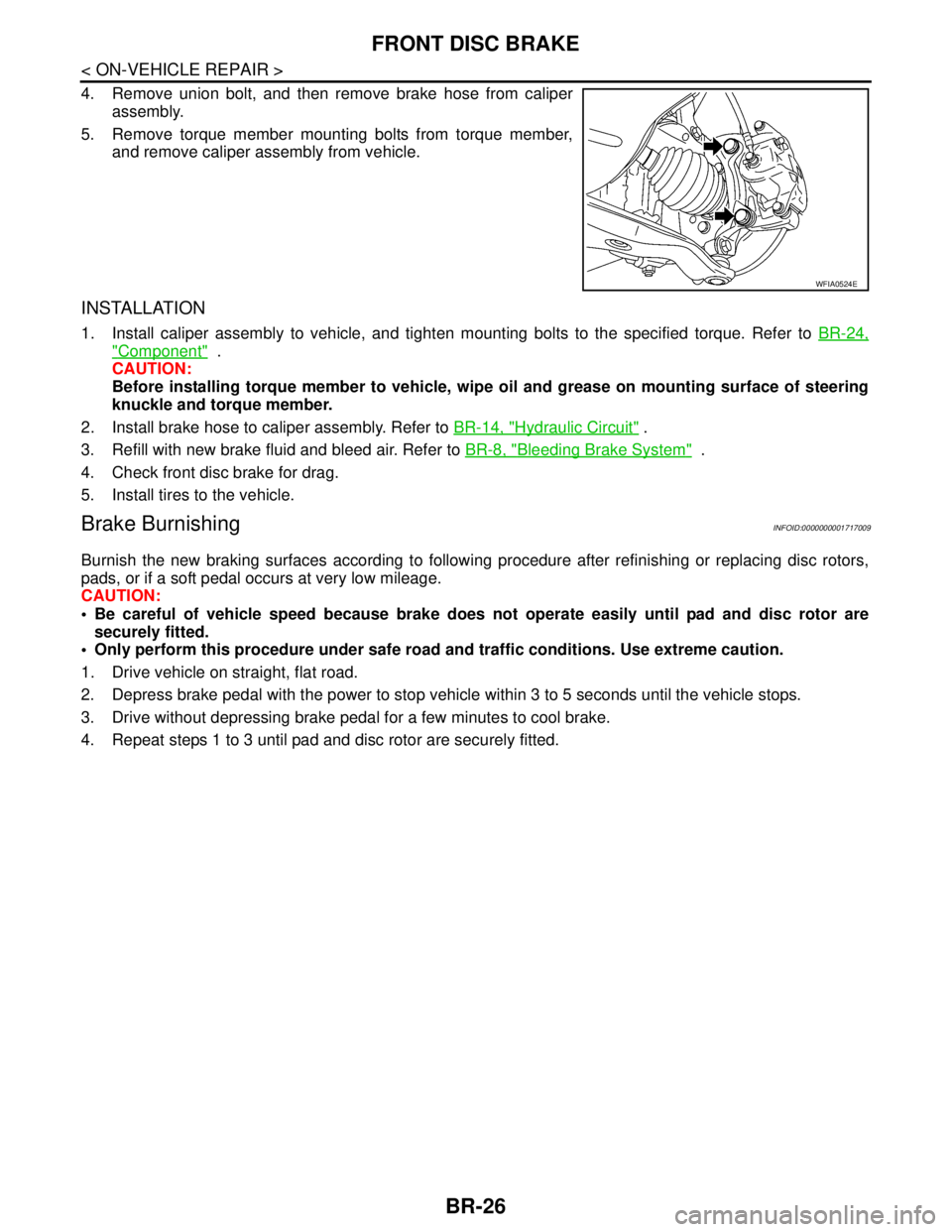

2. Apply M7439 grease or equivalent to pad contact surface on pad retainers. Install pad retainers and pads

to the torque member.

CAUTION:

When installing pad retainer, attach it firmly so that it is

not lifted up from torque member, as shown.

3. Install cylinder body to torque member.

NOTE:

Use a disc brake piston tool (commercial service tool) to easily press to piston in.

CAUTION:

Check the brake fluid level in the reservoir tank for fluid level because brake fluid returns to mas-

ter cylinder reservoir tank when pressing piston in.

4. Install lower sliding pin bolt (lower side), and tighten it to the specified torque. Refer to BR-24, "

Compo-

nent" .

5. Check brake for drag.

6. Install tires to the vehicle.

Removal and Installation of Brake Caliper AssemblyINFOID:0000000001717007

REMOVAL

1. Remove tires from vehicle.

2. Secure disc rotor using wheel nuts.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor, if it is necessary to remove disc rotor.

3. Drain brake fluid. Refer to BR-8, "

Drain and Refill" .

SBR556E

PFIA0273E

Page 218 of 5883

BR-26

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

4. Remove union bolt, and then remove brake hose from caliper

assembly.

5. Remove torque member mounting bolts from torque member,

and remove caliper assembly from vehicle.

INSTALLATION

1. Install caliper assembly to vehicle, and tighten mounting bolts to the specified torque. Refer to BR-24,

"Component" .

CAUTION:

Before installing torque member to vehicle, wipe oil and grease on mounting surface of steering

knuckle and torque member.

2. Install brake hose to caliper assembly. Refer to BR-14, "

Hydraulic Circuit" .

3. Refill with new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System" .

4. Check front disc brake for drag.

5. Install tires to the vehicle.

Brake BurnishingINFOID:0000000001717009

Burnish the new braking surfaces according to following procedure after refinishing or replacing disc rotors,

pads, or if a soft pedal occurs at very low mileage.

CAUTION:

Be careful of vehicle speed because brake does not operate easily until pad and disc rotor are

securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake pedal for a few minutes to cool brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

WFIA0524E

Page 221 of 5883

REAR DISC BRAKE

BR-29

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

3. Drain brake fluid. Refer to BR-8, "Bleeding Brake System".

4. Remove connecting bolt and torque member bolts using power tool, and remove cylinder body.

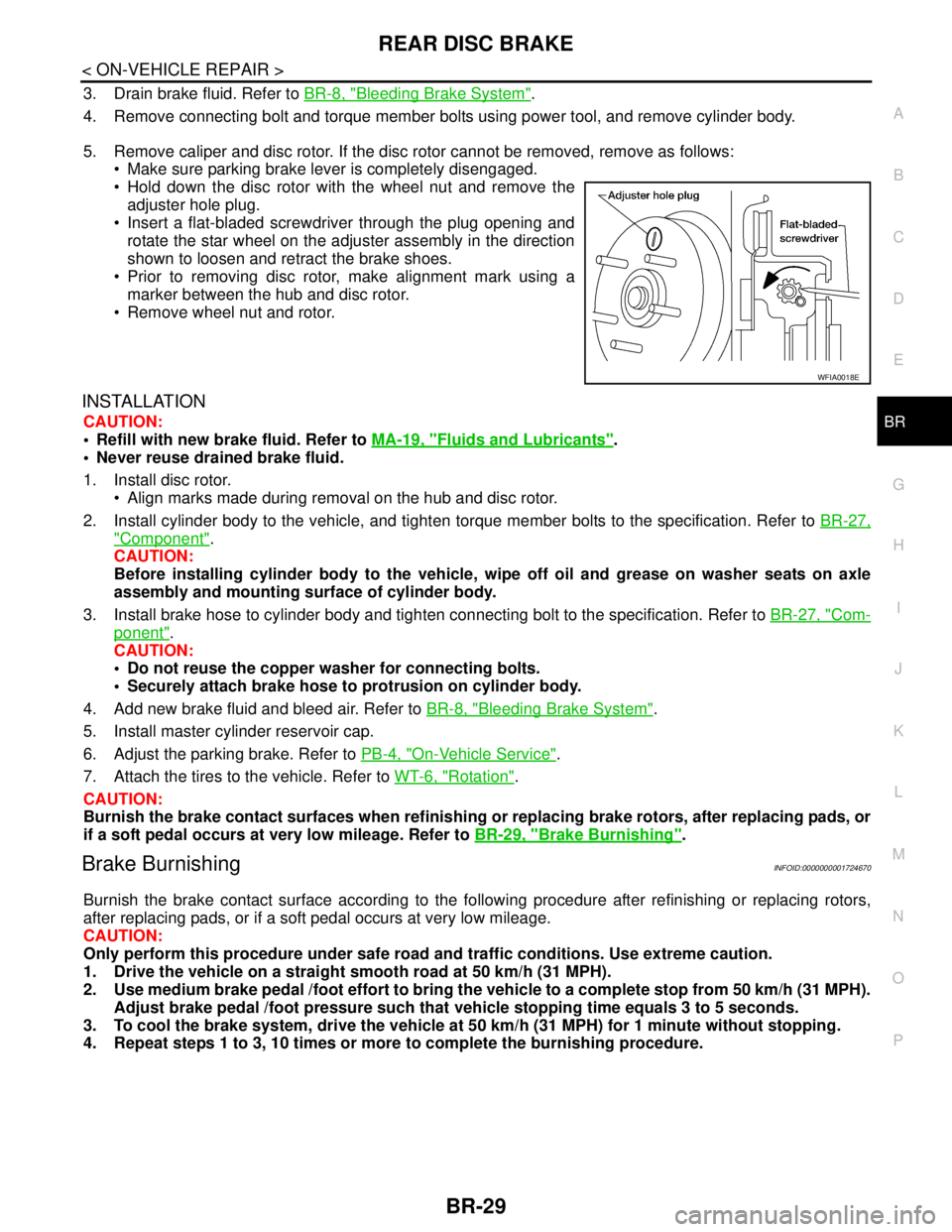

5. Remove caliper and disc rotor. If the disc rotor cannot be removed, remove as follows:

Make sure parking brake lever is completely disengaged.

Hold down the disc rotor with the wheel nut and remove the

adjuster hole plug.

Insert a flat-bladed screwdriver through the plug opening and

rotate the star wheel on the adjuster assembly in the direction

shown to loosen and retract the brake shoes.

Prior to removing disc rotor, make alignment mark using a

marker between the hub and disc rotor.

Remove wheel nut and rotor.

INSTALLATION

CAUTION:

Refill with new brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

1. Install disc rotor.

Align marks made during removal on the hub and disc rotor.

2. Install cylinder body to the vehicle, and tighten torque member bolts to the specification. Refer to BR-27,

"Component".

CAUTION:

Before installing cylinder body to the vehicle, wipe off oil and grease on washer seats on axle

assembly and mounting surface of cylinder body.

3. Install brake hose to cylinder body and tighten connecting bolt to the specification. Refer to BR-27, "

Com-

ponent".

CAUTION:

Do not reuse the copper washer for connecting bolts.

Securely attach brake hose to protrusion on cylinder body.

4. Add new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System".

5. Install master cylinder reservoir cap.

6. Adjust the parking brake. Refer to PB-4, "

On-Vehicle Service".

7. Attach the tires to the vehicle. Refer to WT-6, "

Rotation".

CAUTION:

Burnish the brake contact surfaces when refinishing or replacing brake rotors, after replacing pads, or

if a soft pedal occurs at very low mileage. Refer to BR-29, "

Brake Burnishing".

Brake BurnishingINFOID:0000000001724670

Burnish the brake contact surface according to the following procedure after refinishing or replacing rotors,

after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive the vehicle on a straight smooth road at 50 km/h (31 MPH).

2. Use medium brake pedal /foot effort to bring the vehicle to a complete stop from 50 km/h (31 MPH).

Adjust brake pedal /foot pressure such that vehicle stopping time equals 3 to 5 seconds.

3. To cool the brake system, drive the vehicle at 50 km/h (31 MPH) for 1 minute without stopping.

4. Repeat steps 1 to 3, 10 times or more to complete the burnishing procedure.

WFIA0018E

Page 222 of 5883

BR-30

< DISASSEMBLY AND ASSEMBLY >

BRAKE MASTER CYLINDER

DISASSEMBLY AND ASSEMBLY

BRAKE MASTER CYLINDER

Disassembly and AssemblyINFOID:0000000001717016

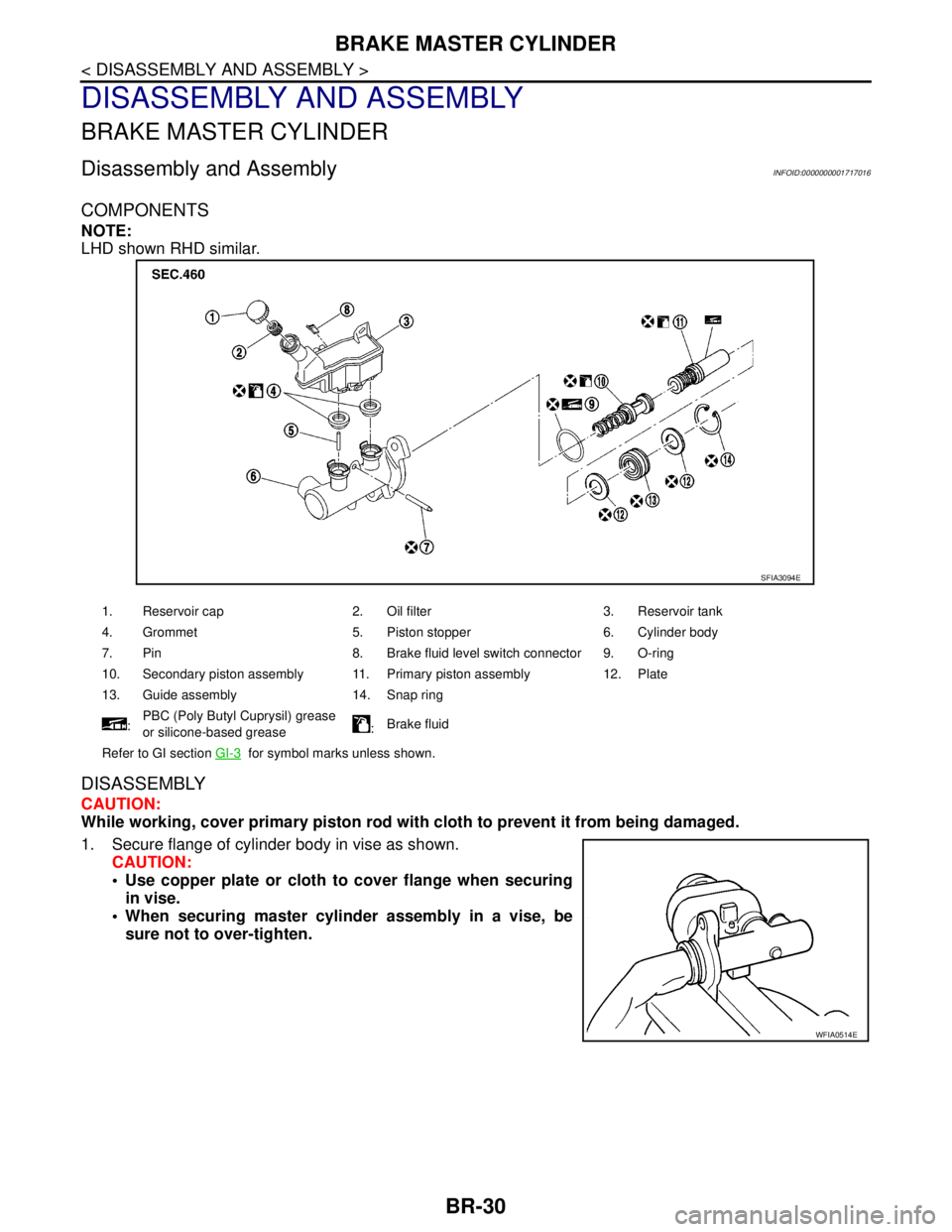

COMPONENTS

NOTE:

LHD shown RHD similar.

DISASSEMBLY

CAUTION:

While working, cover primary piston rod with cloth to prevent it from being damaged.

1. Secure flange of cylinder body in vise as shown.

CAUTION:

Use copper plate or cloth to cover flange when securing

in vise.

When securing master cylinder assembly in a vise, be

sure not to over-tighten.

1. Reservoir cap 2. Oil filter 3. Reservoir tank

4. Grommet 5. Piston stopper 6. Cylinder body

7. Pin 8. Brake fluid level switch connector 9. O-ring

10. Secondary piston assembly 11. Primary piston assembly 12. Plate

13. Guide assembly 14. Snap ring

:PBC (Poly Butyl Cuprysil) grease

or silicone-based grease:Brake fluid

Refer to GI section GI-3

for symbol marks unless shown.

SFIA3094E

WFIA0514E

Page 224 of 5883

BR-32

< DISASSEMBLY AND ASSEMBLY >

BRAKE MASTER CYLINDER

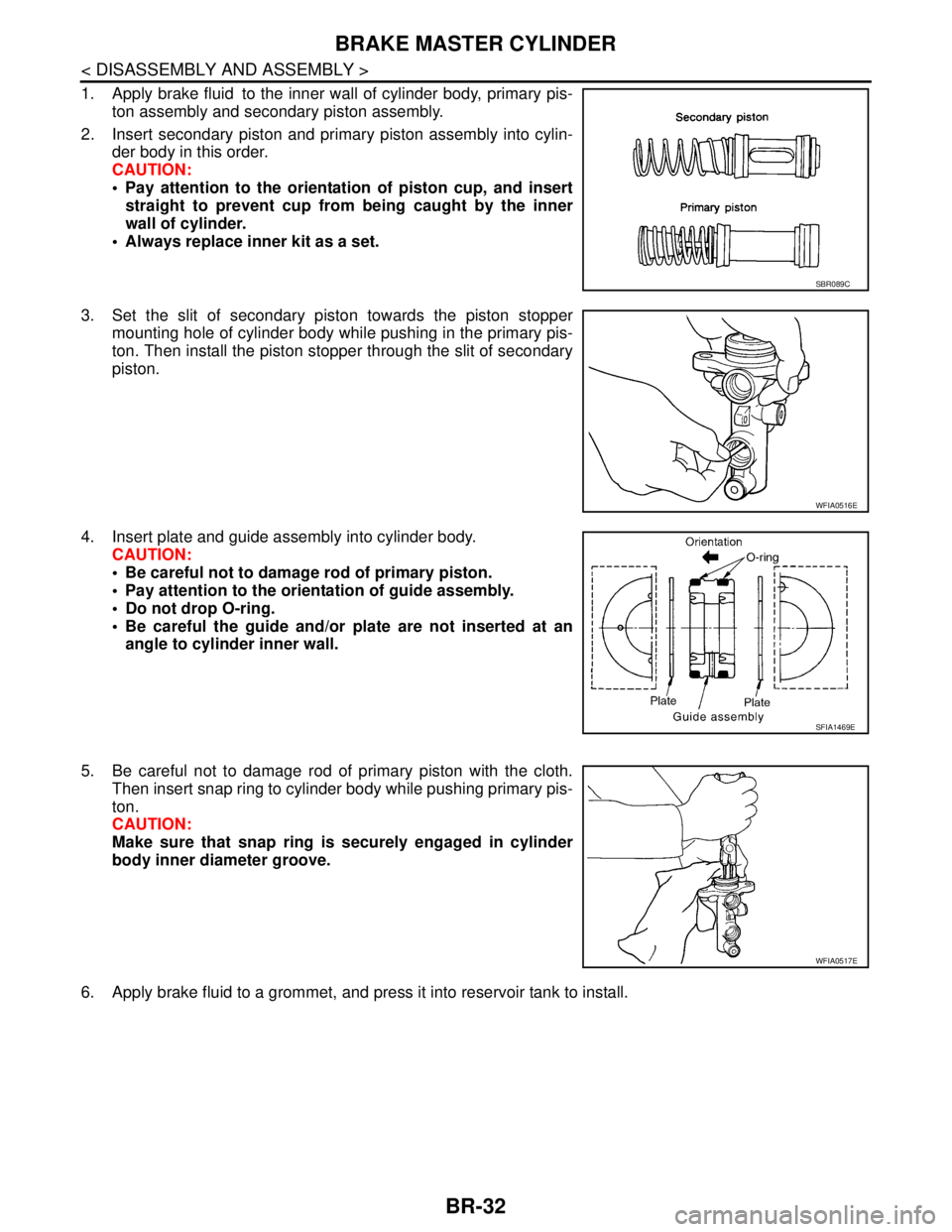

1. Apply brake fluid to the inner wall of cylinder body, primary pis-

ton assembly and secondary piston assembly.

2. Insert secondary piston and primary piston assembly into cylin-

der body in this order.

CAUTION:

Pay attention to the orientation of piston cup, and insert

straight to prevent cup from being caught by the inner

wall of cylinder.

Always replace inner kit as a set.

3. Set the slit of secondary piston towards the piston stopper

mounting hole of cylinder body while pushing in the primary pis-

ton. Then install the piston stopper through the slit of secondary

piston.

4. Insert plate and guide assembly into cylinder body.

CAUTION:

Be careful not to damage rod of primary piston.

Pay attention to the orientation of guide assembly.

Do not drop O-ring.

Be careful the guide and/or plate are not inserted at an

angle to cylinder inner wall.

5. Be careful not to damage rod of primary piston with the cloth.

Then insert snap ring to cylinder body while pushing primary pis-

ton.

CAUTION:

Make sure that snap ring is securely engaged in cylinder

body inner diameter groove.

6. Apply brake fluid to a grommet, and press it into reservoir tank to install.

SBR089C

WFIA0516E

SFIA1469E

WFIA0517E

Page 225 of 5883

BRAKE MASTER CYLINDER

BR-33

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

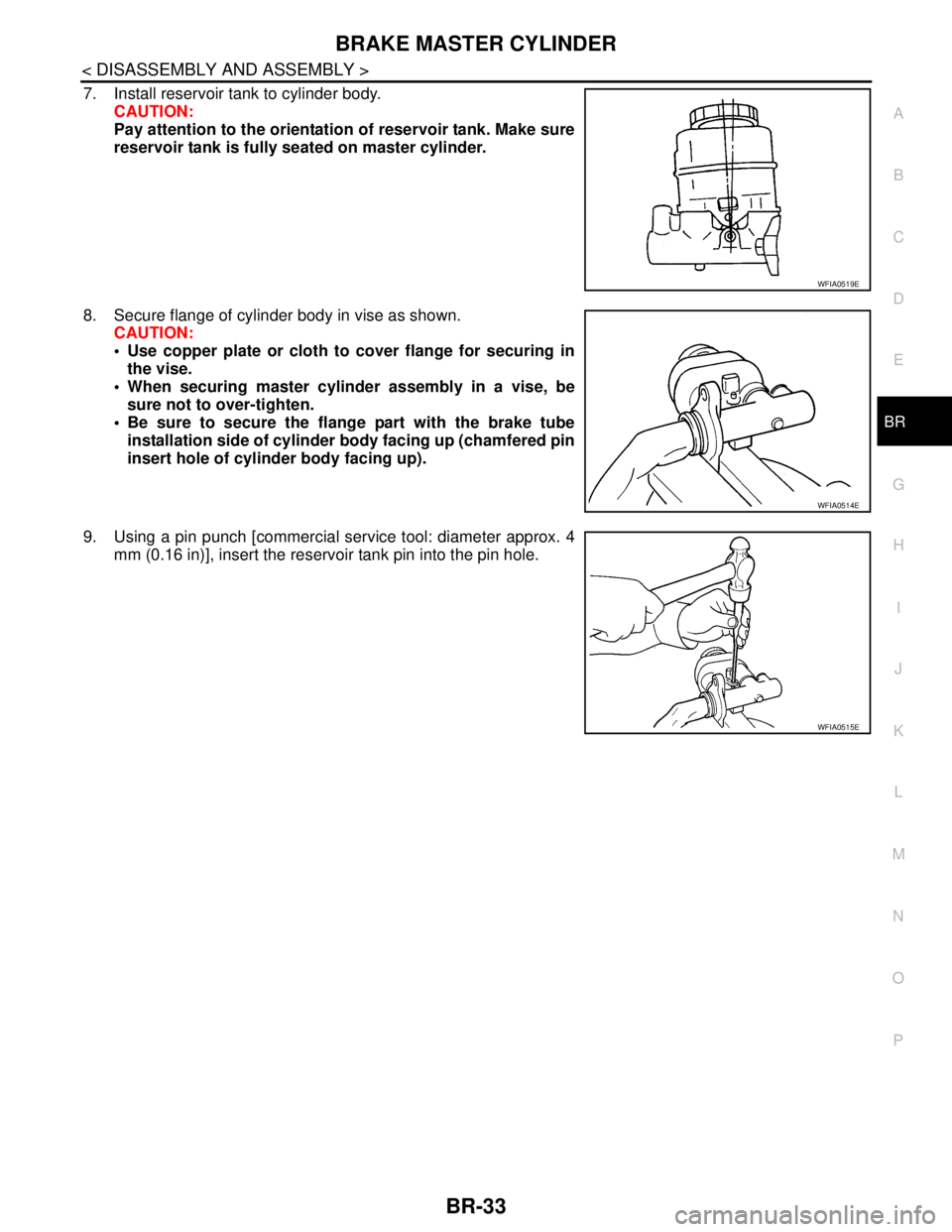

7. Install reservoir tank to cylinder body.

CAUTION:

Pay attention to the orientation of reservoir tank. Make sure

reservoir tank is fully seated on master cylinder.

8. Secure flange of cylinder body in vise as shown.

CAUTION:

Use copper plate or cloth to cover flange for securing in

the vise.

When securing master cylinder assembly in a vise, be

sure not to over-tighten.

Be sure to secure the flange part with the brake tube

installation side of cylinder body facing up (chamfered pin

insert hole of cylinder body facing up).

9. Using a pin punch [commercial service tool: diameter approx. 4

mm (0.16 in)], insert the reservoir tank pin into the pin hole.

WFIA0519E

WFIA0514E

WFIA0515E