coolant capacity NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 508 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

CO-27

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) NISSAN TIIDA 2007 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

CO-27

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)](/img/5/57395/w960_57395-507.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-27

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Periodical Maintenance SpecificationINFOID:0000000001381577

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (Imp qt)

RadiatorINFOID:0000000001381578

RESERVOIR TANK CAP

Unit: kPa (bar, kg/cm2, psi)

RADIATOR

Unit: kPa (bar, kg/cm2, psi)

ThermostatINFOID:0000000001381579

Engine coolant capacity [With reservoir tank (“MAX” level)] 6.3 (5-3/8)

Cap relief pressureStandard 140 (1.4, 1.43, 20.3)

Limit 150 (1.5, 1.53, 21.75)

Leakage testing pressure 150 (1.5, 1.53, 21.75)

ThermostatStandard

Valve opening temperature 80.5 - 83.5°C (177 - 182°F)

Maximum valve lift 8.0 mm/95°C (0.315 in/203°F)

Valve closing temperature 77°C (171°F)

Page 532 of 5883

![NISSAN TIIDA 2007 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

CO-51

< SERVICE DATA AND SPECIFICATIONS (SDS) [MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) NISSAN TIIDA 2007 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

CO-51

< SERVICE DATA AND SPECIFICATIONS (SDS) [MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)](/img/5/57395/w960_57395-531.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-51

< SERVICE DATA AND SPECIFICATIONS (SDS) [MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000001337854

CAPACITY

Unit: (lmp qt)

THERMOSTAT

WATER CONTROL VALVE

RADIATOR

Unit: kPa (bar, kg/cm2, psi)

Engine coolant capacity (with reservoir tank at “MAX” level) Approx. 6.8 (6.0)

Valve opening temperature 80.5 - 83.5°C (177 - 182°F)

Maximum valve lift 8 mm/ 95°C (0.315 in/ 203°F)

Valve closing temperature 77°C (171°F)

Valve opening temperature 93.5 - 96.5°C (200 - 206°F)

Maximum valve lift 8 mm/ 108°C (0.315 in/ 226°F)

Valve closing temperature 90°C (194°F)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11- 14)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Page 540 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ENGINE COOLANT

CO-59

< ON-VEHICLE MAINTENANCE >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Put a cloth under the air relief plug to prevent engine coolant from dampening the crankshaft

position sensor.

Po NISSAN TIIDA 2007 Service Repair Manual ENGINE COOLANT

CO-59

< ON-VEHICLE MAINTENANCE >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Put a cloth under the air relief plug to prevent engine coolant from dampening the crankshaft

position sensor.

Po](/img/5/57395/w960_57395-539.png)

ENGINE COOLANT

CO-59

< ON-VEHICLE MAINTENANCE >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Put a cloth under the air relief plug to prevent engine coolant from dampening the crankshaft

position sensor.

Pour coolant to the MAX level line of the reservoir tank at

a rate of 2 liter (1-3/4 lamp qt.)/min. or lower.

3. Close the air relief plug.

CAUTION:

If the filling rate is too fast, this could lead to air being

mixed in the coolant. Be sure to fill the coolant slowly

according to the rate indicated above.

Use Insane Genuine Engine Coolant or equivalent mixed

with water (distilled or demineralized). Refer to MA-21,

"Engine Coolant Mixture Ratio".

4. Start engine without closing reservoir tank cap and keep engine racing at 1,500 rpm for about 2-3 minutes.

If necessary, pour engine coolant up to MAX level.

If coolant overflows reservoir tank hole, install filler cap.

Watch engine coolant temperature gauge so as not overheat the engine.

WARNING:

Be careful not to be scaled with hot engine coolant or vacuum pump when operating.

Radiator fan blade can start at any time and cause personal injuries.

5. Turn off the engine and loosen air relief plug until coolant spills from air relief hole.

6. Close the air relief plug and run the engine at 2,000 rpm until the upper hose becomes hot and radiator

fan operates. Leave the engine running approximately 5 minutes at idle speed and check for sound of

coolant flow while running engine from idle up to 3,000 rpm.

Sound may be noticeable at heater water cock.

7. If sound is heard, bleed air from cooling system by repeating steps 4 to 6 until coolant level no longer

drops.

Check the radiator lower hose for any signs of leakage.

8. Turn off the engine and let it cool down.

Cool down using a fan to reduce the time.

9. After cooling period, loosen the air relief plug and check if coolant spills from the air relief hole. if not,

remove the air relief plug until the coolant spills, and then close the relief air plug. Bleed air from cooling

system by repeating steps 6 to 10 until the coolant spills immediately.

10. Check the engine coolant level when engine is cool and refill to MAX level line if the level is lower.

Clean excess coolant from engine.

11. Check that the reservoir tank cap is tightened.

FlushingINFOID:0000000001381588

1. Install reservoir tank if removed.

If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-314, "

Exploded

View".

2. Fill reservoir tank with water until water spills from the air relief hole, then close air relief plug. Reinstall

reservoir tank cap.

3. Run engine and warm it up to normal operating temperature.

4. Rev engine two or three times under no-load.

5. Stop engine and wait until it cools down.

6. Drain water.

7. Repeat steps 1 through 6 until clear water begins to drain from radiator.

8. Blow compressed air into cooling circuit through the reservoir tank valve hole to drain all the water.

JPBIA0306ZZ

Engine coolant capacity

(With reservoir tank at MAX): Refer to MA-19, "Fluids and Lubricants".

Reservoir tank capacity : Refer to MA-19, "

Fluids and Lubricants".

Page 551 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CO-70

< SERVICE DATA AND SPECIFICATIONS (SDS) [K9K]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Periodical Maintenance Specificati NISSAN TIIDA 2007 Service Repair Manual CO-70

< SERVICE DATA AND SPECIFICATIONS (SDS) [K9K]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Periodical Maintenance Specificati](/img/5/57395/w960_57395-550.png)

CO-70

< SERVICE DATA AND SPECIFICATIONS (SDS) [K9K]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Periodical Maintenance SpecificationINFOID:0000000001381604

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (Imp qt)

RadiatorINFOID:0000000001381605

Unit: kPa (kg/cm2, psi, bar)

ThermostatINFOID:0000000001381606

Unit: °C (°F)

Engine coolant capacity [With reservoir tank (“MAX” level)] 7.0 (6-1/8)

Reservoir tank engine coolant capacity (At “MAX” level) 0.8 (3/4)

Reservoir tank cap relief pressure 130 - 150 (1.33 - 1.53, 18.9 - 21.8, 1.3 - 1.5)

Leakage testing pressure 10 (0.10, 1.5, 0.1)

Temperature of start opening 89 (192)

Temperature of end opening 97 - 101 (207 - 214)

Page 2741 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-94

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

ENGINE STAND SETTING

DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

SettingINFOID:0000000001381427

NOTE:

Explained here is how to disassemble with engine stan NISSAN TIIDA 2007 Service Repair Manual EM-94

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

ENGINE STAND SETTING

DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

SettingINFOID:0000000001381427

NOTE:

Explained here is how to disassemble with engine stan](/img/5/57395/w960_57395-2740.png)

EM-94

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

ENGINE STAND SETTING

DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

SettingINFOID:0000000001381427

NOTE:

Explained here is how to disassemble with engine stand supporting transmission surface. When using differ-

ent type of engine stand, note with difference in steps and etc.

1. Remove the engine and the transaxle assembly from the vehicle, and separate the transaxle from the

engine. Refer to EM-89, "

Exploded View".

2. Remove clutch cover and clutch disc. Refer to CL-13, "

Removal and Installation".

3. Remove flywheel.

Secure flywheel with a stopper plate [SST: KV11105210], and remove mounting bolts.

CAUTION:

Never disassemble flywheel.

Never place flywheel with signal plate facing down.

When handling signal plate, take care not to damage or scratch it.

Handle signal plate in a manner that prevents it from becoming magnetized.

4. Lift the engine with a hoist to install it onto widely use engine stand.

CAUTION:

Use the engine stand that has a load capacity [approximately 135 kg (298 lb) or more] large

enough for supporting the engine weight.

If the load capacity of stand is not adequate, remove the following parts beforehand to reduce the poten-

tial risk of overturning stand.

- Intake manifold: Refer to EM-29, "

Exploded View".

- Exhaust manifold: Refer to EM-32, "

Exploded View".

- Rocker cover: Refer to EM-47, "

Exploded View".

NOTE:

The figure shows an example of widely use engine stand that

can support mating surface of transaxle with flywheel removed.

CAUTION:

Before removing the hanging chains, make sure the engine

stand is stable and there is no risk of overturning.

5. Drain engine oil. Refer to LU-7, "

Draining".

6. Drain engine coolant by removing water drain plug (1) from

inside of the engine.

Use Genuine Liquid Gasket or equivalent.

PBIC0085E

: Engine front

PBIC3742E

Page 4259 of 5883

RECOMMENDED FLUIDS AND LUBRICANTS

MA-19

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

RECOMMENDED FLUIDS AND LUBRICANTS

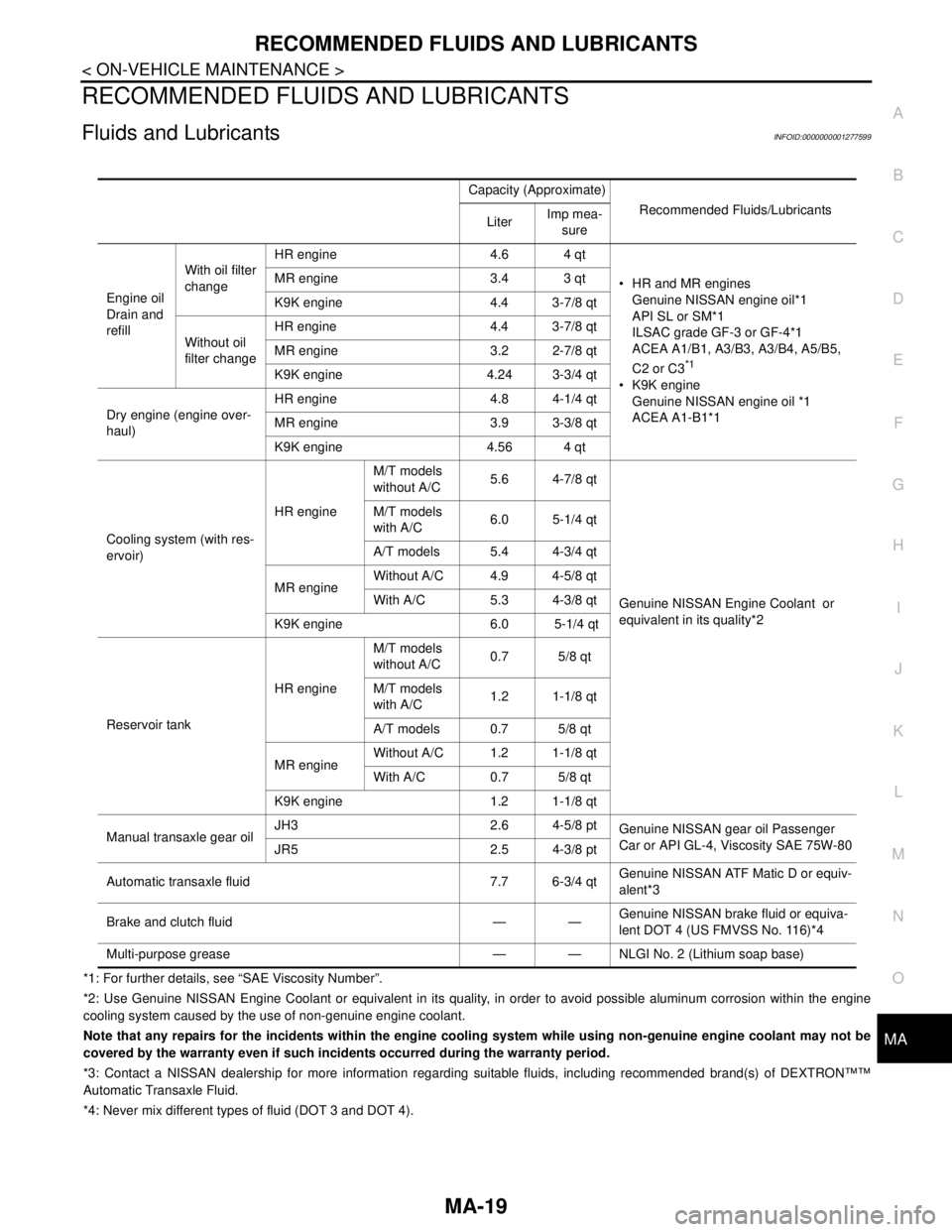

Fluids and LubricantsINFOID:0000000001277599

*1: For further details, see “SAE Viscosity Number”.

*2: Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine

cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*3: Contact a NISSAN dealership for more information regarding suitable fluids, including recommended brand(s) of DEXTRON™™

Automatic Transaxle Fluid.

*4: Never mix different types of fluid (DOT 3 and DOT 4).Capacity (Approximate)

Recommended Fluids/Lubricants

LiterImp mea-

sure

Engine oil

Drain and

refillWith oil filter

changeHR engine 4.6 4 qt

HR and MR engines

Genuine NISSAN engine oil*1

API SL or SM*1

ILSAC grade GF-3 or GF-4*1

ACEA A1/B1, A3/B3, A3/B4, A5/B5,

C2 or C3

*1

K9K engine

Genuine NISSAN engine oil *1

ACEA A1-B1*1 MR engine 3.4 3 qt

K9K engine 4.4 3-7/8 qt

Without oil

filter changeHR engine 4.4 3-7/8 qt

MR engine 3.2 2-7/8 qt

K9K engine 4.24 3-3/4 qt

Dry engine (engine over-

haul)HR engine 4.8 4-1/4 qt

MR engine 3.9 3-3/8 qt

K9K engine 4.56 4 qt

Cooling system (with res-

ervoir)HR engineM/T models

without A/C5.6 4-7/8 qt

Genuine NISSAN Engine Coolant or

equivalent in its quality*2 M/T models

with A/C6.0 5-1/4 qt

A/T models 5.4 4-3/4 qt

MR engineWithout A/C 4.9 4-5/8 qt

With A/C 5.3 4-3/8 qt

K9K engine 6.0 5-1/4 qt

Reservoir tankHR engineM/T models

without A/C0.7 5/8 qt

M/T models

with A/C1.2 1-1/8 qt

A/T models 0.7 5/8 qt

MR engineWithout A/C 1.2 1-1/8 qt

With A/C 0.7 5/8 qt

K9K engine 1.2 1-1/8 qt

Manual transaxle gear oilJH3 2.6 4-5/8 pt

Genuine NISSAN gear oil Passenger

Car or API GL-4, Viscosity SAE 75W-80

JR5 2.5 4-3/8 pt

Automatic transaxle fluid 7.7 6-3/4 qtGenuine NISSAN ATF Matic D or equiv-

alent*3

Brake and clutch fluid — —Genuine NISSAN brake fluid or equiva-

lent DOT 4 (US FMVSS No. 116)*4

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)

Page 4283 of 5883

ENGINE MAINTENANCE (K9K)

MA-43

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

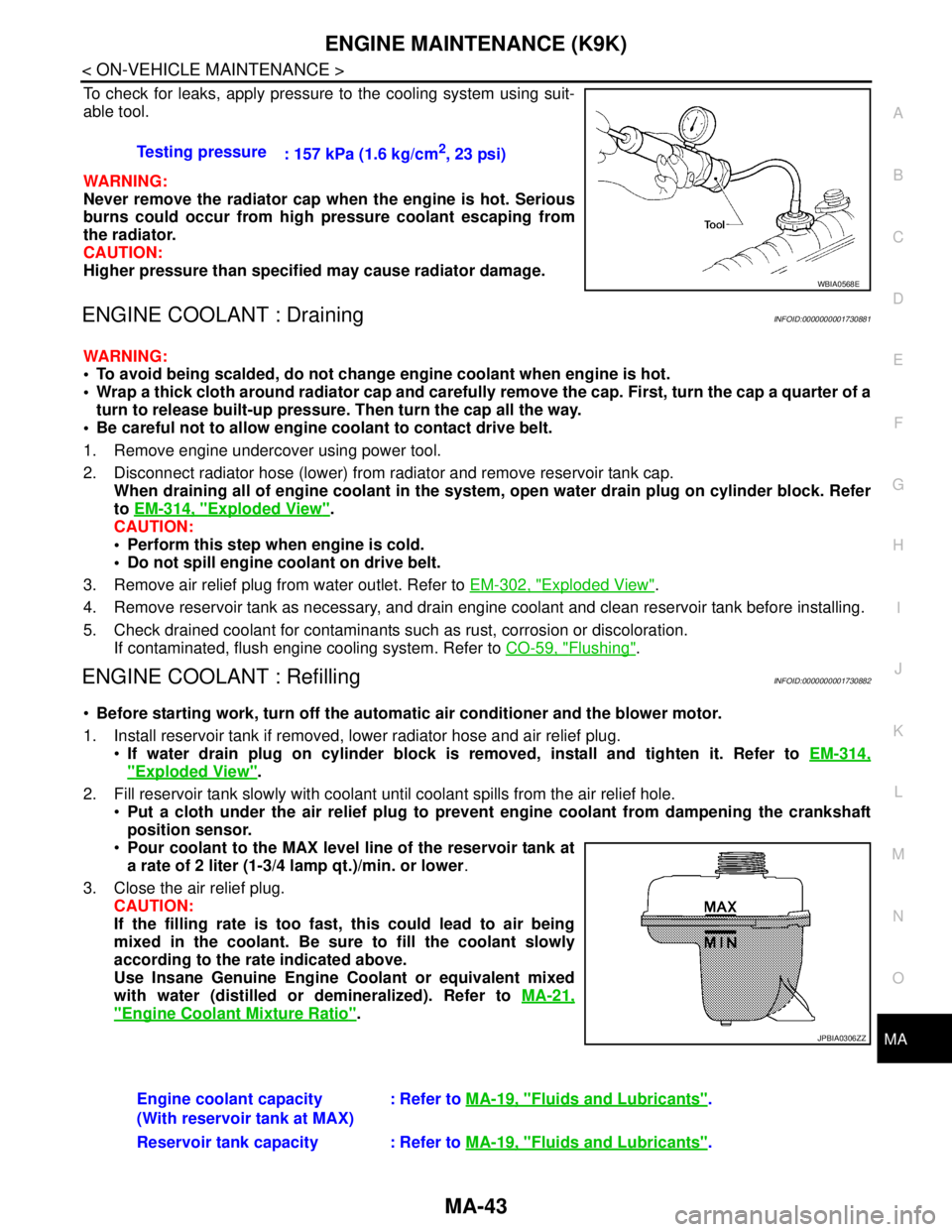

To check for leaks, apply pressure to the cooling system using suit-

able tool.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLANT : DrainingINFOID:0000000001730881

WARNING:

To avoid being scalded, do not change engine coolant when engine is hot.

Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

Be careful not to allow engine coolant to contact drive belt.

1. Remove engine undercover using power tool.

2. Disconnect radiator hose (lower) from radiator and remove reservoir tank cap.

When draining all of engine coolant in the system, open water drain plug on cylinder block. Refer

to EM-314, "

Exploded View".

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belt.

3. Remove air relief plug from water outlet. Refer to EM-302, "

Exploded View".

4. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

5. Check drained coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush engine cooling system. Refer to CO-59, "

Flushing".

ENGINE COOLANT : RefillingINFOID:0000000001730882

Before starting work, turn off the automatic air conditioner and the blower motor.

1. Install reservoir tank if removed, lower radiator hose and air relief plug.

If water drain plug on cylinder block is removed, install and tighten it. Refer to EM-314,

"Exploded View".

2. Fill reservoir tank slowly with coolant until coolant spills from the air relief hole.

Put a cloth under the air relief plug to prevent engine coolant from dampening the crankshaft

position sensor.

Pour coolant to the MAX level line of the reservoir tank at

a rate of 2 liter (1-3/4 lamp qt.)/min. or lower.

3. Close the air relief plug.

CAUTION:

If the filling rate is too fast, this could lead to air being

mixed in the coolant. Be sure to fill the coolant slowly

according to the rate indicated above.

Use Insane Genuine Engine Coolant or equivalent mixed

with water (distilled or demineralized). Refer to MA-21,

"Engine Coolant Mixture Ratio". Testing pressure

: 157 kPa (1.6 kg/cm

2, 23 psi)

WBIA0568E

JPBIA0306ZZ

Engine coolant capacity

(With reservoir tank at MAX): Refer to MA-19, "Fluids and Lubricants".

Reservoir tank capacity : Refer to MA-19, "

Fluids and Lubricants".