front axle NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 1 of 5883

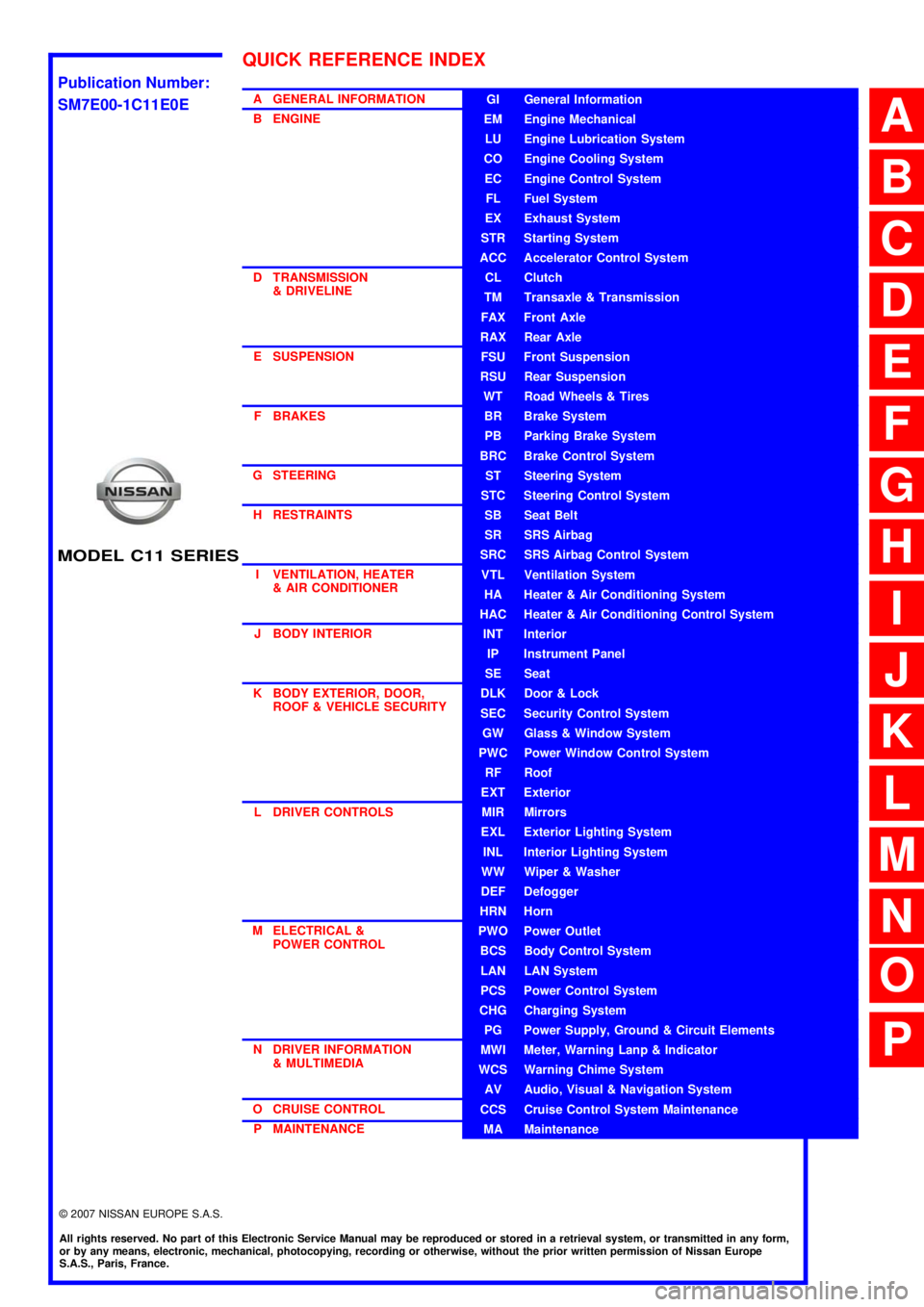

MODEL C11 SERIES

2007 NISSAN EUROPE S.A.S.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any form,

or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan Europe

S.A.S., Paris, France.

A GENERAL INFORMATION

B ENGINE

D TRANSMISSION& DRIVELINE

E SUSPENSION F BRAKES

G STEERING H RESTRAINTS

I VENTILATION, HEATER & AIR CONDITIONER

J BODY INTERIOR

K BODY EXTERIOR, DOOR, ROOF & VEHICLE SECURITY

L DRIVER CONTROLS

M ELECTRICAL & POWER CONTROL

N DRIVER INFORMATION & MULTIMEDIA

O CRUISE CONTROL P MAINTENANCEGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

STR Starting System

ACC Accelerator Control System

CL Clutch

TM Transaxle & Transmission

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

ST Steering System

STC Steering Control System

SB Seat Belt

SR SRS Airbag

SRC SRS Airbag Control System

VTL Ventilation System

HA Heater & Air Conditioning System

HAC Heater & Air Conditioning Control System

INT Interior

IP Instrument Panel

SE Seat

DLK Door & Lock

SEC Security Control System

GW Glass & Window System

PWC Power Window Control System

RF Roof

EXT Exterior

MIR Mirrors

EXL Exterior Lighting System

INL Interior Lighting System

WW Wiper & Washer

DEF Defogger

HRN Horn

PWO Power Outlet

BCS Body Control System

LAN LAN System

PCS Power Control System

CHG Charging System

PG Power Supply, Ground & Circuit Elements

MWI Meter, Warning Lanp & Indicator

WCS Warning Chime System

AV Audio, Visual & Navigation System

CCS Cruise Control System Maintenance

MA Maintenance

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

M

Publication Number:

SM7E00-1C11E0E

Page 306 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ABS

BRC-73

< SYMPTOM DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SYMPTOM DIAGNOSIS

ABS

Symptom TableINFOID:0000000001731343

If ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp tu NISSAN TIIDA 2007 Service Repair Manual ABS

BRC-73

< SYMPTOM DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SYMPTOM DIAGNOSIS

ABS

Symptom TableINFOID:0000000001731343

If ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp tu](/img/5/57395/w960_57395-305.png)

ABS

BRC-73

< SYMPTOM DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SYMPTOM DIAGNOSIS

ABS

Symptom TableINFOID:0000000001731343

If ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp turn ON, perform self-diagnosis.

NOTE:

1: The ABS does not operate when the speed is 10 km/h (6 MPH) or less.

2: Under the following conditions, ABS is activated and vibration is felt when brake pedal is lightly depressed. However, this is normal.

- When shifting gears

- When driving on slippery road

- During cornering at high speed

- When passing over bumps or grooves [at approximately 50 mm (1.97 in) or more]

- When pulling away just after starting engine [at approximately 10 km/h (6 MPH) or higher]Symptom Check item Reference

Excessive ABS function operation fre-

quencyBrake force distribution

BRC-74, "

Diagno-

sis Procedure"Looseness of front and rear axle

Wheel sensor and rotor system

Unexpected pedal reactionBrake pedal stroke

BRC-75, "

Diagno-

sis Procedure"Make sure the braking force is sufficient when the ABS is not operating.

The braking distance is long Check stopping distance when the ABS is not operating.BRC-76, "

Diagno-

sis Procedure"

ABS function does not operate (Note 1) ABS actuator and electric unit (control unit)BRC-77, "Diagno-

sis Procedure"

Pedal vibration or ABS operation sound

occurs (Note 2)Brake pedal

BRC-78, "Diagno-

sis Procedure"ABS actuator and electric unit (control unit)

Page 307 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRC-74

< SYMPTOM DIAGNOSIS >[ABS]

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

Diagnosis ProcedureINFOID:0000000001731344

1.CHECK START

Check front and rear br NISSAN TIIDA 2007 Service Repair Manual BRC-74

< SYMPTOM DIAGNOSIS >[ABS]

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

Diagnosis ProcedureINFOID:0000000001731344

1.CHECK START

Check front and rear br](/img/5/57395/w960_57395-306.png)

BRC-74

< SYMPTOM DIAGNOSIS >[ABS]

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

Diagnosis ProcedureINFOID:0000000001731344

1.CHECK START

Check front and rear brake force distribution using a brake tester.

Is the inspection result normal?

YES >> GO TO 2

NO >> Check brake system.

2.CHECK FRONT AND REAR AXLE

Make sure that there is no excessive play in the front and rear axles. Refer to front: FA X - 6 , "

On-Vehicle

Inspection and Service", Rear: RAX-5, "On-Vehicle Inspection and Service".

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace malfunctioning components.

3.CHECK WHEEL SENSOR AND SENSOR ROTOR

Check the following.

Wheel sensor installation for damage.

Sensor rotor installation for damage.

Wheel sensor connector connection.

Wheel sensor harness inspection.

Is the inspection result normal?

YES >> GO TO 4

NO >> Replace wheel sensor or sensor rotor. Refer to BRC-83, "

Removal and Installation".

Repair harness.

4.CHECK ABS WARNING LAMP DISPLAY

Make sure that the ABS warning lamp is turned off after the ignition switch is turned ON or when driving.

Is the ABS warning lamp illuminated?

YES >> Perform self-diagnosis. Refer to BRC-25, "CONSULT-III Function (ABS)".

NO >> Normal

Page 404 of 5883

![NISSAN TIIDA 2007 Service Repair Manual VDC/TCS/ABS

BRC-171

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SYMPTOM DIAGNOSIS

VDC/TCS/ABS

Symptom TableINFOID:0000000001731200

If ABS warning lamp, VDC OFF indicator lamp a NISSAN TIIDA 2007 Service Repair Manual VDC/TCS/ABS

BRC-171

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SYMPTOM DIAGNOSIS

VDC/TCS/ABS

Symptom TableINFOID:0000000001731200

If ABS warning lamp, VDC OFF indicator lamp a](/img/5/57395/w960_57395-403.png)

VDC/TCS/ABS

BRC-171

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SYMPTOM DIAGNOSIS

VDC/TCS/ABS

Symptom TableINFOID:0000000001731200

If ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp turn ON, perform self-diagnosis.

NOTE:

1: The ABS does not operate when the speed is 10 km/h (6 MPH) or less.

2: Under the following conditions, ABS is activated and vibration is felt when brake pedal is lightly depressed. However, this is normal.

- When shifting gears

- When driving on slippery road

- During cornering at high speed

- When passing over bumps or grooves [at approximately 50 mm (1.97 in) or more]

- When pulling away just after starting engine [at approximately 10 km/h (6 MPH) or higher]Symptom Check item Reference

Excessive ABS function operation fre-

quencyBrake force distribution

BRC-74, "

Diagno-

sis Procedure"Looseness of front and rear axle

Wheel sensor and rotor system

Unexpected pedal reactionBrake pedal stroke

BRC-75, "

Diagno-

sis Procedure"Make sure the braking force is sufficient when the ABS is not operating.

The braking distance is long Check stopping distance when the ABS is not operating.BRC-76, "

Diagno-

sis Procedure"

ABS function does not operate (Note 1) ABS actuator and electric unit (control unit)BRC-77, "Diagno-

sis Procedure"

Pedal vibration or ABS operation sound

occurs (Note 2)Brake pedal

BRC-78, "Diagno-

sis Procedure"ABS actuator and electric unit (control unit)

Vehicle jerks during VDC/TCS/ABS con-

trolABS actuator and electric unit (control unit)

XX-XX, "*****"

TCM

ECM

Page 405 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRC-172

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

Diagnosis ProcedureINFOID:0000000001731201

1.CHECK START

Check front an NISSAN TIIDA 2007 Service Repair Manual BRC-172

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

Diagnosis ProcedureINFOID:0000000001731201

1.CHECK START

Check front an](/img/5/57395/w960_57395-404.png)

BRC-172

< SYMPTOM DIAGNOSIS >[ESP/TCS/ABS]

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

EXCESSIVE ABS FUNCTION OPERATION FREQUENCY

Diagnosis ProcedureINFOID:0000000001731201

1.CHECK START

Check front and rear brake force distribution using a brake tester.

Is the inspection result normal?

YES >> GO TO 2

NO >> Check brake system.

2.CHECK FRONT AND REAR AXLE

Make sure that there is no excessive play in the front and rear axles. Refer to front: FA X - 5 , "

On-Vehicle

Inspection and Service", Rear: RAX-5, "On-Vehicle Inspection and Service".

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace malfunctioning components.

3.CHECK WHEEL SENSOR AND SENSOR ROTOR

Check the following.

Wheel sensor installation for damage.

Sensor rotor installation for damage.

Wheel sensor connector connection.

Wheel sensor harness inspection.

Is the inspection result normal?

YES >> GO TO 4

NO >> Replace wheel sensor or sensor rotor. Refer to BRC-182, "

Removal and Installation".

Repair harness.

4.CHECK ABS WARNING LAMP DISPLAY

Make sure that the ABS warning lamp is turned off after the ignition switch is turned ON or when driving.

Is the ABS warning lamp illuminated?

YES >> Perform self-diagnosis. Refer to BRC-105, "CONSULT-III Function (ABS)".

NO >> Normal

Page 467 of 5883

CL-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001375288

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Service Notice or PrecautionINFOID:0000000001375289

Use recommended brake fluid when adding fluid to the clutch reservoir tank. Refer to MA-19, "Fluids

and Lubricants".

Do not reuse fluid drained from clutch system.

Do not splash brake fluid on painted areas.

Use new brake fluid to clean or wash all parts of master cylinder and operating cylinder.

Do not use mineral oils such as gasoline or kerosene. It will ruin the rubber parts of the hydraulic

system.

If transaxle assembly is removed from the vehicle, always replace CSC (Concentric slave cylinder).

Return CSC to original position to remove transaxle assembly. Dust on clutch disc sliding parts may

damage CSC seal and may cause clutch fluid leakage.

Do not disassemble clutch master cylinder and CSC.

WARNING:

After cleaning clutch disc, clean it with a dust collector. Do not use compressed air.

Page 2722 of 5883

![NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-75

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, chec NISSAN TIIDA 2007 Service Repair Manual CAMSHAFT

EM-75

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, chec](/img/5/57395/w960_57395-2721.png)

CAMSHAFT

EM-75

< ON-VEHICLE REPAIR >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-19, "

Fluids and Lubricants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

Warm up engine thoroughly to make sure there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

Perform this inspection only when DTC P0011 is detected in self-diagnostic results of CONSULT-III

and it is directed according to inspection procedure of EC section. Refer to EC-131, "

Diagnosis Pro-

cedure" (EURO-OBD), EC-484, "Diagnosis Procedure" (WITHOUT EURO-OBD).

Check when engine is cold so as to prevent burns from the splashing engine oil.

1. Check engine oil level. Refer to LU-6, "

Inspection".

2. Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a. Release the fuel pressure. Refer to EC-377, "

Inspection" (EURO-OBD), EC-681, "Inspection" (WITHOUT

EURO-OBD).

b. Remove intake manifold. Refer to EM-29, "

Exploded View".

c. Disconnect ignition coil and injector harness connectors. Refer to EM-47, "

Exploded View".

3. Remove intake valve timing control solenoid valve. Refer to EM-50, "

Exploded View".

4. Crank engine, and then make sure that engine oil comes out

from intake valve timing control solenoid valve hole (A). End

crank after checking.

WARNING:

Be careful not to touch rotating parts (drive belts, idler pul-

ley, and crankshaft pulley, etc.).

CAUTION:

Prevent splashing by using a shop cloth so as to prevent

the worker from injury from engine oil and so as to prevent engine oil contamination.

Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to

engine and vehicle. Especially, be careful not to apply engine oil to rubber parts of drive belts,

engine mounting insulator, etc. Wipe engine oil off immediately if it is splashed.

Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

1: Plug

:Engine front

PBIC3706E

Page 2725 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-78

< ON-VEHICLE REPAIR >[HR16DE]

OIL SEAL

FRONT OIL SEAL : Removal and Installation

INFOID:0000000001381418

REMOVAL

1. Remove the following parts:

Front fender protector (RH): Refer to EXT-22, "

NISSAN TIIDA 2007 Service Repair Manual EM-78

< ON-VEHICLE REPAIR >[HR16DE]

OIL SEAL

FRONT OIL SEAL : Removal and Installation

INFOID:0000000001381418

REMOVAL

1. Remove the following parts:

Front fender protector (RH): Refer to EXT-22, "](/img/5/57395/w960_57395-2724.png)

EM-78

< ON-VEHICLE REPAIR >[HR16DE]

OIL SEAL

FRONT OIL SEAL : Removal and Installation

INFOID:0000000001381418

REMOVAL

1. Remove the following parts:

Front fender protector (RH): Refer to EXT-22, "

Removal and Installation".

Drive belt: Refer to EM-16, "

Removal and Installation".

Crankshaft pulley: Refer to EM-50, "

Exploded View".

2. Remove front oil seal using a suitable tool.

CAUTION:

Be careful not to damage front timing chain case and crankshaft.

INSTALLATION

1. Apply new engine oil to both oil seal lip and dust seal lip of new front oil seal.

2. Install front oil seal.

Install front oil seal so that each seal lip is oriented as shown.

Using a suitable drift, press-fit until the height of front oil seal

(2) is level with the mounting surface.

- Suitable drift (A): outer diameter 50 mm (1.97 in), inner diame-

ter 44 mm (1.73 in).

Make sure the garter spring is in position and seal lips not

inverted

CAUTION:

Be careful not to damage front timing chain case and

crankshaft.

Press-fit straight and avoid causing burrs or tilting oil seal.

3. Install in the reverse order of removal, for the rest of parts.

REAR OIL SEAL

REAR OIL SEAL : Removal and InstallationINFOID:0000000001381419

REMOVAL

1. Remove transaxle assembly. Refer to TM-210, "Removal and Installation" (A/T), TM-633, "Removal and

Installation" (M/T).

2. Remove clutch cover and clutch disk. Refer to CL-13, "

Removal and Installation".

3. Remove flywheel. Refer to EM-100, "

Exploded View".

4. Remove rear oil seal with a suitable tool.

CAUTION:

Be careful not to damage crankshaft and cylinder block.

INSTALLATION

1. Apply the liquid gasket lightly to entire outside area of new rear oil seal.

A : Dust seal lip

B: Oil seal lip

: Engine outside

: Engine inside

PBIC3485J

1 : Front cover

: Engine outside

PBIC3729E

Page 2737 of 5883

![NISSAN TIIDA 2007 Service Repair Manual EM-90

< REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

If items or work required are not covered by the engine section, follow the procedures in the applica-

ble sections.

Always use the suppo NISSAN TIIDA 2007 Service Repair Manual EM-90

< REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

If items or work required are not covered by the engine section, follow the procedures in the applica-

ble sections.

Always use the suppo](/img/5/57395/w960_57395-2736.png)

EM-90

< REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

If items or work required are not covered by the engine section, follow the procedures in the applica-

ble sections.

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for unavoid-

able reasons, support at the rear axle jacking point with a transmission jack or similar tool before

starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-48, "

Garage Jack and

Safety Stand and 2-Pole Lift".

REMOVAL

Outline

Remove the engine and the transaxle assembly from the vehicle downward. Separate the engine and the tran-

saxle.

Preparation

1. Remove the hood assembly. Refer to DLK-214, "Removal and Installation".

2. Remove the cowl top cover and cowl top extension assembly. Refer to EXT-20, "

Removal and Installa-

tion".

3. Release fuel pressure. Refer to EC-377, "

Inspection" (EURO-OBD), EC-681, "Inspection" (WITHOUT

EURO-OBD).

4. Drain engine coolant from radiator. Refer to CO-11, "

Changing Engine Coolant".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

5. Drain the transmission fluid. Refer to TM-628, "

Draining" (M/T models), TM-171, "Changing A/T Fluid" (A/

T models).

6. Remove the following parts.

Engine undercover

Front road wheels and tires: Refer to WT-6, "

Rotation".

Front fender protector (RH and LH): Refer to EXT-22, "

Removal and Installation".

Battery and battery tray: Refer to PG-6, "

Removal and Installation".

Drive belt: Refer to EM-16, "

Removal and Installation".

Air duct and air cleaner case assembly: Refer to EM-27, "

Exploded View".

Radiator hose (upper and lower): Refer to CO-16, "

Component".

Disconnect cooling fan controller wiring harness.

Remove coolant reservoir tank.

Remove fan shroud and cooling fan assembly. Refer to CO-16, "

Component".

Engine Room LH

1. Disconnect all connections of engine harness around the engine mounting insulator (LH), and then tem-

porarily secure the engine harness into the engine side.

CAUTION:

Protect connectors using a resin bag against foreign materials.

2. Remove ground cable at transaxle side.

3. Disconnect fuel feed hose at engine side. Refer to EM-35, "

Exploded View".

4. Disconnect EVAP purge hose and brake booster vacuum hose.

5. Disconnect heater hoses, and install plugs them to prevent engine coolant from draining. Refer to CO-24,

"Exploded View".

6. Disconnect control linkage from transaxle. Refer to TM-189, "

Exploded View" (A/T), TM-630, "Exploded

View" (M/T).

7. Disconnect the clutch tube at transmission side. Refer to CL-12, "

Removal and Installation".

Engine Room RH

1. Remove ground cable between front cover and vehicle.

2. Remove generator and generator bracket; Refer to CHG-15, "

Removal and Installation".

3. Remove A/C compressor with piping connected from the engine. Temporarily secure it on the vehicle side

with a rope to avoid putting load on it. (with A/C models) Refer to HA-34, "

Removal and Installation of

Compressor - HR16DE".

Page 2738 of 5883

![NISSAN TIIDA 2007 Service Repair Manual ENGINE ASSEMBLY

EM-91

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Vehicle Underbody

1. Remove front wheel sensor (LH and RH) for ABS from steering knuckle. Refer to BRC-83, "R NISSAN TIIDA 2007 Service Repair Manual ENGINE ASSEMBLY

EM-91

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Vehicle Underbody

1. Remove front wheel sensor (LH and RH) for ABS from steering knuckle. Refer to BRC-83, "R](/img/5/57395/w960_57395-2737.png)

ENGINE ASSEMBLY

EM-91

< REMOVAL AND INSTALLATION >[HR16DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O Vehicle Underbody

1. Remove front wheel sensor (LH and RH) for ABS from steering knuckle. Refer to BRC-83, "Removal and

Installation".

2. Remove brake caliper assembly with piping connected from steering knuckle. Temporarily secure it on the

vehicle side with a rope to avoid load on it. Refer to BR-24, "

Component".

3. Remove drive shafts (LH and RH) from steering knuckle. Refer to FAX-7, "

Removal and Installation".

4. Remove exhaust front tube. Refer to EX-5, "

Component".

5. Remove rear torque rod.

NOTE:

A/T models shown.

6. Remove A/T cooler hoses from transmission (A/T models).

7. Preparation for the separation work of transaxle is as follows:

Remove transaxle joint bolts which pierce at oil pan (upper) lower rear side. Refer to EM-89, "

Exploded

View".

Removal

1. Install engine slinger to cylinder head front left side (A) and rear

right side (B) and support the engine with a hoist.

2. Lift with a hoist and secure the engine in appropriate position.

3. Use a suitable tool to securely support bottom of the engine and

the transaxle assembly and simultaneously adjust hoist tension.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

PBIC3737E

PBIC3738E

PBIC3223J