vtl NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 1 of 5883

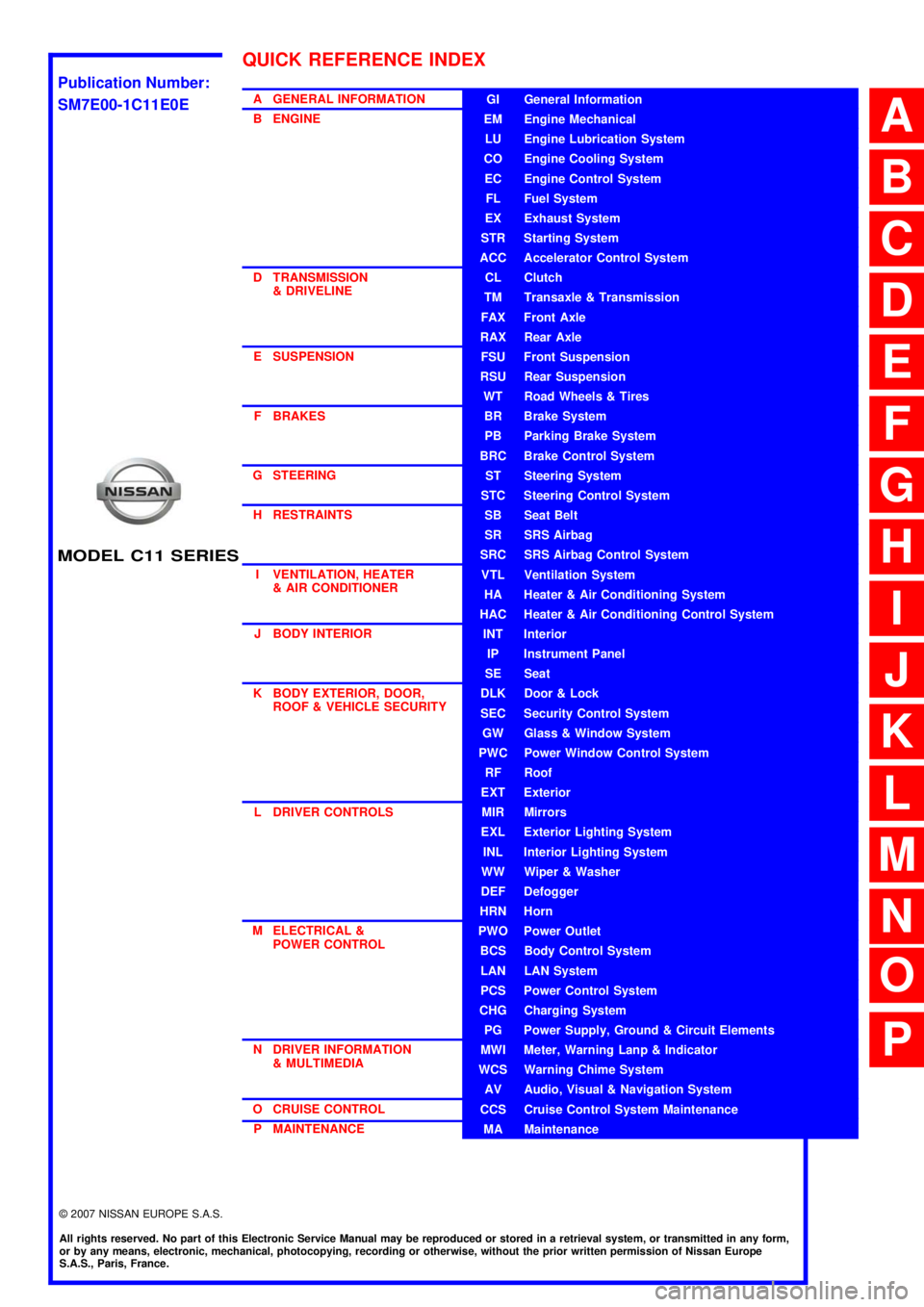

MODEL C11 SERIES

2007 NISSAN EUROPE S.A.S.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any form,

or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan Europe

S.A.S., Paris, France.

A GENERAL INFORMATION

B ENGINE

D TRANSMISSION& DRIVELINE

E SUSPENSION F BRAKES

G STEERING H RESTRAINTS

I VENTILATION, HEATER & AIR CONDITIONER

J BODY INTERIOR

K BODY EXTERIOR, DOOR, ROOF & VEHICLE SECURITY

L DRIVER CONTROLS

M ELECTRICAL & POWER CONTROL

N DRIVER INFORMATION & MULTIMEDIA

O CRUISE CONTROL P MAINTENANCEGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

STR Starting System

ACC Accelerator Control System

CL Clutch

TM Transaxle & Transmission

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

ST Steering System

STC Steering Control System

SB Seat Belt

SR SRS Airbag

SRC SRS Airbag Control System

VTL Ventilation System

HA Heater & Air Conditioning System

HAC Heater & Air Conditioning Control System

INT Interior

IP Instrument Panel

SE Seat

DLK Door & Lock

SEC Security Control System

GW Glass & Window System

PWC Power Window Control System

RF Roof

EXT Exterior

MIR Mirrors

EXL Exterior Lighting System

INL Interior Lighting System

WW Wiper & Washer

DEF Defogger

HRN Horn

PWO Power Outlet

BCS Body Control System

LAN LAN System

PCS Power Control System

CHG Charging System

PG Power Supply, Ground & Circuit Elements

MWI Meter, Warning Lanp & Indicator

WCS Warning Chime System

AV Audio, Visual & Navigation System

CCS Cruise Control System Maintenance

MA Maintenance

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

M

Publication Number:

SM7E00-1C11E0E

Page 4248 of 5883

MA-8

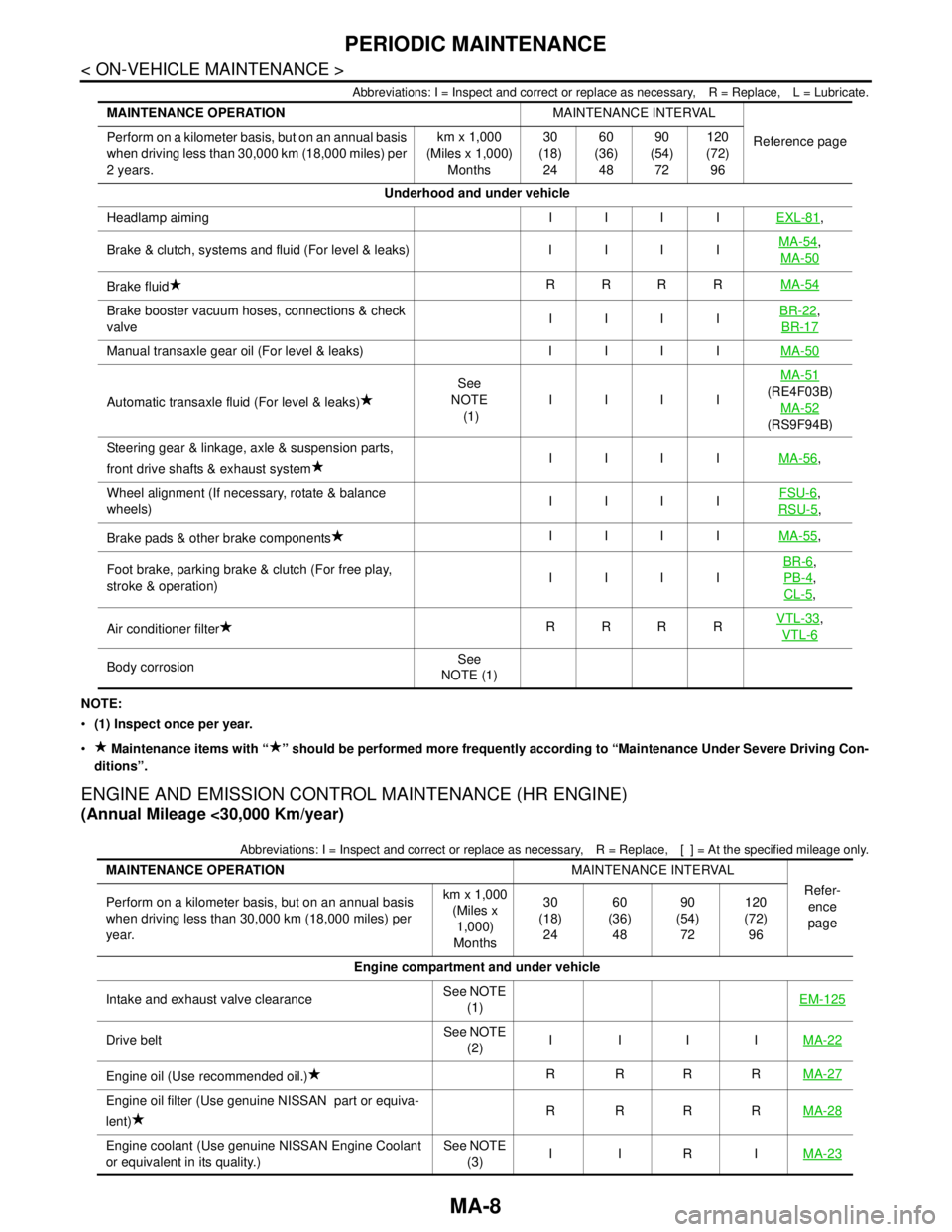

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

NOTE:

(1) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

ENGINE AND EMISSION CONTROL MAINTENANCE (HR ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,[ ] = At the specified mileage only.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page Perform on a kilometer basis, but on an annual basis

when driving less than 30,000 km (18,000 miles) per

2 years.km x 1,000

(Miles x 1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Underhood and under vehicle

Headlamp aiming I I I IEXL-81

,

Brake & clutch, systems and fluid (For level & leaks) I I I IMA-54

,

MA-50

Brake fluidRRRRMA-54

Brake booster vacuum hoses, connections & check

valveIIIIBR-22,

BR-17

Manual transaxle gear oil (For level & leaks) I I I IMA-50

Automatic transaxle fluid (For level & leaks)See

NOTE

(1)IIIIMA-51(RE4F03B)

MA-52

(RS9F94B)

Steering gear & linkage, axle & suspension parts,

front drive shafts & exhaust systemIIIIMA-56

,

Wheel alignment (If necessary, rotate & balance

wheels)IIIIFSU-6

,

RSU-5

,

Brake pads & other brake componentsIIIIMA-55

,

Foot brake, parking brake & clutch (For free play,

stroke & operation)IIIIBR-6

,

PB-4

,

CL-5

,

Air conditioner filterRRRRVTL-33

,

VTL-6

Body corrosionSee

NOTE (1)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on an annual basis

when driving less than 30,000 km (18,000 miles) per

year.km x 1,000

(Miles x

1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Engine compartment and under vehicle

Intake and exhaust valve clearanceSee NOTE

(1)EM-125

Drive beltSee NOTE

(2)IIIIMA-22

Engine oil (Use recommended oil.)R RRRMA-27

Engine oil filter (Use genuine NISSAN part or equiva-

lent)R RRRMA-28

Engine coolant (Use genuine NISSAN Engine Coolant

or equivalent in its quality.)See NOTE

(3)IIRIMA-23

Page 4250 of 5883

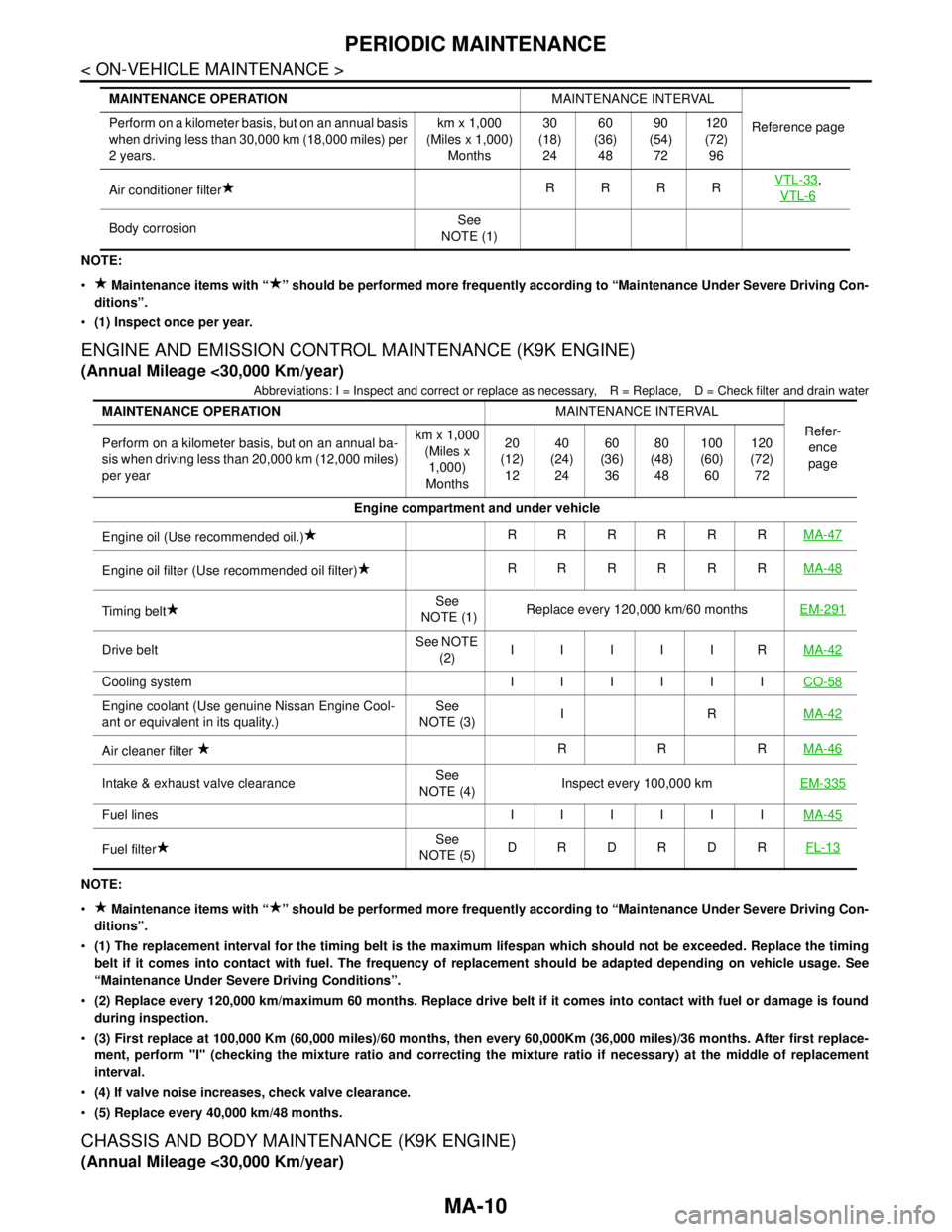

MA-10

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1) Inspect once per year.

ENGINE AND EMISSION CONTROL MAINTENANCE (K9K ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, D = Check filter and drain water

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1) The replacement interval for the timing belt is the maximum lifespan which should not be exceeded. Replace the timing

belt if it comes into contact with fuel. The frequency of replacement should be adapted depending on vehicle usage. See

“Maintenance Under Severe Driving Conditions”.

(2) Replace every 120,000 km/maximum 60 months. Replace drive belt if it comes into contact with fuel or damage is found

during inspection.

(3) First replace at 100,000 Km (60,000 miles)/60 months, then every 60,000Km (36,000 miles)/36 months. After first replace-

ment, perform "I" (checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement

interval.

(4) If valve noise increases, check valve clearance.

(5) Replace every 40,000 km/48 months.

CHASSIS AND BODY MAINTENANCE (K9K ENGINE)

(Annual Mileage <30,000 Km/year)

Air conditioner filterRRRRVTL-33,

VTL-6

Body corrosionSee

NOTE (1) MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page Perform on a kilometer basis, but on an annual basis

when driving less than 30,000 km (18,000 miles) per

2 years.km x 1,000

(Miles x 1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on an annual ba-

sis when driving less than 20,000 km (12,000 miles)

per yearkm x 1,000

(Miles x

1,000)

Months20

(12)

1240

(24)

2460

(36)

3680

(48)

48100

(60)

60120

(72)

72

Engine compartment and under vehicle

Engine oil (Use recommended oil.)RRRRRRMA-47

Engine oil filter (Use recommended oil filter)RRRRRRMA-48

Timing beltSee

NOTE (1)Replace every 120,000 km/60 monthsEM-291

Drive beltSee NOTE

(2)IIIIIRMA-42

Cooling system IIIIIICO-58

Engine coolant (Use genuine Nissan Engine Cool-

ant or equivalent in its quality.)See

NOTE (3)IRMA-42

Air cleaner filter RRRMA-46

Intake & exhaust valve clearanceSee

NOTE (4)Inspect every 100,000 kmEM-335

Fuel lines IIIIIIMA-45

Fuel filterSee

NOTE (5)DRDRDRFL-13

Page 4251 of 5883

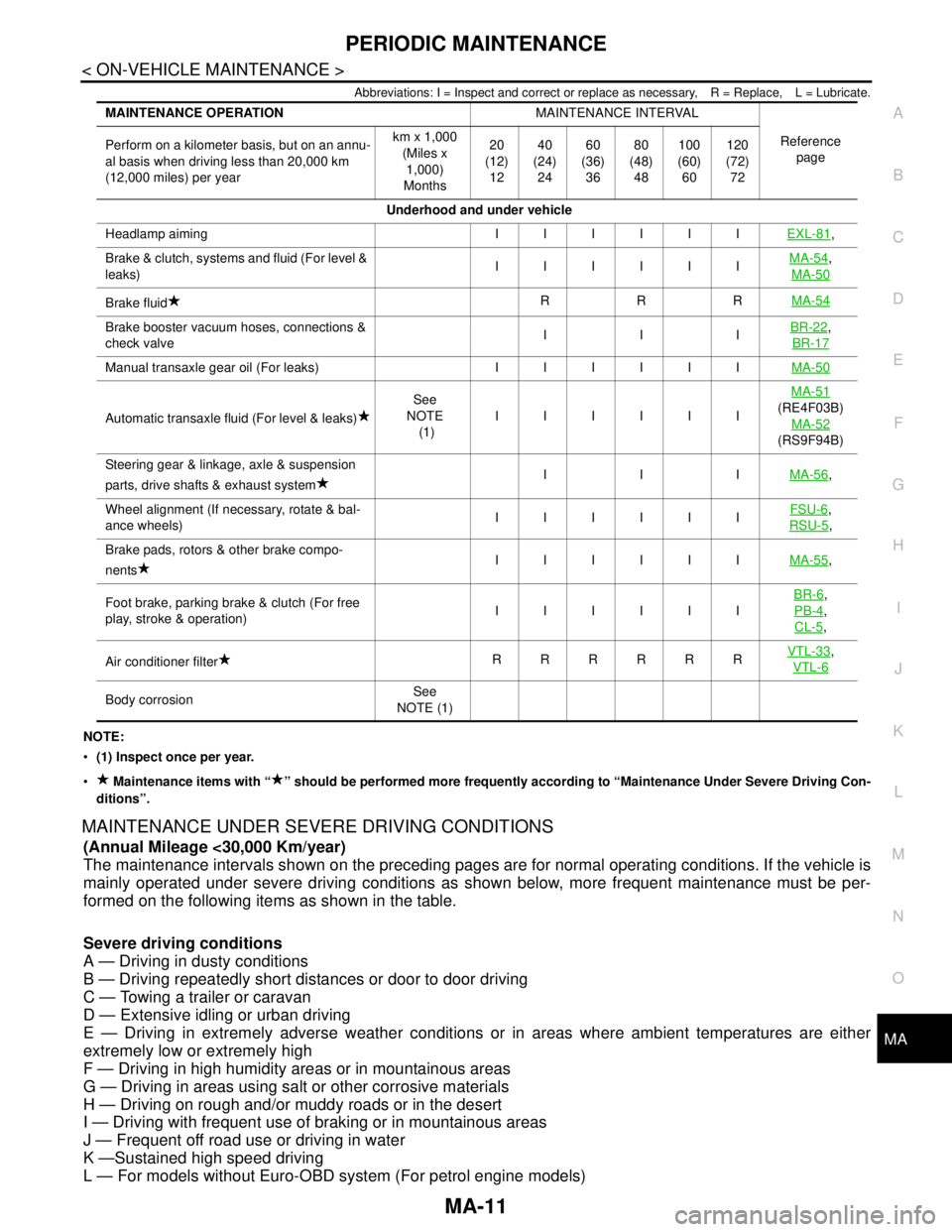

PERIODIC MAINTENANCE

MA-11

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

NOTE:

(1) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage <30,000 Km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Driving repeatedly short distances or door to door driving

C — Towing a trailer or caravan

D — Extensive idling or urban driving

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K —Sustained high speed driving

L — For models without Euro-OBD system (For petrol engine models)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform on a kilometer basis, but on an annu-

al basis when driving less than 20,000 km

(12,000 miles) per yearkm x 1,000

(Miles x

1,000)

Months20

(12)

1240

(24)

2460

(36)

3680

(48)

48100

(60)

60120

(72)

72

Underhood and under vehicle

Headlamp aiming IIIIIIEXL-81

,

Brake & clutch, systems and fluid (For level &

leaks)IIIIIIMA-54

,

MA-50

Brake fluidRRRMA-54

Brake booster vacuum hoses, connections &

check valveIIIBR-22,

BR-17

Manual transaxle gear oil (For leaks) IIIIIIMA-50

Automatic transaxle fluid (For level & leaks)See

NOTE

(1)IIIIIIMA-51(RE4F03B)

MA-52

(RS9F94B)

Steering gear & linkage, axle & suspension

parts, drive shafts & exhaust systemIIIMA-56

,

Wheel alignment (If necessary, rotate & bal-

ance wheels)IIIIIIFSU-6

,

RSU-5

,

Brake pads, rotors & other brake compo-

nentsIIIIIIMA-55

,

Foot brake, parking brake & clutch (For free

play, stroke & operation)IIIIIIBR-6

,

PB-4

,

CL-5

,

Air conditioner filterRRRRRRVTL-33

,

VTL-6

Body corrosionSee

NOTE (1)

Page 4254 of 5883

MA-14

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

(1) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

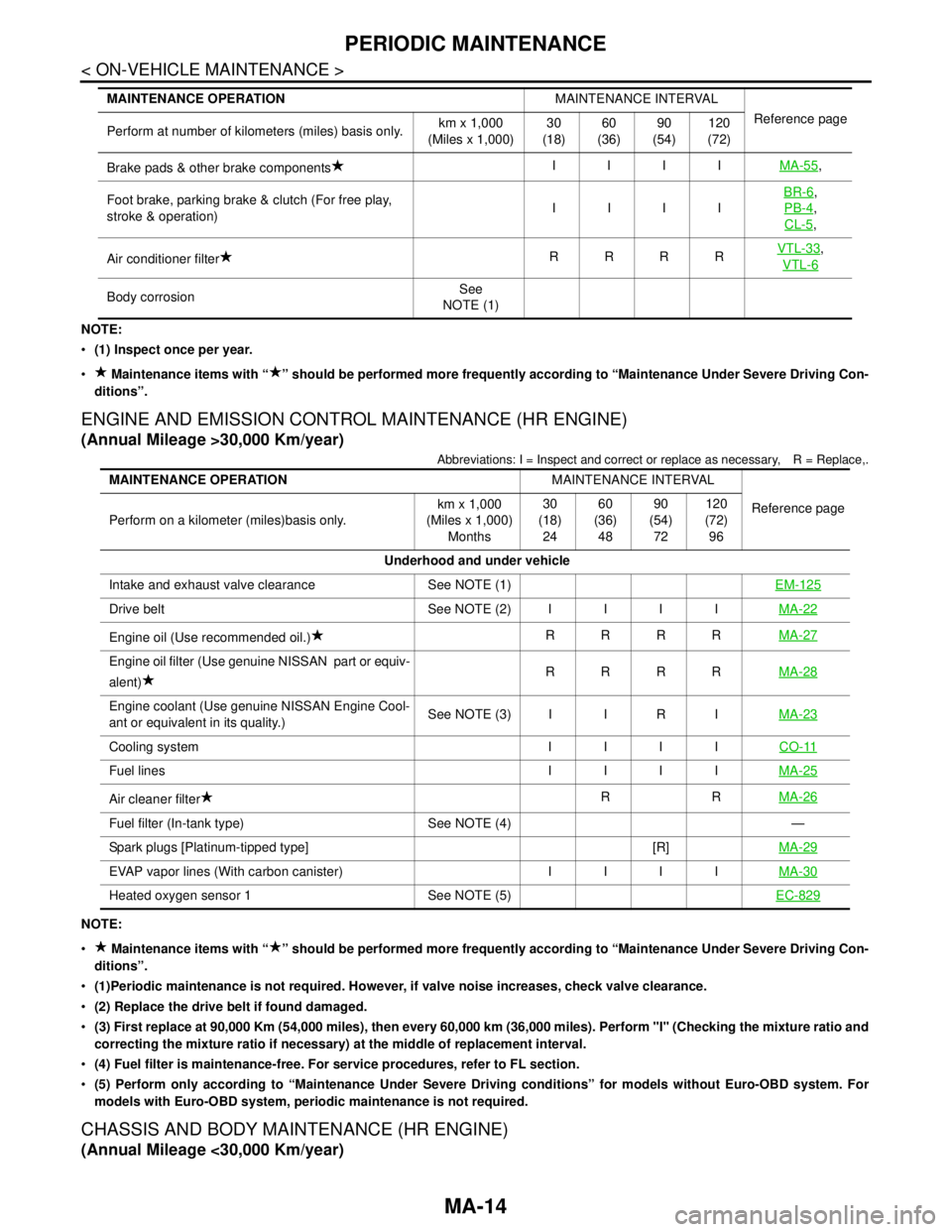

ENGINE AND EMISSION CONTROL MAINTENANCE (HR ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,.

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged.

(3) First replace at 90,000 Km (54,000 miles), then every 60,000 km (36,000 miles). Perform "I" (Checking the mixture ratio and

correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Perform only according to “Maintenance Under Severe Driving conditions” for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (HR ENGINE)

(Annual Mileage <30,000 Km/year)

Brake pads & other brake componentsIIIIMA-55,

Foot brake, parking brake & clutch (For free play,

stroke & operation)IIIIBR-6

,

PB-4

,

CL-5

,

Air conditioner filterRRRRVTL-33

,

VTL-6

Body corrosionSee

NOTE (1) MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x 1,000)30

(18)60

(36)90

(54)120

(72)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page

Perform on a kilometer (miles)basis only.km x 1,000

(Miles x 1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Underhood and under vehicle

Intake and exhaust valve clearance See NOTE (1)EM-125

Drive belt See NOTE (2)IIIIMA-22

Engine oil (Use recommended oil.)RRRRMA-27

Engine oil filter (Use genuine NISSAN part or equiv-

alent)RRRRMA-28

Engine coolant (Use genuine NISSAN Engine Cool-

ant or equivalent in its quality.)See NOTE (3) I I R IMA-23

Cooling system IIIICO-11

Fuel lines IIIIMA-25

Air cleaner filterRRMA-26

Fuel filter (In-tank type) See NOTE (4) —

Spark plugs [Platinum-tipped type] [R]MA-29

EVAP vapor lines (With carbon canister) IIIIMA-30

Heated oxygen sensor 1 See NOTE (5)EC-829

Page 4255 of 5883

PERIODIC MAINTENANCE

MA-15

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

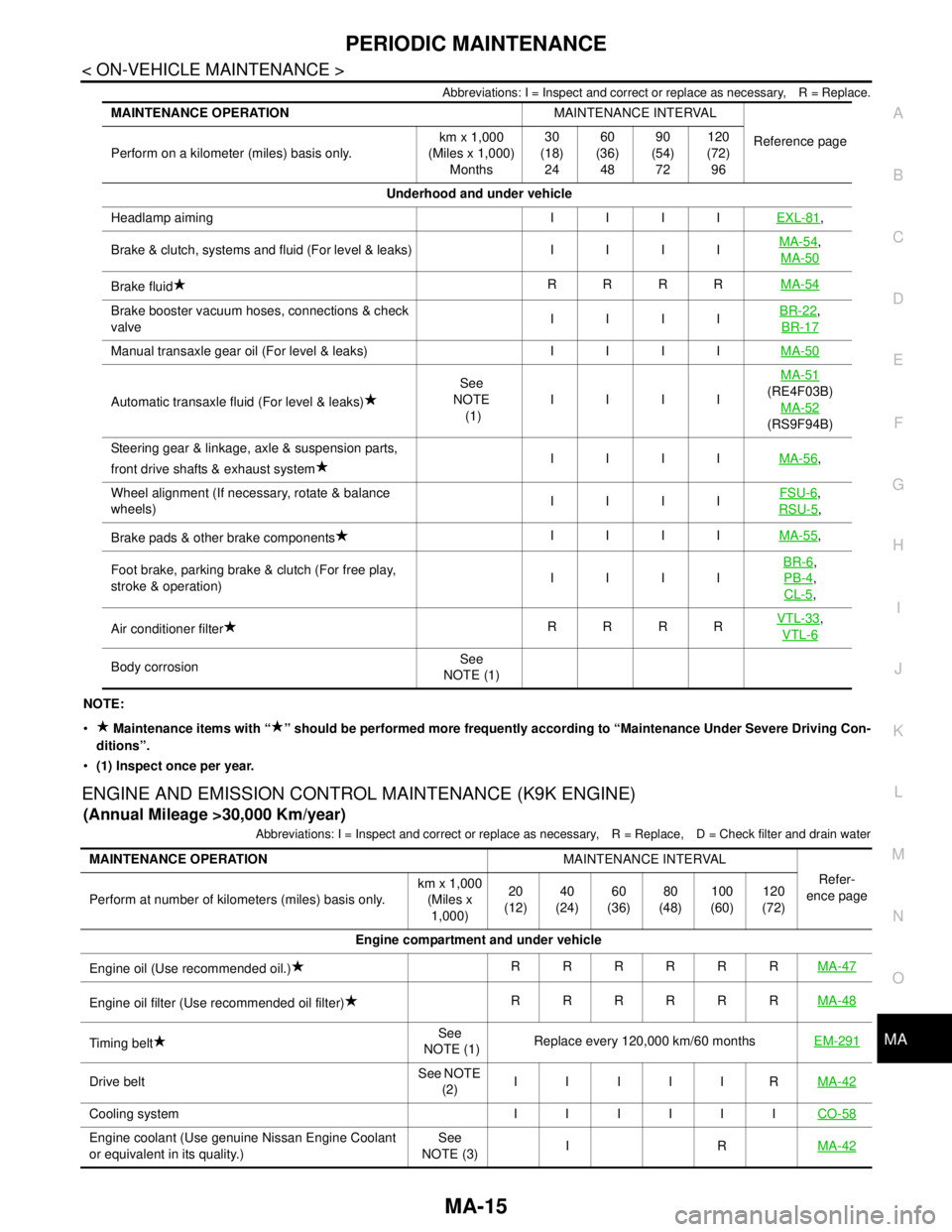

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace.

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1) Inspect once per year.

ENGINE AND EMISSION CONTROL MAINTENANCE (K9K ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, D = Check filter and drain water

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference page

Perform on a kilometer (miles) basis only.km x 1,000

(Miles x 1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Underhood and under vehicle

Headlamp aiming IIIIEXL-81

,

Brake & clutch, systems and fluid (For level & leaks) IIIIMA-54

,

MA-50

Brake fluidRRRRMA-54

Brake booster vacuum hoses, connections & check

valveIIIIBR-22,

BR-17

Manual transaxle gear oil (For level & leaks) IIIIMA-50

Automatic transaxle fluid (For level & leaks)See

NOTE

(1)IIIIMA-51(RE4F03B)

MA-52

(RS9F94B)

Steering gear & linkage, axle & suspension parts,

front drive shafts & exhaust systemIIIIMA-56

,

Wheel alignment (If necessary, rotate & balance

wheels)IIIIFSU-6

,

RSU-5

,

Brake pads & other brake componentsIIIIMA-55

,

Foot brake, parking brake & clutch (For free play,

stroke & operation)IIIIBR-6

,

PB-4

,

CL-5

,

Air conditioner filterRRRRVTL-33

,

VTL-6

Body corrosionSee

NOTE (1)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x

1,000)20

(12)40

(24)60

(36)80

(48)100

(60)120

(72)

Engine compartment and under vehicle

Engine oil (Use recommended oil.)RRRRRRMA-47

Engine oil filter (Use recommended oil filter)RRRRRRMA-48

Timing beltSee

NOTE (1)Replace every 120,000 km/60 monthsEM-291

Drive beltSee NOTE

(2)IIIIIRMA-42

Cooling system IIIIIICO-58

Engine coolant (Use genuine Nissan Engine Coolant

or equivalent in its quality.)See

NOTE (3)IRMA-42

Page 4256 of 5883

MA-16

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

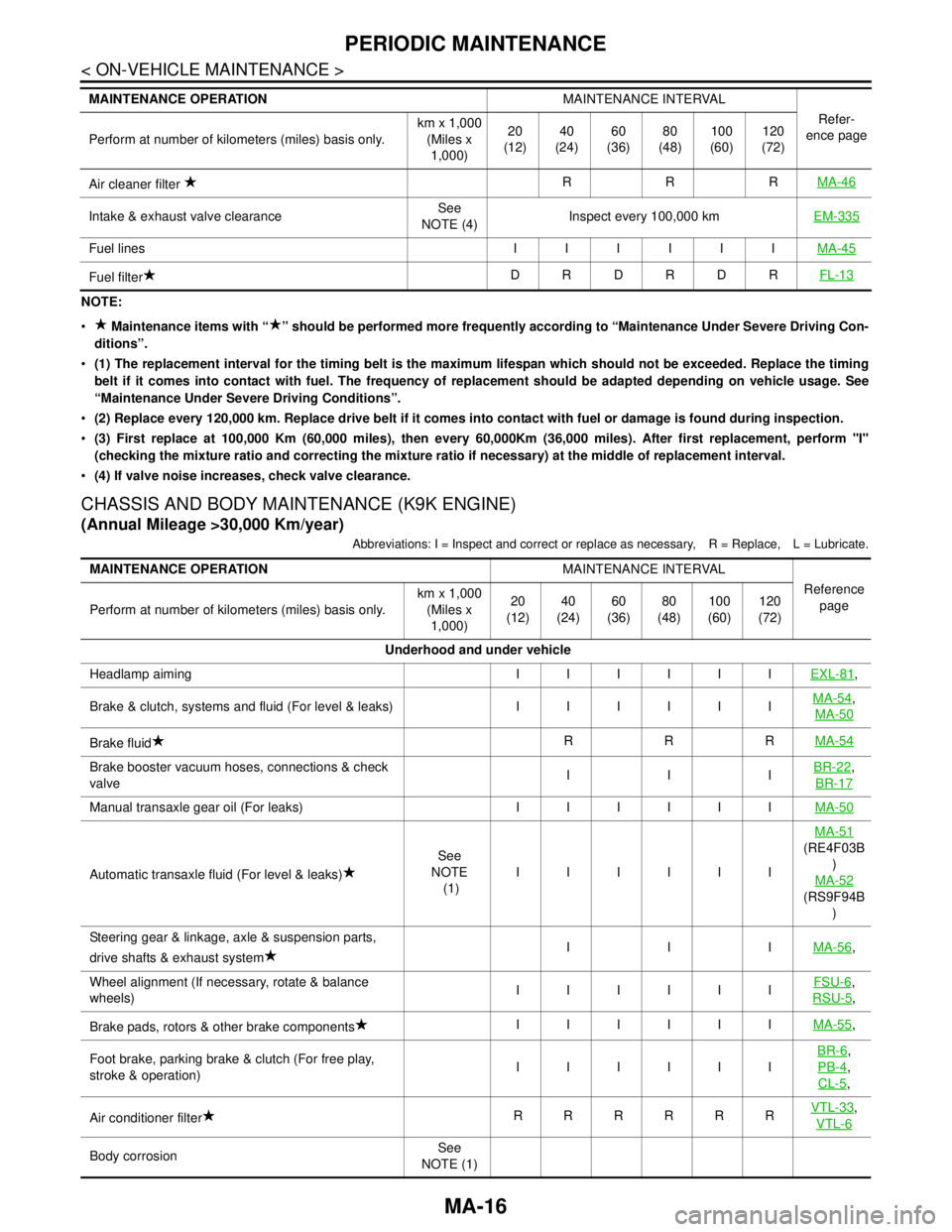

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Con-

ditions”.

(1) The replacement interval for the timing belt is the maximum lifespan which should not be exceeded. Replace the timing

belt if it comes into contact with fuel. The frequency of replacement should be adapted depending on vehicle usage. See

“Maintenance Under Severe Driving Conditions”.

(2) Replace every 120,000 km. Replace drive belt if it comes into contact with fuel or damage is found during inspection.

(3) First replace at 100,000 Km (60,000 miles), then every 60,000Km (36,000 miles). After first replacement, perform "I"

(checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) If valve noise increases, check valve clearance.

CHASSIS AND BODY MAINTENANCE (K9K ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

Air cleaner filter RRRMA-46

Intake & exhaust valve clearanceSee

NOTE (4)Inspect every 100,000 kmEM-335

Fuel lines IIIIIIMA-45

Fuel filterDRDRDRFL-13

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x

1,000)20

(12)40

(24)60

(36)80

(48)100

(60)120

(72)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page

Perform at number of kilometers (miles) basis only.km x 1,000

(Miles x

1,000)20

(12)40

(24)60

(36)80

(48)100

(60)120

(72)

Underhood and under vehicle

Headlamp aiming IIIIIIEXL-81

,

Brake & clutch, systems and fluid (For level & leaks) I I I I I IMA-54

,

MA-50

Brake fluidRRRMA-54

Brake booster vacuum hoses, connections & check

valveIIIBR-22,

BR-17

Manual transaxle gear oil (For leaks) I I I I I IMA-50

Automatic transaxle fluid (For level & leaks)See

NOTE

(1)IIIIIIMA-51

(RE4F03B

)

MA-52

(RS9F94B

)

Steering gear & linkage, axle & suspension parts,

drive shafts & exhaust systemIIIMA-56

,

Wheel alignment (If necessary, rotate & balance

wheels)IIIIIIFSU-6

,

RSU-5

,

Brake pads, rotors & other brake componentsIIIIIIMA-55

,

Foot brake, parking brake & clutch (For free play,

stroke & operation)IIIIIIBR-6

,

PB-4

,

CL-5

,

Air conditioner filterRRRRRRVTL-33

,

VTL-6

Body corrosionSee

NOTE (1)

Page 4342 of 5883

MWI

AMBIENT SENSOR SIGNAL CIRCUIT

MWI-35

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

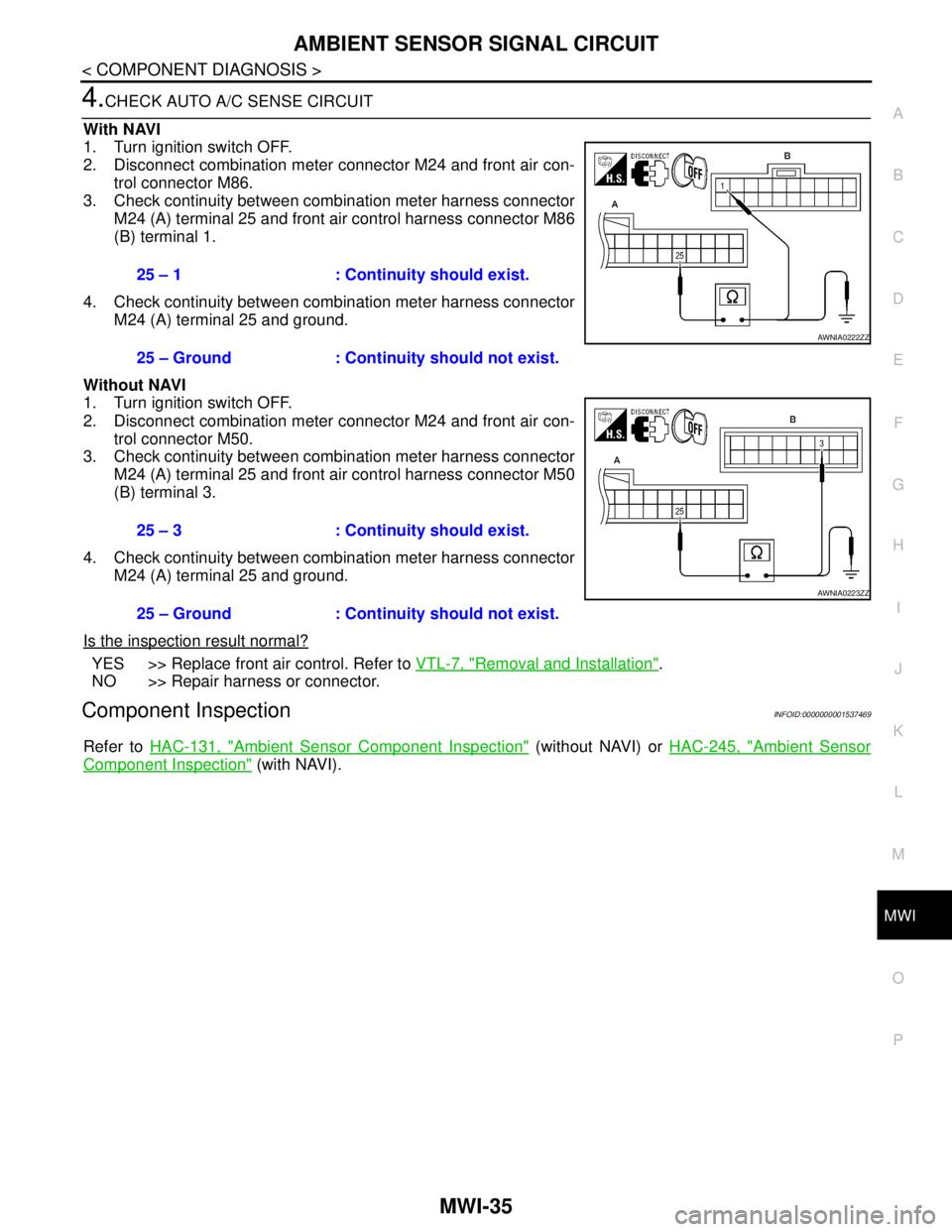

4.CHECK AUTO A/C SENSE CIRCUIT

With NAVI

1. Turn ignition switch OFF.

2. Disconnect combination meter connector M24 and front air con-

trol connector M86.

3. Check continuity between combination meter harness connector

M24 (A) terminal 25 and front air control harness connector M86

(B) terminal 1.

4. Check continuity between combination meter harness connector

M24 (A) terminal 25 and ground.

Without NAVI

1. Turn ignition switch OFF.

2. Disconnect combination meter connector M24 and front air con-

trol connector M50.

3. Check continuity between combination meter harness connector

M24 (A) terminal 25 and front air control harness connector M50

(B) terminal 3.

4. Check continuity between combination meter harness connector

M24 (A) terminal 25 and ground.

Is the inspection result normal?

YES >> Replace front air control. Refer to VTL-7, "Removal and Installation".

NO >> Repair harness or connector.

Component InspectionINFOID:0000000001537469

Refer to HAC-131, "Ambient Sensor Component Inspection" (without NAVI) or HAC-245, "Ambient Sensor

Component Inspection" (with NAVI). 25 – 1 : Continuity should exist.

25 – Ground : Continuity should not exist.

25 – 3 : Continuity should exist.

25 – Ground : Continuity should not exist.

AWNIA0222ZZ

AWNIA0223ZZ

Page 4752 of 5883

FRONT PASSENGER AIR BAG MODULE

SR-9

< ON-VEHICLE REPAIR >

C

D

E

F

G

I

J

K

L

MA

B

SR

N

O

P

FRONT PASSENGER AIR BAG MODULE

Removal and InstallationINFOID:0000000001350506

REMOVAL

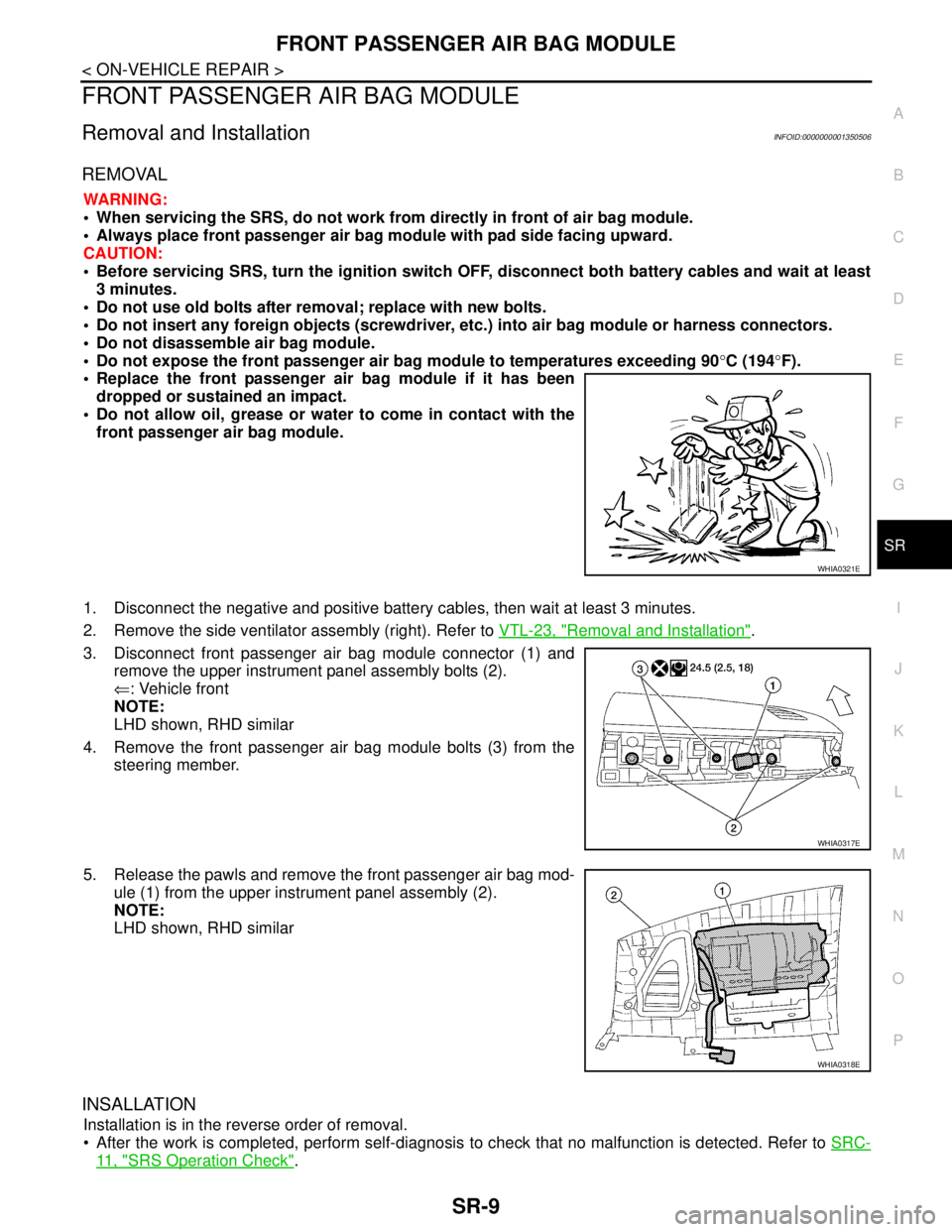

WARNING:

When servicing the SRS, do not work from directly in front of air bag module.

Always place front passenger air bag module with pad side facing upward.

CAUTION:

Before servicing SRS, turn the ignition switch OFF, disconnect both battery cables and wait at least

3 minutes.

Do not use old bolts after removal; replace with new bolts.

Do not insert any foreign objects (screwdriver, etc.) into air bag module or harness connectors.

Do not disassemble air bag module.

Do not expose the front passenger air bag module to temperatures exceeding 90°C (194°F).

Replace the front passenger air bag module if it has been

dropped or sustained an impact.

Do not allow oil, grease or water to come in contact with the

front passenger air bag module.

1. Disconnect the negative and positive battery cables, then wait at least 3 minutes.

2. Remove the side ventilator assembly (right). Refer to VTL-23, "

Removal and Installation".

3. Disconnect front passenger air bag module connector (1) and

remove the upper instrument panel assembly bolts (2).

⇐: Vehicle front

NOTE:

LHD shown, RHD similar

4. Remove the front passenger air bag module bolts (3) from the

steering member.

5. Release the pawls and remove the front passenger air bag mod-

ule (1) from the upper instrument panel assembly (2).

NOTE:

LHD shown, RHD similar

INSALLATION

Installation is in the reverse order of removal.

After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRC-

11 , "SRS Operation Check".

WHIA0321E

WHIA0317E

WHIA0318E

Page 5662 of 5883

VTL-1

VENTILATION, HEATER & AIR CONDITIONER

C

D

E

F

G

H

J

K

L

M

SECTION VTL

A

B

VTL

N

O

P

CONTENTS

VENTILATION SYSTEM

AUTOMATIC AIR CONDITIONER

PRECAUTION ...............................................

3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Working with HFC-134a (R-134a) ......3

PREPARATION ............................................4

PREPARATION ...................................................4

Commercial Service Tool ..........................................4

FUNCTION DIAGNOSIS ...............................5

AIR CONDITIONER FILTER ...............................5

Description ................................................................5

ON-VEHICLE MAINTENANCE .....................6

AIR CONDITIONER FILTER ...............................6

Removal and Installation ...........................................6

ON-VEHICLE REPAIR ..................................7

CONTROLLER ....................................................7

Removal and Installation ...........................................7

Disassembly and Assembly ......................................7

IN-VEHICLE SENSOR ........................................9

Removal and Installation ...........................................9

SUNLOAD SENSOR ..........................................10

Removal and Installation .........................................10

INTAKE SENSOR ..............................................11

Removal and Installation .........................................11

A/C UNIT ASSEMBLY .......................................12

Removal and Installation .........................................12

Disassembly and Assembly ....................................14

EVAPORATOR .................................................16

Removal and Installation .........................................16

HEATER CORE .................................................17

Removal and Installation .........................................17

BLOWER MOTOR ............................................18

Removal and Installation .........................................18

FAN CONTROL AMPLIFIER ............................19

Removal and Installation .........................................19

INTAKE DOOR MOTOR ...................................20

Removal and Installation .........................................20

AIR MIX DOOR MOTOR ...................................21

Removal and Installation .........................................21

MODE DOOR MOTOR ......................................22

Removal and Installation .........................................22

DUCTS AND GRILLES .....................................23

Removal and Installation .........................................23

PTC HEATER ....................................................28

Removal and Installation of PTC Control Unit .........28

Removal and Installation of PTC Heater .................28

Removal and Installation of Water Temperature

Sensor .....................................................................

28

MANUAL AIR CONDITIONER

PRECAUTION ..............................................

30

PRECAUTIONS .................................................30

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

30

Precaution for Working with HFC-134a (R-134a) ....30

PREPARATION ...........................................31

PREPARATION .................................................31

Commercial Service Tool ........................................31