NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1311 of 2771

DTC P0137 HO2S2

EC-237

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Start engine and warm it up to normal operating temperature.

2. Select “SELF-LEARNING CONT” in “WORK SUPPORT” mode

with CONSULT-II.

3. Clear the self-learning control coefficient by touching “CLEAR”.

4. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 detected?

Is it difficult to start engine?

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF.

3. Disconnect mass air flow sensor (1) harness connector, and

restart and run engine for at least 5 seconds at idle speed.

4. Stop engine and reconnect mass air flow sensor harness con-

nector.

5. Make sure DTC P0102 is displayed.

6. Erase the DTC memory. Refer to EC-47, "

Emission-related

Diagnostic Information".

7. Make sure DTC P0000 is displayed.

8. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 detected?

Is it difficult to start engine?

Ye s o r N o

Yes >> Perform trouble diagnosis for DTC P0171. Refer to EC-257.

No >> GO TO 3.

3.CHECK HO2S2 GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

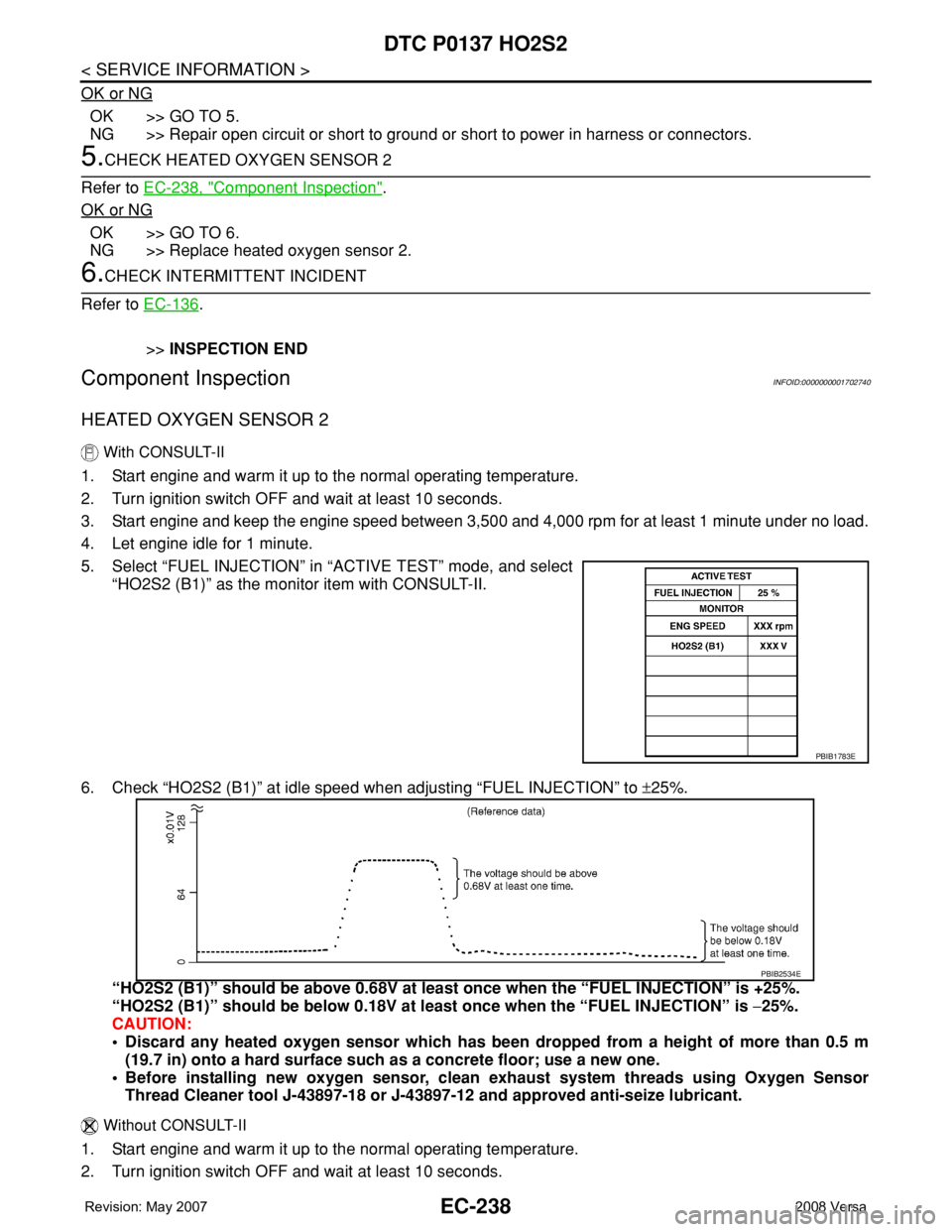

2. Disconnect heated oxygen sensor 2 harness connector (2).

- : Vehicle front

- Heated oxygen sensor 2 (1)

3. Disconnect ECM harness connector.

4. Check harness continuity between ECM terminal 59 and HO2S2

terminal 1.

Refer to Wiring Diagram.

5. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK HO2S2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 50 and HO2S2 terminal 4.

Refer to Wiring Diagram.

2. Check harness continuity between ECM terminal 50 or HO2S2 terminal 4 and ground.

Refer to Wiring Diagram.

3. Also check harness for short to power.

SEF215Z

BBIA0701E

Continuity should exist.

BBIA0700E

Continuity should exist.

Continuity should not exist.

Page 1312 of 2771

EC-238

< SERVICE INFORMATION >

DTC P0137 HO2S2

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK HEATED OXYGEN SENSOR 2

Refer to EC-238, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace heated oxygen sensor 2.

6.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

>>INSPECTION END

Component InspectionINFOID:0000000001702740

HEATED OXYGEN SENSOR 2

With CONSULT-II

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

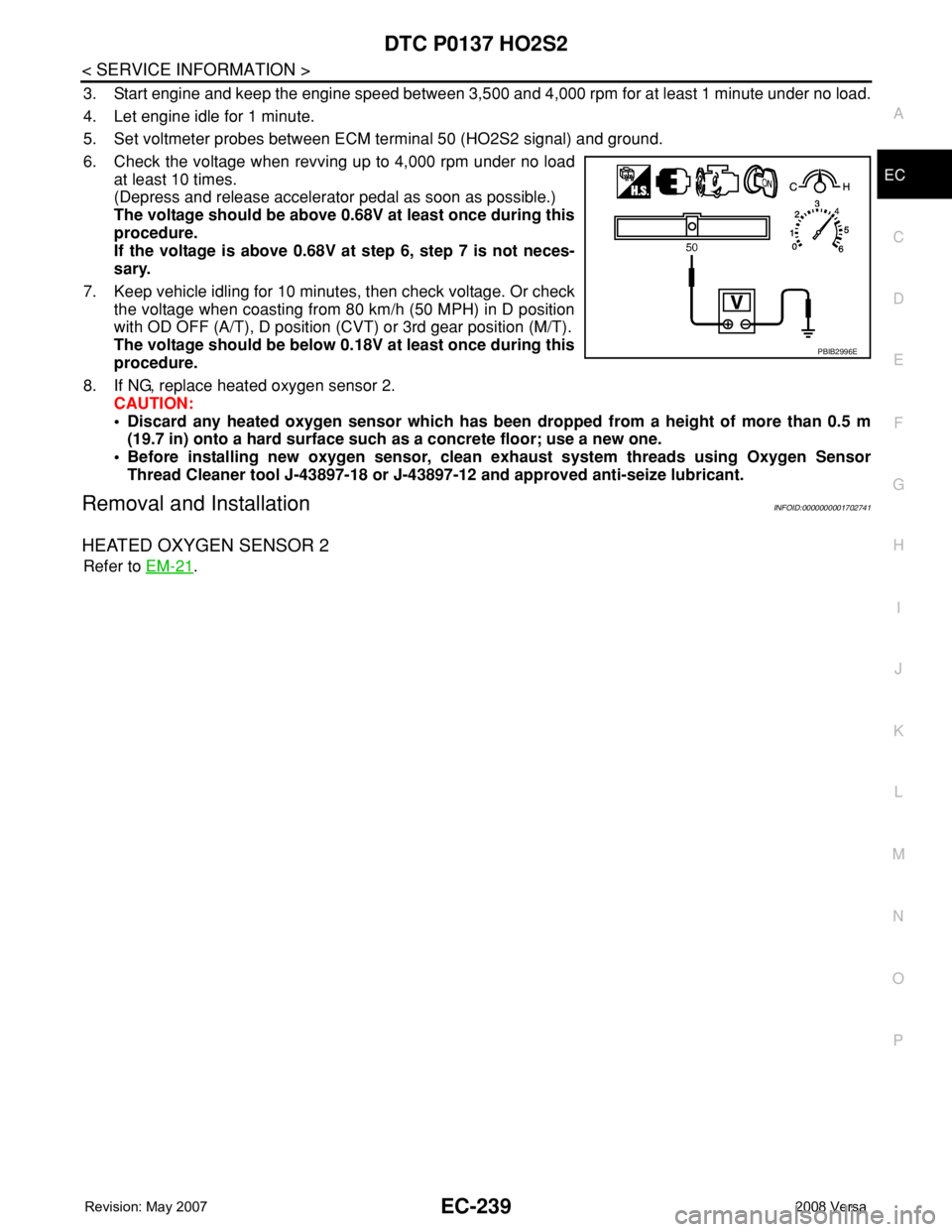

5. Select “FUEL INJECTION” in “ACTIVE TEST” mode, and select

“HO2S2 (B1)” as the monitor item with CONSULT-II.

6. Check “HO2S2 (B1)” at idle speed when adjusting “FUEL INJECTION” to ±25%.

“HO2S2 (B1)” should be above 0.68V at least once when the “FUEL INJECTION” is +25%.

“HO2S2 (B1)” should be below 0.18V at least once when the “FUEL INJECTION” is −25%.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor

Thread Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

Without CONSULT-II

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

PBIB1783E

PBIB2534E

Page 1313 of 2771

DTC P0137 HO2S2

EC-239

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Set voltmeter probes between ECM terminal 50 (HO2S2 signal) and ground.

6. Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be above 0.68V at least once during this

procedure.

If the voltage is above 0.68V at step 6, step 7 is not neces-

sary.

7. Keep vehicle idling for 10 minutes, then check voltage. Or check

the voltage when coasting from 80 km/h (50 MPH) in D position

with OD OFF (A/T), D position (CVT) or 3rd gear position (M/T).

The voltage should be below 0.18V at least once during this

procedure.

8. If NG, replace heated oxygen sensor 2.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor

Thread Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

Removal and InstallationINFOID:0000000001702741

HEATED OXYGEN SENSOR 2

Refer to EM-21.

PBIB2996E

Page 1314 of 2771

EC-240

< SERVICE INFORMATION >

DTC P0138 HO2S2

DTC P0138 HO2S2

Component DescriptionINFOID:0000000001702742

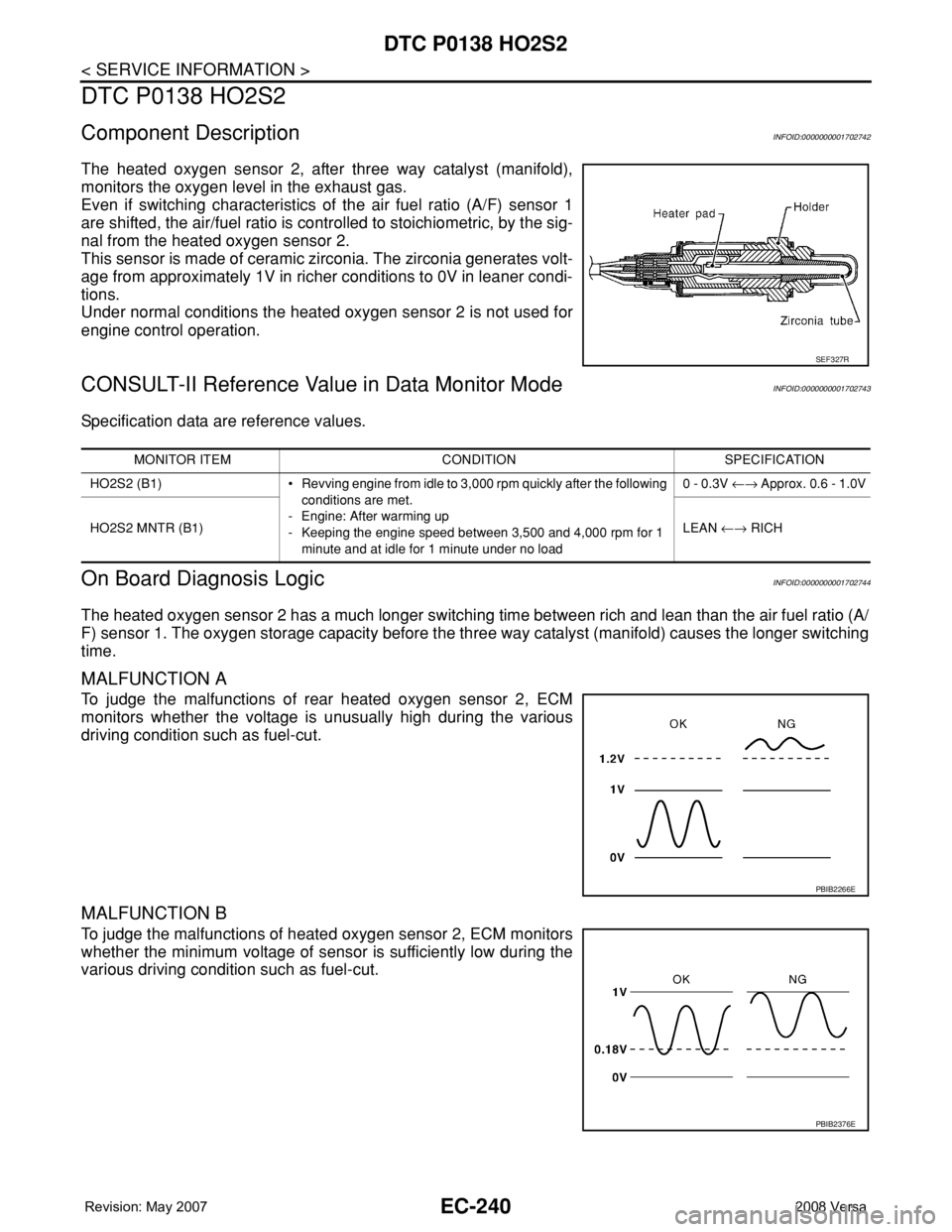

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air/fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702743

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702744

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/

F) sensor 1. The oxygen storage capacity before the three way catalyst (manifold) causes the longer switching

time.

MALFUNCTION A

To judge the malfunctions of rear heated oxygen sensor 2, ECM

monitors whether the voltage is unusually high during the various

driving condition such as fuel-cut.

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the minimum voltage of sensor is sufficiently low during the

various driving condition such as fuel-cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1) • Revving engine from idle to 3,000 rpm quickly after the following

conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1

minute and at idle for 1 minute under no load0 - 0.3V ←→ Approx. 0.6 - 1.0V

HO2S2 MNTR (B1) LEAN ←→ RICH

PBIB2266E

PBIB2376E

Page 1315 of 2771

DTC P0138 HO2S2

EC-241

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

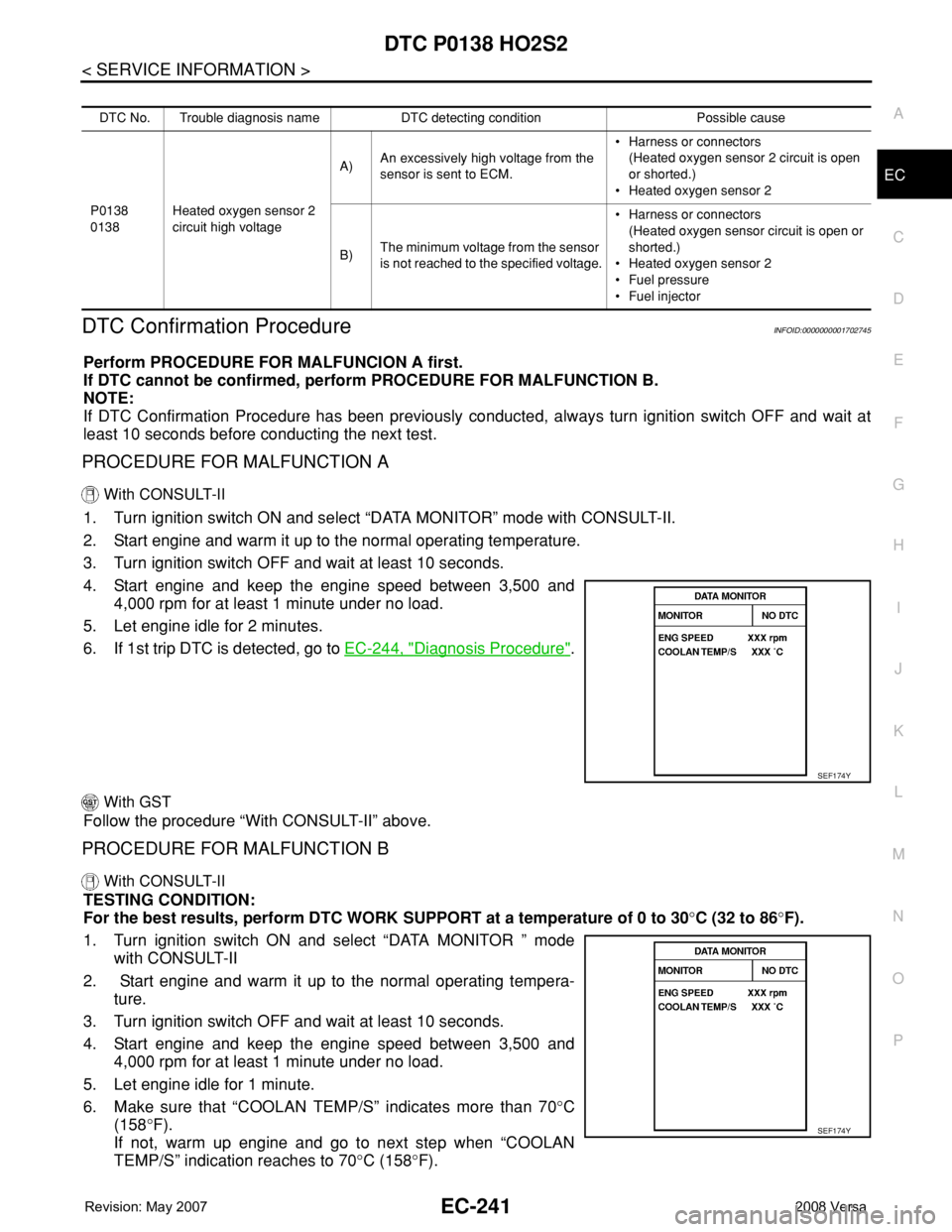

DTC Confirmation ProcedureINFOID:0000000001702745

Perform PROCEDURE FOR MALFUNCION A first.

If DTC cannot be confirmed, perform PROCEDURE FOR MALFUNCTION B.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

PROCEDURE FOR MALFUNCTION A

With CONSULT-II

1. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-II.

2. Start engine and warm it up to the normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and

4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 2 minutes.

6. If 1st trip DTC is detected, go to EC-244, "

Diagnosis Procedure".

With GST

Follow the procedure “With CONSULT-II” above.

PROCEDURE FOR MALFUNCTION B

With CONSULT-II

TESTING CONDITION:

For the best results, perform DTC WORK SUPPORT at a temperature of 0 to 30°C (32 to 86°F).

1. Turn ignition switch ON and select “DATA MONITOR ” mode

with CONSULT-II

2. Start engine and warm it up to the normal operating tempera-

ture.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and

4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 1 minute.

6. Make sure that “COOLAN TEMP/S” indicates more than 70°C

(158°F).

If not, warm up engine and go to next step when “COOLAN

TEMP/S” indication reaches to 70°C (158°F).

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0138

0138Heated oxygen sensor 2

circuit high voltageA)An excessively high voltage from the

sensor is sent to ECM.• Harness or connectors

(Heated oxygen sensor 2 circuit is open

or shorted.)

• Heated oxygen sensor 2

B)The minimum voltage from the sensor

is not reached to the specified voltage.• Harness or connectors

(Heated oxygen sensor circuit is open or

shorted.)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector

SEF174Y

SEF174Y

Page 1316 of 2771

EC-242

< SERVICE INFORMATION >

DTC P0138 HO2S2

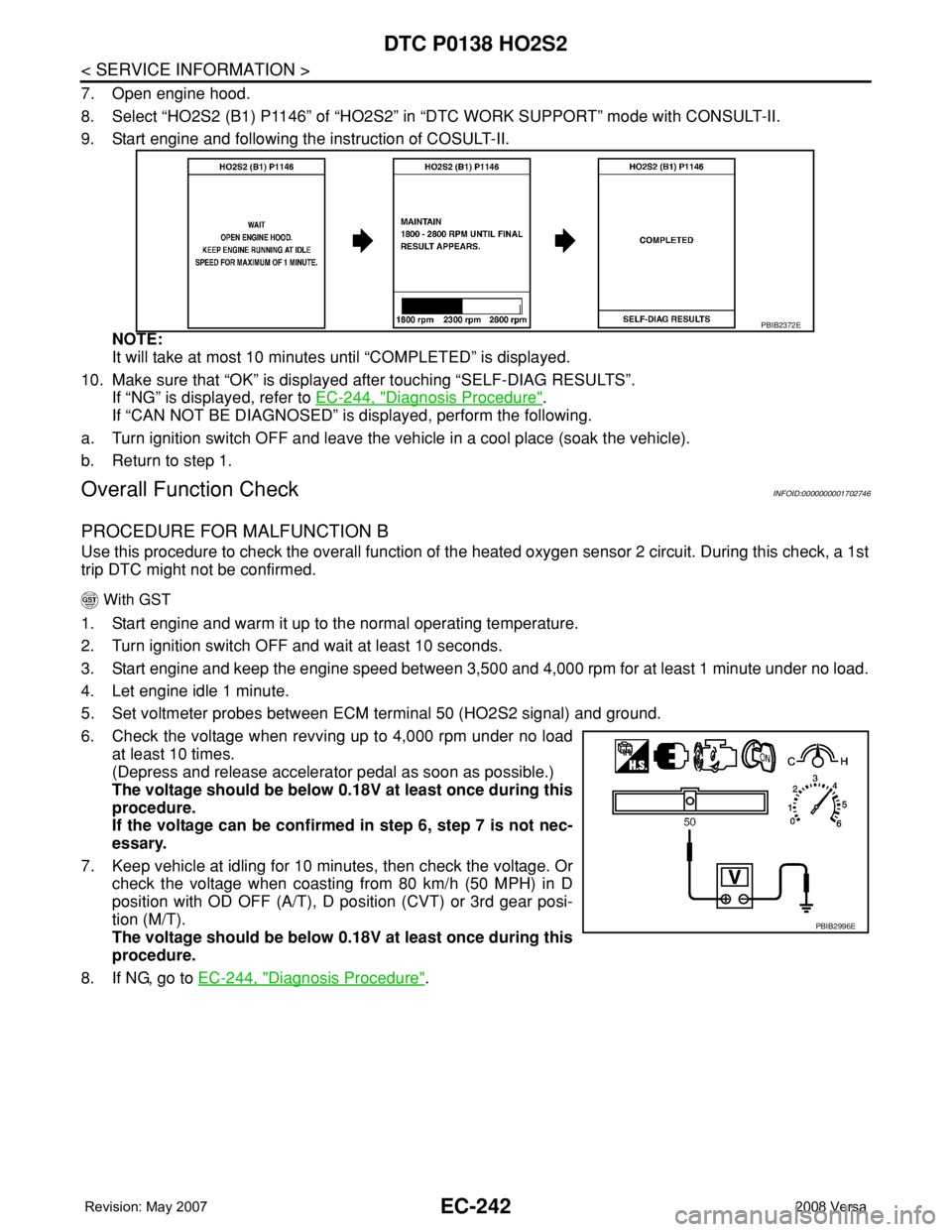

7. Open engine hood.

8. Select “HO2S2 (B1) P1146” of “HO2S2” in “DTC WORK SUPPORT” mode with CONSULT-II.

9. Start engine and following the instruction of COSULT-II.

NOTE:

It will take at most 10 minutes until “COMPLETED” is displayed.

10. Make sure that “OK” is displayed after touching “SELF-DIAG RESULTS”.

If “NG” is displayed, refer to EC-244, "

Diagnosis Procedure".

If “CAN NOT BE DIAGNOSED” is displayed, perform the following.

a. Turn ignition switch OFF and leave the vehicle in a cool place (soak the vehicle).

b. Return to step 1.

Overall Function CheckINFOID:0000000001702746

PROCEDURE FOR MALFUNCTION B

Use this procedure to check the overall function of the heated oxygen sensor 2 circuit. During this check, a 1st

trip DTC might not be confirmed.

With GST

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle 1 minute.

5. Set voltmeter probes between ECM terminal 50 (HO2S2 signal) and ground.

6. Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be below 0.18V at least once during this

procedure.

If the voltage can be confirmed in step 6, step 7 is not nec-

essary.

7. Keep vehicle at idling for 10 minutes, then check the voltage. Or

check the voltage when coasting from 80 km/h (50 MPH) in D

position with OD OFF (A/T), D position (CVT) or 3rd gear posi-

tion (M/T).

The voltage should be below 0.18V at least once during this

procedure.

8. If NG, go to EC-244, "

Diagnosis Procedure".

PBIB2372E

PBIB2996E

Page 1317 of 2771

DTC P0138 HO2S2

EC-243

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

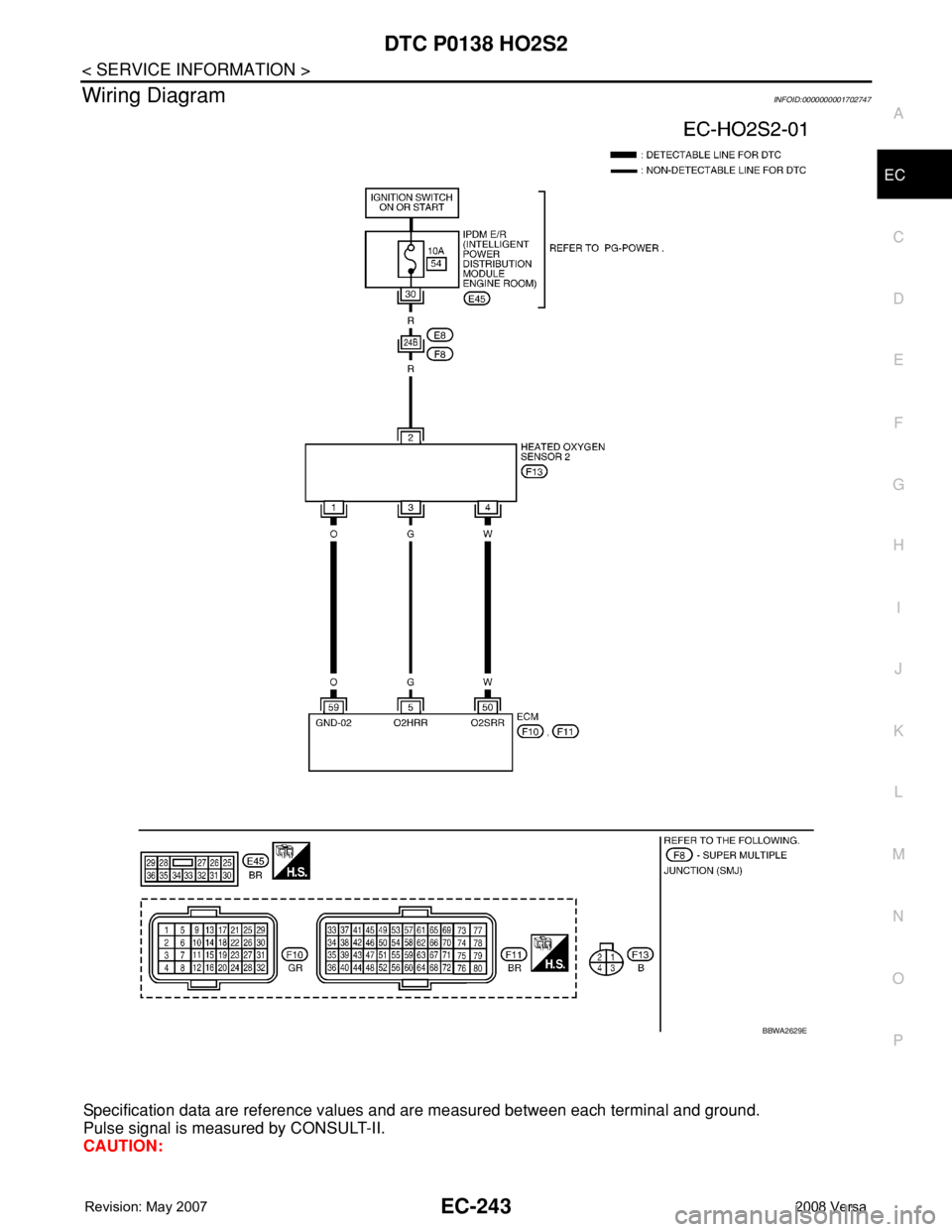

Wiring DiagramINFOID:0000000001702747

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

BBWA2629E

Page 1318 of 2771

EC-244

< SERVICE INFORMATION >

DTC P0138 HO2S2

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

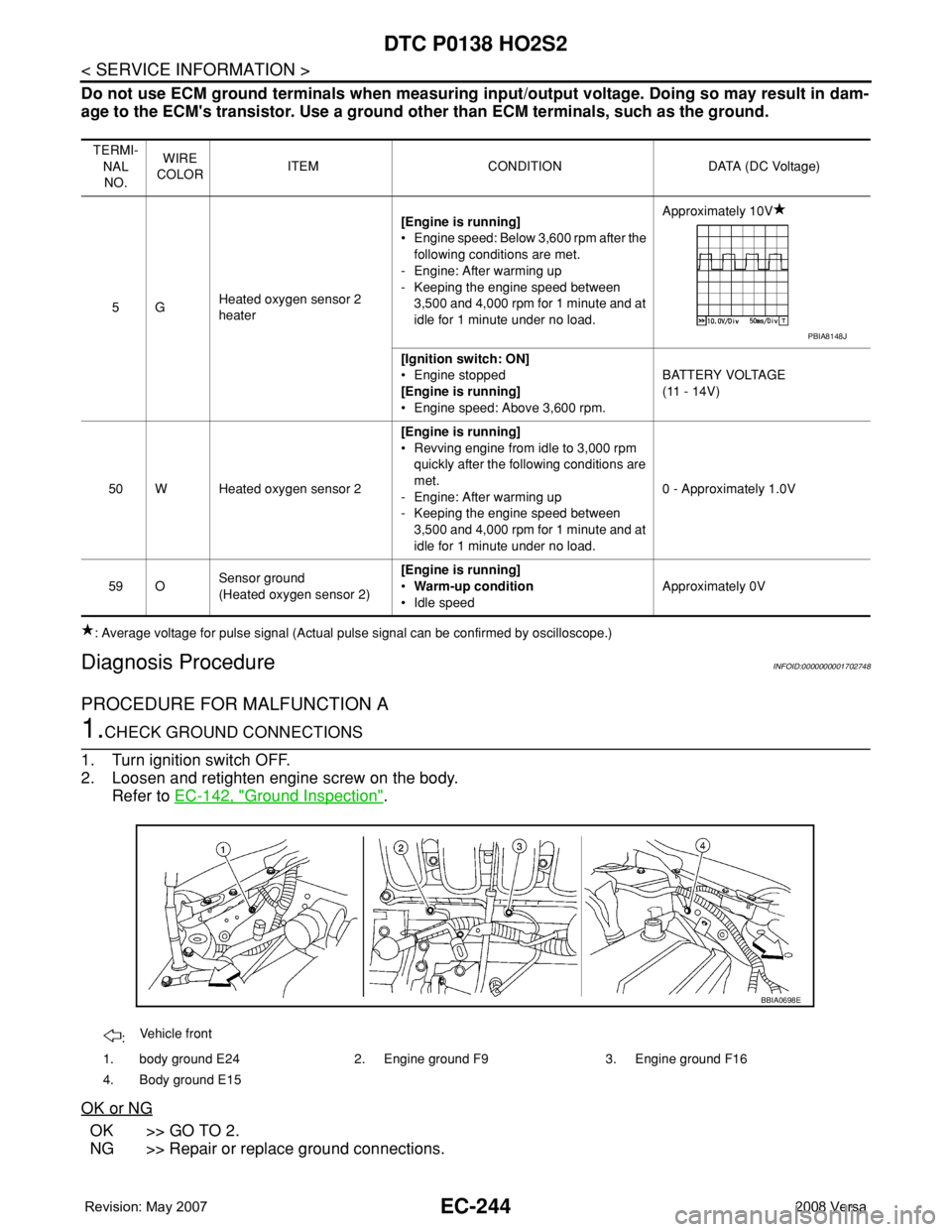

Diagnosis ProcedureINFOID:0000000001702748

PROCEDURE FOR MALFUNCTION A

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten engine screw on the body.

Refer to EC-142, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

5GHeated oxygen sensor 2

heater[Engine is running]

• Engine speed: Below 3,600 rpm after the

following conditions are met.

- Engine: After warming up

- Keeping the engine speed between

3,500 and 4,000 rpm for 1 minute and at

idle for 1 minute under no load.Approximately 10V

[Ignition switch: ON]

• Engine stopped

[Engine is running]

• Engine speed: Above 3,600 rpm.BATTERY VOLTAGE

(11 - 14V)

50 W Heated oxygen sensor 2[Engine is running]

• Revving engine from idle to 3,000 rpm

quickly after the following conditions are

met.

- Engine: After warming up

- Keeping the engine speed between

3,500 and 4,000 rpm for 1 minute and at

idle for 1 minute under no load.0 - Approximately 1.0V

59 OSensor ground

(Heated oxygen sensor 2)[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

PBIA8148J

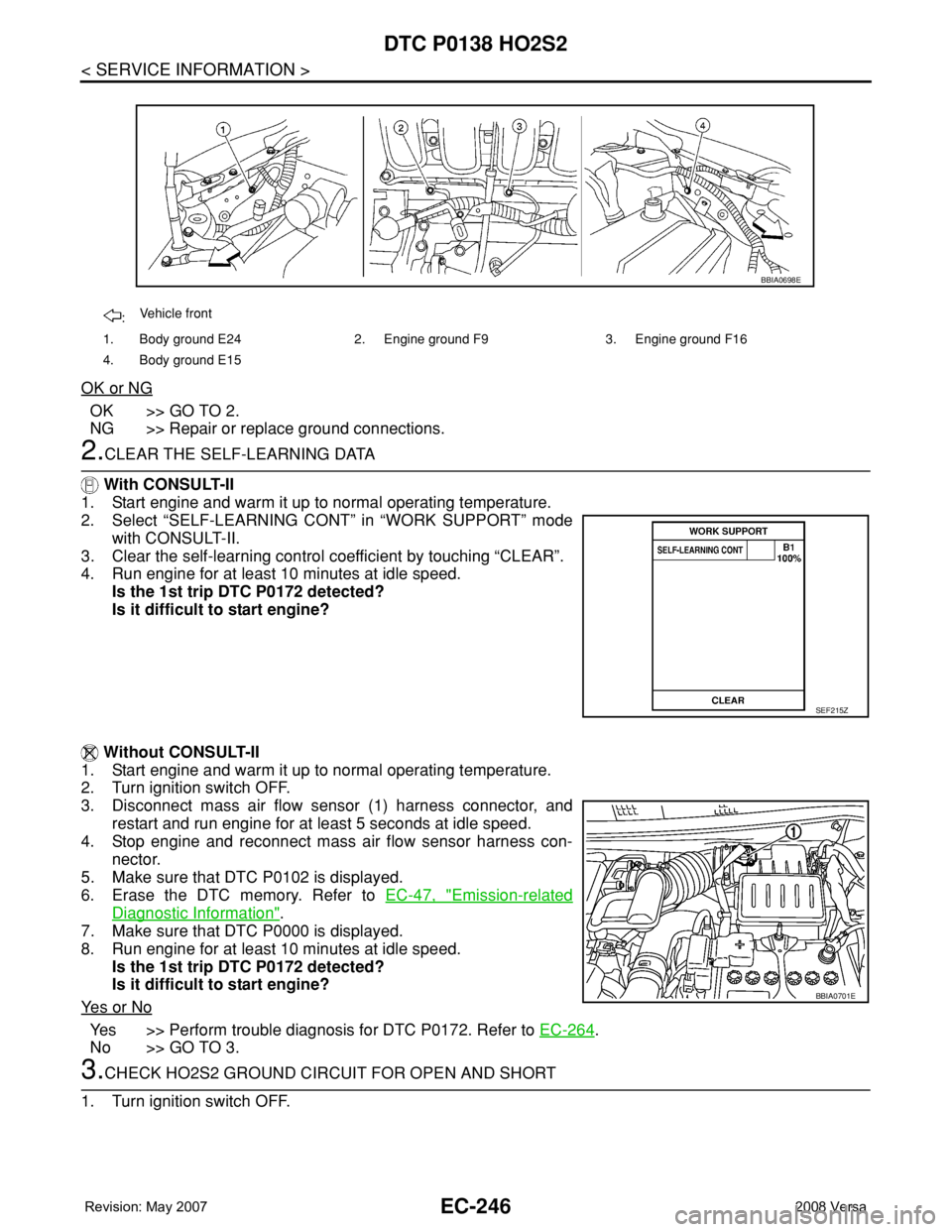

:Vehicle front

1. body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0698E

Page 1319 of 2771

DTC P0138 HO2S2

EC-245

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

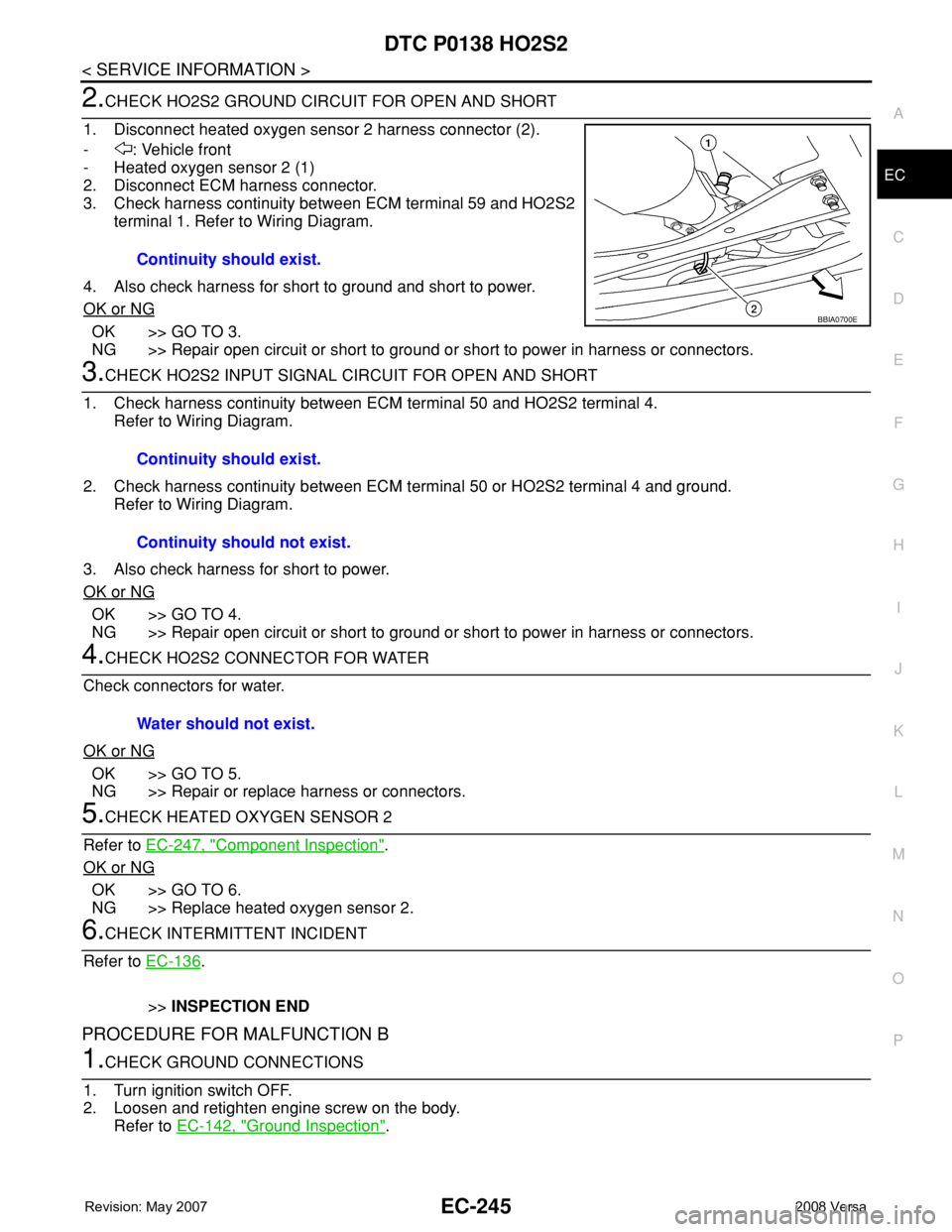

2.CHECK HO2S2 GROUND CIRCUIT FOR OPEN AND SHORT

1. Disconnect heated oxygen sensor 2 harness connector (2).

- : Vehicle front

- Heated oxygen sensor 2 (1)

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 59 and HO2S2

terminal 1. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK HO2S2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 50 and HO2S2 terminal 4.

Refer to Wiring Diagram.

2. Check harness continuity between ECM terminal 50 or HO2S2 terminal 4 and ground.

Refer to Wiring Diagram.

3. Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK HO2S2 CONNECTOR FOR WATER

Check connectors for water.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace harness or connectors.

5.CHECK HEATED OXYGEN SENSOR 2

Refer to EC-247, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace heated oxygen sensor 2.

6.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

>>INSPECTION END

PROCEDURE FOR MALFUNCTION B

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten engine screw on the body.

Refer to EC-142, "

Ground Inspection". Continuity should exist.

BBIA0700E

Continuity should exist.

Continuity should not exist.

Water should not exist.

Page 1320 of 2771

EC-246

< SERVICE INFORMATION >

DTC P0138 HO2S2

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CLEAR THE SELF-LEARNING DATA

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select “SELF-LEARNING CONT” in “WORK SUPPORT” mode

with CONSULT-II.

3. Clear the self-learning control coefficient by touching “CLEAR”.

4. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0172 detected?

Is it difficult to start engine?

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF.

3. Disconnect mass air flow sensor (1) harness connector, and

restart and run engine for at least 5 seconds at idle speed.

4. Stop engine and reconnect mass air flow sensor harness con-

nector.

5. Make sure that DTC P0102 is displayed.

6. Erase the DTC memory. Refer to EC-47, "

Emission-related

Diagnostic Information".

7. Make sure that DTC P0000 is displayed.

8. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0172 detected?

Is it difficult to start engine?

Ye s o r N o

Yes >> Perform trouble diagnosis for DTC P0172. Refer to EC-264.

No >> GO TO 3.

3.CHECK HO2S2 GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0698E

SEF215Z

BBIA0701E