NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1341 of 2771

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

EC-267

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001702767

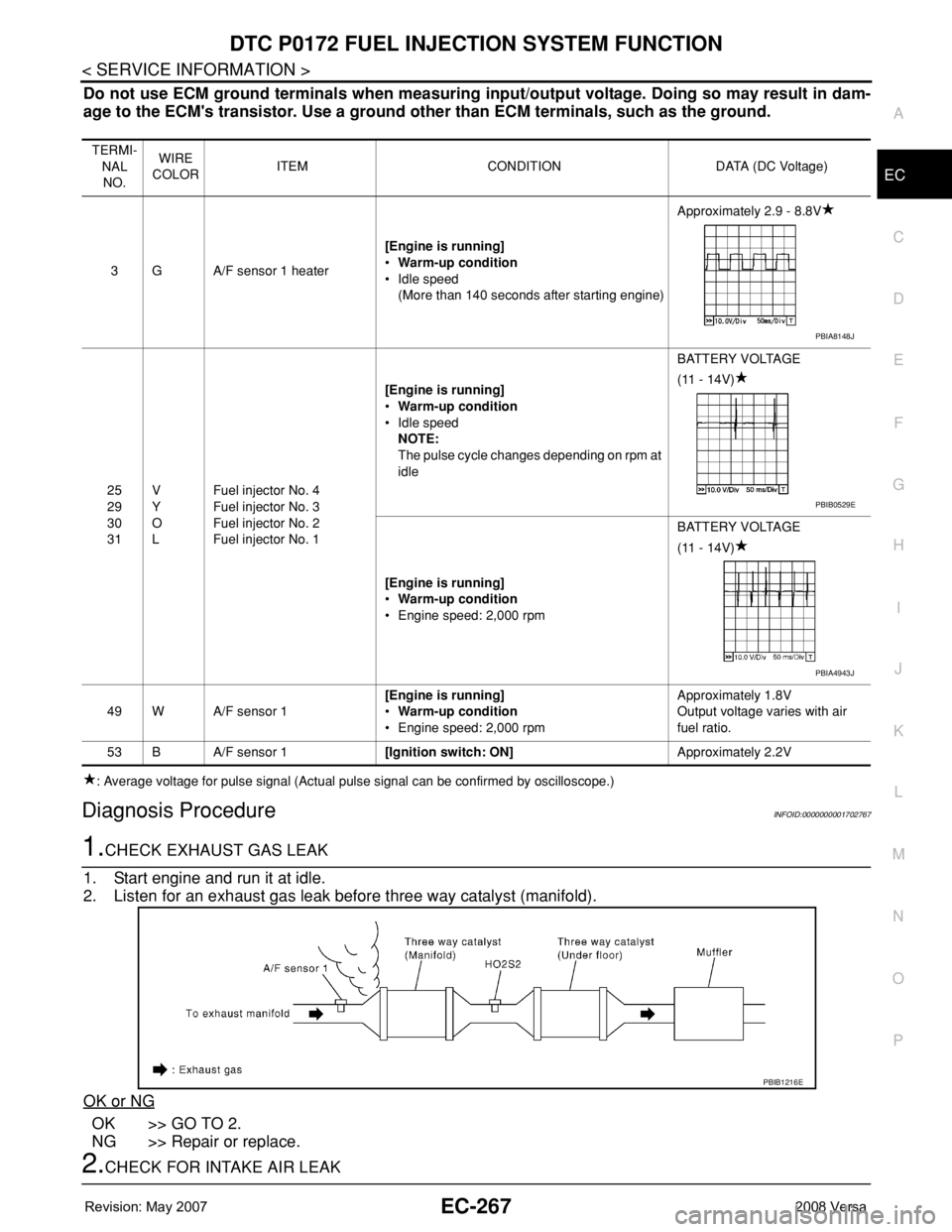

1.CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak before three way catalyst (manifold).

OK or NG

OK >> GO TO 2.

NG >> Repair or replace.

2.CHECK FOR INTAKE AIR LEAK

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

3 G A/F sensor 1 heater[Engine is running]

•Warm-up condition

• Idle speed

(More than 140 seconds after starting engine)Approximately 2.9 - 8.8V

25

29

30

31V

Y

O

LFuel injector No. 4

Fuel injector No. 3

Fuel injector No. 2

Fuel injector No. 1[Engine is running]

•Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm at

idleBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

•Warm-up condition

• Engine speed: 2,000 rpmBATTERY VOLTAGE

(11 - 14V)

49 W A/F sensor 1[Engine is running]

•Warm-up condition

• Engine speed: 2,000 rpmApproximately 1.8V

Output voltage varies with air

fuel ratio.

53 B A/F sensor 1[Ignition switch: ON]Approximately 2.2V

PBIA8148J

PBIB0529E

PBIA4943J

PBIB1216E

Page 1342 of 2771

EC-268

< SERVICE INFORMATION >

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace.

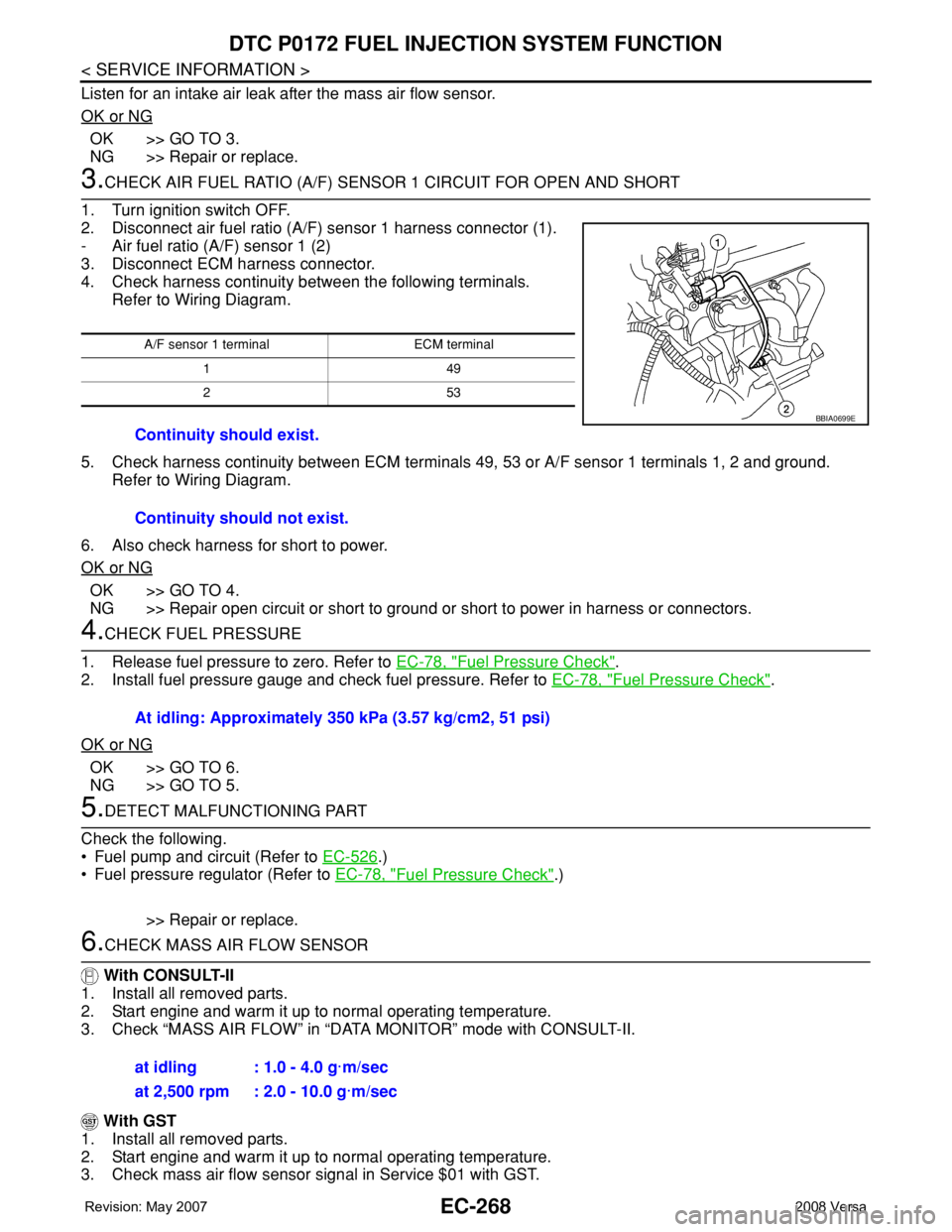

3.CHECK AIR FUEL RATIO (A/F) SENSOR 1 CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect air fuel ratio (A/F) sensor 1 harness connector (1).

- Air fuel ratio (A/F) sensor 1 (2)

3. Disconnect ECM harness connector.

4. Check harness continuity between the following terminals.

Refer to Wiring Diagram.

5. Check harness continuity between ECM terminals 49, 53 or A/F sensor 1 terminals 1, 2 and ground.

Refer to Wiring Diagram.

6. Also check harness for short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK FUEL PRESSURE

1. Release fuel pressure to zero. Refer to EC-78, "

Fuel Pressure Check".

2. Install fuel pressure gauge and check fuel pressure. Refer to EC-78, "

Fuel Pressure Check".

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• Fuel pump and circuit (Refer to EC-526

.)

• Fuel pressure regulator (Refer to EC-78, "

Fuel Pressure Check".)

>> Repair or replace.

6.CHECK MASS AIR FLOW SENSOR

With CONSULT-II

1. Install all removed parts.

2. Start engine and warm it up to normal operating temperature.

3. Check “MASS AIR FLOW” in “DATA MONITOR” mode with CONSULT-II.

With GST

1. Install all removed parts.

2. Start engine and warm it up to normal operating temperature.

3. Check mass air flow sensor signal in Service $01 with GST.

A/F sensor 1 terminal ECM terminal

149

253

Continuity should exist.

Continuity should not exist.

BBIA0699E

At idling: Approximately 350 kPa (3.57 kg/cm2, 51 psi)

at idling : 1.0 - 4.0 g·m/sec

at 2,500 rpm : 2.0 - 10.0 g·m/sec

Page 1343 of 2771

DTC P0172 FUEL INJECTION SYSTEM FUNCTION

EC-269

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P OOK or NG

OK >> GO TO 7.

NG >> Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or

ground. Refer to EC-167

.

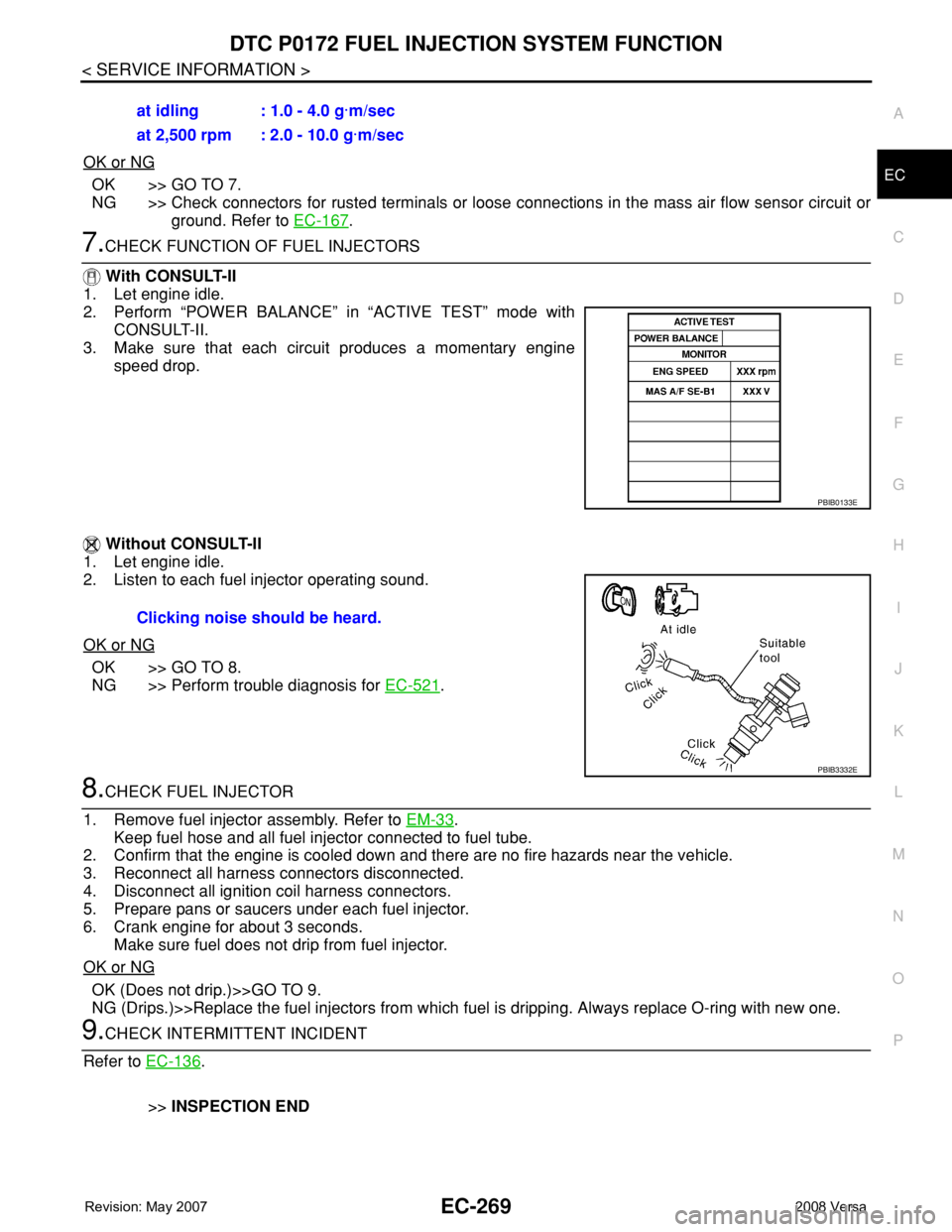

7.CHECK FUNCTION OF FUEL INJECTORS

With CONSULT-II

1. Let engine idle.

2. Perform “POWER BALANCE” in “ACTIVE TEST” mode with

CONSULT-II.

3. Make sure that each circuit produces a momentary engine

speed drop.

Without CONSULT-II

1. Let engine idle.

2. Listen to each fuel injector operating sound.

OK or NG

OK >> GO TO 8.

NG >> Perform trouble diagnosis for EC-521

.

8.CHECK FUEL INJECTOR

1. Remove fuel injector assembly. Refer to EM-33

.

Keep fuel hose and all fuel injector connected to fuel tube.

2. Confirm that the engine is cooled down and there are no fire hazards near the vehicle.

3. Reconnect all harness connectors disconnected.

4. Disconnect all ignition coil harness connectors.

5. Prepare pans or saucers under each fuel injector.

6. Crank engine for about 3 seconds.

Make sure fuel does not drip from fuel injector.

OK or NG

OK (Does not drip.)>>GO TO 9.

NG (Drips.)>>Replace the fuel injectors from which fuel is dripping. Always replace O-ring with new one.

9.CHECK INTERMITTENT INCIDENT

Refer to EC-136

.

>>INSPECTION END at idling : 1.0 - 4.0 g·m/sec

at 2,500 rpm : 2.0 - 10.0 g·m/sec

PBIB0133E

Clicking noise should be heard.

PBIB3332E

Page 1344 of 2771

EC-270

< SERVICE INFORMATION >

DTC P0181 FTT SENSOR

DTC P0181 FTT SENSOR

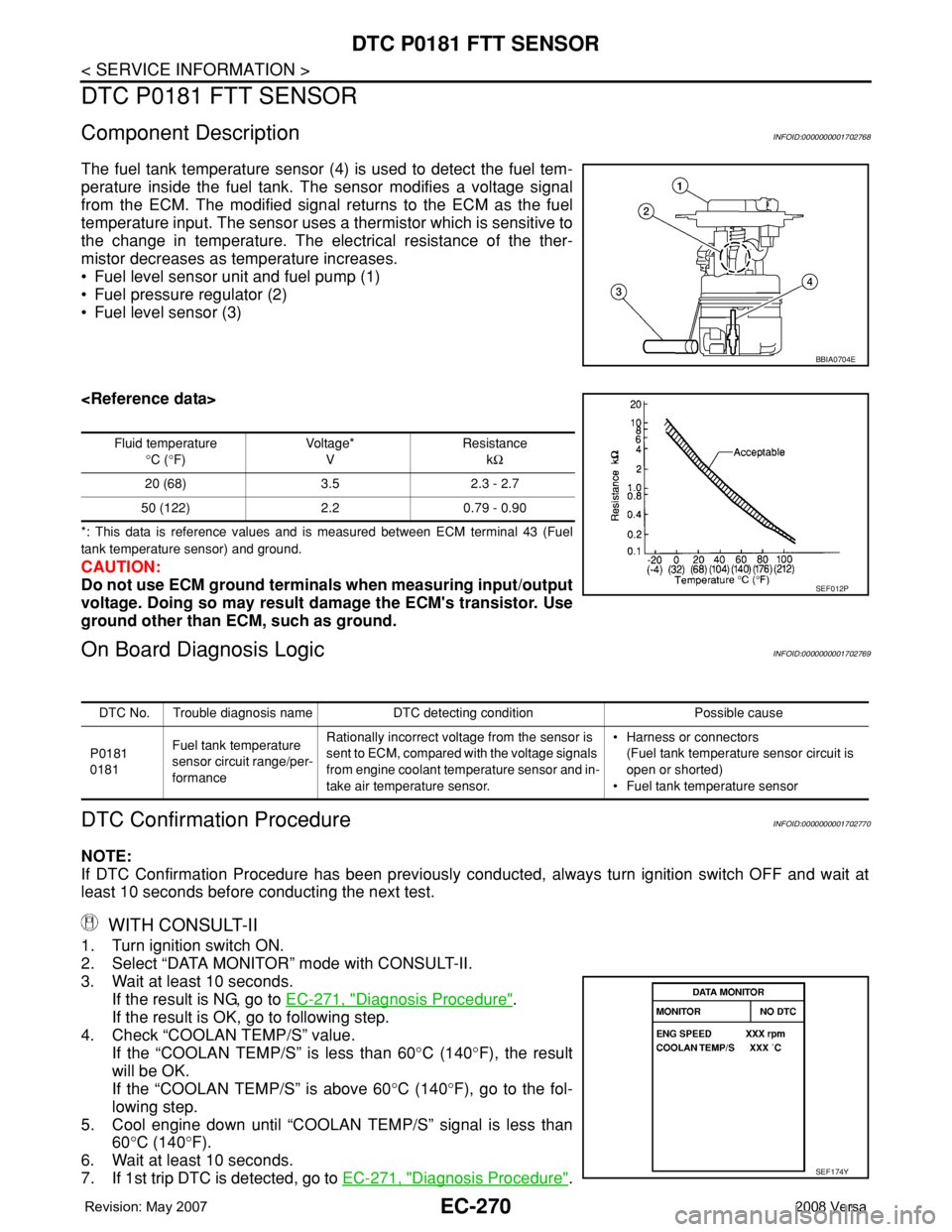

Component DescriptionINFOID:0000000001702768

The fuel tank temperature sensor (4) is used to detect the fuel tem-

perature inside the fuel tank. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the fuel

temperature input. The sensor uses a thermistor which is sensitive to

the change in temperature. The electrical resistance of the ther-

mistor decreases as temperature increases.

• Fuel level sensor unit and fuel pump (1)

• Fuel pressure regulator (2)

• Fuel level sensor (3)

*: This data is reference values and is measured between ECM terminal 43 (Fuel

tank temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output

voltage. Doing so may result damage the ECM's transistor. Use

ground other than ECM, such as ground.

On Board Diagnosis LogicINFOID:0000000001702769

DTC Confirmation ProcedureINFOID:0000000001702770

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 10 seconds.

If the result is NG, go to EC-271, "

Diagnosis Procedure".

If the result is OK, go to following step.

4. Check “COOLAN TEMP/S” value.

If the “COOLAN TEMP/S” is less than 60°C (140°F), the result

will be OK.

If the “COOLAN TEMP/S” is above 60°C (140°F), go to the fol-

lowing step.

5. Cool engine down until “COOLAN TEMP/S” signal is less than

60°C (140°F).

6. Wait at least 10 seconds.

7. If 1st trip DTC is detected, go to EC-271, "

Diagnosis Procedure".

BBIA0704E

Fluid temperature

°C (°F)Voltage*

VResistance

kΩ

20 (68) 3.5 2.3 - 2.7

50 (122) 2.2 0.79 - 0.90

SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0181

0181Fuel tank temperature

sensor circuit range/per-

formanceRationally incorrect voltage from the sensor is

sent to ECM, compared with the voltage signals

from engine coolant temperature sensor and in-

take air temperature sensor.• Harness or connectors

(Fuel tank temperature sensor circuit is

open or shorted)

• Fuel tank temperature sensor

SEF174Y

Page 1345 of 2771

DTC P0181 FTT SENSOR

EC-271

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

WITH GST

Follow the procedure “WITH CONSULT-II” above.

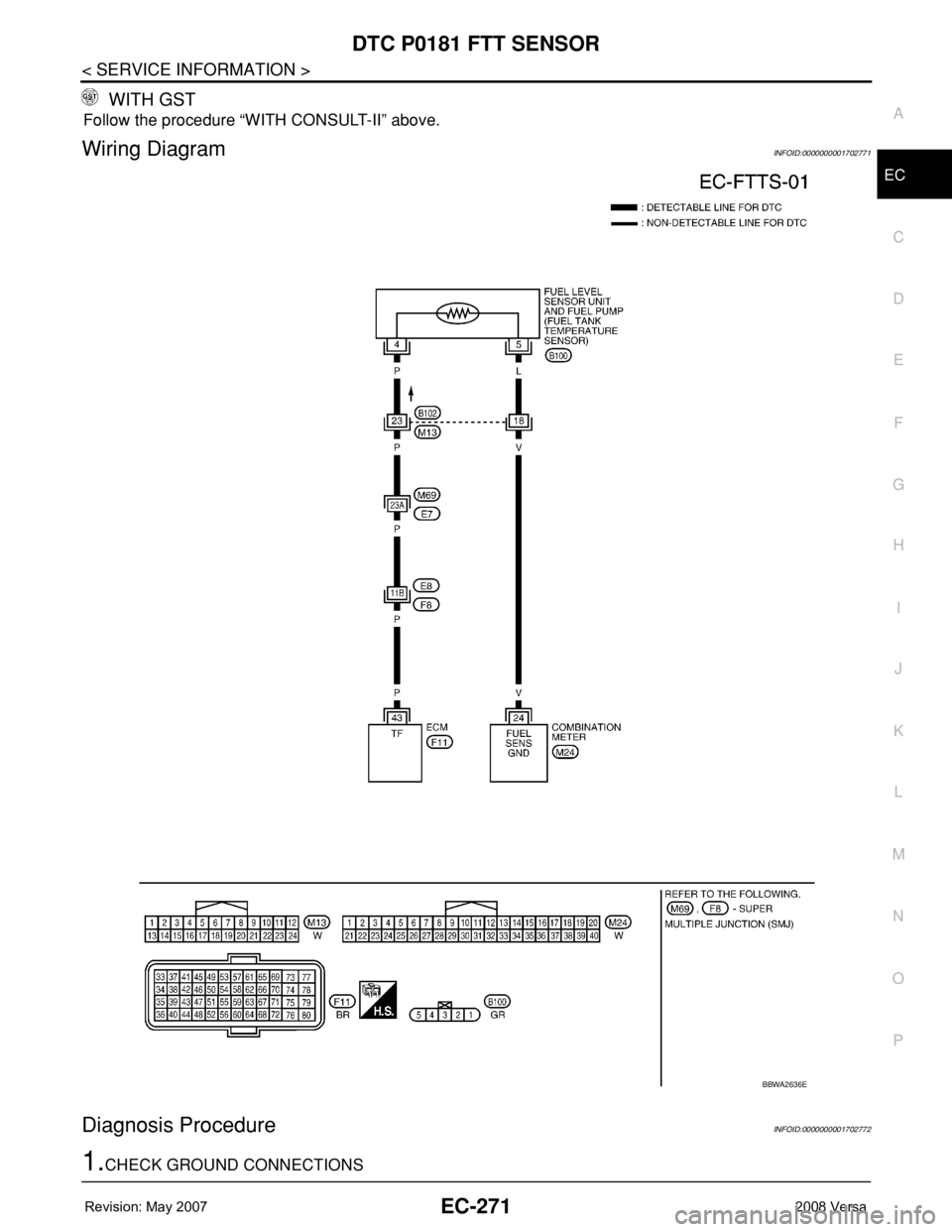

Wiring DiagramINFOID:0000000001702771

Diagnosis ProcedureINFOID:0000000001702772

1.CHECK GROUND CONNECTIONS

BBWA2636E

Page 1346 of 2771

EC-272

< SERVICE INFORMATION >

DTC P0181 FTT SENSOR

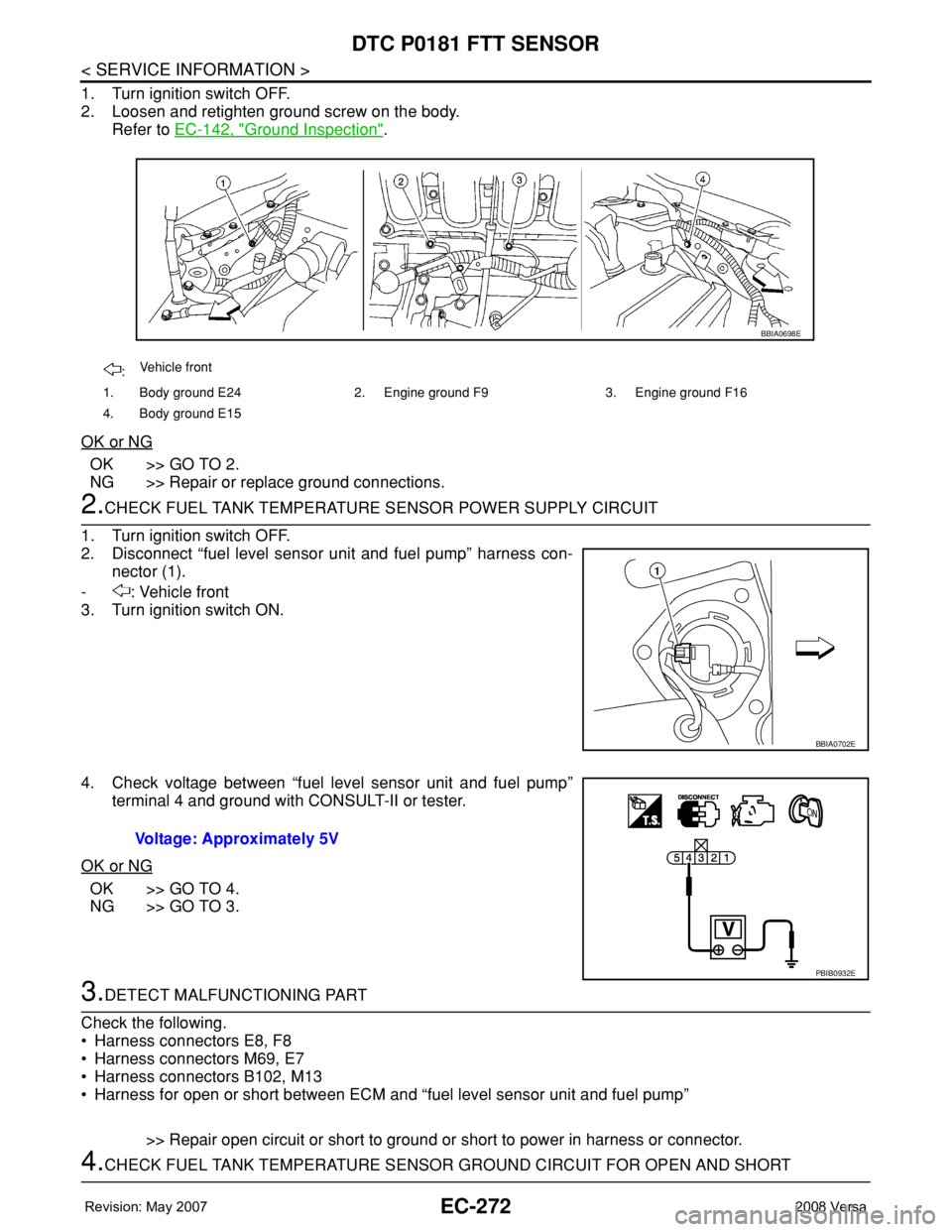

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body.

Refer to EC-142, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK FUEL TANK TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor unit and fuel pump” harness con-

nector (1).

- : Vehicle front

3. Turn ignition switch ON.

4. Check voltage between “fuel level sensor unit and fuel pump”

terminal 4 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness connectors M69, E7

• Harness connectors B102, M13

• Harness for open or short between ECM and “fuel level sensor unit and fuel pump”

>> Repair open circuit or short to ground or short to power in harness or connector.

4.CHECK FUEL TANK TEMPERATURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0698E

BBIA0702E

Voltage: Approximately 5V

PBIB0932E

Page 1347 of 2771

DTC P0181 FTT SENSOR

EC-273

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Turn ignition switch OFF.

2. Check harness continuity between “fuel level sensor unit and fuel pump” terminal 5 and combination

meter terminal 24. Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors B102, M13

• Harness for open or short between “fuel level sensor unit and fuel pump” and ground.

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK FUEL TANK TEMPERATURE SENSOR

Refer to, EC-273, "

Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> Replace “fuel level sensor unit and fuel pump”.

7.CHECK INTERMITTENT INCIDENT

Perform EC-136

.

>>INSPECTION END

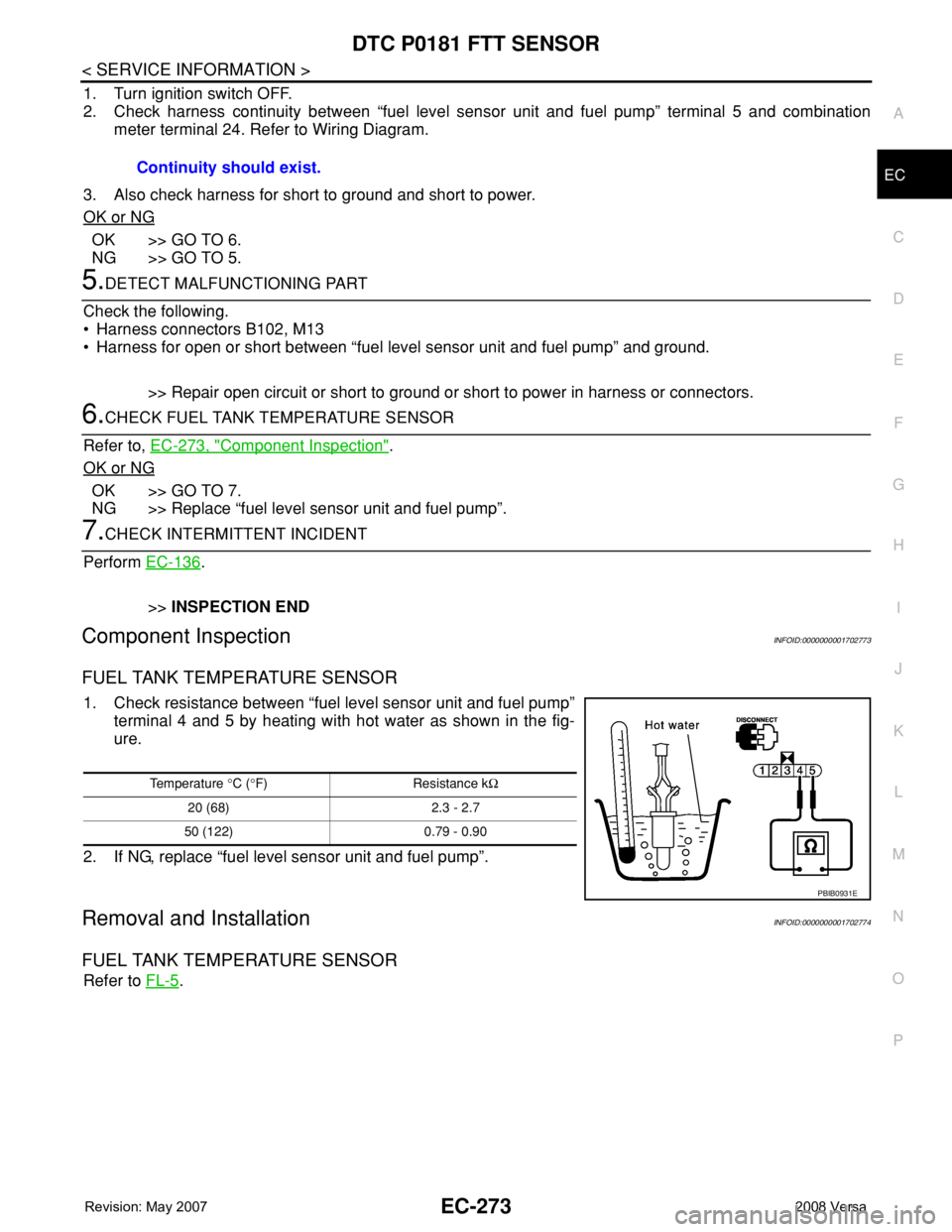

Component InspectionINFOID:0000000001702773

FUEL TANK TEMPERATURE SENSOR

1. Check resistance between “fuel level sensor unit and fuel pump”

terminal 4 and 5 by heating with hot water as shown in the fig-

ure.

2. If NG, replace “fuel level sensor unit and fuel pump”.

Removal and InstallationINFOID:0000000001702774

FUEL TANK TEMPERATURE SENSOR

Refer to FL-5. Continuity should exist.

Temperature °C (°F) Resistance kΩ

20 (68) 2.3 - 2.7

50 (122) 0.79 - 0.90

PBIB0931E

Page 1348 of 2771

EC-274

< SERVICE INFORMATION >

DTC P0182, P0183 FTT SENSOR

DTC P0182, P0183 FTT SENSOR

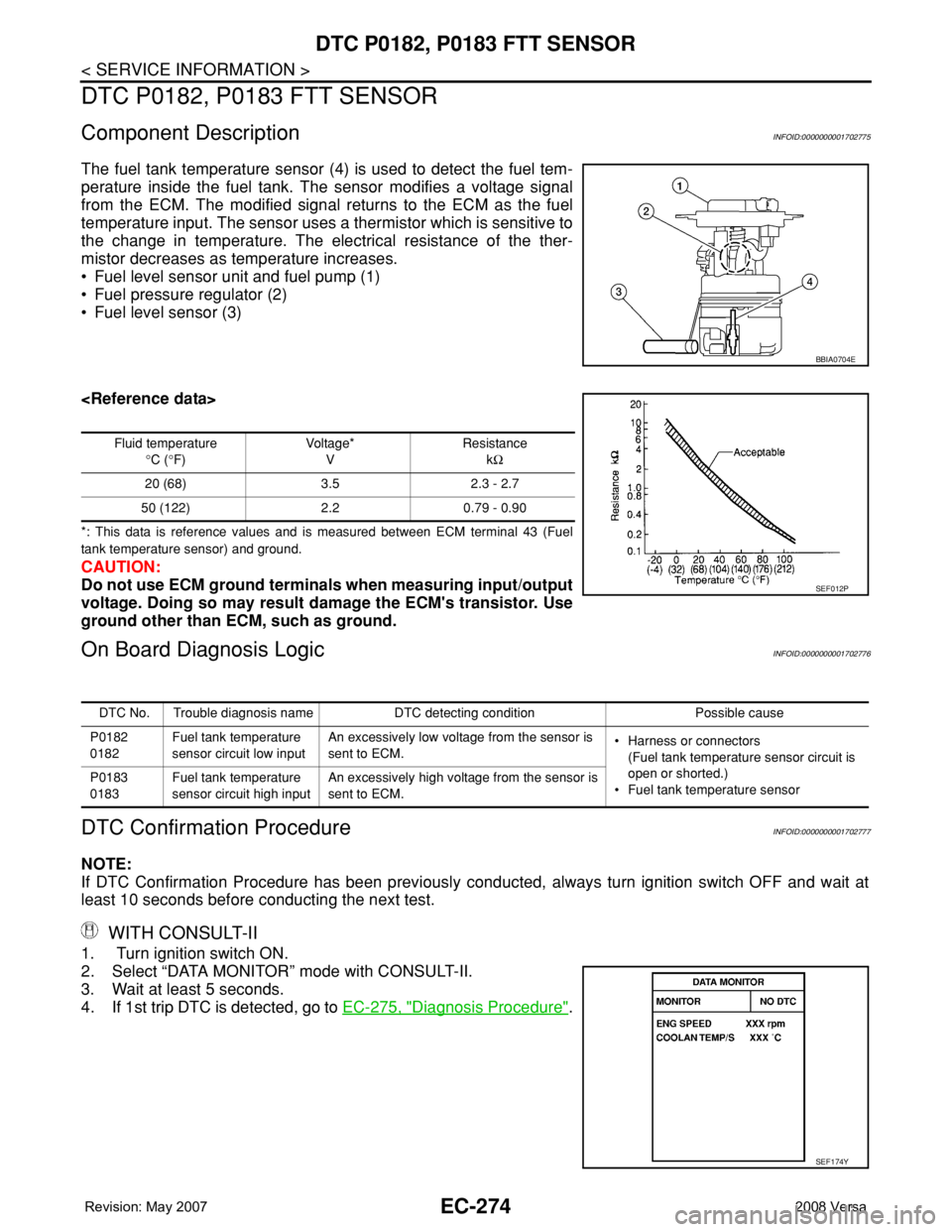

Component DescriptionINFOID:0000000001702775

The fuel tank temperature sensor (4) is used to detect the fuel tem-

perature inside the fuel tank. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the fuel

temperature input. The sensor uses a thermistor which is sensitive to

the change in temperature. The electrical resistance of the ther-

mistor decreases as temperature increases.

• Fuel level sensor unit and fuel pump (1)

• Fuel pressure regulator (2)

• Fuel level sensor (3)

*: This data is reference values and is measured between ECM terminal 43 (Fuel

tank temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output

voltage. Doing so may result damage the ECM's transistor. Use

ground other than ECM, such as ground.

On Board Diagnosis LogicINFOID:0000000001702776

DTC Confirmation ProcedureINFOID:0000000001702777

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If 1st trip DTC is detected, go to EC-275, "

Diagnosis Procedure".

BBIA0704E

Fluid temperature

°C (°F)Voltage*

VResistance

kΩ

20 (68) 3.5 2.3 - 2.7

50 (122) 2.2 0.79 - 0.90

SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0182

0182Fuel tank temperature

sensor circuit low inputAn excessively low voltage from the sensor is

sent to ECM.• Harness or connectors

(Fuel tank temperature sensor circuit is

open or shorted.)

• Fuel tank temperature sensor P0183

0183Fuel tank temperature

sensor circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF174Y

Page 1349 of 2771

DTC P0182, P0183 FTT SENSOR

EC-275

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

WITH GST

Follow the procedure “WITH CONSULT-II” above.

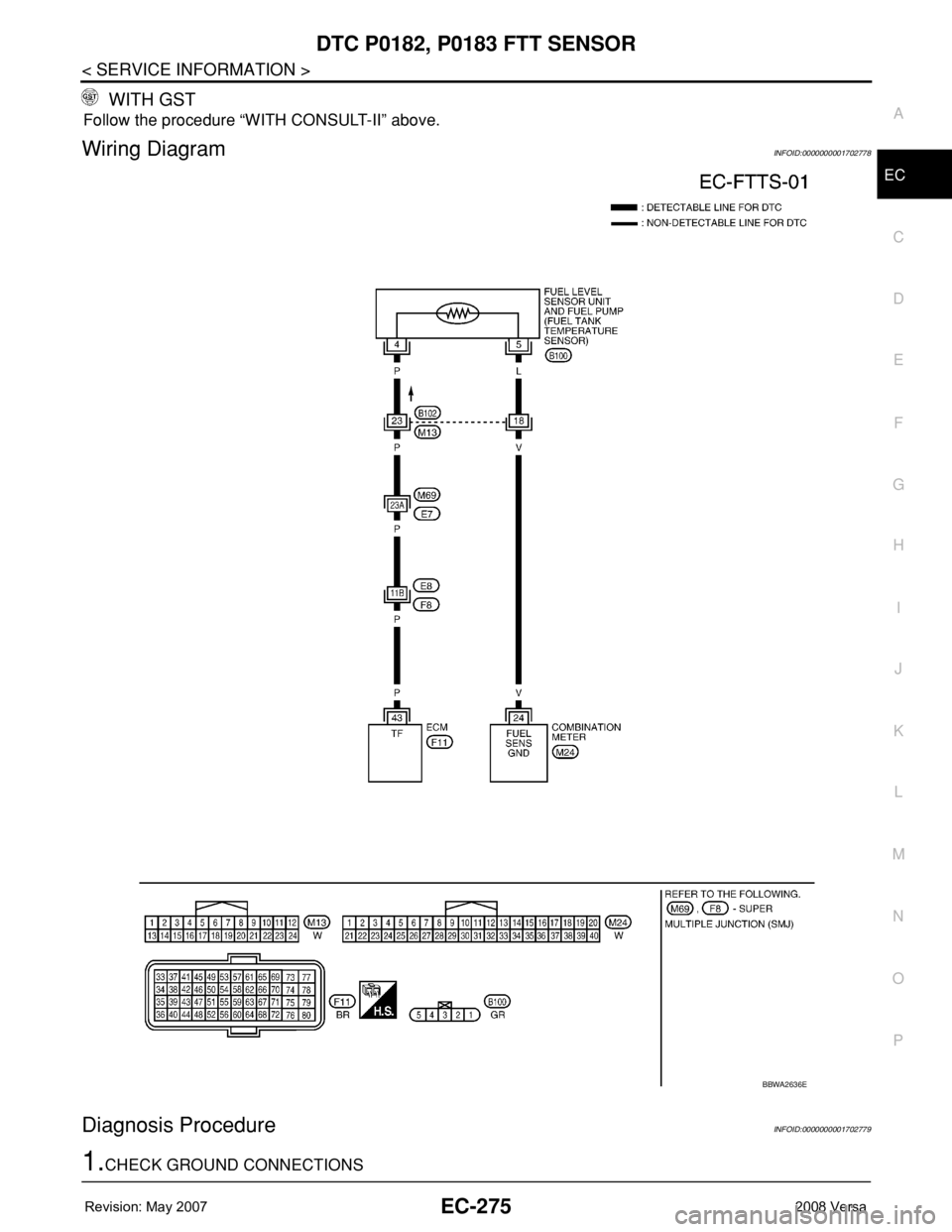

Wiring DiagramINFOID:0000000001702778

Diagnosis ProcedureINFOID:0000000001702779

1.CHECK GROUND CONNECTIONS

BBWA2636E

Page 1350 of 2771

EC-276

< SERVICE INFORMATION >

DTC P0182, P0183 FTT SENSOR

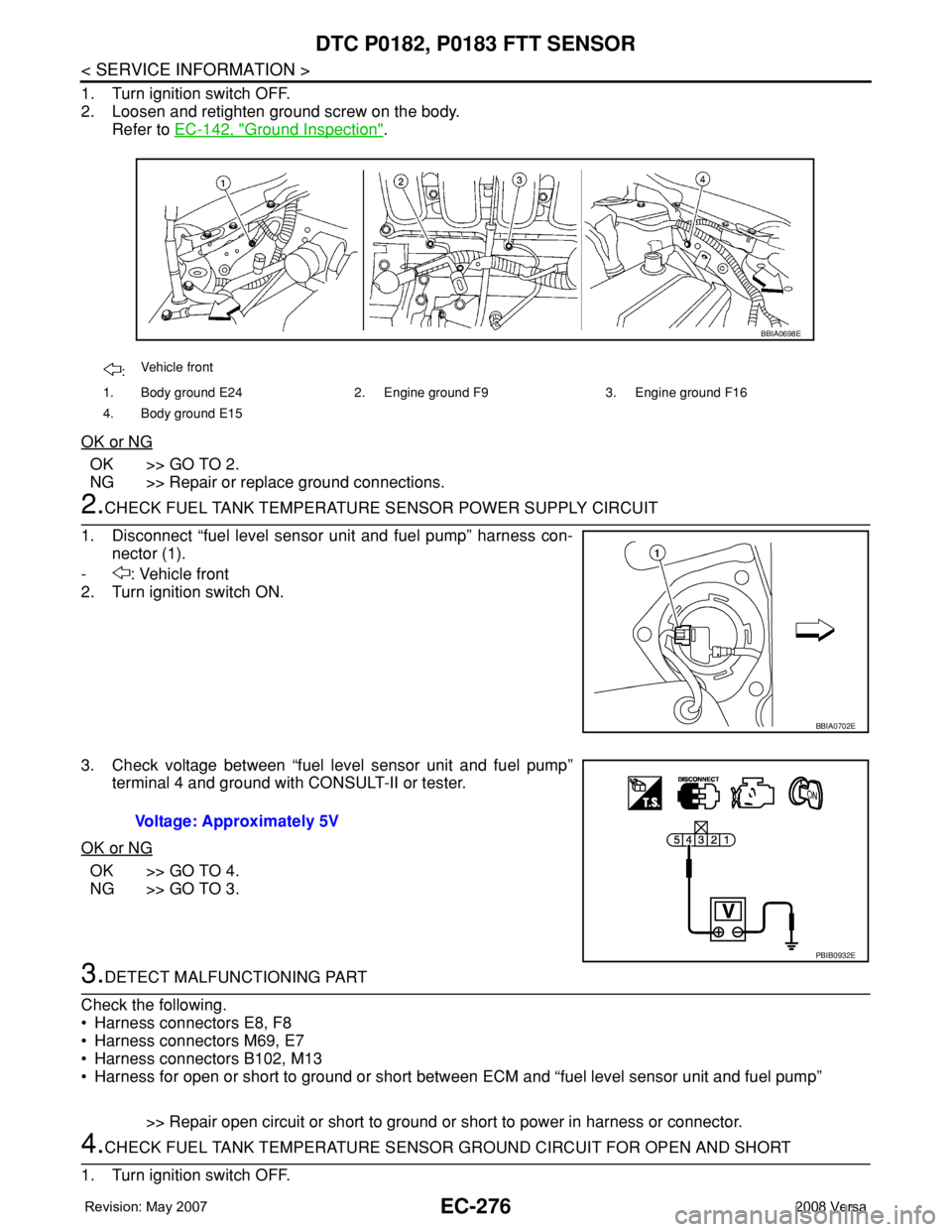

1. Turn ignition switch OFF.

2. Loosen and retighten ground screw on the body.

Refer to EC-142, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK FUEL TANK TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Disconnect “fuel level sensor unit and fuel pump” harness con-

nector (1).

- : Vehicle front

2. Turn ignition switch ON.

3. Check voltage between “fuel level sensor unit and fuel pump”

terminal 4 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness connectors M69, E7

• Harness connectors B102, M13

• Harness for open or short to ground or short between ECM and “fuel level sensor unit and fuel pump”

>> Repair open circuit or short to ground or short to power in harness or connector.

4.CHECK FUEL TANK TEMPERATURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0698E

BBIA0702E

Voltage: Approximately 5V

PBIB0932E