NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1371 of 2771

DTC P0335 CKP SENSOR (POS)

EC-297

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

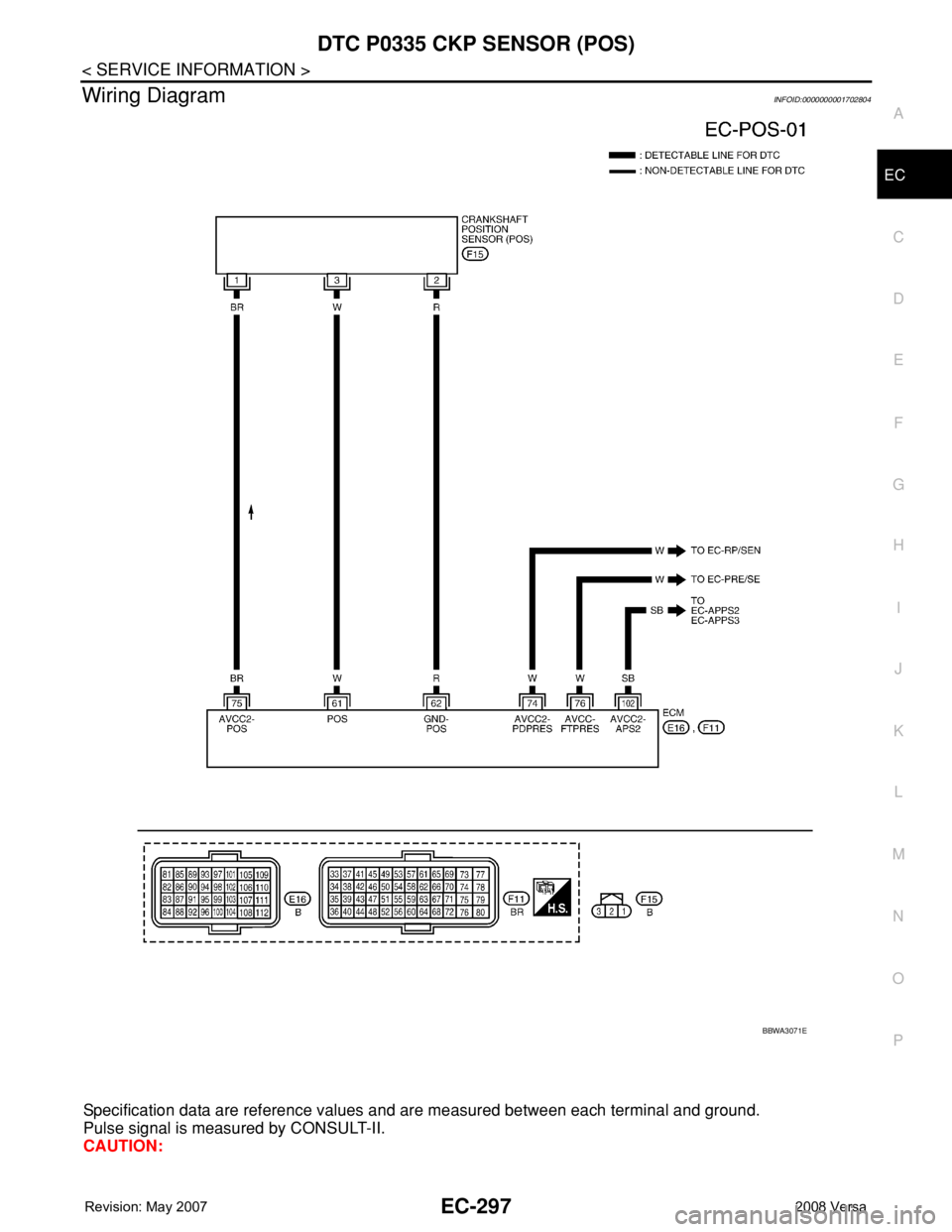

Wiring DiagramINFOID:0000000001702804

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

BBWA3071E

Page 1372 of 2771

EC-298

< SERVICE INFORMATION >

DTC P0335 CKP SENSOR (POS)

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001702805

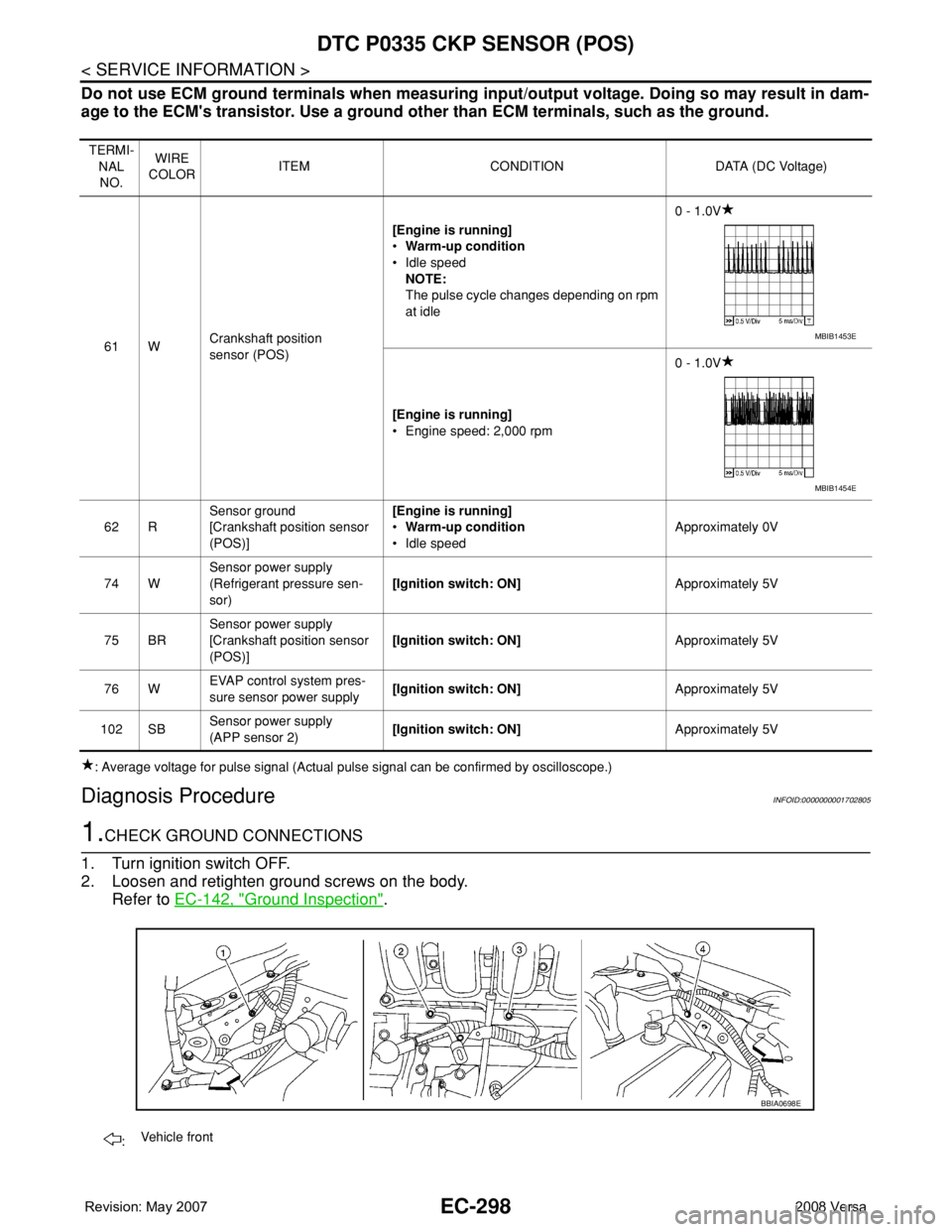

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body.

Refer to EC-142, "

Ground Inspection".

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

61 WCrankshaft position

sensor (POS)[Engine is running]

•Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm

at idle0 - 1.0V

[Engine is running]

• Engine speed: 2,000 rpm0 - 1.0V

62 RSensor ground

[Crankshaft position sensor

(POS)][Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

74 WSensor power supply

(Refrigerant pressure sen-

sor)[Ignition switch: ON]Approximately 5V

75 BRSensor power supply

[Crankshaft position sensor

(POS)][Ignition switch: ON]Approximately 5V

76 WEVAP control system pres-

sure sensor power supply[Ignition switch: ON]Approximately 5V

102 SBSensor power supply

(APP sensor 2)[Ignition switch: ON]Approximately 5V

MBIB1453E

MBIB1454E

:Vehicle front

BBIA0698E

Page 1373 of 2771

DTC P0335 CKP SENSOR (POS)

EC-299

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

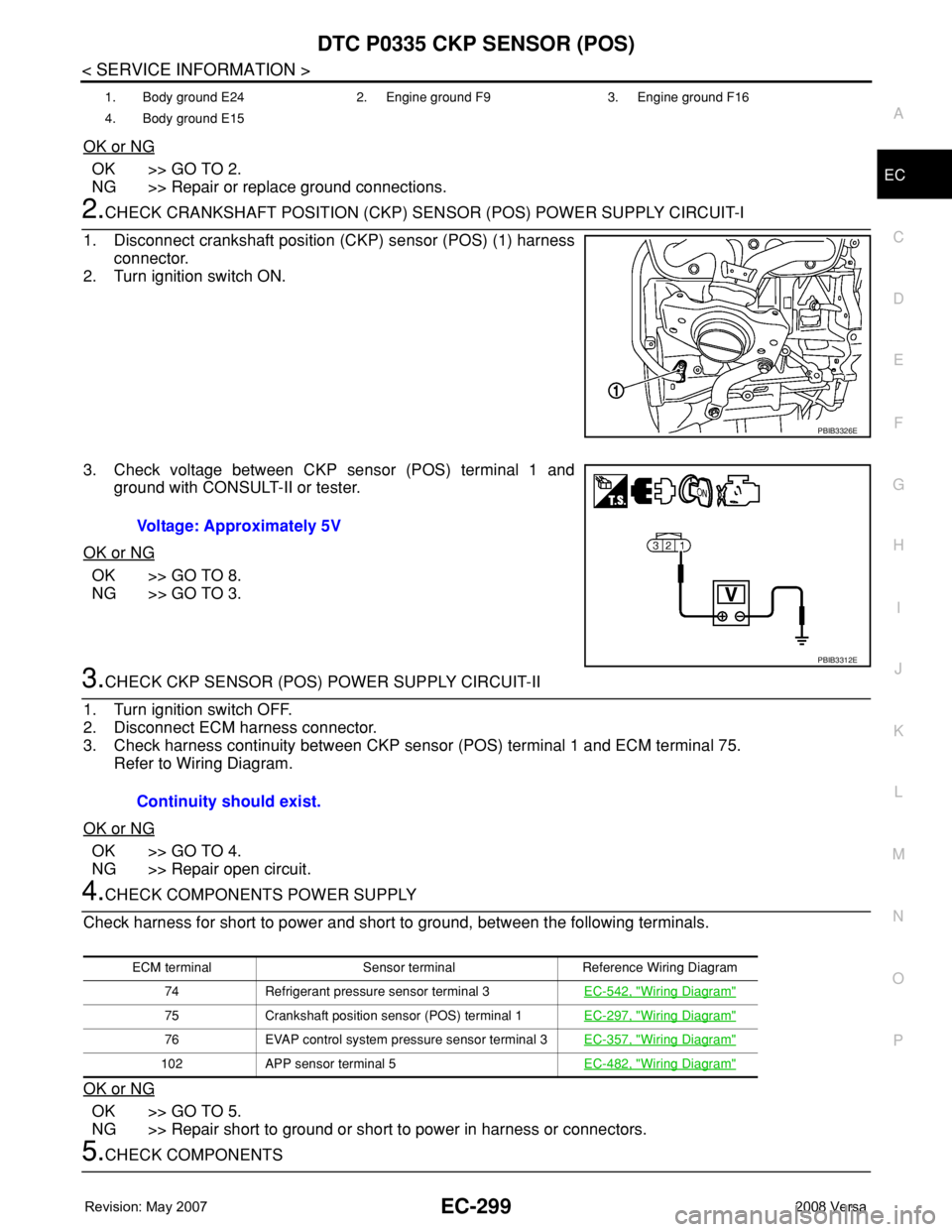

2.CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY CIRCUIT-I

1. Disconnect crankshaft position (CKP) sensor (POS) (1) harness

connector.

2. Turn ignition switch ON.

3. Check voltage between CKP sensor (POS) terminal 1 and

ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 8.

NG >> GO TO 3.

3.CHECK CKP SENSOR (POS) POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between CKP sensor (POS) terminal 1 and ECM terminal 75.

Refer to Wiring Diagram.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit.

4.CHECK COMPONENTS POWER SUPPLY

Check harness for short to power and short to ground, between the following terminals.

OK or NG

OK >> GO TO 5.

NG >> Repair short to ground or short to power in harness or connectors.

5.CHECK COMPONENTS

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

PBIB3326E

Voltage: Approximately 5V

PBIB3312E

Continuity should exist.

ECM terminal Sensor terminal Reference Wiring Diagram

74 Refrigerant pressure sensor terminal 3EC-542, "

Wiring Diagram"

75 Crankshaft position sensor (POS) terminal 1EC-297, "Wiring Diagram"

76 EVAP control system pressure sensor terminal 3EC-357, "Wiring Diagram"

102 APP sensor terminal 5EC-482, "Wiring Diagram"

Page 1374 of 2771

EC-300

< SERVICE INFORMATION >

DTC P0335 CKP SENSOR (POS)

Check the following.

• Refrigerant pressure sensor. (Refer to MTC-22

.)

• EVAP control system pressure sensor. (Refer to EC-361, "

Component Inspection".)

OK or NG

OK >> GO TO 6.

NG >> Replace malfunctioning components.

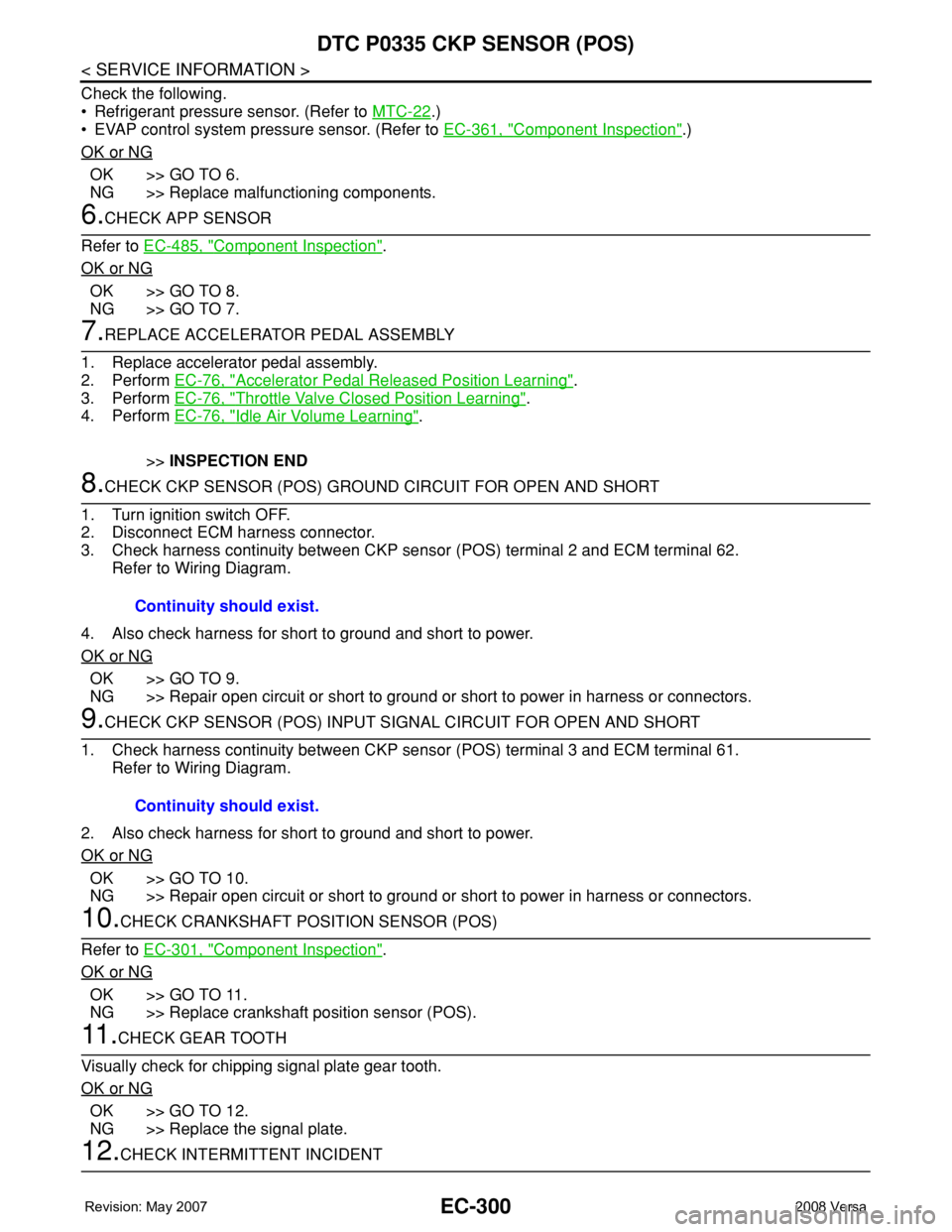

6.CHECK APP SENSOR

Refer to EC-485, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> GO TO 7.

7.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Perform EC-76, "

Accelerator Pedal Released Position Learning".

3. Perform EC-76, "

Throttle Valve Closed Position Learning".

4. Perform EC-76, "

Idle Air Volume Learning".

>>INSPECTION END

8.CHECK CKP SENSOR (POS) GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between CKP sensor (POS) terminal 2 and ECM terminal 62.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 9.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK CKP SENSOR (POS) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between CKP sensor (POS) terminal 3 and ECM terminal 61.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 10.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

10.CHECK CRANKSHAFT POSITION SENSOR (POS)

Refer to EC-301, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> Replace crankshaft position sensor (POS).

11 .CHECK GEAR TOOTH

Visually check for chipping signal plate gear tooth.

OK or NG

OK >> GO TO 12.

NG >> Replace the signal plate.

12.CHECK INTERMITTENT INCIDENTContinuity should exist.

Continuity should exist.

Page 1375 of 2771

DTC P0335 CKP SENSOR (POS)

EC-301

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Refer to EC-136.

>>INSPECTION END

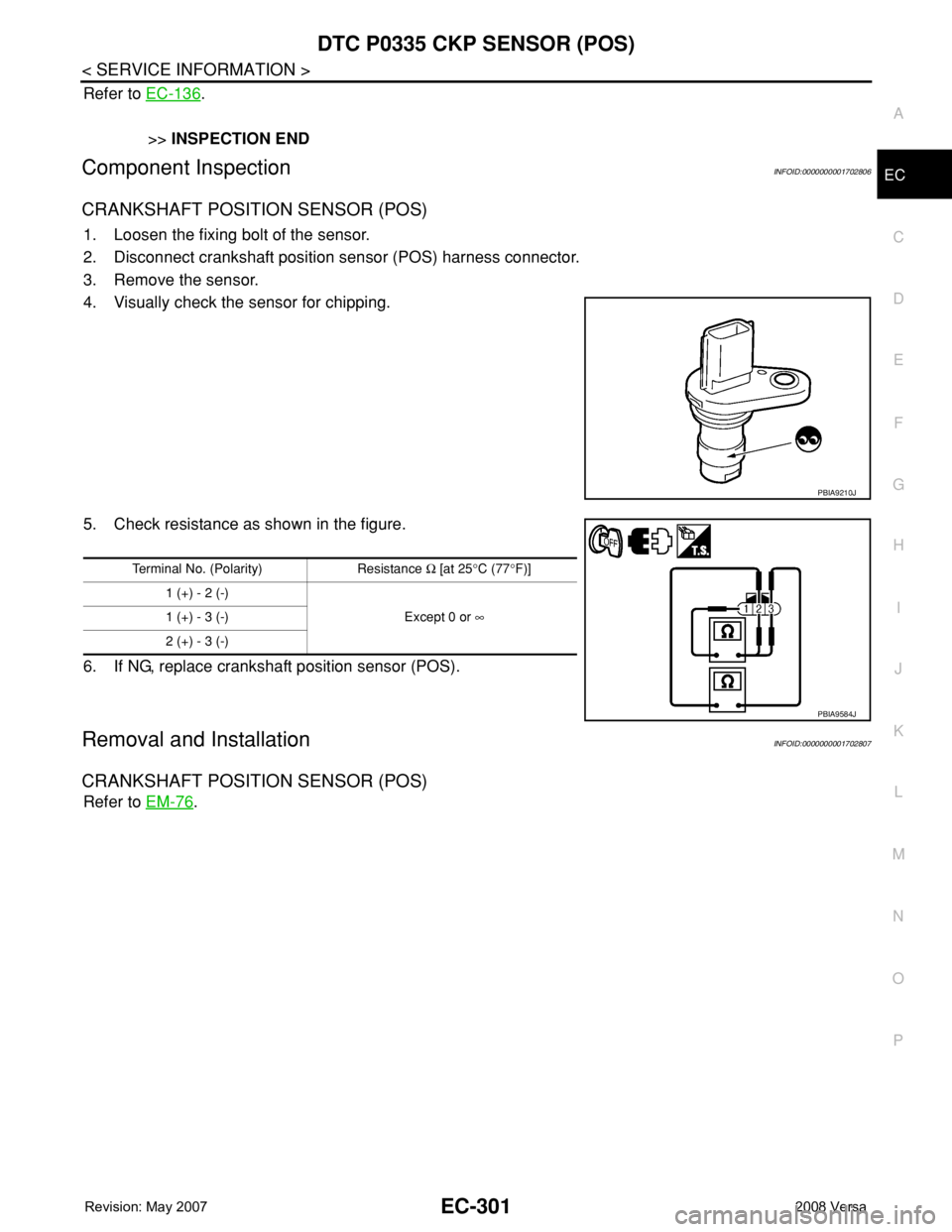

Component InspectionINFOID:0000000001702806

CRANKSHAFT POSITION SENSOR (POS)

1. Loosen the fixing bolt of the sensor.

2. Disconnect crankshaft position sensor (POS) harness connector.

3. Remove the sensor.

4. Visually check the sensor for chipping.

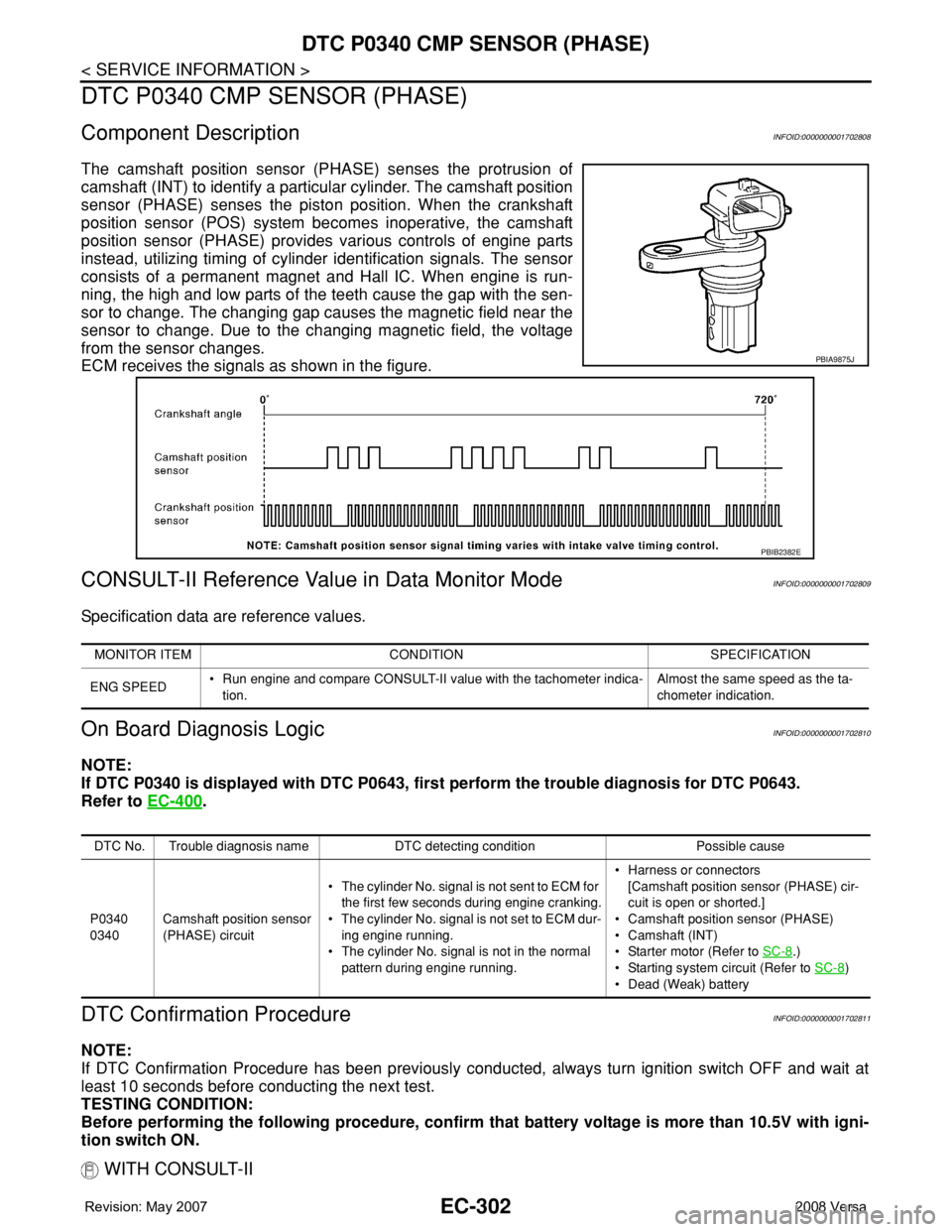

5. Check resistance as shown in the figure.

6. If NG, replace crankshaft position sensor (POS).

Removal and InstallationINFOID:0000000001702807

CRANKSHAFT POSITION SENSOR (POS)

Refer to EM-76.

PBIA9210J

Terminal No. (Polarity) Resistance Ω [at 25°C (77°F)]

1 (+) - 2 (-)

Except 0 or ∞ 1 (+) - 3 (-)

2 (+) - 3 (-)

PBIA9584J

Page 1376 of 2771

EC-302

< SERVICE INFORMATION >

DTC P0340 CMP SENSOR (PHASE)

DTC P0340 CMP SENSOR (PHASE)

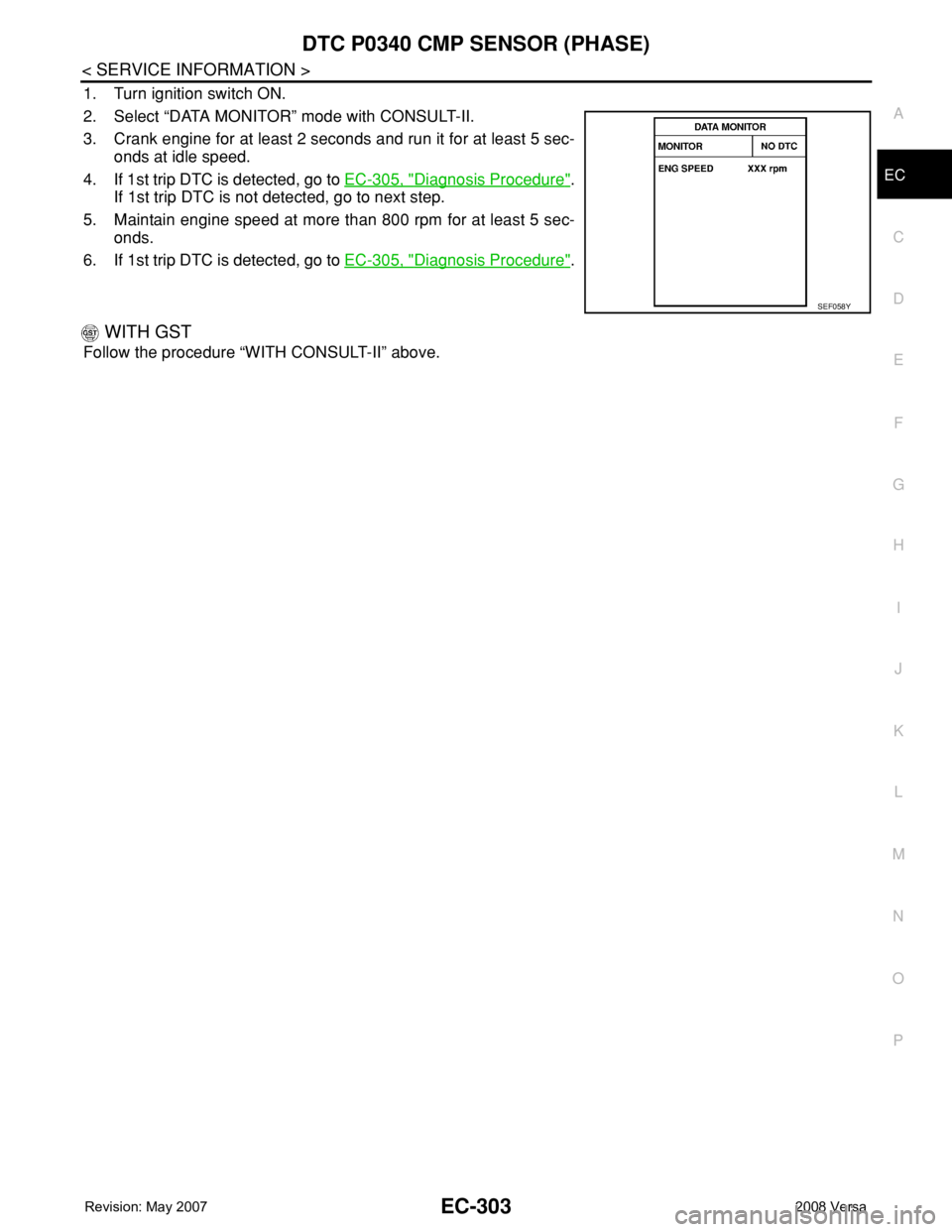

Component DescriptionINFOID:0000000001702808

The camshaft position sensor (PHASE) senses the protrusion of

camshaft (INT) to identify a particular cylinder. The camshaft position

sensor (PHASE) senses the piston position. When the crankshaft

position sensor (POS) system becomes inoperative, the camshaft

position sensor (PHASE) provides various controls of engine parts

instead, utilizing timing of cylinder identification signals. The sensor

consists of a permanent magnet and Hall IC. When engine is run-

ning, the high and low parts of the teeth cause the gap with the sen-

sor to change. The changing gap causes the magnetic field near the

sensor to change. Due to the changing magnetic field, the voltage

from the sensor changes.

ECM receives the signals as shown in the figure.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000001702809

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001702810

NOTE:

If DTC P0340 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Refer to EC-400

.

DTC Confirmation ProcedureINFOID:0000000001702811

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5V with igni-

tion switch ON.

WITH CONSULT-II

PBIA9875J

PBIB2382E

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED• Run engine and compare CONSULT-II value with the tachometer indica-

tion.Almost the same speed as the ta-

chometer indication.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0340

0340Camshaft position sensor

(PHASE) circuit• The cylinder No. signal is not sent to ECM for

the first few seconds during engine cranking.

• The cylinder No. signal is not set to ECM dur-

ing engine running.

• The cylinder No. signal is not in the normal

pattern during engine running.• Harness or connectors

[Camshaft position sensor (PHASE) cir-

cuit is open or shorted.]

• Camshaft position sensor (PHASE)

• Camshaft (INT)

• Starter motor (Refer to SC-8

.)

• Starting system circuit (Refer to SC-8

)

• Dead (Weak) battery

Page 1377 of 2771

DTC P0340 CMP SENSOR (PHASE)

EC-303

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Crank engine for at least 2 seconds and run it for at least 5 sec-

onds at idle speed.

4. If 1st trip DTC is detected, go to EC-305, "

Diagnosis Procedure".

If 1st trip DTC is not detected, go to next step.

5. Maintain engine speed at more than 800 rpm for at least 5 sec-

onds.

6. If 1st trip DTC is detected, go to EC-305, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

SEF058Y

Page 1378 of 2771

EC-304

< SERVICE INFORMATION >

DTC P0340 CMP SENSOR (PHASE)

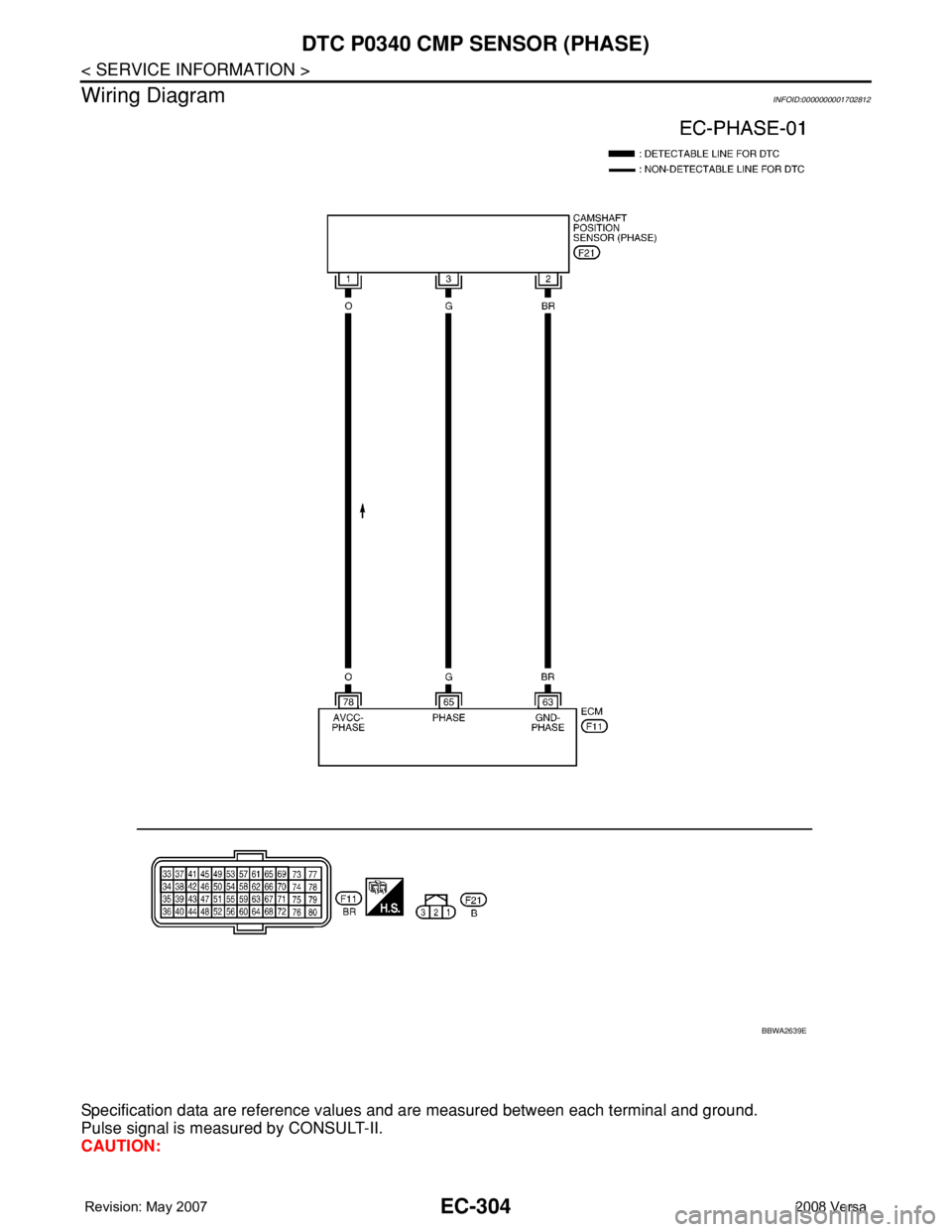

Wiring Diagram

INFOID:0000000001702812

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

BBWA2639E

Page 1379 of 2771

DTC P0340 CMP SENSOR (PHASE)

EC-305

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000001702813

1.CHECK STARTING SYSTEM

Turn ignition switch to START position.

Ye s o r N o

Yes >> GO TO 2.

No >> Check starting system. (Refer to SC-8

.)

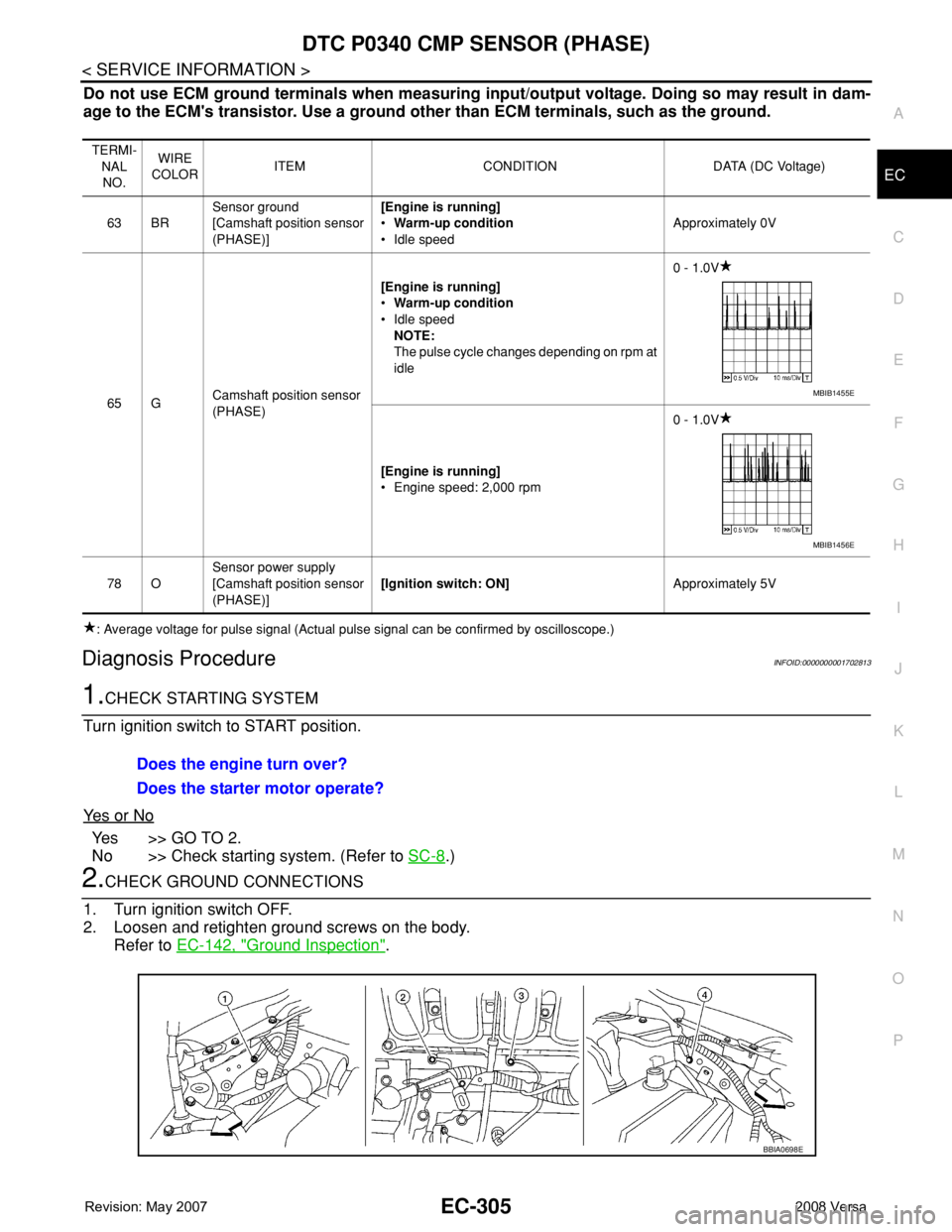

2.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground screws on the body.

Refer to EC-142, "

Ground Inspection".

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

63 BRSensor ground

[Camshaft position sensor

(PHASE)][Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

65 GCamshaft position sensor

(PHASE)[Engine is running]

•Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm at

idle0 - 1.0V

[Engine is running]

• Engine speed: 2,000 rpm0 - 1.0V

78 OSensor power supply

[Camshaft position sensor

(PHASE)][Ignition switch: ON]Approximately 5V

MBIB1455E

MBIB1456E

Does the engine turn over?

Does the starter motor operate?

BBIA0698E

Page 1380 of 2771

EC-306

< SERVICE INFORMATION >

DTC P0340 CMP SENSOR (PHASE)

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

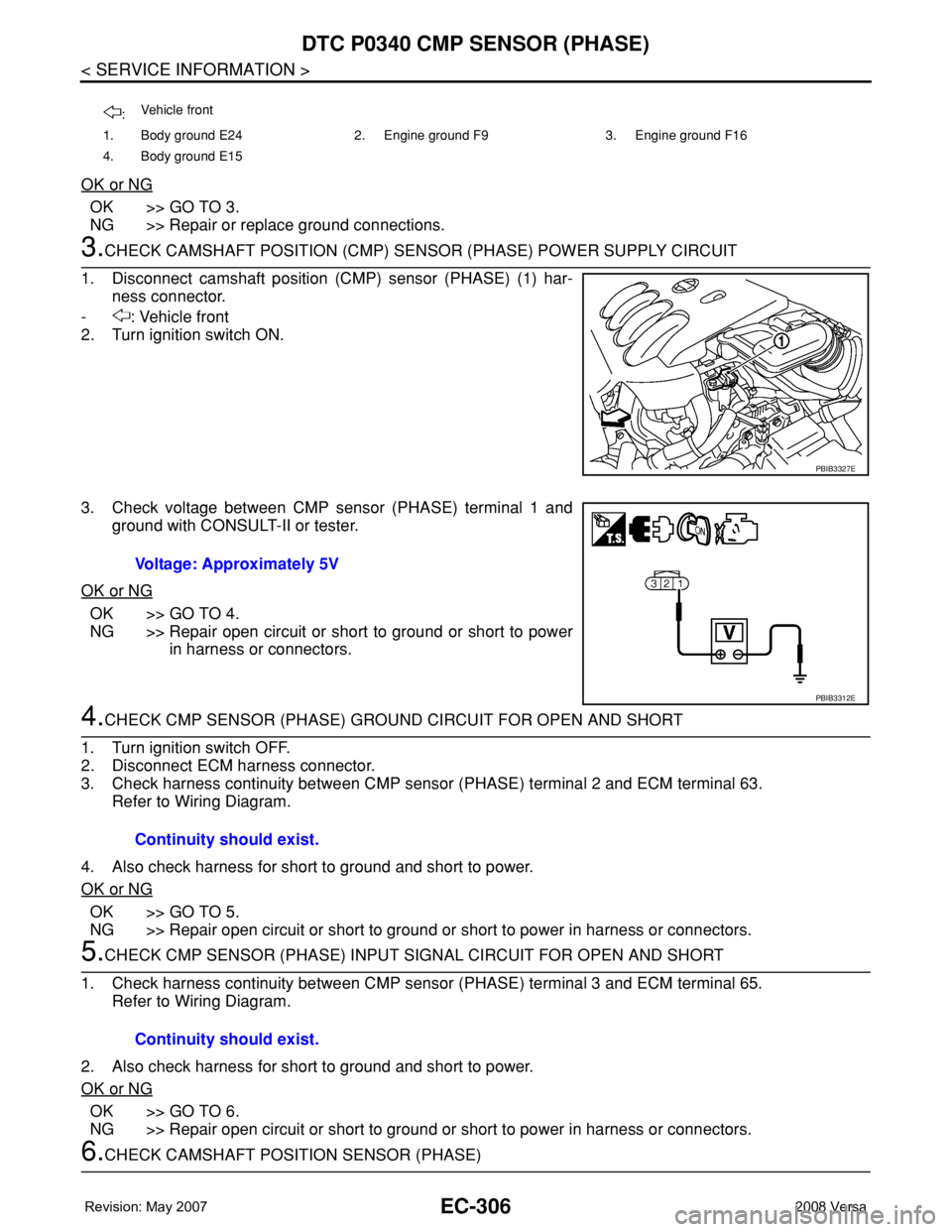

3.CHECK CAMSHAFT POSITION (CMP) SENSOR (PHASE) POWER SUPPLY CIRCUIT

1. Disconnect camshaft position (CMP) sensor (PHASE) (1) har-

ness connector.

- : Vehicle front

2. Turn ignition switch ON.

3. Check voltage between CMP sensor (PHASE) terminal 1 and

ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

4.CHECK CMP SENSOR (PHASE) GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between CMP sensor (PHASE) terminal 2 and ECM terminal 63.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK CMP SENSOR (PHASE) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between CMP sensor (PHASE) terminal 3 and ECM terminal 65.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK CAMSHAFT POSITION SENSOR (PHASE)

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

PBIB3327E

Voltage: Approximately 5V

PBIB3312E

Continuity should exist.

Continuity should exist.