NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 1911 of 2771

GW-10

< SERVICE INFORMATION >

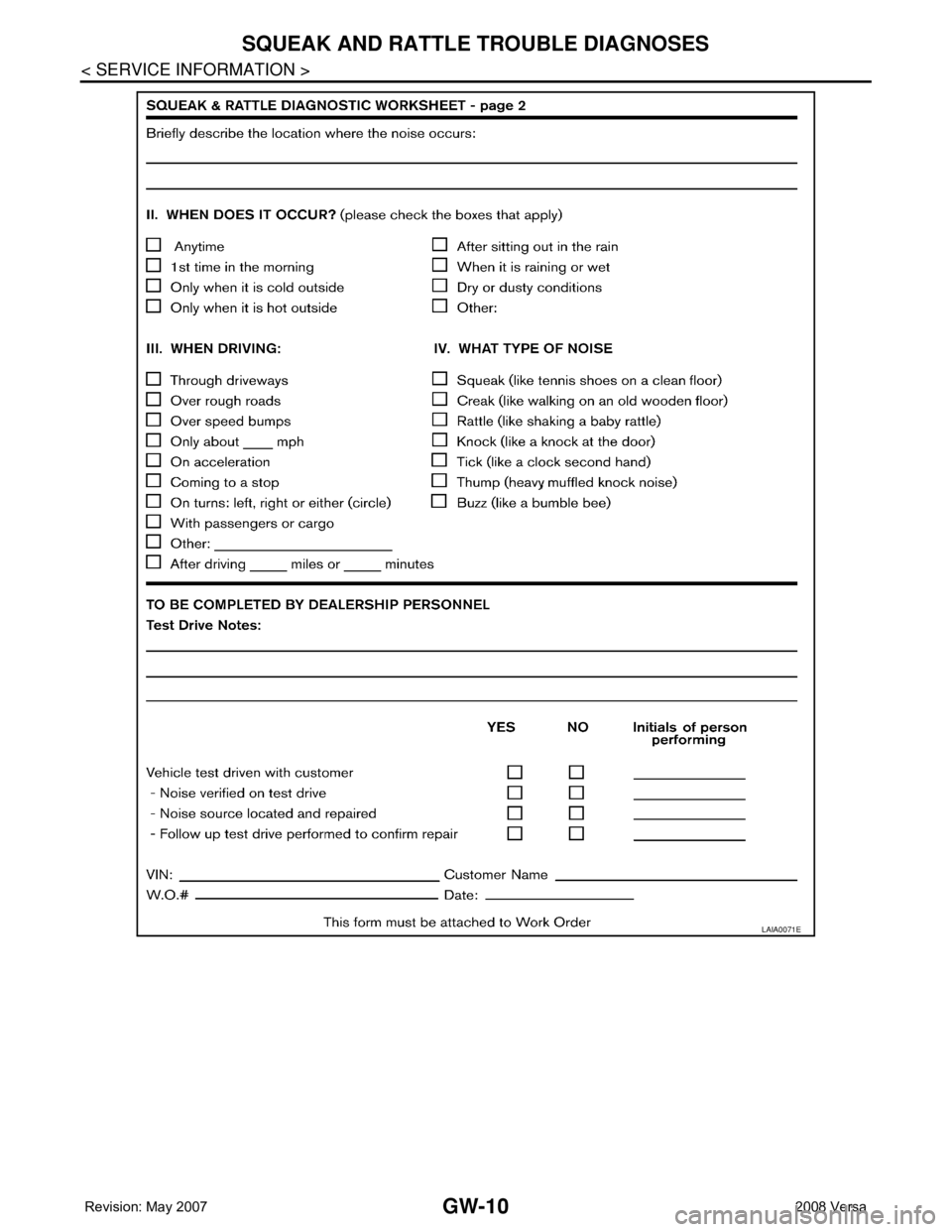

SQUEAK AND RATTLE TROUBLE DIAGNOSES

LAIA0071E

Page 1912 of 2771

WINDSHIELD GLASS

GW-11

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

WINDSHIELD GLASS

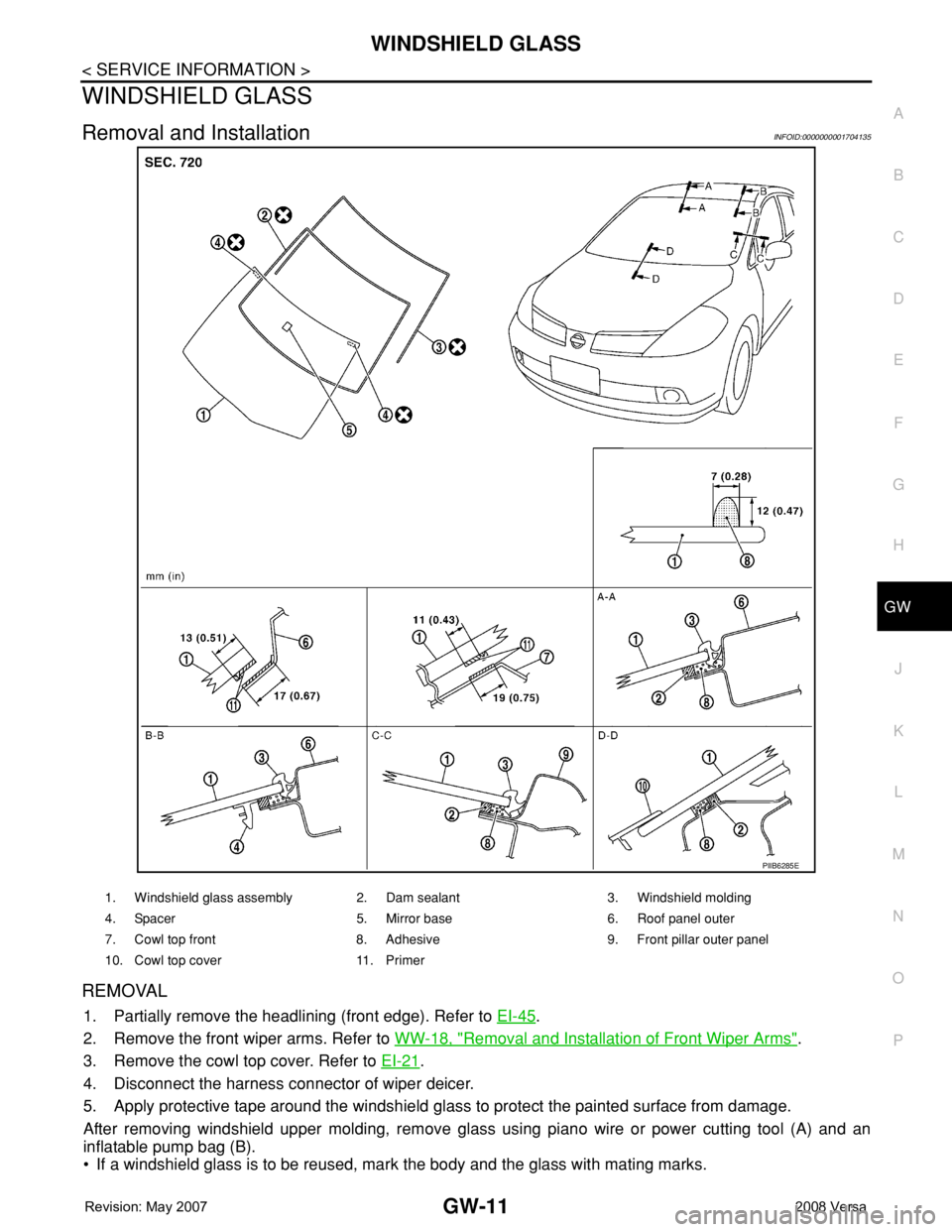

Removal and InstallationINFOID:0000000001704135

REMOVAL

1. Partially remove the headlining (front edge). Refer to EI-45.

2. Remove the front wiper arms. Refer to WW-18, "

Removal and Installation of Front Wiper Arms".

3. Remove the cowl top cover. Refer to EI-21

.

4. Disconnect the harness connector of wiper deicer.

5. Apply protective tape around the windshield glass to protect the painted surface from damage.

After removing windshield upper molding, remove glass using piano wire or power cutting tool (A) and an

inflatable pump bag (B).

• If a windshield glass is to be reused, mark the body and the glass with mating marks.

PIIB6285E

1. Windshield glass assembly 2. Dam sealant 3. Windshield molding

4. Spacer 5. Mirror base 6. Roof panel outer

7. Cowl top front 8. Adhesive 9. Front pillar outer panel

10. Cowl top cover 11. Primer

Page 1913 of 2771

GW-12

< SERVICE INFORMATION >

WINDSHIELD GLASS

WARNING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

• When a windshield glass is to be reused, do not use a cutting knife or power cutting tool.

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its edge. Small chips may develop into cracks.

INSTALLATION

• Use a genuine NISSAN Urethane Adhesive Kit (if available) or equivalent and follow the instructions fur-

nished with it.

• While the urethane adhesive is curing, open a door window. This will prevent the glass from being forced out

by passenger room air pressure when a door is closed.

• The molding must be installed securely so that it is in position and leaves no gap.

• Inform the customer that the vehicle should remain stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, immediately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the windshield in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable term. Shelf life of the adhesive is limited to six

months after the date of manufacture. Carefully adhere to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depending on temperature and humidities. The curing time will increase

under lower temperatures and lower humidities.

Repairing Water Leaks

Leaks can be repaired without removing and reinstalling glass.

If water is leaking between the urethane adhesive material and body or glass, determine the extent of leakage.

This can be done by applying water to the windshield area while pushing glass outward.

To stop the leak, apply primer (if necessary) and then urethane adhesive to the leak point.

PIIB5779E

Page 1914 of 2771

OPERA WINDOW GLASS

GW-13

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

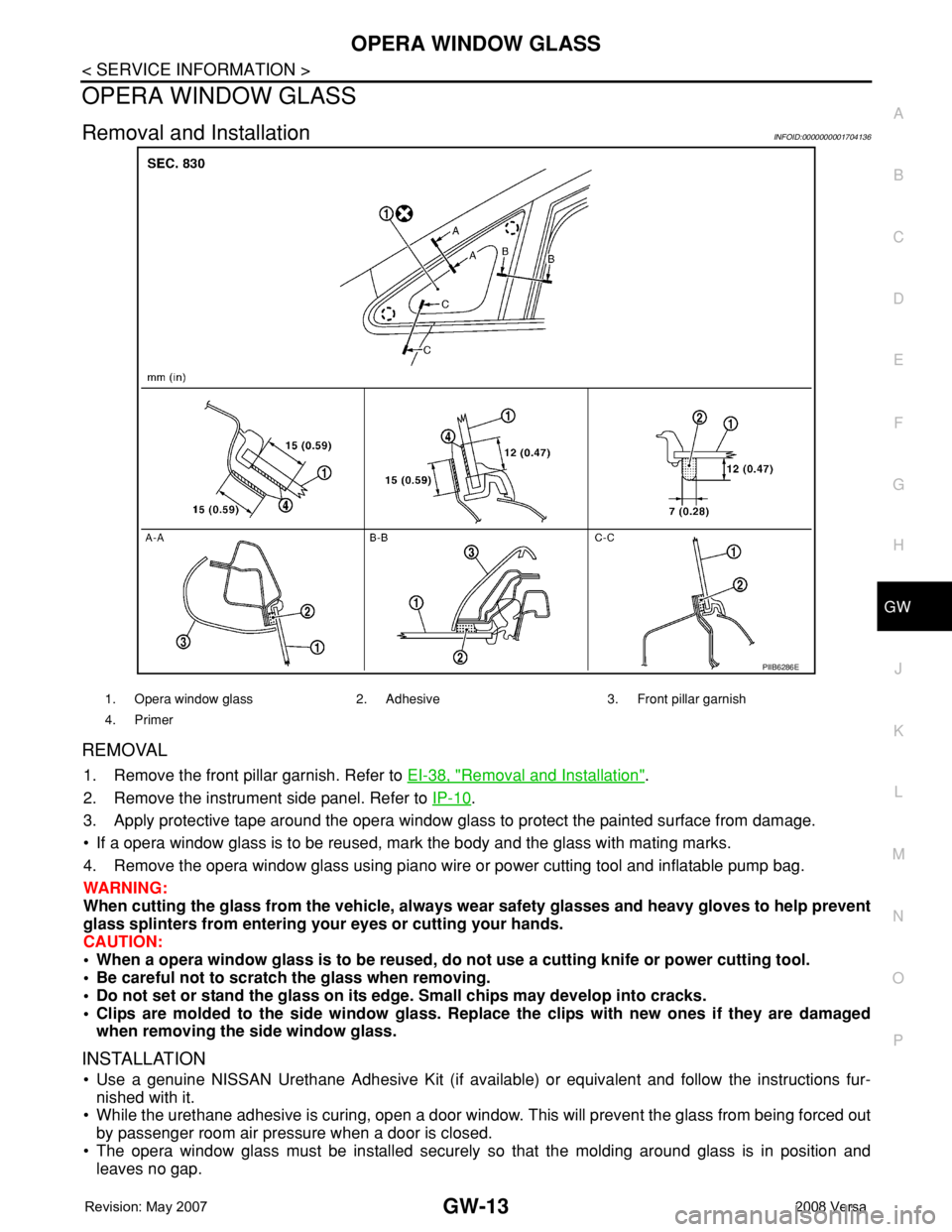

OPERA WINDOW GLASS

Removal and InstallationINFOID:0000000001704136

REMOVAL

1. Remove the front pillar garnish. Refer to EI-38, "Removal and Installation".

2. Remove the instrument side panel. Refer to IP-10

.

3. Apply protective tape around the opera window glass to protect the painted surface from damage.

• If a opera window glass is to be reused, mark the body and the glass with mating marks.

4. Remove the opera window glass using piano wire or power cutting tool and inflatable pump bag.

WARNING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

• When a opera window glass is to be reused, do not use a cutting knife or power cutting tool.

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its edge. Small chips may develop into cracks.

• Clips are molded to the side window glass. Replace the clips with new ones if they are damaged

when removing the side window glass.

INSTALLATION

• Use a genuine NISSAN Urethane Adhesive Kit (if available) or equivalent and follow the instructions fur-

nished with it.

• While the urethane adhesive is curing, open a door window. This will prevent the glass from being forced out

by passenger room air pressure when a door is closed.

• The opera window glass must be installed securely so that the molding around glass is in position and

leaves no gap.

PIIB6286E

1. Opera window glass 2. Adhesive 3. Front pillar garnish

4. Primer

Page 1915 of 2771

GW-14

< SERVICE INFORMATION >

OPERA WINDOW GLASS

• Inform the customer that the vehicle should remain stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, immediately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the side window in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable term. Shelf life of the adhesive is limited to six

months after the date of manufacture. Carefully adhere to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depending on temperature and humidities. The curing time will increase

under lower temperature and lower humidity.

Repairing Water Leaks

Leaks can be repaired without removing and reinstalling glass.

If water is leaking between the urethane adhesive material and body or glass, determine the extent of leakage.

This can be done by applying water to the side window area while pushing glass outward.

To stop the leak, apply primer (if necessary) and then urethane adhesive to the leak point.

Page 1916 of 2771

REAR WINDOW GLASS AND MOLDING

GW-15

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

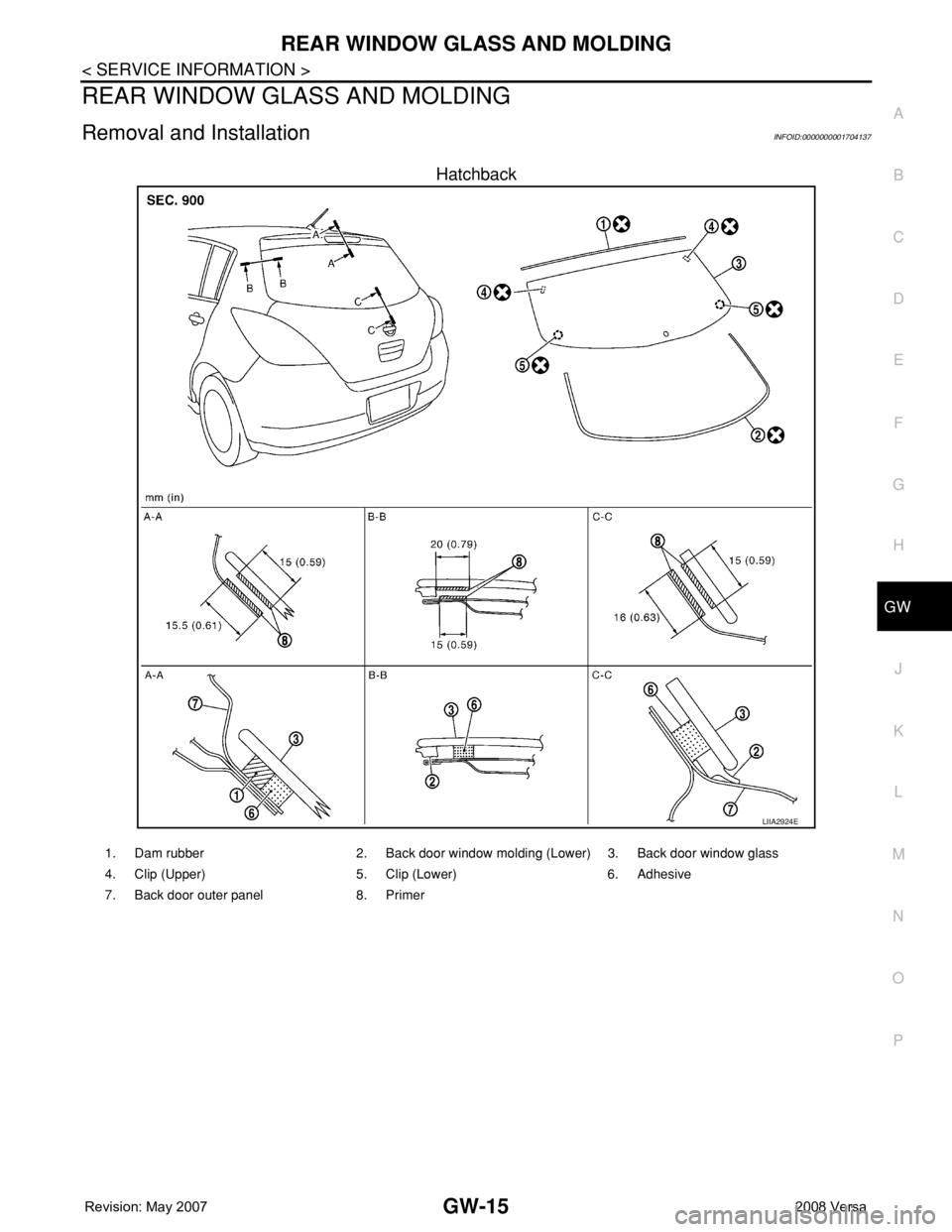

REAR WINDOW GLASS AND MOLDING

Removal and InstallationINFOID:0000000001704137

Hatchback

LIIA2924E

1. Dam rubber 2. Back door window molding (Lower) 3. Back door window glass

4. Clip (Upper) 5. Clip (Lower) 6. Adhesive

7. Back door outer panel 8. Primer

Page 1917 of 2771

GW-16

< SERVICE INFORMATION >

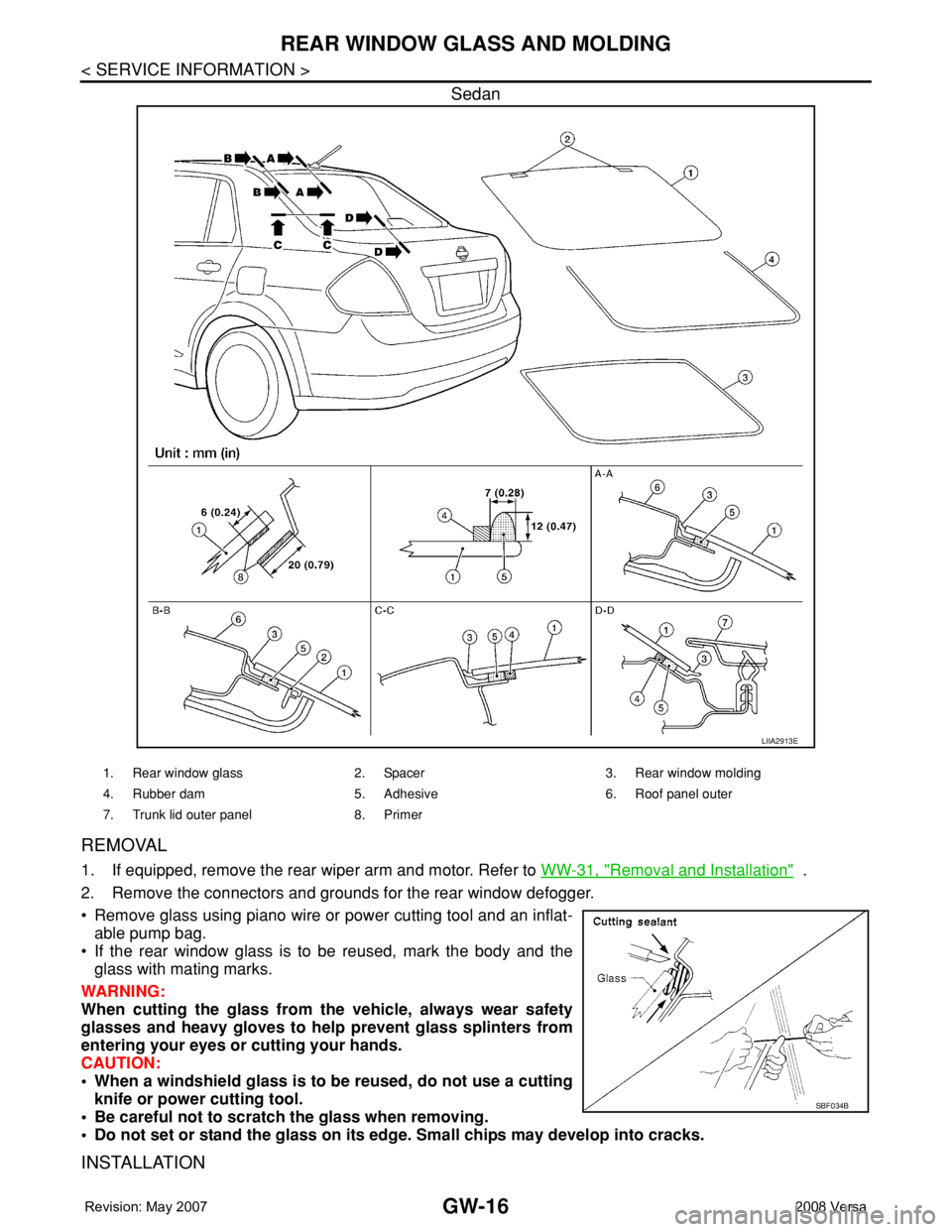

REAR WINDOW GLASS AND MOLDING

Sedan

REMOVAL

1. If equipped, remove the rear wiper arm and motor. Refer to WW-31, "Removal and Installation" .

2. Remove the connectors and grounds for the rear window defogger.

• Remove glass using piano wire or power cutting tool and an inflat-

able pump bag.

• If the rear window glass is to be reused, mark the body and the

glass with mating marks.

WARNING:

When cutting the glass from the vehicle, always wear safety

glasses and heavy gloves to help prevent glass splinters from

entering your eyes or cutting your hands.

CAUTION:

• When a windshield glass is to be reused, do not use a cutting

knife or power cutting tool.

• Be careful not to scratch the glass when removing.

• Do not set or stand the glass on its edge. Small chips may develop into cracks.

INSTALLATION

LIIA2913E

1. Rear window glass 2. Spacer 3. Rear window molding

4. Rubber dam 5. Adhesive 6. Roof panel outer

7. Trunk lid outer panel 8. Primer

SBF034B

Page 1918 of 2771

REAR WINDOW GLASS AND MOLDING

GW-17

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

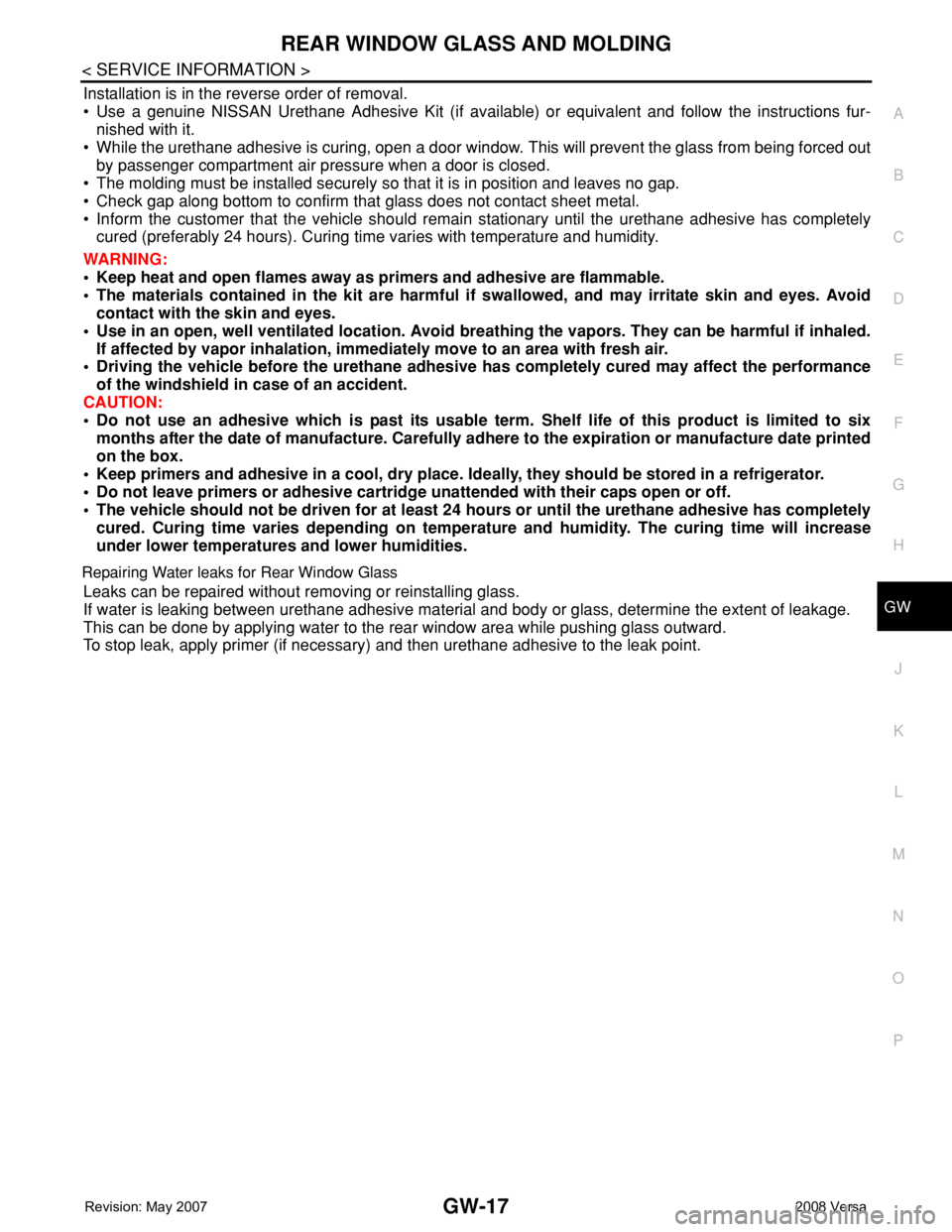

Installation is in the reverse order of removal.

• Use a genuine NISSAN Urethane Adhesive Kit (if available) or equivalent and follow the instructions fur-

nished with it.

• While the urethane adhesive is curing, open a door window. This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• The molding must be installed securely so that it is in position and leaves no gap.

• Check gap along bottom to confirm that glass does not contact sheet metal.

• Inform the customer that the vehicle should remain stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if inhaled.

If affected by vapor inhalation, immediately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the windshield in case of an accident.

CAUTION:

• Do not use an adhesive which is past its usable term. Shelf life of this product is limited to six

months after the date of manufacture. Carefully adhere to the expiration or manufacture date printed

on the box.

• Keep primers and adhesive in a cool, dry place. Ideally, they should be stored in a refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depending on temperature and humidity. The curing time will increase

under lower temperatures and lower humidities.

Repairing Water leaks for Rear Window Glass

Leaks can be repaired without removing or reinstalling glass.

If water is leaking between urethane adhesive material and body or glass, determine the extent of leakage.

This can be done by applying water to the rear window area while pushing glass outward.

To stop leak, apply primer (if necessary) and then urethane adhesive to the leak point.

Page 1919 of 2771

GW-18

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

POWER WINDOW SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000001704138

System DescriptionINFOID:0000000001704139

Power is supplied at all times

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70.

With ignition switch in ON or START position, power is supplied

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38

1. Main power window and door lock/

unlock switch D7, D82. Power window and door lock/unlock

switch RH D1053. Rear power window switch LH D203,

RH D303

4. BCM M18, M19, M20 (view with

glove box removed)5. Front power window motor LH D9,

RH D1046. Rear power window motor LH D204,

RH D304

7. Front door switch LH B8, RH B108

LIIA2529E

Page 1920 of 2771

POWER WINDOW SYSTEM

GW-19

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

• through BCM terminal 68

• to main power window and door lock/unlock switch terminal 10

• to power window and door lock/unlock switch RH terminal 8 and

• to rear power window switches LH and RH terminal 1.

Ground is supplied

• to BCM terminal 67

• to main power window and door lock/unlock switch terminal 17 and

• to power window and door lock/unlock switch RH terminal 3

• through body grounds M57 and M61.

With ignition switch in ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in the fuse block (J/B)]

• to BCM terminal 11.

MANUAL OPERATION

Front Door LH

WINDOW UP

When the front LH switch in the main power window and door lock/unlock switch is pulled in the up position,

power is supplied

• through main power window and door lock/unlock switch terminal 8

• to front power window motor LH terminal 2.

Ground is supplied

• through main power window and door lock/unlock switch terminal 11

• to front power window motor LH terminal 3.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the front LH switch in the main power window and door lock/unlock switch is pressed in the down posi-

tion, power is supplied

• through main power window and door lock/unlock switch terminal 11

• to front power window motor LH terminal 3.

Ground is supplied

• through main power window and door lock/unlock switch terminal 8

• to front power window motor LH terminal 2.

Then, the motor lowers the window until the switch is released.

Front Door RH

POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH RH OPERATION

WINDOW UP

When the power window and door lock/unlock switch RH is pulled in the up position, power is supplied

• through power window and door lock/unlock switch RH terminal 7

• to front power window motor RH terminal 2.

Ground is supplied

• through power window and door lock/unlock switch RH terminal 6

• to front power window motor RH terminal 1.

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the power window and door lock/unlock switch RH is pressed in the down position, power is supplied

• through power window and door lock/unlock switch RH terminal 6

• to front power window motor RH terminal 1.

Ground is supplied

• through power window and door lock/unlock switch RH terminal 7

• to front power window motor RH terminal 2.

Then, the motor lowers the window until the switch is released.

MAIN POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH OPERATION

WINDOW UP

When the main power window and door lock/unlock switch (front RH) is pulled in the up position, power is sup-

plied

• through main power window and door lock/unlock switch terminal 16

• to power window and door lock/unlock switch RH terminal 12

• through power window and door lock/unlock switch RH terminal 7

• to front power window motor RH terminal 2.

Ground is supplied