NISSAN TIIDA 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TIIDA, Model: NISSAN TIIDA 2008Pages: 2771, PDF Size: 60.61 MB

Page 221 of 2771

A/T SHIFT LOCK SYSTEM

AT-209

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

A/T SHIFT LOCK SYSTEM

DescriptionINFOID:0000000001703361

• The mechanical key interlock mechanism also operates as a shift lock:

With the ignition switch turned to ON, selector lever cannot be shifted from “P” position to any other position

unless brake pedal is depressed.

With the key removed, selector lever cannot be shifted from “P” position to any other position.

The key cannot be removed unless selector lever is placed in “P” position.

• The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock sole-

noid and by the operation of the rotator and slider located inside key cylinder, respectively.

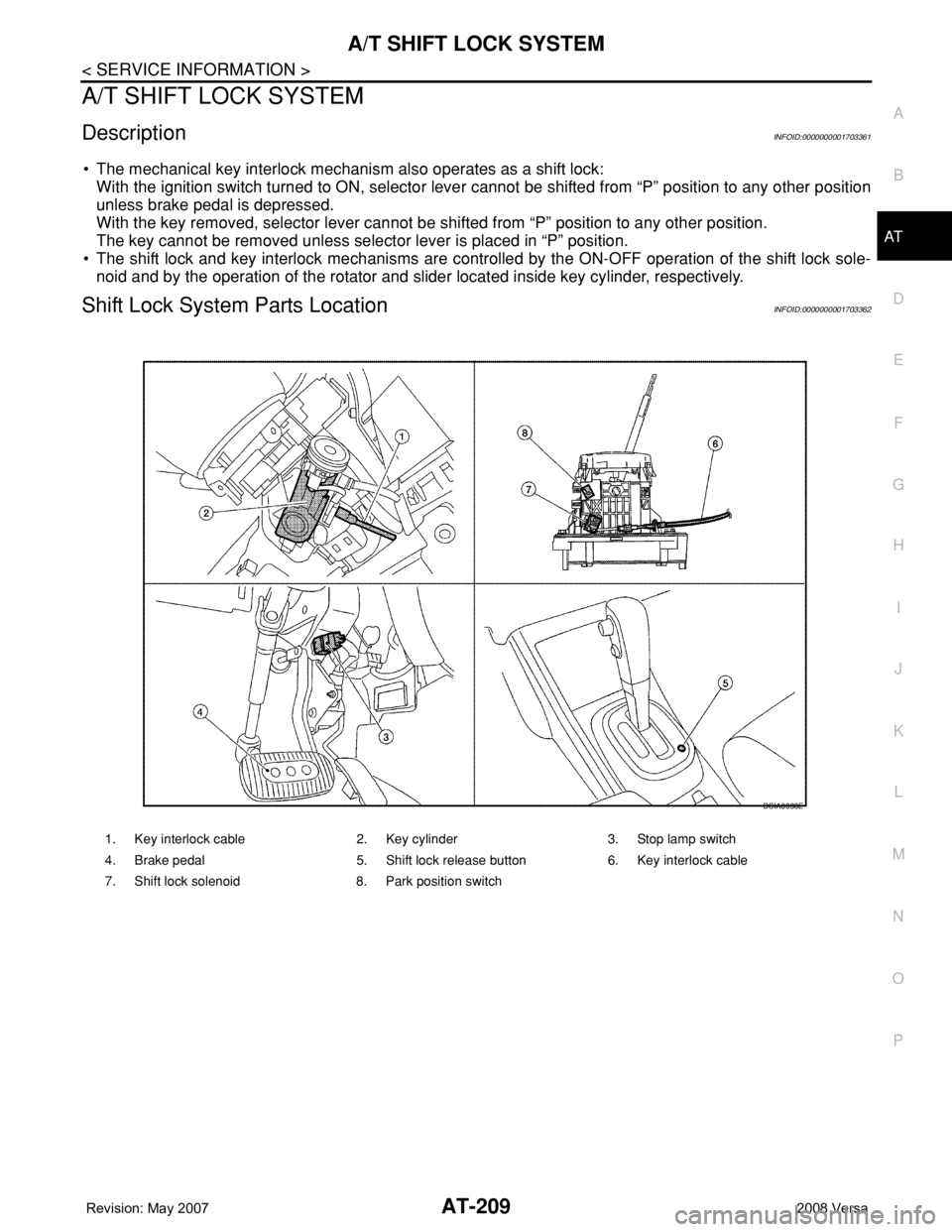

Shift Lock System Parts LocationINFOID:0000000001703362

1. Key interlock cable 2. Key cylinder 3. Stop lamp switch

4. Brake pedal 5. Shift lock release button 6. Key interlock cable

7. Shift lock solenoid 8. Park position switch

BCIA0038E

Page 222 of 2771

AT-210

< SERVICE INFORMATION >

A/T SHIFT LOCK SYSTEM

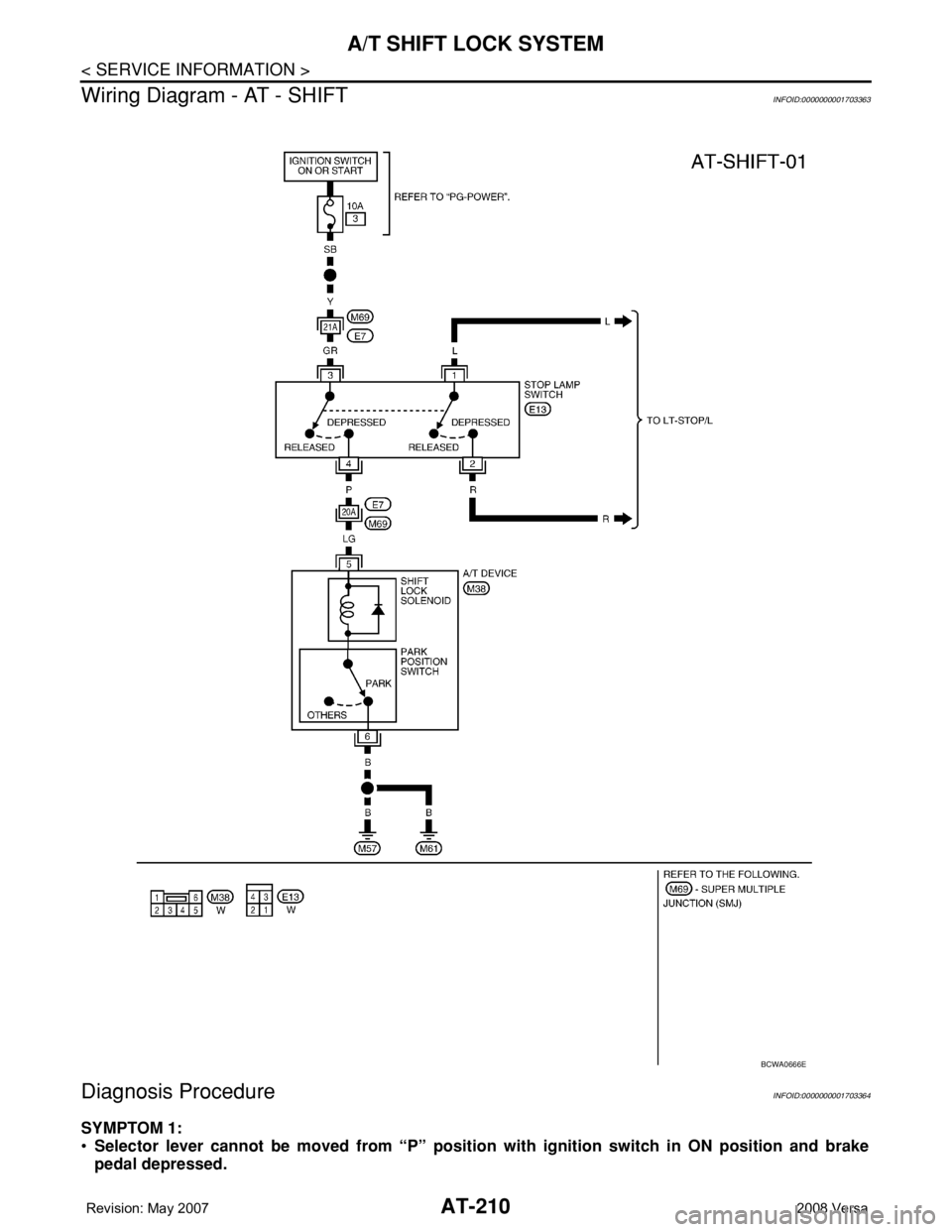

Wiring Diagram - AT - SHIFT

INFOID:0000000001703363

Diagnosis ProcedureINFOID:0000000001703364

SYMPTOM 1:

•Selector lever cannot be moved from “P” position with ignition switch in ON position and brake

pedal depressed.

BCWA0666E

Page 223 of 2771

A/T SHIFT LOCK SYSTEM

AT-211

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

•Selector lever can be moved from “P” position with ignition key in ON position and brake pedal

released.

•Selector lever can be moved from “P” position when ignition switch is removed from key cylinder.

SYMPTOM 2:

•Ignition key cannot be removed when selector lever is set to “P” position.

•Ignition key can be removed when selector lever is set to any position except “P” position.

1.CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK >> GO TO 2.

NG >> Repair key interlock cable. Refer to AT-213, "

Removal and Installation" .

2.CHECK A/T POSITION

Check A/T position. Refer to AT-207, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 3.

NG >> Adjust control cable. Refer to AT-207, "

Adjustment of A/T Position" .

3.CHECK SHIFT LOCK SOLENOID AND PARK POSITION SWITCH

1. Turn ignition switch ON. (Do not start engine.)

2. Selector lever is set in “P” position.

3. Check operation sound.

OK or NG

OK >>INSPECTION END

NG >> GO TO 4.

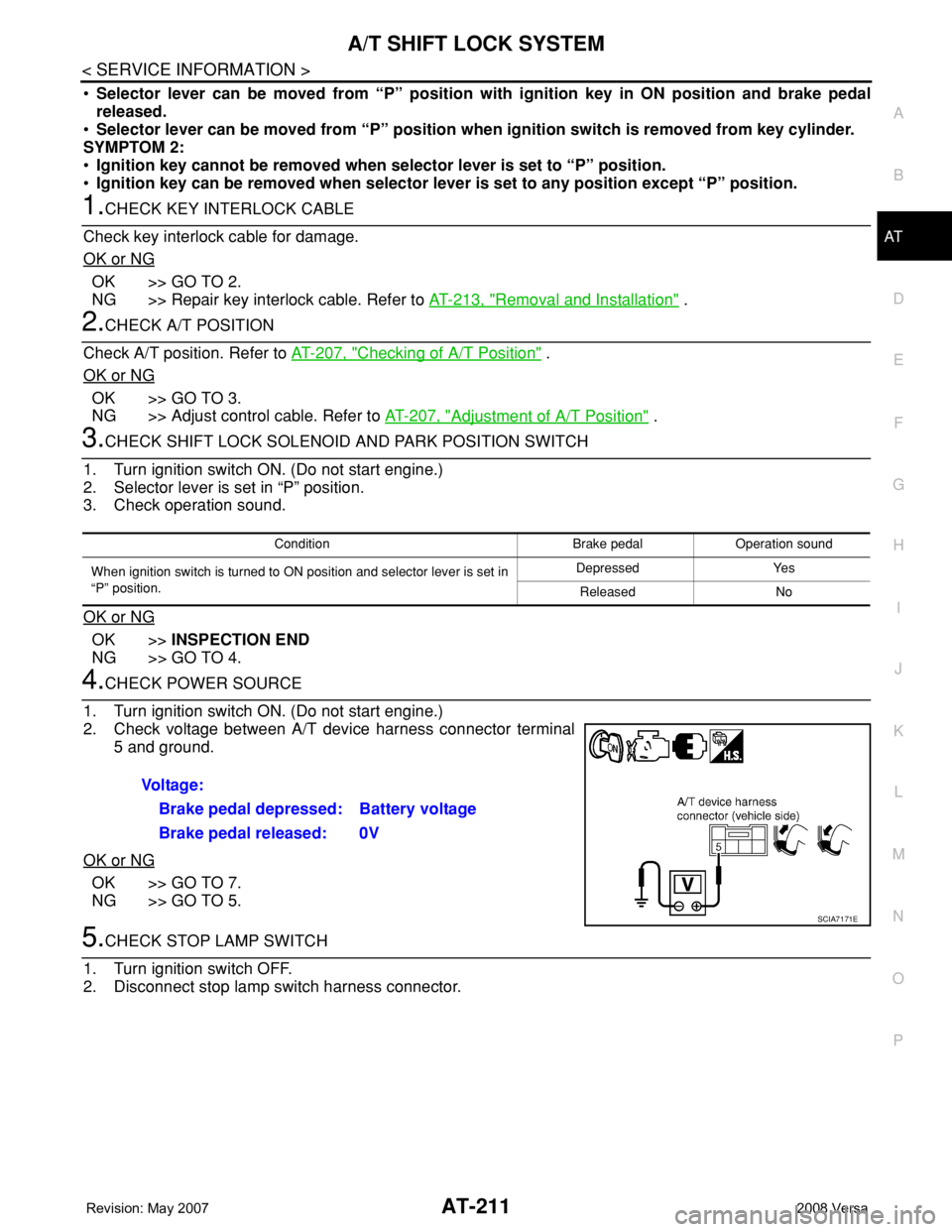

4.CHECK POWER SOURCE

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between A/T device harness connector terminal

5 and ground.

OK or NG

OK >> GO TO 7.

NG >> GO TO 5.

5.CHECK STOP LAMP SWITCH

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

Condition Brake pedal Operation sound

When ignition switch is turned to ON position and selector lever is set in

“P” position.Depressed Yes

Released No

Voltage:

Brake pedal depressed: Battery voltage

Brake pedal released: 0V

SCIA7171E

Page 224 of 2771

AT-212

< SERVICE INFORMATION >

A/T SHIFT LOCK SYSTEM

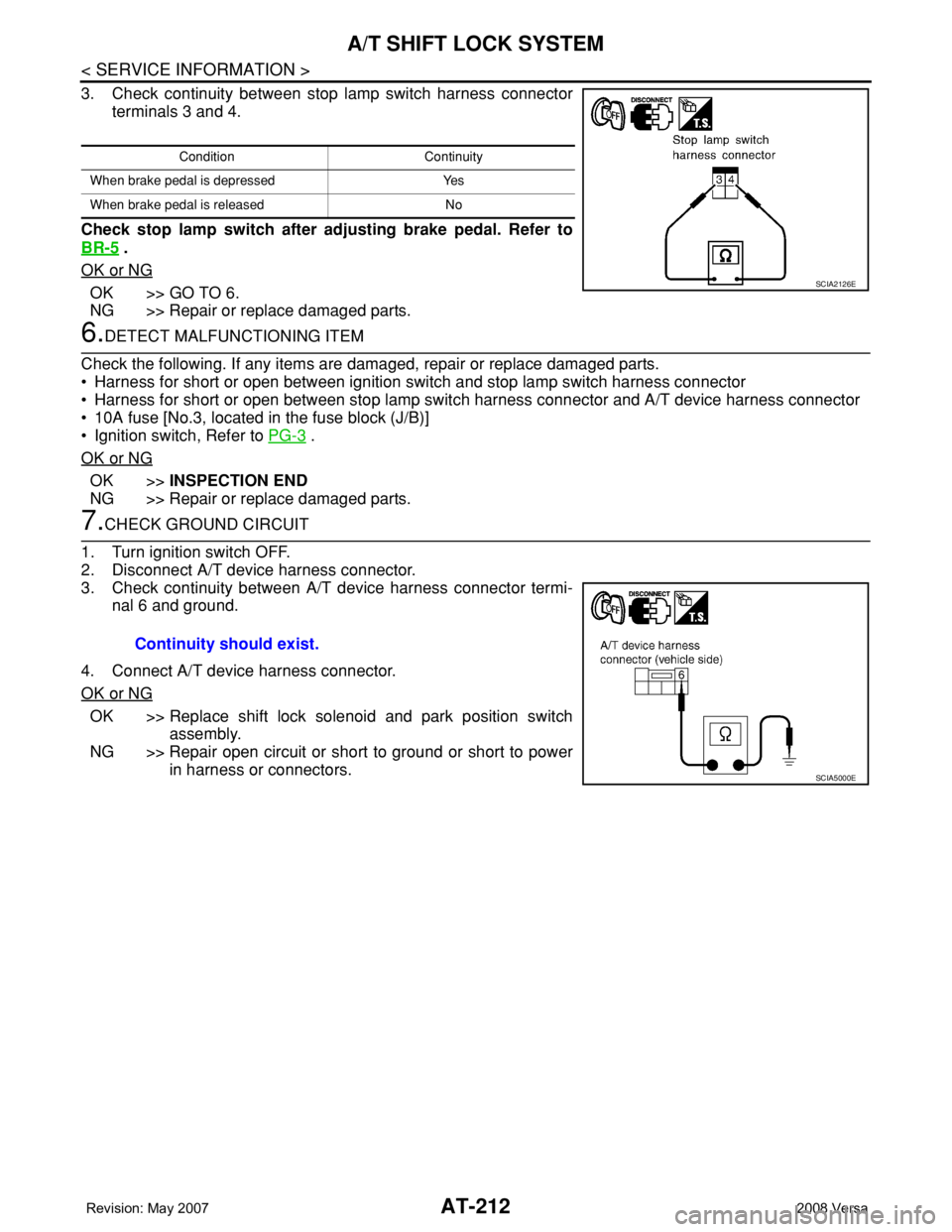

3. Check continuity between stop lamp switch harness connector

terminals 3 and 4.

Check stop lamp switch after adjusting brake pedal. Refer to

BR-5

.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

Check the following. If any items are damaged, repair or replace damaged parts.

• Harness for short or open between ignition switch and stop lamp switch harness connector

• Harness for short or open between stop lamp switch harness connector and A/T device harness connector

• 10A fuse [No.3, located in the fuse block (J/B)]

• Ignition switch, Refer to PG-3

.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

7.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness connector termi-

nal 6 and ground.

4. Connect A/T device harness connector.

OK or NG

OK >> Replace shift lock solenoid and park position switch

assembly.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

SCIA2126E

Continuity should exist.

SCIA5000E

Page 225 of 2771

KEY INTERLOCK CABLE

AT-213

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

KEY INTERLOCK CABLE

Removal and InstallationINFOID:0000000001703365

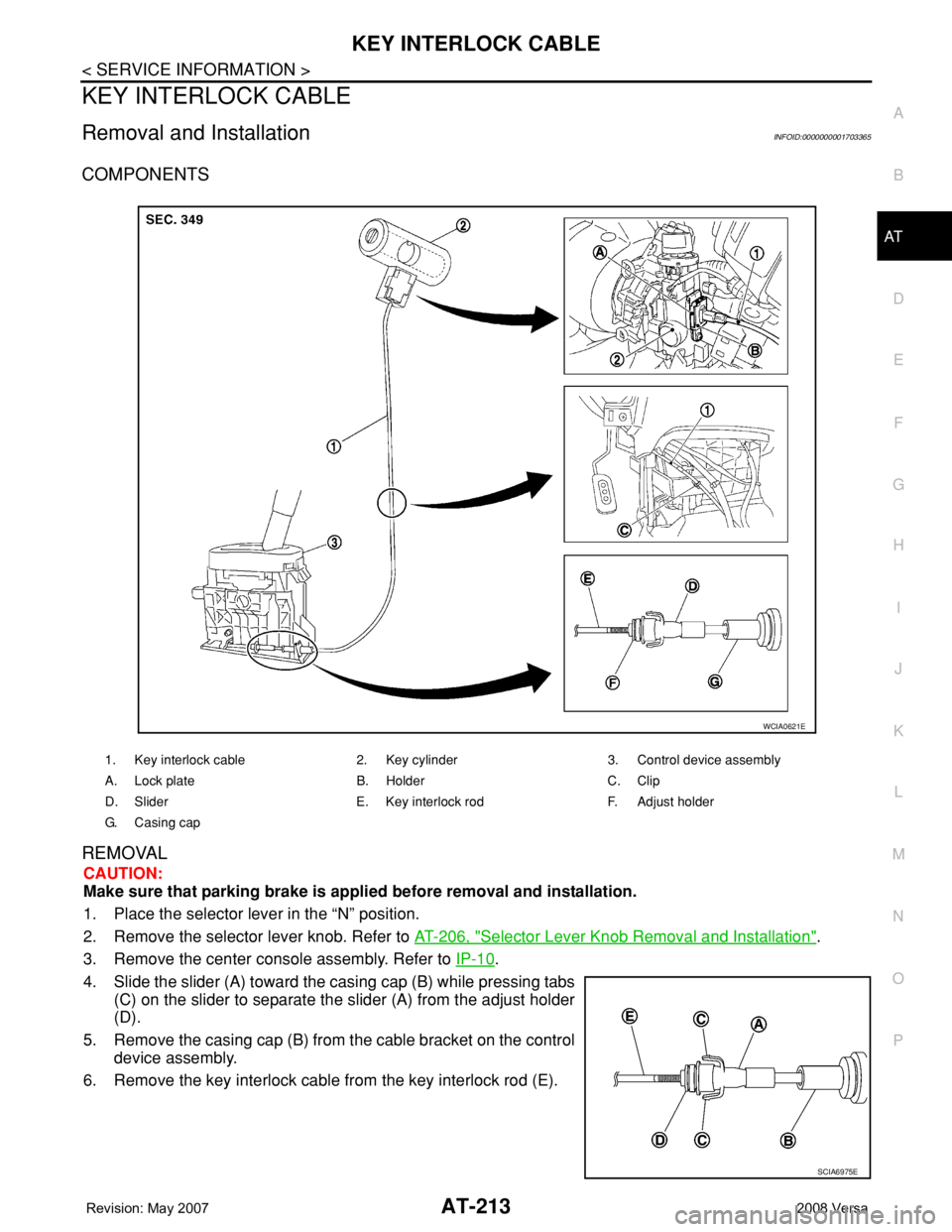

COMPONENTS

REMOVAL

CAUTION:

Make sure that parking brake is applied before removal and installation.

1. Place the selector lever in the “N” position.

2. Remove the selector lever knob. Refer to AT-206, "

Selector Lever Knob Removal and Installation".

3. Remove the center console assembly. Refer to IP-10

.

4. Slide the slider (A) toward the casing cap (B) while pressing tabs

(C) on the slider to separate the slider (A) from the adjust holder

(D).

5. Remove the casing cap (B) from the cable bracket on the control

device assembly.

6. Remove the key interlock cable from the key interlock rod (E).

1. Key interlock cable 2. Key cylinder 3. Control device assembly

A. Lock plate B. Holder C. Clip

D. Slider E. Key interlock rod F. Adjust holder

G. C a s i n g c a p

WCIA0621E

SCIA6975E

Page 226 of 2771

AT-214

< SERVICE INFORMATION >

KEY INTERLOCK CABLE

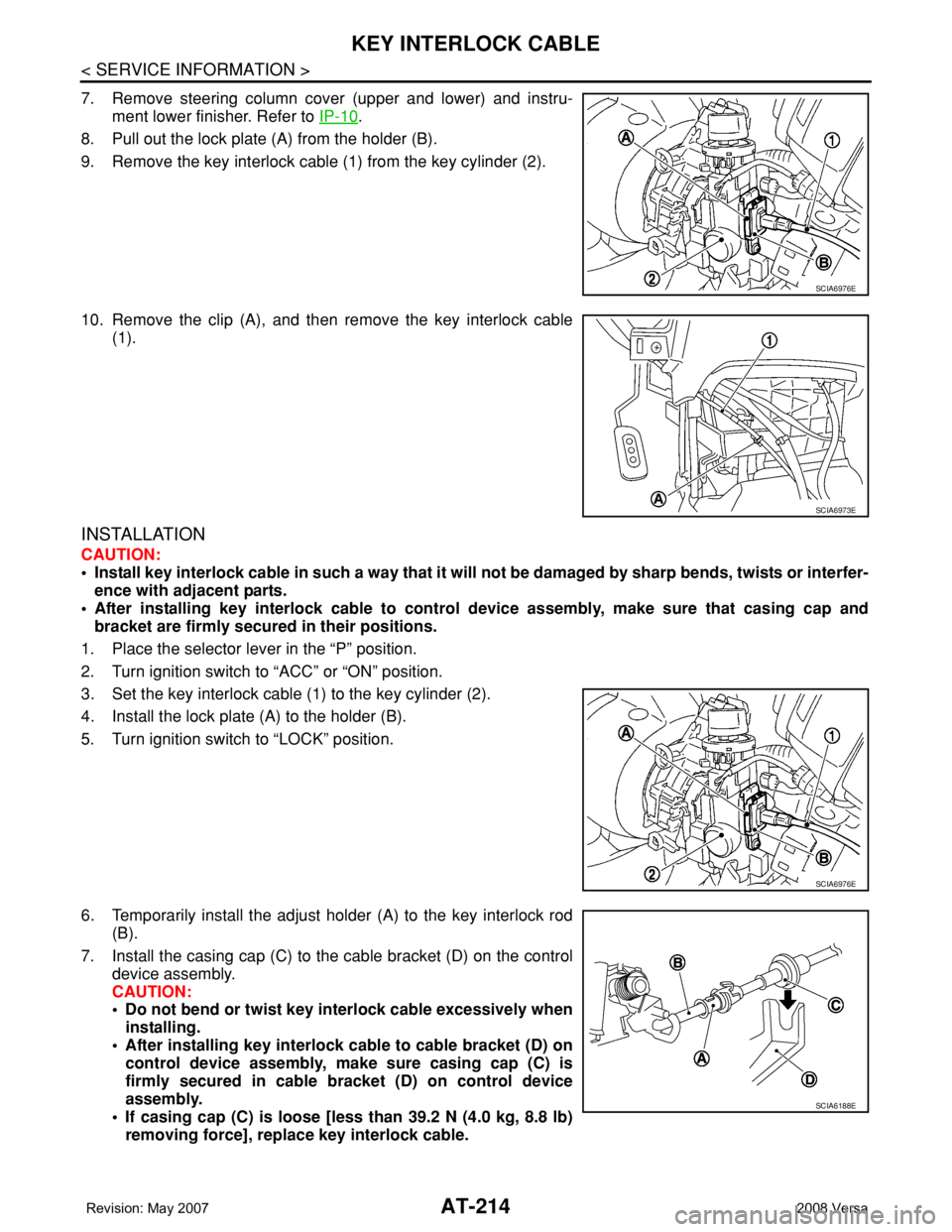

7. Remove steering column cover (upper and lower) and instru-

ment lower finisher. Refer to IP-10

.

8. Pull out the lock plate (A) from the holder (B).

9. Remove the key interlock cable (1) from the key cylinder (2).

10. Remove the clip (A), and then remove the key interlock cable

(1).

INSTALLATION

CAUTION:

• Install key interlock cable in such a way that it will not be damaged by sharp bends, twists or interfer-

ence with adjacent parts.

• After installing key interlock cable to control device assembly, make sure that casing cap and

bracket are firmly secured in their positions.

1. Place the selector lever in the “P” position.

2. Turn ignition switch to “ACC” or “ON” position.

3. Set the key interlock cable (1) to the key cylinder (2).

4. Install the lock plate (A) to the holder (B).

5. Turn ignition switch to “LOCK” position.

6. Temporarily install the adjust holder (A) to the key interlock rod

(B).

7. Install the casing cap (C) to the cable bracket (D) on the control

device assembly.

CAUTION:

• Do not bend or twist key interlock cable excessively when

installing.

• After installing key interlock cable to cable bracket (D) on

control device assembly, make sure casing cap (C) is

firmly secured in cable bracket (D) on control device

assembly.

• If casing cap (C) is loose [less than 39.2 N (4.0 kg, 8.8 lb)

removing force], replace key interlock cable.

SCIA6976E

SCIA6973E

SCIA6976E

SCIA6188E

Page 227 of 2771

KEY INTERLOCK CABLE

AT-215

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

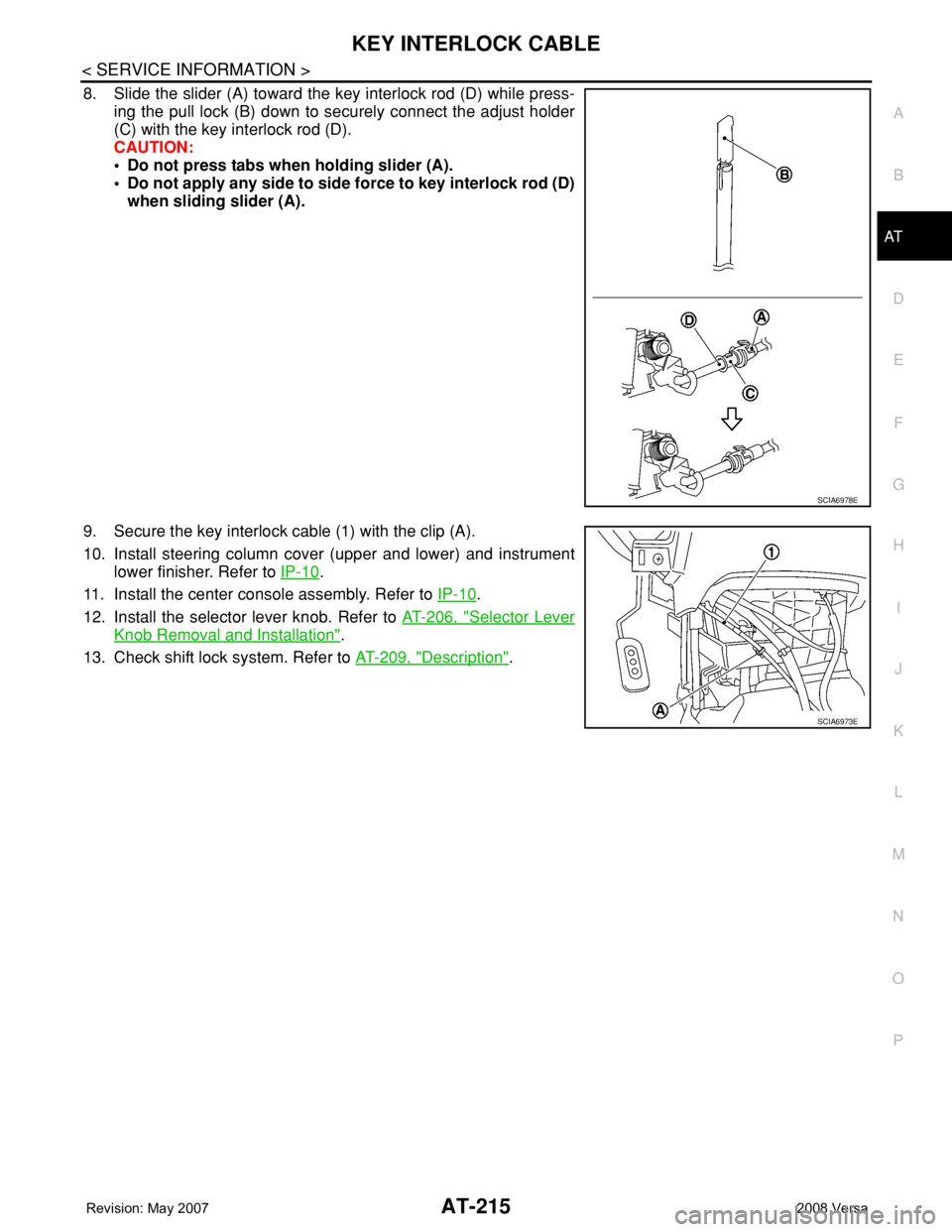

8. Slide the slider (A) toward the key interlock rod (D) while press-

ing the pull lock (B) down to securely connect the adjust holder

(C) with the key interlock rod (D).

CAUTION:

• Do not press tabs when holding slider (A).

• Do not apply any side to side force to key interlock rod (D)

when sliding slider (A).

9. Secure the key interlock cable (1) with the clip (A).

10. Install steering column cover (upper and lower) and instrument

lower finisher. Refer to IP-10

.

11. Install the center console assembly. Refer to IP-10

.

12. Install the selector lever knob. Refer to AT-206, "

Selector Lever

Knob Removal and Installation".

13. Check shift lock system. Refer to AT-209, "

Description".

SCIA6978E

SCIA6973E

Page 228 of 2771

AT-216

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Control Valve Assembly and AccumulatorsINFOID:0000000001703366

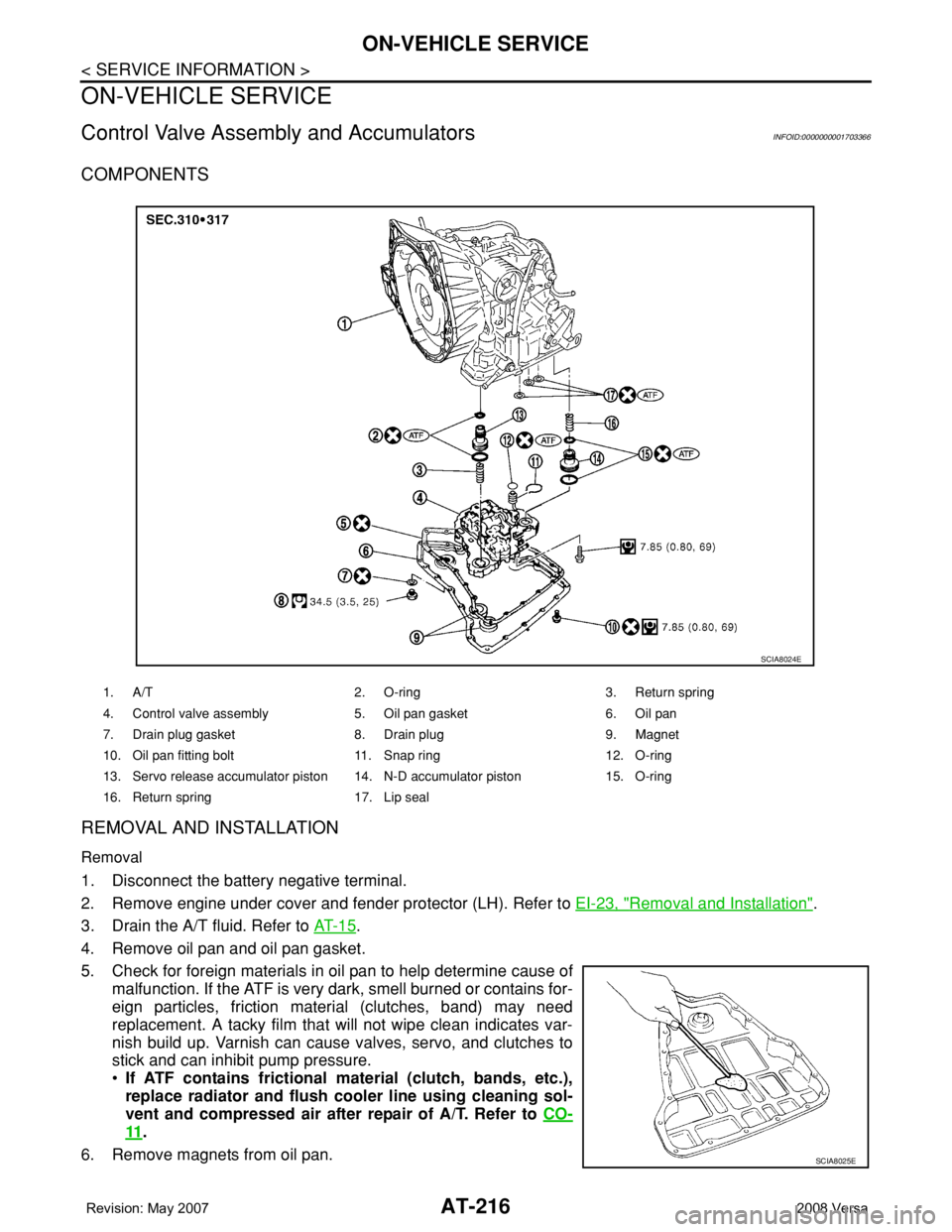

COMPONENTS

REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery negative terminal.

2. Remove engine under cover and fender protector (LH). Refer to EI-23, "

Removal and Installation".

3. Drain the A/T fluid. Refer to AT- 1 5

.

4. Remove oil pan and oil pan gasket.

5. Check for foreign materials in oil pan to help determine cause of

malfunction. If the ATF is very dark, smell burned or contains for-

eign particles, friction material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates var-

nish build up. Varnish can cause valves, servo, and clutches to

stick and can inhibit pump pressure.

•If ATF contains frictional material (clutch, bands, etc.),

replace radiator and flush cooler line using cleaning sol-

vent and compressed air after repair of A/T. Refer to CO-

11.

6. Remove magnets from oil pan.

1. A/T 2. O-ring 3. Return spring

4. Control valve assembly 5. Oil pan gasket 6. Oil pan

7. Drain plug gasket 8. Drain plug 9. Magnet

10. Oil pan fitting bolt 11. Snap ring 12. O-ring

13. Servo release accumulator piston 14. N-D accumulator piston 15. O-ring

16. Return spring 17. Lip seal

SCIA8024E

SCIA8025E

Page 229 of 2771

ON-VEHICLE SERVICE

AT-217

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

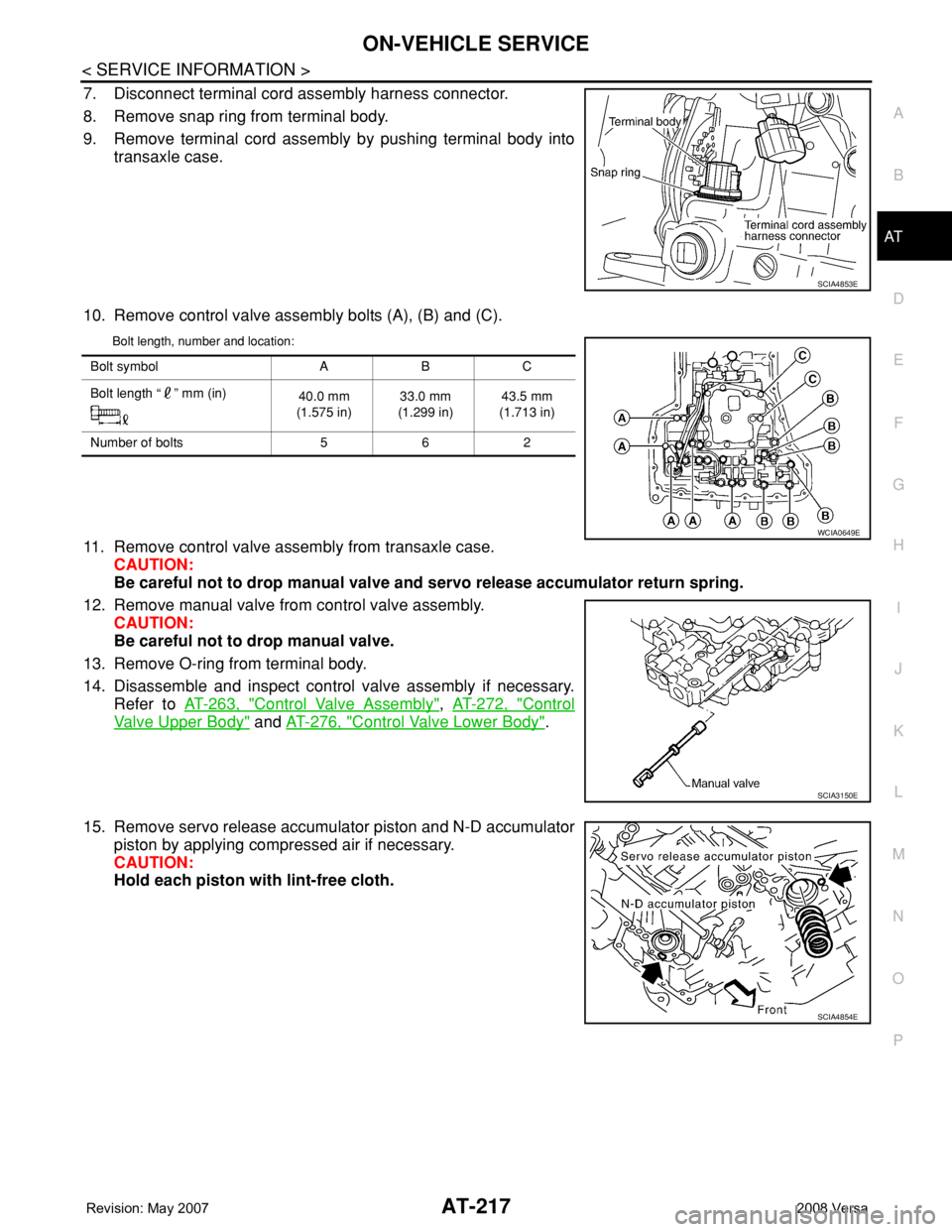

7. Disconnect terminal cord assembly harness connector.

8. Remove snap ring from terminal body.

9. Remove terminal cord assembly by pushing terminal body into

transaxle case.

10. Remove control valve assembly bolts (A), (B) and (C).

Bolt length, number and location:

11. Remove control valve assembly from transaxle case.

CAUTION:

Be careful not to drop manual valve and servo release accumulator return spring.

12. Remove manual valve from control valve assembly.

CAUTION:

Be careful not to drop manual valve.

13. Remove O-ring from terminal body.

14. Disassemble and inspect control valve assembly if necessary.

Refer to AT-263, "

Control Valve Assembly", AT-272, "Control

Valve Upper Body" and AT-276, "Control Valve Lower Body".

15. Remove servo release accumulator piston and N-D accumulator

piston by applying compressed air if necessary.

CAUTION:

Hold each piston with lint-free cloth.

SCIA4853E

Bolt symbol A B C

Bolt length “ ” mm (in)

40.0 mm

(1.575 in)33.0 mm

(1.299 in)43.5 mm

(1.713 in)

Number of bolts 5 6 2

WCIA0649E

SCIA3150E

SCIA4854E

Page 230 of 2771

AT-218

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

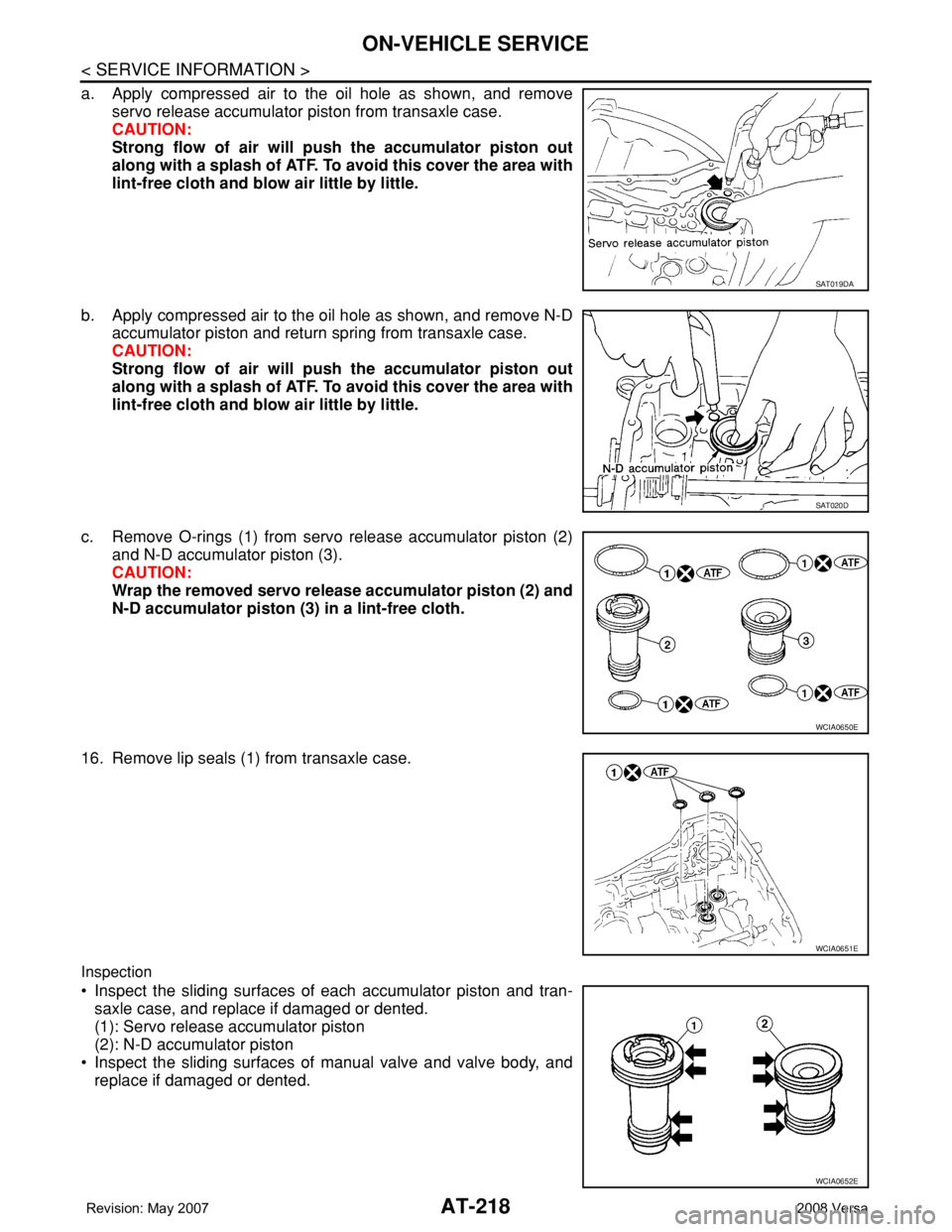

a. Apply compressed air to the oil hole as shown, and remove

servo release accumulator piston from transaxle case.

CAUTION:

Strong flow of air will push the accumulator piston out

along with a splash of ATF. To avoid this cover the area with

lint-free cloth and blow air little by little.

b. Apply compressed air to the oil hole as shown, and remove N-D

accumulator piston and return spring from transaxle case.

CAUTION:

Strong flow of air will push the accumulator piston out

along with a splash of ATF. To avoid this cover the area with

lint-free cloth and blow air little by little.

c. Remove O-rings (1) from servo release accumulator piston (2)

and N-D accumulator piston (3).

CAUTION:

Wrap the removed servo release accumulator piston (2) and

N-D accumulator piston (3) in a lint-free cloth.

16. Remove lip seals (1) from transaxle case.

Inspection

• Inspect the sliding surfaces of each accumulator piston and tran-

saxle case, and replace if damaged or dented.

(1): Servo release accumulator piston

(2): N-D accumulator piston

• Inspect the sliding surfaces of manual valve and valve body, and

replace if damaged or dented.

SAT019DA

SAT020D

WCIA0650E

WCIA0651E

WCIA0652E