NISSAN TIIDA 2008 Service Repair Manual

TIIDA 2008

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57399/w960_57399-0.png

NISSAN TIIDA 2008 Service Repair Manual

Trending: jack points, power steering fluid, scheduled maintenance, lever, Pressure, battery location, Fluid

Page 261 of 2771

DISASSEMBLY

AT-249

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

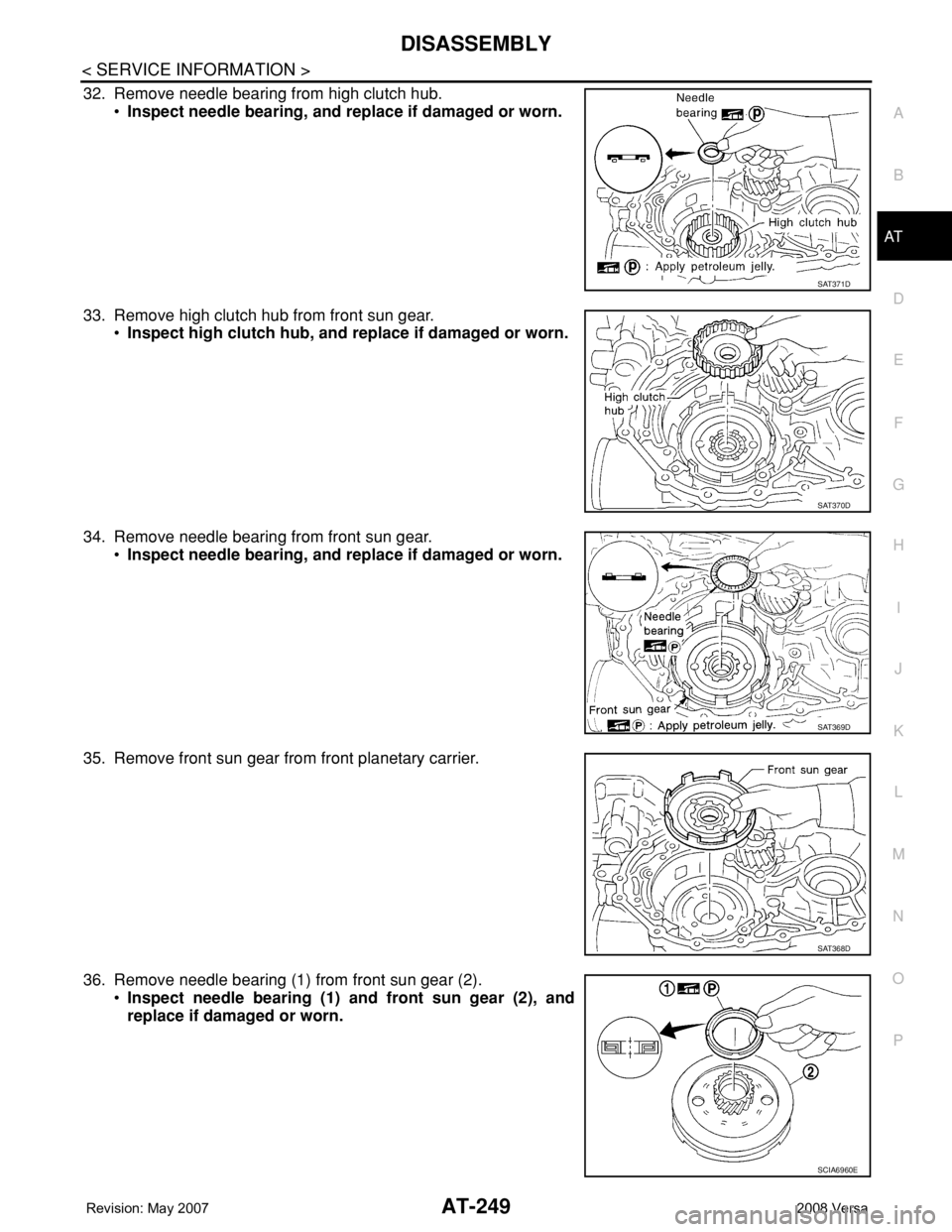

32. Remove needle bearing from high clutch hub.

•Inspect needle bearing, and replace if damaged or worn.

33. Remove high clutch hub from front sun gear.

•Inspect high clutch hub, and replace if damaged or worn.

34. Remove needle bearing from front sun gear.

•Inspect needle bearing, and replace if damaged or worn.

35. Remove front sun gear from front planetary carrier.

36. Remove needle bearing (1) from front sun gear (2).

•Inspect needle bearing (1) and front sun gear (2), and

replace if damaged or worn.

SAT371D

SAT370D

SAT369D

SAT368D

SCIA6960E

Page 262 of 2771

AT-250

< SERVICE INFORMATION >

DISASSEMBLY

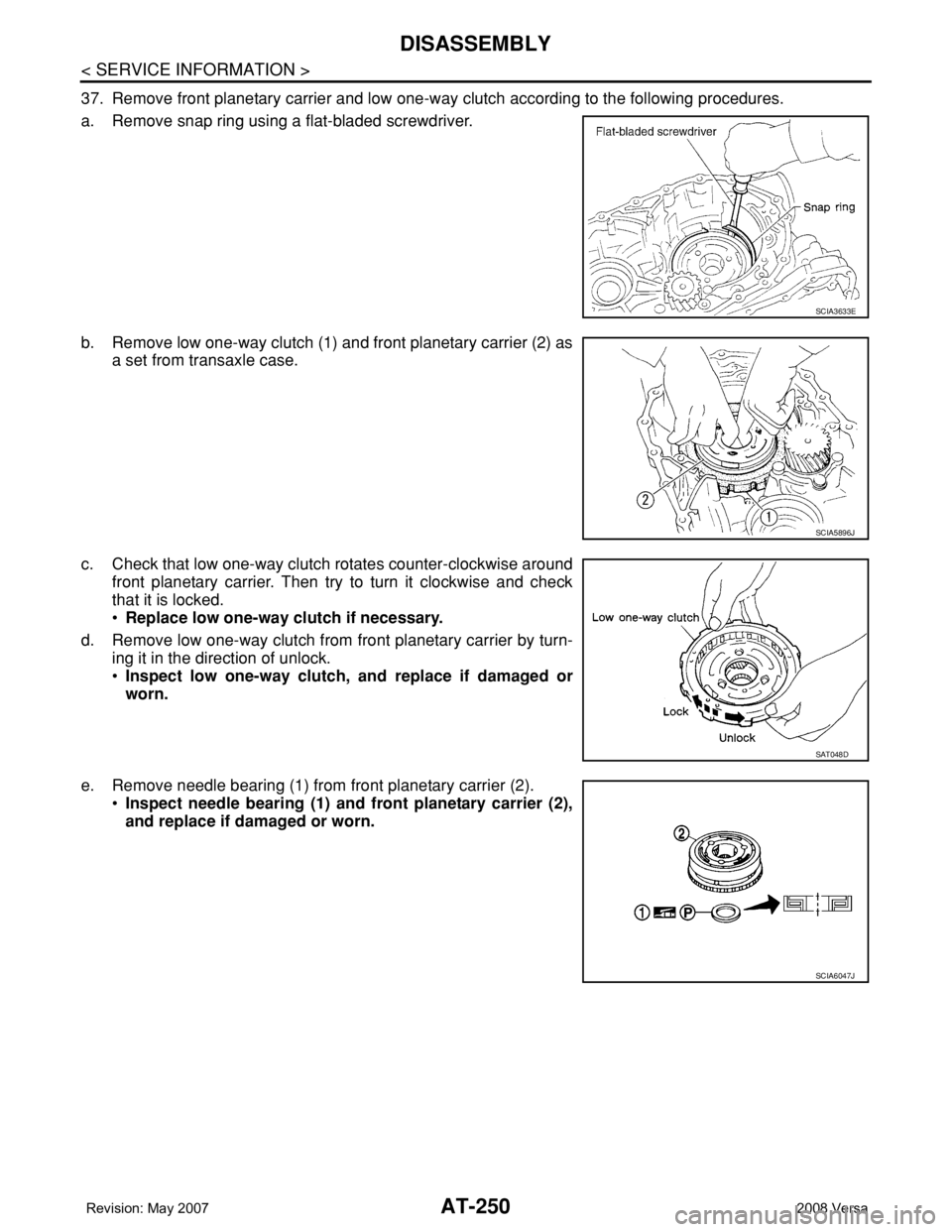

37. Remove front planetary carrier and low one-way clutch according to the following procedures.

a. Remove snap ring using a flat-bladed screwdriver.

b. Remove low one-way clutch (1) and front planetary carrier (2) as

a set from transaxle case.

c. Check that low one-way clutch rotates counter-clockwise around

front planetary carrier. Then try to turn it clockwise and check

that it is locked.

•Replace low one-way clutch if necessary.

d. Remove low one-way clutch from front planetary carrier by turn-

ing it in the direction of unlock.

•Inspect low one-way clutch, and replace if damaged or

worn.

e. Remove needle bearing (1) from front planetary carrier (2).

•Inspect needle bearing (1) and front planetary carrier (2),

and replace if damaged or worn.

SCIA3633E

SCIA5896J

SAT048D

SCIA6047J

Page 263 of 2771

DISASSEMBLY

AT-251

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

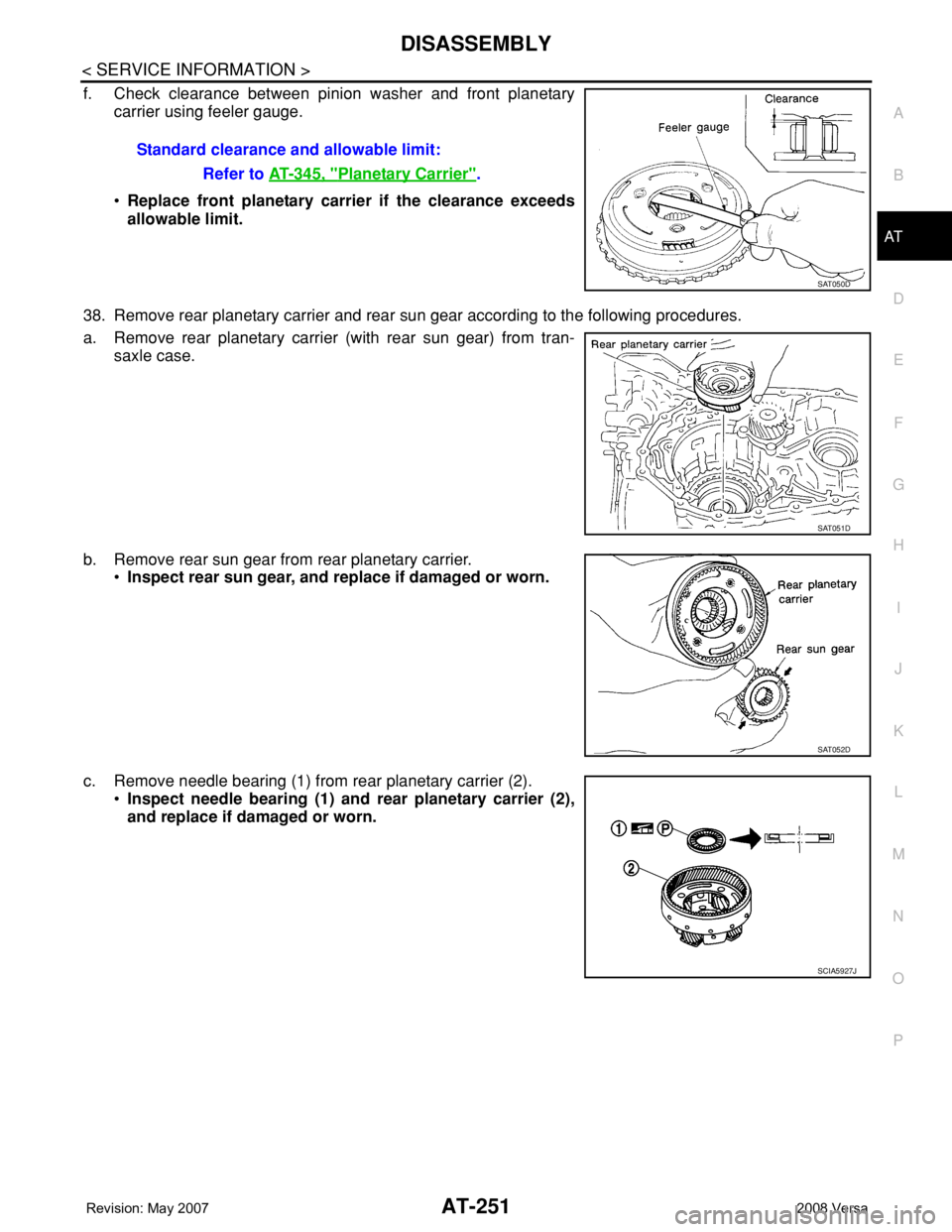

f. Check clearance between pinion washer and front planetary

carrier using feeler gauge.

•Replace front planetary carrier if the clearance exceeds

allowable limit.

38. Remove rear planetary carrier and rear sun gear according to the following procedures.

a. Remove rear planetary carrier (with rear sun gear) from tran-

saxle case.

b. Remove rear sun gear from rear planetary carrier.

•Inspect rear sun gear, and replace if damaged or worn.

c. Remove needle bearing (1) from rear planetary carrier (2).

•Inspect needle bearing (1) and rear planetary carrier (2),

and replace if damaged or worn. Standard clearance and allowable limit:

Refer to AT-345, "

Planetary Carrier".

SAT050D

SAT051D

SAT052D

SCIA5927J

Page 264 of 2771

AT-252

< SERVICE INFORMATION >

DISASSEMBLY

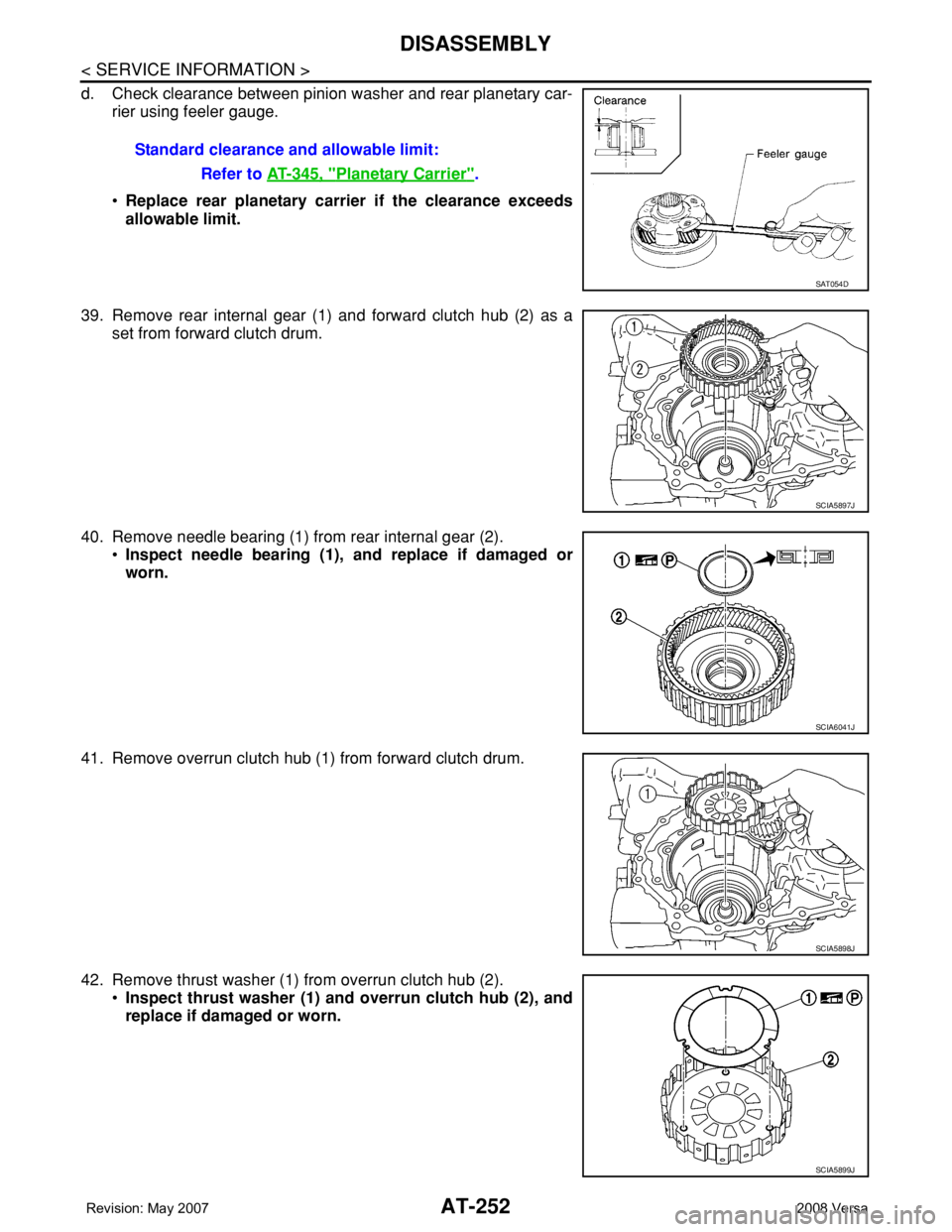

d. Check clearance between pinion washer and rear planetary car-

rier using feeler gauge.

•Replace rear planetary carrier if the clearance exceeds

allowable limit.

39. Remove rear internal gear (1) and forward clutch hub (2) as a

set from forward clutch drum.

40. Remove needle bearing (1) from rear internal gear (2).

•Inspect needle bearing (1), and replace if damaged or

worn.

41. Remove overrun clutch hub (1) from forward clutch drum.

42. Remove thrust washer (1) from overrun clutch hub (2).

•Inspect thrust washer (1) and overrun clutch hub (2), and

replace if damaged or worn.Standard clearance and allowable limit:

Refer to AT-345, "

Planetary Carrier".

SAT054D

SCIA5897J

SCIA6041J

SCIA5898J

SCIA5899J

Page 265 of 2771

DISASSEMBLY

AT-253

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

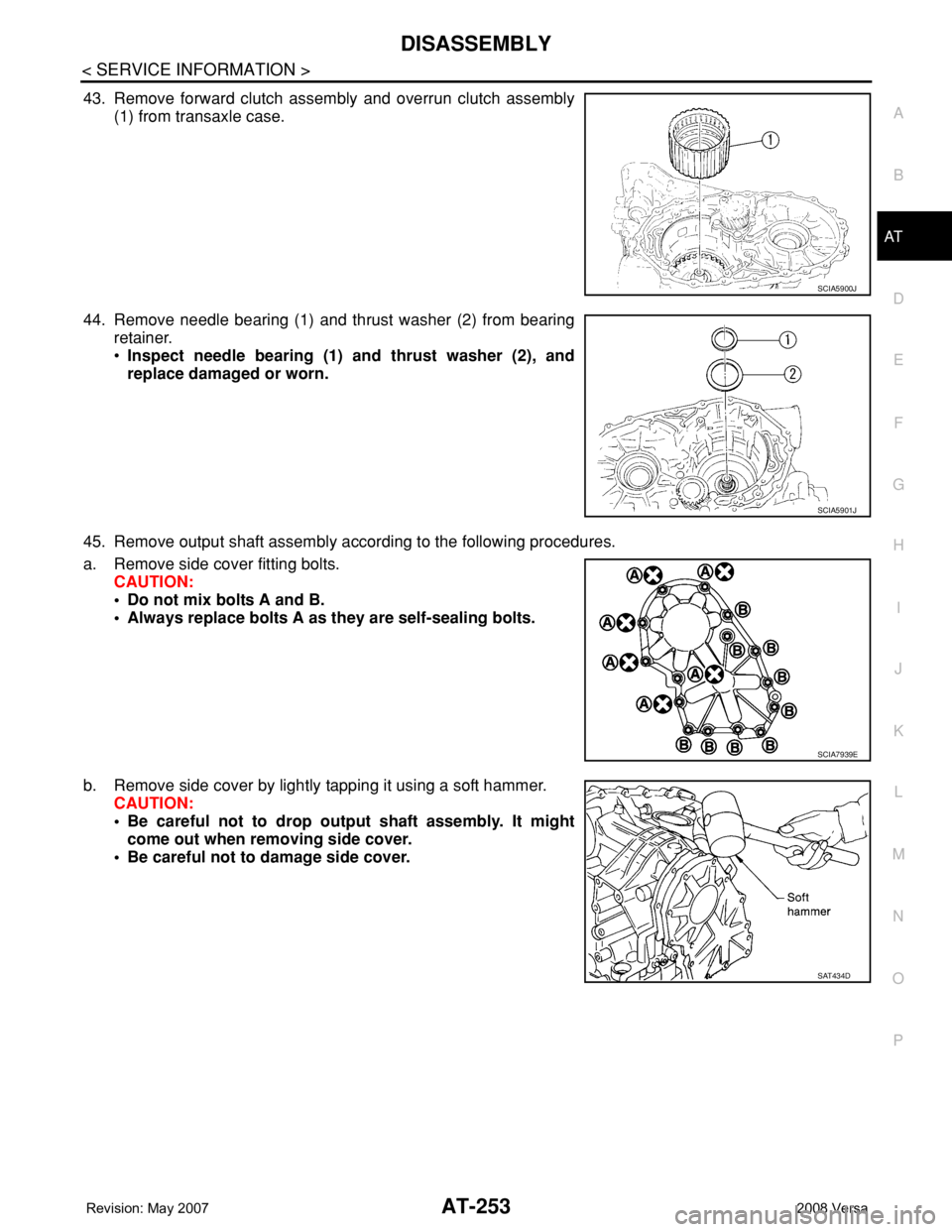

43. Remove forward clutch assembly and overrun clutch assembly

(1) from transaxle case.

44. Remove needle bearing (1) and thrust washer (2) from bearing

retainer.

•Inspect needle bearing (1) and thrust washer (2), and

replace damaged or worn.

45. Remove output shaft assembly according to the following procedures.

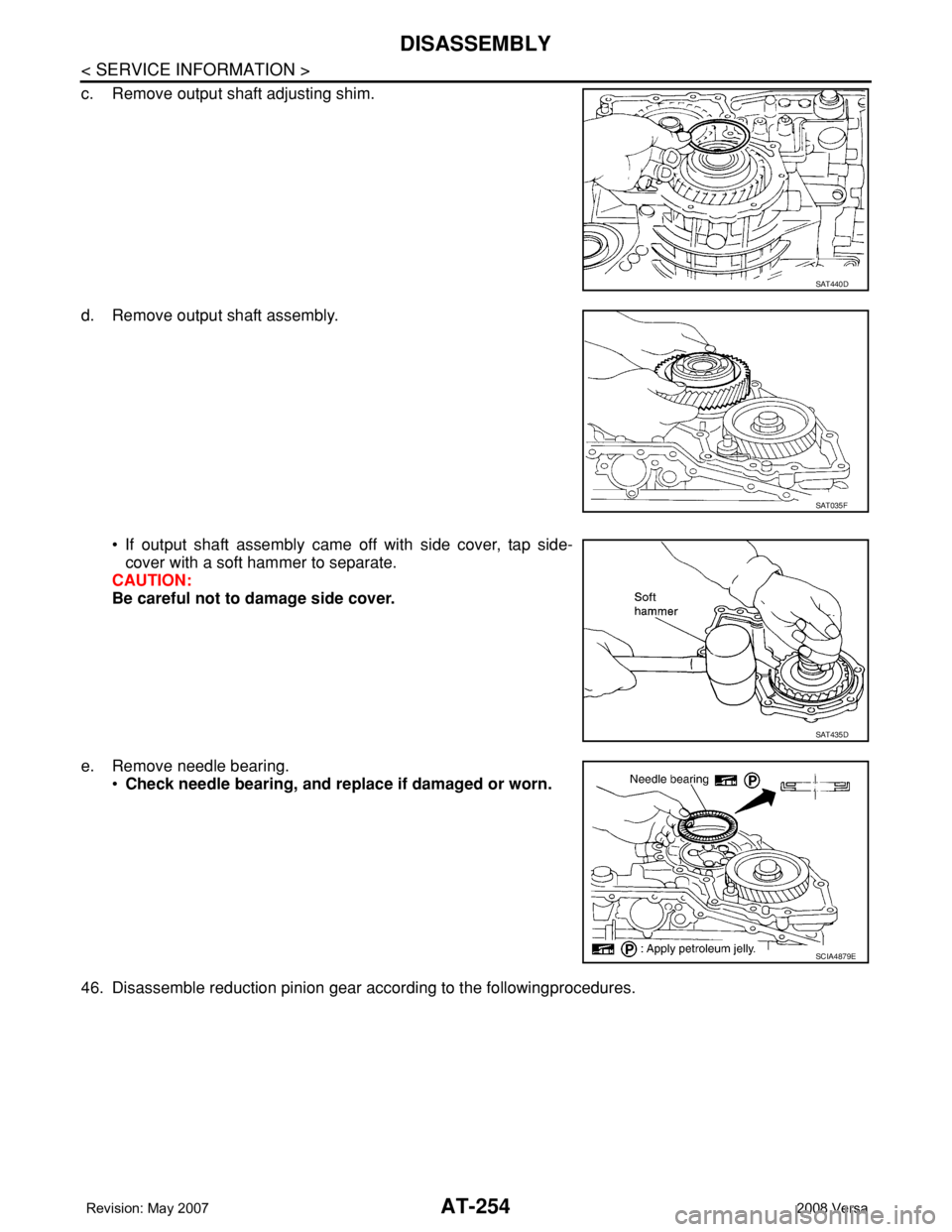

a. Remove side cover fitting bolts.

CAUTION:

• Do not mix bolts A and B.

• Always replace bolts A as they are self-sealing bolts.

b. Remove side cover by lightly tapping it using a soft hammer.

CAUTION:

• Be careful not to drop output shaft assembly. It might

come out when removing side cover.

• Be careful not to damage side cover.

SCIA5900J

SCIA5901J

SCIA7939E

SAT434D

Page 266 of 2771

AT-254

< SERVICE INFORMATION >

DISASSEMBLY

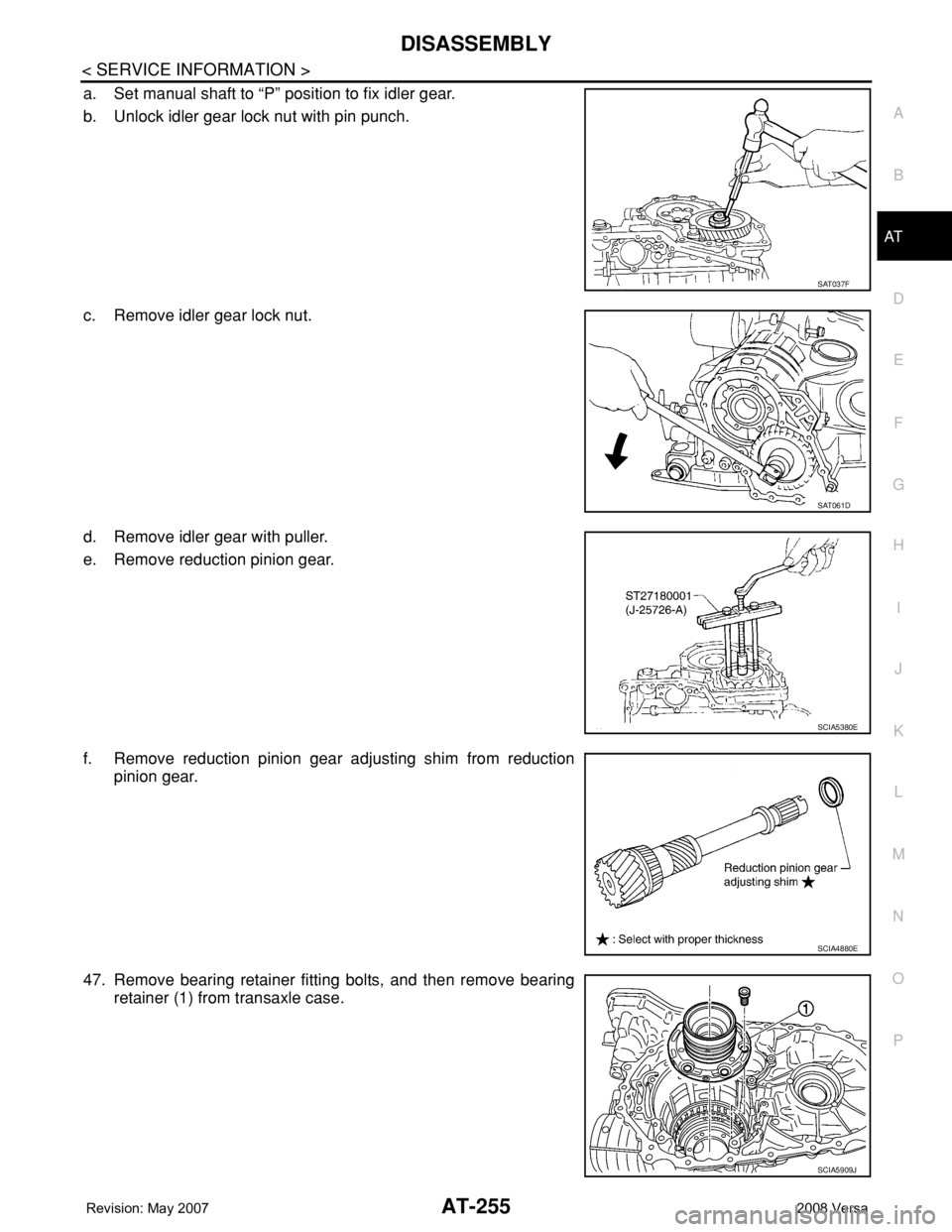

c. Remove output shaft adjusting shim.

d. Remove output shaft assembly.

• If output shaft assembly came off with side cover, tap side-

cover with a soft hammer to separate.

CAUTION:

Be careful not to damage side cover.

e. Remove needle bearing.

•Check needle bearing, and replace if damaged or worn.

46. Disassemble reduction pinion gear according to the followingprocedures.

SAT440D

SAT035F

SAT435D

SCIA4879E

Page 267 of 2771

DISASSEMBLY

AT-255

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

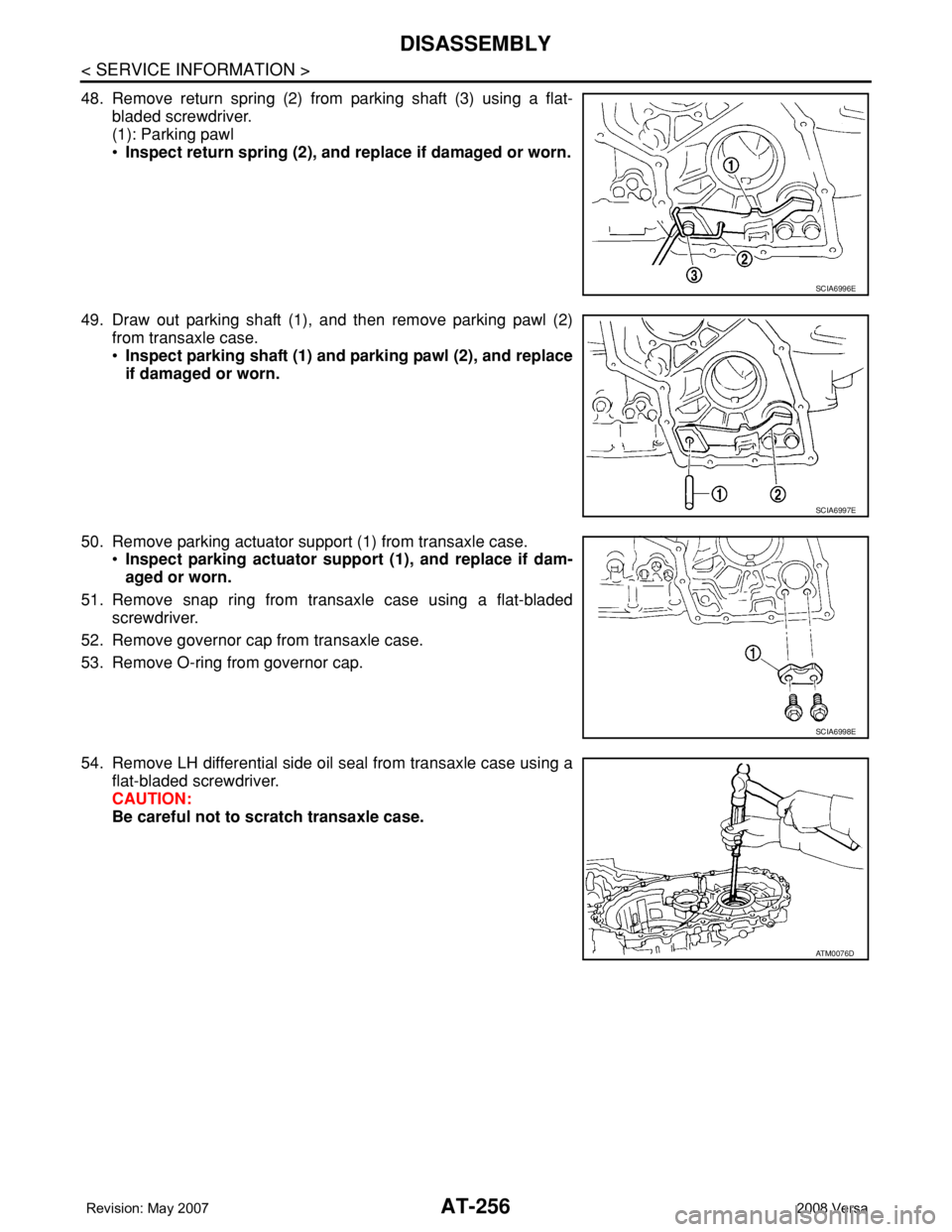

a. Set manual shaft to “P” position to fix idler gear.

b. Unlock idler gear lock nut with pin punch.

c. Remove idler gear lock nut.

d. Remove idler gear with puller.

e. Remove reduction pinion gear.

f. Remove reduction pinion gear adjusting shim from reduction

pinion gear.

47. Remove bearing retainer fitting bolts, and then remove bearing

retainer (1) from transaxle case.

SAT037F

SAT061D

SCIA5380E

SCIA4880E

SCIA5909J

Page 268 of 2771

AT-256

< SERVICE INFORMATION >

DISASSEMBLY

48. Remove return spring (2) from parking shaft (3) using a flat-

bladed screwdriver.

(1): Parking pawl

•Inspect return spring (2), and replace if damaged or worn.

49. Draw out parking shaft (1), and then remove parking pawl (2)

from transaxle case.

•Inspect parking shaft (1) and parking pawl (2), and replace

if damaged or worn.

50. Remove parking actuator support (1) from transaxle case.

•Inspect parking actuator support (1), and replace if dam-

aged or worn.

51. Remove snap ring from transaxle case using a flat-bladed

screwdriver.

52. Remove governor cap from transaxle case.

53. Remove O-ring from governor cap.

54. Remove LH differential side oil seal from transaxle case using a

flat-bladed screwdriver.

CAUTION:

Be careful not to scratch transaxle case.

SCIA6996E

SCIA6997E

SCIA6998E

ATM0076D

Page 269 of 2771

REPAIR FOR COMPONENT PARTS

AT-257

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

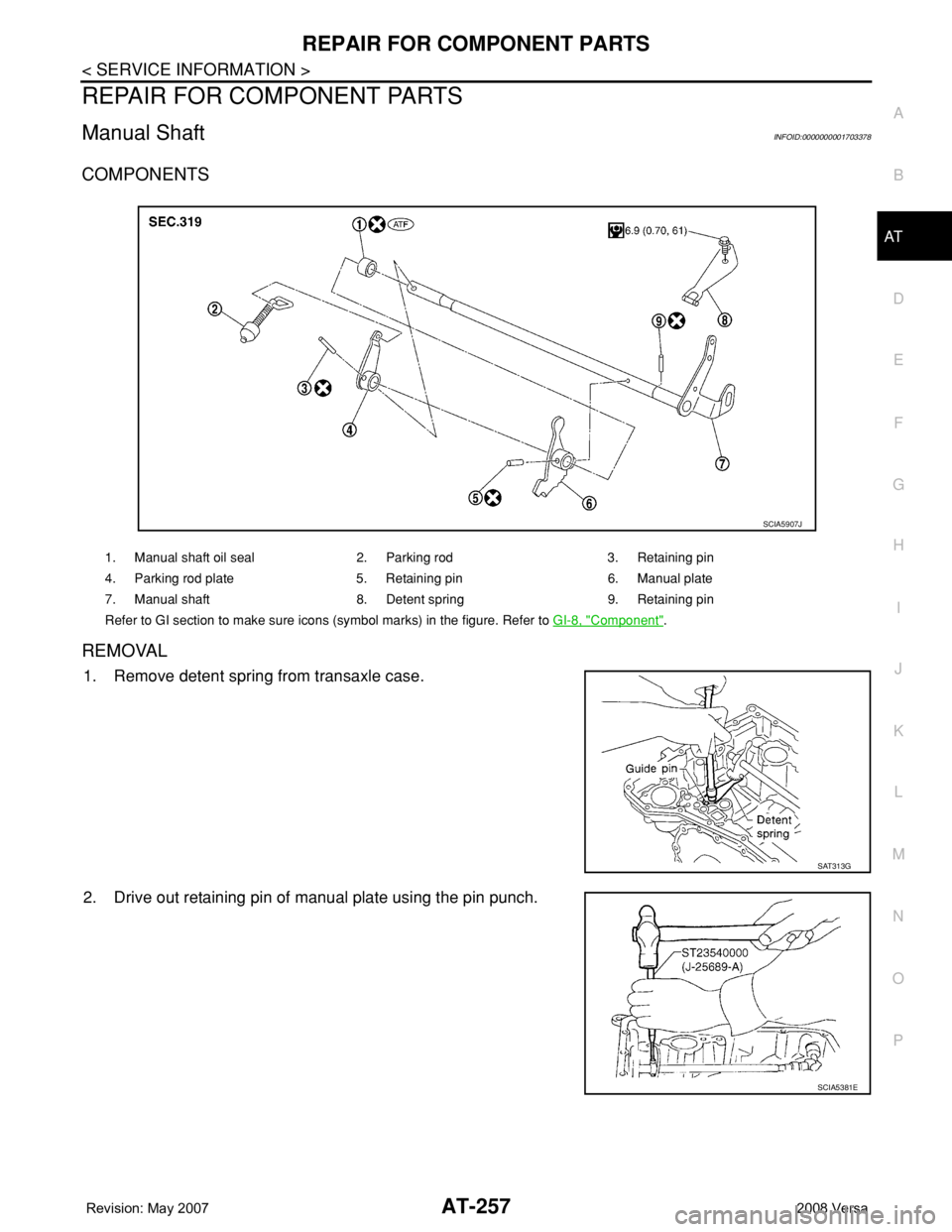

REPAIR FOR COMPONENT PARTS

Manual ShaftINFOID:0000000001703378

COMPONENTS

REMOVAL

1. Remove detent spring from transaxle case.

2. Drive out retaining pin of manual plate using the pin punch.

1. Manual shaft oil seal 2. Parking rod 3. Retaining pin

4. Parking rod plate 5. Retaining pin 6. Manual plate

7. Manual shaft 8. Detent spring 9. Retaining pin

Refer to GI section to make sure icons (symbol marks) in the figure. Refer to GI-8, "

Component".

SCIA5907J

SAT313G

SCIA5381E

Page 270 of 2771

AT-258

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

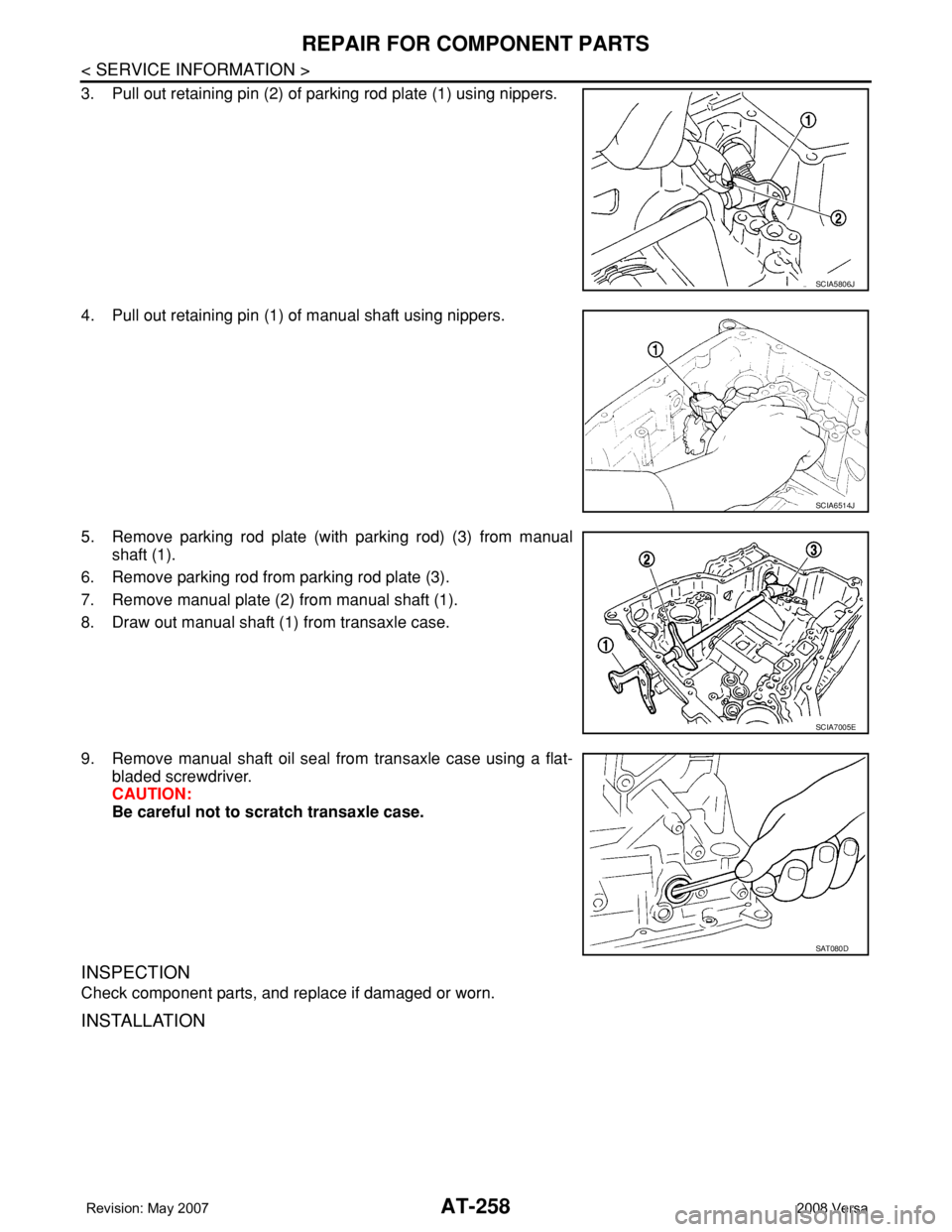

3. Pull out retaining pin (2) of parking rod plate (1) using nippers.

4. Pull out retaining pin (1) of manual shaft using nippers.

5. Remove parking rod plate (with parking rod) (3) from manual

shaft (1).

6. Remove parking rod from parking rod plate (3).

7. Remove manual plate (2) from manual shaft (1).

8. Draw out manual shaft (1) from transaxle case.

9. Remove manual shaft oil seal from transaxle case using a flat-

bladed screwdriver.

CAUTION:

Be careful not to scratch transaxle case.

INSPECTION

Check component parts, and replace if damaged or worn.

INSTALLATION

SCIA5806J

SCIA6514J

SCIA7005E

SAT080D

Trending: ENGINE OIL FLUID, oil dipstick, Engine mechanical, Canister, radio, child lock, Washer