Back door NISSAN TIIDA 2009 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3697 of 4331

LT

N

O P

INTERIOR ROOM LAMP

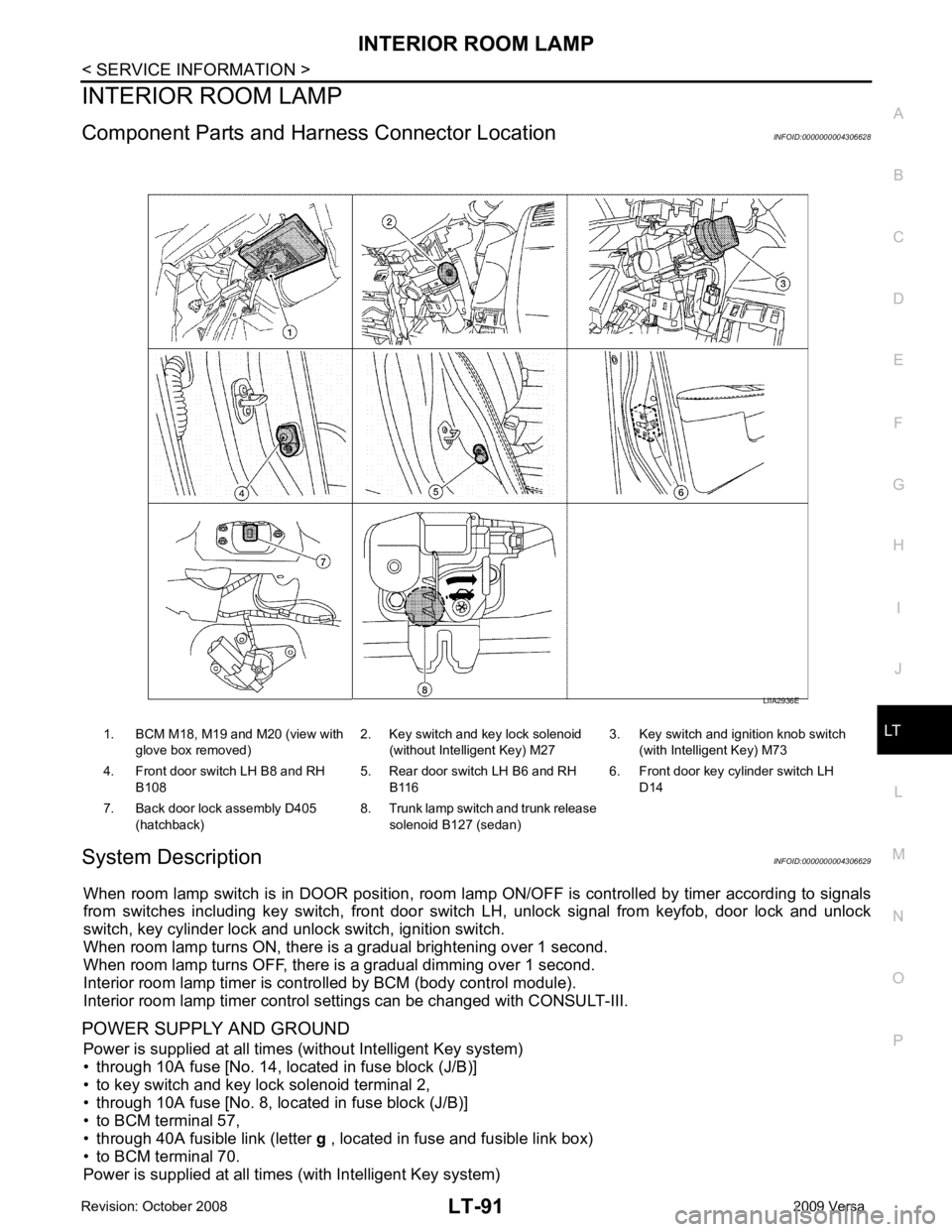

Component Parts and Har ness Connector Location INFOID:0000000004306628

System Description INFOID:0000000004306629

When room lamp switch is in DOOR position, room la mp ON/OFF is controlled by timer according to signals

from switches including key switch, front door switch LH, unlock signal from keyfob, door lock and unlock

switch, key cylinder lock and unlock switch, ignition switch.

When room lamp turns ON, there is a gradual brightening over 1 second.

When room lamp turns OFF, there is a gradual dimming over 1 second.

Interior room lamp timer is controlled by BCM (body control module).

Interior room lamp timer control settings can be changed with CONSULT-III.

POWER SUPPLY AND GROUND Power is supplied at all times (without Intelligent Key system)

• through 10A fuse [No. 14, located in fuse block (J/B)]

• to key switch and key lock solenoid terminal 2,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 40A fusible link (letter g , located in fuse and fusible link box)

• to BCM terminal 70.

Power is supplied at all times (with Intelligent Key system) 1. BCM M18, M19 and M20 (view with

glove box removed) 2. Key switch and key lock solenoid

(without Intelligent Key) M27 3. Key switch and ignition knob switch

(with Intelligent Key) M73

4. Front door switch LH B8 and RH B108 5. Rear door switch LH B6 and RH

B116 6. Front door key cylinder switch LH

D14

7. Back door lock assembly D405 (hatchback) 8. Trunk lamp switch and trunk release

solenoid B127 (sedan)

Page 3707 of 4331

LT

N

O P

3. Perform the preliminary check. Refer to

LT-101, " Preliminary Check " .

4. Check symptom and repair or replace the cause of the malfunction.

5. Does the interior room lamp operate norma lly? If YES, GO TO 6. If NO, GO TO 4.

6. Inspection End

Preliminary Check INFOID:0000000004306634

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR BCM Refer to BCS-15, " BCM Power Supply and Ground Circuit Inspection " .

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR IPDM E/R Refer to LT-11, " Preliminary Check " .

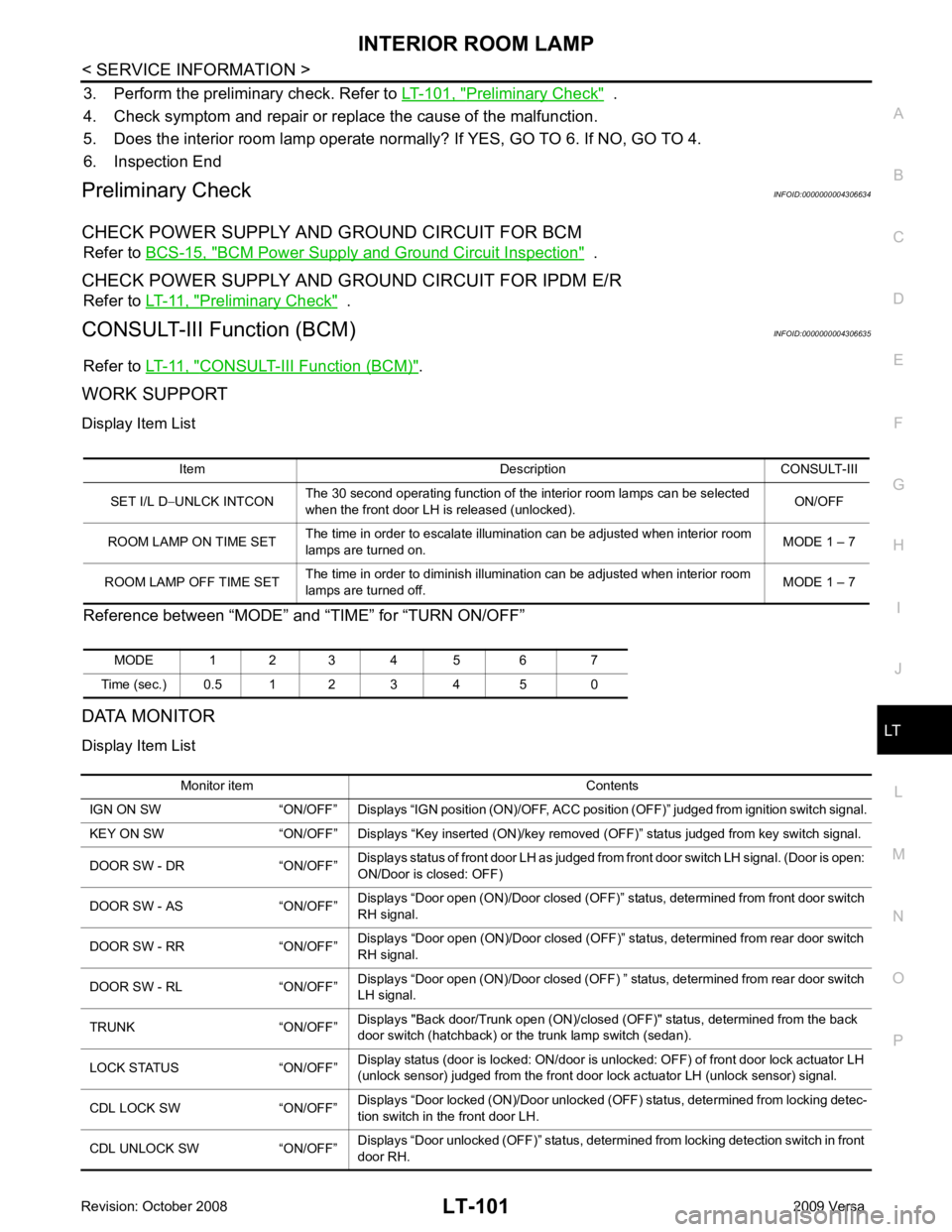

CONSULT-III Function (BCM) INFOID:0000000004306635

Refer to LT-11, " CONSULT-III Function (BCM) " .

WORK SUPPORT

Display Item List

Reference between “MODE” and “TIME” for “TURN ON/OFF”

DATA MONITOR

Display Item List Item Description CONSULT-III

SET I/L D −UNLCK INTCON The 30 second operating function of the interior room lamps can be selected

when the front door LH is released (unlocked). ON/OFF

ROOM LAMP ON TIME SET The time in order to escalate illumination can be adjusted when interior room

lamps are turned on. MODE 1 – 7

ROOM LAMP OFF TIME SET The time in order to diminish illumination can be adjusted when interior room

lamps are turned off. MODE 1 – 7

MODE 1 2 3 4 5 6 7

Time (sec.) 0.5 1 2 3 4 5 0 Monitor item Contents

IGN ON SW “ON/OFF” Displays “IGN position (ON)/OFF, ACC position (OFF)” judged from ignition switch signal.

KEY ON SW “ON/OFF” Displays “Key inse rted (ON)/key removed (OFF)” status judged from key switch signal.

DOOR SW - DR “ON/OFF” Displays status of front door LH as judged from front door switch LH signal. (Door is open:

ON/Door is closed: OFF)

DOOR SW - AS “ON/OFF” Displays “Door open (ON)/Door closed (OFF)” status, determined from front door switch

RH signal.

DOOR SW - RR “ON/OFF” Displays “Door open (ON)/Door closed (OFF)” status, determined from rear door switch

RH signal.

DOOR SW - RL “ON/OFF” Displays “Door open (ON)/Door closed (OFF) ” status, determined from rear door switch

LH signal.

TRUNK “ON/OFF” Displays "Back door/Trunk open (ON)/closed (OFF)" status, determined from the back

door switch (hatchback) or the trunk lamp switch (sedan).

LOCK STATUS “ON/OFF” Display status (door is locked: ON/door is unlocked: OFF) of front door lock actuator LH

(unlock sensor) judged from the front door lock actuator LH (unlock sensor) signal.

CDL LOCK SW “ON/OFF” Displays “Door locked (ON)/Door unlocked (OFF) status, determined from locking detec-

tion switch in the front door LH.

CDL UNLOCK SW “ON/OFF” Displays “Door unlocked (OFF)” status, determined from locking detection switch in front

door RH.

Page 4003 of 4331

Door Switch Check (Hatchback) " when the auto active test cannot be

performed.

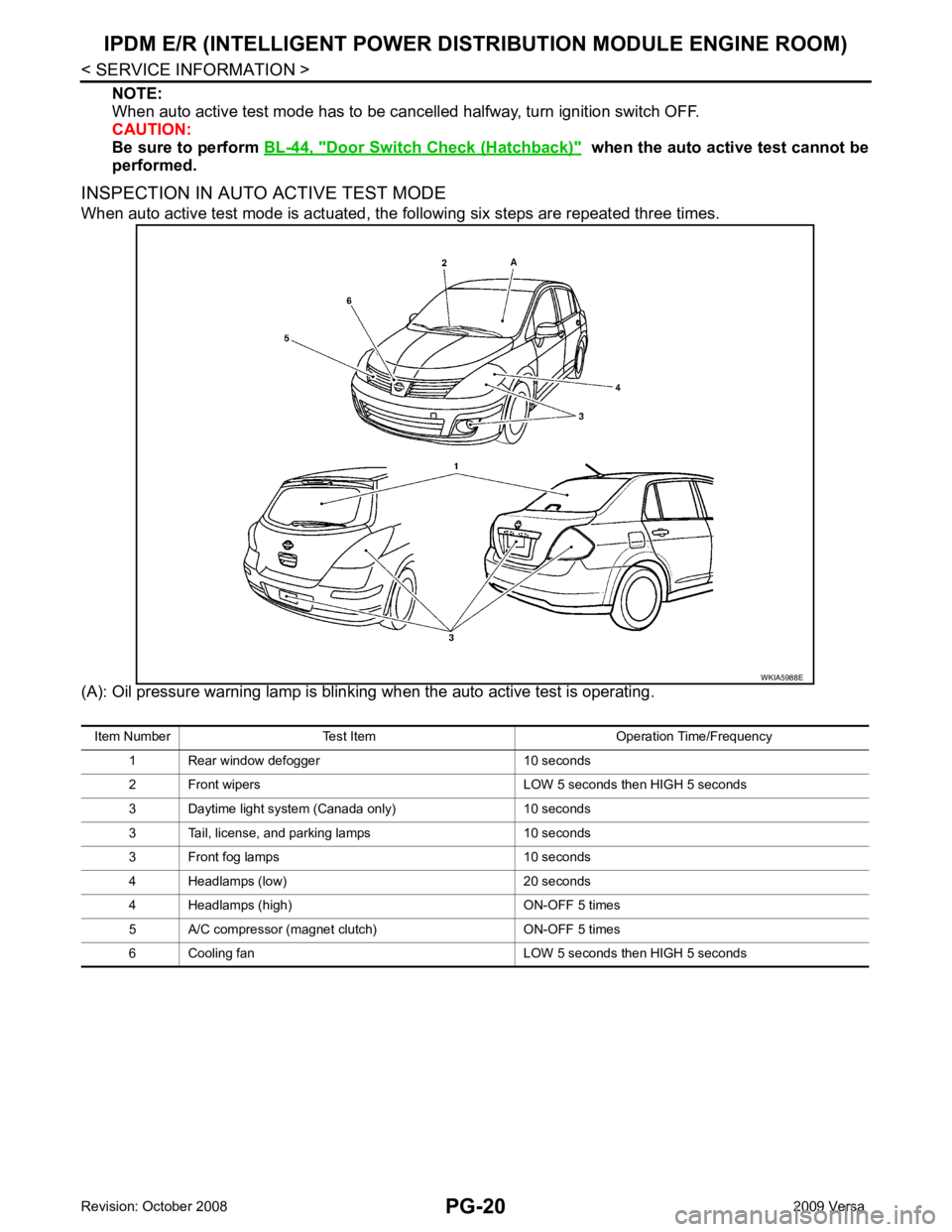

INSPECTION IN AUTO ACTIVE TEST MODE

When auto active test mode is actuated, t he following six steps are repeated three times.

(A): Oil pressure warning lamp is blin king when the auto active test is operating.

Page 4020 of 4331

PG

N

O P

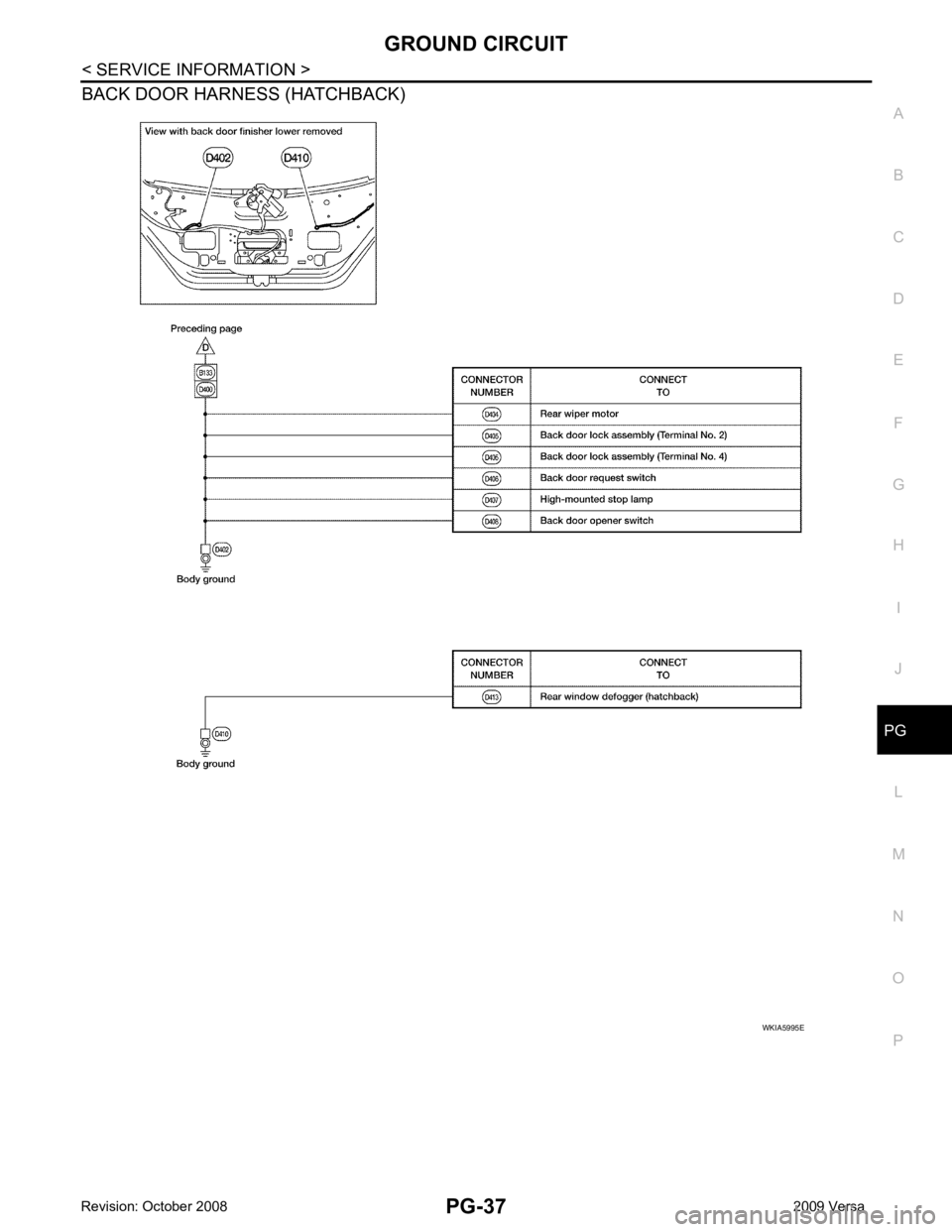

BACK DOOR HARNESS (HATCHBACK)

Page 4040 of 4331

PG

N

O P

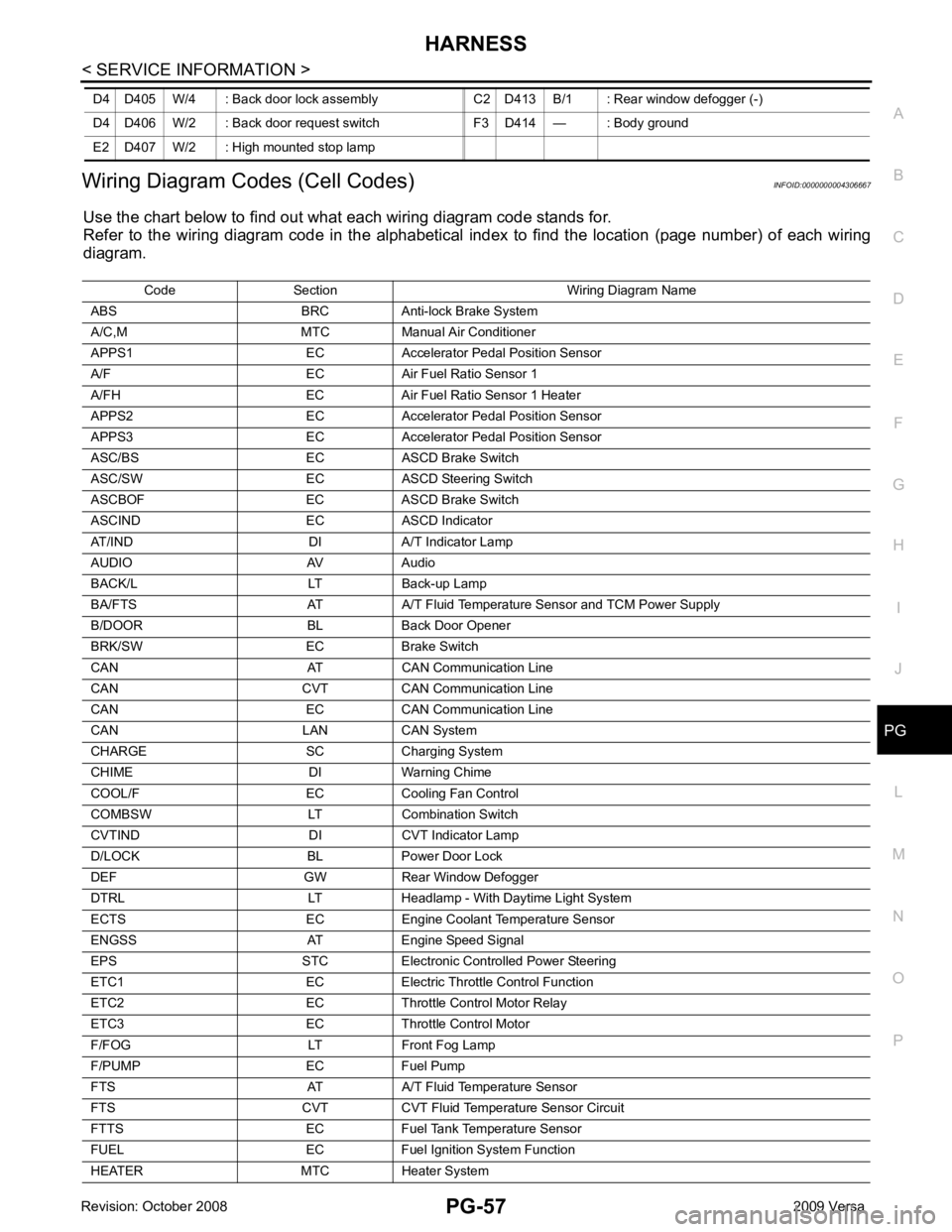

Wiring Diagram Codes (Cell Codes)

INFOID:0000000004306667

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram. D4 D405 W/4 : Back door lock assembly C2 D413 B/1 : Rear window defogger (-)

D4 D406 W/2 : Back door request switch F3 D414 — : Body ground

E2 D407 W/2 : High mounted stop lamp Code Section Wiring Diagram Name

ABS BRC Anti-lock Brake System

A/C,M MTC Manual Air Conditioner

APPS1 EC Accelerator Pe dal Position Sensor

A/F EC Air Fuel Ratio Sensor 1

A/FH EC Air Fuel Ratio Sensor 1 Heater

APPS2 EC Accelerator Pe dal Position Sensor

APPS3 EC Accelerator Pe dal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

BACK/L LT Back-up Lamp

BA/FTS AT A/T Fluid Temperature Sensor and TCM Power Supply

B/DOOR BL Back Door Opener

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN CVT CAN Comm unication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - Wi th Daytime Light System

ECTS EC Engine Coolant Temperature Sensor

ENGSS AT Engine Speed Signal

EPS STC Electronic Controlled Power Steering

ETC1 EC Electric Throttle Control Function

ETC2 EC Throttle Control Motor Relay

ETC3 EC Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor

FTS CVT CVT Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUEL EC Fuel Ignition System Function

HEATER MTC Heater System

Page 4093 of 4331

Work Support " .

ANTI-PINCH FUNCTION

The CPU (central processing unit) of sunroof motor as sembly monitors the sunroof motor operation and the

sunroof position (fully-closed or other ) by the signals from sunroof motor.

When sunroof motor detects an interruption during the following slide close and tilt down operation, sunroof

switch controls the motor for open and the sunroof will oper ate until it reaches full up position (during tilt down

operation) or 125 mm (4.92 in) or more in an open direction (during slide close operation).

• close operation and tilt down when igniti on switch is in the ON position.

• close operation and tilt down during retained power operation.

INITIALIZATION FAILURE CONDITIONS

Initialization and teaching of system should be conducted if the following conditions exist:

• sunroof will only move in the UP/CLOSE direction, having a step by step motion

• sunroof does not have any auto operation.

INITIALIZATION PROCEDURE

If the sunroof does not close or open automatically, use the following procedure to return sunroof operation to

normal.

1. Press the switch to the UP/CLOSE position to tilt t he sunroof up fully. When the sunroof reaches the full tilt

up position it will back up a few millimeters and stop.

2. Release the UP/CLOSE switch.

3. Within 5 seconds of releasing the UP/CLOSE sw itch, press and hold the UP/CLOSE switch again. The

sunroof will move to the full open position and back to the closed position.

NOTE:

If the UP/CLOSE switch is released anytime during th is teaching process, all learned profile data will be dis-

carded and the procedure will have to be started over.

4. Release the UP/CLOSE switch. Do not disconnect power for at least two seconds. The sunroof is now ini-

tialized and taught.

Initializing procedure is complete. Confirm proper operation of the sunroof (slide open, slide closed, tilt up, tilt

down).

RE-TEACHING CONDITIONS

Re-teaching of system should be conducted if any of the following conditions exist:

• the sunroof is manually operated using the sunroof wrench with the battery discharged or disconnected.

• the sunroof is manually operated using the sunroof wrench with the key switch in the OFF position and

retained power timed out (after approximat ely 45 seconds or with a front door open).

• the sunroof motor assembly is replaced with a new one.

• the sunroof motor is removed from the sunroof assembly and operated before it is reinstalled.

Page 4327 of 4331

WW

N

O P

Removal

1. Remove the back door window garnish. Refer to EI-38, " Removal and Installation " .

2. Disconnect rear washer tube from rear washer nozzle.

3. Release retaining clips and remove washer nozzle.

Installation Installation is in the reverse order of removal.

NOTE:

Inspect rear washer nozzle for proper spray pattern, adjust as necessary. Refer to WW-35, " Washer Nozzle

Adjustment " .

WASHER FLUID RESERVOIR Refer to WW-23, " Removal and Installation of Washer Tank " .

WIPER AND WASHER SWITCH Refer to WW-23, " Removal and Installation of Front Wiper and Washer Switch " .

WASHER MOTOR Refer to WW-24, " Removal and Installation of Front Washer Motor " .

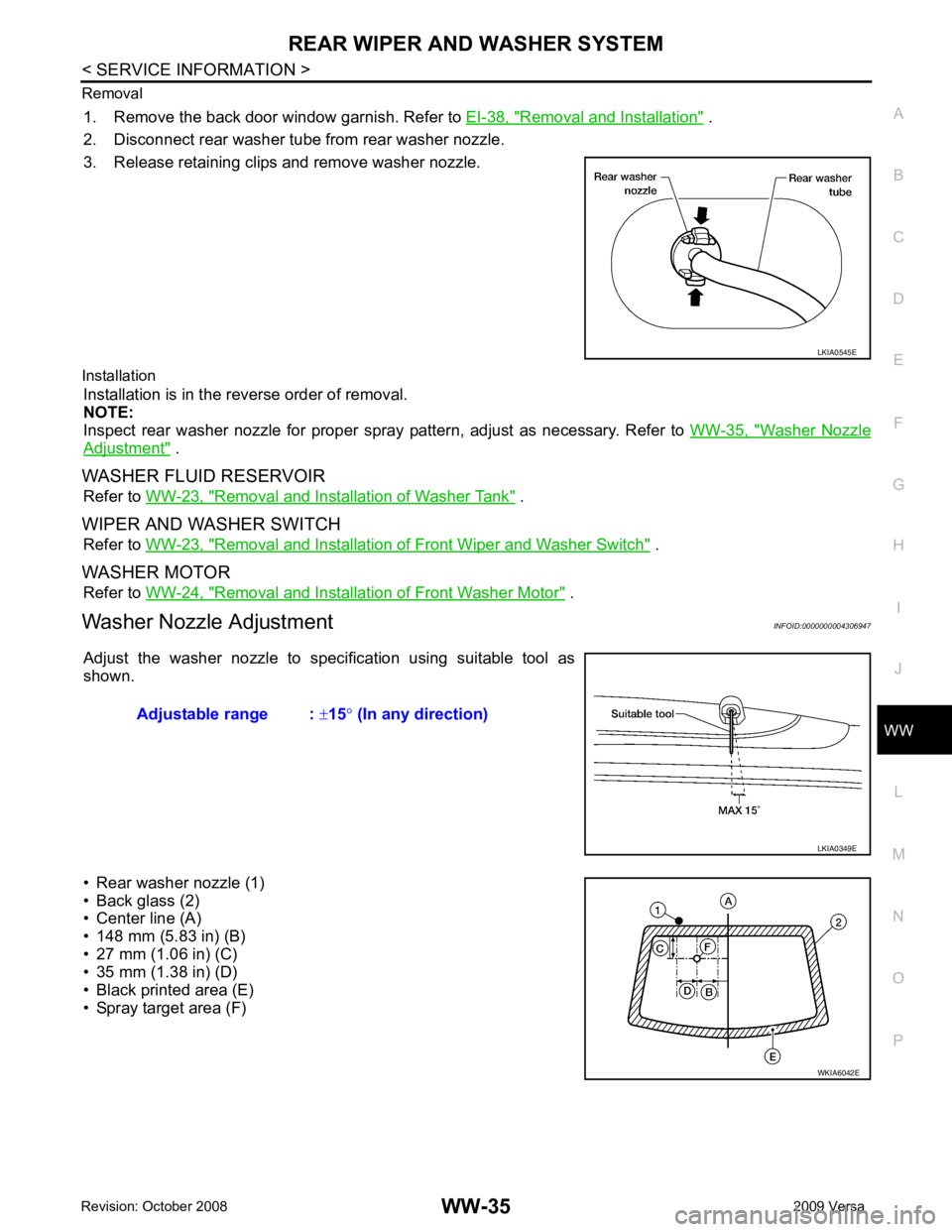

Washer Nozzle Adjustment INFOID:0000000004306947

Adjust the washer nozzle to specification using suitable tool as

shown.

• Rear washer nozzle (1)

• Back glass (2)

• Center line (A)

• 148 mm (5.83 in) (B)

• 27 mm (1.06 in) (C)

• 35 mm (1.38 in) (D)

• Black printed area (E)

• Spray target area (F) WKIA6042E