RAP NISSAN TIIDA 2009 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 930 of 4331

![NISSAN TIIDA 2009 Service Owners Manual CO-36< SERVICE INFORMATION >

[MR18DE]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

syst NISSAN TIIDA 2009 Service Owners Manual CO-36< SERVICE INFORMATION >

[MR18DE]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

syst](/img/5/57398/w960_57398-929.png)

CO-36< SERVICE INFORMATION >

[MR18DE]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be complete ly empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product and Sealant " .

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

Radiator drain plug : Refer to

CO-38, " Component " .

Cylinder block drain plug : Refer to EM-200, " Disassembly and Assembly " .

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

MA-14, " Fluids

and Lubricants " .

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2

,

80 - 120 psi) LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum LLIA0057E

Page 933 of 4331

![NISSAN TIIDA 2009 Service Owners Manual RADIATOR

CO-39

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Do not remove radiator cap when the engine is

hot. Serious burns could occur from high-pressure

engine c NISSAN TIIDA 2009 Service Owners Manual RADIATOR

CO-39

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Do not remove radiator cap when the engine is

hot. Serious burns could occur from high-pressure

engine c](/img/5/57398/w960_57398-932.png)

RADIATOR

CO-39

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A CO

NP

O

Do not remove radiator cap when the engine is

hot. Serious burns could occur from high-pressure

engine coolant escaping from radiator. Wrap a thick cl oth around the cap. Slowly turn it a quarter of a

turn to release built-up pressure. Carefully remove radiator cap by turning it all the way.

REMOVAL 1. Drain engine coolant from radiator. Refer to CO-35, " Changing Engine Coolant " .

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove engine undercover.

3. Remove air duct (inlet). Refer to EM-139 .

4. Remove reservoir tank as follows:

a. Disconnect reservoir tank hose.

b. Release the tab (A) in the direction shown by the arrow ( ).

c. Lift up while removing the reservoir tank hose, and remove it.

5. Disconnect harness connector from fan motor, and move harness aside.

6. Disconnect CVT or A/T fluid cooler hoses if equipped. • Install plug to avoid leakage of CVT or A/T fluid if equipped.

7. Remove radiator hoses (upper and lower).

8. Remove radiator core support cover. Refer to BL-19 .

9. Remove radiator core support (upper) bolts, bolts of stationary part on the radiator core support side and clip. Lift radiator from

radiator (upper) mount part of radiator core support (upper) (2).

10. Move radiator assembly (1) to the rearward direction of vehicle, and then lift it upward to remove.

CAUTION:

Do not damage or scratch A/C condenser if equipped and

radiator core when removing.

INSTALLATION Installation is in the reverse order of removal.

CAUTION:

Do not damage or scratch A/C condenser if eq uipped and radiator core when installing.

INSPECTION AFTER INSTALLATION • Check for leaks of engine coolant. Refer to CO-35, " Inspection " .

• Start and warm up engine. Visually check for leaks of engine coolant and CVT or A/T fluid if equipped. Refer

to CVT-196 or

AT-17 . PBIC3800E

PBIC3805E

Page 963 of 4331

CVT

N

O P

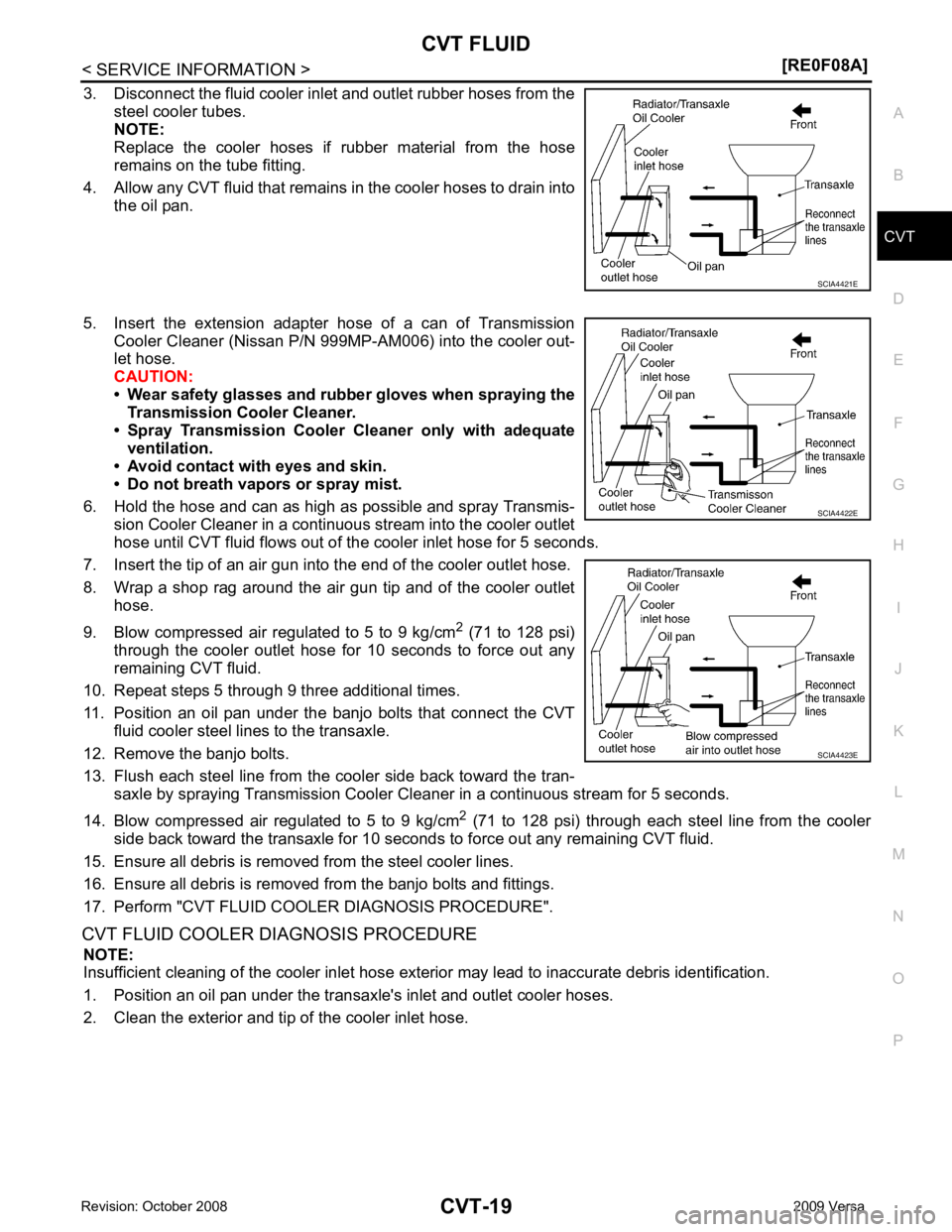

3. Disconnect the fluid cooler inle

t and outlet rubber hoses from the

steel cooler tubes.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

4. Allow any CVT fluid that remains in the cooler hoses to drain into the oil pan.

5. Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

6. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until CVT fluid flows out of t he cooler inlet hose for 5 seconds.

7. Insert the tip of an air gun into the end of the cooler outlet hose.

8. Wrap a shop rag around the air gun tip and of the cooler outlet hose.

9. Blow compressed air regulated to 5 to 9 kg/cm 2

(71 to 128 psi)

through the cooler outlet hose for 10 seconds to force out any

remaining CVT fluid.

10. Repeat steps 5 through 9 three additional times.

11. Position an oil pan under the banjo bolts that connect the CVT fluid cooler steel lines to the transaxle.

12. Remove the banjo bolts.

13. Flush each steel line from the cooler side back toward the tran- saxle by spraying Transmission Cooler Cleaner in a continuous stream for 5 seconds.

14. Blow compressed air regulated to 5 to 9 kg/cm 2

(71 to 128 psi) through each steel line from the cooler

side back toward the transaxle for 10 seconds to force out any remaining CVT fluid.

15. Ensure all debris is removed from the steel cooler lines.

16. Ensure all debris is removed from the banjo bolts and fittings.

17. Perform "CVT FLUID COOLER DIAGNOSIS PROCEDURE".

CVT FLUID COOLER DIAGNOSIS PROCEDURE NOTE:

Insufficient cleaning of the cooler inlet hose exte rior may lead to inaccurate debris identification.

1. Position an oil pan under the transax le's inlet and outlet cooler hoses.

2. Clean the exterior and tip of the cooler inlet hose.

Page 964 of 4331

![NISSAN TIIDA 2009 Service Owners Manual CVT-20< SERVICE INFORMATION >

[RE0F08A]

CVT FLUID

3. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION NISSAN TIIDA 2009 Service Owners Manual CVT-20< SERVICE INFORMATION >

[RE0F08A]

CVT FLUID

3. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION](/img/5/57398/w960_57398-963.png)

CVT-20< SERVICE INFORMATION >

[RE0F08A]

CVT FLUID

3. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

4. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until CVT fluid flows out of the cooler inlet hose for 5 seconds.

5. Tie a common white, basket-type coffee filter to the end of the cooler inlet hose.

6. Insert the tip of an air gun into the end of the cooler outlet hose.

7. Wrap a shop rag around the air gun tip and end of cooler outlet hose.

8. Blow compressed air regulated to 5 to 9 kg/cm 2

(71 to 128 psi)

through the cooler outlet hose to force any remaining CVT fluid

into the coffee filter.

9. Remove the coffee filter from the end of the cooler inlet hose.

10. Perform "CVT FLUID COOLER INSPECTION PROCEDURE".

CVT FLUID COOLER INSPECTION PROCEDURE

1. Inspect the coffee filter for debris.

a. If small metal debris less than 1 mm (0.040 in) in size or metal powder is found in the coffee filter, this is normal. If normal

debris is found, the CVT fluid cooler/radiator can be re-used and

the procedure is ended. SCIA4421E

SCIA4424E

SCIA4425E

SCIA2967E

Page 989 of 4331

![NISSAN TIIDA 2009 Service Owners Manual TROUBLE DIAGNOSIS

CVT-45

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perfor NISSAN TIIDA 2009 Service Owners Manual TROUBLE DIAGNOSIS

CVT-45

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perfor](/img/5/57398/w960_57398-988.png)

TROUBLE DIAGNOSIS

CVT-45

< SERVICE INFORMATION >

[RE0F08A] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perform tests on all items until specified symptom is found. Trou-

bleshoot items which check out No Good after road test.

CONSULT-III START PROCEDURE • Using CONSULT-III, perform a cruise test and record the result.

• Print the result and ensure that shifts and lock-ups take place as per Shift Schedule.

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch “MAIN SIGNALS” to set recording condition.

3. See “Numerical Display”, “Barchart Display” or “Line Graph Display”.

4. Touch “START”.

5. When performing cruise test. Refer to CVT-47, " Cruise Test " .

6. After finishing cruise test part, touch “RECORD”.

7. Touch “STORE”.

8. Touch “BACK”.

9. Touch “DISPLAY”.

10. Touch “PRINT”.

11. Check the monitor data printed out.

Check before Engi ne Is Started INFOID:00000000046668871.

CHECK O/D OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does O/D OFF indicator lamp come on for about 2 seconds? YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnosis and note NG items.Refer to CVT-51, " CONSULT-III Function (TRANSMISSION) " .

3. Go to CVT-45, " Check at Idle " .

NO >> Stop “Road Test”. Go to CVT-155, " O/D OFF Indicator Lamp Does Not Come On " .

Check at Idle INFOID:00000000046668881.

CHECK STARTING THE ENGINE

1. Park vehicle on flat surface.

2. Move selector lever to “P” or “N” position.

3. Turn ignition switch OFF.

4. Turn ignition switch START.

Is engine started? SAT496G

Page 1141 of 4331

![NISSAN TIIDA 2009 Service Owners Manual CVT FLUID

CVT-197

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

FLUID CONDITION CHECK

Changing CVT Fluid INFOID:0000000004305571

1. Warm up CVT fluid by driving the vehicle for 1 NISSAN TIIDA 2009 Service Owners Manual CVT FLUID

CVT-197

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

FLUID CONDITION CHECK

Changing CVT Fluid INFOID:0000000004305571

1. Warm up CVT fluid by driving the vehicle for 1](/img/5/57398/w960_57398-1140.png)

CVT FLUID

CVT-197

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

FLUID CONDITION CHECK

Changing CVT Fluid INFOID:0000000004305571

1. Warm up CVT fluid by driving the vehicle for 10 minutes.

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. Drain CVT fluid from CVT fluid cooler hose [outlet side (1)] and refill with new specified NISSAN CVT fluid in the CVT fluid

charging pipe with the engine running at idle speed.

CAUTION:

Only use the specifi ed NISSAN CVT fluid.

3. Refill until new CVT fluid comes out from CVT fluid cooler hose [outlet side (1)]. NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to CVT-196, " Checking CVT Fluid " .

CAUTION:

Delete CVT fluid deterioration date with CO NSULT-III after changing CVT fluid. Refer to CVT-230," CONSULT-III Function (TRANSMISSION) " .

CVT Fluid Cooler Cleaning INFOID:0000000004305572

Whenever a CVT is repaired, overhauled, or replaced, t he CVT fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can be trapped or become deposit in the CVT fluid cooler. This

debris can contaminate the newly serviced CVT or, in severe cases, can block or restrict the flow of CVT fluid.

In either case, malfunction of the newly serviced CVT may occur.

Debris, if present, may deposit as CVT fluid enters the cool er inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

CVT FLUID COOLER CLEANING PROCEDURE 1. Identify the CVT inlet and outlet fluid cooler hoses.

2. Position an oil pan under the inlet and outlet cooler hoses. Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorched Replace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harness, cooler

pipes, etc.)

Milky white or cloudy Water in the fluid Replace the CVT fluid and check for places where water is getting in.

Large amount of

metal powder mixed

in fluid Unusual wear of

sliding parts within

CVT Replace the CVT fluid and check for

improper operation of the CVT. ATA0022D

Fluid capacity and grade: Refer to

MA-14, " Fluids

and Lubricants " .

SCIA6088E

Page 1142 of 4331

![NISSAN TIIDA 2009 Service Owners Manual CVT-198< SERVICE INFORMATION >

[RE0F08B]

CVT FLUID

3. Disconnect the fluid cooler inle t and outlet rubber hoses from the

steel cooler tubes.

NOTE:

Replace the cooler hoses if rubber material f NISSAN TIIDA 2009 Service Owners Manual CVT-198< SERVICE INFORMATION >

[RE0F08B]

CVT FLUID

3. Disconnect the fluid cooler inle t and outlet rubber hoses from the

steel cooler tubes.

NOTE:

Replace the cooler hoses if rubber material f](/img/5/57398/w960_57398-1141.png)

CVT-198< SERVICE INFORMATION >

[RE0F08B]

CVT FLUID

3. Disconnect the fluid cooler inle t and outlet rubber hoses from the

steel cooler tubes.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

4. Allow any CVT fluid that remains in the cooler hoses to drain into the oil pan.

5. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

6. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until CVT fluid flows out of the cooler inlet hose for 5 seconds.

7. Insert the tip of an air gun into the end of the cooler outlet hose.

8. Wrap a shop rag around the air gun tip and of the cooler outlet hose.

9. Blow compressed air regulated to 5 to 9 kg/cm 2

(71 to 128 psi)

through the cooler outlet hose for 10 seconds to force out any

remaining CVT fluid.

10. Repeat steps 5 through 9 three additional times.

11. Position an oil pan under the banjo bolts that connect the CVT fluid cooler steel lines to the transaxle.

12. Remove the banjo bolts.

13. Flush each steel line from the cooler side back toward the tran- saxle by spraying Transmission Cooler Cleaner in a continuous stream for 5 seconds.

14. Blow compressed air regulated to 5 to 9 kg/cm 2

(71 to 128 psi) through each steel line from the cooler

side back toward the transaxle for 10 seconds to force out any remaining CVT fluid.

15. Ensure all debris is removed from the steel cooler lines.

16. Ensure all debris is removed from the banjo bolts and fittings.

17. Perform "CVT FLUID COOLER DIAGNOSIS PROCEDURE".

CVT FLUID COOLER DIAGNOSIS PROCEDURE

NOTE:

Insufficient cleaning of the cooler inlet hose exte rior may lead to inaccurate debris identification.

1. Position an oil pan under the transaxle's inlet and outlet cooler hoses.

2. Clean the exterior and tip of the cooler inlet hose. SCIA4421E

SCIA4422E

SCIA4423E

Page 1143 of 4331

![NISSAN TIIDA 2009 Service Owners Manual CVT FLUID

CVT-199

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

3. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) int NISSAN TIIDA 2009 Service Owners Manual CVT FLUID

CVT-199

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

3. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) int](/img/5/57398/w960_57398-1142.png)

CVT FLUID

CVT-199

< SERVICE INFORMATION >

[RE0F08B] D

E

F

G H

I

J

K L

M A

B CVT

N

O P

3. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

4. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until CVT fluid flows out of t he cooler inlet hose for 5 seconds.

5. Tie a common white, basket-type coffee filter to the end of the cooler inlet hose.

6. Insert the tip of an air gun into the end of the cooler outlet hose.

7. Wrap a shop rag around the air gun tip and end of cooler outlet hose.

8. Blow compressed air regulated to 5 to 9 kg/cm 2

(71 to 128 psi)

through the cooler outlet hose to force any remaining CVT fluid

into the coffee filter.

9. Remove the coffee filter from the end of the cooler inlet hose.

10. Perform "CVT FLUID COOLER INSPECTION PROCEDURE".

CVT FLUID COOLER INSPECTION PROCEDURE 1. Inspect the coffee filter for debris.

a. If small metal debris less than 1 mm (0.040 in) in size or metal powder is found in the coffee filter, this is normal. If normal

debris is found, the CVT fluid cooler/radiator can be re-used and

the procedure is ended. SCIA4421E

SCIA4424E

SCIA4425E

SCIA2967E

Page 1168 of 4331

![NISSAN TIIDA 2009 Service Owners Manual CVT-224< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS

• Before road test, familiarize yourself with all test procedures and items to check.

• Perform tests on all items until s NISSAN TIIDA 2009 Service Owners Manual CVT-224< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS

• Before road test, familiarize yourself with all test procedures and items to check.

• Perform tests on all items until s](/img/5/57398/w960_57398-1167.png)

CVT-224< SERVICE INFORMATION >

[RE0F08B]

TROUBLE DIAGNOSIS

• Before road test, familiarize yourself with all test procedures and items to check.

• Perform tests on all items until s pecified symptom is found. Trou-

bleshoot items which check out No Good after road test.

CONSULT-III START PROCEDURE

• Using CONSULT-III, perform a cruise test and record the result.

• Print the result and ensure that shifts and lock-ups take place as per Shift Schedule.

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch “MAIN SIGNALS” to set recording condition.

3. See “Numerical Display”, “Barchart Display” or “Line Graph Display”.

4. Touch “START”.

5. When performing cruise test. Refer to CVT-226, " Cruise Test " .

6. After finishing cruise test part, touch “RECORD”.

7. Touch “STORE”.

8. Touch “BACK”.

9. Touch “DISPLAY”.

10. Touch “PRINT”.

11. Check the monitor data printed out. Check before Engine Is Started INFOID:00000000043055951.

CHECK O/D OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does O/D OFF indicator lamp come on for about 2 seconds? YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnosis and note NG items.Refer to CVT-230, " CONSULT-III Function (TRANSMISSION) " .

3. Go to CVT-224, " Check at Idle " .

NO >> Stop “Road Test”. Go to CVT-325, " O/D OFF Indicator Lamp Does Not Come On " .

Check at Idle INFOID:00000000043055961.

CHECK STARTING THE ENGINE

1. Park vehicle on flat surface.

2. Move selector lever to “P” or “N” position.

3. Turn ignition switch OFF.

4. Turn ignition switch START.

Is engine started? SAT496G

Page 1888 of 4331

![NISSAN TIIDA 2009 Service Owners Manual EC-532< SERVICE INFOMATION >

[MR TYPE 1]

EVAPORATIVE EMISSION SYSTEM

3. Turn ignition switch ON.

4. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

5. Touch “START� NISSAN TIIDA 2009 Service Owners Manual EC-532< SERVICE INFOMATION >

[MR TYPE 1]

EVAPORATIVE EMISSION SYSTEM

3. Turn ignition switch ON.

4. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

5. Touch “START�](/img/5/57398/w960_57398-1887.png)

EC-532< SERVICE INFOMATION >

[MR TYPE 1]

EVAPORATIVE EMISSION SYSTEM

3. Turn ignition switch ON.

4. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

5. Touch “START”. A bar graph (Pressure indicating display) will appear on the screen.

6. Apply positive pressure to the EVAP system until t he pressure indicator reaches the middle of the bar

graph.

7. Remove EVAP service port adapter and hose with pressure pump.

8. Locate the leak using a leak detector. Refer to EC-527," Description " .

WITHOUT CONSULT-III

1. Attach the EVAP service port adapter securely to the EVAP ser- vice port.

2. Also attach the pressure pump with pressure gauge to the EVAP service port adapter.

3. Apply battery voltage to the terminal of EVAP canister vent con- trol valve (3) to make a closed EVAP system.

• EVAP control system pressure sensor (1)

• EVAP canister (2)

4. To locate the leak, deliver positive pressure to the EVAP system until pressure gauge points reach 1.38 to

2.76 kPa (0.014 to 0.028 kg/cm 2

, 0.2 to 0.4 psi).

5. Remove EVAP service port adapter and hose with pressure pump.

6. Locate the leak using a leak detector. Refer to EC-527, " Description " . SEF200U

SEF462UC

BBIA0693E