RAP NISSAN TIIDA 2009 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3418 of 4331

![NISSAN TIIDA 2009 Service Manual PDF PRECAUTIONS

LAN-23

< PRECAUTION >

[CAN] C

D E

F

G H

I

J

L

M A

B LAN

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:000 NISSAN TIIDA 2009 Service Manual PDF PRECAUTIONS

LAN-23

< PRECAUTION >

[CAN] C

D E

F

G H

I

J

L

M A

B LAN

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:000](/img/5/57398/w960_57398-3417.png)

PRECAUTIONS

LAN-23

< PRECAUTION >

[CAN] C

D E

F

G H

I

J

L

M A

B LAN

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004498345

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIRBAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

• Never use electrical test equipment on any circuit re lated to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identifi ed by yellow and/or orange harnesses or harness

connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precautions for Trouble Diagnosis INFOID:0000000004306699

CAUTION:

• Never apply 7.0 V or more to the measurement terminal.

• Use a tester with open terminal voltage of 7.0 V or less.

• Turn the ignition switch OFF and disconnect th e battery cable from the negative terminal when

checking the harness.

Precautions for Harness Repair INFOID:0000000004306700

• Solder the repaired area and wrap tape around the soldered area. NOTE:

A fray of twisted lines must be within 110 mm (4.33 in). SKIB8766E

Page 3724 of 4331

![NISSAN TIIDA 2009 Service Manual PDF PRECAUTIONS

LU-3

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

Precaution for Liquid Gasket

INFOID:0000000004784386

REMOVAL OF LIQUID GASKET SEALING • After removing nuts and bolts, separa NISSAN TIIDA 2009 Service Manual PDF PRECAUTIONS

LU-3

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

Precaution for Liquid Gasket

INFOID:0000000004784386

REMOVAL OF LIQUID GASKET SEALING • After removing nuts and bolts, separa](/img/5/57398/w960_57398-3723.png)

PRECAUTIONS

LU-3

< PRECAUTION >

[HR16DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

Precaution for Liquid Gasket

INFOID:0000000004784386

REMOVAL OF LIQUID GASKET SEALING • After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap Tool to insert it (1), and then slide it by tapping on the side (2) as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE 1. Remove old liquid gasket adhering to the liquid gasket applica- tion surface and the mating surface, using scraper.

• Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-42, " Recommended Chemical Prod-

uct and Sealant " .

4. Apply liquid gasket without breaks to the spec ified location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

• As for the bolt holes, normally apply liquid gasket inside the holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

• Within five minutes of liquid gasket application, install the mat- ing component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten nuts or bolts after the installation.

• After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

Tool number : WS39930000 ( — )

PBIC0003E

WBIA0567E

SEM159F

Page 3733 of 4331

![NISSAN TIIDA 2009 Service Manual PDF LU-12< SERVICE INFORMATION >

[MR18DE]

PRECAUTIONS

Precaution for Liquid Gasket INFOID:0000000004788557

REMOVAL OF LIQUID GASKET SEALING

• After removing nuts and bolts, separate the mating surface, NISSAN TIIDA 2009 Service Manual PDF LU-12< SERVICE INFORMATION >

[MR18DE]

PRECAUTIONS

Precaution for Liquid Gasket INFOID:0000000004788557

REMOVAL OF LIQUID GASKET SEALING

• After removing nuts and bolts, separate the mating surface,](/img/5/57398/w960_57398-3732.png)

LU-12< SERVICE INFORMATION >

[MR18DE]

PRECAUTIONS

Precaution for Liquid Gasket INFOID:0000000004788557

REMOVAL OF LIQUID GASKET SEALING

• After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap Tool to insert it (1), and then slide it by tapping on the side (2) as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful no t to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket applica- tion surface and the mating surface, using scraper.

• Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-42, " Recommended Chemical Prod-

uct and Sealant " .

4. Apply liquid gasket without breaks to the specif ied location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

• As for the bolt holes, normally apply liquid gasket inside the holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

• Within five minutes of liquid gasket application, install the mat- ing component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten nuts or bolts after the installation.

• After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

Tool number : WS39930000 ( — )

PBIC0003E

WBIA0567E

SEM159F

Page 3760 of 4331

ENGINE MAINTENANCE (HR16DE)

MA-17

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K

M A

B MA

N

O P

• When the lock nut is loosened excessively, the idle

r pulley tilts and the correct tension adjust-

ment cannot be performed. Never loo sen it excessively (more than 45 degrees).

• Put a matching mark on the lock nut, and check turning angle with a protractor. Never visually

check the tightening angle.

2. Adjust the belt tension by turning the adjusting bolt. CAUTION:

• When checking immediately after in stallation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, re-adjust to the specified value to avoid variation in deflec-

tion between pulleys.

• When the tension adjustment is performed, the lo ck nut should be in the condition at step“2”. If

the tension adjustment is performed when the lo ck nut is loosened more than the standard, the

idler pulley tilts and the correct tens ion adjustment cannot be performed.

3. Tighten the idler pulley lock nut.

ENGINE COOLANT

ENGINE COOLANT : Inspection INFOID:0000000004806014

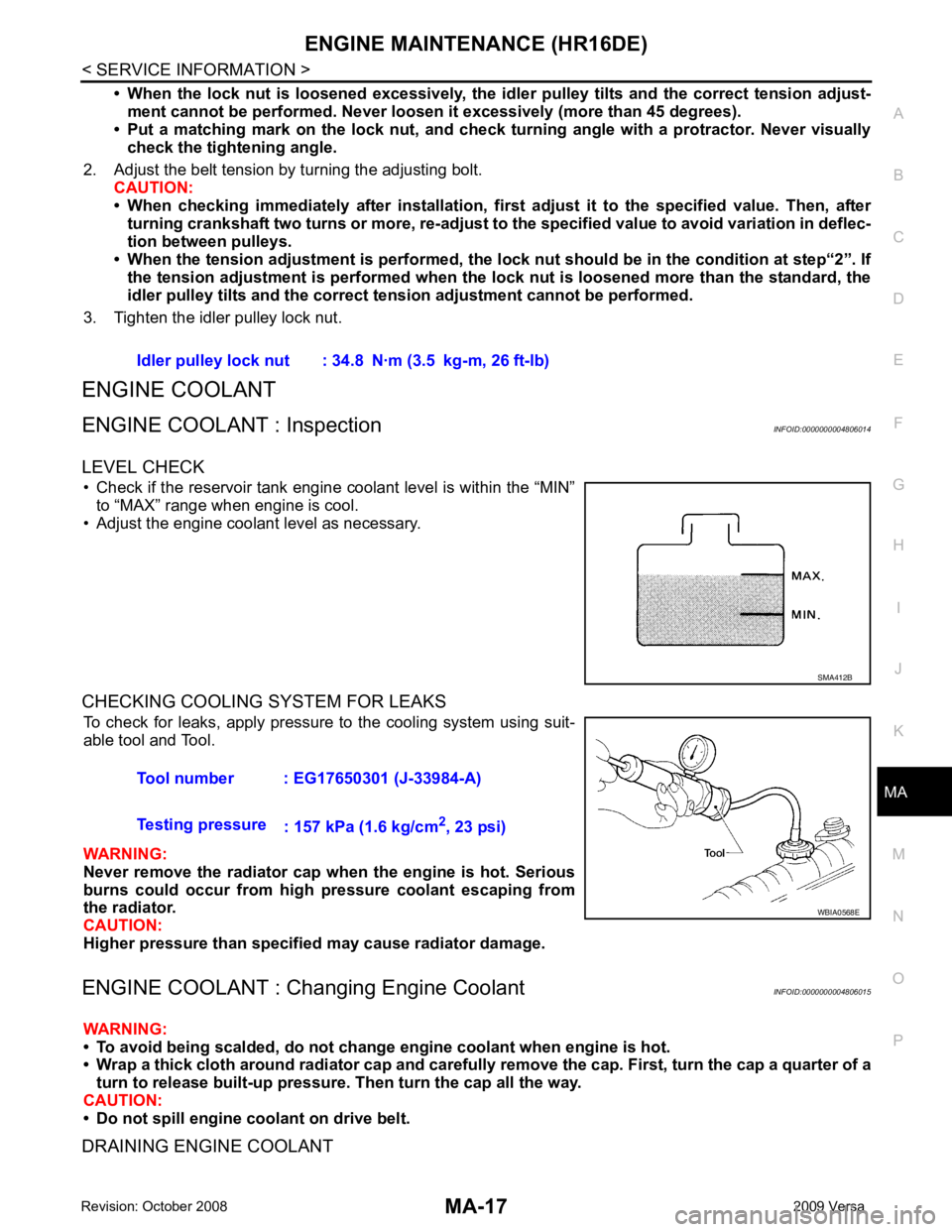

LEVEL CHECK • Check if the reservoir tank engine coolant level is within the “MIN” to “MAX” range when engine is cool.

• Adjust the engine coolant level as necessary.

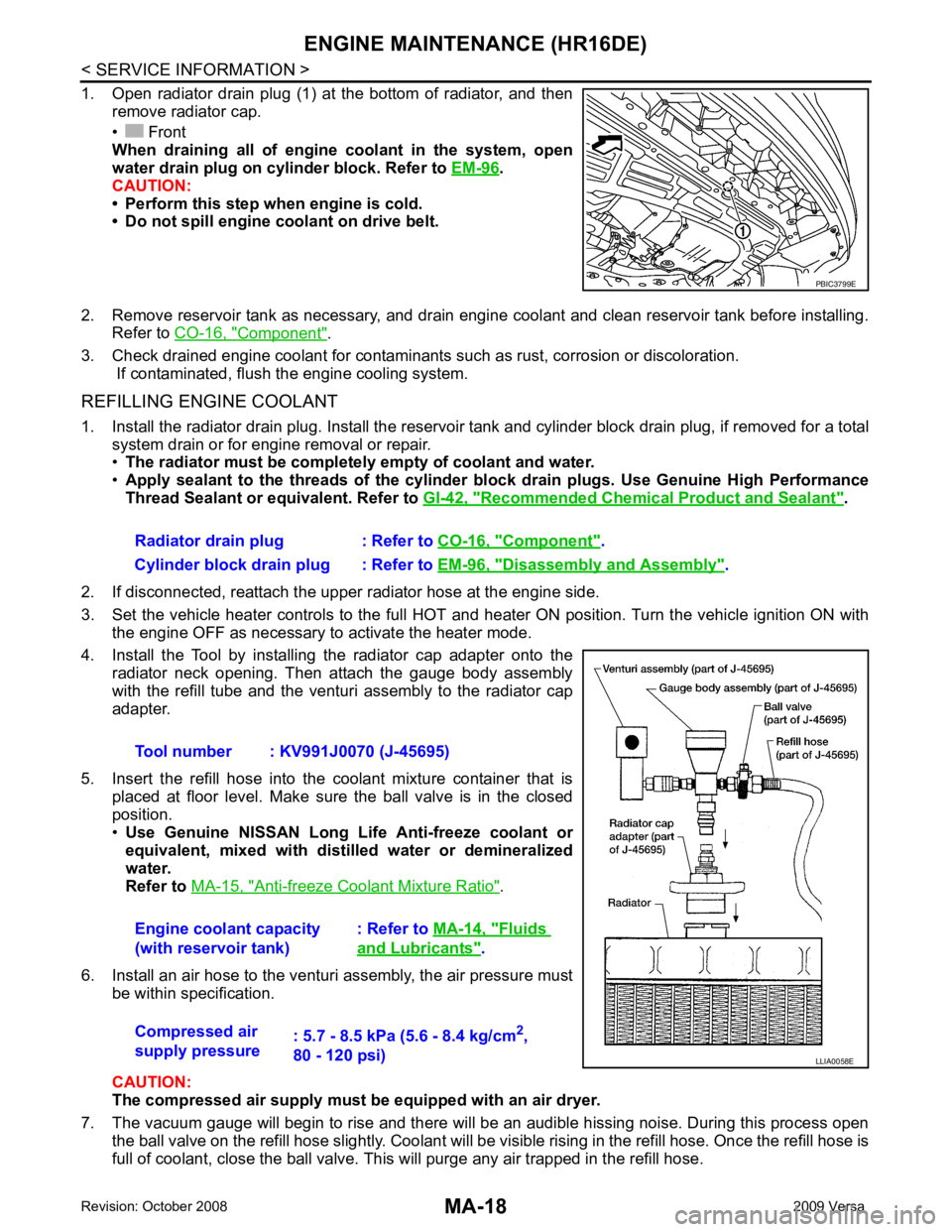

CHECKING COOLING SYSTEM FOR LEAKS To check for leaks, apply pressure to the cooling system using suit-

able tool and Tool.

WARNING:

Never remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLANT : Chang ing Engine Coolant INFOID:0000000004806015

WARNING:

• To avoid being scalded, do not change engine coolant when engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

CAUTION:

• Do not spill engine coolant on drive belt.

DRAINING ENGINE COOLANT Idler pulley lock nut : 34.8 N·m (3.5 kg-m, 26 ft-lb)

SMA412B

Tool number : EG17650301 (J-33984-A)

Testing pressure : 157 kPa (1.6 kg/cm 2

, 23 psi) WBIA0568E

Page 3761 of 4331

MA-18< SERVICE INFORMATION >

ENGINE MAINTENANCE (HR16DE)

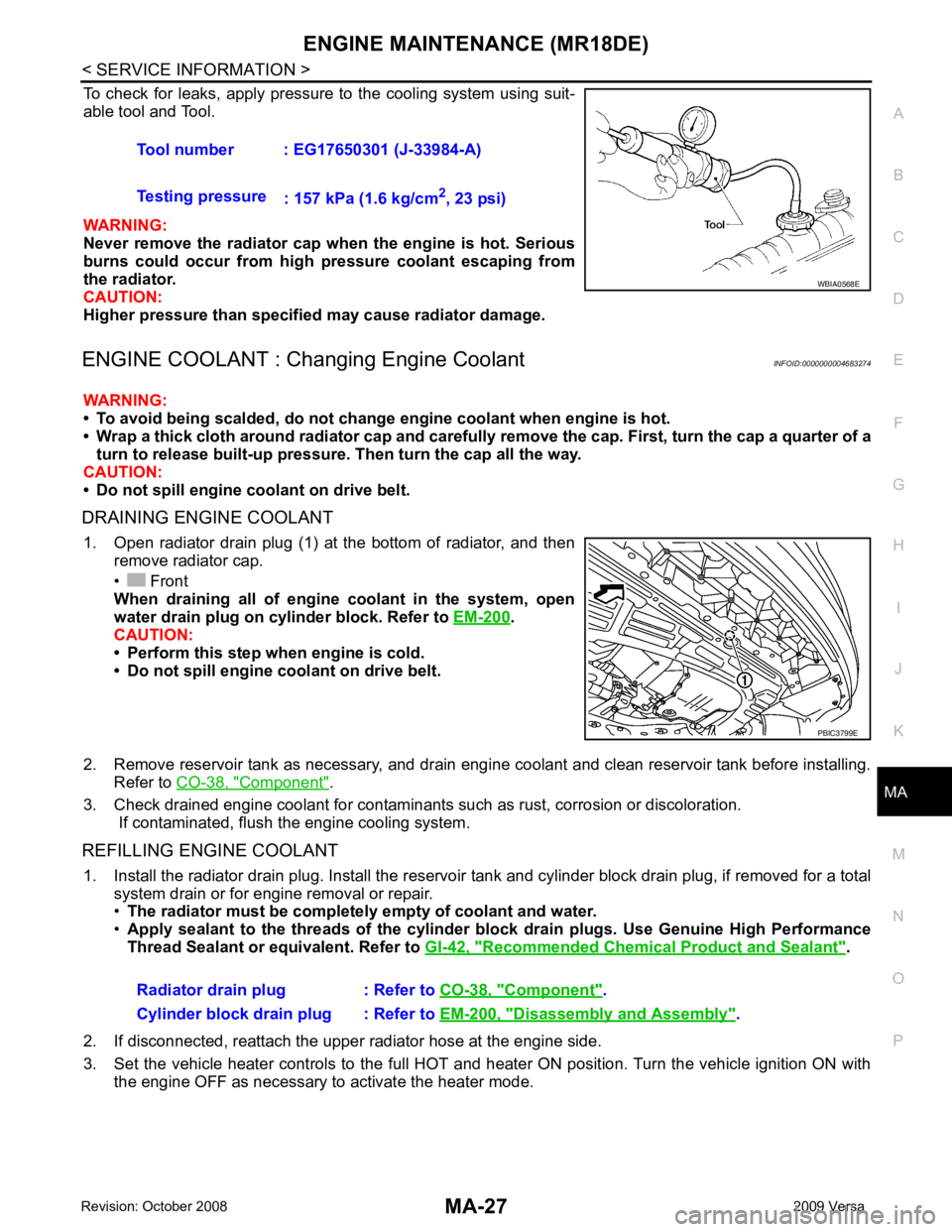

1. Open radiator drain plug (1) at the bottom of radiator, and then remove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-96 .

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing. Refer to CO-16, " Component " .

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be complete ly empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product and Sealant " .

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose. PBIC3799E

Radiator drain plug : Refer to

CO-16, " Component " .

Cylinder block drain plug : Refer to EM-96, " Disassembly and Assembly " .

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

MA-14, " Fluids

and Lubricants " .

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2

,

80 - 120 psi) LLIA0058E

Page 3770 of 4331

ENGINE MAINTENANCE (MR18DE)

MA-27

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K

M A

B MA

N

O P

To check for leaks, apply pressure to the cooling system using suit-

able tool and Tool.

WARNING:

Never remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLANT : Chang ing Engine Coolant INFOID:0000000004683274

WARNING:

• To avoid being scalded, do not change engine coolant when engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

CAUTION:

• Do not spill engine coolant on drive belt.

DRAINING ENGINE COOLANT 1. Open radiator drain plug (1) at the bottom of radiator, and then remove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-200 .

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engi ne coolant and clean reservoir tank before installing.

Refer to CO-38, " Component " .

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT 1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be complete ly empty of coolant and water.

• Apply sealant to the threads of the cylinder blo ck drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product and Sealant " .

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode. Tool number : EG17650301 (J-33984-A)

Testing pressure : 157 kPa (1.6 kg/cm 2

, 23 psi) WBIA0568E

PBIC3799E

Radiator drain plug : Refer to

CO-38, " Component " .

Cylinder block drain plug : Refer to EM-200, " Disassembly and Assembly " .

Page 3771 of 4331

MA-28< SERVICE INFORMATION >

ENGINE MAINTENANCE (MR18DE)

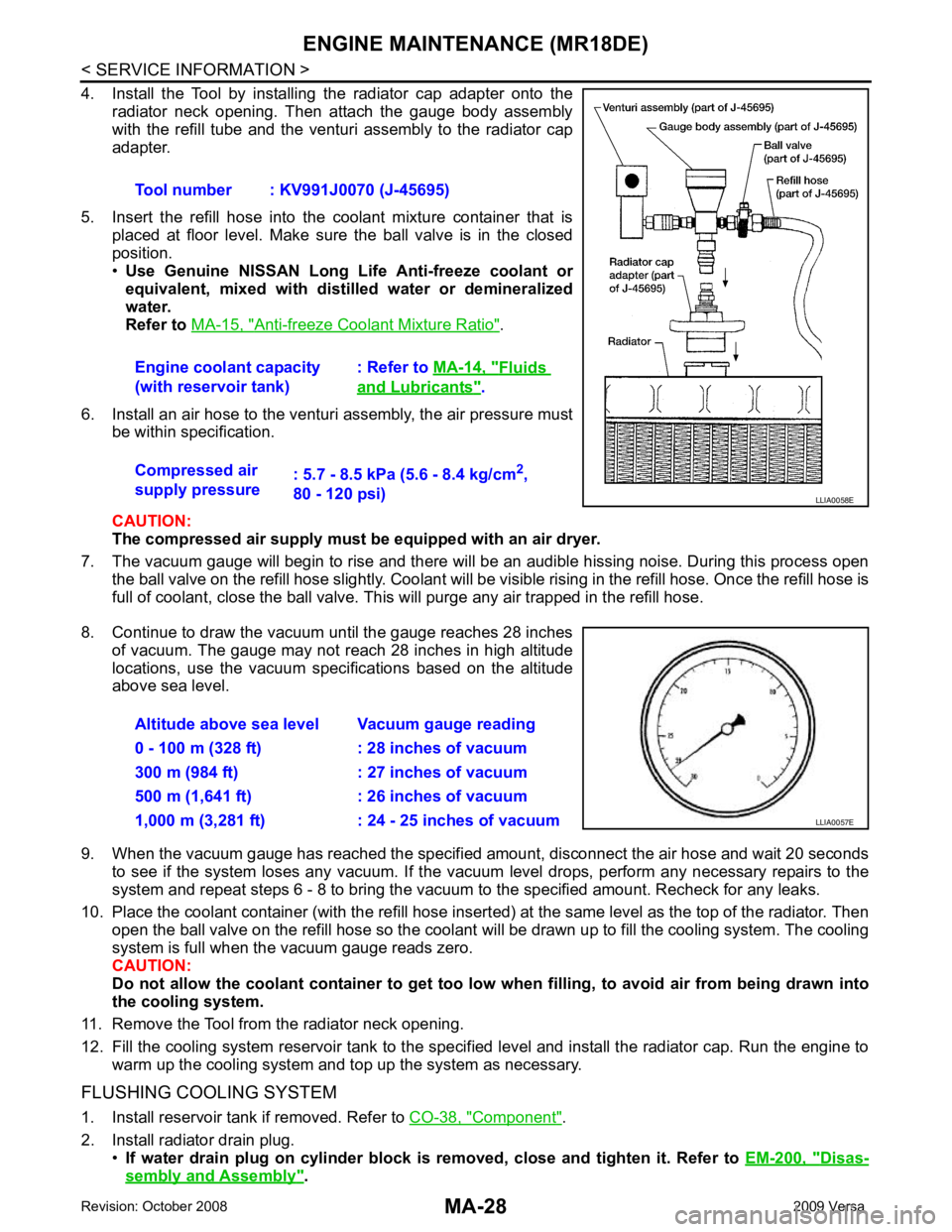

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, " Anti-freeze Coolant Mixture Ratio " .

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose insert ed) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specif ied level and install the radiator cap. Run the engine to

warm up the cooling system and t op up the system as necessary.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed. Refer to CO-38, " Component " .

2. Install radiator drain plug. •If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-200, " Disas-

sembly and Assembly " .

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

MA-14, " Fluids

and Lubricants " .

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2

,

80 - 120 psi) LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum LLIA0057E

Page 3823 of 4331

MT

N

O P

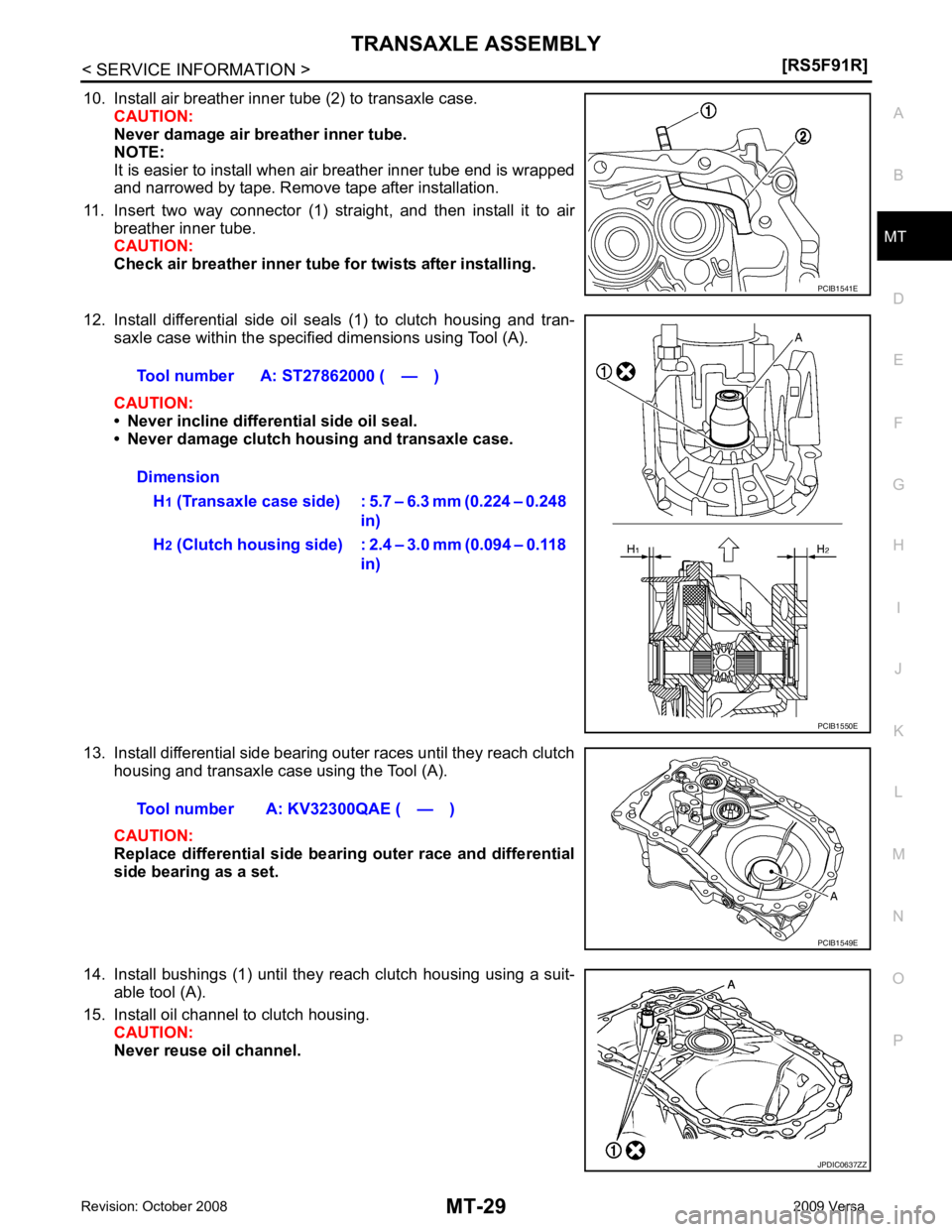

10. Install air breather inner tube (2) to transaxle case.

CAUTION:

Never damage air breather inner tube.

NOTE:

It is easier to install when air breather inner tube end is wrapped

and narrowed by tape. Remove tape after installation.

11. Insert two way connector (1) straight, and then install it to air breather inner tube.

CAUTION:

Check air breather inner tube fo r twists after installing.

12. Install differential side oil seals (1) to clutch housing and tran- saxle case within the specified dimensions using Tool (A).

CAUTION:

• Never incline differential side oil seal.

• Never damage clutch housing and transaxle case.

13. Install differential side bearing outer races until they reach clutch housing and transaxle case using the Tool (A).

CAUTION:

Replace differential side bearing outer race and differential

side bearing as a set.

14. Install bushings (1) until they reach clutch housing using a suit- able tool (A).

15. Install oil channel to clutch housing. CAUTION:

Never reuse oil channel. JPDIC0637ZZ

Page 3889 of 4331

MTC-4< SERVICE INFORMATION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Procedure without Cowl Top Cover INFOID:0000000004307042

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Working with HFC-134a (R-134a) INFOID:0000000004307043

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) re frigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. If the refrigerants are mixed a compressor mal-

function is likely to occur.

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specifi ed is used, compressor malf unction is likely to occur.

• The specified HFC-134a (R-134a) oi l rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

- When installing refrigerant co mponents to a vehicle, do not remove the caps (unseal) until just

before connecting the components . Connect all refrigerant loop components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without

proper sealing, oil will become moisture saturat ed and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If acci-

dental system discharge occurs, ventilate work area before resuming service. Additional health and

safety information may be obtained fr om refrigerant and oil manufacturers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

General Refrigerant Precaution INFOID:0000000004307044

WARNING:

• Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If acci-

dental system discharge occurs, ventilate work area before resuming service. Additional health and

safety information may be obtained fr om refrigerant and oil manufacturers.

• Do not release refrigerant into th e air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

• Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

• Do not store or heat refrigerant containers above 52 °C (126 ° F).

• Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

• Do not intentionally drop, puncture, or incinerate refrigerant containers.

• Keep refrigerant away from open flames: poisonou s gas will be produced if refrigerant burns.

• Refrigerant will displace oxygen, therefore be certa in to work in well ventilated areas to prevent suf-

focation.

• Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condition-

ing systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have PIIB3706J

Page 3890 of 4331

MTC

N

O P

been shown to be combustible at

elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional health and safety info rmation may be obtained from refrigerant manu-

facturers.

Oil Precaution INFOID:0000000004307045

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If oil

other than that specified is used, comp ressor malfunction is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorbs mo isture from the atmosphere. The following handling

precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to minimize the entry of moisture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just before con- necting the components. Connect all refrigerant loop components as quickly as possible to minimize the

entry of moisture into system.

- Only use the specified oil from a sealed container. Imm ediately reseal containers of oil. Without proper seal-

ing, oil will become moisture saturated and should not be used.

• Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant. If accidental

system discharge occurs, ventilate work area before re suming service. Additional health and safety informa-

tion may be obtained from refrigerant and oil manufacturers.

• Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Precaution for Refrigerant Connection INFOID:0000000004307046

A new type refrigerant connection has been introduced to a ll refrigerant lines except the following location.

• Expansion valve to evaporator

• Refrigerant pressure sensor to condenser

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

• The O-ring has been relocated. It has also been provided with a groove for proper installation. This elimi- nates the chance of the O-ring being caught in, or damaged by, the mating part. The sealing direction of the

O-ring is now set vertically in relation to the contacti ng surface of the mating part to improve sealing charac-

teristics.

• The reaction force of the O-ring will not occur in the dire ction that causes the joint to pull out, thereby facili-

tating piping connections.

O-RING AND REFRIGERANT CONNECTION