RAP NISSAN TIIDA 2009 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3998 of 4331

PG

N

O P

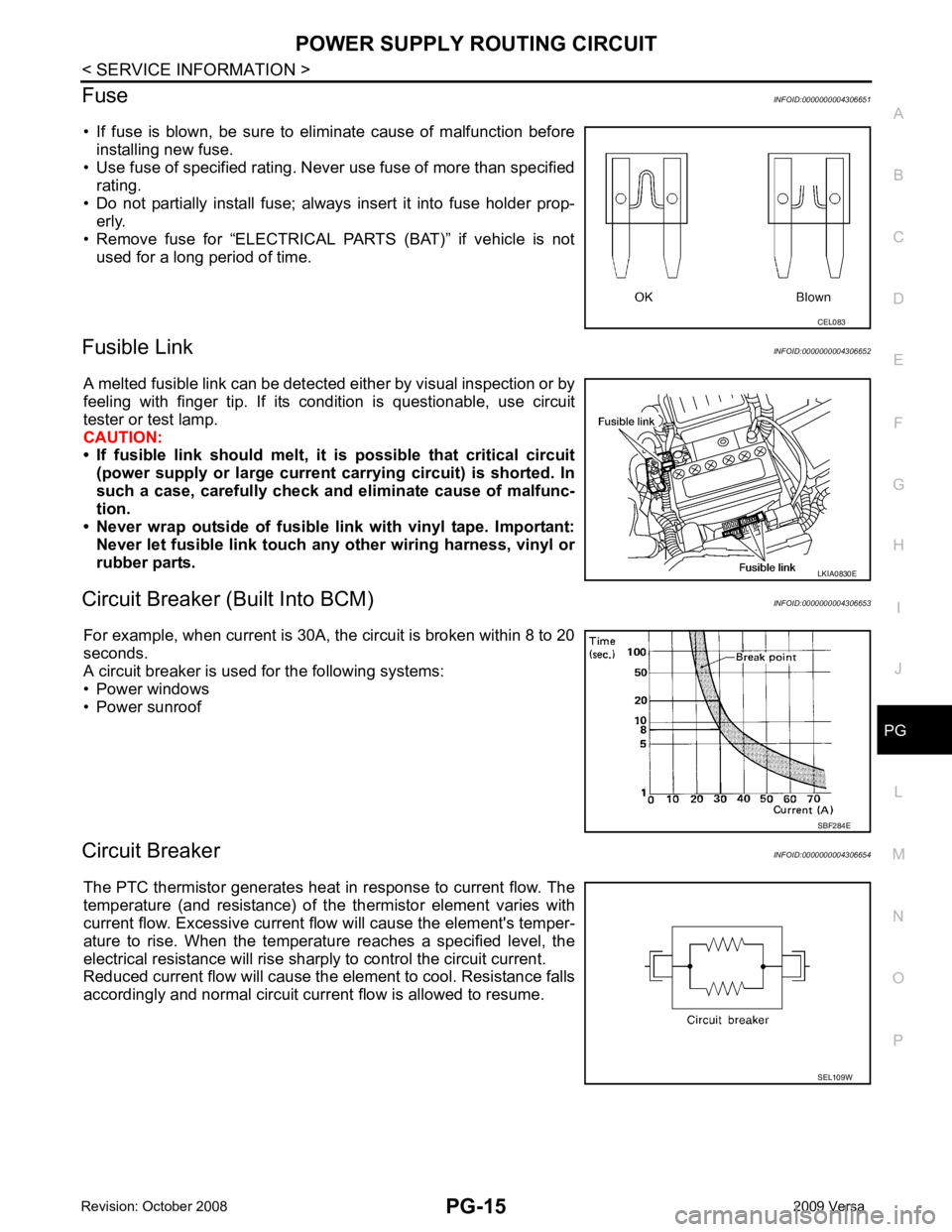

Fuse

INFOID:0000000004306651

• If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

• Use fuse of specified rating. Never use fuse of more than specified

rating.

• Do not partially install fuse; always insert it into fuse holder prop- erly.

• Remove fuse for “ELECTRICAL PARTS (BAT)” if vehicle is not

used for a long period of time.

Fusible Link INFOID:0000000004306652

A melted fusible link can be detected either by visual inspection or by

feeling with finger tip. If its condition is questionable, use circuit

tester or test lamp.

CAUTION:

• If fusible link should melt, it is possible that critical circuit

(power supply or large current carrying circuit) is shorted. In

such a case, carefully check and eliminate cause of malfunc-

tion.

• Never wrap outside of fusible li nk with vinyl tape. Important:

Never let fusible link touch any other wiring harness, vinyl or

rubber parts.

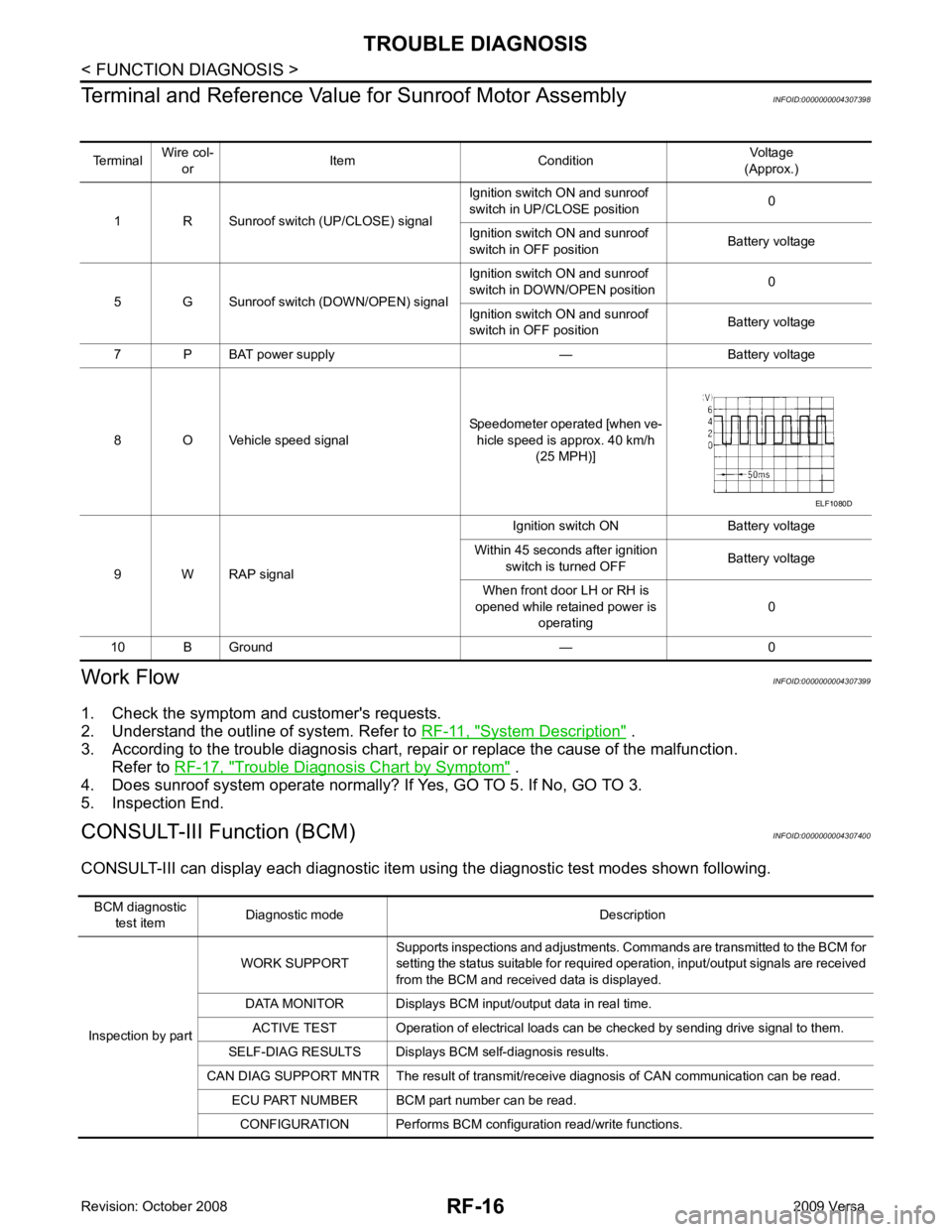

Circuit Breaker (B uilt Into BCM) INFOID:0000000004306653

For example, when current is 30A, the circuit is broken within 8 to 20

seconds.

A circuit breaker is used for the following systems:

• Power windows

• Power sunroof

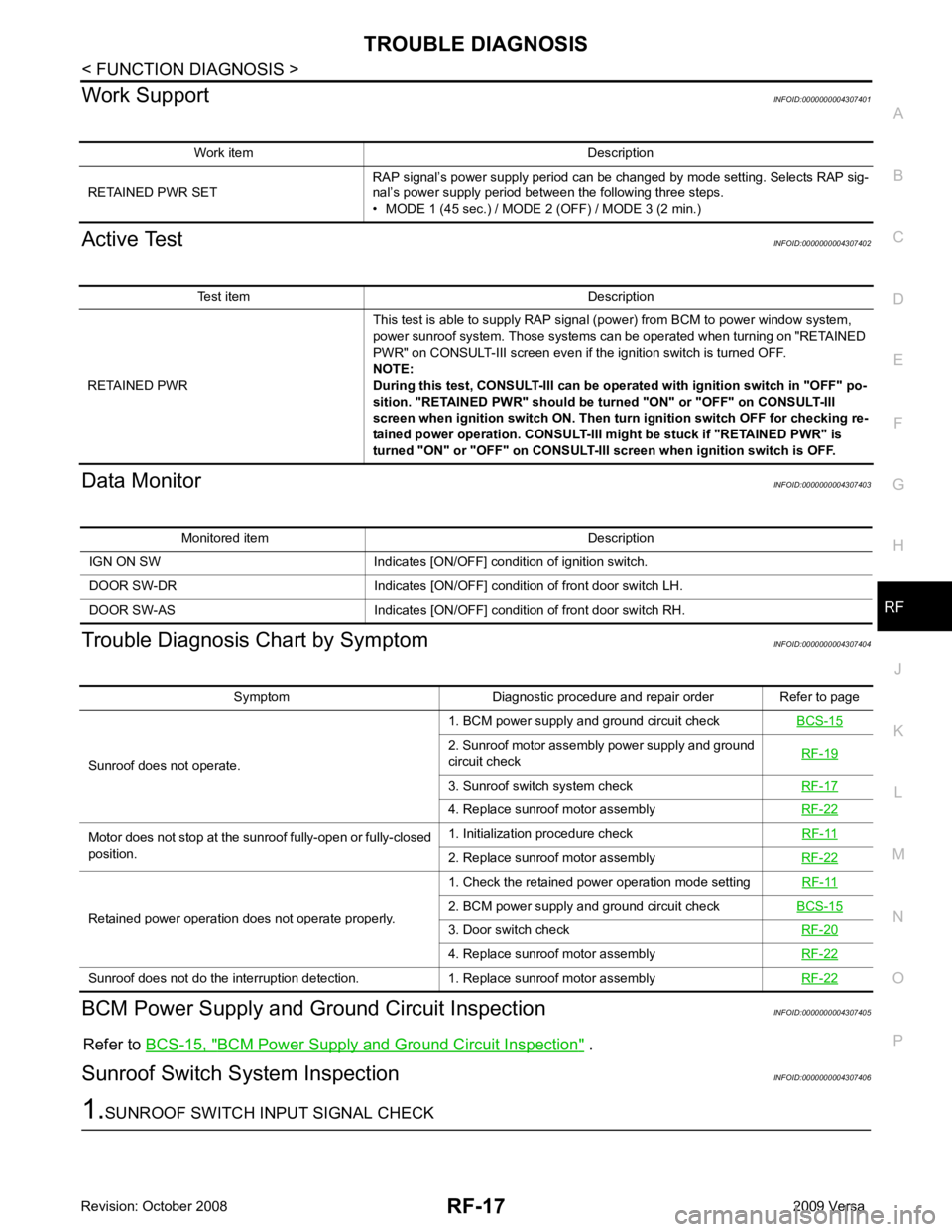

Circuit Breaker INFOID:0000000004306654

The PTC thermistor generates heat in response to current flow. The

temperature (and resistance) of t he thermistor element varies with

current flow. Excessive current flow will cause the element's temper-

ature to rise. When the temperature reaches a specified level, the

electrical resistance will rise shar ply to control the circuit current.

Reduced current flow will cause the element to cool. Resistance falls

accordingly and normal circuit current flow is allowed to resume. LKIA0830E

SEL109W

Page 4084 of 4331

RF

N

O P

• When removing or disassembling any part, be careful

not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts with a screwdriver or other tool , protect parts by wrapping them with vinyl or tape.

• Keep removed parts protected with cloth.

• If a clip is deformed or damaged, replace it.

• If an unreusable part is removed, replace it with a new one.

• Tighten bolts and nuts firmly to the specified torque.

• After re-assembly has been completed, make sure each part functions correctly.

• Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tight ly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

• Do not use any organic solvent, such as thinner or benzine.

Page 4097 of 4331

System Description " .

3. According to the trouble diagnosis chart, repa ir or replace the cause of the malfunction.

Refer to RF-17, " Trouble Diagnosis Chart by Symptom " .

4. Does sunroof system operate normally? If Yes, GO TO 5. If No, GO TO 3.

5. Inspection End.

CONSULT-III Function (BCM) INFOID:0000000004307400

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

Terminal

Wire col-

or Item Condition

Voltage

(Approx.)

1 R Sunroof switch (UP/CLOSE) signal Ignition switch ON and sunroof

switch in UP/CLOSE position 0

Ignition switch ON and sunroof

switch in OFF position Battery voltage

5 G Sunroof switch (DOWN/OPEN) signal Ignition switch ON and sunroof

switch in DOWN/OPEN position 0

Ignition switch ON and sunroof

switch in OFF position Battery voltage

7 P BAT power supply — Battery voltage

8 O Vehicle speed signal Speedometer operated [when ve-

hicle speed is approx. 40 km/h (25 MPH)]

9 W RAP signal Ignition switch ON Battery voltage

Within 45 seconds after ignition switch is turned OFF Battery voltage

When front door LH or RH is

opened while retained power is

operating 0

10 B Ground — 0

Page 4098 of 4331

RF

N

O P

Work Support

INFOID:0000000004307401

Active Test INFOID:0000000004307402

Data Monitor INFOID:0000000004307403

Trouble Diagnosis Chart by Symptom INFOID:0000000004307404

BCM Power Supply and Gr ound Circuit Inspection INFOID:0000000004307405

Refer to BCS-15, " BCM Power Supply and Ground Circuit Inspection " .

Sunroof Switch System Inspection INFOID:0000000004307406Test item Description

RETAINED PWR This test is able to supply RAP signal (power) from BCM to power window system,

power sunroof system. Those systems can be operated when turning on "RETAINED

PWR" on CONSULT-III screen even if the ignition switch is turned OFF.

NOTE:

During this test, CONSULT-III can be operated with ignition switch in "OFF" po-

sition. "RETAINED PWR" should be turned "ON" or "OFF" on CONSULT-III

screen when ignition switch ON. Then turn ignition switch OFF for checking re-

tained power operation. CONSULT-III might be stuck if "RETAINED PWR" is

turned "ON" or "OFF" on CONSULT-III screen when ignition switch is OFF. Symptom Diagnostic procedure and repair order Refer to page

Sunroof does not operate. 1. BCM power supply and ground circuit check

BCS-15 2. Sunroof motor assembly power supply and ground

circuit check RF-19 3. Sunroof switch system check

RF-17 4. Replace sunroof motor assembly

RF-22Motor does not stop at the sunroof fully-open or fully-closed

position. 1. Initialization procedure check

RF-11 2. Replace sunroof motor assembly

RF-22Retained power operation does not operate properly.

1. Check the retained power operation mode setting

RF-11 2. BCM power supply and ground circuit check

BCS-15 3. Door switch check

RF-20 4. Replace sunroof motor assembly

RF-22Sunroof does not do the interruption detection. 1. Replace sunroof motor assembly

RF-22

Page 4120 of 4331

RSU

N

O P

SHOCK ABSORBER

Removal and Installation INFOID:0000000004305881

REMOVAL 1. Remove wheel and tire using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly and rear suspension beam. Refer to BRC-32 .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove shock absorber mask from trunk side fini sher using a flat-bladed screwdriver. Refer to EI-53 .

CAUTION:

Wrap the tip of a screwdriver with cl oth to avoid damaging components.

4. Set jack under rear suspension beam.

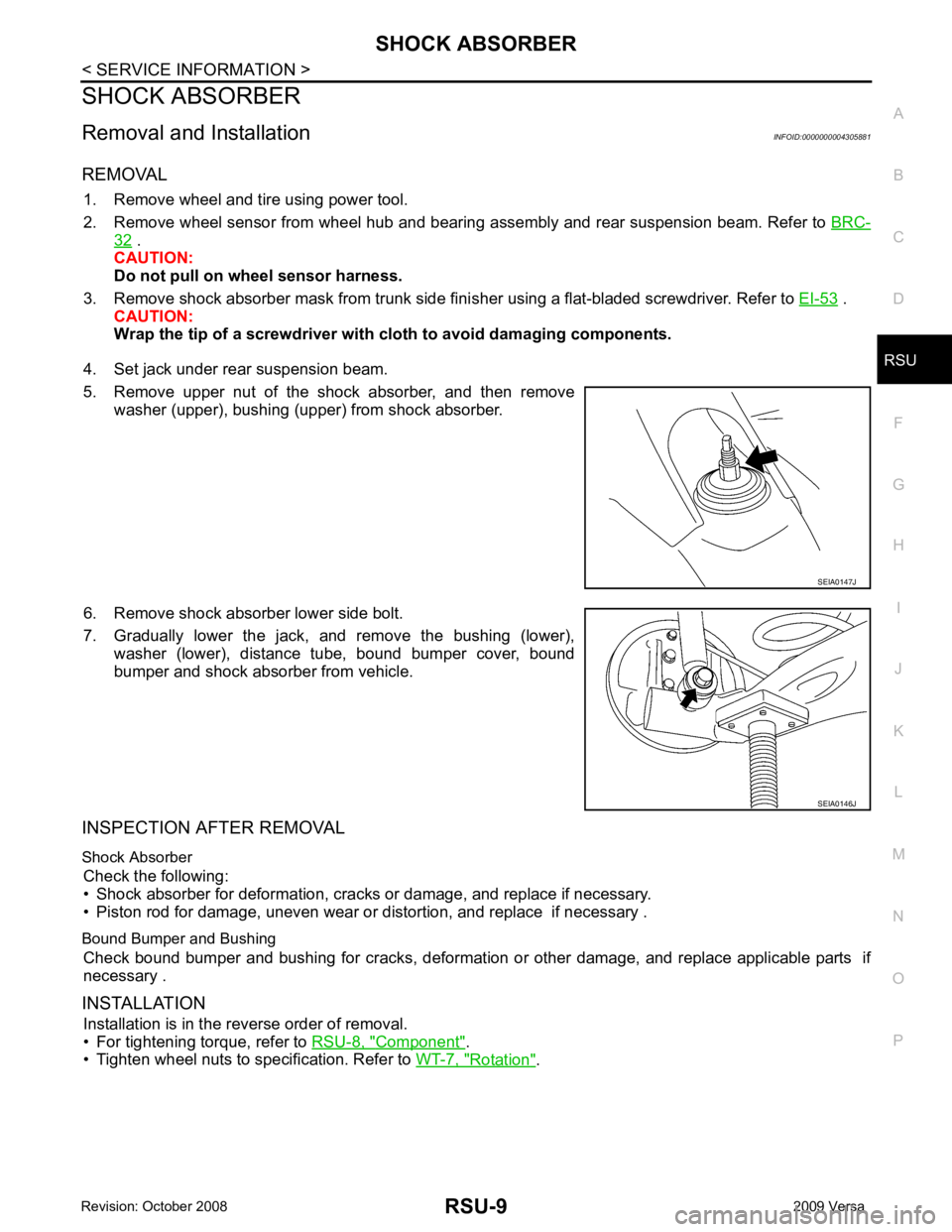

5. Remove upper nut of the shock absorber, and then remove washer (upper), bushing (upper) from shock absorber.

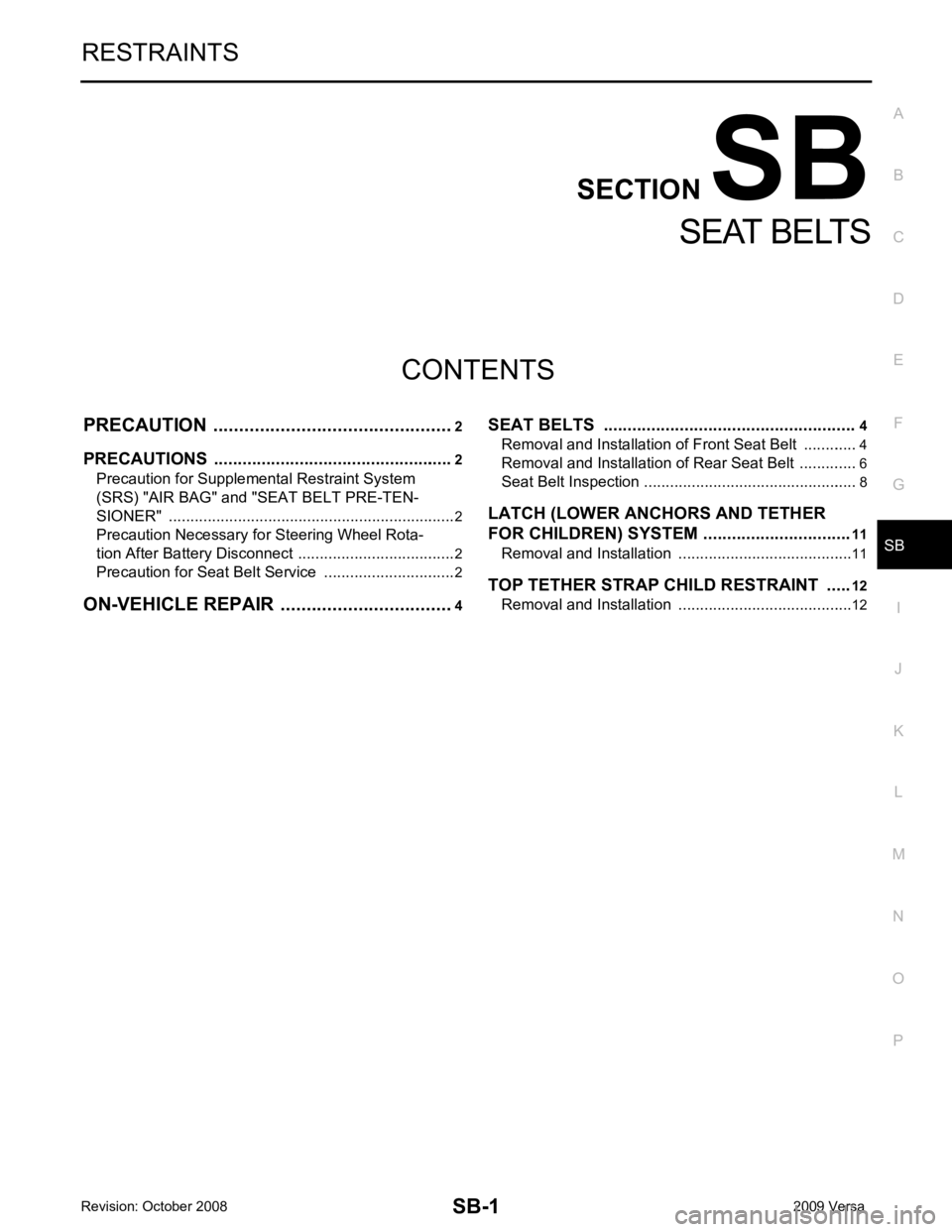

6. Remove shock absorber lower side bolt.

7. Gradually lower the jack, and remove the bushing (lower), washer (lower), distance tube, bound bumper cover, bound

bumper and shock absorber from vehicle.

INSPECTION AFTER REMOVAL

Shock Absorber Check the following:

• Shock absorber for deformation, cracks or damage, and replace if necessary.

• Piston rod for damage, uneven wear or di stortion, and replace if necessary .

Bound Bumper and Bushing Check bound bumper and bushing for cracks, deformation or other damage, and replace applicable parts if

necessary .

INSTALLATION Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, " Component " .

• Tighten wheel nuts to specification. Refer to WT-7, " Rotation " .

Page 4125 of 4331

SB

N

O P

CONTENTS

SEAT BELTS

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary fo r Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Seat Belt Service ......................... ......2

ON-VEHICLE REPAIR .... ..............................4 SEAT BELTS .....................................................

4

Removal and Installation of Front Seat Belt ........ .....4

Removal and Installation of Rear Seat Belt ..............6

Seat Belt Inspection ............................................. .....8

LATCH (LOWER ANCHORS AND TETHER

FOR CHILDREN) SYSTEM ............................... 11

Removal and Installation ..................................... ....11

TOP TETHER STRAP CHILD RESTRAINT ..... 12

Removal and Installation ..................................... ....12

Page 4166 of 4331

SE

N

O P

• Handle trim, molding instruments, grille, etc. carefully during removing or installing. Be careful not to oil or

damage them.

• Apply sealing compound where necessary when installing parts.

• When applying sealing compound, be careful that the sealing compound does not protrude from parts.

• When replacing any metal parts (for example body outer panel, member, etc.), be sure to take rust preven-

tion measures.

Precaution INFOID:0000000004306501

• When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts with a screwdriver or other tool , protect parts by wrapping tools with vinyl or tape.

• Keep removed parts protected with cloth.

• If a clip is deformed or damaged, replace it.

• If an unreusable part is removed, replace it with a new one.

• Tighten bolts and nuts firmly to the specified torque.

• After re-assembly has been completed, make sure each part functions correctly.

• Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tight ly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

• Do not use any organic solvent, such as thinner or benzine.