RAP NISSAN TIIDA 2009 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 1909 of 4331

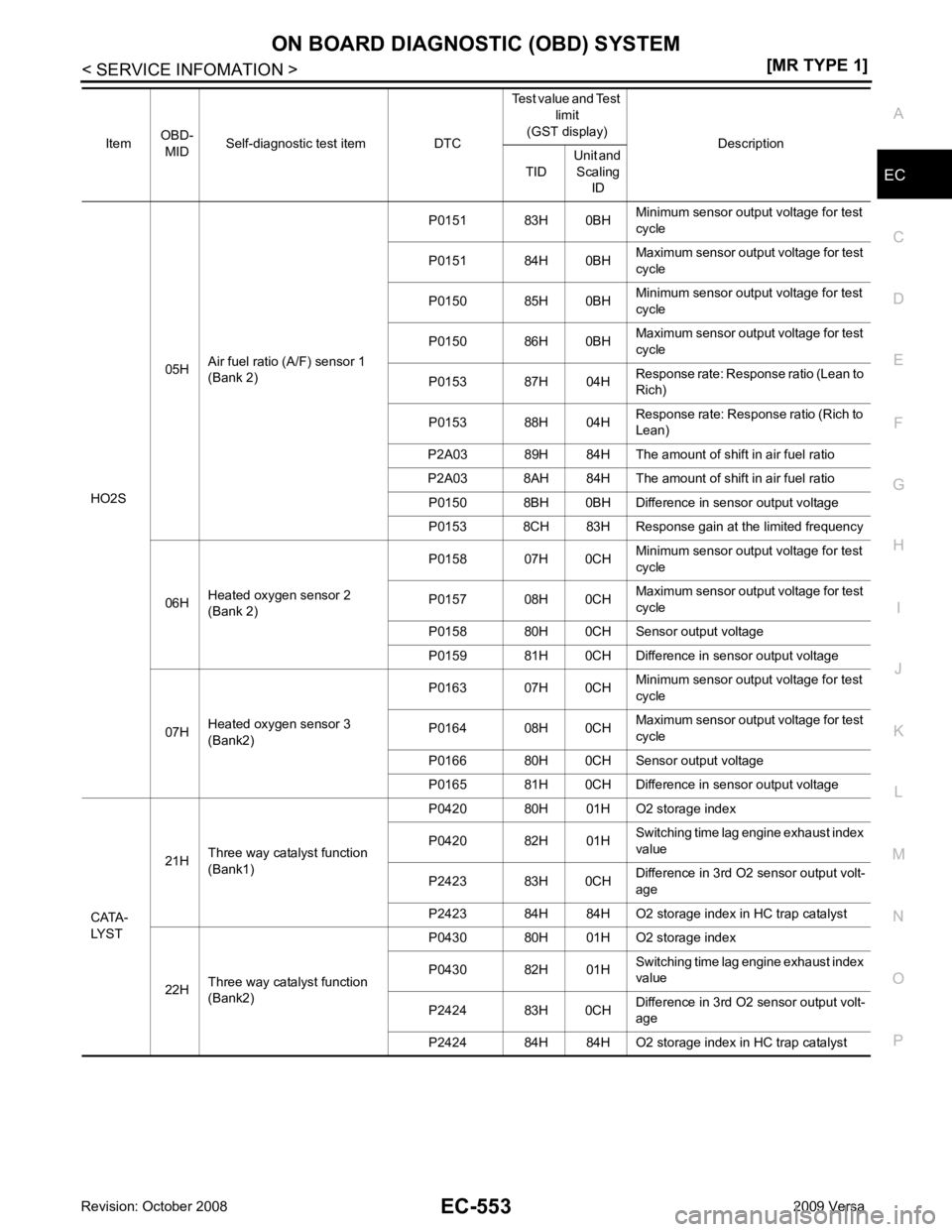

EC

NP

O

HO2S

05H

Air fuel ratio (A/F) sensor 1

(Bank 2) P0151 83H 0BH

Minimum sensor output voltage for test

cycle

P0151 84H 0BH Maximum sensor output voltage for test

cycle

P0150 85H 0BH Minimum sensor output voltage for test

cycle

P0150 86H 0BH Maximum sensor output voltage for test

cycle

P0153 87H 04H Response rate: Response ratio (Lean to

Rich)

P0153 88H 04H Response rate: Response ratio (Rich to

Lean)

P2A03 89H 84H The amount of shift in air fuel ratio

P2A03 8AH 84H The amount of shift in air fuel ratio P0150 8BH 0BH Difference in sensor output voltage

P0153 8CH 83H Response gain at the limited frequency

06H Heated oxygen sensor 2

(Bank 2) P0158 07H 0CH

Minimum sensor output voltage for test

cycle

P0157 08H 0CH Maximum sensor output voltage for test

cycle

P0158 80H 0CH Sensor output voltage

P0159 81H 0CH Difference in sensor output voltage

07H Heated oxygen sensor 3

(Bank2) P0163 07H 0CH

Minimum sensor output voltage for test

cycle

P0164 08H 0CH Maximum sensor output voltage for test

cycle

P0166 80H 0CH Sensor output voltage

P0165 81H 0CH Difference in sensor output voltage

CATA-

LYST 21H

Three way catalyst function

(Bank1) P0420 80H 01H O2 storage index

P0420 82H 01H Switching time lag engine exhaust index

value

P2423 83H 0CH Difference in 3rd O2 sensor output volt-

age

P2423 84H 84H O2 storage index in HC trap catalyst

22H Three way catalyst function

(Bank2) P0430 80H 01H O2 storage index

P0430 82H 01H Switching time lag engine exhaust index

value

P2424 83H 0CH Difference in 3rd O2 sensor output volt-

age

P2424 84H 84H O2 storage index in HC trap catalyst

Item

OBD-

MID Self-diagnostic test item DTC Test value and Test

limit

(GST display) Description

TID Unit and

Scaling ID

Page 2206 of 4331

![NISSAN TIIDA 2009 Service Owners Guide EC-850< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0455 EVAP CONTROL SYSTEM

With CONSULT-III>>GO TO 9.

Without CONSULT-III>>GO TO 10. 9.

CHECK FOR EVAP LEAK

With CONSULT-III

1. Turn ignition switch ON.

2 NISSAN TIIDA 2009 Service Owners Guide EC-850< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0455 EVAP CONTROL SYSTEM

With CONSULT-III>>GO TO 9.

Without CONSULT-III>>GO TO 10. 9.

CHECK FOR EVAP LEAK

With CONSULT-III

1. Turn ignition switch ON.

2](/img/5/57398/w960_57398-2205.png)

EC-850< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0455 EVAP CONTROL SYSTEM

With CONSULT-III>>GO TO 9.

Without CONSULT-III>>GO TO 10. 9.

CHECK FOR EVAP LEAK

With CONSULT-III

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

3. Touch “START” and apply pressure into the EVAP line until the pressure indicator reaches the middle of the bar graph.

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm 2

, 0.6 psi) of pressure in the system.

4. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more details.

Refer to EC-527, " Description " .

OK or NG OK >> GO TO 11.

NG >> Repair or replace. 10.

CHECK FOR EVAP LEAK

Without CONSULT-III

1. Turn ignition switch OFF.

2. Apply 12 volts DC to EVAP canister vent control valve (3). The valve will close. (Continue to appl y 12 volts until the end of test.)

- EVAP control system pressure sensor (1)

- EVAP canister (2)

3. Pressurize the EVAP line using pressure pump with 1.3 to 2.7 kPa (10 to 20 mmHg, 0.39 to 0.79 inHg),

then remove pump and EVAP service port adapter.

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm 2

, 0.6 psi) of pressure in the system. SEF916U

SEF200U

BBIA0693E

Page 2212 of 4331

![NISSAN TIIDA 2009 Service Owners Guide EC-856< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0456 EVAP CONTROL SYSTEM 5.

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service NISSAN TIIDA 2009 Service Owners Guide EC-856< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0456 EVAP CONTROL SYSTEM 5.

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service](/img/5/57398/w960_57398-2211.png)

EC-856< SERVICE INFOMATION >

[MR TYPE 1]

DTC P0456 EVAP CONTROL SYSTEM 5.

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port securely. For the location of EVAP

service port (2), refer to EC-527, " Description " .

• EVAP canister purge volume control solenoid valve (1)

• : Vehicle front NOTE:

Improper installation of the EV AP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-III>>GO TO 6.

Without CONSULT-III>>GO TO 7. 6.

CHECK FOR EVAP LEAK

With CONSULT-III

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

3. Touch “START” and apply pressure into the EVAP line until the pressure indicator reaches the middle of the bar graph.

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm 2

, 0.6 psi) of pressure in the system.

4. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more details.

Refer to EC-527, " Description " .

OK or NG OK >> GO TO 8.

NG >> Repair or replace. 7.

CHECK FOR EVAP LEAK

Without CONSULT-III

1. Turn ignition switch OFF. BBIA0703E

SEF916U

SEF200U

Page 2244 of 4331

![NISSAN TIIDA 2009 Service Owners Guide EC-888< SERVICE INFOMATION >

[MR TYPE 1]

DTC P1217 ENGINE

OVER TEMPERATURE

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure flui NISSAN TIIDA 2009 Service Owners Guide EC-888< SERVICE INFOMATION >

[MR TYPE 1]

DTC P1217 ENGINE

OVER TEMPERATURE

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure flui](/img/5/57398/w960_57398-2243.png)

EC-888< SERVICE INFOMATION >

[MR TYPE 1]

DTC P1217 ENGINE

OVER TEMPERATURE

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the reser voir tank or the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-up

pressure to escape. Then turn the cap all the way off.

WITH CONSULT-III

1. Check the coolant level in the reservoir tank and radiator. Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-890," Diagnosis Procedure " or

EC-890, " Diagnosis Procedure " .

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-890," Diagnosis Procedure " or

EC-890, " Diagnosis Procedure " .

3. Turn ignition switch ON.

4. Perform “COOLING FAN” in “ACTIVE TEST” mode with CON- SULT-III.

5. If the results are NG, go to EC-890, " Diagnosis Procedure " or

EC-890, " Diagnosis Procedure " .

WITH GST

1. Check the coolant level in the reservoir tank and radiator. Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-890," Diagnosis Procedure " .

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-890," Diagnosis Procedure " .

3. Perform IPDM/ER auto active te st and check cooling fan motor

operation. Refer to PG-19, " Auto Active Test " .

4. If NG, go to EC-890, " Diagnosis Procedure " . SEF621W

SEF621W

Page 2397 of 4331

![NISSAN TIIDA 2009 Service Owners Guide EVAPORATIVE EMISSION SYSTEM

EC-1041

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

3. Turn ignition switch ON.

4. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode wit NISSAN TIIDA 2009 Service Owners Guide EVAPORATIVE EMISSION SYSTEM

EC-1041

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

3. Turn ignition switch ON.

4. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode wit](/img/5/57398/w960_57398-2396.png)

EVAPORATIVE EMISSION SYSTEM

EC-1041

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

3. Turn ignition switch ON.

4. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

5. Touch “START”. A bar graph (Pressure indicating display) will appear on the screen.

6. Apply positive pressure to the EVAP system until t he pressure indicator reaches the middle of the bar

graph.

7. Remove EVAP service port adapter and hose with pressure pump.

8. Locate the leak using a leak detector. Refer to EC-1036," Description " .

WITHOUT CONSULT-III

1. Attach the EVAP service port adapter securely to the EVAP ser- vice port.

2. Also attach the pressure pump with pressure gauge to the EVAP service port adapter.

3. Apply battery voltage to the termi nal of EVAP canister vent con-

trol valve (3) to make a closed EVAP system.

• EVAP control system pressure sensor (1)

• EVAP canister (2)

4. To locate the leak, deliver positive pressure to the EVAP system until pressure gauge points reach 1.38 to

2.76 kPa (0.014 to 0.028 kg/cm 2

, 0.2 to 0.4 psi).

5. Remove EVAP service port adapter and hose with pressure pump.

6. Locate the leak using a leak detector. Refer to EC-1036, " Description " . SEF200U

SEF462UC

BBIA0693E

Page 2673 of 4331

![NISSAN TIIDA 2009 Service Owners Guide DTC P0442 EVAP CONTROL SYSTEM

EC-1317

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and fuel filler neck thre NISSAN TIIDA 2009 Service Owners Guide DTC P0442 EVAP CONTROL SYSTEM

EC-1317

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and fuel filler neck thre](/img/5/57398/w960_57398-2672.png)

DTC P0442 EVAP CONTROL SYSTEM

EC-1317

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

OK or NG OK >> GO TO 3.

NG >> 1. Open fuel filler cap, then clean cap and fuel filler neck threads using air blower.

2. Retighten until reteaching sound is heard. 3.

CHECK FUEL FILLER CAP FUNCTION

Check for air releasing sound while opening the fuel filler cap.

OK or NG OK >> GO TO 5.

NG >> GO TO 4. 4.

CHECK FUEL TANK VACUUM RELIEF VALVE

Refer to EC-1038, " Component Inspection " .

OK or NG OK >> GO TO 5.

NG >> Replace fuel filler cap with a genuine one. 5.

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pressure pump to EVAP service port securely.

For the location of EVAP service port (2), refer to EC-1036, " Descrip-

tion " .

• EVAP canister purge volume control solenoid valve (1)

• : Vehicle front

NOTE:

Improper installation of the EV AP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-III>>GO TO 6.

Without CONSULT-III>>GO TO 7. 6.

CHECK FOR EVAP LEAK

With CONSULT-III

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

3. Touch “START” and apply pressure into the EVAP li ne until the pressure indicator reaches the middle of

the bar graph.

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm 2

, 0.6 psi) of pressure in the system. BBIA0703E

SEF916U

Page 2725 of 4331

![NISSAN TIIDA 2009 Service Owners Guide DTC P0455 EVAP CONTROL SYSTEM

EC-1369

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

• : Vehicle front

NOTE:

Improper installation of the EV AP service port adapter to t NISSAN TIIDA 2009 Service Owners Guide DTC P0455 EVAP CONTROL SYSTEM

EC-1369

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

• : Vehicle front

NOTE:

Improper installation of the EV AP service port adapter to t](/img/5/57398/w960_57398-2724.png)

DTC P0455 EVAP CONTROL SYSTEM

EC-1369

< SERVICE INFOMATION >

[MR TYPE 2] C

D E

F

G H

I

J

K L

M A EC

NP

O

• : Vehicle front

NOTE:

Improper installation of the EV AP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-III>>GO TO 10.

Without CONSULT-III>>GO TO 11. 10.

CHECK FOR EVAP LEAK

With CONSULT-III

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

3. Touch “START” and apply pressure into the EVAP li ne until the pressure indicator reaches the middle of

the bar graph.

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm 2

, 0.6 psi) of pressure in the system.

4. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more details.

Refer to EC-1036, " Description " .

OK or NG OK >> GO TO 12.

NG >> Repair or replace. 11.

CHECK FOR EVAP LEAK

Without CONSULT-III

1. Turn ignition switch OFF. BBIA0703E

SEF916U

SEF200U

Page 2732 of 4331

![NISSAN TIIDA 2009 Service Owners Guide EC-1376< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0456 EVAP CONTROL SYSTEM 5.

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service NISSAN TIIDA 2009 Service Owners Guide EC-1376< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0456 EVAP CONTROL SYSTEM 5.

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service](/img/5/57398/w960_57398-2731.png)

EC-1376< SERVICE INFOMATION >

[MR TYPE 2]

DTC P0456 EVAP CONTROL SYSTEM 5.

INSTALL THE PRESSURE PUMP

To locate the EVAP leak, install EVAP service port adapter and pres-

sure pump to EVAP service port securely. For the location of EVAP

service port (2), refer to EC-1036, " Description " .

• EVAP canister purge volume control solenoid valve (1)

• : Vehicle front NOTE:

Improper installation of the EV AP service port adapter to the

EVAP service port may cause leaking.

With CONSULT-III>>GO TO 6.

Without CONSULT-III>>GO TO 7. 6.

CHECK FOR EVAP LEAK

With CONSULT-III

1. Turn ignition switch ON.

2. Select “EVAP SYSTEM CLOSE” of “WORK SUPPORT” mode with CONSULT-III.

3. Touch “START” and apply pressure into the EVAP line until the pressure indicator reaches the middle of the bar graph.

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm 2

, 0.6 psi) of pressure in the system.

4. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more details.

Refer to EC-1036, " Description " .

OK or NG OK >> GO TO 8.

NG >> Repair or replace. 7.

CHECK FOR EVAP LEAK

Without CONSULT-III

1. Turn ignition switch OFF. BBIA0703E

SEF916U

SEF200U

Page 2766 of 4331

![NISSAN TIIDA 2009 Service Owners Guide EC-1410< SERVICE INFOMATION >

[MR TYPE 2]

DTC P1217 ENGINE

OVER TEMPERATURE

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure flu NISSAN TIIDA 2009 Service Owners Guide EC-1410< SERVICE INFOMATION >

[MR TYPE 2]

DTC P1217 ENGINE

OVER TEMPERATURE

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure flu](/img/5/57398/w960_57398-2765.png)

EC-1410< SERVICE INFOMATION >

[MR TYPE 2]

DTC P1217 ENGINE

OVER TEMPERATURE

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the reser voir tank or the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-up

pressure to escape. Then turn the cap all the way off.

WITH CONSULT-III

1. Check the coolant level in the reservoir tank and radiator. Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-1412," Diagnosis Procedure " or

EC-1412, " Diagnosis Procedure " .

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-1412," Diagnosis Procedure " or

EC-1412, " Diagnosis Procedure " .

3. Turn ignition switch ON.

4. Perform “COOLING FAN” in “ACTIVE TEST” mode with CON- SULT-III.

5. If the results are NG, go to EC-1412, " Diagnosis Procedure " or

EC-1412, " Diagnosis Procedure " .

WITH GST

1. Check the coolant level in the reservoir tank and radiator. Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-1412," Diagnosis Procedure " .

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-1412," Diagnosis Procedure " .

3. Perform IPDM/ER auto active te st and check cooling fan motor

operation. Refer to PG-19, " Auto Active Test " .

4. If NG, go to EC-1412, " Diagnosis Procedure " . SEF621W

SEF621W

Page 2895 of 4331

EI-4< PRECAUTION >

PRECAUTIONS

Precaution INFOID:0000000004307207

• When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

• Keep removed parts protected with cloth.

• If a clip is deformed or damaged, replace it.

• If an unreusable part is removed, replace it with a new one.

• Tighten bolts and nuts firmly to the specified torque.

• After re-assembly has been completed, make sure each part functions correctly.

• Remove stains in the following way.

- Water-soluble stains: Dip a cloth in warm water, and squeeze tightly. After wiping the stain, wipe with a soft dry cloth.

- Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the

stain with the cloth. Next, dip the soft cloth in fr esh water, and then squeeze it tightly. Then clean off the

detergent completely. Then wipe the area with a soft dry cloth.

• Do not use any organic solvent, such as thinner or benzine.

• When performing procedures that require removal of the cowl top, cover the lower end of the windshield with a suitable protection

material. PIIB3706J