RAP NISSAN TIIDA 2009 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3134 of 4331

![NISSAN TIIDA 2009 Service Workshop Manual CYLINDER HEAD

EM-187

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

4. Remove drive belt. Refer to

EM-136, " Removal and Installation " .

5. Remove the following components and rela NISSAN TIIDA 2009 Service Workshop Manual CYLINDER HEAD

EM-187

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

4. Remove drive belt. Refer to

EM-136, " Removal and Installation " .

5. Remove the following components and rela](/img/5/57398/w960_57398-3133.png)

CYLINDER HEAD

EM-187

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

4. Remove drive belt. Refer to

EM-136, " Removal and Installation " .

5. Remove the following components and related parts. • Exhaust manifold; Refer to EM-144 .

• Intake manifold; Refer to EM-141 .

• Fuel tube and fuel injector assembly; Refer to EM-156 .

• Water outlet; Refer to CO-47 .

• Rocker cover; Refer to EM-153 .

• Front cover, timing chain; Refer to EM-160 .

• Camshaft; Refer to EM-170 .

6. Remove cylinder head. • Loosen bolts in reverse order as shown.

• Using TORX socket (size E18), loosen cylinder head bolts.

7. Remove cylinder head gasket.

INSPECTION AFTER REMOVAL

Cylinder Head Bolts Outer Diameter • Cylinder head bolts are tightened by plastic zone tightening method. Whenever the size difference between (d1) and (d2)

exceeds the limit, replac e them with a new one.

• If reduction of outer diameter appear s in a position other than (d2),

use it as (d2) point.

Cylinder Head Distortion NOTE:

When performing this inspection, cylinder block distortion should be also checked. Refer to EM-216, " Inspec-

tion After Disassembly " .

1. Wipe off engine oil and remove water scale (like deposit ), gasket, sealant, carbon, etc. with a scraper.

CAUTION:

Never allow gasket debris to enter passag es for engine oil or engine coolant.

2. At each of several locations on bottom surface of cylinder head, measure the distortion in six di rections using straightedge (A)

and feeler gauge (B).

• If it exceeds the limit, replace cylinder head.

INSTALLATION 1. Install cylinder head gasket.

2. Apply new engine oil to threads and seating surface of bolts. CAUTION: : Engine front

PBIC3206J

Limit [(d1) – (d2)]: 0.15 mm (0.0059 in)

PBIC3994E

Limit: 0.1 mm (0.004 in)

PBIC3207J

Page 3247 of 4331

FSU

N

O P

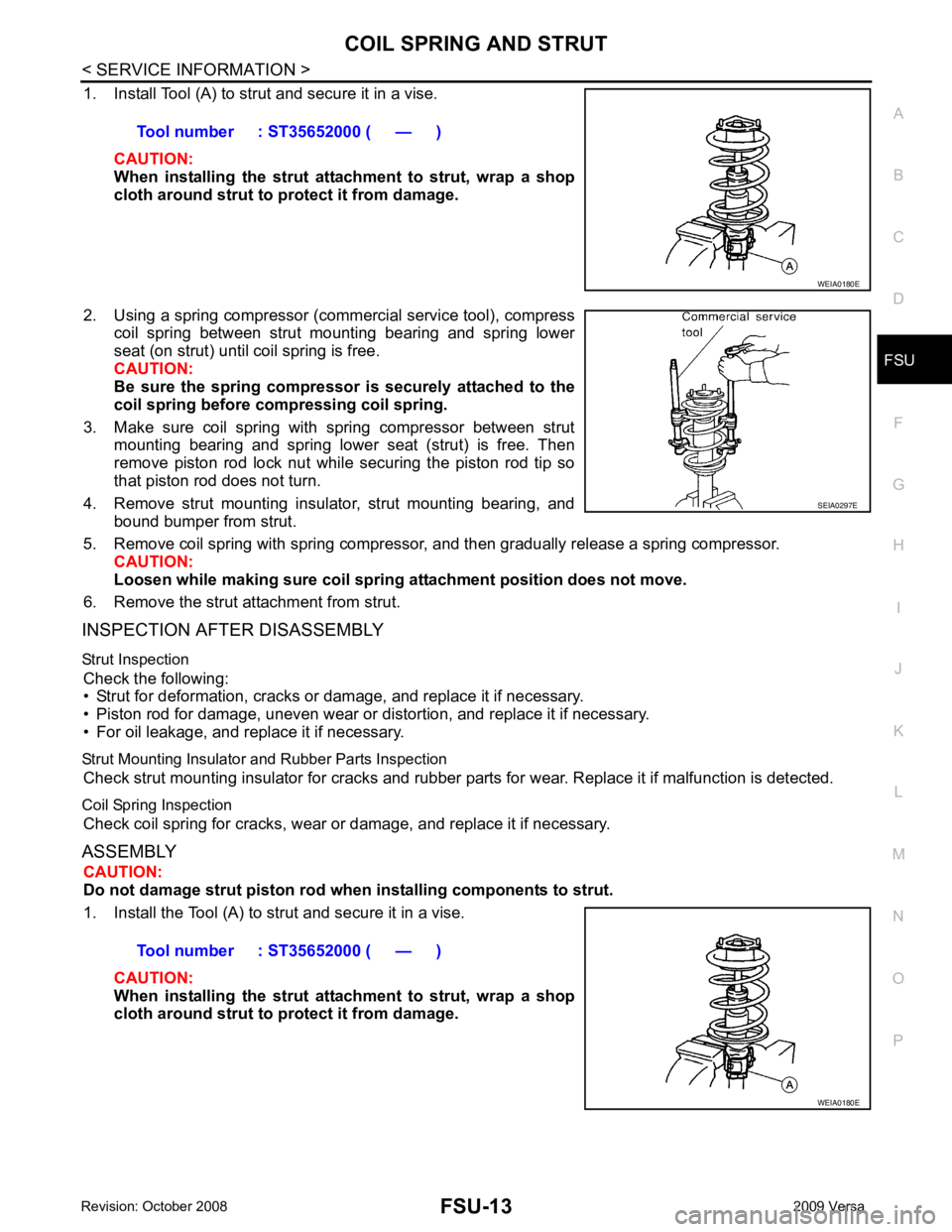

1. Install Tool (A) to strut and secure it in a vise.

CAUTION:

When installing the strut att achment to strut, wrap a shop

cloth around strut to protect it from damage.

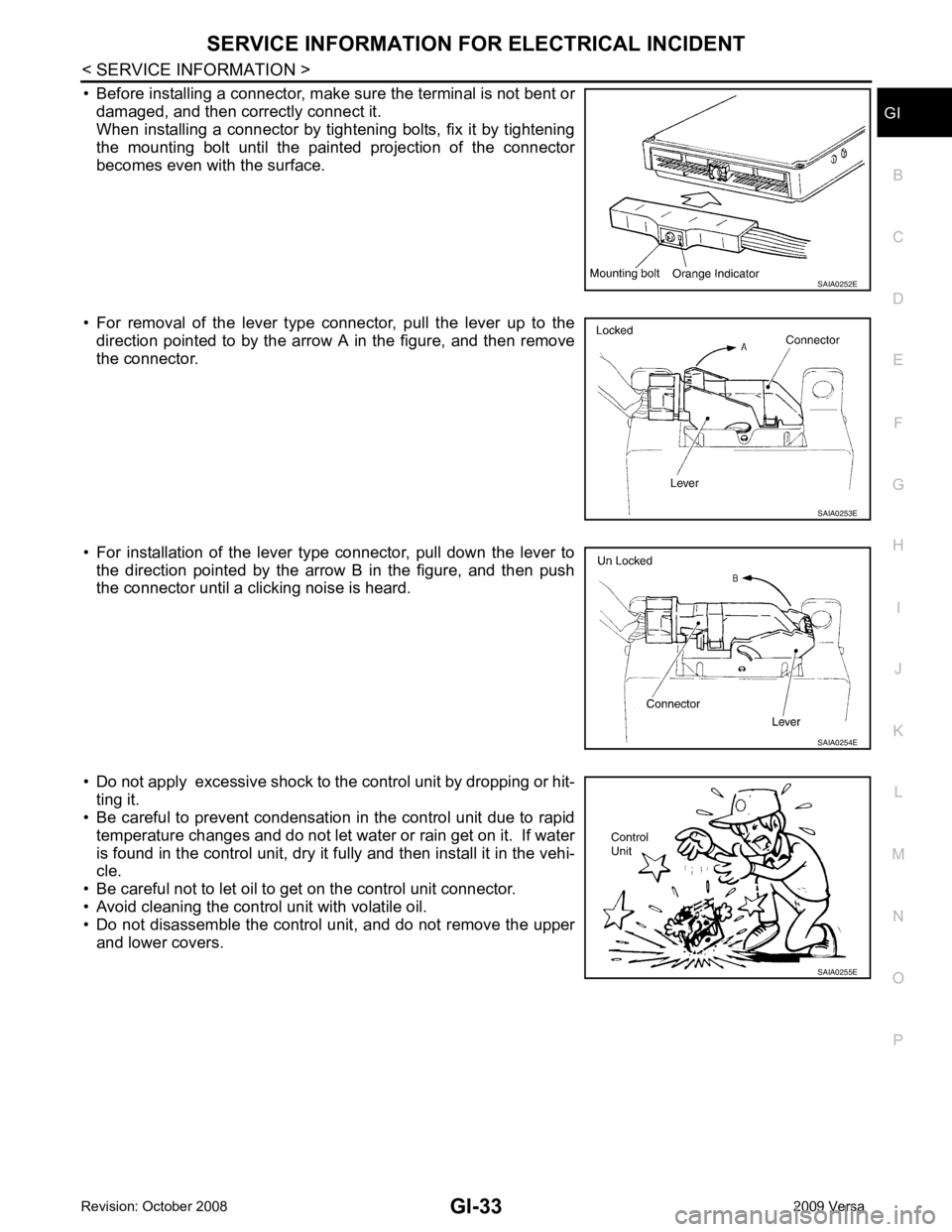

2. Using a spring compressor (commercial service tool), compress coil spring between strut mounting bearing and spring lower

seat (on strut) until coil spring is free.

CAUTION:

Be sure the spring compressor is securely attached to the

coil spring before co mpressing coil spring.

3. Make sure coil spring with spring compressor between strut mounting bearing and spring lower seat (strut) is free. Then

remove piston rod lock nut while securing the piston rod tip so

that piston rod does not turn.

4. Remove strut mounting insulator, strut mounting bearing, and bound bumper from strut.

5. Remove coil spring with spring compressor, and then gradually release a spring compressor. CAUTION:

Loosen while making sure coil spring attachment position does not move.

6. Remove the strut attachment from strut.

INSPECTION AFTER DISASSEMBLY

Strut Inspection Check the following:

• Strut for deformation, cracks or damage, and replace it if necessary.

• Piston rod for damage, uneven wear or di stortion, and replace it if necessary.

• For oil leakage, and replace it if necessary.

Strut Mounting Insulator and Rubber Parts Inspection Check strut mounting insulator for cracks and rubber part s for wear. Replace it if malfunction is detected.

Coil Spring Inspection Check coil spring for cracks, wear or damage, and replace it if necessary.

ASSEMBLY CAUTION:

Do not damage strut piston rod when installing components to strut.

1. Install the Tool (A) to strut and secure it in a vise.

CAUTION:

When installing the strut att achment to strut, wrap a shop

cloth around strut to protect it from damage. Tool number : ST35652000 ( — )

SEIA0297E

Page 3286 of 4331

GI

N

O P

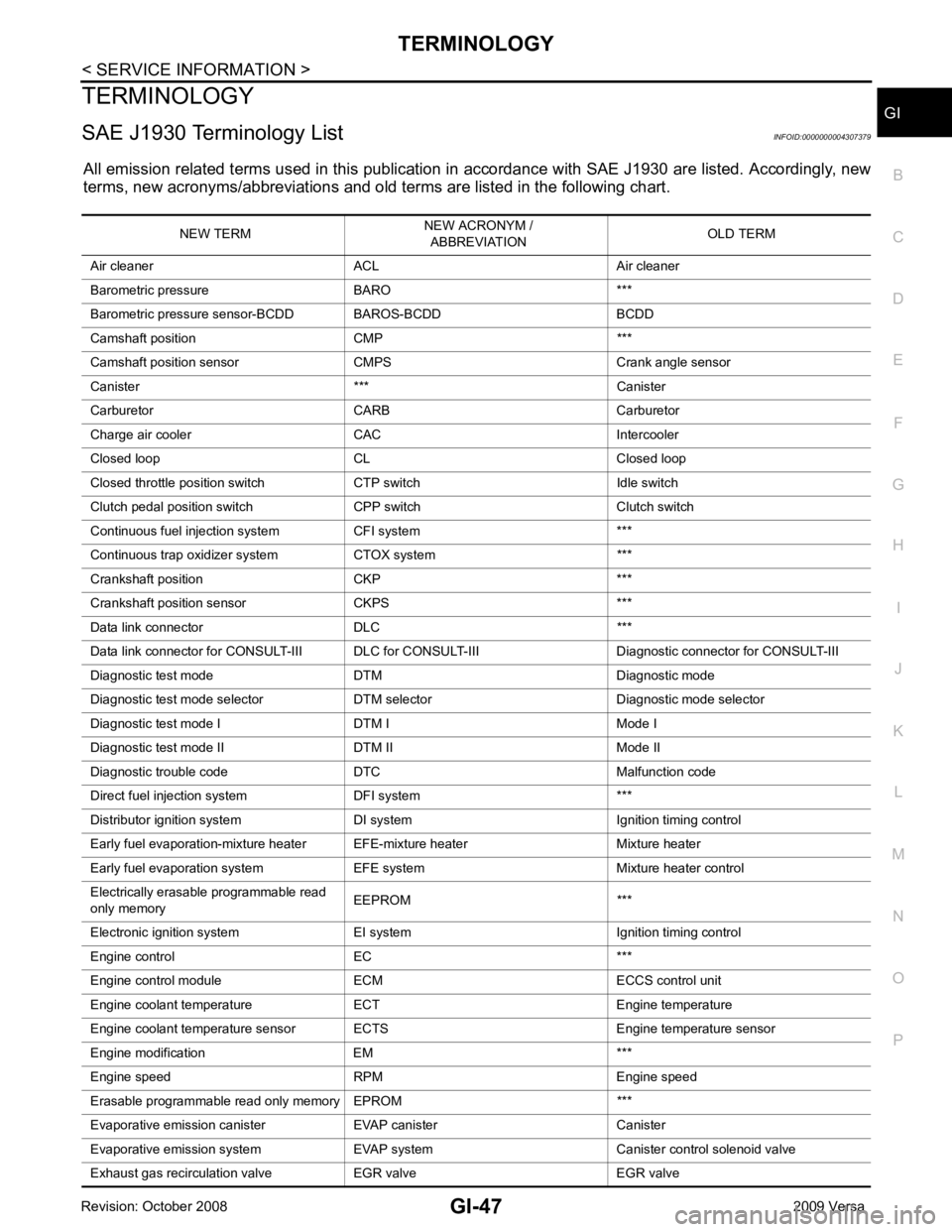

• Before installing a connector, make sure the terminal is not bent or

damaged, and then correctly connect it.

When installing a connector by tightening bolts, fix it by tightening

the mounting bolt until the painted projection of the connector

becomes even with the surface.

• For removal of the lever type connector, pull the lever up to the direction pointed to by the arrow A in the figure, and then remove

the connector.

• For installation of the lever type connector, pull down the lever to the direction pointed by the arrow B in the figure, and then push

the connector until a clicking noise is heard.

• Do not apply excessive shock to the control unit by dropping or hit- ting it.

• Be careful to prevent condensation in the control unit due to rapid

temperature changes and do not let water or rain get on it. If water

is found in the control unit, dry it fully and then install it in the vehi-

cle.

• Be careful not to let oil to get on the control unit connector.

• Avoid cleaning the control unit with volatile oil.

• Do not disassemble the control unit, and do not remove the upper

and lower covers.

Page 3300 of 4331

GI

N

O P

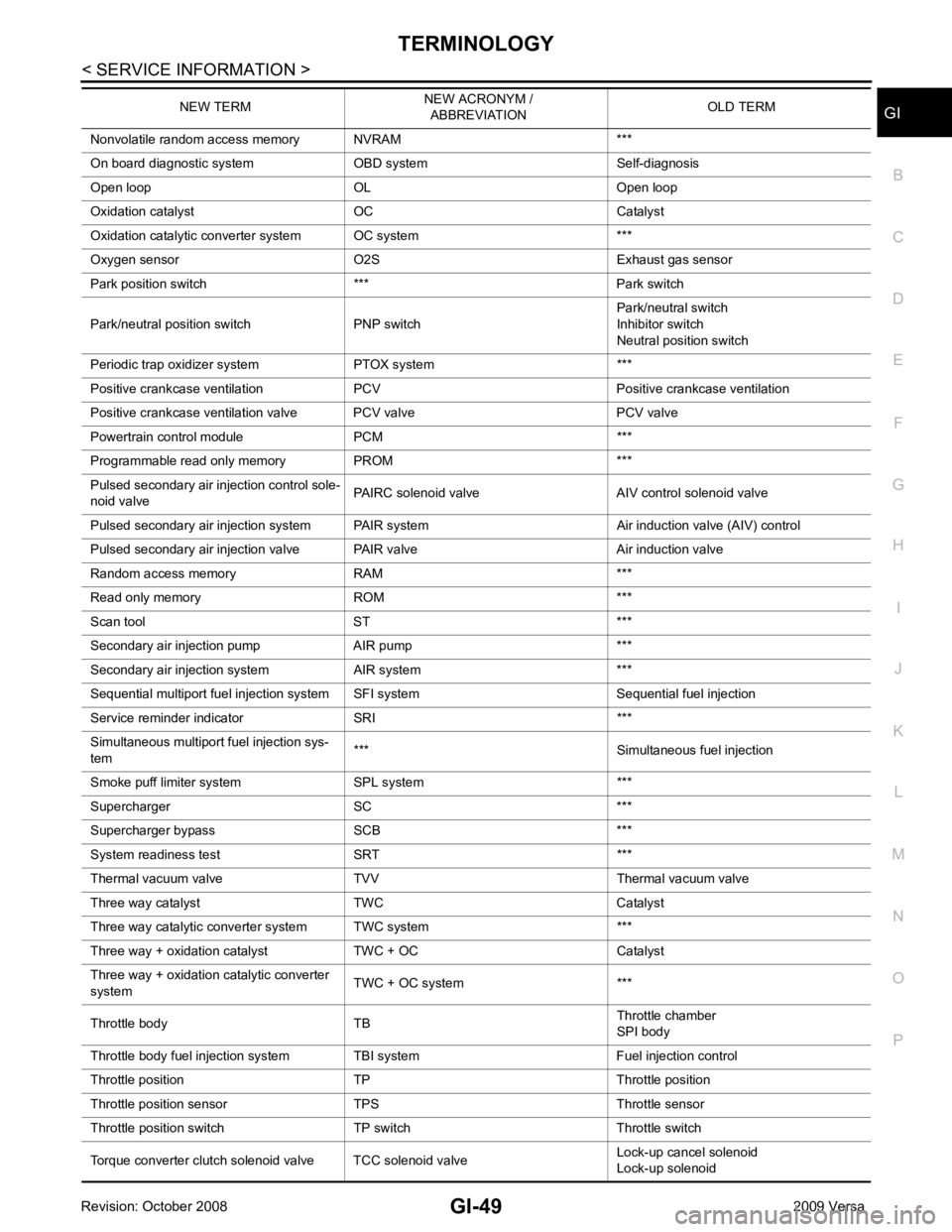

TERMINOLOGY

SAE J1930 Terminology List INFOID:0000000004307379

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERM NEW ACRONYM /

ABBREVIATION OLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure se nsor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector fo r CONSULT-III DLC for CONSULT-III Di agnostic connector for CONSULT-III

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memory EEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

Page 3302 of 4331

GI

N

O P

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch Park/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain cont rol module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control sole-

noid valve PAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

Simultaneous multiport fuel injection sys-

tem *** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

system TWC + OC system ***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancel solenoid

Lock-up solenoid

NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

Page 3333 of 4331

Terminal and Reference Value for BCM " .

Work Flow INFOID:0000000004306861

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to GW-19, " System Description " .

3. According to the trouble diagnosis chart, repa ir or replace the cause of the malfunction.

Refer to GW-31, " Trouble Diagnosis Symptom Chart " .

4. Does power window system operate normally? If Yes, GO TO 5, If No, GO TO 3.

5. Inspection End.

CONSULT-III Function (BCM) INFOID:0000000004306862

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

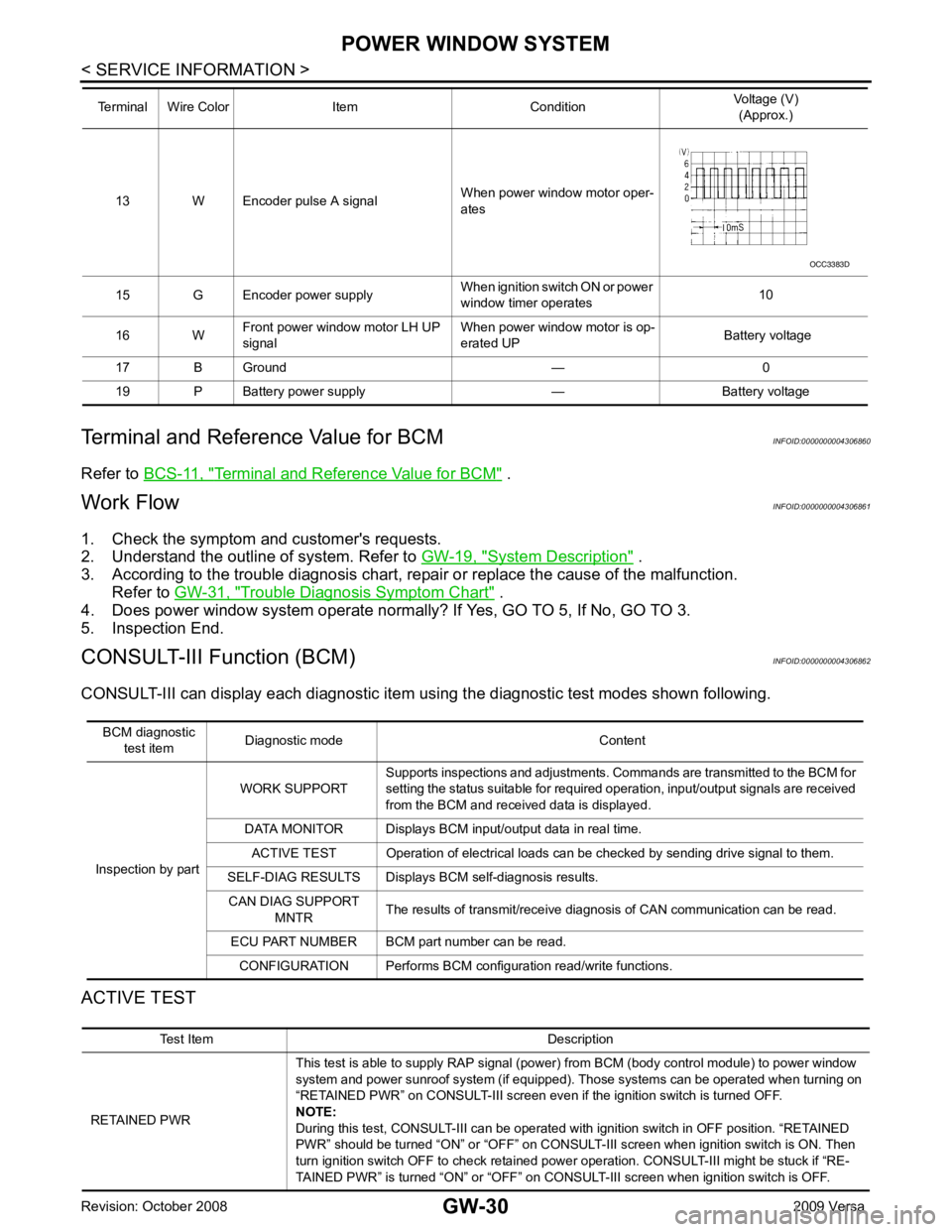

ACTIVE TEST 13 W Encoder pulse A signal

When power window motor oper-

ates

15 G Encoder power supply When ignition switch ON or power

window timer operates 10

16 W Front power window motor LH UP

signal When power window motor is op-

erated UP Battery voltage

17 B Ground — 0

19 P Battery power supply — Battery voltage

Terminal Wire Color Item Condition

Voltage (V)

(Approx.) Test Item Description

RETAINED PWR This test is able to supply RAP signal (powe

r) from BCM (body control module) to power window

system and power sunroof system (if equipped). Those systems can be operated when turning on

“RETAINED PWR” on CONSULT-III screen even if the ignition switch is turned OFF.

NOTE:

During this test, CONSULT-III can be operated with ignition switch in OFF position. “RETAINED

PWR” should be turned “ON” or “OFF” on CONSULT-III screen when ignition switch is ON. Then

turn ignition switch OFF to check retained power operation. CONSULT-III might be stuck if “RE-

TAINED PWR” is turned “ON” or “OFF” on CO NSULT-III screen when ignition switch is OFF.

Page 3334 of 4331

GW

N

O P

WORK SUPPORT

DATA MONITOR

Power Window Auto Operation Initialization INFOID:0000000004306863

1. Turn the ignition switch ON.

2. Open the window—all the way DOWN.

3. Pull all the way UP on the switch and hold (close the window). • Continue holding the switch all the way UP for 4 seconds after the window is closed.

4. Confirm the window is now operating correctly. NOTE:

• If the window is still not operating correctly, refer to GW-31, " Trouble Diagnosis Symptom Chart " .

• The above initialization procedure must be performed if any of the following occur:

- Battery cable is disconnected

- Power window switch connector is disconnected

- Power window regulator is replaced

- Power window motor is replaced

- Window glass is removed

- Window glass run rubber is replaced

- Power window fuse is blown

- Window is partly opened and/or closed many times without being fully closed.

Trouble Diagnosis Symptom Chart INFOID:0000000004306864

Check that other systems us ing the signal of the following systems operate normally.

Work item Description

RETAINED PWR RAP signal’s power supply period can be changed by mode setting. Selects RAP signal’s power

supply period between three steps

• MODE1 (45 sec.)/MODE2 (OFF)/MODE3 (2 min.). Work item Description

IGN ON SW Indicates (ON/OFF) condition of ignition switch

DOOR SW-DR Indicates (ON/OFF) condition of front door switch LH

DOOR SW-AS Indicates (ON/OFF) condition of front door switch RH Symptom Repair order Refer to page

None of the power windows can be operated using any switch 1. BCM power supply and ground circuit check

BCS-15 2. Main power window and door lock/unlock

power supply and ground circuit check GW-32 3. Replace main power window and door lock/

unlock switch EI-34Front power window LH alone does not operate

1. Front power window motor LH circuit check

GW-33 2. Replace main power window and door lock/

unlock switch EI-34Front power window RH does not operate from power window and

door lock/unlock switch RH only 1. Front power window RH circuit check (power

window and door lock/unlock switch RH opera-

tion) GW-34Front power window RH does not operate from main power window

and door lock/unlock switch only 1. Replace main power window and door lock/

unlock switch EI-34Front power window RH does not operate from any switch 1. Front power window motor RH circuit check

GW-34

Page 3364 of 4331

GW

N

O P

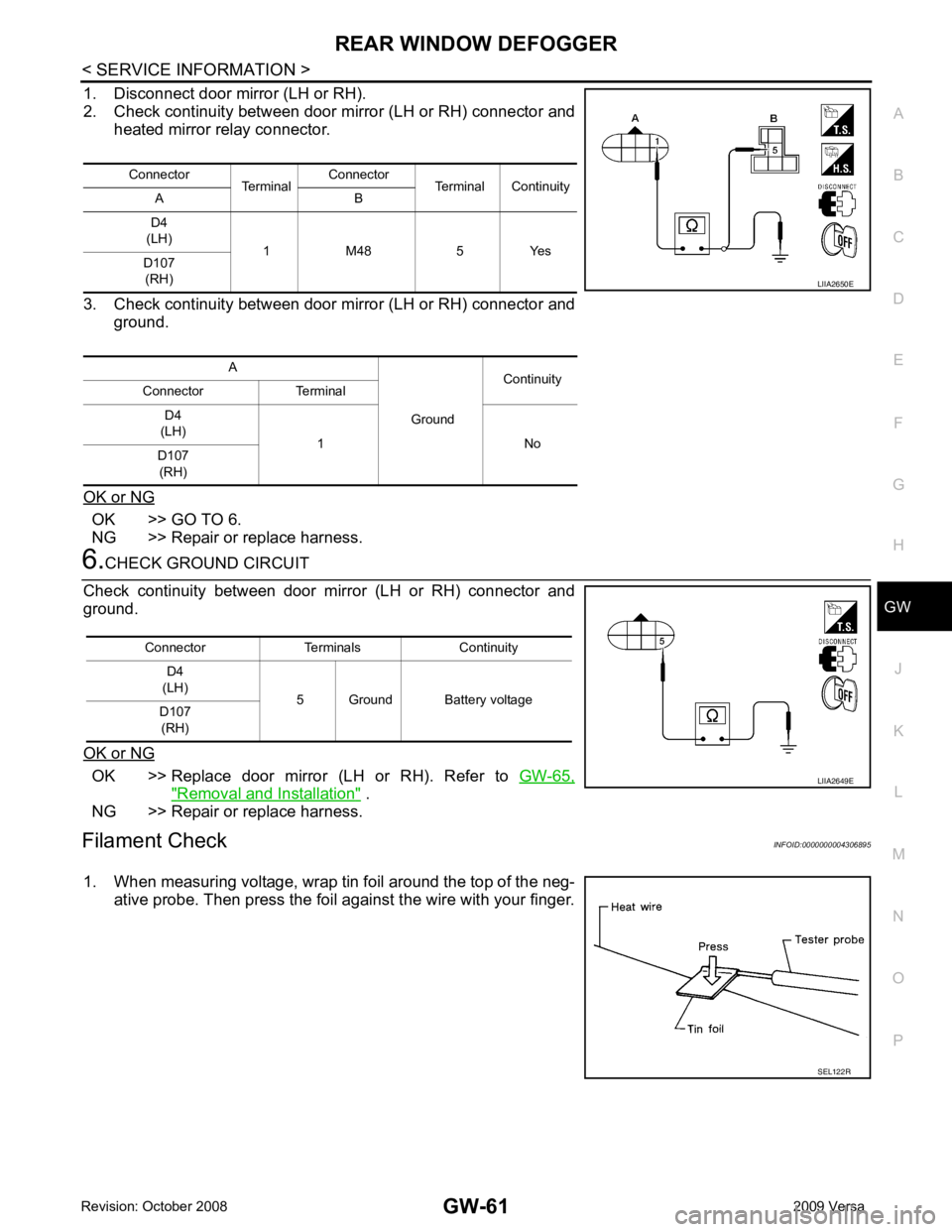

1. Disconnect door mirror (LH or RH).

2. Check continuity between door mirror (LH or RH) connector and heated mirror relay connector.

3. Check continuity between door mirror (LH or RH) connector and ground.

OK or NG OK >> GO TO 6.

NG >> Repair or replace harness. OK >> Replace door mirror (LH or RH). Refer to

GW-65," Removal and Installation " .

NG >> Repair or replace harness.

Filament Check INFOID:0000000004306895

1. When measuring voltage, wrap tin foil around the top of the neg- ative probe. Then press the foil against the wire with your finger.Connector

TerminalConnector

Terminal Continuity

A B

D4

(LH) 1 M48 5 Yes

D107

(RH)

A GroundContinuity

Connector Terminal

D4

(LH) 1 No

D107

(RH) SEL122R

Page 3373 of 4331

IP

N

O P

• Be careful not to scratch pad and other parts.

• When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts, protect parts by wrapping tools with vinyl or tape.

• Keep removed parts protected with cloth.

• If a clip is deformed or damaged, replace it.

• If an non-reusable part is removed, replace it with a new one.

• Tighten bolts and nuts firmly to the specified torque.

• After re-assembly has been completed, make sure each part functions correctly.

• Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tight ly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

• Do not use any organic solvent, such as thinner or benzine.

Page 3402 of 4331

LAN

N

O P

PRECAUTION

PRECAUTIONS

Precautions for Trouble Diagnosis INFOID:0000000004306681

CAUTION:

• Never apply 7.0 V or more to the measurement terminal.

• Use a tester with open terminal voltage of 7.0 V or less.

• Turn the ignition switch OFF and disconnect th e battery cable from the negative terminal when

checking the harness.

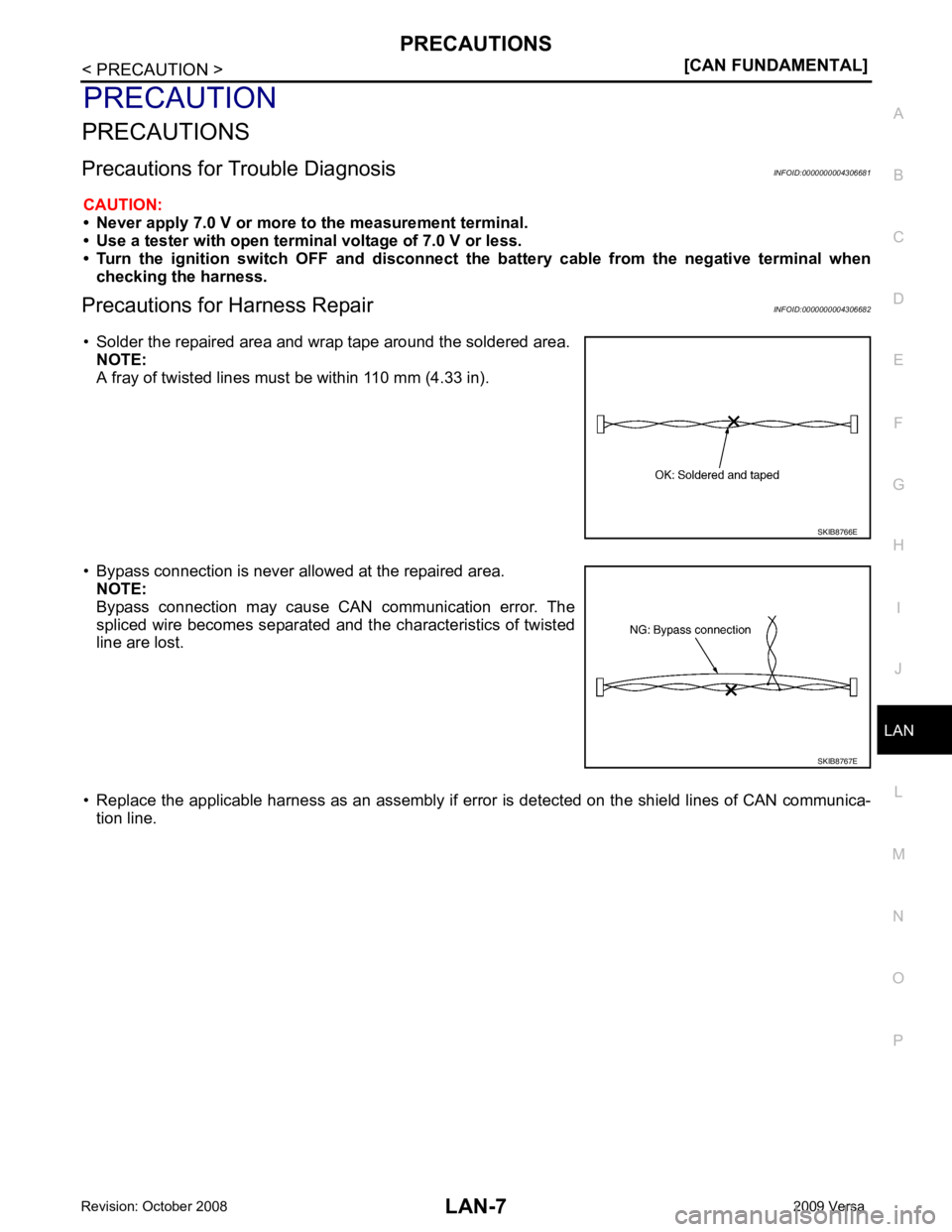

Precautions for Harness Repair INFOID:0000000004306682

• Solder the repaired area and wrap tape around the soldered area. NOTE:

A fray of twisted lines must be within 110 mm (4.33 in).

• Bypass connection is never allowed at the repaired area. NOTE:

Bypass connection may cause CAN communication error. The

spliced wire becomes separated and t he characteristics of twisted

line are lost.

• Replace the applicable harness as an assembly if error is detected on the shield lines of CAN communica-

tion line.