engine control NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 4040 of 4331

PG

N

O P

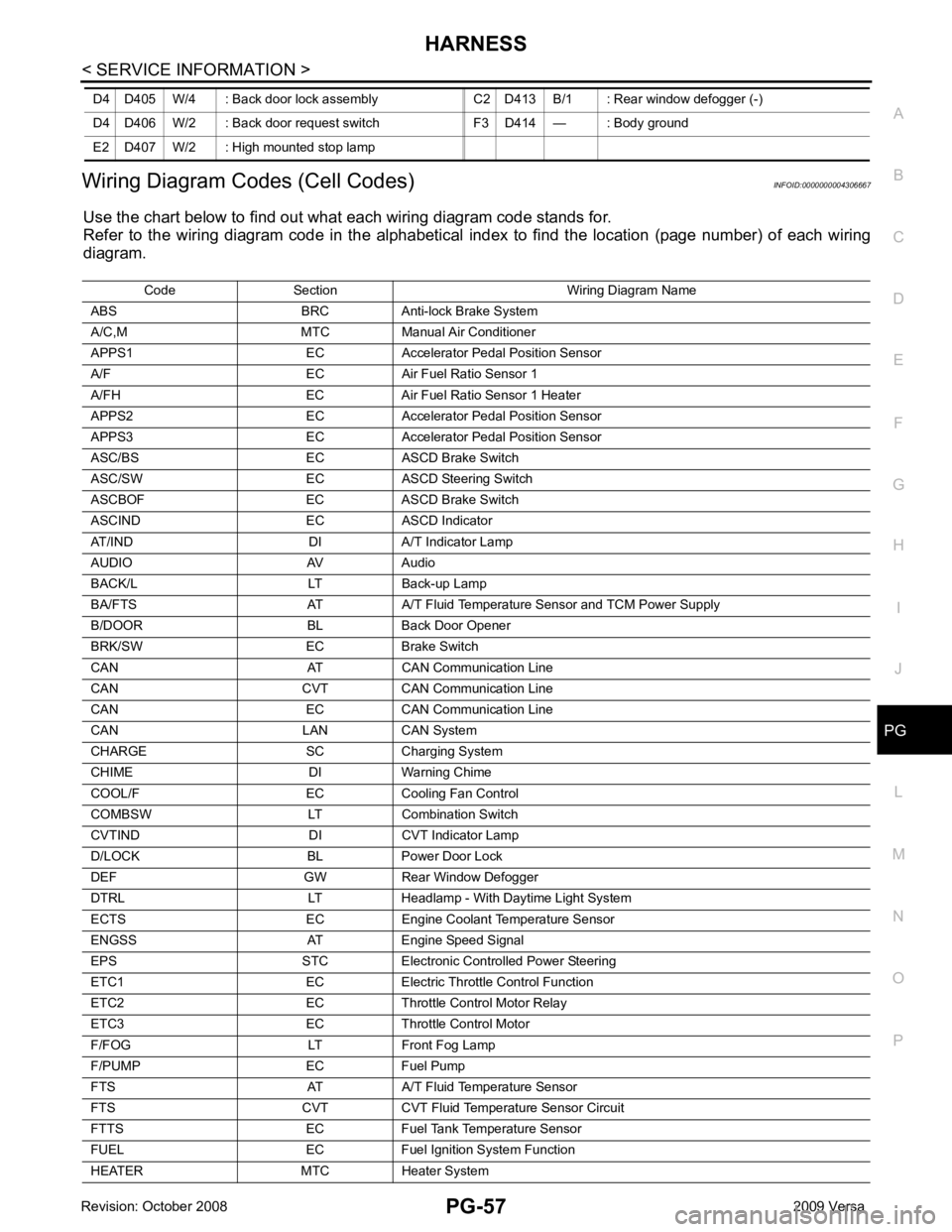

Wiring Diagram Codes (Cell Codes)

INFOID:0000000004306667

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram. D4 D405 W/4 : Back door lock assembly C2 D413 B/1 : Rear window defogger (-)

D4 D406 W/2 : Back door request switch F3 D414 — : Body ground

E2 D407 W/2 : High mounted stop lamp Code Section Wiring Diagram Name

ABS BRC Anti-lock Brake System

A/C,M MTC Manual Air Conditioner

APPS1 EC Accelerator Pe dal Position Sensor

A/F EC Air Fuel Ratio Sensor 1

A/FH EC Air Fuel Ratio Sensor 1 Heater

APPS2 EC Accelerator Pe dal Position Sensor

APPS3 EC Accelerator Pe dal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

BACK/L LT Back-up Lamp

BA/FTS AT A/T Fluid Temperature Sensor and TCM Power Supply

B/DOOR BL Back Door Opener

BRK/SW EC Brake Switch

CAN AT CAN Communication Line

CAN CVT CAN Comm unication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

CVTIND DI CVT Indicator Lamp

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - Wi th Daytime Light System

ECTS EC Engine Coolant Temperature Sensor

ENGSS AT Engine Speed Signal

EPS STC Electronic Controlled Power Steering

ETC1 EC Electric Throttle Control Function

ETC2 EC Throttle Control Motor Relay

ETC3 EC Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTS AT A/T Fluid Temperature Sensor

FTS CVT CVT Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUEL EC Fuel Ignition System Function

HEATER MTC Heater System

Page 4114 of 4331

RSU

N

O P

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Rear Suspension INFOID:0000000004305875

• When installing the rubber bushings, the final tightening must be done under unladen condition and with the tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and l ubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre-

oiled, do not apply any additional lubrication.

Page 4157 of 4331

SC

N

O P

CHARGING SYSTEM

System Description INFOID:0000000004306825

The generator provides DC voltage to operate the vehicl e's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to generator terminal 3 through

• 10A fuse (No. 29, located in the fuse and fusible link box).

Power is supplied through terminal 1 to charge the batte ry and operate the vehicle's electrical system. Output

voltage is monitored at terminal 3 by the IC regulator. The charging circuit is protected by the 120A fusible link

[letter a , located in the fusible link box (battery)].

Ground is supplied

• to generator terminal 5

• through body ground F5, and

• through the generator case to the cylinder block

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 3, located in the fuse block (J/B)]

• to combination meter terminal 28 for the charge warning lamp.

The IC regulator controls ground to terminal 38 of the combination meter through terminal 2 of the generator.

When the ignition is turned on and power becomes availabl e at terminal 2, this "wakes up" the regulator. The

regulator monitors charge output and grounds terminal 2 or leaves it open depending on charge output. With

power and ground supplied, the charge warning lamp will il luminate. When the generator is providing sufficient

voltage, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

Page 4251 of 4331

STC

N

O P

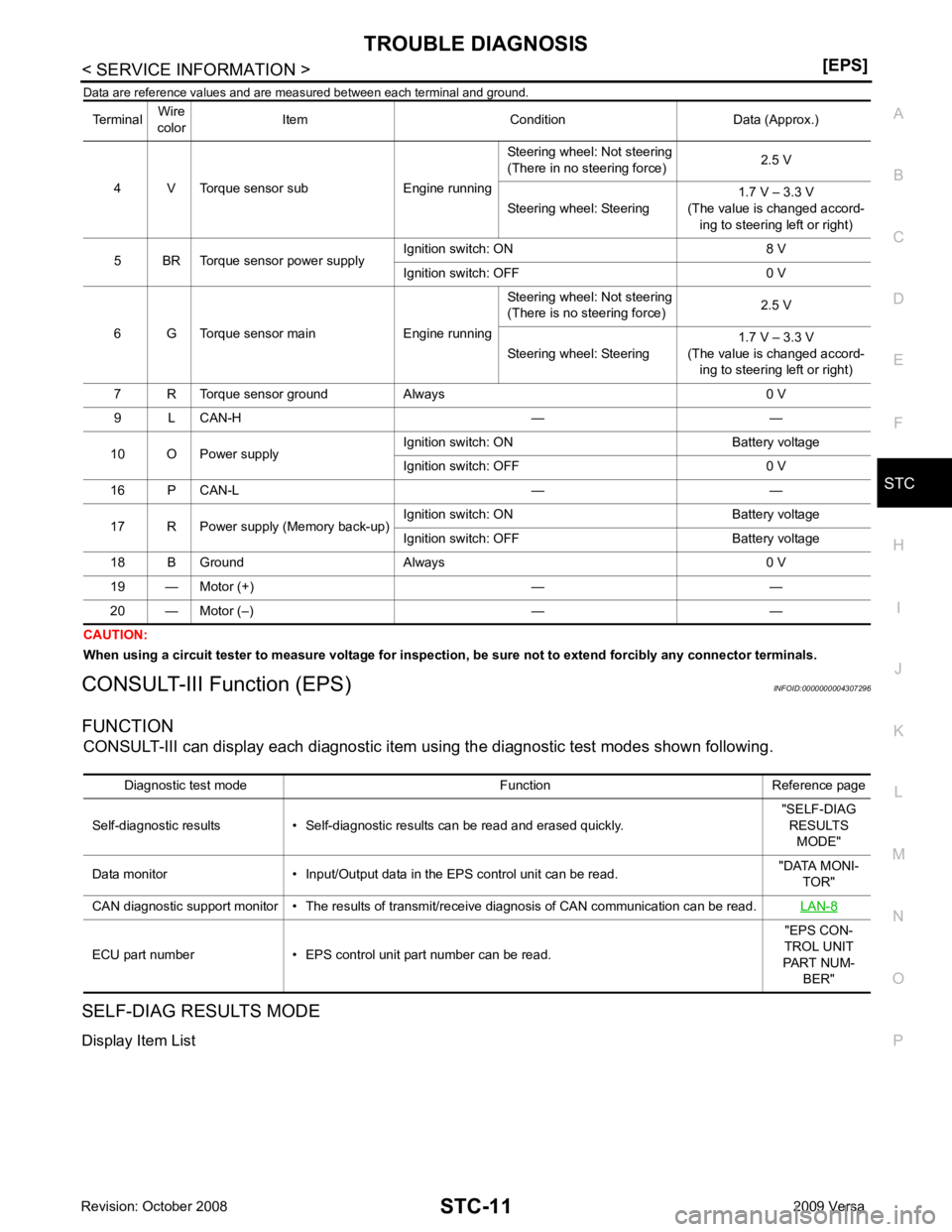

Data are reference values and are

measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection , be sure not to extend forcibly any connector terminals.

CONSULT-III Function (EPS) INFOID:0000000004307296

FUNCTION CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

SELF-DIAG RESULTS MODE

Display Item List Terminal

Wire

color Item Condition Data (Approx.)

4 V Torque sensor sub Engine running Steering wheel: Not steering

(There in no steering force) 2.5 V

Steering wheel: Steering 1.7 V – 3.3 V

(The value is changed accord- ing to steering left or right)

5 BR Torque sensor power supply Ignition switch: ON 8 V

Ignition switch: OFF 0 V

6 G Torque sensor main Engine running Steering wheel: Not steering

(There is no steering force) 2.5 V

Steering wheel: Steering 1.7 V – 3.3 V

(The value is changed accord- ing to steering left or right)

7 R Torque sensor ground Always 0 V

9 L CAN-H — —

10 O Power supply Ignition switch: ON Battery voltage

Ignition switch: OFF 0 V

16 P CAN-L — —

17 R Power supply (Memory back-up) Ignition switch: ON Battery voltage

Ignition switch: OFF Battery voltage

18 B Ground Always 0 V

19 — Motor (+) — —

20 — Motor (–) — — Diagnostic test mode Function Reference page

Self-diagnostic results • Self-diagnostic results can be read and erased quickly. "SELF-DIAG

RESULTS MODE"

Data monitor • Inpu t/Output data in the EPS control unit can be read. "DATA MONI-

TOR"

CAN diagnostic support monitor • The results of transmit/receive diagnosis of CAN communication can be read. LAN-8ECU part number • EPS control unit

part number can be read. "EPS CON-

TROL UNIT

PART NUM- BER"

Page 4252 of 4331

![NISSAN TIIDA 2009 Service Repair Manual DTC C1601

BATTERY VOLT "

TORQUE SENSOR

[C1604] When the torque sensor malfunction assembled in steering column

assembly is detected. STC-15, " DTC C1604

TORQUE SENSOR "

EPS MOTOR

[C1606] When the NISSAN TIIDA 2009 Service Repair Manual DTC C1601

BATTERY VOLT "

TORQUE SENSOR

[C1604] When the torque sensor malfunction assembled in steering column

assembly is detected. STC-15, " DTC C1604

TORQUE SENSOR "

EPS MOTOR

[C1606] When the](/img/5/57398/w960_57398-4251.png)

DTC C1601

BATTERY VOLT "

TORQUE SENSOR

[C1604] When the torque sensor malfunction assembled in steering column

assembly is detected. STC-15, " DTC C1604

TORQUE SENSOR "

EPS MOTOR

[C1606] When the motor driver

malfunction of EPS control unit or EPS motor

malfunction is detected. STC-16, " DTC C1606

EPS MOTOR "

EEPROM

[C1607] When the memory (EEPROM) system malfunction is detected in

EPS control unit. STC-17, " DTC C1607

EEPROM "

CONTROL UNIT

[C1608] When the internal malfunction is detected in EPS control unit. STC-17, " DTC C1608

CONTROL UNIT "

CAN VHCL SPEED

[C1609] When the malfunction is detected in vehicle speed signal received

with CAN communication. STC-18, " DTC C1609

CAN VHCL SPEED "

CAN ENG RPM

[C1610] When the malfunction is detected in engine status signal received

with CAN communication. STC-19, " DTC C1610

CAN ENG RPM "

CAN COMM CIRCUIT

[U1000] When EPS control unit is

not transmitting or receiving CAN commu-

nication signal 2 seconds or more. STC-19, " DTC U1000

CAN COMM CIRCUIT "

NO DTC IS DETECTED.

FURTHER TESTING MAY BE RE-

QUIRED. No NG item has been detected. —Monitor item (Unit) Remarks

MOTOR VOL (V) Power supply voltage for EPS control unit is displayed

TORQUE SENSOR (Nm) Steering wheel turning force detected by torque sensor is displayed

MOTOR SIG (A) Current commanded value to EPS motor is displayed

MOTOR CURRENT (A) Current value cons umed by EPS motor is displayed

VEHICLE SPEED (km/h) or (mph) Vehicle speed is displayed from vehicle speed signal with CAN communication

WARNING LAMP (ON/OFF) EPS warning la mp control status is displayed

DERATING STAT (ON/OFF) Protect overload status is displayed

ENGINE STATUS (STOP/RUN) Engine spee d is displayed from engine status signal with CAN communication

Page 4253 of 4331

STC

N

O P

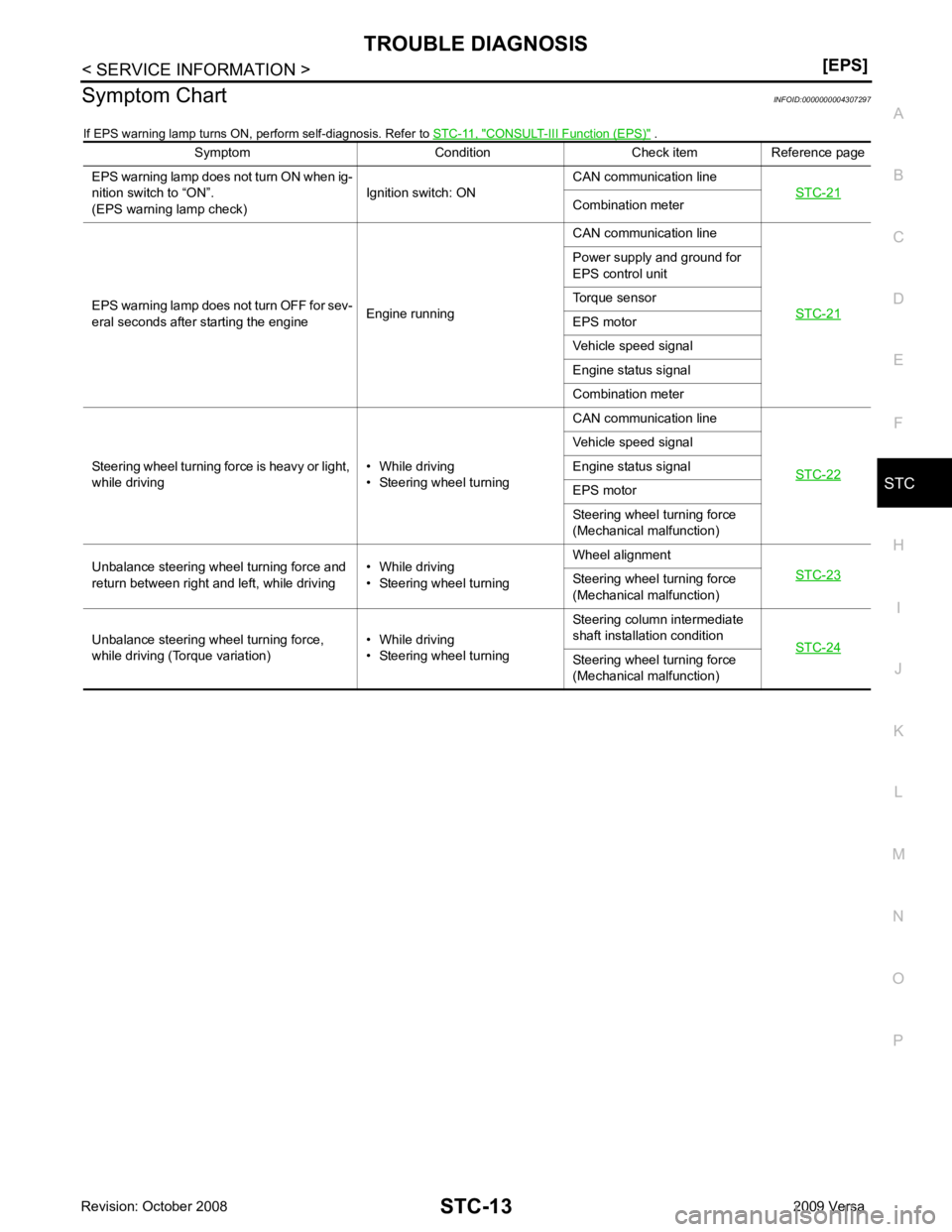

Symptom Chart

INFOID:0000000004307297

If EPS warning lamp turns ON, perform self-diagnosis. Refer to STC-11, " CONSULT-III Function (EPS) " .

Symptom Condition Check item Reference page

EPS warning lamp does not turn ON when ig-

nition switch to “ON”.

(EPS warning lamp check) Ignition switch: ONCAN communication line

STC-21 Combination meter

EPS warning lamp does not turn OFF for sev-

eral seconds after starting the engine Engine runningCAN communication line

STC-21 Power supply and ground for

EPS control unit

Torque sensor

EPS motor

Vehicle speed signal

Engine status signal

Combination meter

Steering wheel turning force is heavy or light,

while driving • While driving

• Steering wheel turning CAN communication line

STC-22 Vehicle speed signal

Engine status signal

EPS motor

Steering wheel turning force

(Mechanical malfunction)

Unbalance steering wheel turning force and

return between right and left, while driving • While driving

• Steering wheel turning Wheel alignment

STC-23 Steering wheel

turning force

(Mechanical malfunction)

Unbalance steering wheel turning force,

while driving (Torque variation) • While driving

• Steering wheel turning Steering column intermediate

shaft installation condition STC-24 Steering wheel

turning force

(Mechanical malfunction)

Page 4255 of 4331

STC

N

O P

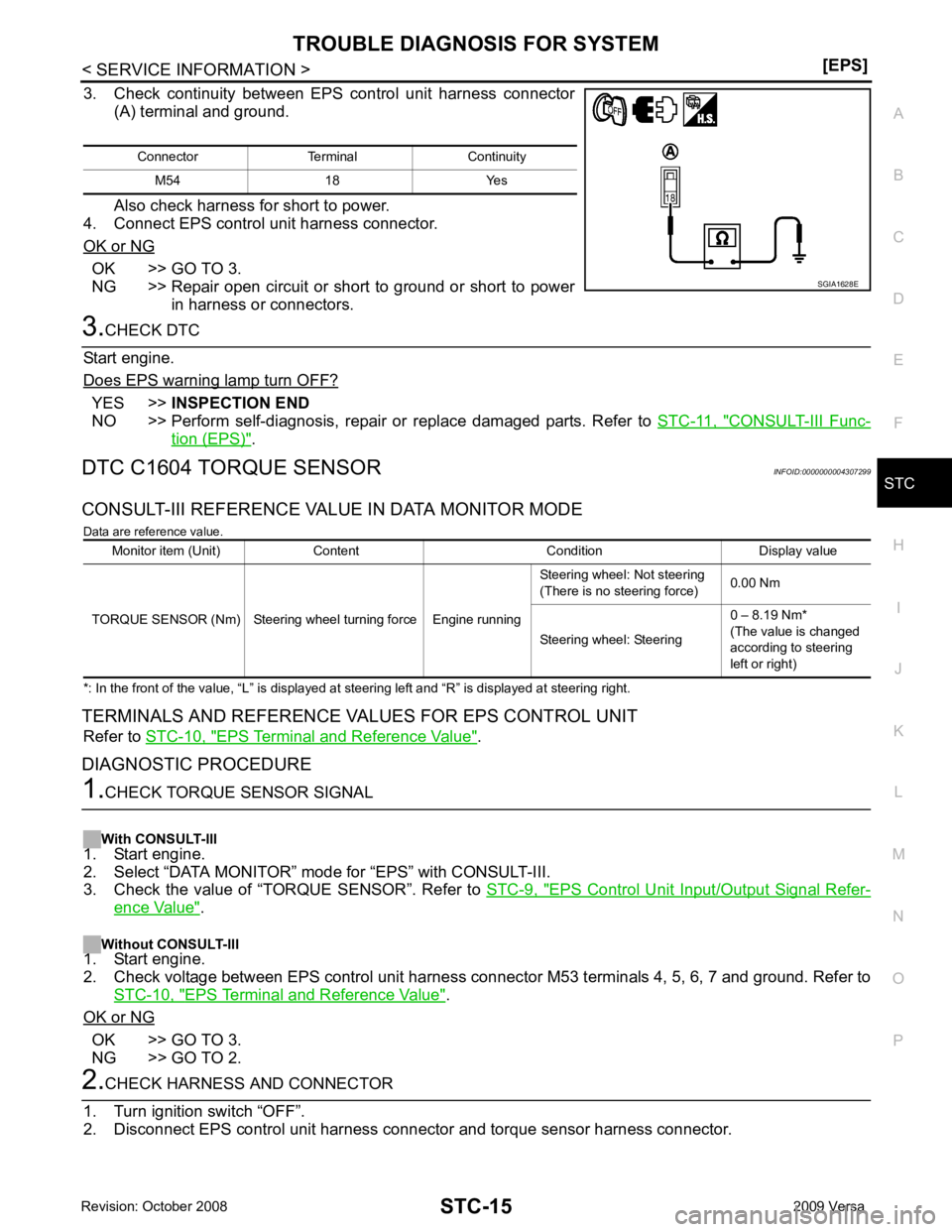

3. Check continuity between EPS control unit harness connector

(A) terminal and ground.

Also check harness for short to power.

4. Connect EPS control unit harness connector.

OK or NG OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors. YES >>

INSPECTION END

NO >> Perform self-diagnosis, repair or replace damaged parts. Refer to STC-11, " CONSULT-III Func-

tion (EPS) " .

DTC C1604 TORQUE SENSOR INFOID:0000000004307299

CONSULT-III REFERENCE VALUE IN DATA MONITOR MODE Data are reference value.

*: In the front of the value, “L” is displayed at steering left and “R” is displayed at steering right.

TERMINALS AND REFERENCE VA LUES FOR EPS CONTROL UNIT

Refer to STC-10, " EPS Terminal and Reference Value " .

DIAGNOSTIC PROCEDURE EPS Control Unit Input/Output Signal Refer-

ence Value " .

Without CONSULT-III

1. Start engine.

2. Check voltage between EPS control unit harness connec tor M53 terminals 4, 5, 6, 7 and ground. Refer to

STC-10, " EPS Terminal and Reference Value " .

OK or NG OK >> GO TO 3.

NG >> GO TO 2.

Page 4257 of 4331

STC

N

O P

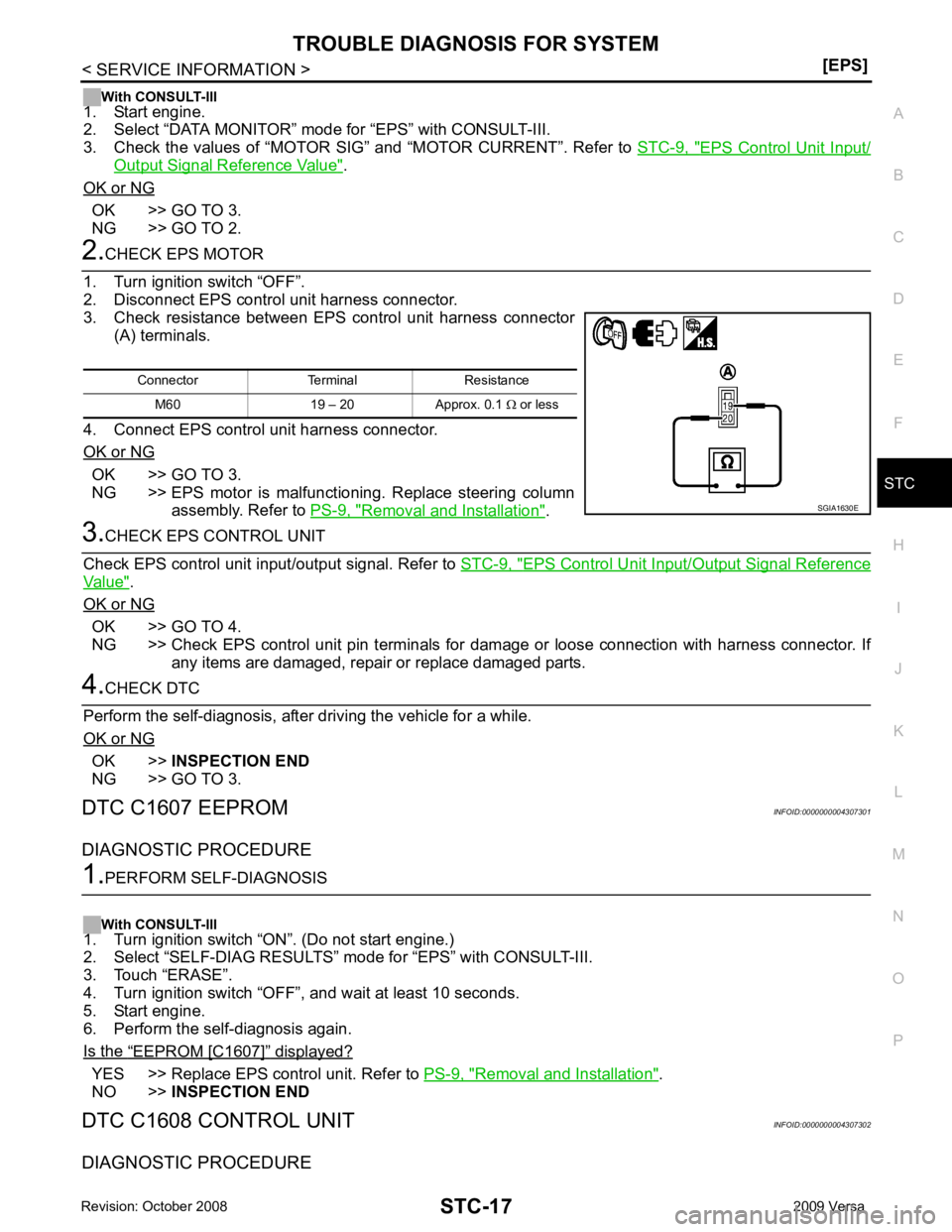

With CONSULT-III

1. Start engine.

2. Select “DATA MONITOR” mode for “EPS” with CONSULT-III.

3. Check the values of “MOTOR SIG” and “MOTOR CURRENT”. Refer to STC-9, " EPS Control Unit Input/

Output Signal Reference Value " .

OK or NG OK >> GO TO 3.

NG >> GO TO 2. OK >> GO TO 3.

NG >> EPS motor is malfunctioning. Replace steering column

assembly. Refer to PS-9, " Removal and Installation " .

EPS Control Unit Input/Output Signal Reference

Value " .

OK or NG OK >> GO TO 4.

NG >> Check EPS control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts. OK >>

INSPECTION END

NG >> GO TO 3.

DTC C1607 EEPROM INFOID:0000000004307301

DIAGNOSTIC PROCEDURE “ EEPROM [C1607] ” displayed?

YES >> Replace EPS control unit. Refer to

PS-9, " Removal and Installation " .

NO >> INSPECTION END

DTC C1608 CONTROL UNIT INFOID:0000000004307302

DIAGNOSTIC PROCEDURE

Page 4259 of 4331

STC

N

O P

OK >>

INSPECTION END

NG >> Perform self-diagnosis with ABS actuator and el ectric unit (control unit) and combination meter.

Refer to BRC-18, " CONSULT-III Function (ABS) " ,

DI-12, " CONSULT-III Function (METER/M&A) "

.

DTC C1610 CAN ENG RPM INFOID:0000000004307304

CONSULT-III REFERENCE VALUE IN DATA MONITOR MODE Data are reference value.

DIAGNOSTIC PROCEDURE CONSULT-III Function (ENGINE) " (MR TYPE 1),

EC-1116, " CONSULT-III F

unction (ENGINE) " (MR TYPE 2) or

EC-103, " CONSULT-III Function " (HR16DE).

Is any malfunction detected by self-diagnosis? YES >> Check the malfunctioning system.

NO >> GO TO 2. EPS Control Unit Input/Output Signal Reference

Value " .

OK or NG OK >> GO TO 3.

NG >> Check EPS control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts. OK >>

INSPECTION END

NG >> Perform self-diagnosis with ECM again. Refer EC-604, " CONSULT-III Function (ENGINE) " (MR

TYPE 1), EC-1116, " CONSULT-III Function (ENGINE) " (MR TYPE 2) or

EC-103, " CONSULT-III

Function " (HR16DE).

DTC U1000 CAN COMM CIRCUIT INFOID:0000000004307305

DIAGNOSTIC PROCEDURE “ CAN COMM CIRCUIT [U1000] ” displayed?

YES >> Print out CONSULT-III screen and go to

LAN-17, " Trouble Diagnosis Flow Chart " .

NO >> INSPECTION END

Component Inspection INFOID:0000000004307306

EPS MOTOR 1. Turn ignition switch “OFF”.

2. Disconnect EPS control unit harness connector. Monitor item (Unit) Content Condition Display value

ENGINE STATUS (RUN/STOP) Engine status Engine stopped (Engine speed: Less than 400 rpm) STOP

Engine running (Engine speed: 400 rpm or more) RUN

Page 4261 of 4331

![NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

STC-21

< SERVICE INFORMATION >

[EPS] C

D E

F

H I

J

K L

M A

B STC

N

O

P

TROUBLE DIAGNOSIS FOR SYMPTOMS

EPS Warning Lamp Does Not Turn ON INFOID:0000000004307307

SYMPTOM: NISSAN TIIDA 2009 Service Repair Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

STC-21

< SERVICE INFORMATION >

[EPS] C

D E

F

H I

J

K L

M A

B STC

N

O

P

TROUBLE DIAGNOSIS FOR SYMPTOMS

EPS Warning Lamp Does Not Turn ON INFOID:0000000004307307

SYMPTOM:](/img/5/57398/w960_57398-4260.png)

TROUBLE DIAGNOSIS FOR SYMPTOMS

STC-21

< SERVICE INFORMATION >

[EPS] C

D E

F

H I

J

K L

M A

B STC

N

O

P

TROUBLE DIAGNOSIS FOR SYMPTOMS

EPS Warning Lamp Does Not Turn ON INFOID:0000000004307307

SYMPTOM: EPS warning lamp does not turn ON when ignition switch to “ON”.

DIAGNOSTIC PROCEDURE 1.

CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to STC-11, " CONSULT-III Function (EPS) " .

Is the “ CAN COMM CIRCUIT [U1000] ” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to

STC-19, " DTC U1000 CAN

COMM CIRCUIT " .

NO >> GO TO 2. 2.

CHECK EPS CONTROL UNIT

Check EPS control unit input/output signal. Refer to STC-9, " EPS Control Unit Input/Output Signal Reference

Value " .

OK or NG OK >> GO TO 3.

NG >> Check EPS control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts. 3.

SYMPTOM CHECK

Check again.

OK or NG OK >>

INSPECTION END

NG >> Replace combination meter. Refer to DI-19, " Removal and Installation " .

EPS Warning Lamp Does Not Turn OFF INFOID:0000000004307308

SYMPTOM: EPS warning lamp does not turn OFF for several seconds after starting the engine.

DIAGNOSTIC PROCEDURE 1.

CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to STC-11, " CONSULT-III Function (EPS) " .

Is any malfunction detected by self-diagnosis? YES >> Check the malfunctioning system.

NO >> GO TO 2. 2.

CHECK EPS CONTROL UNI T POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect EPS control unit harness connector.

3. Turn ignition switch “ON”. (Do not start engine.)

4. Check voltage between EPS control unit harness connector (A) terminals and ground.

Connector Terminal VoltageM53 10 – Ground Battery voltage

M54 17 – Ground Battery voltage SGIA1626E