engine control NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3770 of 4331

ENGINE MAINTENANCE (MR18DE)

MA-27

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K

M A

B MA

N

O P

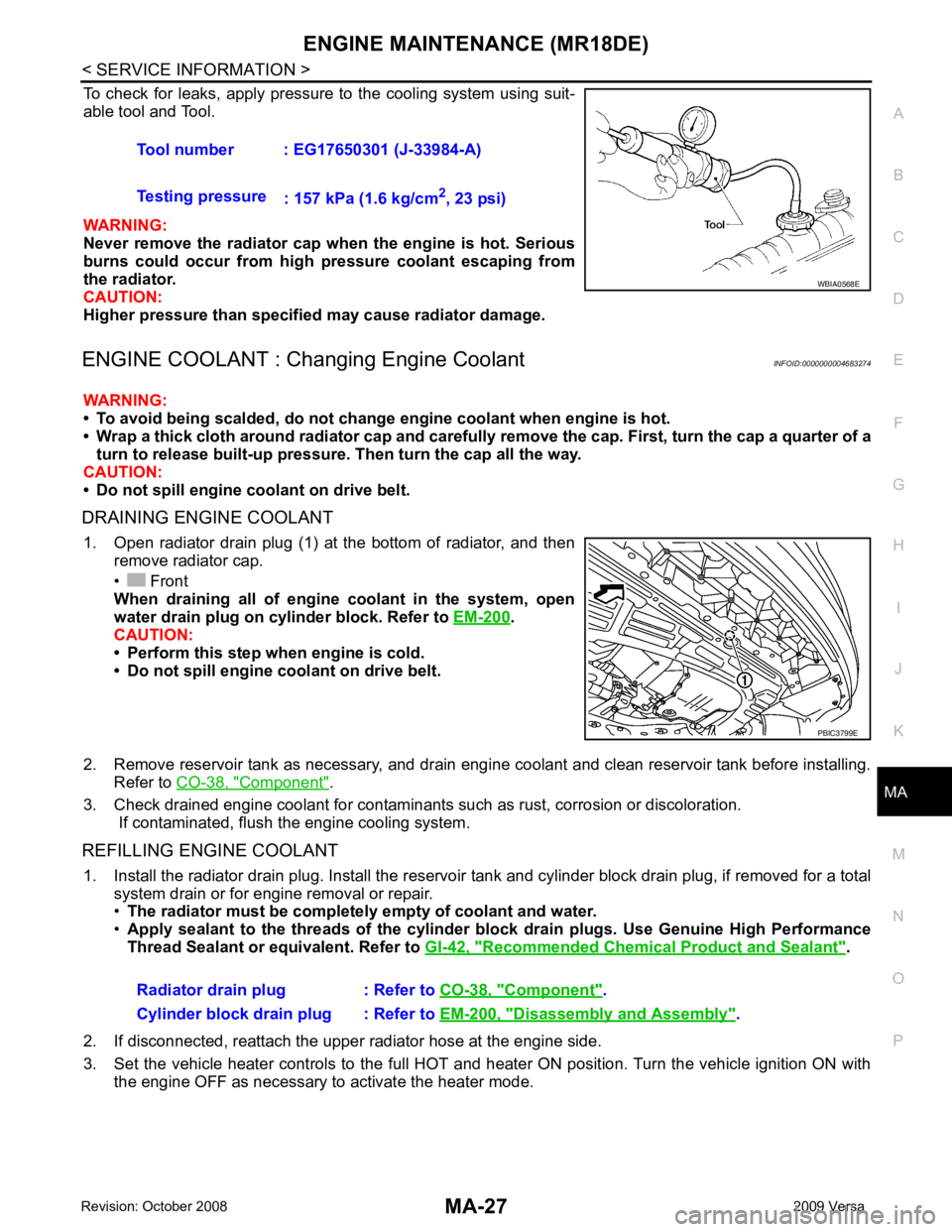

To check for leaks, apply pressure to the cooling system using suit-

able tool and Tool.

WARNING:

Never remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLANT : Chang ing Engine Coolant INFOID:0000000004683274

WARNING:

• To avoid being scalded, do not change engine coolant when engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

CAUTION:

• Do not spill engine coolant on drive belt.

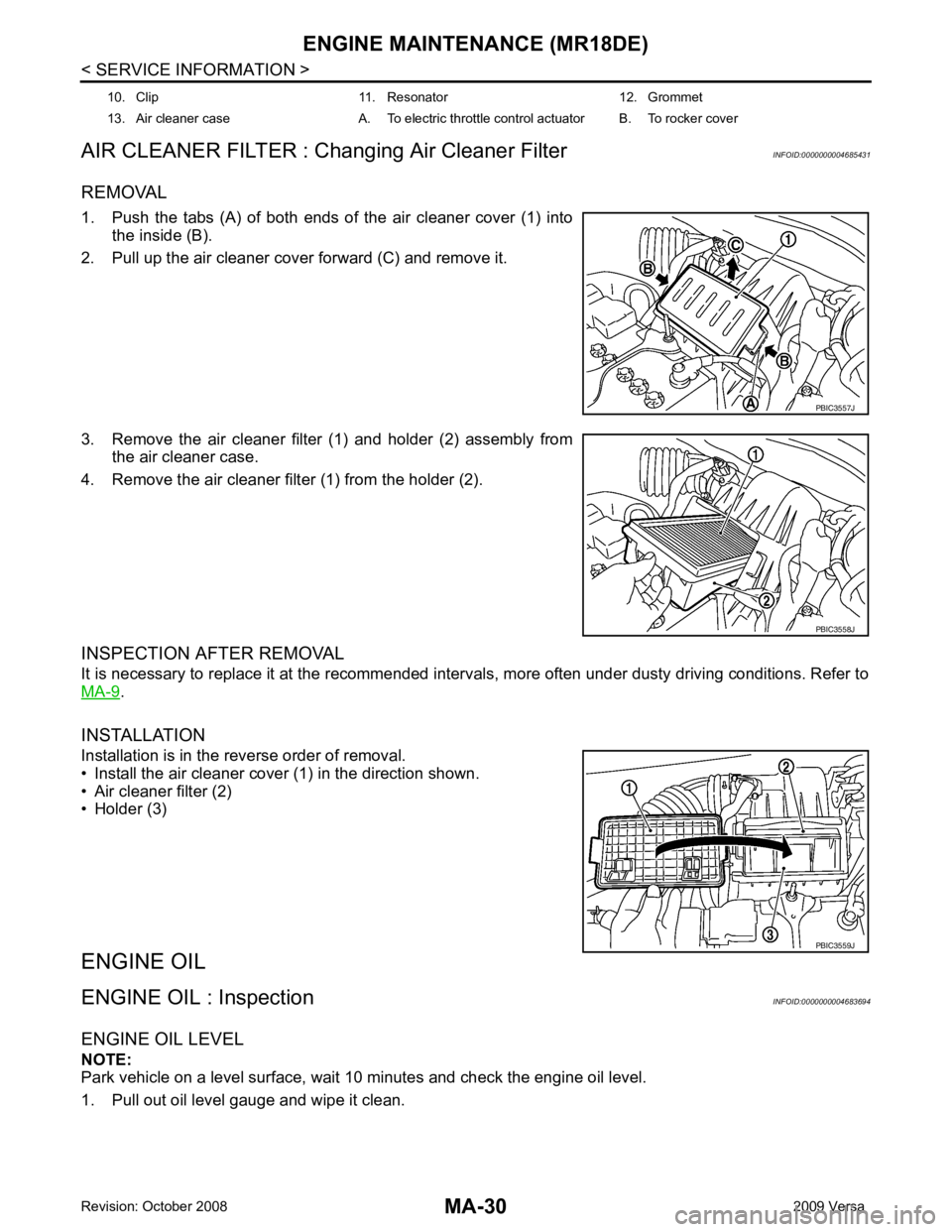

DRAINING ENGINE COOLANT 1. Open radiator drain plug (1) at the bottom of radiator, and then remove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-200 .

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engi ne coolant and clean reservoir tank before installing.

Refer to CO-38, " Component " .

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT 1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be complete ly empty of coolant and water.

• Apply sealant to the threads of the cylinder blo ck drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product and Sealant " .

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode. Tool number : EG17650301 (J-33984-A)

Testing pressure : 157 kPa (1.6 kg/cm 2

, 23 psi) WBIA0568E

PBIC3799E

Radiator drain plug : Refer to

CO-38, " Component " .

Cylinder block drain plug : Refer to EM-200, " Disassembly and Assembly " .

Page 3773 of 4331

MA-30< SERVICE INFORMATION >

ENGINE MAINTENANCE (MR18DE)

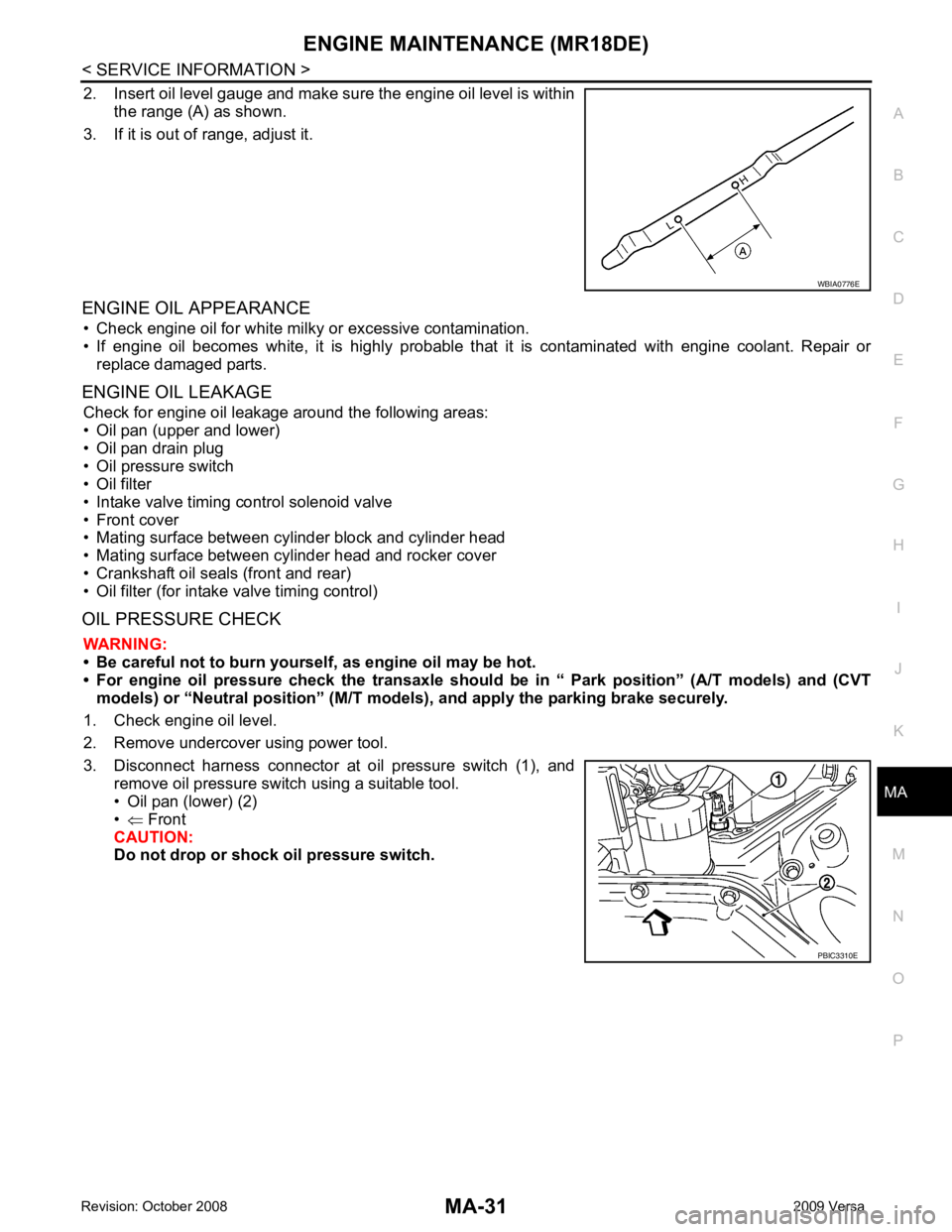

AIR CLEANER FILTER : Changing Air Cleaner Filter INFOID:0000000004685431

REMOVAL

1. Push the tabs (A) of both ends of the air cleaner cover (1) into the inside (B).

2. Pull up the air cleaner cover forward (C) and remove it.

3. Remove the air cleaner filter (1) and holder (2) assembly from the air cleaner case.

4. Remove the air cleaner filter (1) from the holder (2).

INSPECTION AFTER REMOVAL

It is necessary to replace it at the recommended interv als, more often under dusty driving conditions. Refer to

MA-9 .

INSTALLATION

Installation is in the reverse order of removal.

• Install the air cleaner cover (1) in the direction shown.

• Air cleaner filter (2)

• Holder (3)

ENGINE OIL

ENGINE OIL : Inspection INFOID:0000000004683694

ENGINE OIL LEVEL

NOTE:

Park vehicle on a level surface, wait 10 minutes and check the engine oil level.

1. Pull out oil level gauge and wipe it clean. 10. Clip 11. Resonator 12. Grommet

13. Air cleaner case A. To electric throttle control actuator B. To rocker cover PBIC3557J

PBIC3558J

PBIC3559J

Page 3774 of 4331

ENGINE MAINTENANCE (MR18DE)

MA-31

< SERVICE INFORMATION >

C

D E

F

G H

I

J

K

M A

B MA

N

O P

2. Insert oil level gauge and make sure the engine oil level is within

the range (A) as shown.

3. If it is out of range, adjust it.

ENGINE OIL APPEARANCE • Check engine oil for white milky or excessive contamination.

• If engine oil becomes white, it is highly probable t hat it is contaminated with engine coolant. Repair or

replace damaged parts.

ENGINE OIL LEAKAGE Check for engine oil leakage around the following areas:

• Oil pan (upper and lower)

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seals (front and rear)

• Oil filter (for intake valve timing control)

OIL PRESSURE CHECK WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• For engine oil pressure check the transaxle should be in “ Park position” (A/T models) and (CVT

models) or “Neutral position” (M/T mode ls), and apply the parking brake securely.

1. Check engine oil level.

2. Remove undercover using power tool.

3. Disconnect harness connector at oil pressure switch (1), and remove oil pressure switch using a suitable tool.

• Oil pan (lower) (2)

• ⇐ Front

CAUTION:

Do not drop or shock oil pressure switch. WBIA0776E

PBIC3310E

Page 3811 of 4331

MT

N

O P

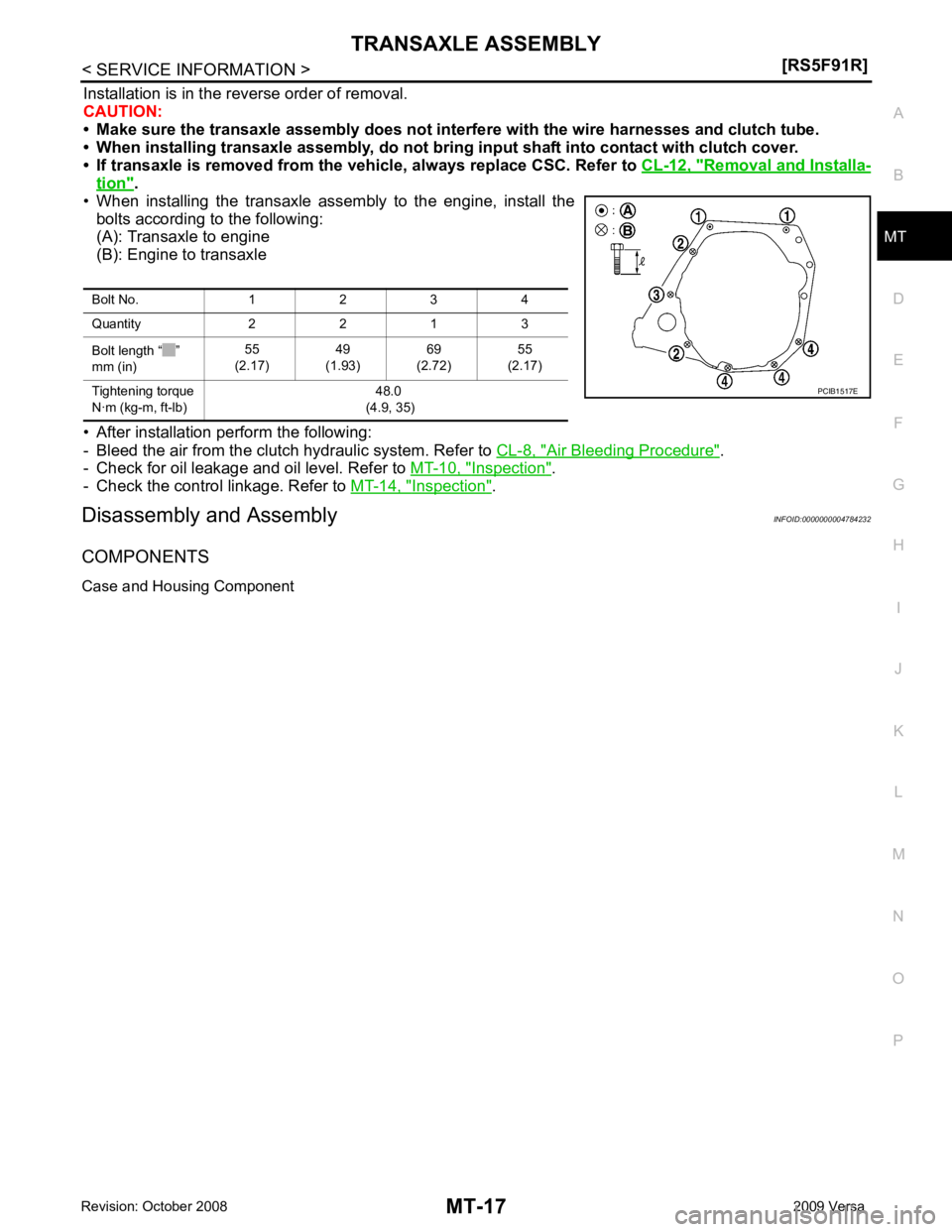

Installation is in the reverse order of removal.

CAUTION:

• Make sure the transaxle assembly does not interfer e with the wire harnesses and clutch tube.

• When installing transaxle assembly, do not bring input shaft into contact with clutch cover.

• If transaxle is removed from the vehicle, always replace CSC. Refer to CL-12, " Removal and Installa-

tion " .

• When installing the transaxle assembly to the engine, install the bolts according to the following:

(A): Transaxle to engine

(B): Engine to transaxle

• After installation perform the following:

- Bleed the air from the clutch hydraulic system. Refer to CL-8, " Air Bleeding Procedure " .

- Check for oil leakage and oil level. Refer to MT-10, " Inspection " .

- Check the control linkage. Refer to MT-14, " Inspection " .

Disassembly and Assembly INFOID:0000000004784232

COMPONENTS

Case and Housing Component Bolt No. 1 2 3 4

Quantity 2 2 1 3

Bolt length “ ”

mm (in) 55

(2.17) 49

(1.93) 69

(2.72) 55

(2.17)

Tightening torque

N·m (kg-m, ft-lb) 48.0

(4.9, 35)

Page 3888 of 4331

MTC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784399

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004687764

NOTE:

• This Procedure is applied only to models with Inte lligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Page 3934 of 4331

MTC

N

O P

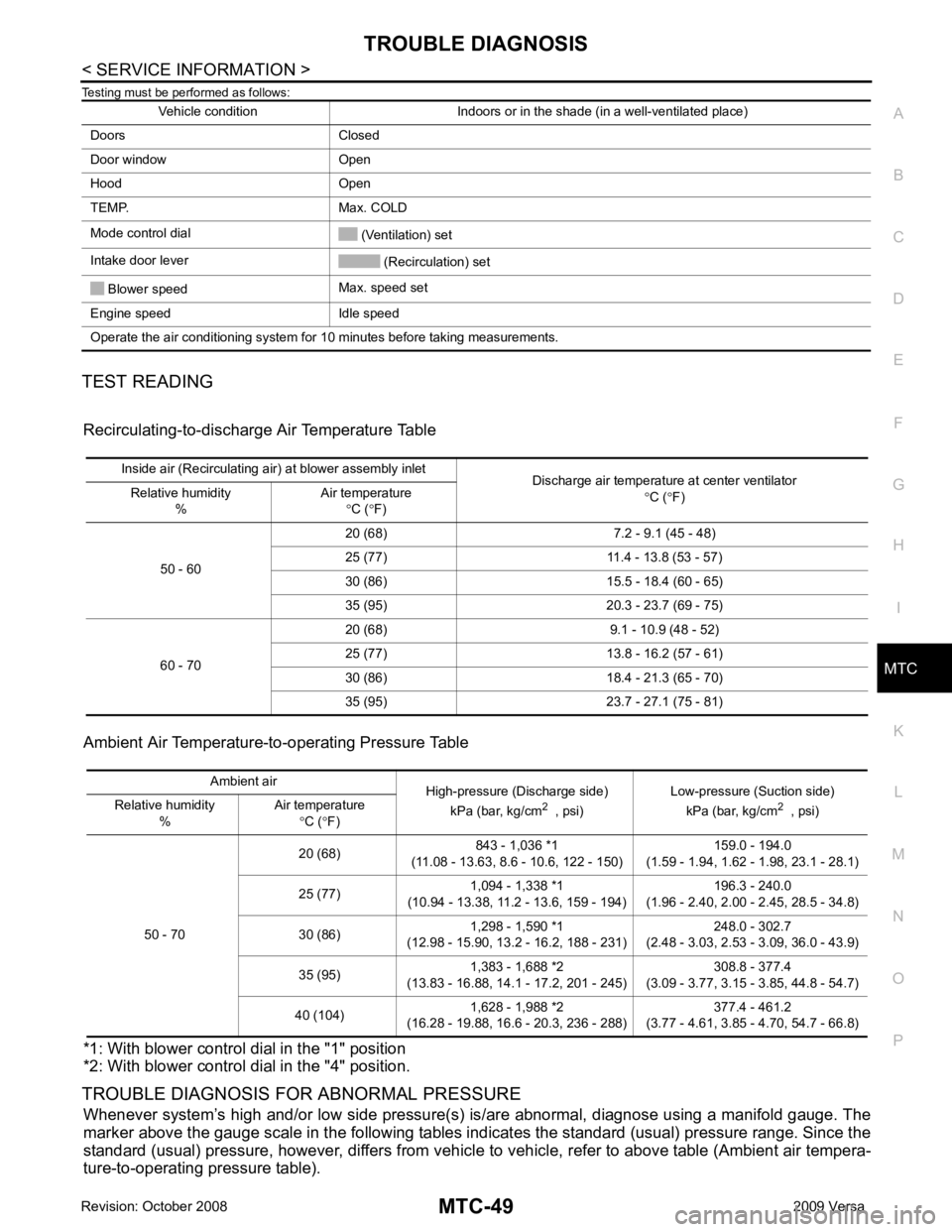

Testing must be performed as follows:

TEST READING Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

*1: With blower control dial in the "1" position

*2: With blower control dial in the "4" position.

TROUBLE DIAGNOSIS FOR ABNORMAL PRESSURE Whenever system’s high and/or low side pressure(s) is /are abnormal, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table). Vehicle condition Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode control dial (Ventilation) set

Intake door lever (Recirculation) set

Blower speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements. Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68) 7.2 - 9.1 (45 - 48)

25 (77) 11.4 - 13.8 (53 - 57)

30 (86) 15.5 - 18.4 (60 - 65)

35 (95) 20.3 - 23.7 (69 - 75)

60 - 70 20 (68) 9.1 - 10.9 (48 - 52)

25 (77) 13.8 - 16.2 (57 - 61)

30 (86) 18.4 - 21.3 (65 - 70)

35 (95) 23.7 - 27.1 (75 - 81) Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm 2

, psi) Low-pressure (Suction side)

kPa (bar, kg/cm 2

, psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

843 - 1,036 *1

(11.08 - 13.63, 8.6 - 10.6, 122 - 150) 159.0 - 194.0

(1.59 - 1.94, 1.62 - 1.98, 23.1 - 28.1)

25 (77) 1,094 - 1,338 *1

(10.94 - 13.38, 11.2 - 13.6, 159 - 194) 196.3 - 240.0

(1.96 - 2.40, 2.00 - 2.45, 28.5 - 34.8)

30 (86) 1,298 - 1,590 *1

(12.98 - 15.90, 13.2 - 16.2, 188 - 231) 248.0 - 302.7

(2.48 - 3.03, 2.53 - 3.09, 36.0 - 43.9)

35 (95) 1,383 - 1,688 *2

(13.83 - 16.88, 14.1 - 17.2, 201 - 245) 308.8 - 377.4

(3.09 - 3.77, 3.15 - 3.85, 44.8 - 54.7)

40 (104) 1,628 - 1,988 *2

(16.28 - 19.88, 16.6 - 20.3, 236 - 288) 377.4 - 461.2

(3.77 - 4.61, 3.85 - 4.70, 54.7 - 66.8)

Page 3944 of 4331

MTC

N

O P

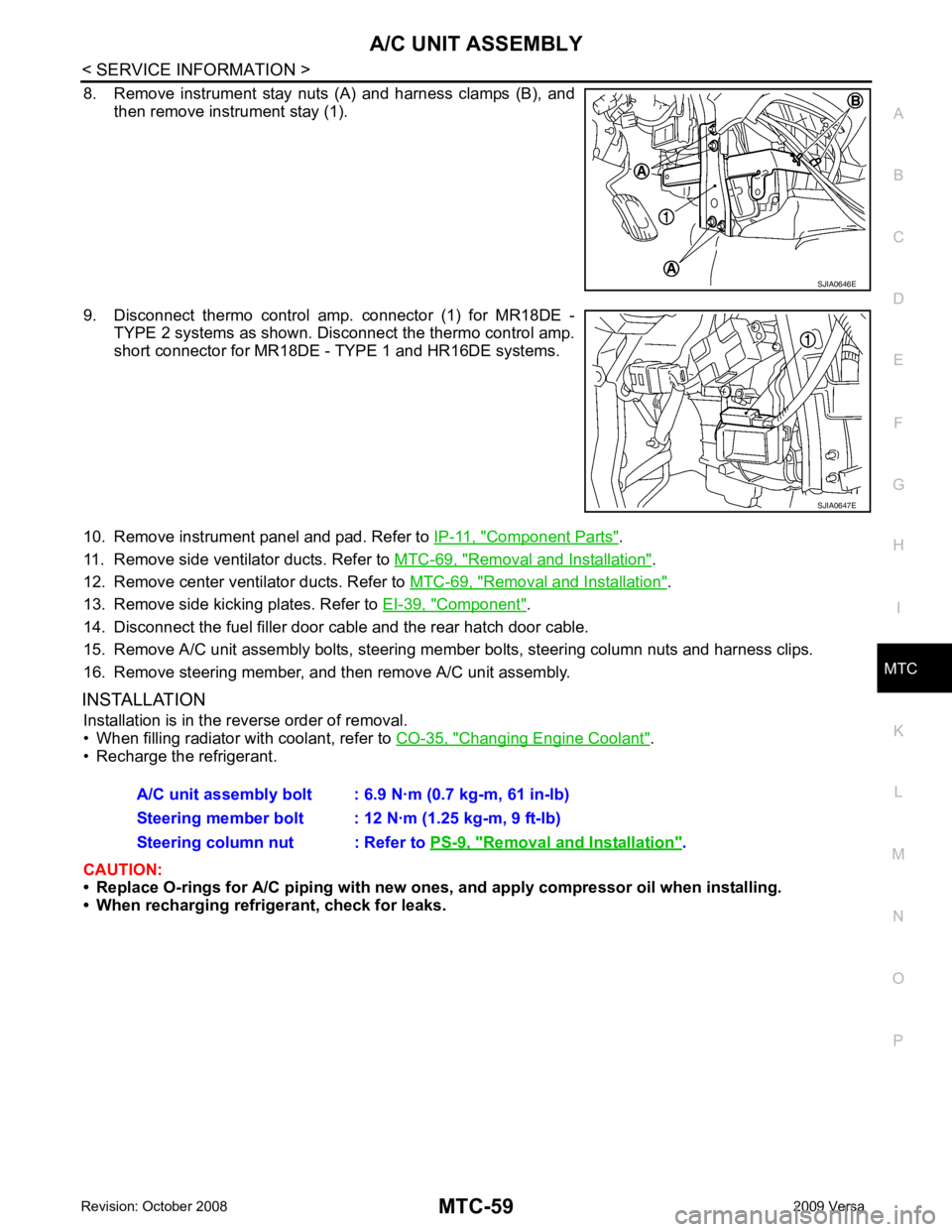

8. Remove instrument stay nuts (A) and harness clamps (B), and

then remove instrument stay (1).

9. Disconnect thermo control amp. connector (1) for MR18DE - TYPE 2 systems as shown. Disconnect the thermo control amp.

short connector for MR18DE - TYPE 1 and HR16DE systems.

10. Remove instrument panel and pad. Refer to IP-11, " Component Parts " .

11. Remove side ventilator ducts. Refer to MTC-69, " Removal and Installation " .

12. Remove center ventilator ducts. Refer to MTC-69, " Removal and Installation " .

13. Remove side kicking plates. Refer to EI-39, " Component " .

14. Disconnect the fuel filler door cable and the rear hatch door cable.

15. Remove A/C unit assembly bolts, steering member bolts, steering column nuts and harness clips.

16. Remove steering member, and then remove A/C unit assembly.

INSTALLATION Installation is in the reverse order of removal.

• When filling radiator with coolant, refer to CO-35, " Changing Engine Coolant " .

• Recharge the refrigerant.

CAUTION:

• Replace O-rings for A/C piping with new on es, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks. Removal and Installation " .

Page 3974 of 4331

MTC

N

O P

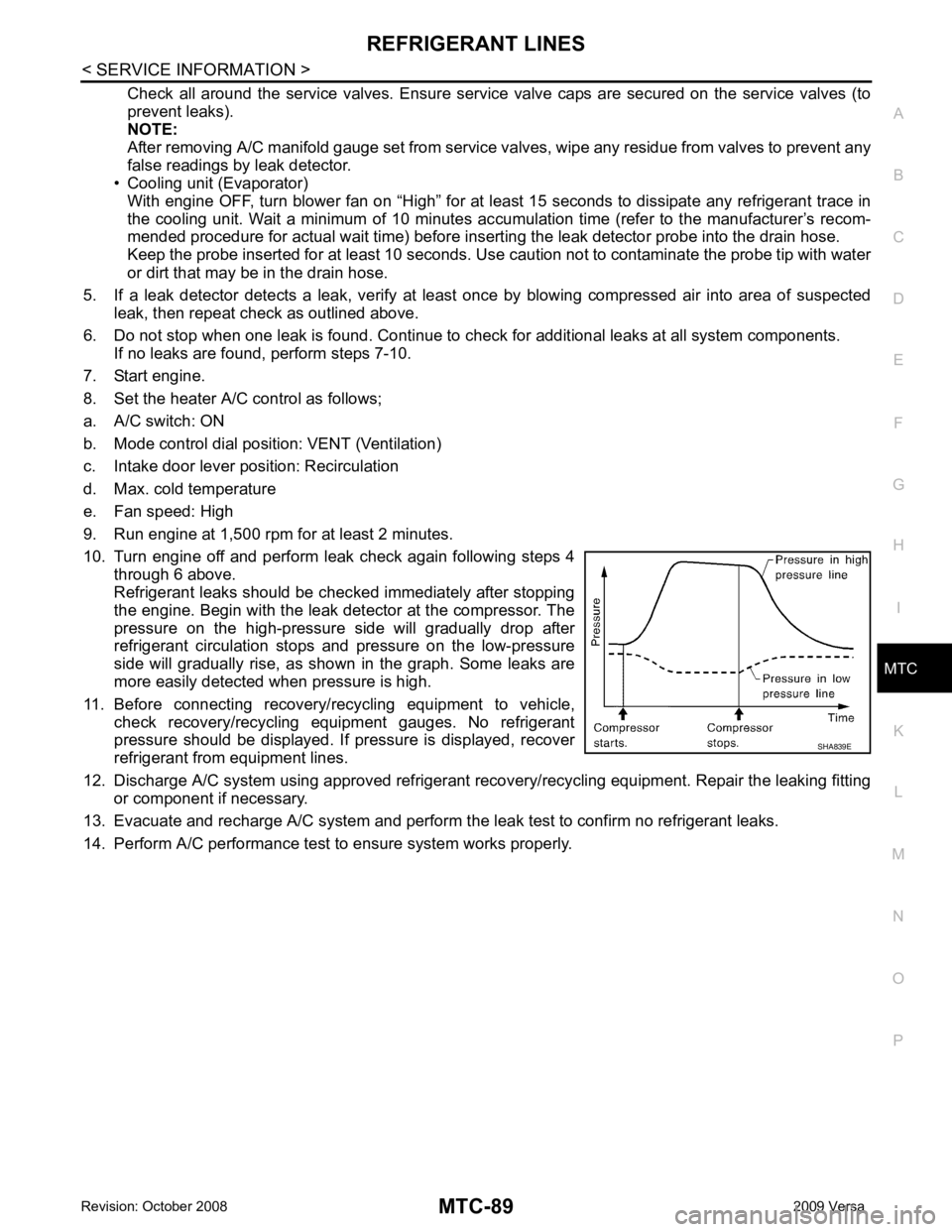

Check all around the service valves. Ensure service valve caps are secured on the service valves (to

prevent leaks).

NOTE:

After removing A/C manifold gauge set from service va lves, wipe any residue from valves to prevent any

false readings by leak detector.

• Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in

the cooling unit. Wait a minimum of 10 minutes ac cumulation time (refer to the manufacturer’s recom-

mended procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use c aution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7-10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. Mode control dial position: VENT (Ventilation)

c. Intake door lever position: Recirculation

d. Max. cold temperature

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps 4 through 6 above.

Refrigerant leaks should be chec ked immediately after stopping

the engine. Begin with the leak detector at the compressor. The

pressure on the high-pressure side will gradually drop after

refrigerant circulation stops and pressure on the low-pressure

side will gradually rise, as shown in the graph. Some leaks are

more easily detected when pressure is high.

11. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges. No refrigerant

pressure should be displayed. If pressure is displayed, recover

refrigerant from equipment lines.

12. Discharge A/C system using approved refrigerant reco very/recycling equipment. Repair the leaking fitting

or component if necessary.

13. Evacuate and recharge A/C system and perform the l eak test to confirm no refrigerant leaks.

14. Perform A/C performance test to ensure system works properly.

Page 4008 of 4331

PG

N

O P

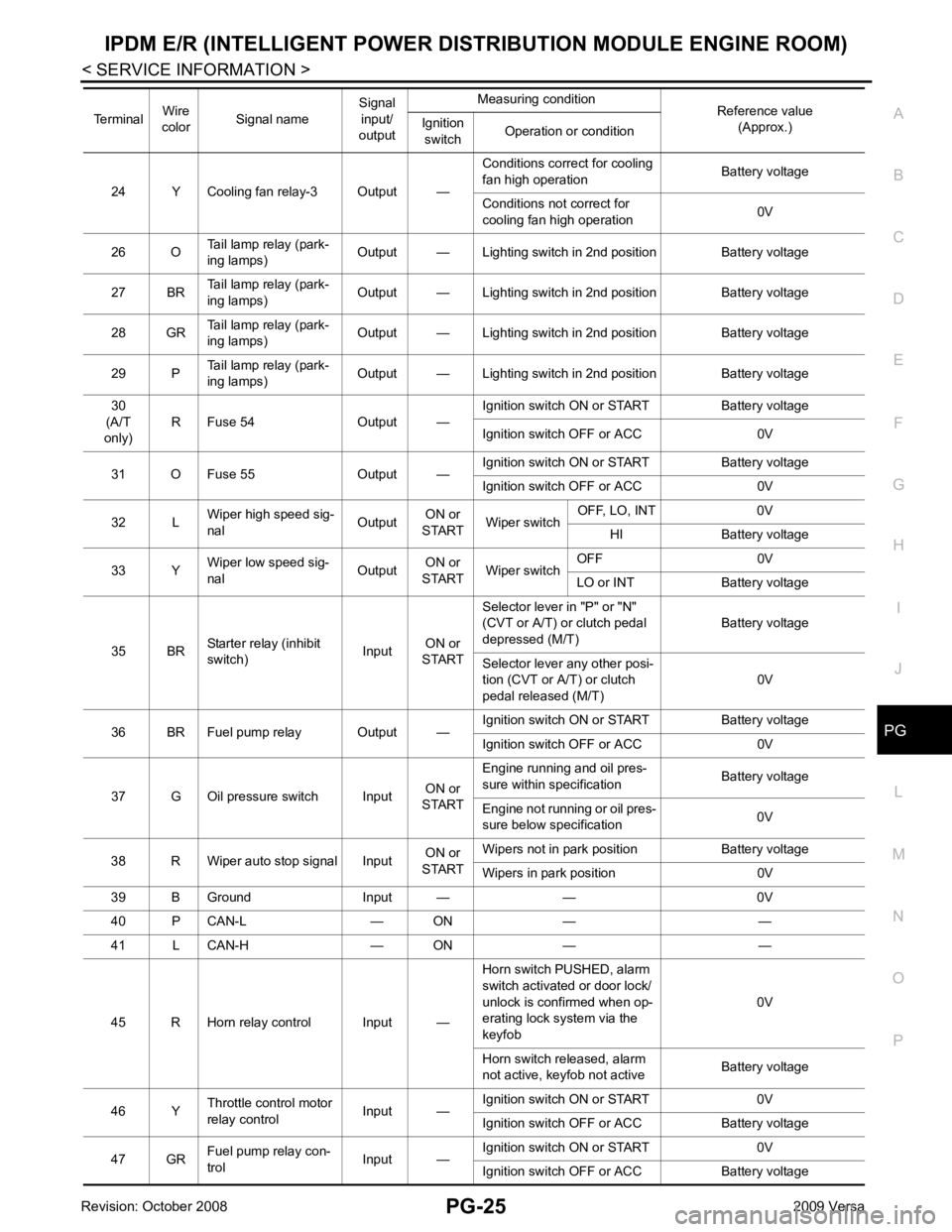

24 Y Cooling fan relay-3 Output —

Conditions correct for cooling

fan high operation Battery voltage

Conditions not correct for

cooling fan high operation 0V

26 O Tail lamp relay (park-

ing lamps) Output — Lighting switch in 2nd position Battery voltage

27 BR Tail lamp relay (park-

ing lamps) Output — Lighting switch in 2nd position Battery voltage

28 GR Tail lamp relay (park-

ing lamps) Output — Lighting switch in 2nd position Battery voltage

29 P Tail lamp relay (park-

ing lamps) Output — Lighting switch in 2nd position Battery voltage

30

(A/T

only) R Fuse 54 Output — Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

31 O Fuse 55 Output — Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

32 L Wiper high speed sig-

nal OutputON or

START Wiper switch OFF, LO, INT 0V

HI Battery voltage

33 Y Wiper low speed sig-

nal OutputON or

START Wiper switch OFF 0V

LO or INT Battery voltage

35 BR Starter relay (inhibit

switch) InputON or

START Selector lever in "P" or "N"

(CVT or A/T) or clutch pedal

depressed (M/T) Battery voltage

Selector lever any other posi-

tion (CVT or A/T) or clutch

pedal released (M/T) 0V

36 BR Fuel pump relay Output — Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

37 G Oil pressure switch Input ON or

START Engine running and oil pres-

sure within specification Battery voltage

Engine not running or oil pres-

sure below specification 0V

38 R Wiper auto stop signal Input ON or

START Wipers not in park position Battery voltage

Wipers in park position 0V

39 B Ground Input — — 0V

40 P CAN-L — ON — —

41 L CAN-H — ON — —

45 R Horn relay control Input — Horn switch PUSHED, alarm

switch activated or door lock/

unlock is confirmed when op-

erating lock system via the

keyfob 0V

Horn switch released, alarm

not active, keyfob not active Battery voltage

46 Y Throttle control motor

relay control Input —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

47 GR Fuel pump relay con-

trol Input —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

Terminal

Wire

color Signal name Signal

input/

output Measuring condition

Reference value

(Approx.)

Ignition

switch Operation or condition

Page 4028 of 4331

PG

N

O P

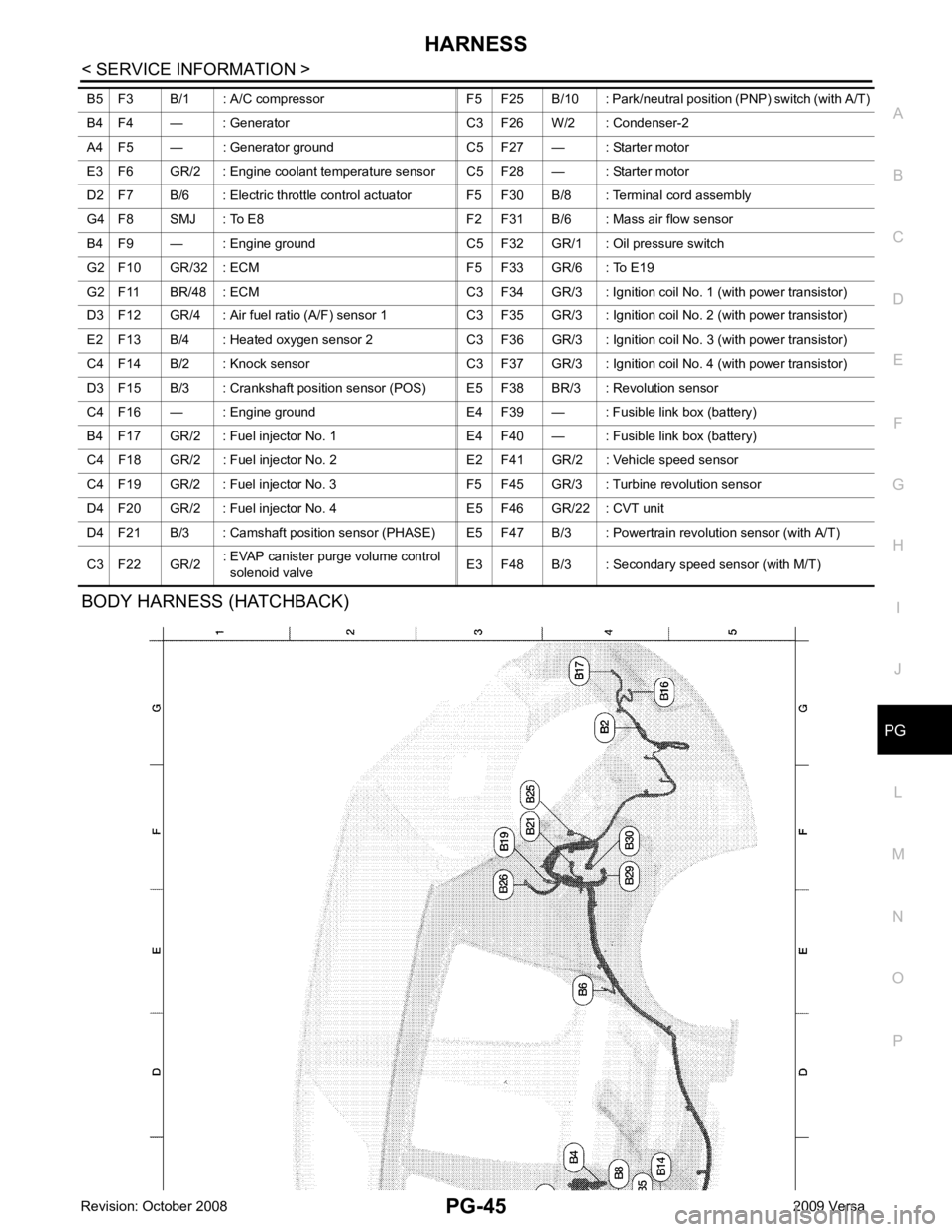

BODY HARNESS (HATCHBACK) B5 F3 B/1 : A/C compressor F5 F25 B/10 : Park/n

eutral position (PNP) switch (with A/T)

B4 F4 — : Generator C3 F26 W/2 : Condenser-2

A4 F5 — : Generator ground C5 F27 — : Starter motor

E3 F6 GR/2 : Engine coolant temperature sensor C5 F28 — : Starter motor

D2 F7 B/6 : Electric throttle control actuator F5 F30 B/8 : Terminal cord assembly

G4 F8 SMJ : To E8 F2 F31 B/6 : Mass air flow sensor

B4 F9 — : Engine ground C5 F32 GR/1 : Oil pressure switch

G2 F10 GR/32 : ECM F5 F33 GR/6 : To E19

G2 F11 BR/48 : ECM C3 F34 GR/3 : Ignition coil No. 1 (with power transistor)

D3 F12 GR/4 : Air fuel ratio (A/F) sensor 1 C3 F35 GR/3 : Ignition coil No. 2 (with power transistor)

E2 F13 B/4 : Heated oxygen sensor 2 C3 F36 GR/3 : Ignition coil No. 3 (with power transistor)

C4 F14 B/2 : Knock sensor C3 F37 GR/3 : Ignition coil No. 4 (with power transistor)

D3 F15 B/3 : Crankshaft position sensor (POS) E5 F38 BR/3 : Revolution sensor

C4 F16 — : Engine ground E4 F39 — : Fusible link box (battery)

B4 F17 GR/2 : Fuel injector No. 1 E4 F40 — : Fusible link box (battery)

C4 F18 GR/2 : Fuel injector No. 2 E2 F41 GR/2 : Vehicle speed sensor

C4 F19 GR/2 : Fuel injector No. 3 F5 F45 GR/3 : Turbine revolution sensor

D4 F20 GR/2 : Fuel injector No. 4 E5 F46 GR/22 : CVT unit

D4 F21 B/3 : Camshaft position sensor (PHASE) E5 F4 7 B/3 : Powertrain revolution sensor (with A/T)

C3 F22 GR/2 : EVAP canister purge volume control

solenoid valve E3 F48 B/3 : Secondary speed sensor (with M/T)