engine control NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 3022 of 4331

EM

NP

O

5. Perform the following inspection if engine oil does not

come out from intake valve timing control solenoid

valve oil hole of the cylinder head.

• Remove oil filter, and then clean it. Refer to EM-70, " Inspection " .

• Clean oil groove between oil strainer and intake valve timing control solenoid valve. Refer to LU-6," Engine Lubrication System " and

LU-6, " Engine Lubrication System Schematic " .

6. Remove components between intake valve timing control solenoid valve and camshaft sprocket (INT), and then check each oil groove for clogging.

• Clean oil groove if necessary. Refer to LU-6, " Engine Lubrication System " and

LU-6, " Engine Lubrica-

tion System Schematic " .

7. After inspection, installation is in the reverse order of removal.

Page 3036 of 4331

EM

NP

O

• If items or work required are not covered by the

engine section, follow the procedures in the applica-

ble sections.

• Always use the support poin t specified for lifting.

• Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for unavoid-

able reasons, support at the rear axle jacking point with a transmission jack or similar tool before

starting work, in prepar ation for the backward shif t of center of gravity.

• For supporting points fo r lifting and jacking point at rear axle, refer to GI-38, " Garage Jack and

Safety Stand and 2-Pole Lift " .

REMOVAL

Outline Remove the engine and the transaxle assembly from t he vehicle downward. Separate the engine and the tran-

saxle.

Preparation 1. Remove the hood assembly. Refer to BL-14, " Removal and Installation " .

2. Remove the cowl top cover and cowl top extension assembly. Refer to EI-22, " Removal and Installation " .

3. Release fuel pressure. Refer to EC-498, " Inspection " .

4. Drain engine coolant from radiator. Refer to CO-11, " Changing Engine Coolant " .

CAUTION:

• Perform this step when the engine is cold.

• Never spill engine coolant on drive belt.

5. Drain the transmission fluid. Refer to MT-10, " Draining " (M/T),

AT-17, " Changing A/T Fluid " (A/T).

6. Remove the following parts. • Engine undercover

• Front road wheels and tires: Refer to WT-7, " Rotation " .

• Front fender protector (RH and LH): Refer to EI-24, " Removal and Installation " .

• Battery and battery tray: Refer to SC-7, " Removal and Installation " .

• Drive belt: Refer to EM-15, " Removal and Installation " .

• Air duct and air cleaner case assembly: Refer to EM-26, " Exploded View " .

• Radiator hose (upper and lower): Refer to CO-16, " Component " .

• Disconnect cooling fan controller wiring harness.

• Remove coolant reservoir tank.

• Remove fan shroud and cooling fan assembly. Refer to CO-18, " Component (Models with A/C) " or

CO- 18, " Component (Models without A/C) " .

Engine Room LH 1. Disconnect all connections of engine harness around the engine mounting insulator (LH), and then tem- porarily secure the engine harness into the engine side.

CAUTION:

Protect connectors using a resin bag against foreign materials.

2. Remove ground cable at transaxle side.

3. Disconnect fuel feed hose at engine side. Refer to EM-34, " Exploded View " .

4. Disconnect EVAP purge hose and brake booster vacuum hose.

5. Disconnect heater hoses, and install plugs them to prevent engine coolant from draining. Refer to CO-16," Component " .

6. Disconnect control linkage from transaxle. Refer to AT-212, " Control Device Removal and Installation " (A/

T), MT-13, " Exploded View " (M/T).

7. Disconnect the clutch tube at tr ansmission side (if equipped). Refer to CL-14, " Removal and Installation " .

Engine Room RH 1. Remove ground cable between front cover and vehicle.

2. Remove generator and generator bracket; Refer to SC-25, " Removal and Installation " .

3. Remove A/C compressor with piping connected from t he engine. Temporarily secure it on the vehicle side

with a rope to avoid putting load on it. (if equipped) Refer to MTC-78, " Removal and Installation of Com-

pressor - HR16DE " .

Vehicle Underbody

Page 3074 of 4331

![NISSAN TIIDA 2009 Service Repair Manual PRECAUTIONS

EM-127

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before c NISSAN TIIDA 2009 Service Repair Manual PRECAUTIONS

EM-127

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before c](/img/5/57398/w960_57398-3073.png)

PRECAUTIONS

EM-127

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Procedur e without Cowl Top Cover INFOID:0000000004307110

When performing the procedure after removing cowl top cover, cover

the lower end of windshield.

Precaution for Drain Coolant INFOID:0000000004307112

• Drain coolant when engine is cooled.

Precaution for Disco nnecting Fuel Piping INFOID:0000000004307113

• Before starting work, make sure no fire or spark producing items are in the work area.

• Release fuel pressure before disassembly.

• After disconnecting pipes, plug openings to stop fuel leakage.

Precaution for Removal and Disassembly INFOID:0000000004307114

• When instructed to use special service tools, use the spec ified tools. Always be careful to work safely, avoid

forceful or uninstructed operations.

• Exercise maximum care to avoid damage to mating or sliding surfaces.

• Cover openings of engine system with tape or the equiva lent, if necessary, to seal out foreign materials.

• Mark and arrange disassembly parts in an organized way for easy troubleshooting and assembly.

• When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally opposite, and so on. If the order of loosening is specif ied, do exactly as specified. Power tools may be used

where noted in the step.

Precaution for Inspection, Repair and Replacement INFOID:0000000004307115

• Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precaution for Assembly and Installation INFOID:0000000004307116

• Use torque wrench to tighten bolts or nuts to specification.

• When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified,

do exactly as specified.

• Replace with new gasket, packing, oil seal or O-ring.

• Thoroughly wash, clean, and air-blow each part. Carefully check oil or coolant passages for any restriction

and blockage.

• Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust. Before assembly, oil sliding surfaces well.

• Release air within route after draining coolant.

• Before starting engine, apply fuel pressure to fuel lines with turning ignition switch ON (with engine stopped). Then make sure that there are no leaks at fuel line connections.

• After repairing, start engine and increase engine speed to check coolant, fuel, oil, and exhaust systems for leakage. PIIB3706J

Page 3088 of 4331

EM

NP

O

INTAKE MANIFOLD

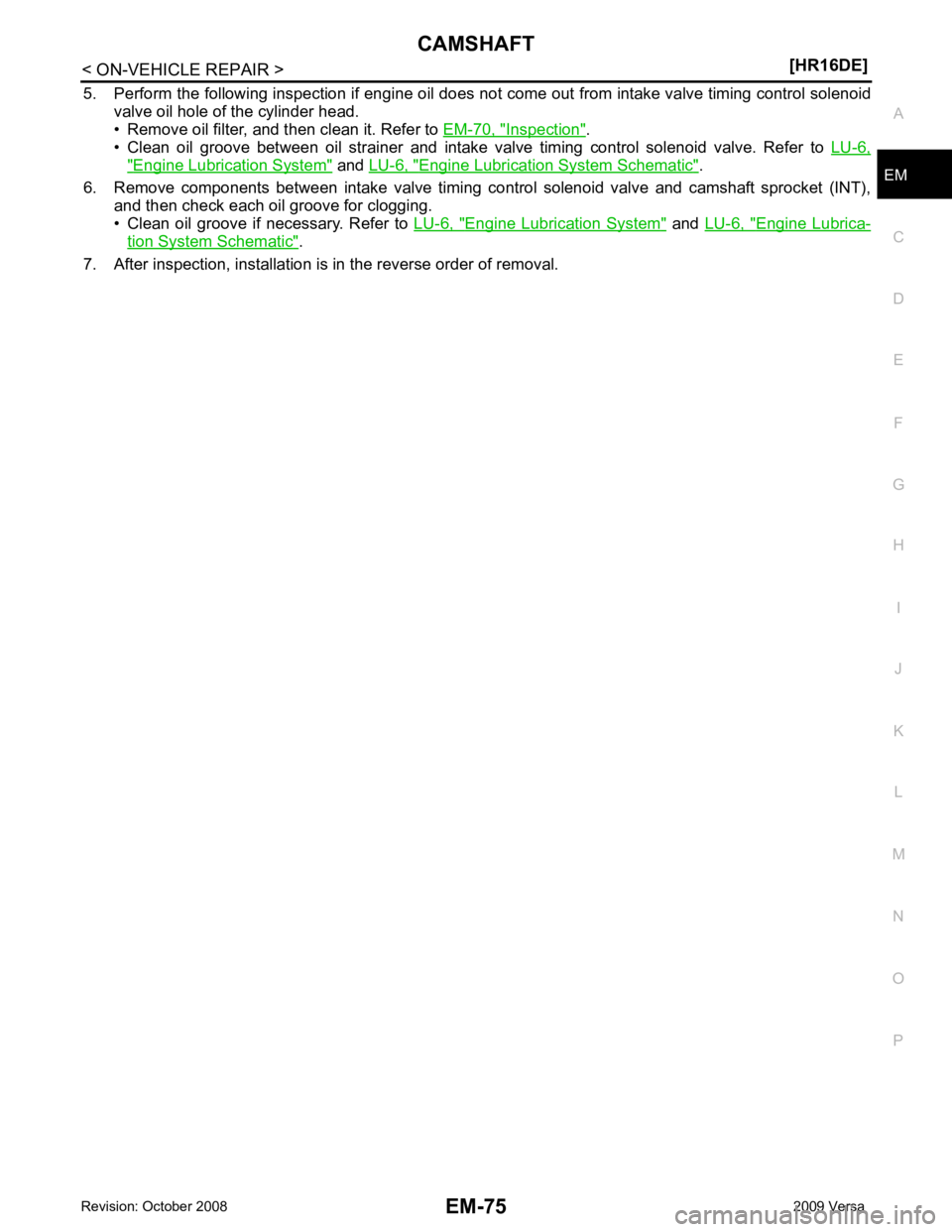

Component INFOID:0000000004307132

Removal and Installation INFOID:0000000004307133

REMOVAL 1. Remove engine cover (1).

2. Remove air duct. Refer to EM-139, " Component " .

3. Drain engine coolant. Refer to CO-35, " Changing Engine Cool-

ant " .

CAUTION:

Perform this step when engine is cold.

NOTE:

This step is unnecessary when putting plugs to water hoses (to

electric throttle control actuator).

a. Disconnect water hoses from electr ic throttle control actuator.

b. Remove electric throttle control actuator. CAUTION:

• Handle electric throttle control act uator carefully and avoid impacts.

• Never disassemble or adjust elect ric throttle control actuator.

4. Remove oil level gauge. CAUTION:

Cover the oil level gauge guide openings to avoid entry of foreign materials.

1. PCV hose 2. Gasket 3. Intake manifold

4. Bracket 5. O-ring 6. EVAP canister purge volume control solenoid valve

7. Water hose 8. Water hose 9. Electric throttle control actuator

10. Gasket A. To water outlet WBIA0845E

Page 3090 of 4331

![NISSAN TIIDA 2009 Service Repair Manual INTAKE MANIFOLD

EM-143

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

3. Tighten intake manifold bolt (A). Then tighten intake manifold

bolt (B).

4. Install electric throttle NISSAN TIIDA 2009 Service Repair Manual INTAKE MANIFOLD

EM-143

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

3. Tighten intake manifold bolt (A). Then tighten intake manifold

bolt (B).

4. Install electric throttle](/img/5/57398/w960_57398-3089.png)

INTAKE MANIFOLD

EM-143

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

3. Tighten intake manifold bolt (A). Then tighten intake manifold

bolt (B).

4. Install electric throttle control actuator.

5. Install water hoses (3), (5) to electric throttle control actuator as shown.

6. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION • Check for leaks of engine coolant. Refer to CO-35, " Inspection " .

• Start and warm up the engine. Visually check for engine coolant leaks. 1 : Intake manifold

: Engine front

Intake manifold bolt (A) : 19.6 N·m (2.0 kg-m, 14 ft-lb)

Intake manifold bolt (B) : 19.6 N·m (2.0 kg-m, 14 ft-lb) PBIC3939E

1 : Electric throttle control actuator

2 : Clamp

4 : Water outlet

A : Paint Mark

B : The clamp shall not interfere with the bulged section. PBIC4703E

Page 3124 of 4331

![NISSAN TIIDA 2009 Service Repair Manual CAMSHAFT

EM-177

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten NISSAN TIIDA 2009 Service Repair Manual CAMSHAFT

EM-177

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten](/img/5/57398/w960_57398-3123.png)

CAMSHAFT

EM-177

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A EM

NP

O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten bolt.

11. Install timing chain and related parts. Refer to EM-160 .

12. Inspect and adjust valve clearance. Refer to EM-178, " Valve Clearance " .

13. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION The following are procedures for chec king fluids leak, lubricates leak.

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to GI-42, " Recommended Chemical Product and Sealant " .

• Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leak age of fuel, or any oil/fluids including engine oil and

engine coolant.

• Bleed air from lines and hoses of applicable lines, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

• Perform this inspection only when DTC P0011 is detected in self-diagnostic results of CONSULT-III

and it is directed according to inspect ion procedure of EC section. Refer to EC-638, " Diagnosis Pro-

cedure " (Type 1) or

EC-1153, " Diagnosis Procedure " (Type 2).

• Check when engine is cold so as to pr event burns from the splashing engine oil.

1. Check engine oil level. Refer to LU-16, " Inspection " .

2. Perform the following procedure so as to prevent the engine from being unintentionally started while checking.

a. Remove intake manifold. Refer to EM-141, " Component " .

b. Disconnect ignition coil and in jector harness connectors.

3. Remove intake valve timing control solenoid valve. Refer to EM-160, " Component " .

1 : Camshaft sprocket (INT)

Camshaft sprocket

bolt (EXH) : 88.2 N·m (9.0 kg-m, 65 ft-lb) PBIC3454J

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 3125 of 4331

Component " .

6. Crank engine, and then make sure that engine oil comes out from intake valve timing control solenoid valve hole (A). End cranking after checking.

• Check engine oil leakage by oil amount adhered to the shop cloth inserted into the oil hole.

WARNING:

• Be careful not to touch rotating parts (drive be lts, idler pulley, and crankshaft pulley, etc.).

• Prevent splashing by using a shop cloth so as to prevent the worker from injury from engine oil

and so as to prevent engi ne oil contamination.

CAUTION:

• Do not perform cranking without installing right engine mount bracket, right engine mount insu-

lator, and right torque rod.

• Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to

engine and vehicle. Especially, be careful not to apply engine oil to rubber parts of drive belts,

engine mounting insulator, etc. Wipe engi ne oil off immediately if it is splashed.

7. Perform the following inspection if engine oil does not come out from intake valve timing control solenoid valve oil hole of the cylinder head.

• Remove oil filter (for intake valve timing control), and then clean it. Refer to EM-199, " Component " .

• Clean oil groove between oil strainer and intake valve timing control solenoid valve. Refer to LU-15 .

8. Remove components between intake valve timing c ontrol solenoid valve and camshaft sprocket (INT),

and then check each oil groove for clogging.

• Clean oil groove if necessary. Refer to LU-15 .

9. Installation of the remaining components is in the reverse order of removal

Valve Clearance INFOID:0000000004307146

INSPECTION

Perform inspection as follows after removal, installation or replacement of camshaft or valve-related parts, or if

there is unusual engine conditions regarding valve clearance.

1. Remove rocker cover. Refer to EM-153 .

2. Measure the valve clearance with the following procedure:

a. Set No. 1 cylinder at TDC of its compression stroke. • Rotate crankshaft pulley (1) clockwise and align TDC mark (no paint) (B) to timing indicator (A) on front

cover. 1 : Front cover

:Vehicle front

Page 3143 of 4331

Garage Jack and

Safety Stand and 2-Pole Lift " .

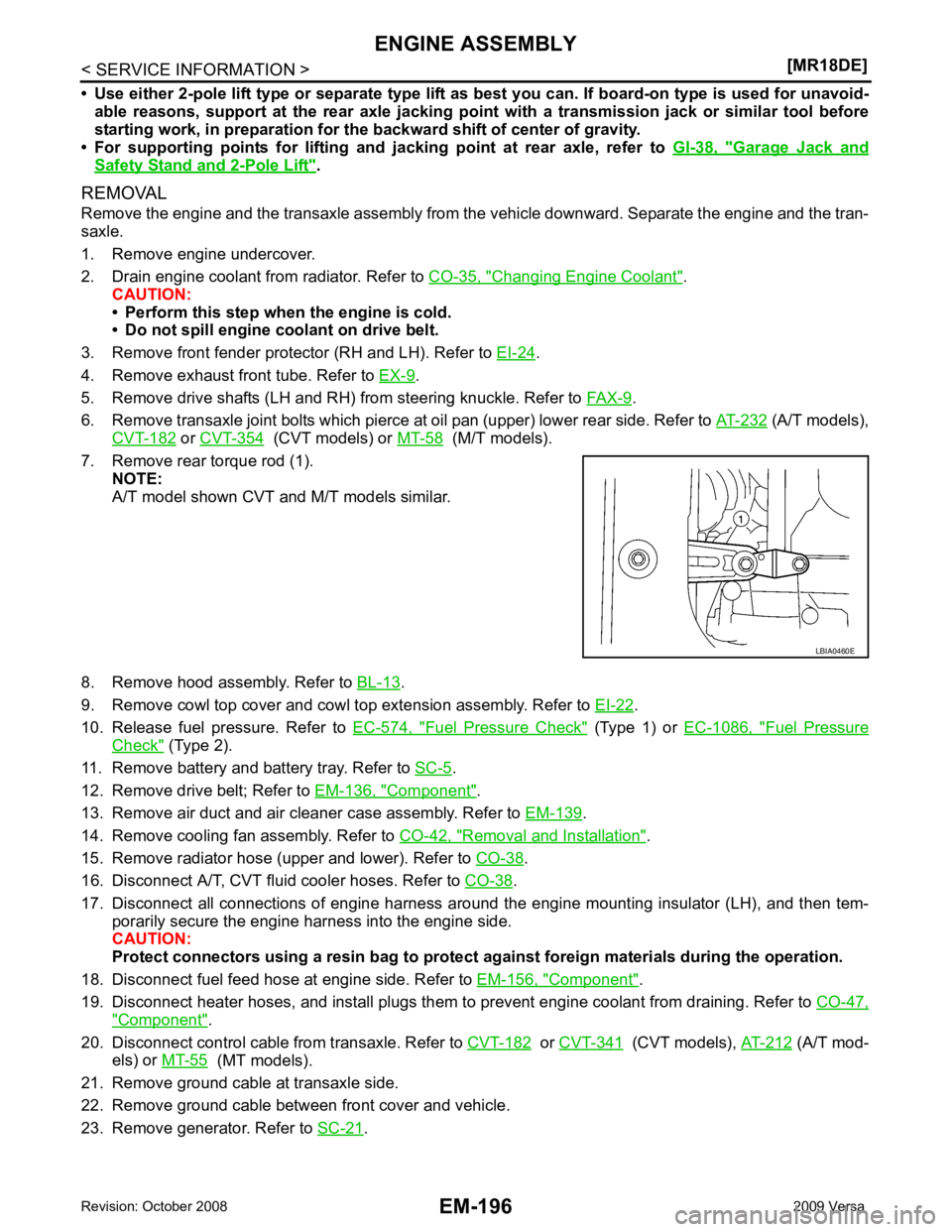

REMOVAL

Remove the engine and the transaxle assembly from t he vehicle downward. Separate the engine and the tran-

saxle.

1. Remove engine undercover.

2. Drain engine coolant from radiator. Refer to CO-35, " Changing Engine Coolant " .

CAUTION:

• Perform this step when the engine is cold.

• Do not spill engine coolant on drive belt.

3. Remove front fender protector (RH and LH). Refer to EI-24 .

4. Remove exhaust front tube. Refer to EX-9 .

5. Remove drive shafts (LH and RH) from steering knuckle. Refer to FAX-9 .

6. Remove transaxle joint bolts which pierce at oil pan (upper) lower rear side. Refer to AT-232 (A/T models),

CVT-182 or

CVT-354 (CVT models) or

MT-58 (M/T models).

7. Remove rear torque rod (1). NOTE:

A/T model shown CVT and M/T models similar.

8. Remove hood assembly. Refer to BL-13 .

9. Remove cowl top cover and cowl top extension assembly. Refer to EI-22 .

10. Release fuel pressure. Refer to EC-574, " Fuel Pressure Check " (Type 1) or

EC-1086, " Fuel Pressure

Check " (Type 2).

11. Remove battery and battery tray. Refer to SC-5 .

12. Remove drive belt; Refer to EM-136, " Component " .

13. Remove air duct and air cleaner case assembly. Refer to EM-139 .

14. Remove cooling fan assembly. Refer to CO-42, " Removal and Installation " .

15. Remove radiator hose (upper and lower). Refer to CO-38 .

16. Disconnect A/T, CVT fluid cooler hoses. Refer to CO-38 .

17. Disconnect all connections of engine harness around the engine mounting insulator (LH), and then tem- porarily secure the engine harness into the engine side.

CAUTION:

Protect connectors using a resin bag to protect against foreign materials during the operation.

18. Disconnect fuel feed hose at engine side. Refer to EM-156, " Component " .

19. Disconnect heater hoses, and install plugs them to prevent engine coolant from draining. Refer to CO-47," Component " .

20. Disconnect control cable from transaxle. Refer to CVT-182 or

CVT-341 (CVT models),

AT-212 (A/T mod-

els) or MT-55 (MT models).

21. Remove ground cable at transaxle side.

22. Remove ground cable between front cover and vehicle.

23. Remove generator. Refer to SC-21 .

Page 3174 of 4331

EM

NP

O

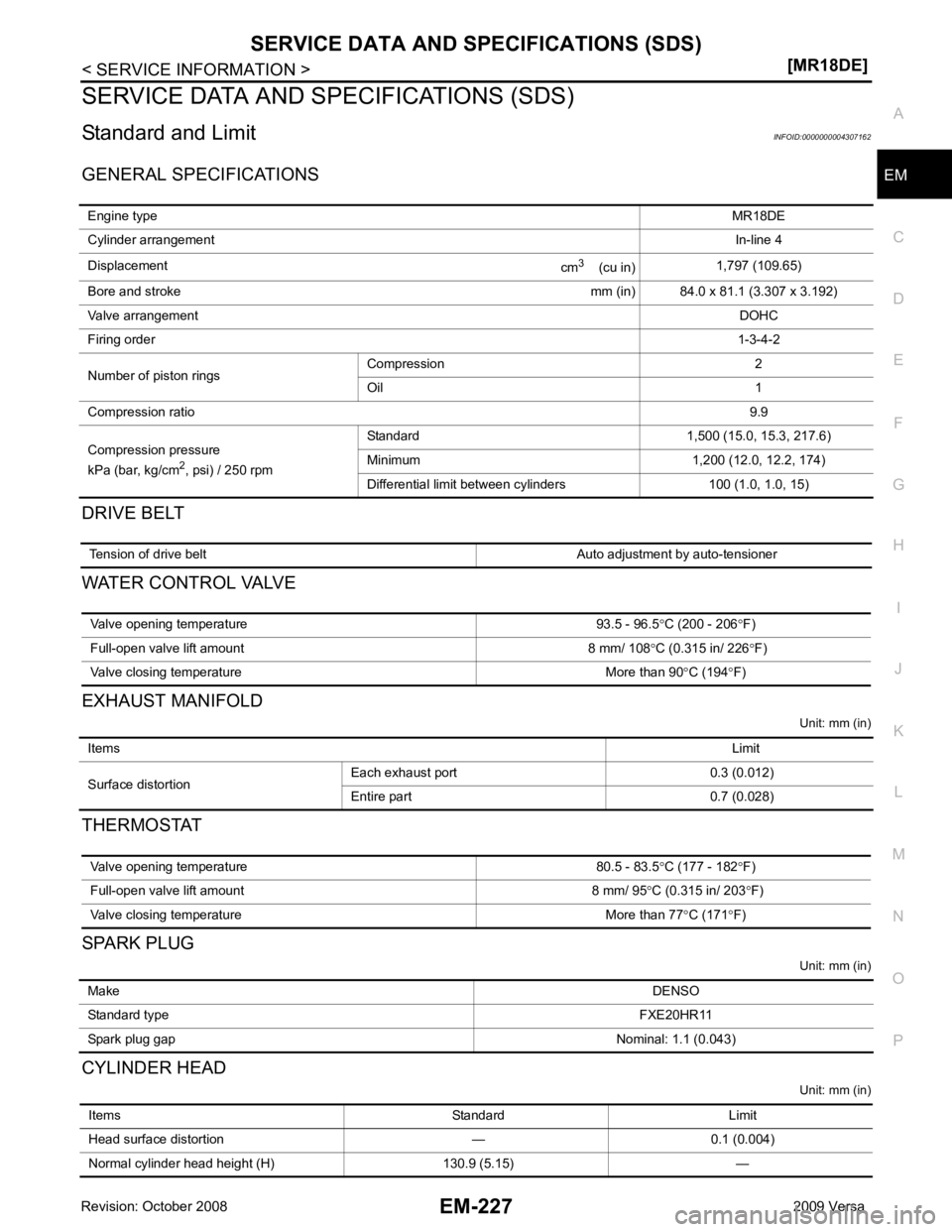

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and Limit INFOID:0000000004307162

GENERAL SPECIFICATIONS

DRIVE BELT

WATER CONTROL VALVE

EXHAUST MANIFOLD Unit: mm (in)

THERMOSTAT

SPARK PLUG Unit: mm (in)

CYLINDER HEAD Unit: mm (in)

Engine type

MR18DE

Cylinder arrangement In-line 4

Displacement cm3

(cu in) 1,797 (109.65)

Bore and stroke mm (in) 84.0 x 81.1 (3.307 x 3.192)

Valve arrangement DOHC

Firing order 1-3-4-2

Number of piston rings Compression 2

Oil 1

Compression ratio 9.9

Compression pressure

kPa (bar, kg/cm 2

, psi) / 250 rpm Standard 1,500 (15.0, 15.3, 217.6)

Minimum 1,200 (12.0, 12.2, 174)

Differential limit between cylinders 100 (1.0, 1.0, 15) Tension of drive belt Auto adjustment by auto-tensioner

Valve opening temperature 93.5 - 96.5

°C (200 - 206 °F)

Full-open valve lift amount 8 mm/ 108 °C (0.315 in/ 226 °F)

Valve closing temperature More than 90 °C (194 °F) Items

Limit

Surface distortion Each exhaust port 0.3 (0.012)

Entire part 0.7 (0.028) Valve opening temperature 80.5 - 83.5

°C (177 - 182 °F)

Full-open valve lift amount 8 mm/ 95 °C (0.315 in/ 203 °F)

Valve closing temperature More than 77 °C (171 °F) Make

DENSO

Standard type FXE20HR11

Spark plug gap Nominal: 1.1 (0.043)Items Standard Limit

Head surface distortion — 0.1 (0.004)

Normal cylinder head height (H) 130.9 (5.15) —

Page 3191 of 4331

EX

NP

O

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784390

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004675325

NOTE:

• This Procedure is applied only to models with Inte lligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.