RAP NISSAN TIIDA 2009 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2009, Model line: TIIDA, Model: NISSAN TIIDA 2009Pages: 4331, PDF Size: 58.04 MB

Page 23 of 4331

Checking A/T Fluid " .

A/T Fluid Cooler Cleaning INFOID:0000000004305297

Whenever the A/T is repaired, overhauled, or replaced, the A/T fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can becom e trapped in the A/T fluid cooler. This debris can con-

taminate the newly serviced A/T or, in severe cases, can bloc k or restrict the flow of A/T fluid. In either case,

malfunction of the newly serviced A/T may result.

Debris, if present, may build up as A/T fluid enters the c ooler inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

A/T FLUID COOLER CLEANING PROCEDURE

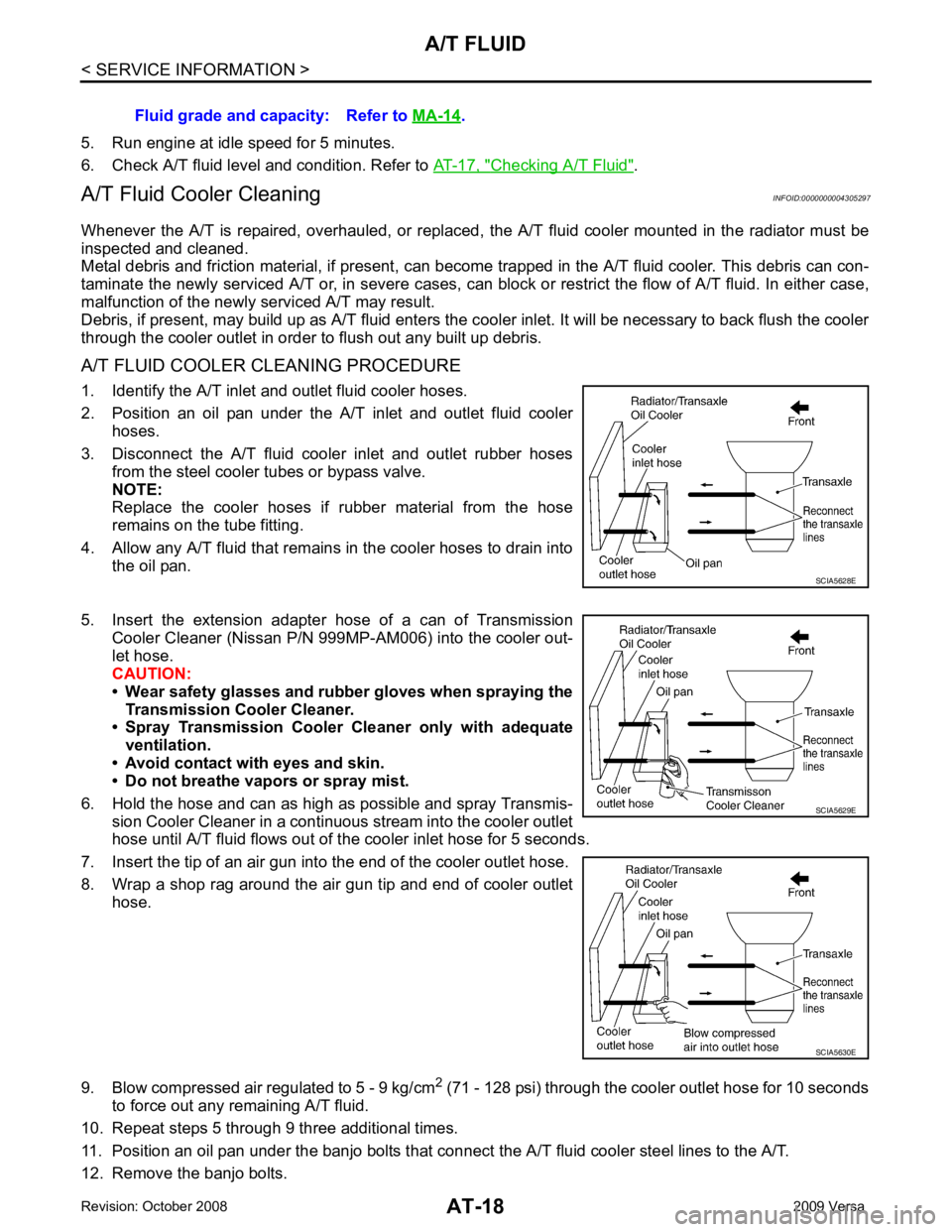

1. Identify the A/T inlet and outlet fluid cooler hoses.

2. Position an oil pan under the A/T inlet and outlet fluid cooler hoses.

3. Disconnect the A/T fluid cooler inlet and outlet rubber hoses from the steel cooler tubes or bypass valve.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

4. Allow any A/T fluid that remains in the cooler hoses to drain into

the oil pan.

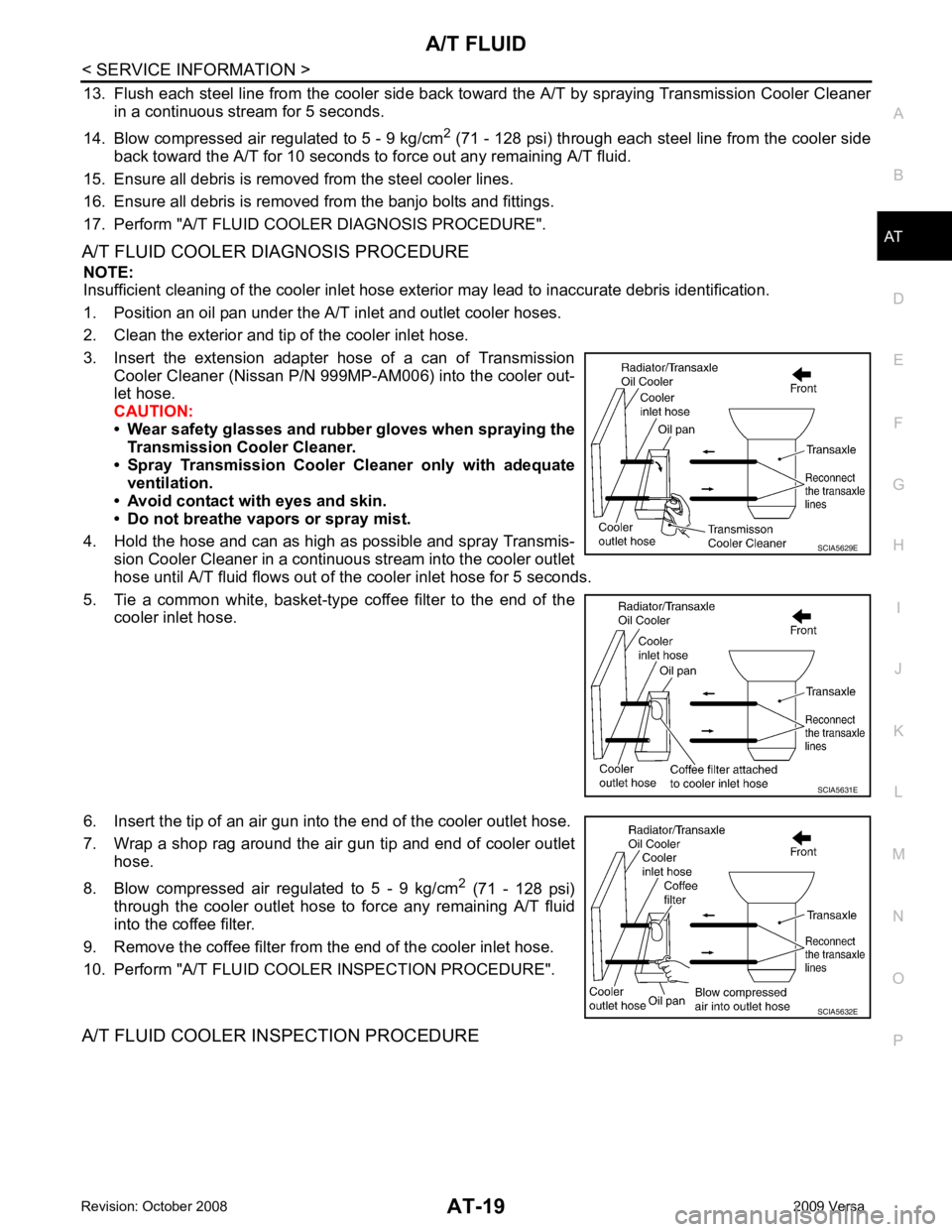

5. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breathe vapors or spray mist.

6. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until A/T fluid flows out of t he cooler inlet hose for 5 seconds.

7. Insert the tip of an air gun into the end of the cooler outlet hose.

8. Wrap a shop rag around the air gun tip and end of cooler outlet hose.

9. Blow compressed air regulated to 5 - 9 kg/cm 2

(71 - 128 psi) through the cooler outlet hose for 10 seconds

to force out any remaining A/T fluid.

10. Repeat steps 5 through 9 three additional times.

11. Position an oil pan under the banjo bolts that connec t the A/T fluid cooler steel lines to the A/T.

12. Remove the banjo bolts. Fluid grade and capacity: Refer to

MA-14 .

SCIA5630E

Page 24 of 4331

A/T FLUID

AT-19

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

13. Flush each steel line from the cooler side back to

ward the A/T by spraying Transmission Cooler Cleaner

in a continuous stream for 5 seconds.

14. Blow compressed air regulated to 5 - 9 kg/cm 2

(71 - 128 psi) through each steel line from the cooler side

back toward the A/T for 10 seconds to force out any remaining A/T fluid.

15. Ensure all debris is removed from the steel cooler lines.

16. Ensure all debris is removed from the banjo bolts and fittings.

17. Perform "A/T FLUID COOL ER DIAGNOSIS PROCEDURE".

A/T FLUID COOLER DIAGNOSIS PROCEDURE NOTE:

Insufficient cleaning of the cooler inlet hose exte rior may lead to inaccurate debris identification.

1. Position an oil pan under the A/T inlet and outlet cooler hoses.

2. Clean the exterior and tip of the cooler inlet hose.

3. Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the

Transmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breathe vapors or spray mist.

4. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until A/T fluid flows out of t he cooler inlet hose for 5 seconds.

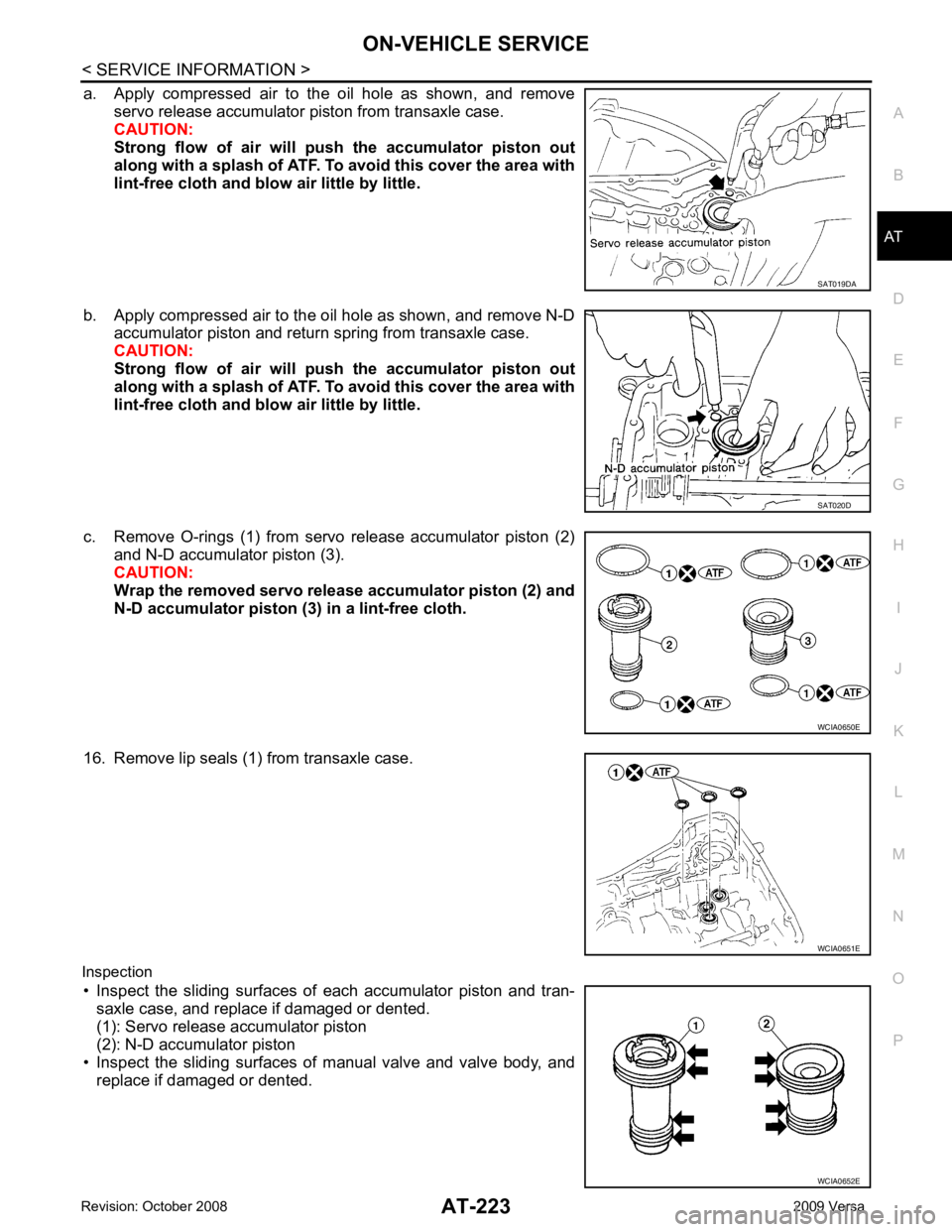

5. Tie a common white, basket-type coffee filter to the end of the cooler inlet hose.

6. Insert the tip of an air gun into the end of the cooler outlet hose.

7. Wrap a shop rag around the air gun tip and end of cooler outlet hose.

8. Blow compressed air regulated to 5 - 9 kg/cm 2

(71 - 128 psi)

through the cooler outlet hose to force any remaining A/T fluid

into the coffee filter.

9. Remove the coffee filter from the end of the cooler inlet hose.

10. Perform "A/T FLUID COOL ER INSPECTION PROCEDURE".

A/T FLUID COOLER INSPECTION PROCEDURE SCIA5629E

SCIA5631E

SCIA5632E

Page 228 of 4331

AT

N

O P

a. Apply compressed air to the oil hole as shown, and remove

servo release accumulator piston from transaxle case.

CAUTION:

Strong flow of air will pu sh the accumulator piston out

along with a splash of ATF. To avoid this cover the area with

lint-free cloth and blow air little by little.

b. Apply compressed air to the oil hole as shown, and remove N-D accumulator piston and return spring from transaxle case.

CAUTION:

Strong flow of air will pu sh the accumulator piston out

along with a splash of ATF. To avoid this cover the area with

lint-free cloth and blow air little by little.

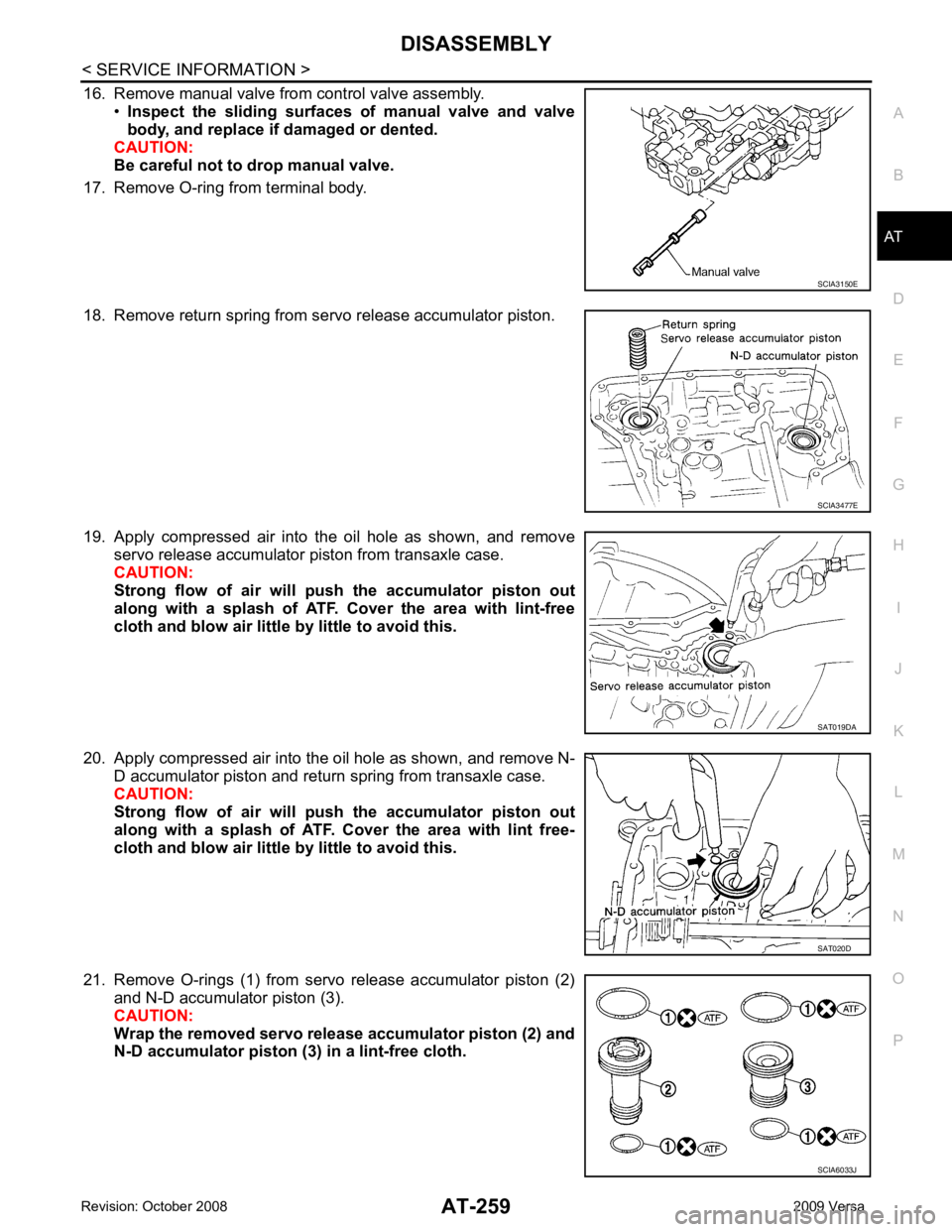

c. Remove O-rings (1) from servo release accumulator piston (2) and N-D accumulator piston (3).

CAUTION:

Wrap the removed servo rel ease accumulator piston (2) and

N-D accumulator piston (3) in a lint-free cloth.

16. Remove lip seals (1) from transaxle case.

Inspection • Inspect the sliding surfaces of each accumulator piston and tran- saxle case, and replace if damaged or dented.

(1): Servo release accumulator piston

(2): N-D accumulator piston

• Inspect the sliding surfaces of manual valve and valve body, and replace if damaged or dented. SAT020D

WCIA0650E

WCIA0652E

Page 264 of 4331

AT

N

O P

16. Remove manual valve from control valve assembly.

•Inspect the sliding surfaces of manual valve and valve

body, and replace if damaged or dented.

CAUTION:

Be careful not to drop manual valve.

17. Remove O-ring from terminal body.

18. Remove return spring from servo release accumulator piston.

19. Apply compressed air into the oil hole as shown, and remove servo release accumulator piston from transaxle case.

CAUTION:

Strong flow of air will pu sh the accumulator piston out

along with a splash of ATF. Cover the area with lint-free

cloth and blow air little by little to avoid this.

20. Apply compressed air into the oil hole as shown, and remove N- D accumulator piston and return spring from transaxle case.

CAUTION:

Strong flow of air will pu sh the accumulator piston out

along with a splash of ATF. Cover the area with lint free-

cloth and blow air little by little to avoid this.

21. Remove O-rings (1) from servo release accumulator piston (2) and N-D accumulator piston (3).

CAUTION:

Wrap the removed servo rel ease accumulator piston (2) and

N-D accumulator piston (3) in a lint-free cloth. SCIA3477E

SAT019DA

Page 285 of 4331

AT-280< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

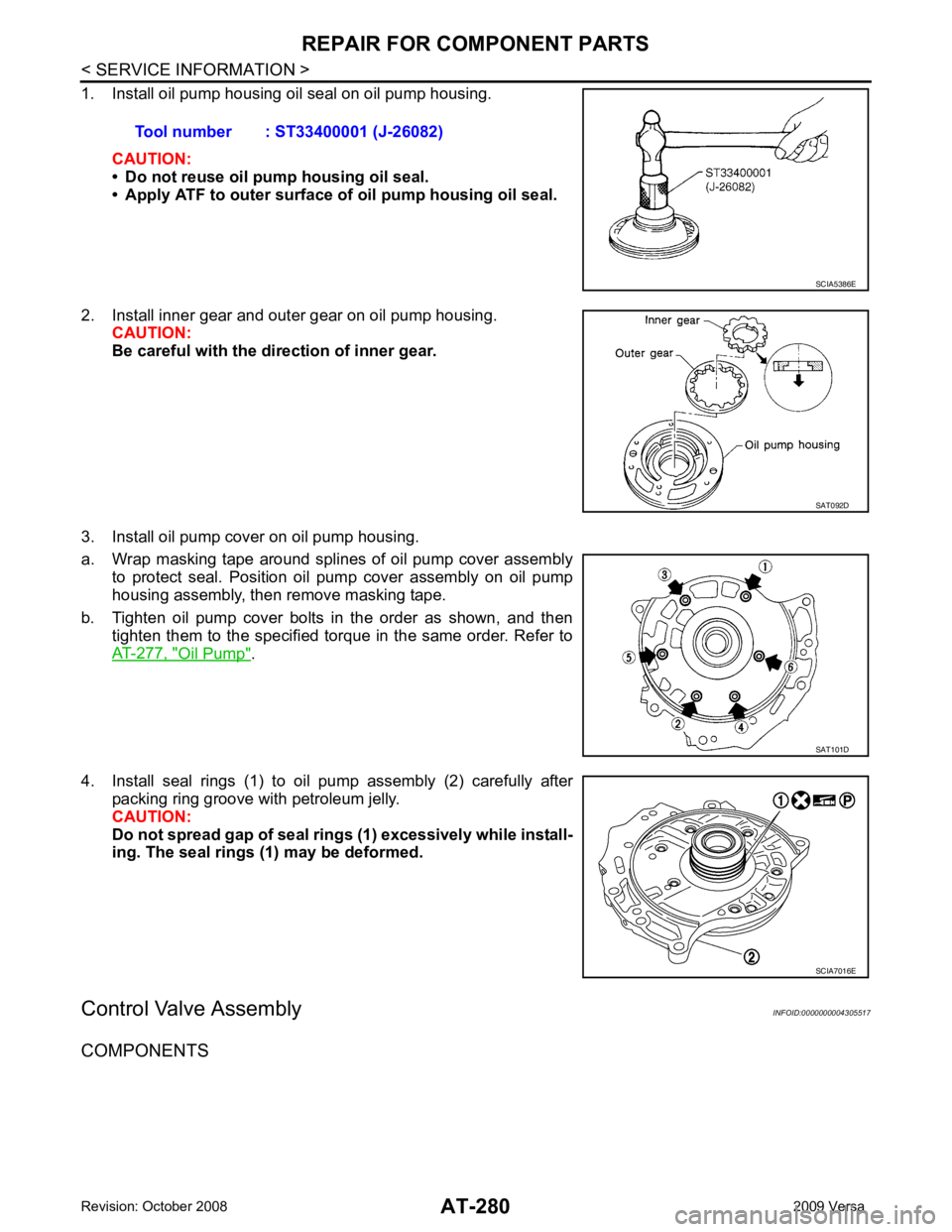

1. Install oil pump housing oil seal on oil pump housing.

CAUTION:

• Do not reuse oil pump housing oil seal.

• Apply ATF to outer surface of oil pump housing oil seal.

2. Install inner gear and outer gear on oil pump housing. CAUTION:

Be careful with the direction of inner gear.

3. Install oil pump cover on oil pump housing.

a. Wrap masking tape around splines of oil pump cover assembly to protect seal. Position oil pump cover assembly on oil pump

housing assembly, then remove masking tape.

b. Tighten oil pump cover bolts in the order as shown, and then tighten them to the specified torque in the same order. Refer to

AT-277, " Oil Pump " .

4. Install seal rings (1) to oil pump assembly (2) carefully after packing ring groove with petroleum jelly.

CAUTION:

Do not spread gap of seal ri ngs (1) excessively while install-

ing. The seal rings (1) may be deformed.

Control Valve Assembly INFOID:0000000004305517

COMPONENTS Tool number : ST33400001 (J-26082) SCIA5386E

SAT092D

SAT101D

SCIA7016E

Page 298 of 4331

AT

N

O P

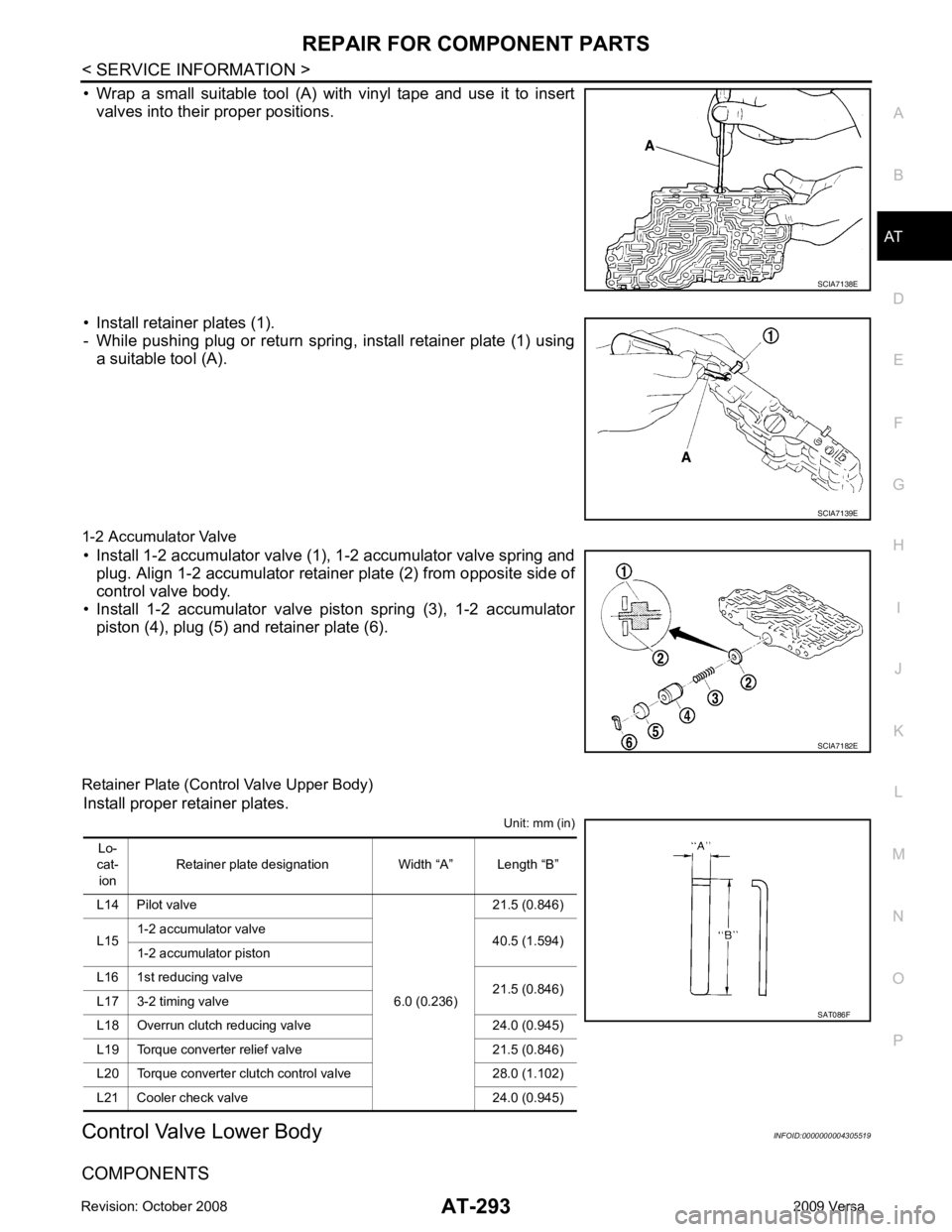

• Wrap a small suitable tool (A) with vinyl tape and use it to insert

valves into their proper positions.

• Install retainer plates (1).

- While pushing plug or return spring, install retainer plate (1) using a suitable tool (A).

1-2 Accumulator Valve • Install 1-2 accumulator valve (1), 1-2 accumulator valve spring and plug. Align 1-2 accumulator retainer plate (2) from opposite side of

control valve body.

• Install 1-2 accumulator valve piston spring (3), 1-2 accumulator

piston (4), plug (5) and retainer plate (6).

Retainer Plate (Control Valve Upper Body) Install proper retainer plates. Unit: mm (in)

Control Valve Lower Body INFOID:0000000004305519

COMPONENTS

Page 448 of 4331

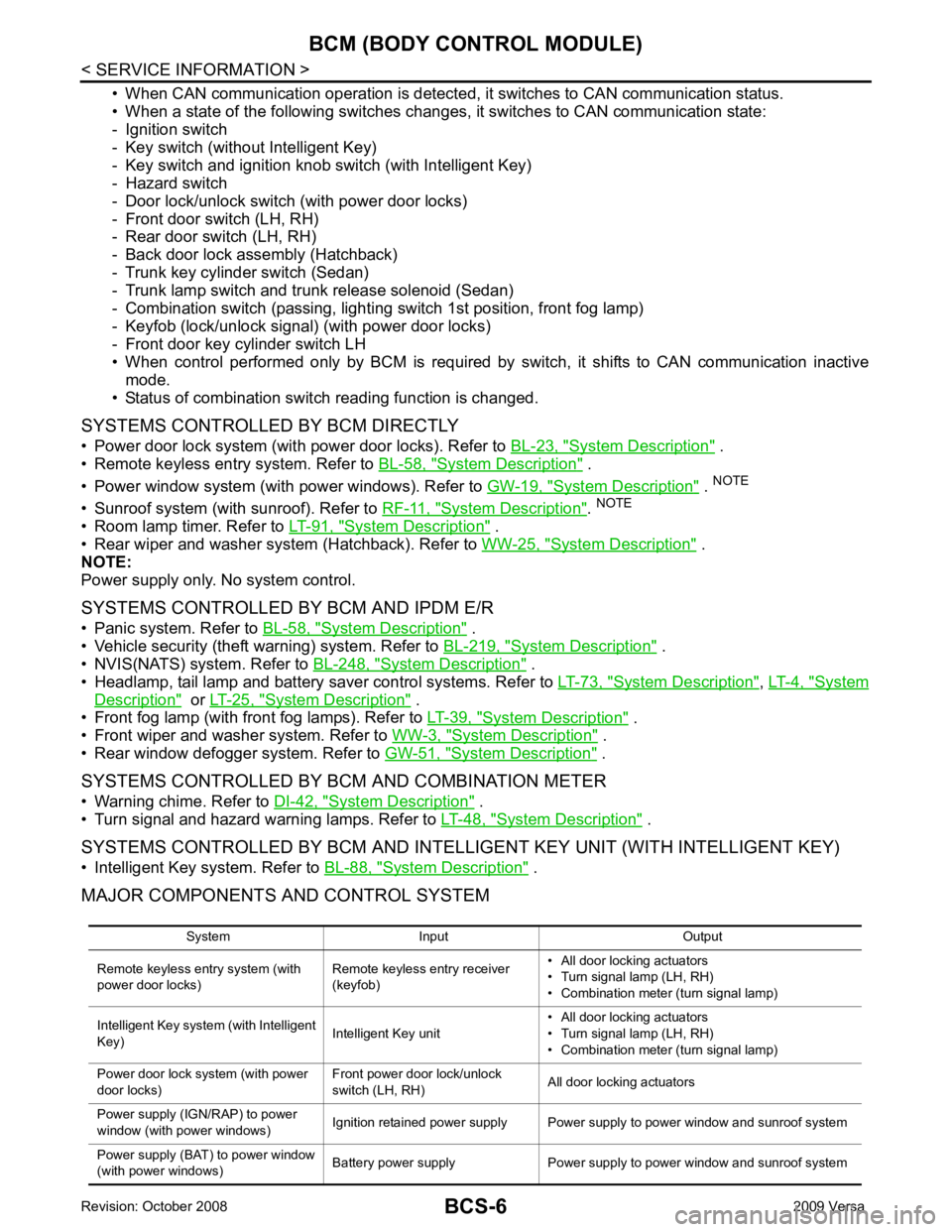

System Description " .

• Remote keyless entry system. Refer to BL-58, " System Description " .

• Power window system (with power windows). Refer to GW-19, " System Description " .

NOTE

• Sunroof system (with sunroof). Refer to RF-11, " System Description " .

NOTE

• Room lamp timer. Refer to LT-91, " System Description " .

• Rear wiper and washer system (Hatchback). Refer to WW-25, " System Description " .

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

• Panic system. Refer to BL-58, " System Description " .

• Vehicle security (theft warning) system. Refer to BL-219, " System Description " .

• NVIS(NATS) system. Refer to BL-248, " System Description " .

• Headlamp, tail lamp and battery saver control systems. Refer to LT-73, " System Description " ,

LT-4, " System

Description " or

LT-25, " System Description " .

• Front fog lamp (with front fog lamps). Refer to LT-39, " System Description " .

• Front wiper and washer system. Refer to WW-3, " System Description " .

• Rear window defogger system. Refer to GW-51, " System Description " .

SYSTEMS CONTROLLED BY BCM AND COMBINATION METER

• Warning chime. Refer to DI-42, " System Description " .

• Turn signal and hazard warning lamps. Refer to LT-48, " System Description " .

SYSTEMS CONTROLLED BY BCM AND INTELLIGENT KEY UNIT (WITH INTELLIGENT KEY)

• Intelligent Key system. Refer to BL-88, " System Description " .

MAJOR COMPONENTS AND CONTROL SYSTEM

System Input Output

Remote keyless entry system (with

power door locks) Remote keyless entry receiver

(keyfob) • All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Intelligent Key system (with Intelligent

Key) Intelligent Key unit• All door locking actuators

• Turn signal lamp (LH, RH)

• Combination meter (turn signal lamp)

Power door lock system (with power

door locks) Front power door lock/unlock

switch (LH, RH) All door locking actuators

Power supply (IGN/RAP) to power

window (with power windows) Ignition retained power supply Power supply to power window and sunroof system

Power supply (BAT) to power window

(with power windows) Battery power supply Power supply to power window and sunroof system

Page 502 of 4331

BL

N

O P

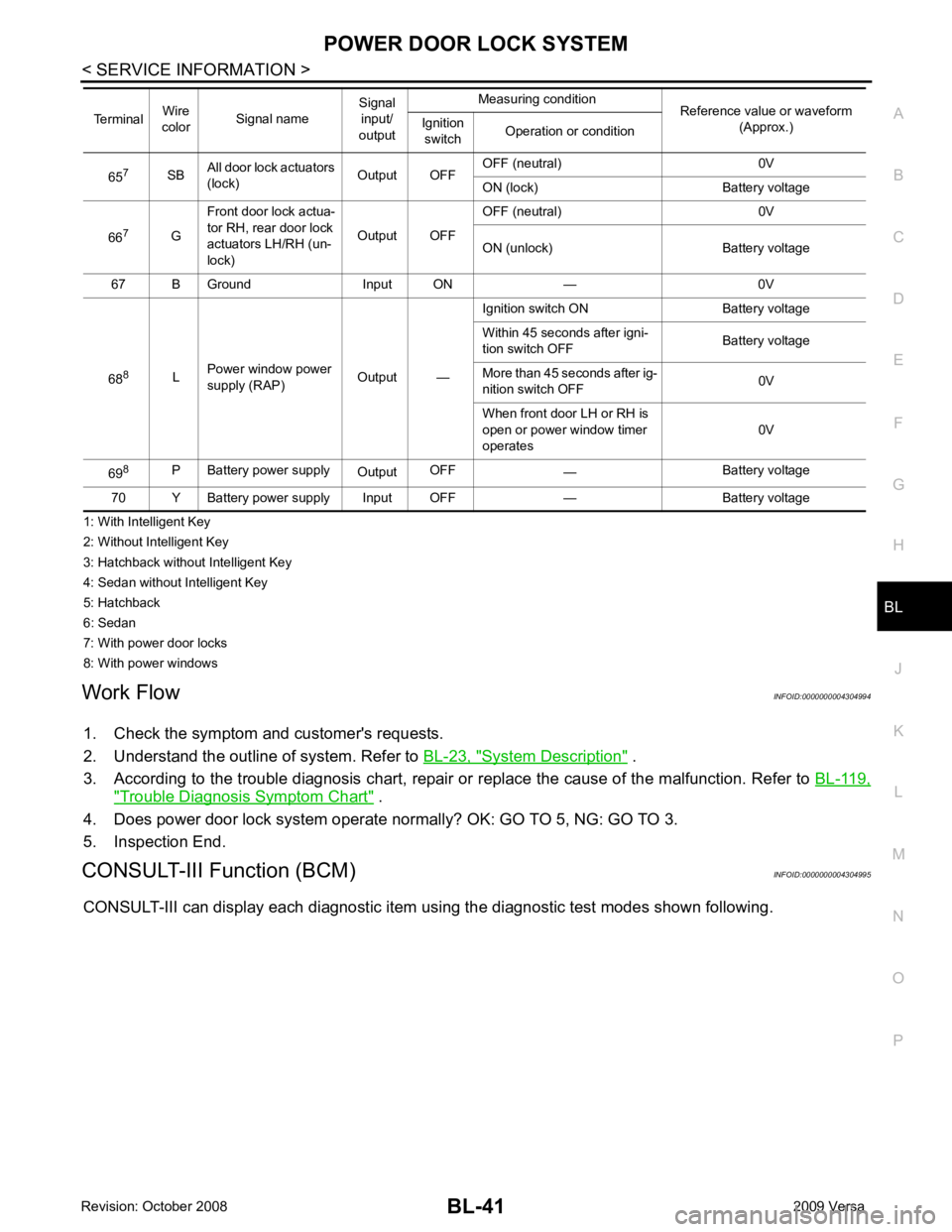

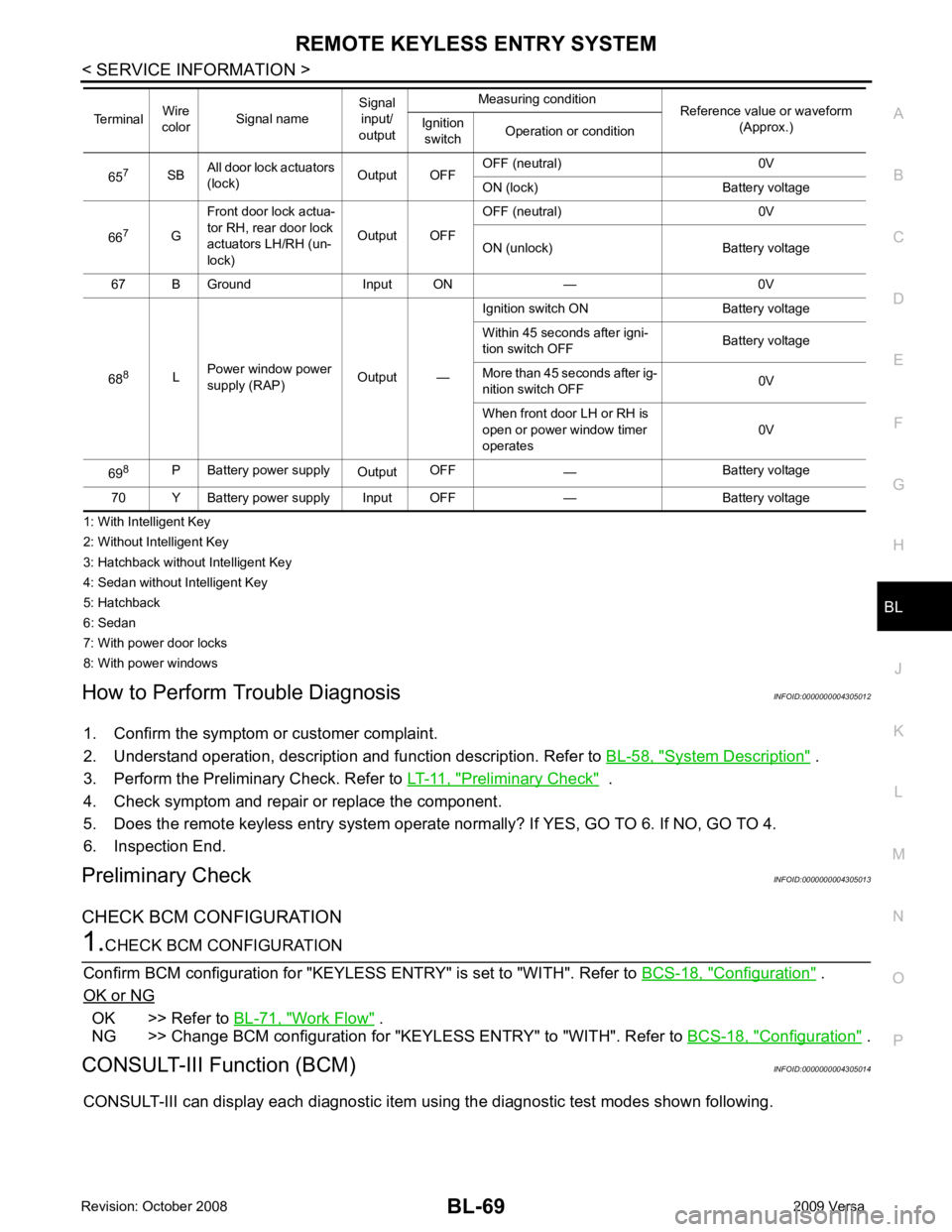

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

Work Flow INFOID:0000000004304994

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to BL-23, " System Description " .

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to BL-119," Trouble Diagnosis Symptom Chart " .

4. Does power door lock system operate normally? OK: GO TO 5, NG: GO TO 3.

5. Inspection End.

CONSULT-III Function (BCM) INFOID:0000000004304995

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following. 65

7

SBAll door lock actuators

(lock) Output OFFOFF (neutral) 0V

ON (lock) Battery voltage

66 7

GFront door lock actua-

tor RH, rear door lock

actuators LH/RH (un-

lock) Output OFFOFF (neutral) 0V

ON (unlock) Battery voltage

67 B Ground Input ON — 0V

68 8

LPower window power

supply (RAP) Output —Ignition switch ON Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69 8

P Battery power supply

OutputOFF

— Battery voltage

70 Y Battery power supply Input OFF — Battery voltage

Terminal

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

Page 530 of 4331

BL

N

O P

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

How to Perform Trouble Diagnosis INFOID:0000000004305012

1. Confirm the symptom or customer complaint.

2. Understand operation, description and function description. Refer to BL-58, " System Description " .

3. Perform the Preliminary Check. Refer to LT-11, " Preliminary Check " .

4. Check symptom and repair or replace the component.

5. Does the remote keyless entry system operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. Inspection End.

Preliminary Check INFOID:0000000004305013

CHECK BCM CONFIGURATION Configuration " .

OK or NG OK >> Refer to

BL-71, " Work Flow " .

NG >> Change BCM configuration for "KEYLESS ENTRY" to "WITH". Refer to BCS-18, " Configuration " .

CONSULT-III Function (BCM) INFOID:0000000004305014

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following. 65

7

SBAll door lock actuators

(lock) Output OFFOFF (neutral) 0V

ON (lock) Battery voltage

66 7

GFront door lock actua-

tor RH, rear door lock

actuators LH/RH (un-

lock) Output OFFOFF (neutral) 0V

ON (unlock) Battery voltage

67 B Ground Input ON — 0V

68 8

LPower window power

supply (RAP) Output —Ignition switch ON Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69 8

P Battery power supply

OutputOFF

— Battery voltage

70 Y Battery power supply Input OFF — Battery voltage

Terminal

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

Page 576 of 4331

BL

N

O P

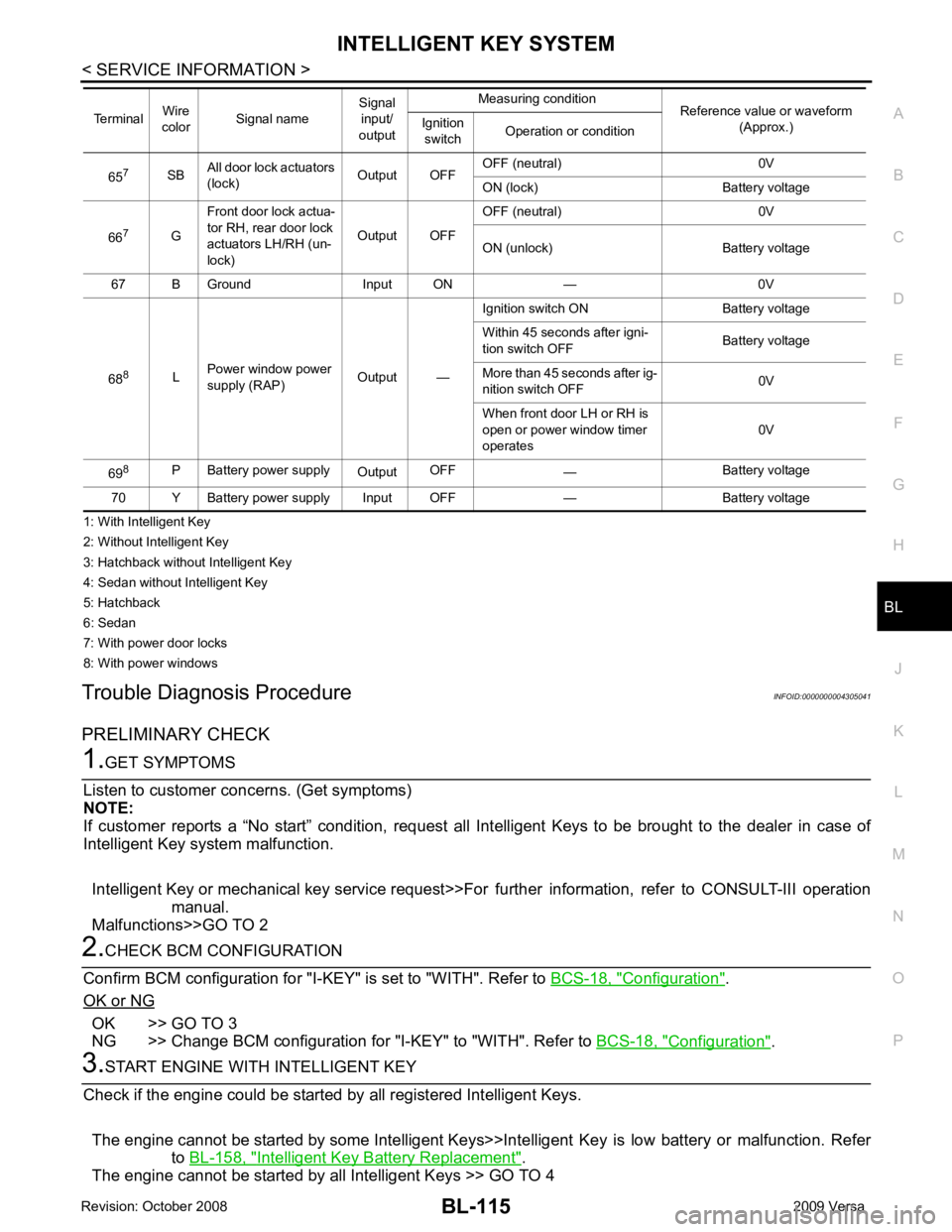

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

Trouble Diagnosis Procedure INFOID:0000000004305041

PRELIMINARY CHECK Configuration " .

OK or NG OK >> GO TO 3

NG >> Change BCM configuration for "I-KEY" to "WITH". Refer to BCS-18, " Configuration " .

Intelligent Key Battery Replacement " .

The engine cannot be started by all Intelligent Keys >> GO TO 4 65

7

SBAll door lock actuators

(lock) Output OFFOFF (neutral) 0V

ON (lock) Battery voltage

66 7

GFront door lock actua-

tor RH, rear door lock

actuators LH/RH (un-

lock) Output OFFOFF (neutral) 0V

ON (unlock) Battery voltage

67 B Ground Input ON — 0V

68 8

LPower window power

supply (RAP) Output —Ignition switch ON Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69 8

P Battery power supply

OutputOFF

— Battery voltage

70 Y Battery power supply Input OFF — Battery voltage

Terminal

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition