NISSAN TIIDA 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 241 of 3745

AT-224

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

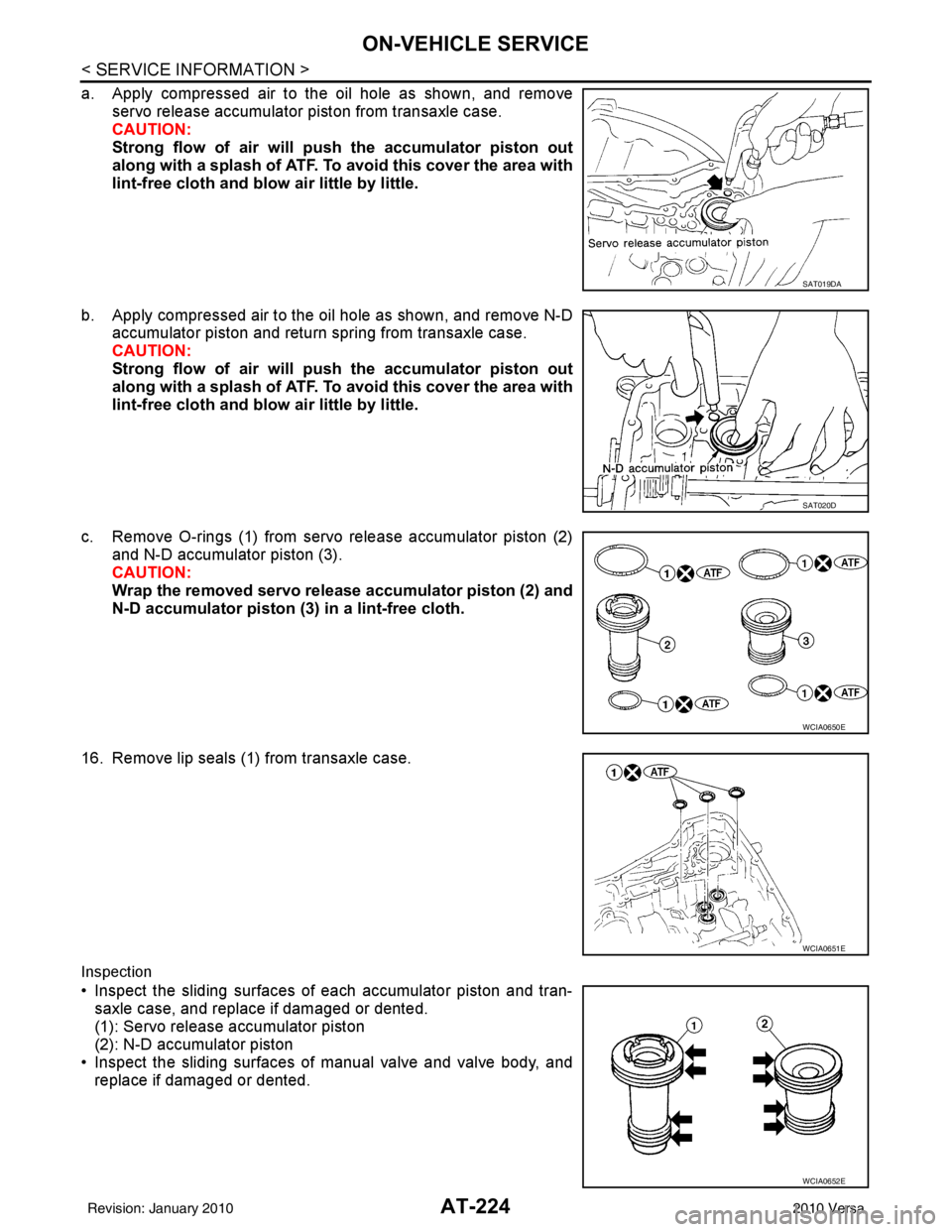

a. Apply compressed air to the oil hole as shown, and removeservo release accumulator piston from transaxle case.

CAUTION:

Strong flow of air will push the accumulator piston out

along with a splash of ATF. To avoid this cover the area with

lint-free cloth and blow air little by little.

b. Apply compressed air to the oil hole as shown, and remove N-D accumulator piston and return spring from transaxle case.

CAUTION:

Strong flow of air will push the accumulator piston out

along with a splash of ATF. To avoid this cover the area with

lint-free cloth and blow air little by little.

c. Remove O-rings (1) from servo release accumulator piston (2) and N-D accumulator piston (3).

CAUTION:

Wrap the removed servo release accumulator piston (2) and

N-D accumulator piston (3) in a lint-free cloth.

16. Remove lip seals (1) from transaxle case.

Inspection

• Inspect the sliding surfaces of each accumulator piston and tran- saxle case, and replace if damaged or dented.

(1): Servo release accumulator piston

(2): N-D accumulator piston

• Inspect the sliding surfaces of manual valve and valve body, and replace if damaged or dented.

SAT019DA

SAT020D

WCIA0650E

WCIA0651E

WCIA0652E

Revision: January 20102010 Versa

Page 242 of 3745

ON-VEHICLE SERVICEAT-225

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

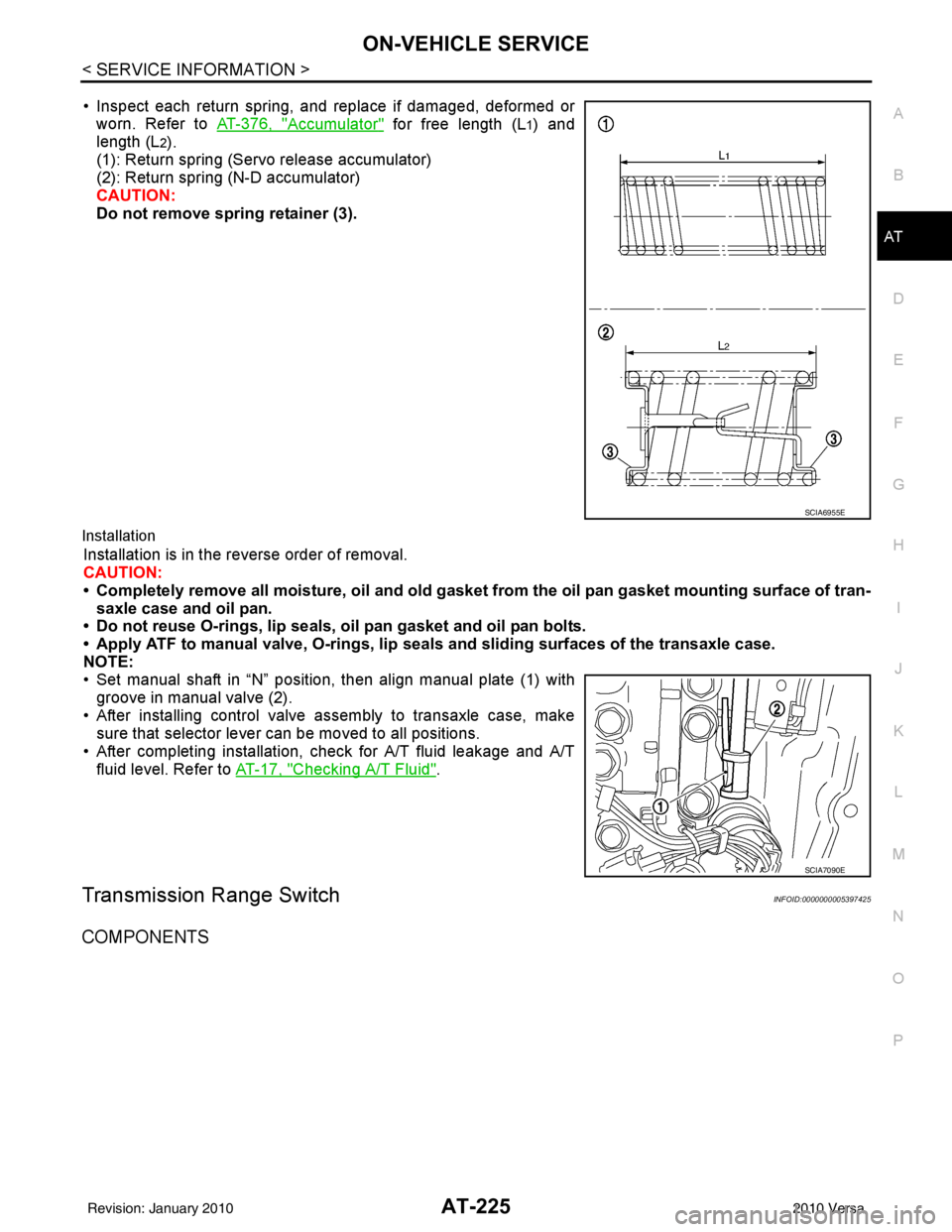

• Inspect each return spring, and replace if damaged, deformed or worn. Refer to AT-376, "

Accumulator" for free length (L1) and

length (L

2).

(1): Return spring (Servo release accumulator)

(2): Return spring (N-D accumulator)

CAUTION:

Do not remove spring retainer (3).

Installation

Installation is in the reverse order of removal.

CAUTION:

• Completely remove all moisture, oil and old gasket from the oil pan gasket mounting surface of tran-

saxle case and oil pan.

• Do not reuse O-rings, lip seals, oil pan gasket and oil pan bolts.

• Apply ATF to manual valve, O-rings, lip seals and sliding surfaces of the transaxle case.

NOTE:

• Set manual shaft in “N” position, then align manual plate (1) with groove in manual valve (2).

• After installing control valve assembly to transaxle case, make sure that selector lever can be moved to all positions.

• After completing installation, check for A/T fluid leakage and A/T fluid level. Refer to AT-17, "

Checking A/T Fluid".

Transmission Range SwitchINFOID:0000000005397425

COMPONENTS

SCIA6955E

SCIA7090E

Revision: January 20102010 Versa

Page 243 of 3745

AT-226

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

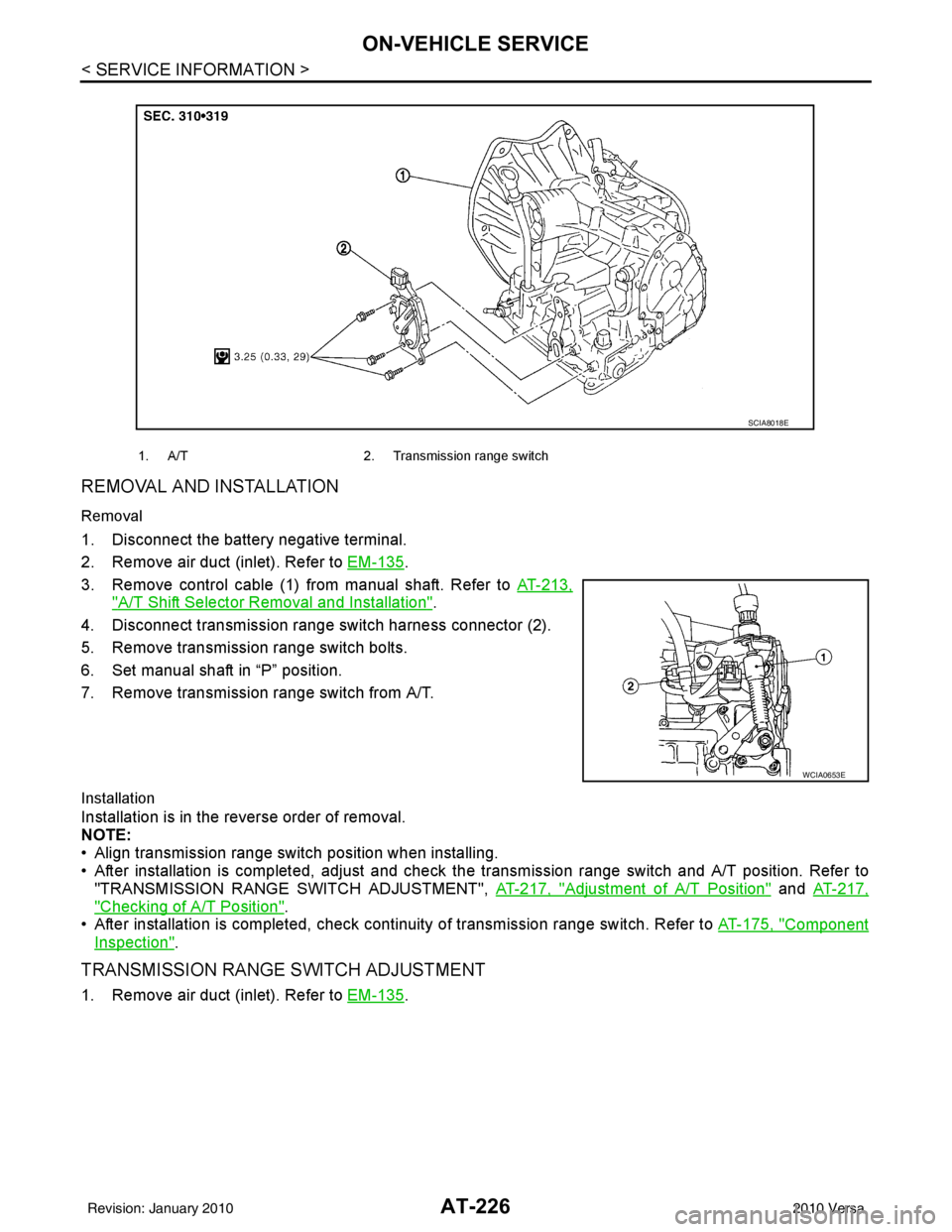

REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery negative terminal.

2. Remove air duct (inlet). Refer to EM-135

.

3. Remove control cable (1) from manual shaft. Refer to AT-213,

"A/T Shift Selector Removal and Installation".

4. Disconnect transmission range switch harness connector (2).

5. Remove transmission range switch bolts.

6. Set manual shaft in “P” position.

7. Remove transmission range switch from A/T.

Installation

Installation is in the reverse order of removal.

NOTE:

• Align transmission range switch position when installing.

• After installation is completed, adjust and check the transmission range switch and A/T position. Refer to

"TRANSMISSION RANGE SWITCH ADJUSTMENT", AT-217, "

Adjustment of A/T Position" and AT-217,

"Checking of A/T Position".

• After installation is completed, check cont inuity of transmission range switch. Refer to AT-175, "

Component

Inspection".

TRANSMISSION RANGE SWITCH ADJUSTMENT

1. Remove air duct (inlet). Refer to EM-135.

1. A/T 2. Transmission range switch

SCIA8018E

WCIA0653E

Revision: January 20102010 Versa

Page 244 of 3745

ON-VEHICLE SERVICEAT-227

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

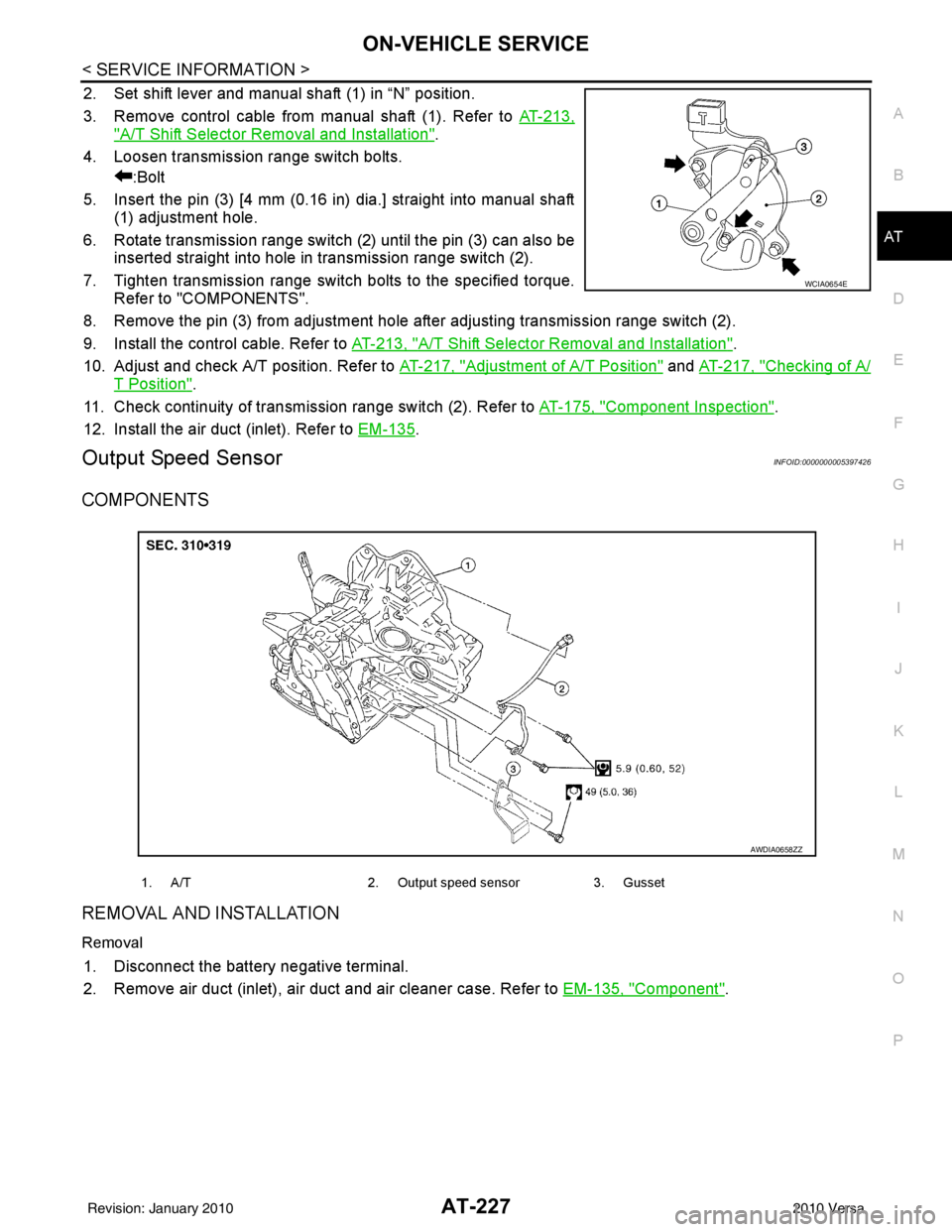

2. Set shift lever and manual shaft (1) in “N” position.

3. Remove control cable from manual shaft (1). Refer to AT-213,

"A/T Shift Selector Removal and Installation".

4. Loosen transmission range switch bolts. :Bolt

5. Insert the pin (3) [4 mm (0.16 in) dia.] straight into manual shaft (1) adjustment hole.

6. Rotate transmission range switch (2) until the pin (3) can also be inserted straight into hole in transmission range switch (2).

7. Tighten transmission range switch bolts to the specified torque. Refer to "COMPONENTS".

8. Remove the pin (3) from adjustment hole after adjusting transmission range switch (2).

9. Install the control cable. Refer to AT-213, "

A/T Shift Selector Removal and Installation".

10. Adjust and check A/T position. Refer to AT-217, "

Adjustment of A/T Position" and AT-217, "Checking of A/

T Position".

11. Check continuity of transmiss ion range switch (2). Refer to AT-175, "

Component Inspection".

12. Install the air duct (inlet). Refer to EM-135

.

Output Speed SensorINFOID:0000000005397426

COMPONENTS

REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery negative terminal.

2. Remove air duct (inlet), air duct and air cleaner case. Refer to EM-135, "

Component".

WCIA0654E

1. A/T2. Output speed sensor3. Gusset

AWDIA0658ZZ

Revision: January 20102010 Versa

Page 245 of 3745

AT-228

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

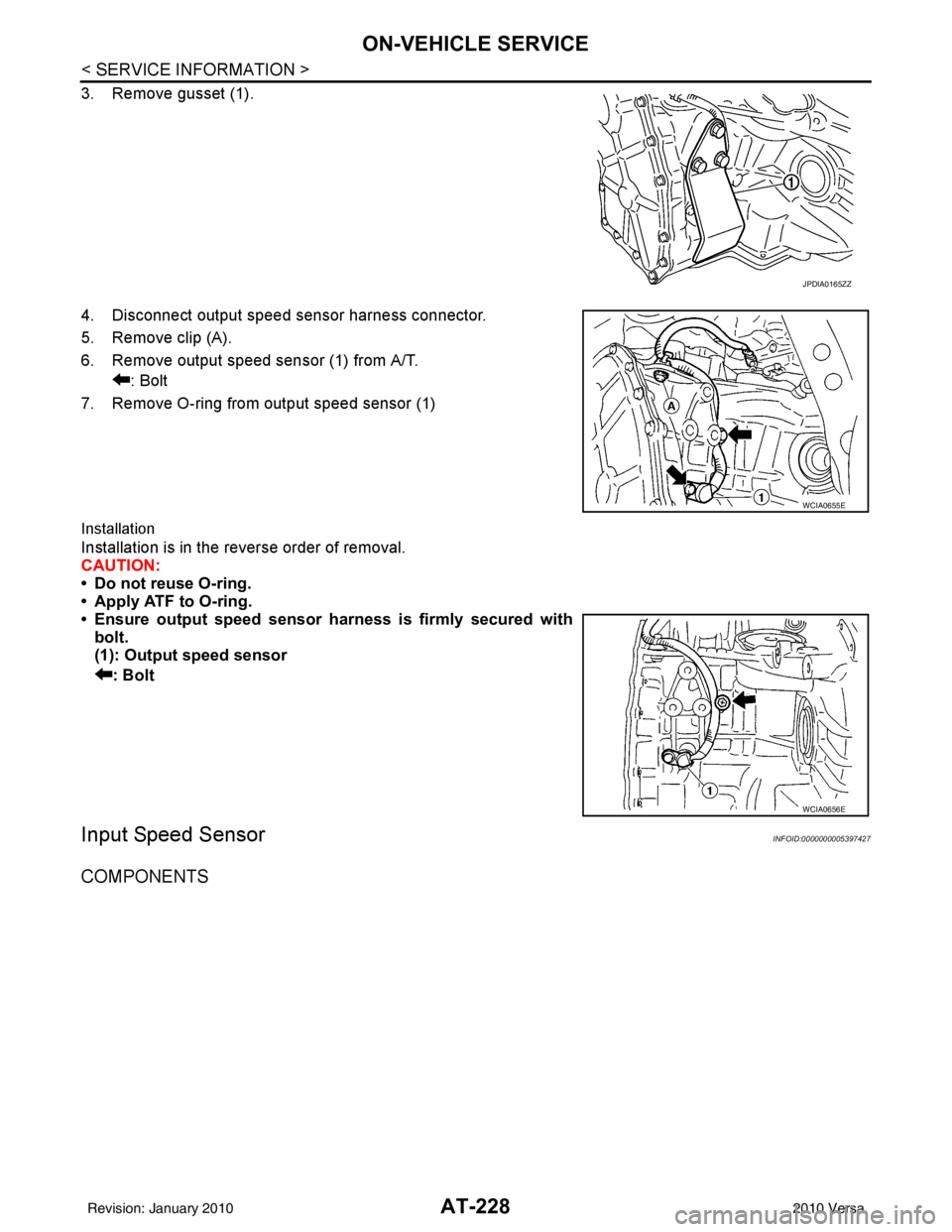

3. Remove gusset (1).

4. Disconnect output speed sensor harness connector.

5. Remove clip (A).

6. Remove output speed sensor (1) from A/T.: Bolt

7. Remove O-ring from output speed sensor (1)

Installation

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

• Ensure output speed sensor harness is firmly secured with bolt.

(1): Output speed sensor

: Bolt

Input Speed SensorINFOID:0000000005397427

COMPONENTS

JPDIA0165ZZ

WCIA0655E

WCIA0656E

Revision: January 20102010 Versa

Page 246 of 3745

ON-VEHICLE SERVICEAT-229

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

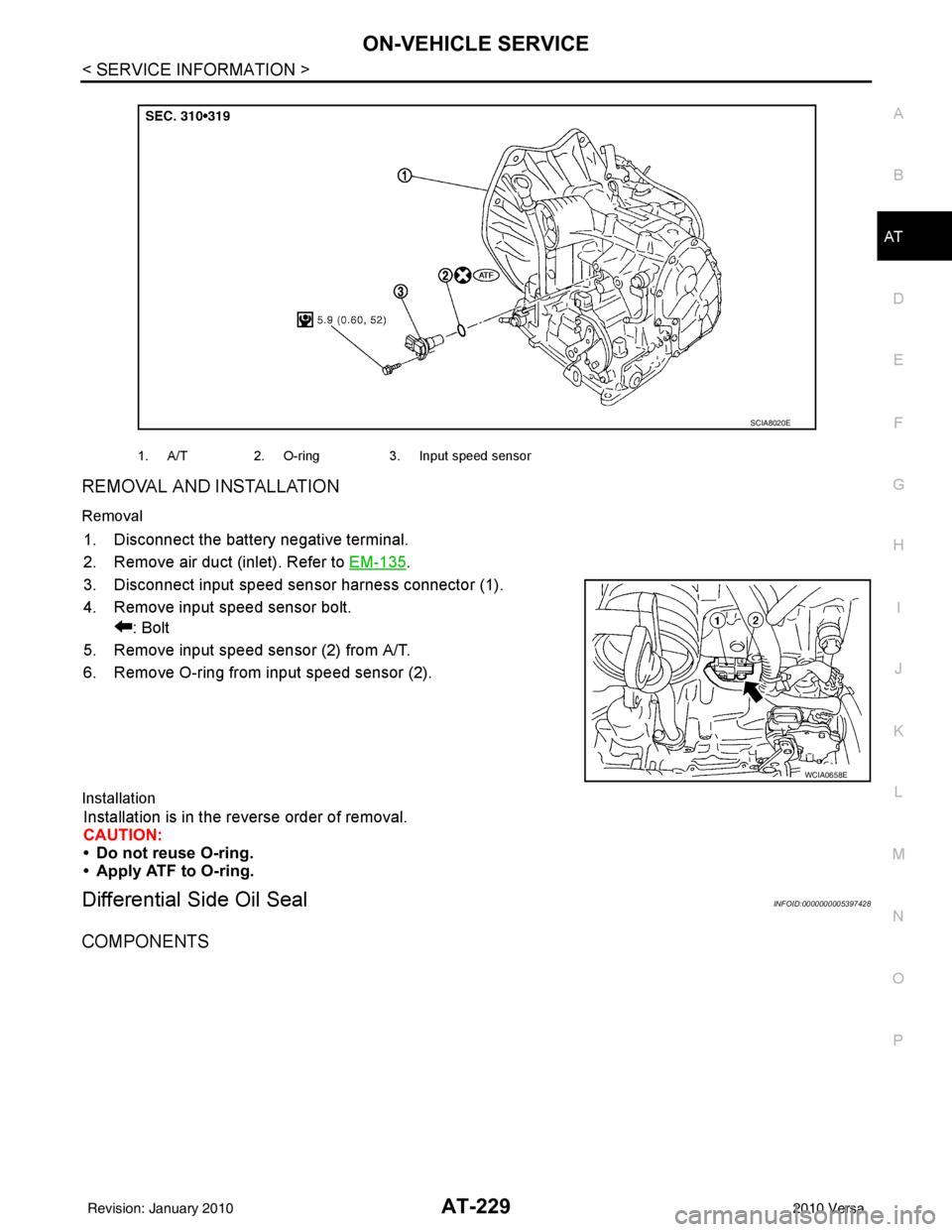

REMOVAL AND INSTALLATION

Removal

1. Disconnect the battery negative terminal.

2. Remove air duct (inlet). Refer to EM-135

.

3. Disconnect input speed sens or harness connector (1).

4. Remove input speed sensor bolt. : Bolt

5. Remove input speed sensor (2) from A/T.

6. Remove O-ring from input speed sensor (2).

Installation

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

Differential Side Oil SealINFOID:0000000005397428

COMPONENTS

1. A/T 2. O-ring 3. Input speed sensor

SCIA8020E

WCIA0658E

Revision: January 20102010 Versa

Page 247 of 3745

AT-230

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

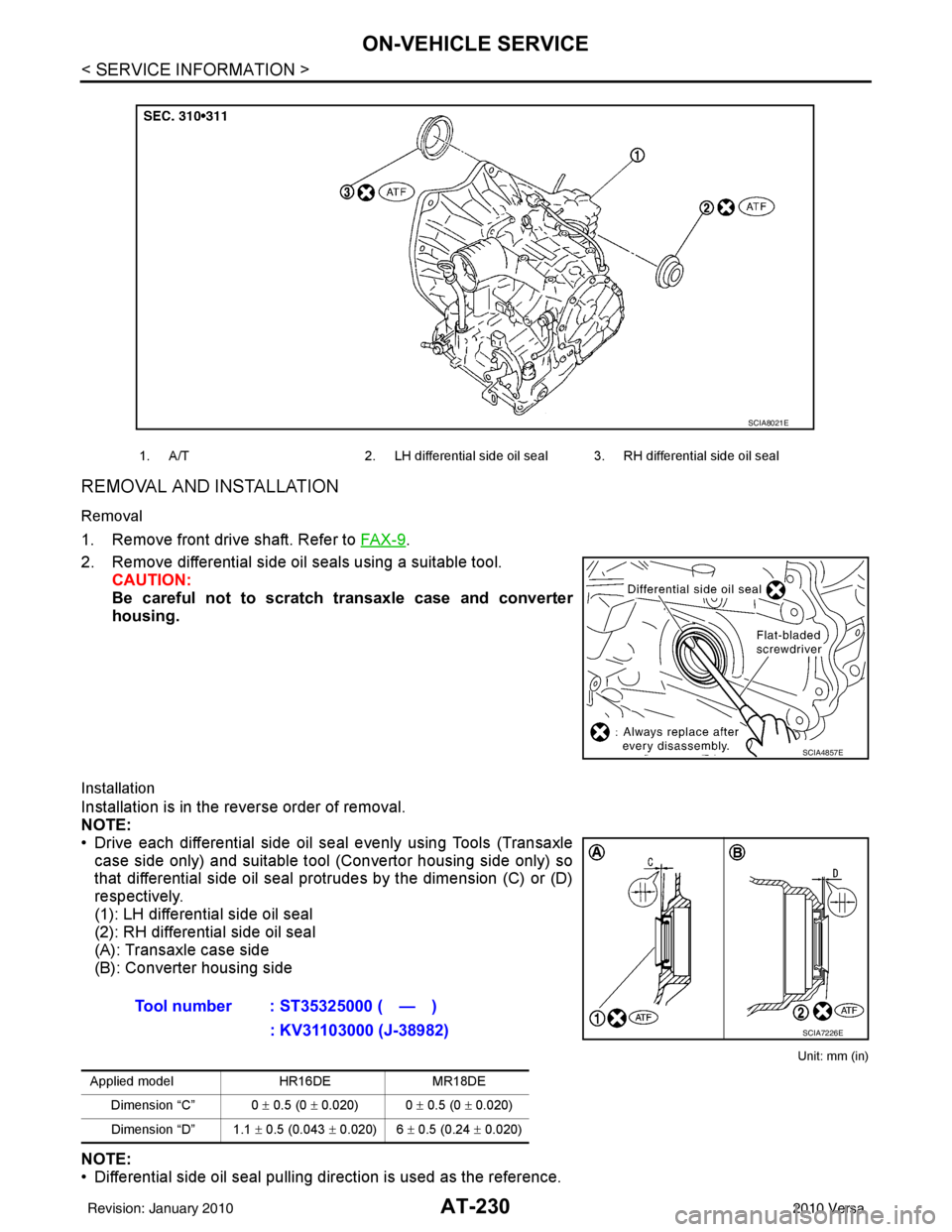

REMOVAL AND INSTALLATION

Removal

1. Remove front drive shaft. Refer to FA X - 9.

2. Remove differential side oil seals using a suitable tool. CAUTION:

Be careful not to scratch transaxle case and converter

housing.

Installation

Installation is in the reverse order of removal.

NOTE:

• Drive each differential side oil seal evenly using Tools (Transaxlecase side only) and suitable tool (Convertor housing side only) so

that differential side oil seal prot rudes by the dimension (C) or (D)

respectively.

(1): LH differential side oil seal

(2): RH differential side oil seal

(A): Transaxle case side

(B): Converter housing side

Unit: mm (in)

NOTE:

• Differential side oil seal pulling direction is used as the reference.

1. A/T 2. LH differential side oil seal 3. RH differential side oil seal

SCIA8021E

SCIA4857E

Tool number : ST35325000 ( — )

: KV31103000 (J-38982)

Applied model HR16DEMR18DE

Dimension “C” 0 ± 0.5 (0 ± 0.020) 0 ± 0.5 (0 ± 0.020)

Dimension “D” 1.1 ± 0.5 (0.043 ± 0.020) 6 ± 0.5 (0.24 ± 0.020)

SCIA7226E

Revision: January 20102010 Versa

Page 248 of 3745

ON-VEHICLE SERVICEAT-231

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

• After installing differential side oil seal, check A/T fluid leakage and A/T fluid level. Refer to AT-17, "Checking

A/T Fluid".

Revision: January 20102010 Versa

Page 249 of 3745

AT-232

< SERVICE INFORMATION >

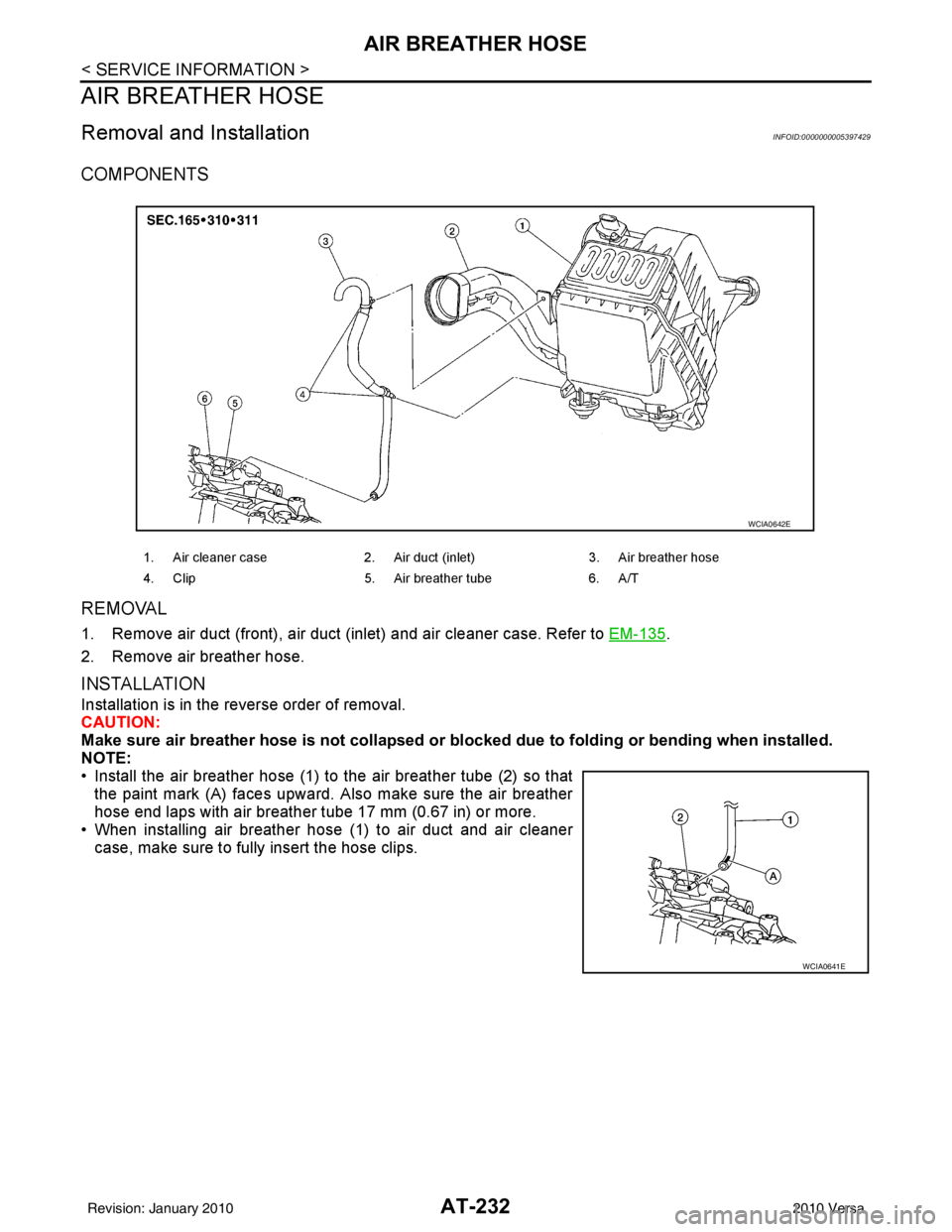

AIR BREATHER HOSE

AIR BREATHER HOSE

Removal and InstallationINFOID:0000000005397429

COMPONENTS

REMOVAL

1. Remove air duct (front), air duct (inlet) and air cleaner case. Refer to EM-135.

2. Remove air breather hose.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Make sure air breather hose is not collapsed or bl ocked due to folding or bending when installed.

NOTE:

• Install the air breather hose (1) to the air breather tube (2) so that

the paint mark (A) faces upward. Also make sure the air breather

hose end laps with air breather tube 17 mm (0.67 in) or more.

• When installing air breather hose (1) to air duct and air cleaner

case, make sure to fully insert the hose clips.

1. Air cleaner case 2. Air duct (inlet) 3. Air breather hose

4. Clip 5. Air breather tube 6. A/T

WCIA0642E

WCIA0641E

Revision: January 20102010 Versa

Page 250 of 3745

TRANSAXLE ASSEMBLYAT-233

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

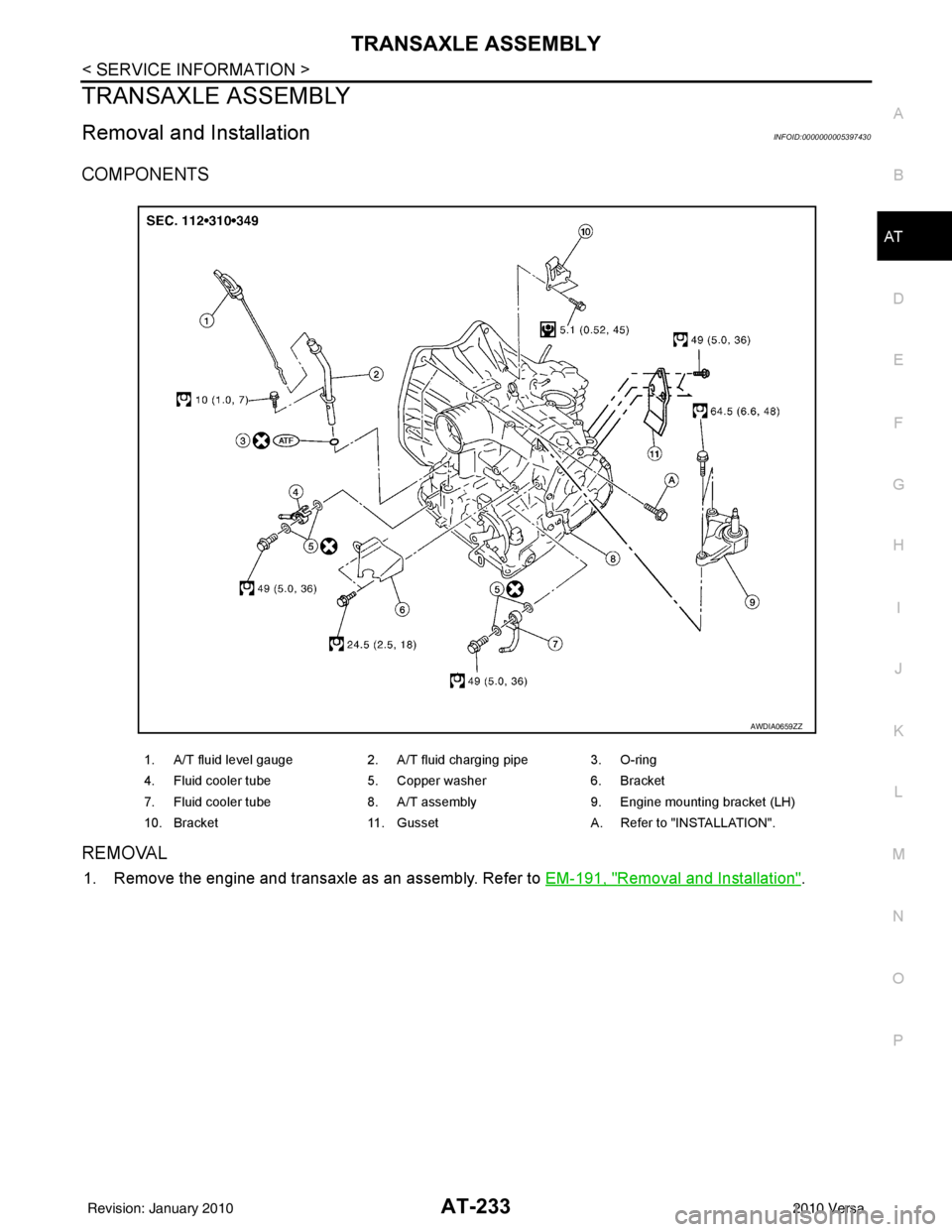

TRANSAXLE ASSEMBLY

Removal and InstallationINFOID:0000000005397430

COMPONENTS

REMOVAL

1. Remove the engine and transaxle as an assembly. Refer to EM-191, "Removal and Installation".

1. A/T fluid level gauge2. A/T fluid charging pipe 3. O-ring

4. Fluid cooler tube 5. Copper washer 6. Bracket

7. Fluid cooler tube 8. A/T assembly9. Engine mounting bracket (LH)

10. Bracket 11. Gusset A. Refer to "INSTALLATION".

AWDIA0659ZZ

Revision: January 20102010 Versa