NISSAN TIIDA 2010 Service Repair Manual

TIIDA 2010

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57397/w960_57397-0.png

NISSAN TIIDA 2010 Service Repair Manual

Trending: jacking points, Lt-6, length, Anchor point, tow bar, horn, transmission oil

Page 271 of 3745

AT-254

< SERVICE INFORMATION >

OVERHAUL

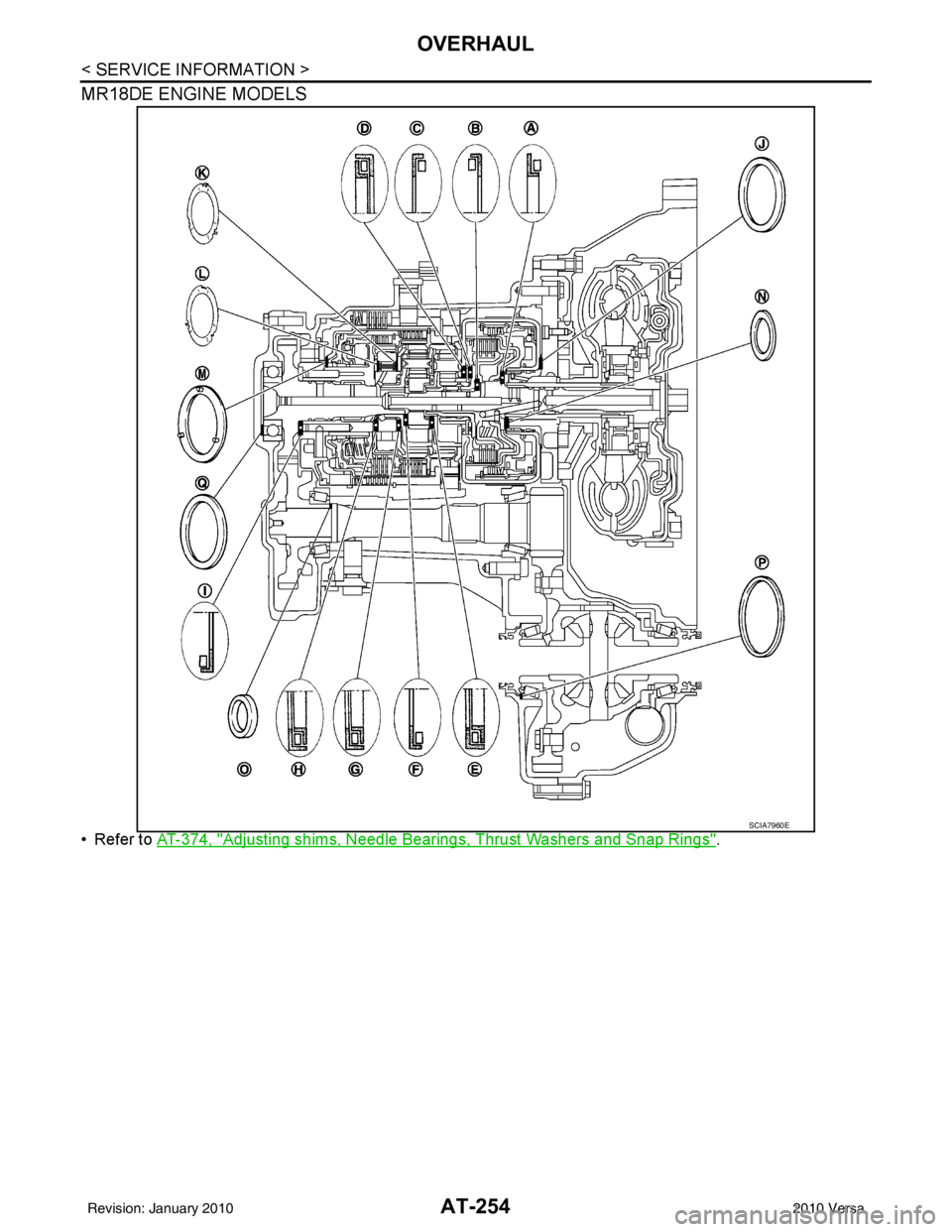

MR18DE ENGINE MODELS

• Refer to AT-374, "Adjusting shims, Needle Bearings, Thrust Washers and Snap Rings".

SCIA7960E

Revision: January 20102010 Versa

Page 272 of 3745

OVERHAULAT-255

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

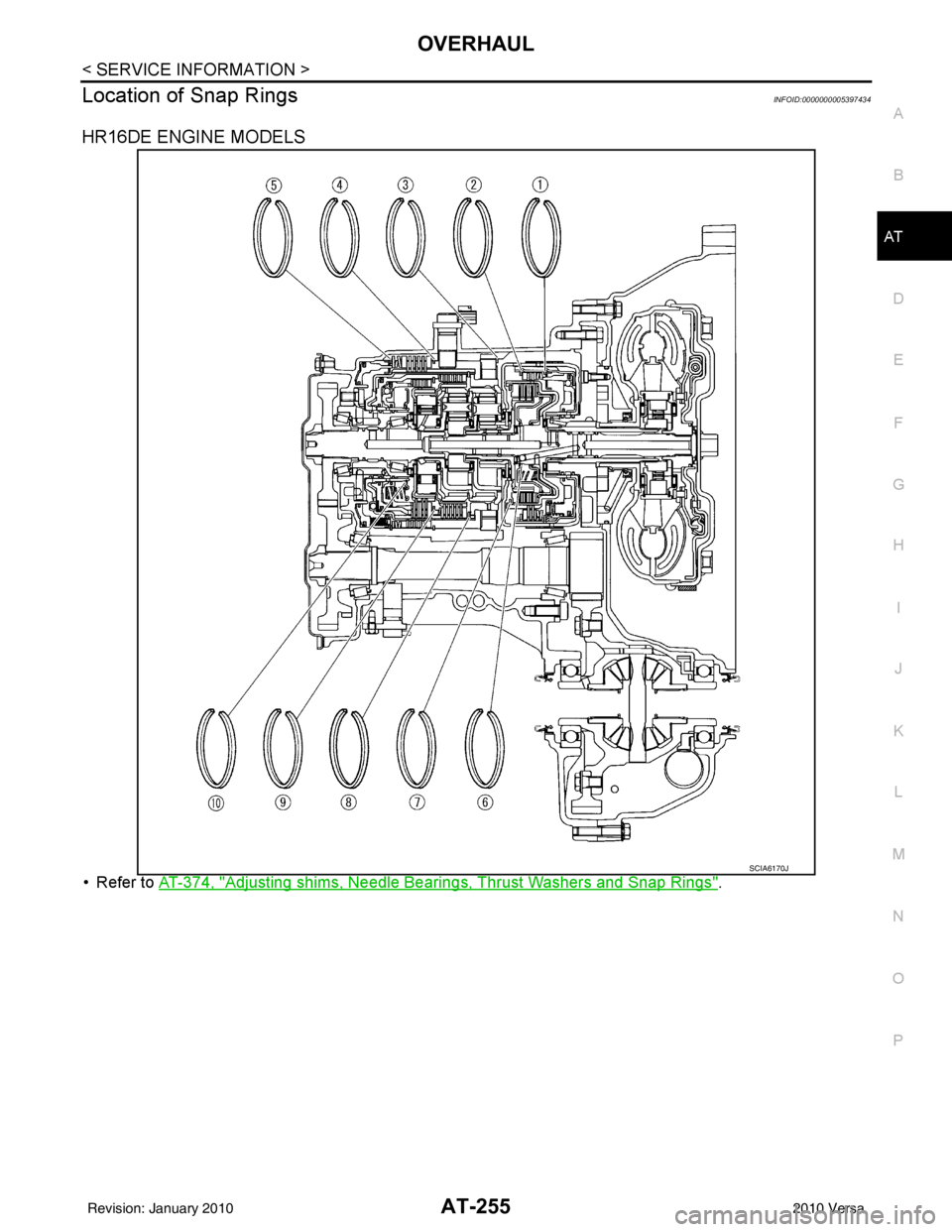

Location of Snap RingsINFOID:0000000005397434

HR16DE ENGINE MODELS

• Refer to AT-374, "Adjusting shims, Needle Bearings, Thrust Washers and Snap Rings".

SCIA6170J

Revision: January 20102010 Versa

Page 273 of 3745

AT-256

< SERVICE INFORMATION >

OVERHAUL

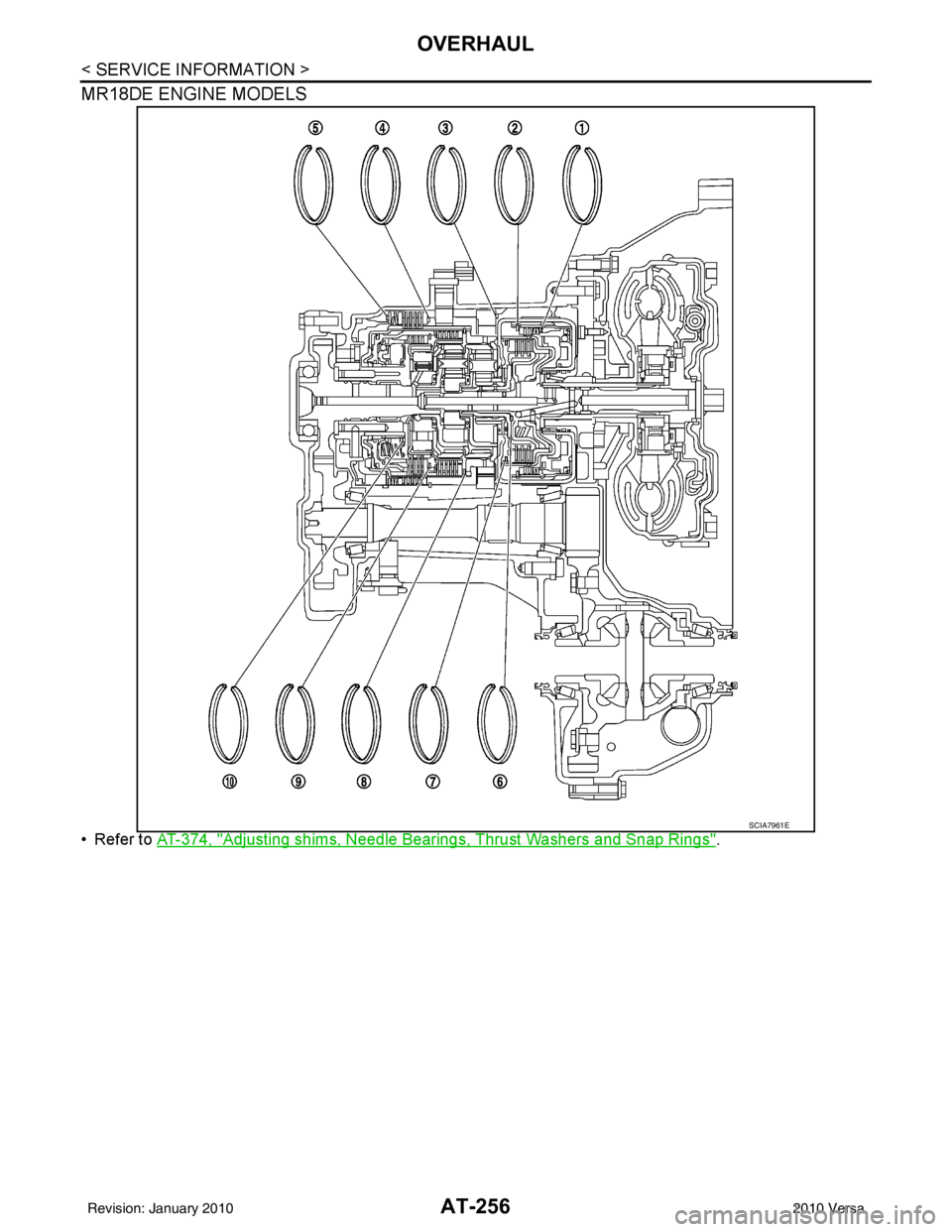

MR18DE ENGINE MODELS

• Refer to AT-374, "Adjusting shims, Needle Bearings, Thrust Washers and Snap Rings".

SCIA7961E

Revision: January 20102010 Versa

Page 274 of 3745

DISASSEMBLYAT-257

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

DISASSEMBLY

DisassemblyINFOID:0000000005397435

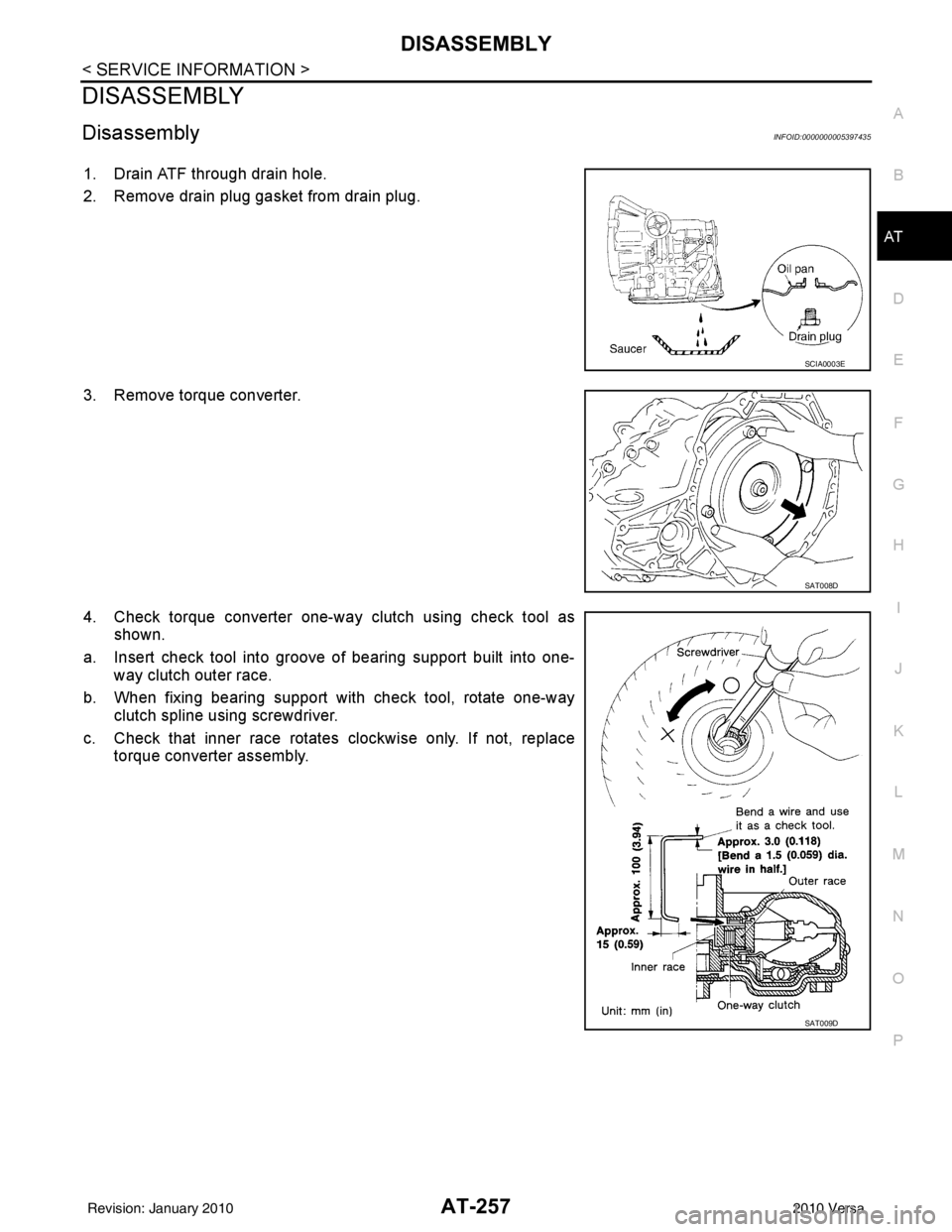

1. Drain ATF through drain hole.

2. Remove drain plug gasket from drain plug.

3. Remove torque converter.

4. Check torque converter one-way clutch using check tool as shown.

a. Insert check tool into groove of bearing support built into one- way clutch outer race.

b. When fixing bearing support with check tool, rotate one-way clutch spline using screwdriver.

c. Check that inner race rotates clockwise only. If not, replace torque converter assembly.

SCIA0003E

SAT008D

SAT009D

Revision: January 20102010 Versa

Page 275 of 3745

AT-258

< SERVICE INFORMATION >

DISASSEMBLY

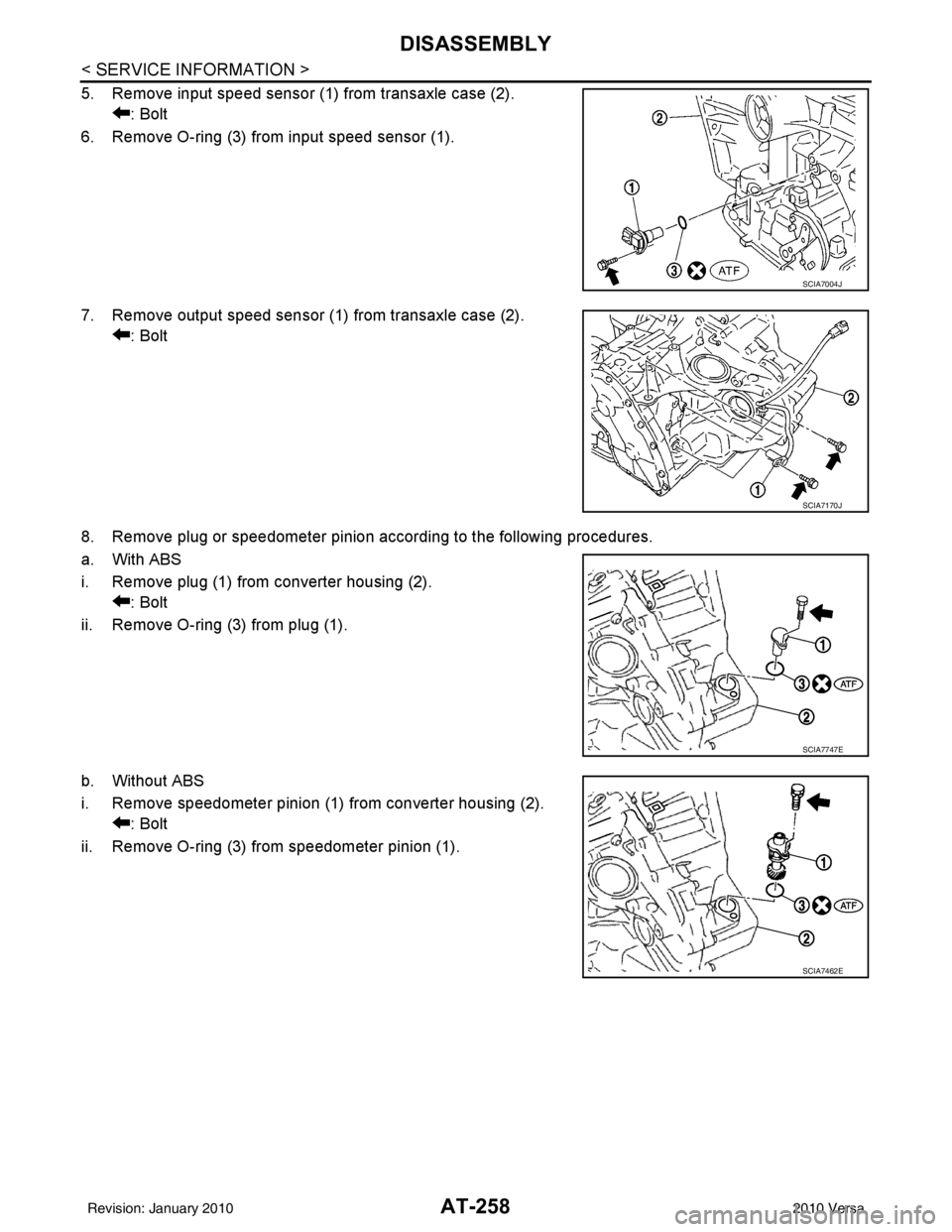

5. Remove input speed sensor (1) from transaxle case (2).: Bolt

6. Remove O-ring (3) from input speed sensor (1).

7. Remove output speed sensor (1) from transaxle case (2). : Bolt

8. Remove plug or speedometer pinion according to the following procedures.

a. With ABS

i. Remove plug (1) from converter housing (2). : Bolt

ii. Remove O-ring (3) from plug (1).

b. Without ABS

i. Remove speedometer pinion (1) from converter housing (2). : Bolt

ii. Remove O-ring (3) from speedometer pinion (1).

SCIA7004J

SCIA7170J

SCIA7747E

SCIA7462E

Revision: January 20102010 Versa

Page 276 of 3745

DISASSEMBLYAT-259

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

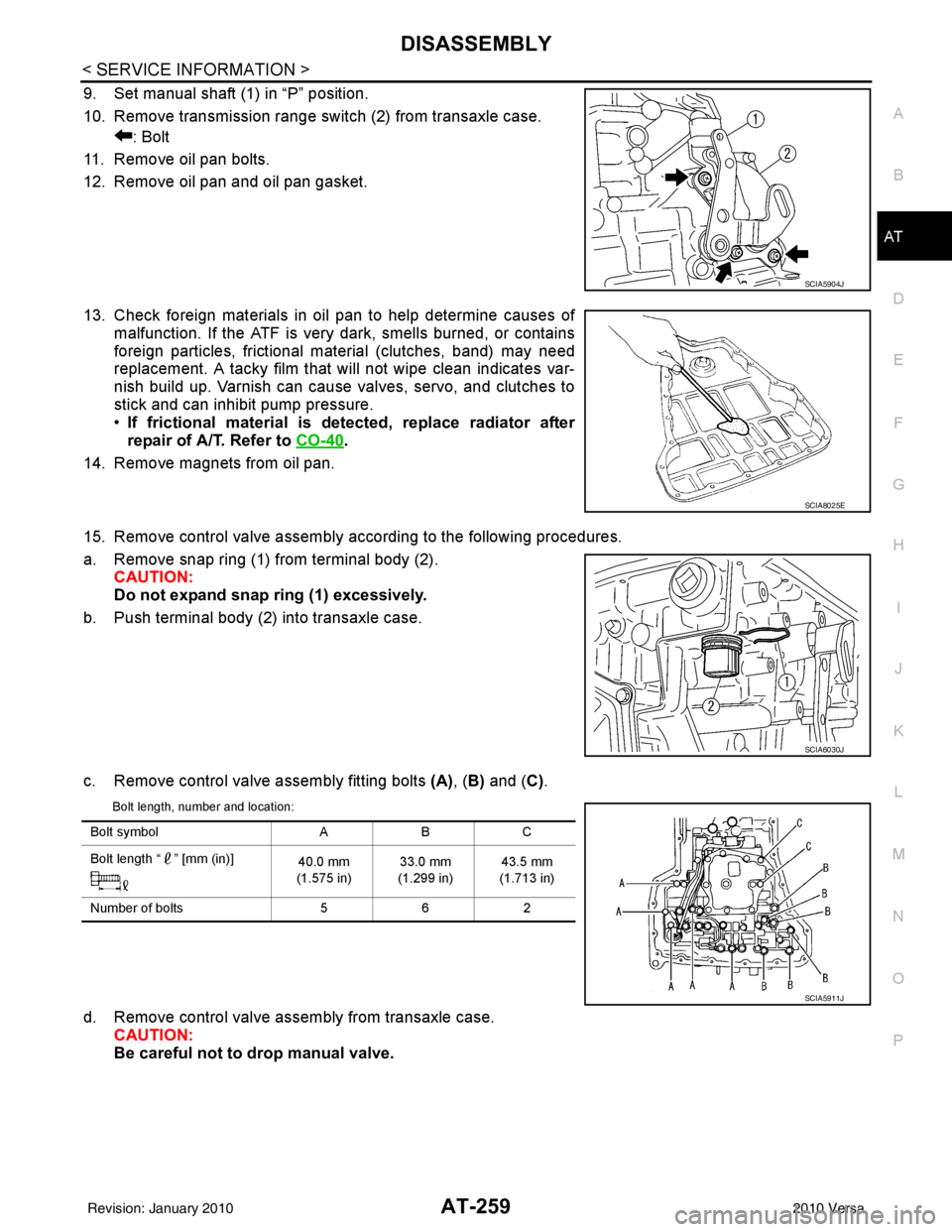

9. Set manual shaft (1) in “P” position.

10. Remove transmission range switch (2) from transaxle case. : Bolt

11. Remove oil pan bolts.

12. Remove oil pan and oil pan gasket.

13. Check foreign materials in oil pan to help determine causes of malfunction. If the ATF is very dark, smells burned, or contains

foreign particles, frictional material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates var-

nish build up. Varnish can cause valves, servo, and clutches to

stick and can inhibit pump pressure.

•If frictional material is detected, replace radiator after

repair of A/T. Refer to CO-40

.

14. Remove magnets from oil pan.

15. Remove control valve assembly according to the following procedures.

a. Remove snap ring (1) from terminal body (2). CAUTION:

Do not expand snap ring (1) excessively.

b. Push terminal body (2) into transaxle case.

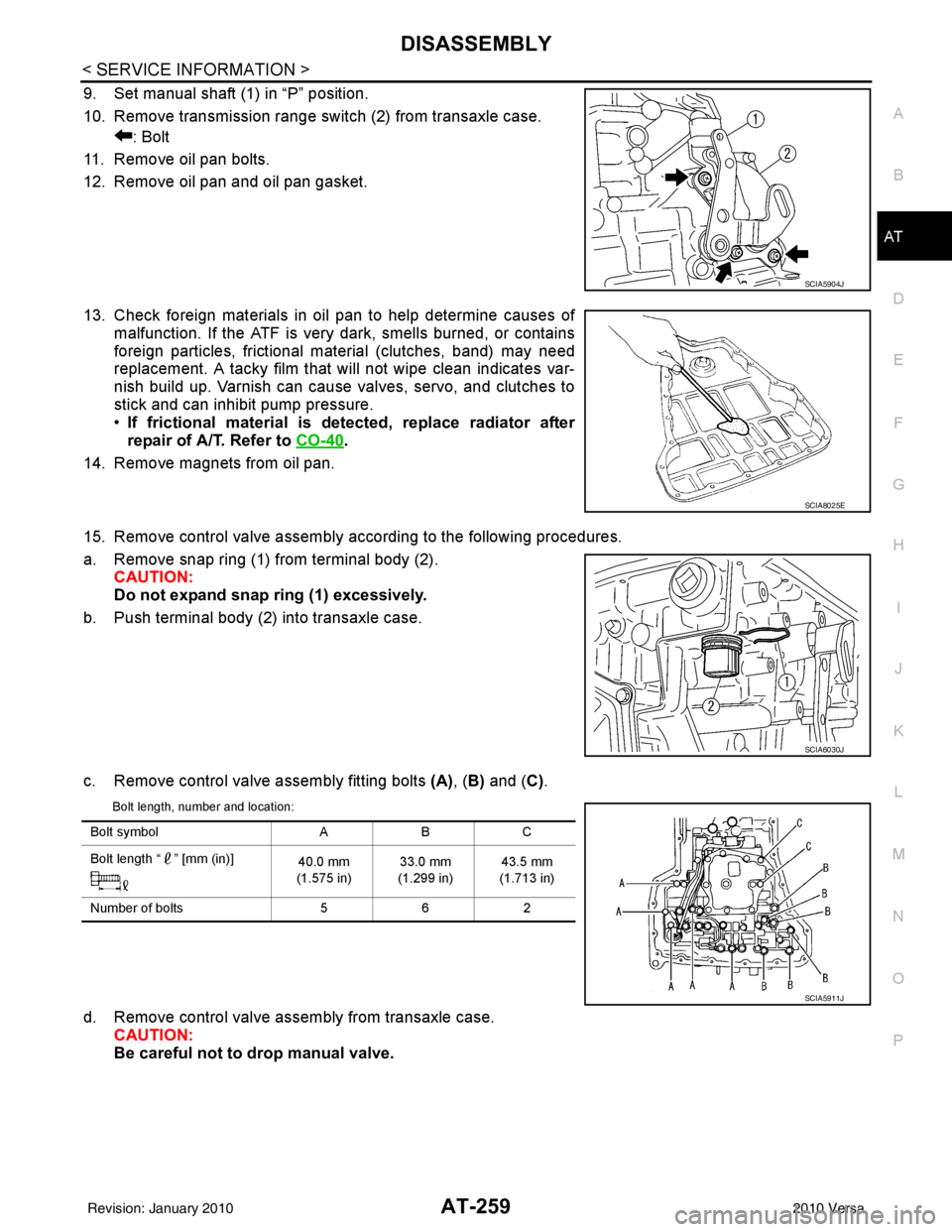

c. Remove control valve assembly fitting bolts (A), (B) and ( C).

Bolt length, number and location:

d. Remove control valve assembly from transaxle case.

CAUTION:

Be careful not to drop manual valve.

SCIA5904J

SCIA8025E

SCIA6030J

Bolt symbol ABC

Bolt length “ ” [mm (in)] 40.0 mm

(1.575 in) 33.0 mm

(1.299 in) 43.5 mm

(1.713 in)

Number of bolts 562

SCIA5911J

Revision: January 20102010 Versa

Page 277 of 3745

AT-260

< SERVICE INFORMATION >

DISASSEMBLY

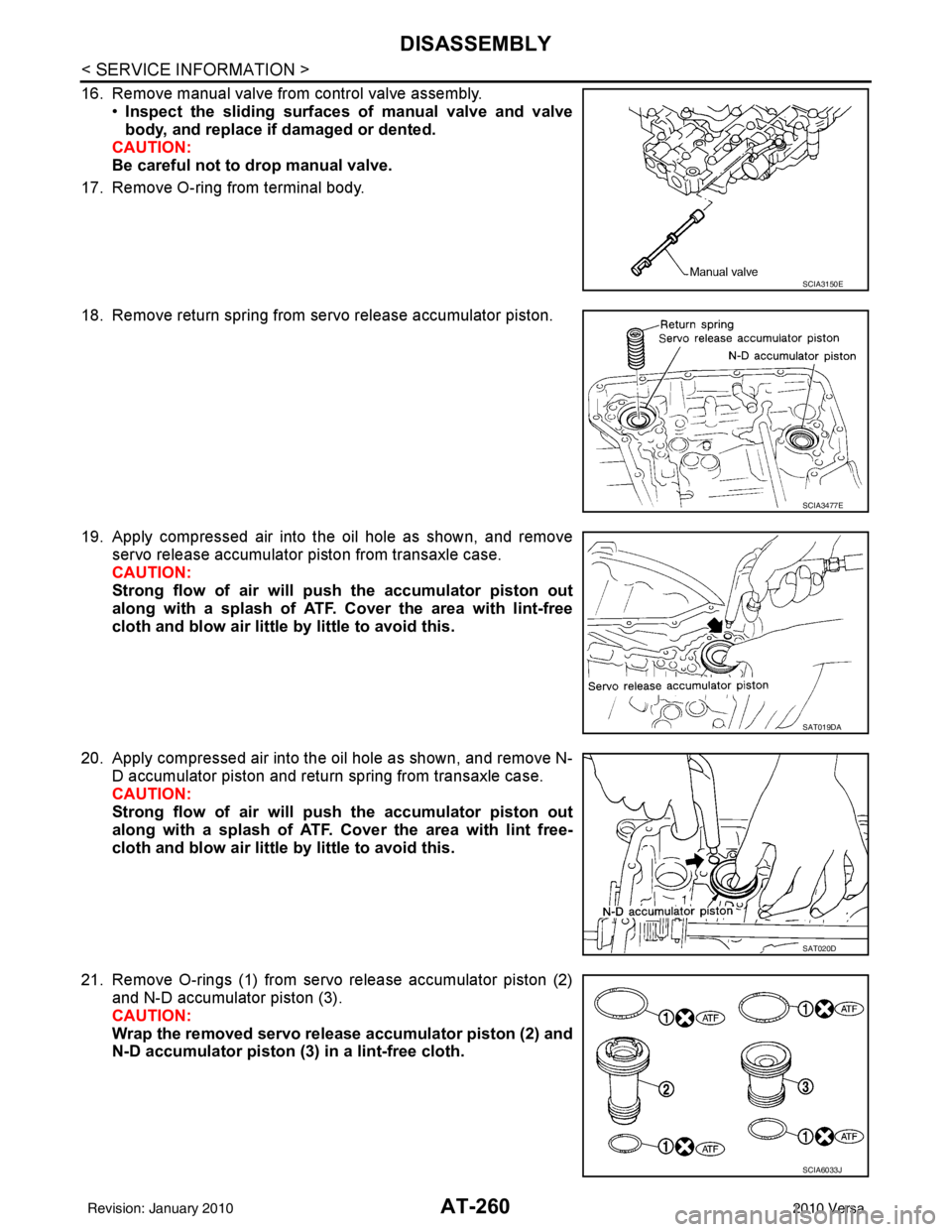

16. Remove manual valve from control valve assembly.•Inspect the sliding surfaces of manual valve and valve

body, and replace if damaged or dented.

CAUTION:

Be careful not to drop manual valve.

17. Remove O-ring from terminal body.

18. Remove return spring from servo release accumulator piston.

19. Apply compressed air into the oil hole as shown, and remove servo release accumulator piston from transaxle case.

CAUTION:

Strong flow of air will push the accumulator piston out

along with a splash of ATF. Cover the area with lint-free

cloth and blow air little by little to avoid this.

20. Apply compressed air into the oil hole as shown, and remove N- D accumulator piston and return spring from transaxle case.

CAUTION:

Strong flow of air will push the accumulator piston out

along with a splash of ATF. Cover the area with lint free-

cloth and blow air little by little to avoid this.

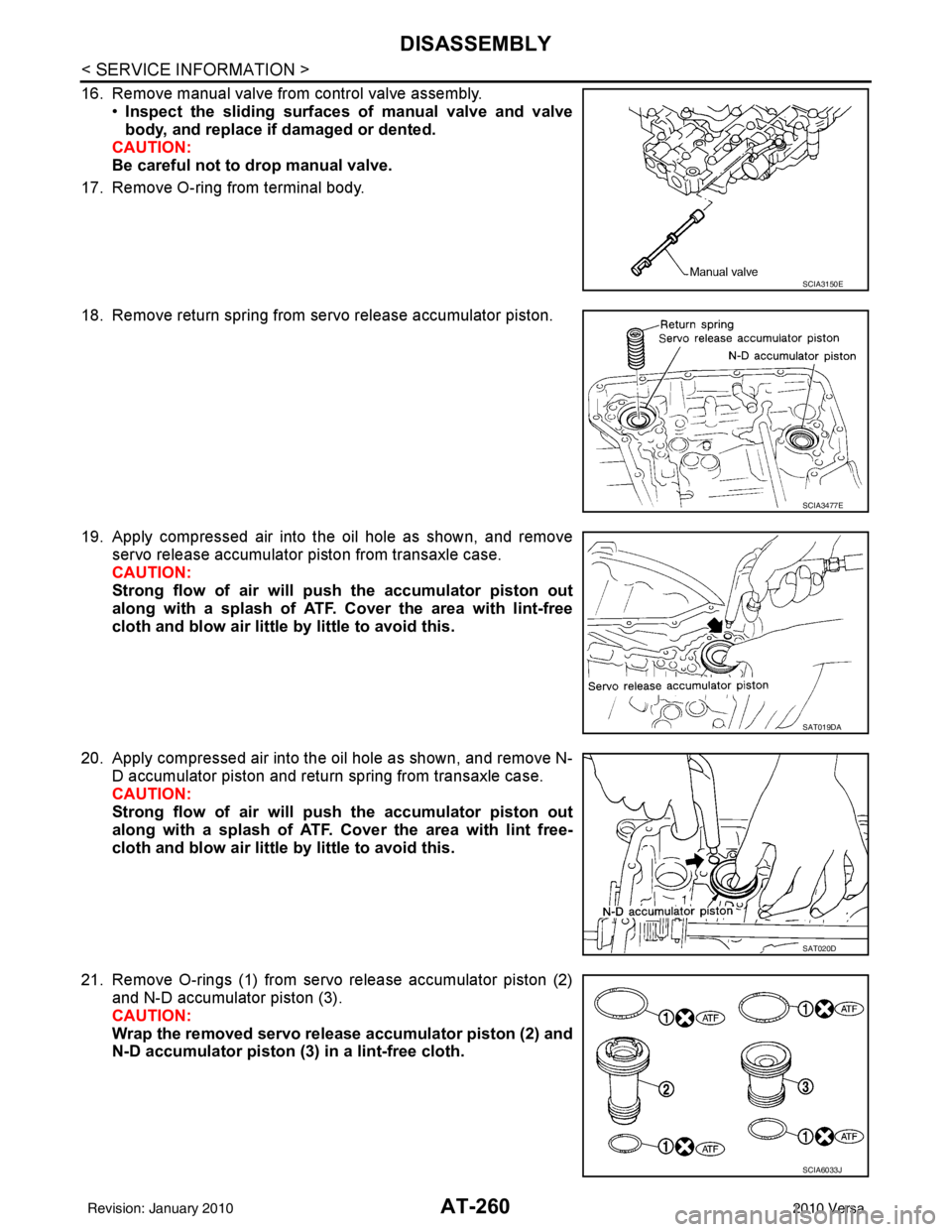

21. Remove O-rings (1) from servo release accumulator piston (2) and N-D accumulator piston (3).

CAUTION:

Wrap the removed servo release accumulator piston (2) and

N-D accumulator piston (3) in a lint-free cloth.

SCIA3150E

SCIA3477E

SAT019DA

SAT020D

SCIA6033J

Revision: January 20102010 Versa

Page 278 of 3745

DISASSEMBLYAT-261

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

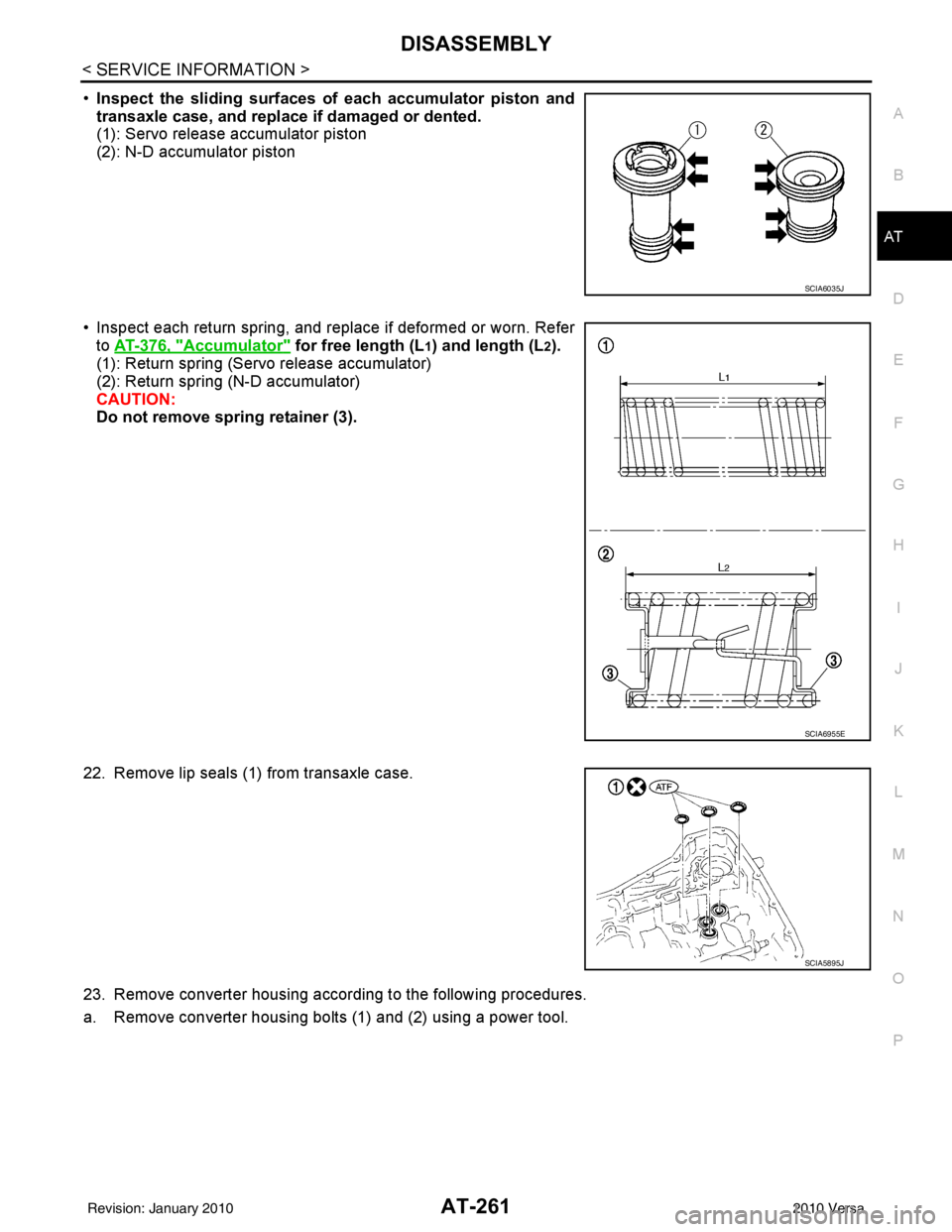

• Inspect the sliding surfaces of each accumulator piston and

transaxle case, and replace if damaged or dented.

(1): Servo release accumulator piston

(2): N-D accumulator piston

• Inspect each return spring, and replace if deformed or worn. Refer to AT-376, "

Accumulator" for free length (L1) and length (L2).

(1): Return spring (Servo release accumulator)

(2): Return spring (N-D accumulator)

CAUTION:

Do not remove spring retainer (3).

22. Remove lip seals (1) from transaxle case.

23. Remove converter housing according to the following procedures.

a. Remove converter housing bolts (1) and (2) using a power tool.

SCIA6035J

SCIA6955E

SCIA5895J

Revision: January 20102010 Versa

Page 279 of 3745

AT-262

< SERVICE INFORMATION >

DISASSEMBLY

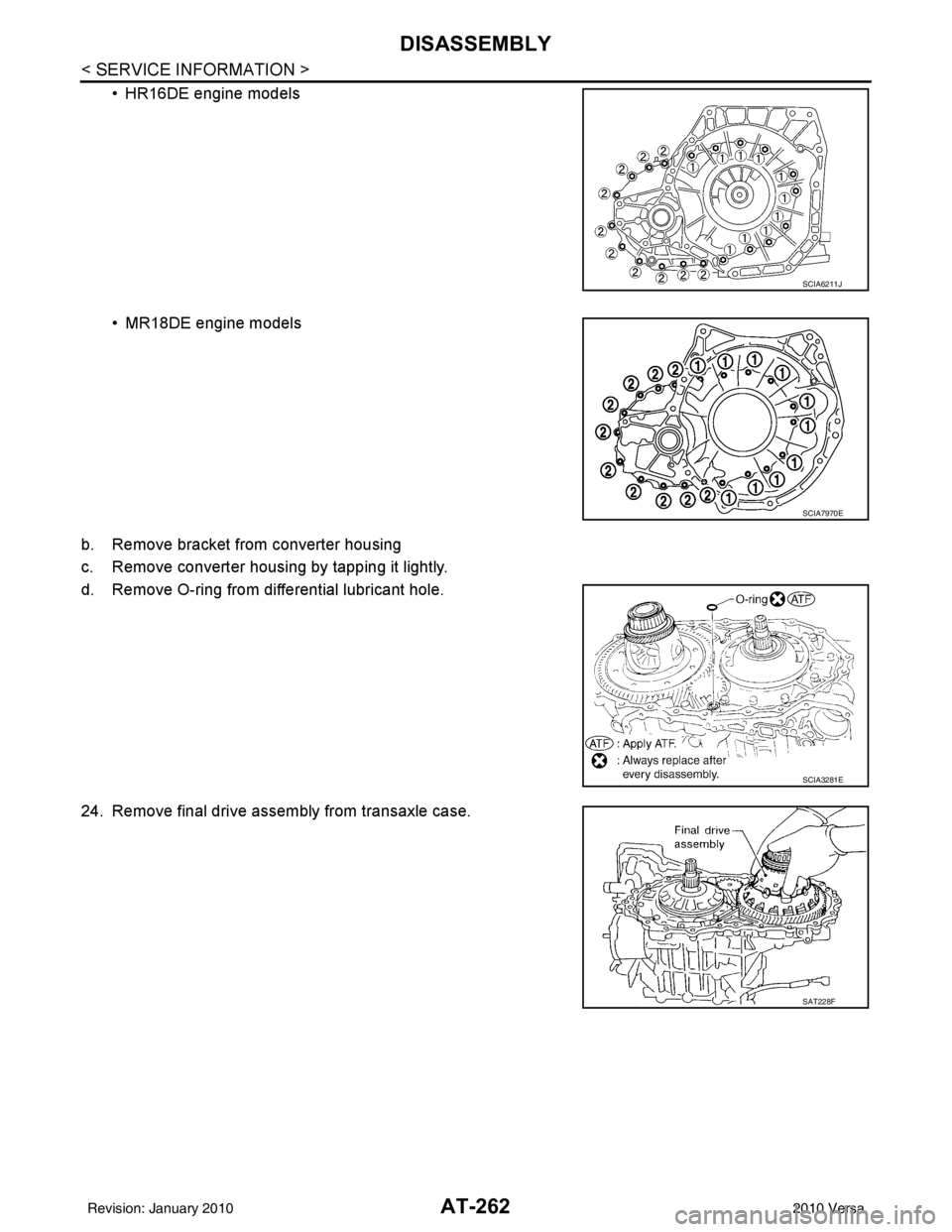

• HR16DE engine models

• MR18DE engine models

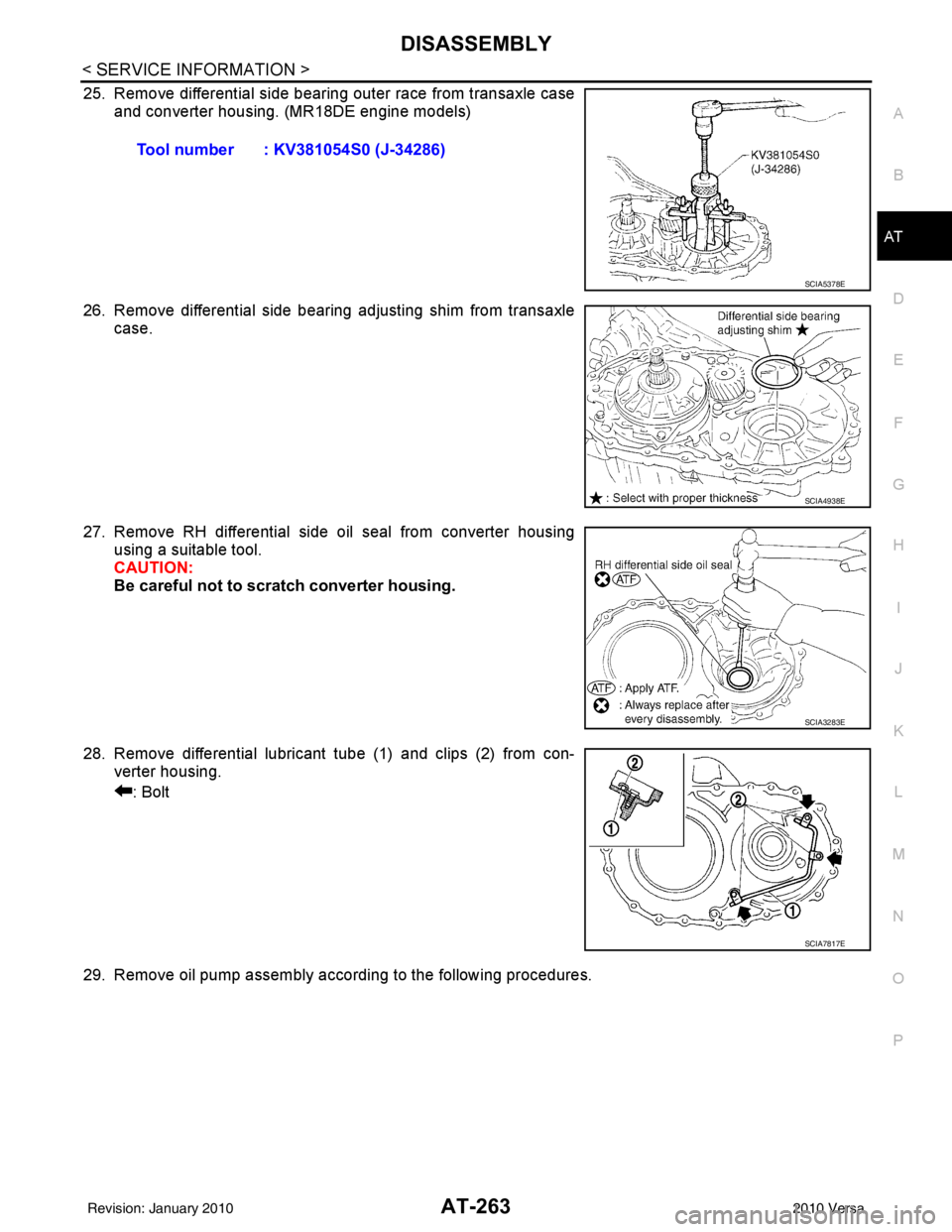

b. Remove bracket from converter housing

c. Remove converter housing by tapping it lightly.

d. Remove O-ring from differential lubricant hole.

24. Remove final drive assembly from transaxle case.

SCIA6211J

SCIA7970E

SCIA3281E

SAT228F

Revision: January 20102010 Versa

Page 280 of 3745

DISASSEMBLYAT-263

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

25. Remove differential side bearing outer race from transaxle case and converter housing. (MR18DE engine models)

26. Remove differential side bearing adjusting shim from transaxle case.

27. Remove RH differential side oil seal from converter housing using a suitable tool.

CAUTION:

Be careful not to scratch converter housing.

28. Remove differential lubricant tube (1) and clips (2) from con- verter housing.

: Bolt

29. Remove oil pump assembly according to the following procedures. Tool number : KV381054S0 (J-34286)

SCIA5378E

SCIA4938E

SCIA3283E

SCIA7817E

Revision: January 20102010 Versa

Trending: engine, Oil viscosity, air suspension, Park light, open hood, PS-9, check oil