NISSAN TIIDA 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 251 of 3745

AT-234

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

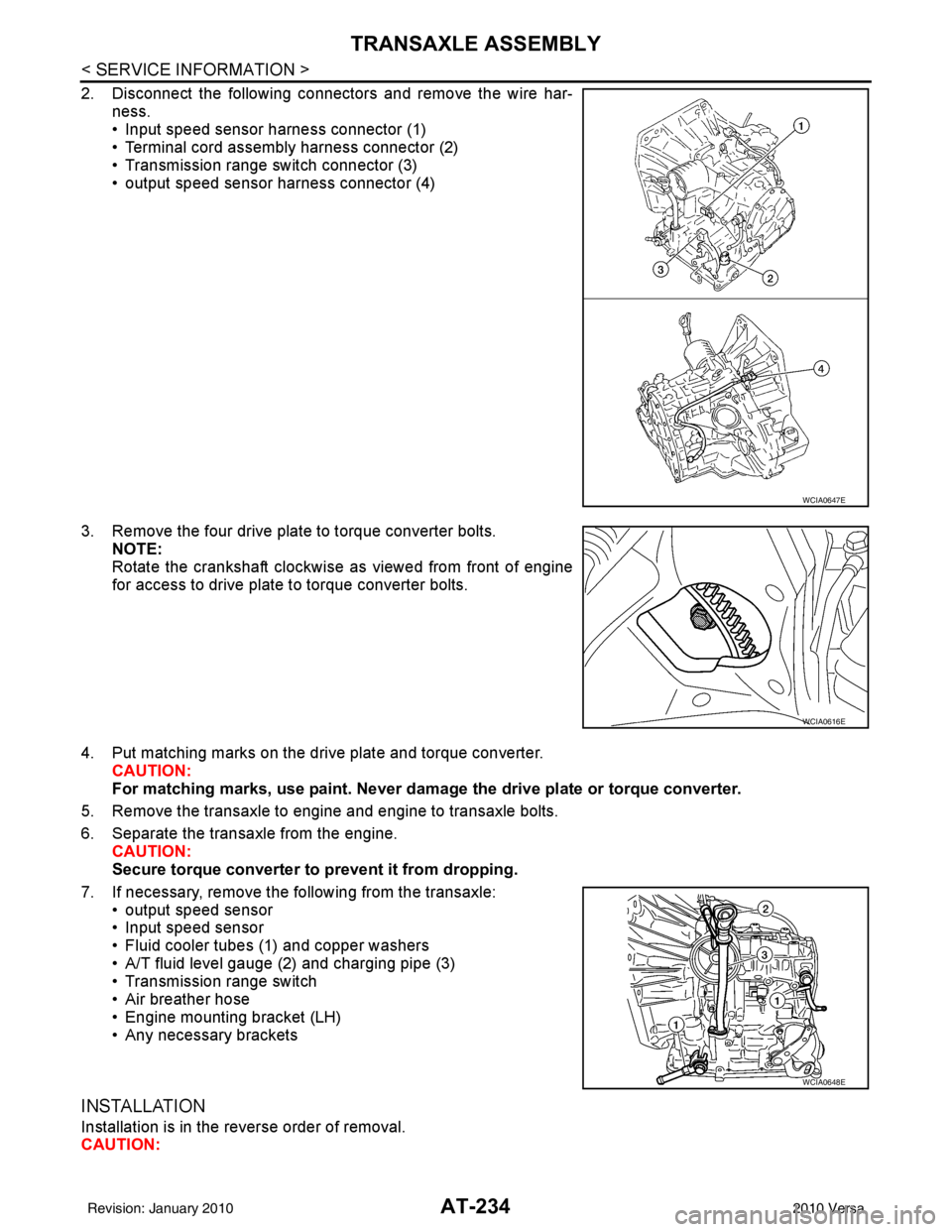

2. Disconnect the following connectors and remove the wire har-ness.

• Input speed sensor harness connector (1)

• Terminal cord assembly harness connector (2)

• Transmission range switch connector (3)

• output speed sensor harness connector (4)

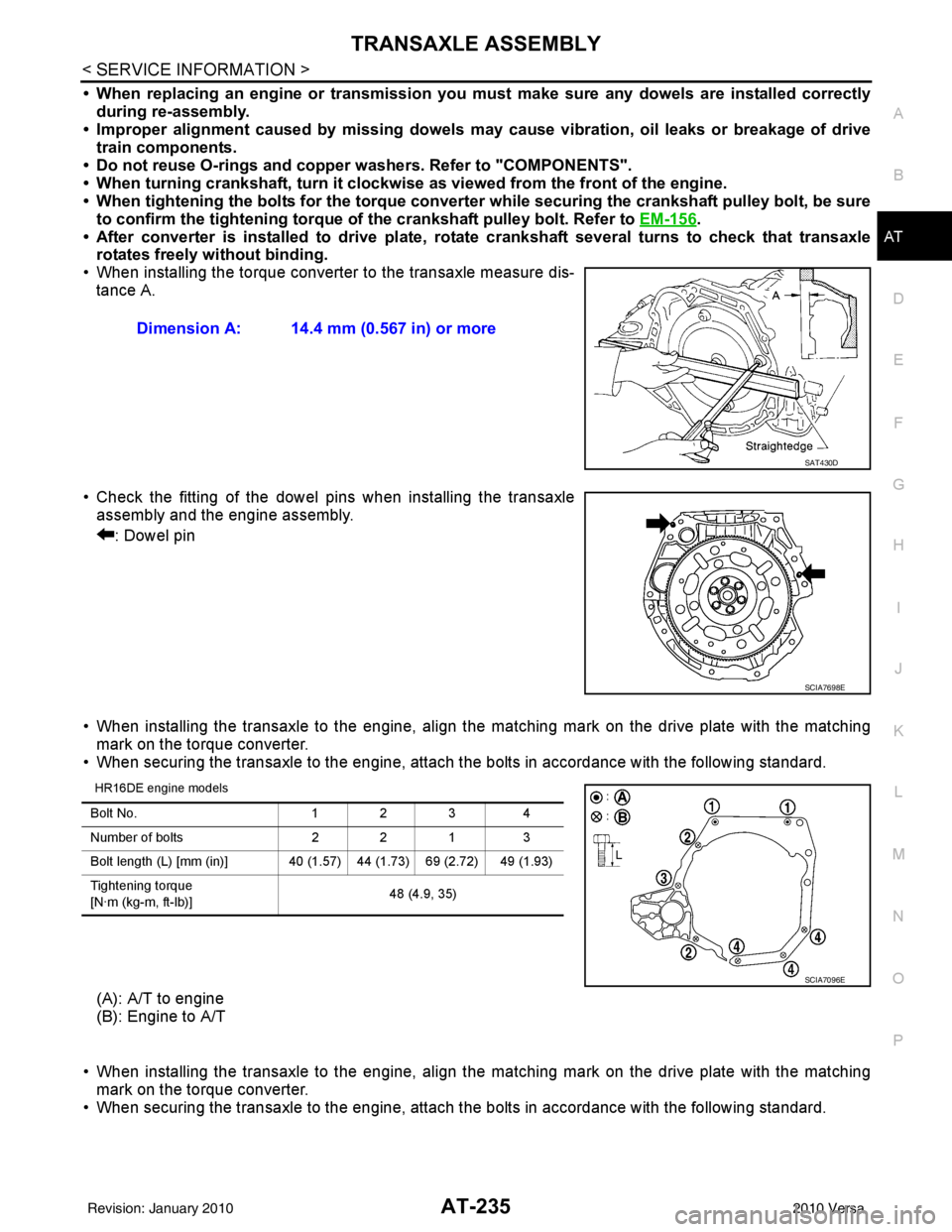

3. Remove the four drive plate to torque converter bolts. NOTE:

Rotate the crankshaft clockwise as viewed from front of engine

for access to drive plate to torque converter bolts.

4. Put matching marks on the drive plate and torque converter. CAUTION:

For matching marks, use paint. Never dama ge the drive plate or torque converter.

5. Remove the transaxle to engine and engine to transaxle bolts.

6. Separate the transaxle from the engine. CAUTION:

Secure torque converter to prevent it from dropping.

7. If necessary, remove the following from the transaxle: • output speed sensor

• Input speed sensor

• Fluid cooler tubes (1) and copper washers

• A/T fluid level gauge (2) and charging pipe (3)

• Transmission range switch

• Air breather hose

• Engine mounting bracket (LH)

• Any necessary brackets

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

WCIA0647E

WCIA0616E

WCIA0648E

Revision: January 20102010 Versa

Page 252 of 3745

TRANSAXLE ASSEMBLYAT-235

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

• When replacing an engine or transmission you must make sure any dowels are installed correctly during re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drive

train components.

• Do not reuse O-rings and copper washers. Refer to "COMPONENTS".

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• When tightening the bolts for th e torque converter while securing the crankshaft pulley bolt, be sure

to confirm the tightening torque of the crankshaft pulley bolt. Refer to EM-156

.

• After converter is installed to drive plate, ro tate crankshaft several turns to check that transaxle

rotates freely without binding.

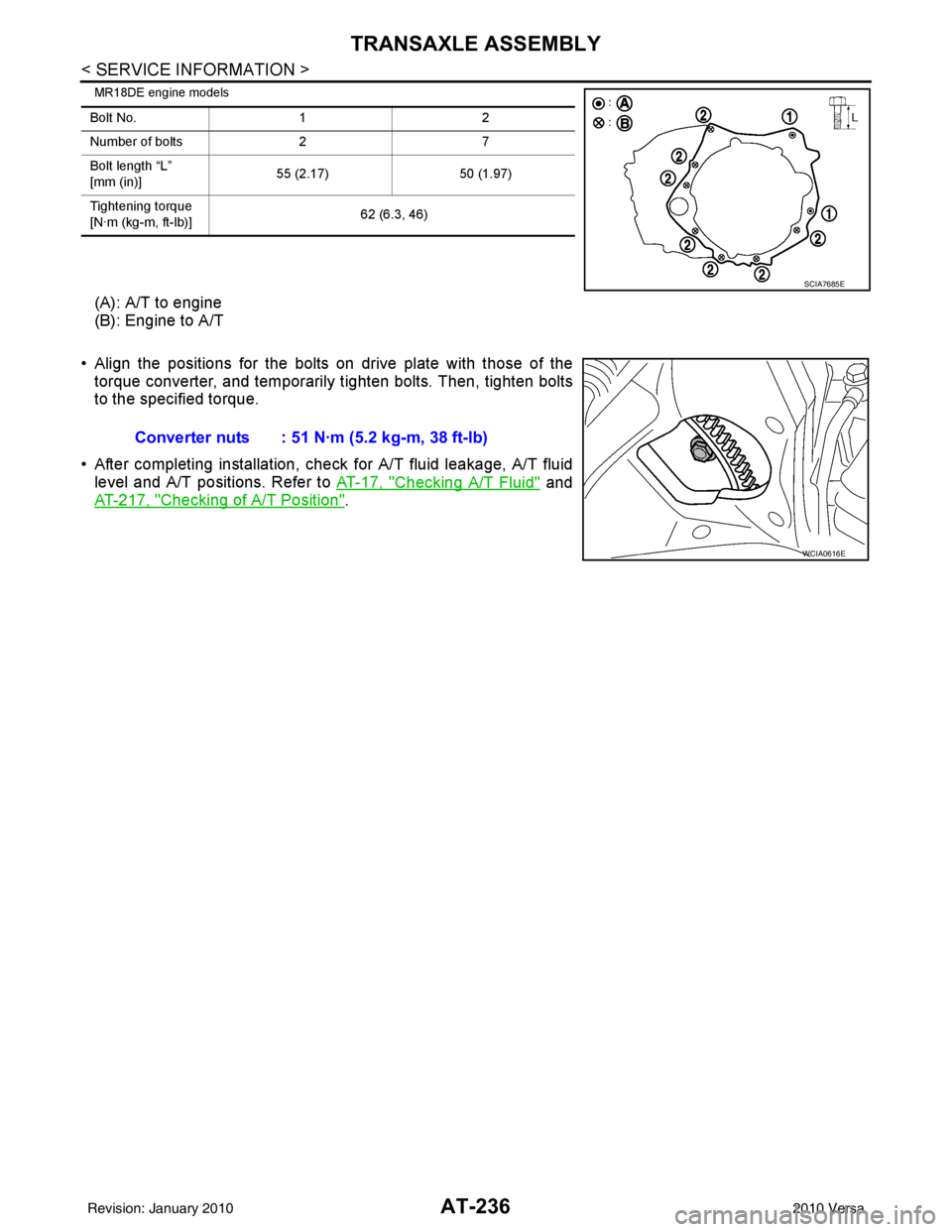

• When installing the torque converter to the transaxle measure dis- tance A.

• Check the fitting of the dowel pins when installing the transaxle assembly and the engine assembly.

: Dowel pin

• When installing the transaxle to the engine, align the matching mark on the drive plate with the matching mark on the torque converter.

• When securing the transaxle to the engine, attach the bolts in accordance with the following standard.

HR16DE engine models

(A): A/T to engine

(B): Engine to A/T

• When installing the transaxle to the engine, align the matching mark on the drive plate with the matching mark on the torque converter.

• When securing the transaxle to the engine, attach the bolts in accordance with the following standard. Dimension A: 14.4 mm (0.567 in) or more

SAT430D

SCIA7698E

Bolt No.

1 2 34

Number of bolts 2 2 13

Bolt length (L) [mm (in)] 40 (1.5 7) 44 (1.73) 69 (2.72) 49 (1.93)

Tightening torque

[N·m (kg-m, ft-lb)] 48 (4.9, 35)

SCIA7096E

Revision: January 20102010 Versa

Page 253 of 3745

AT-236

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

MR18DE engine models

(A): A/T to engine

(B): Engine to A/T

• Align the positions for the bolts on drive plate with those of the torque converter, and temporarily tighten bolts. Then, tighten bolts

to the specified torque.

• After completing installation, check for A/T fluid leakage, A/T fluid level and A/T positions. Refer to AT-17, "

Checking A/T Fluid" and

AT-217, "

Checking of A/T Position".

Bolt No. 12

Number of bolts 27

Bolt length “L”

[mm (in)] 55 (2.17)

50 (1.97)

Tightening torque

[N·m (kg-m, ft-lb)] 62 (6.3, 46)

SCIA7685E

Converter nuts : 51 N·m (5.2 kg-m, 38 ft-lb)

WCIA0616E

Revision: January 20102010 Versa

Page 254 of 3745

OVERHAULAT-237

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

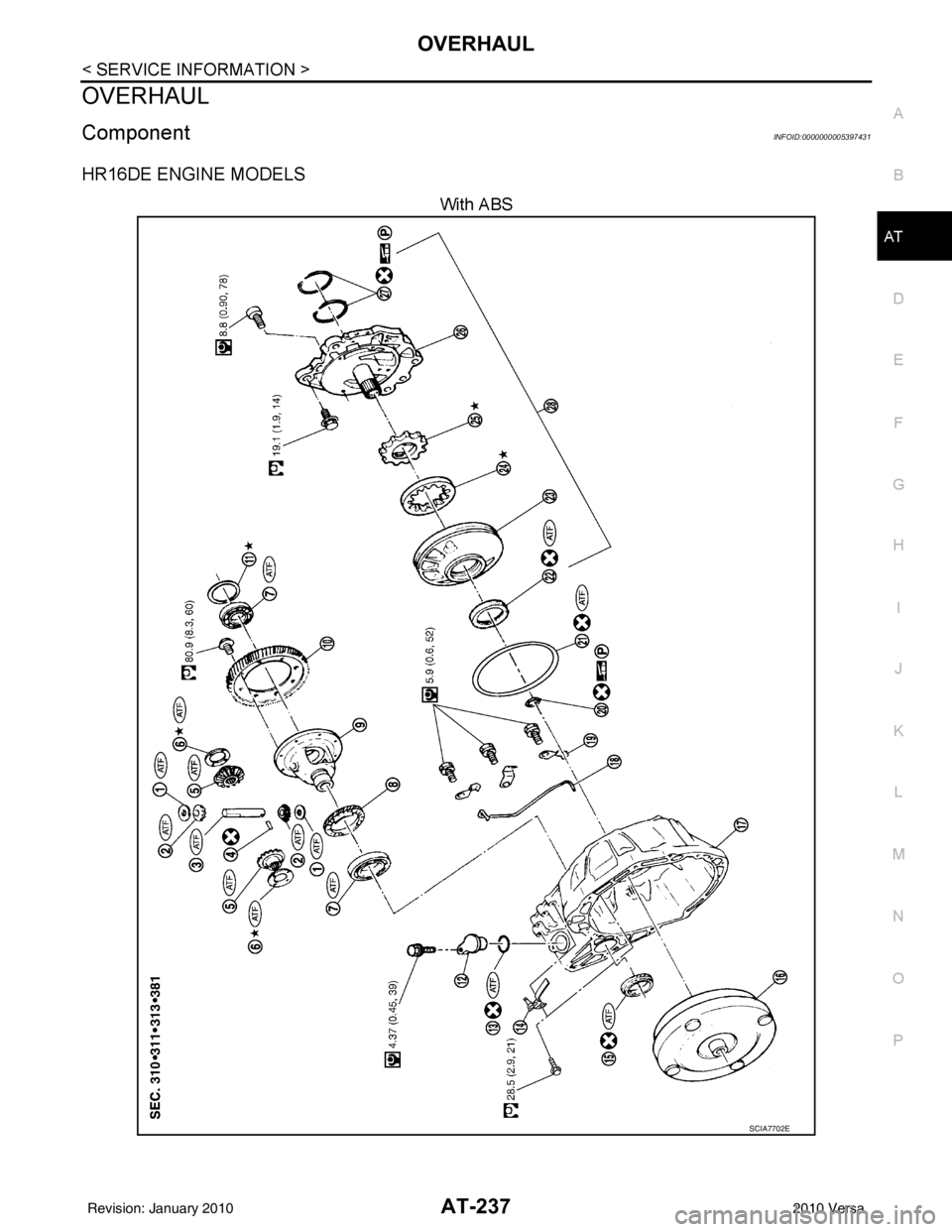

OVERHAUL

ComponentINFOID:0000000005397431

HR16DE ENGINE MODELS

With ABS

SCIA7702E

Revision: January 20102010 Versa

Page 255 of 3745

AT-238

< SERVICE INFORMATION >

OVERHAUL

1. Pinion mate gear thrust washer 2. Pinion mate gear3. Pinion mate shaft

4. Lock pin 5. Side gear 6. Side gear thrust washer

7. Differential side bearing 8. Speedometer drive gear 9. Differential case

10. Final gear 11. Differential side bearing adjusting shim 12. Plug

13. O-ring 14. Bracket 15. RH differential side oil seal

16. Torque converter 17. Converter housing 18. Differential lubricant tube

19. Clip 20. O-ring 21. O-ring

22. Oil pump housing oil seal 23. Oil pump housing 24. Outer gear

25. Inner gear 26. Oil pump cover 27. Seal ring

28. Oil pump assembly

Revision: January 20102010 Versa

Page 256 of 3745

OVERHAULAT-239

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

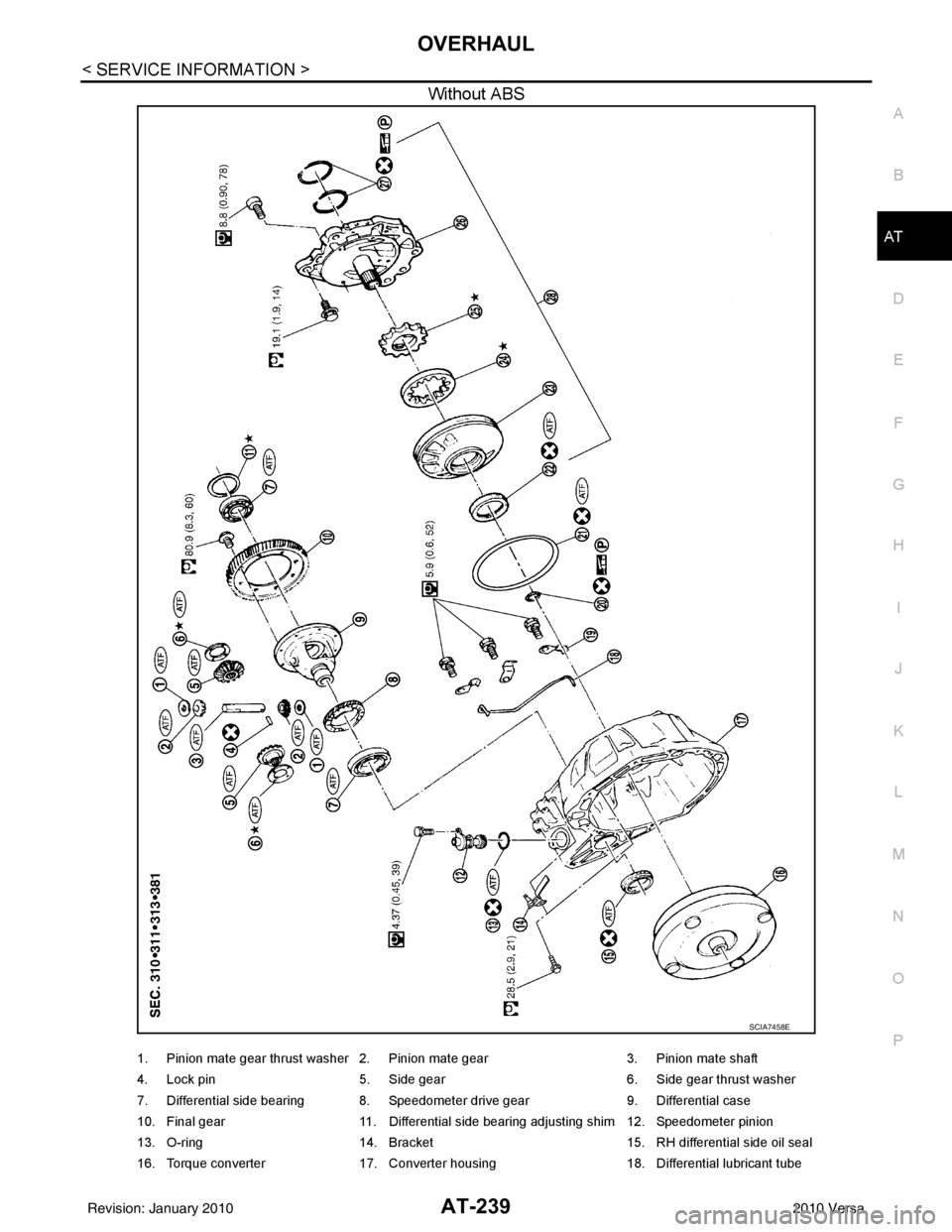

Without ABS

SCIA7458E

1. Pinion mate gear thrust washer 2. Pinion mate gear 3. Pinion mate shaft

4. Lock pin 5. Side gear 6. Side gear thrust washer

7. Differential side bearing 8. Speedometer drive gear 9. Differential case

10. Final gear 11. Differential side bearing adjusting shim 12. Speedometer pinion

13. O-ring 14. Bracket 15. RH differential side oil seal

16. Torque converter 17. Converter housing 18. Differential lubricant tube

Revision: January 20102010 Versa

Page 257 of 3745

AT-240

< SERVICE INFORMATION >

OVERHAUL

19. Clip20. O-ring 21. O-ring

22. Oil pump housing oil seal 23. Oil pump housing 24. Outer gear

25. Inner gear 26. Oil pump cover 27. Seal ring

28. Oil pump assembly

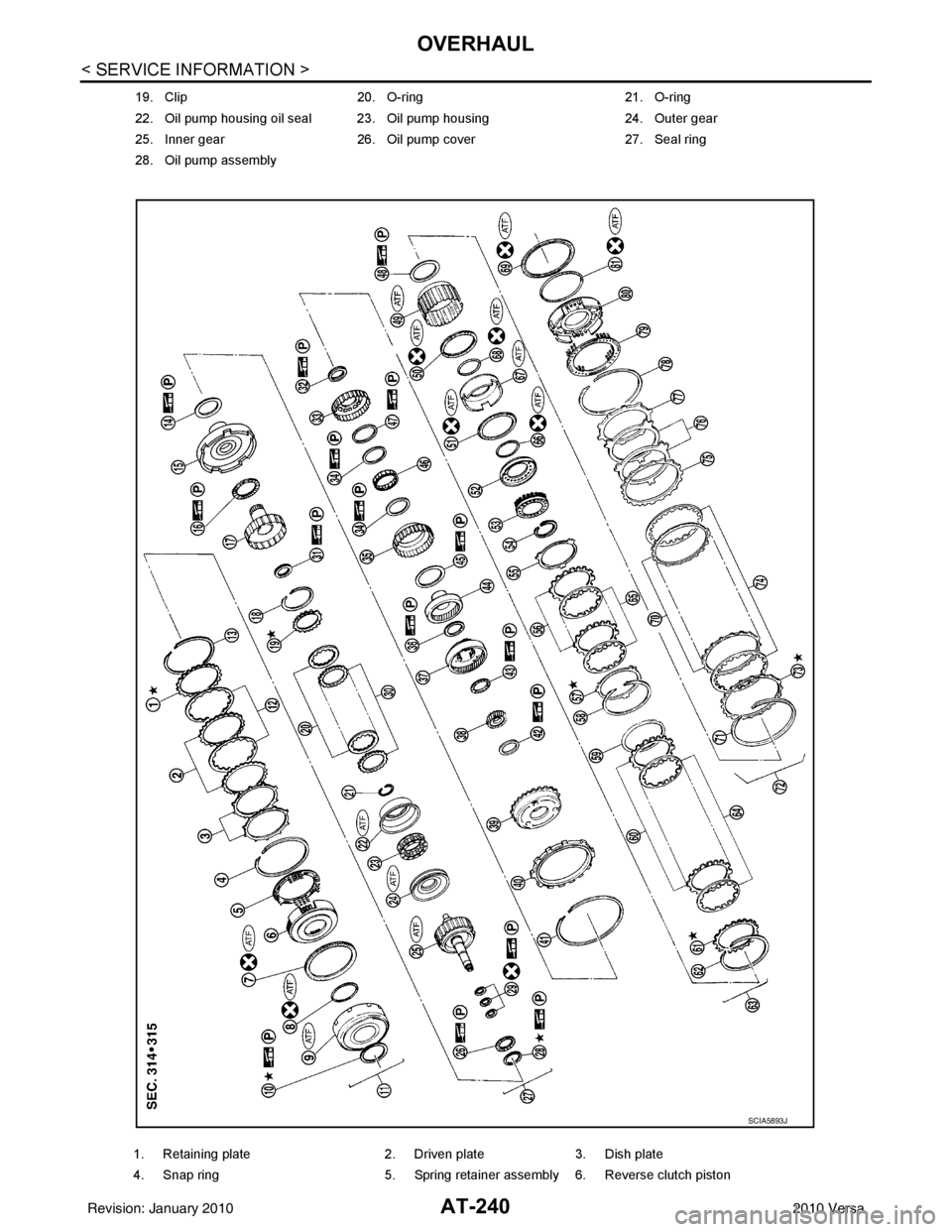

1. Retaining plate 2. Driven plate3. Dish plate

4. Snap ring 5. Spring retainer assembly 6. Reverse clutch piston

SCIA5893J

Revision: January 20102010 Versa

Page 258 of 3745

OVERHAULAT-241

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

7. Seal lip 8. D-ring9. Reverse clutch drum

10. Thrust washer 11. Reverse clutch assembly 12. Drive plate

13. Snap ring 14. Needle bearing15. Front sun gear

16. Needle bearing 17. High clutch hub18. Snap ring

19. Retaining plate 20. Drive plate21. Snap ring

22. Cancel cover 23. Spring retainer assembly 24. High clutch piston

25. Input shaft assembly (high clutch drum) 26. Needle bearing

27. High clutch assembly

28. Bearing race 29. Seal ring30. Driven plate

31. Needle bearing 32. Needle bearing33. Overrun clutch hub

34. End bearing 35. Forward clutch hub 36. Needle bearing

37. Rear planetary carrier 38. Rear sun gear39. Front planetary carrier

40. Low one-way clutch 41. Snap ring42. Needle bearing

43. Needle bearing 44. Rear internal gear 45. Thrust washer

46. Forward one-way clutch 47. Thrust washer48. Thrust washer

49. Forward clutch drum 50. Seal ring51. Seal ring

52. Overrun clutch piston 53. Spring retainer assembly 54. Snap ring

55. Dish plate 56. Driven plate57. Retaining plate

58. Snap ring 59. Dish plate60. Driven plate

61. Retaining plate 62. Snap ring63. Forward clutch assembly and over-

run clutch assembly

64. Drive plate 65. Drive plate66. D-ring

67. Forward clutch piston 68. D-ring69. Seal ring

70. Driven plate 71. Snap ring72. Low & reverse brake assembly

73. Retaining plate 74. Drive plate75. Retaining plate

76. Dish plate 77. Driven plate78. Snap ring

79. Spring retainer assembly 80. Low & reverse brake pis-

ton 81. D-ring

Revision: January 20102010 Versa

Page 259 of 3745

AT-242

< SERVICE INFORMATION >

OVERHAUL

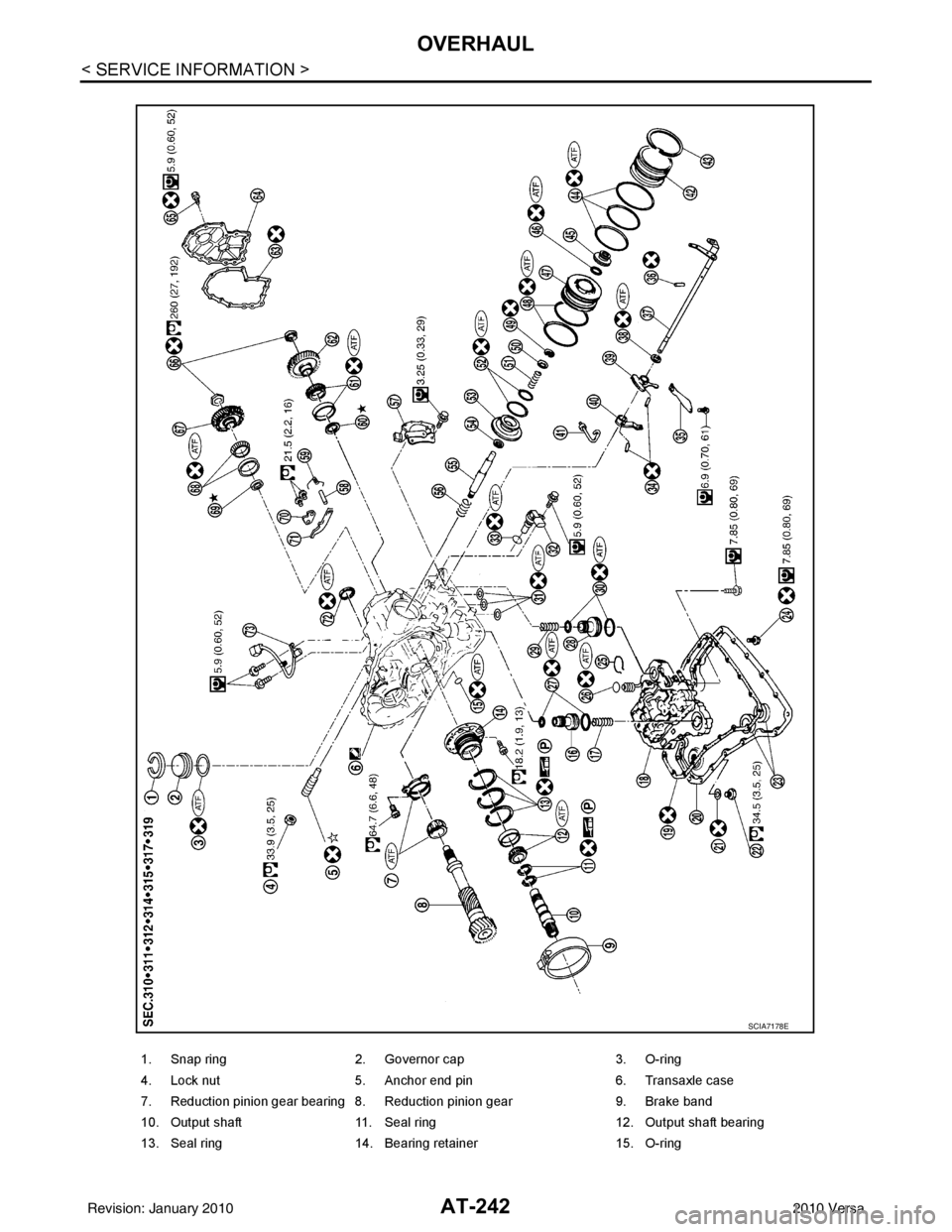

1. Snap ring2. Governor cap 3. O-ring

4. Lock nut 5. Anchor end pin 6. Transaxle case

7. Reduction pinion gear bearing 8. Reduction pinion gear 9. Brake band

10. Output shaft 11. Seal ring 12. Output shaft bearing

13. Seal ring 14. Bearing retainer 15. O-ring

SCIA7178E

Revision: January 20102010 Versa

Page 260 of 3745

OVERHAULAT-243

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

MR18DE ENGINE MODELS

16. Servo release accumulator piston 17. Return spring

18. Control valve assembly

19. Oil pan gasket 20. Oil pan 21. Drain plug gasket

22. Drain plug 23. Magnet 24. Oil pan bolt

25. Snap ring 26. O-ring 27. O-ring

28. N-D accumulator piston 29. Return spring 30. O-ring

31. Lip seal 32. Input speed sensor 33. O-ring

34. Retaining pin 35. Detent spring 36. Retaining pin

37. Manual shaft 38. Manual shaft oil seal 39. Manual plate

40. Parking rod plate 41. Parking rod 42. OD servo piston retainer

43. Snap ring 44. O-ring 45. OD servo piston

46. D-ring 47. Servo release accumulator piston 48. O-ring

49. E-ring 50. Spring retainer 51. OD servo return spring

52. D-ring 53. Band servo piston 54. Band servo thrust washer

55. Band servo piston stem 56. 2nd servo return spring 57. Transmission range switch

58. Parking shaft 59. Return spring 60. Output gear adjusting spac-

er

61. Output gear bearing 62. Output gear 63. Side cover gasket

64. Side cover 65. Side cover bolt 66. Lock nut

67. Idler gear 68. Idler gear bearing 69. Reduction pinion gear ad-

justing shim

70. Parking actuator support 71. Parking pawl 72. LH differential side oil seal

73. Output speed sensor

: Apply Genuine Anaerobic Liquid Gasket or equivalent.

Revision: January 20102010 Versa