Output speed sensor NISSAN TIIDA 2010 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 94 of 3745

TROUBLE DIAGNOSISAT-77

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

*1: These terminals are connected to the data link connector.

*2: These terminals are connected to the ECM.

CONSULT-III Function (TRANSMISSION)INFOID:0000000005397251

CONSULT-III can display each diagnostic item using the diagnostic test models shown following.

FUNCTION

CONSULT-III REFERENCE VALUE

NOTICE:

1. The CONSULT-III electrically displays shift timi ng and lock-up timing (that is, operation timing of each

solenoid).

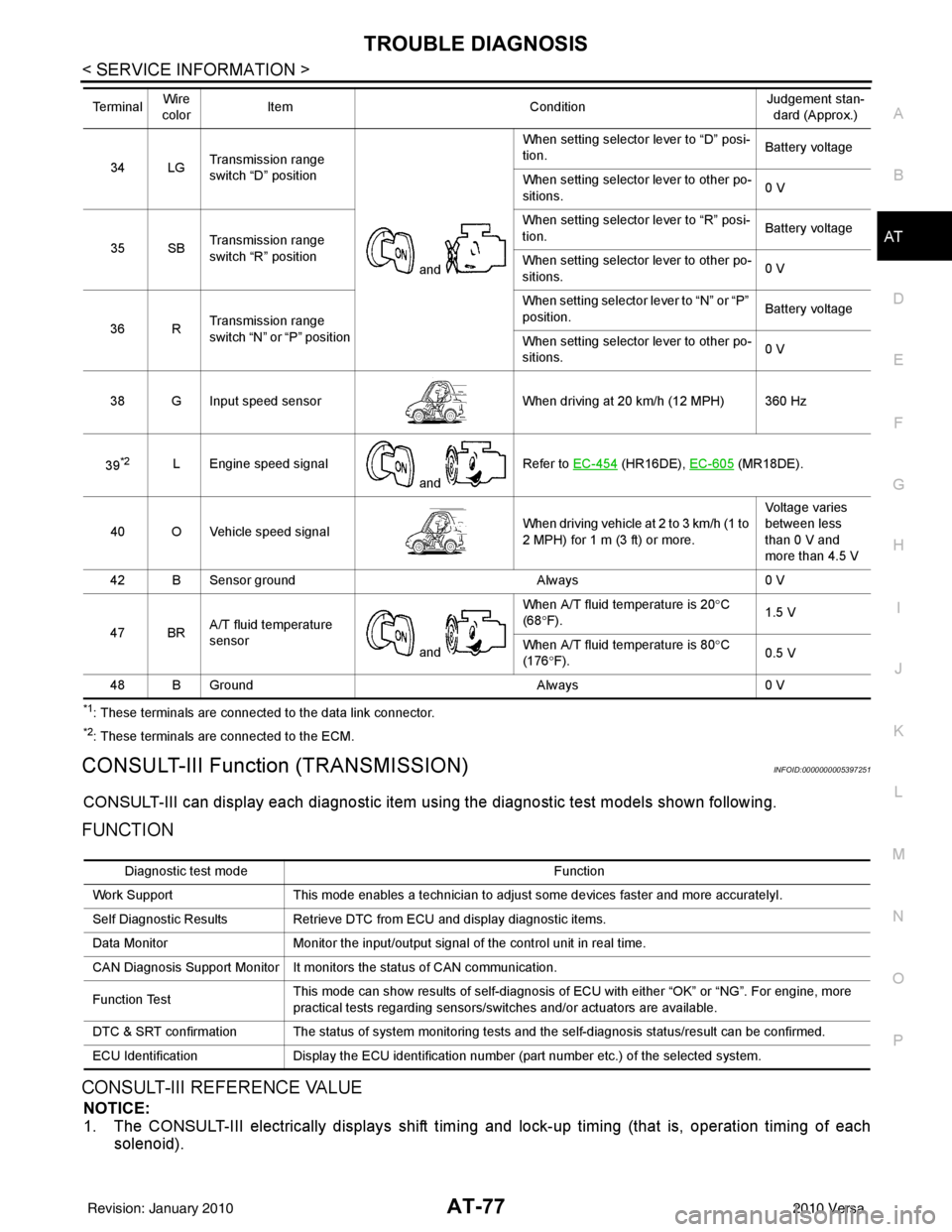

34 LG Transmission range

switch “D” position

and When setting selector lever to “D” posi-

tion.

Battery voltage

When setting selector lever to other po-

sitions. 0 V

35 SB Transmission range

switch “R” position When setting selector lever to “R” posi-

tion.

Battery voltage

When setting selector lever to other po-

sitions. 0 V

36 R Transmission range

switch “N” or “P” position When setting selector

lever to “N” or “P”

position. Battery voltage

When setting selector lever to other po-

sitions. 0 V

38 G Input speed sensor When driving at 20 km/h (12 MPH) 360 Hz

39

*2L Engine speed signal and Refer to EC-454 (HR16DE),

EC-605 (MR18DE).

40 O Vehicle speed signal When driving vehicle at 2 to 3 km/h (1 to

2 MPH) for 1 m (3 ft) or more.Voltage varies

between less

than 0 V and

more than 4.5 V

42 B Sensor ground Always0 V

47 BR A/T fluid temperature

sensor

and When A/T fluid temperature is 20°

C

(68 °F). 1.5 V

When A/T fluid temperature is 80° C

(176 °F). 0.5 V

48 B Ground Always0 V

Te r m i n a l

Wire

color Item

ConditionJudgement stan-

dard (Approx.)

Diagnostic test mode Function

Work Support This mode enables a technician to adjust some devices faster and more accuratelyI.

Self Diagnostic Results Retrieve DTC from ECU and display diagnostic items.

Data Monitor Monitor the input/output signal of the control unit in real time.

CAN Diagnosis Support Monitor It monitors the status of CAN communication.

Function Test This mode can show results of self-diagnosis of ECU with either “OK” or “NG”. For engine, more

practical tests regarding sensors/switches and/or actuators are available.

DTC & SRT confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

ECU Identification Display the ECU identification number (part number etc.) of the selected system.

Revision: January 20102010 Versa

Page 96 of 3745

TROUBLE DIAGNOSISAT-79

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

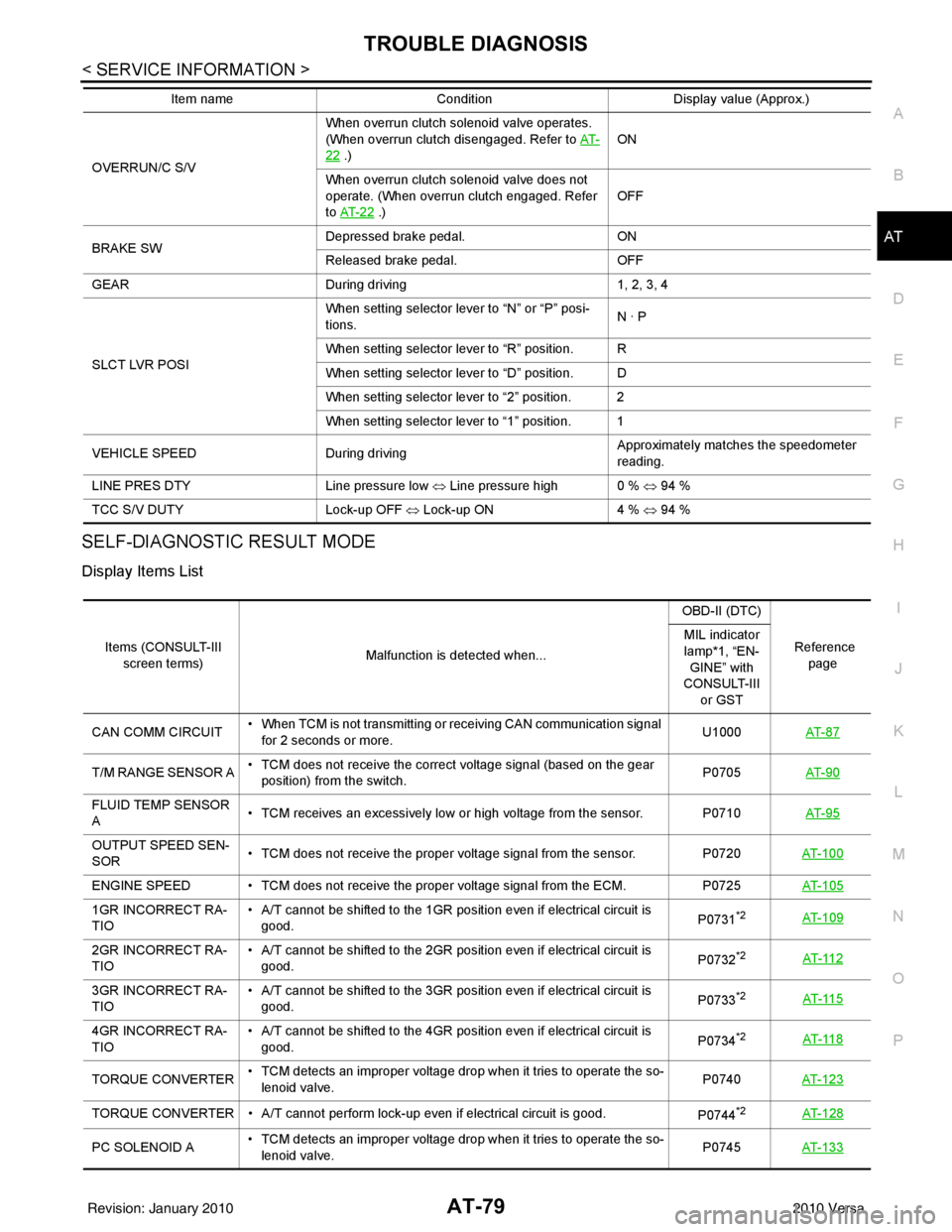

SELF-DIAGNOSTIC RESULT MODE

Display Items List

OVERRUN/C S/V When overrun clutch solenoid valve operates.

(When overrun clutch disengaged. Refer to

AT-22 .) ON

When overrun clutch solenoid valve does not

operate. (When overrun clutch engaged. Refer

to AT- 2 2

.) OFF

BRAKE SW Depressed brake pedal.

ON

Released brake pedal. OFF

GEAR During driving 1, 2, 3, 4

SLCT LVR POSI When setting selector lever to “N” or “P” posi-

tions.

N · P

When setting selector lever to “R” position. R

When setting selector lever to “D” position. D

When setting selector lever to “2” position. 2

When setting selector lever to “1” position. 1

VEHICLE SPEED During driving Approximately matches the speedometer

reading.

LINE PRES DTY Line pressure low ⇔ Line pressure high 0 % ⇔ 94 %

TCC S/V DUTY Lock-up OFF ⇔ Lock-up ON 4 % ⇔ 94 %

Item name

Condition Display value (Approx.)

Items (CONSULT-III

screen terms) Malfunction is detected when... OBD-II (DTC)

Reference page

MIL indicator

lamp*1, “EN-

GINE” with

CONSULT-III

or GST

CAN COMM CIRCUIT • When TCM is not transmitting or receiving CAN communication signal

for 2 seconds or more. U1000

AT- 8 7

T/M RANGE SENSOR A • TCM does not receive the correct voltage signal (based on the gear

position) from the switch. P0705

AT- 9 0

FLUID TEMP SENSOR

A • TCM receives an excessively low or high voltage from the sensor. P0710

AT- 9 5

OUTPUT SPEED SEN-

SOR• TCM does not receive the proper voltage signal from the sensor.

P0720AT- 1 0 0

ENGINE SPEED • TCM does not re ceive the proper voltage signal from the ECM. P0725AT- 1 0 5

1GR INCORRECT RA-

TIO • A/T cannot be shifted to the 1GR position even if electrical circuit is

good. P0731*2AT- 1 0 9

2GR INCORRECT RA-

TIO• A/T cannot be shifted to the 2GR position even if electrical circuit is

good. P0732*2AT- 11 2

3GR INCORRECT RA-

TIO• A/T cannot be shifted to the 3GR position even if electrical circuit is

good. P0733*2AT- 11 5

4GR INCORRECT RA-

TIO• A/T cannot be shifted to the 4GR position even if electrical circuit is

good. P0734*2AT- 11 8

TORQUE CONVERTER• TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P0740

AT- 1 2 3

TORQUE CONVERTER • A/T cannot perform lock-up even if electrical circuit is good.

P0744*2AT- 1 2 8

PC SOLENOID A• TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P0745

AT- 1 3 3

Revision: January 20102010 Versa

Page 97 of 3745

AT-80

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

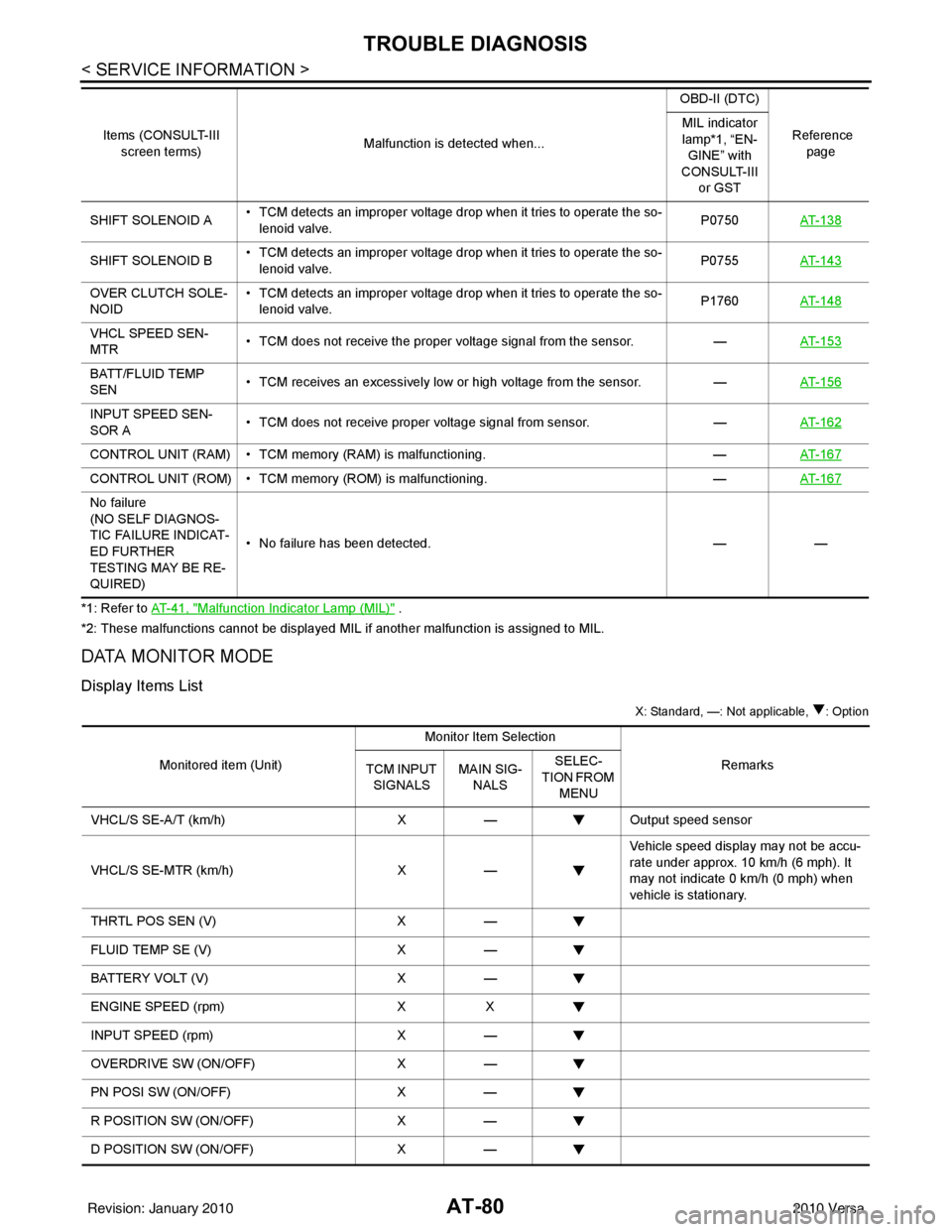

*1: Refer to AT- 4 1 , "Malfunction Indicator Lamp (MIL)" .

*2: These malfunctions cannot be displayed MIL if another malfunction is assigned to MIL.

DATA MONITOR MODE

Display Items List

X: Standard, —: Not applicable, : Option

SHIFT SOLENOID A • TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P0750

AT- 1 3 8

SHIFT SOLENOID B • TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P0755

AT- 1 4 3

OVER CLUTCH SOLE-

NOID • TCM detects an improper voltage drop when it tries to operate the so-

lenoid valve. P1760

AT- 1 4 8

VHCL SPEED SEN-

MTR • TCM does not receive the proper voltage signal from the sensor.

—AT- 1 5 3

BATT/FLUID TEMP

SEN • TCM receives an excessively low or high voltage from the sensor.

—AT- 1 5 6

INPUT SPEED SEN-

SOR A • TCM does not receive proper voltage signal from sensor.

—AT- 1 6 2

CONTROL UNIT (RAM) • TCM memory (RAM) is malfunctioning. —AT- 1 6 7

CONTROL UNIT (ROM) • TCM memory (ROM) is malfunctioning. —AT- 1 6 7

No failure

(NO SELF DIAGNOS-

TIC FAILURE INDICAT-

ED FURTHER

TESTING MAY BE RE-

QUIRED) • No failure has been detected.

——

Items (CONSULT-III

screen terms) Malfunction is detected when... OBD-II (DTC)

Reference page

MIL indicator

lamp*1, “EN-

GINE” with

CONSULT-III or GST

Monitored item (Unit) Monitor Item Selection

Remarks

TCM INPUT

SIGNALS MAIN SIG-

NALS SELEC-

TION FROM MENU

VHCL/S SE-A/T (km/h) X— Output speed sensor

VHCL/S SE-MTR (km/h) X— Vehicle speed display may not be accu-

rate under approx. 10 km/h (6 mph). It

may not indicate 0 km/h (0 mph) when

vehicle is stationary.

THRTL POS SEN (V) X—

FLUID TEMP SE (V) X—

BATTERY VOLT (V) X—

ENGINE SPEED (rpm) XX

INPUT SPEED (rpm) X—

OVERDRIVE SW (ON/OFF) X—

PN POSI SW (ON/OFF) X—

R POSITION SW (ON/OFF) X—

D POSITION SW (ON/OFF) X—

Revision: January 20102010 Versa

Page 101 of 3745

AT-84

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

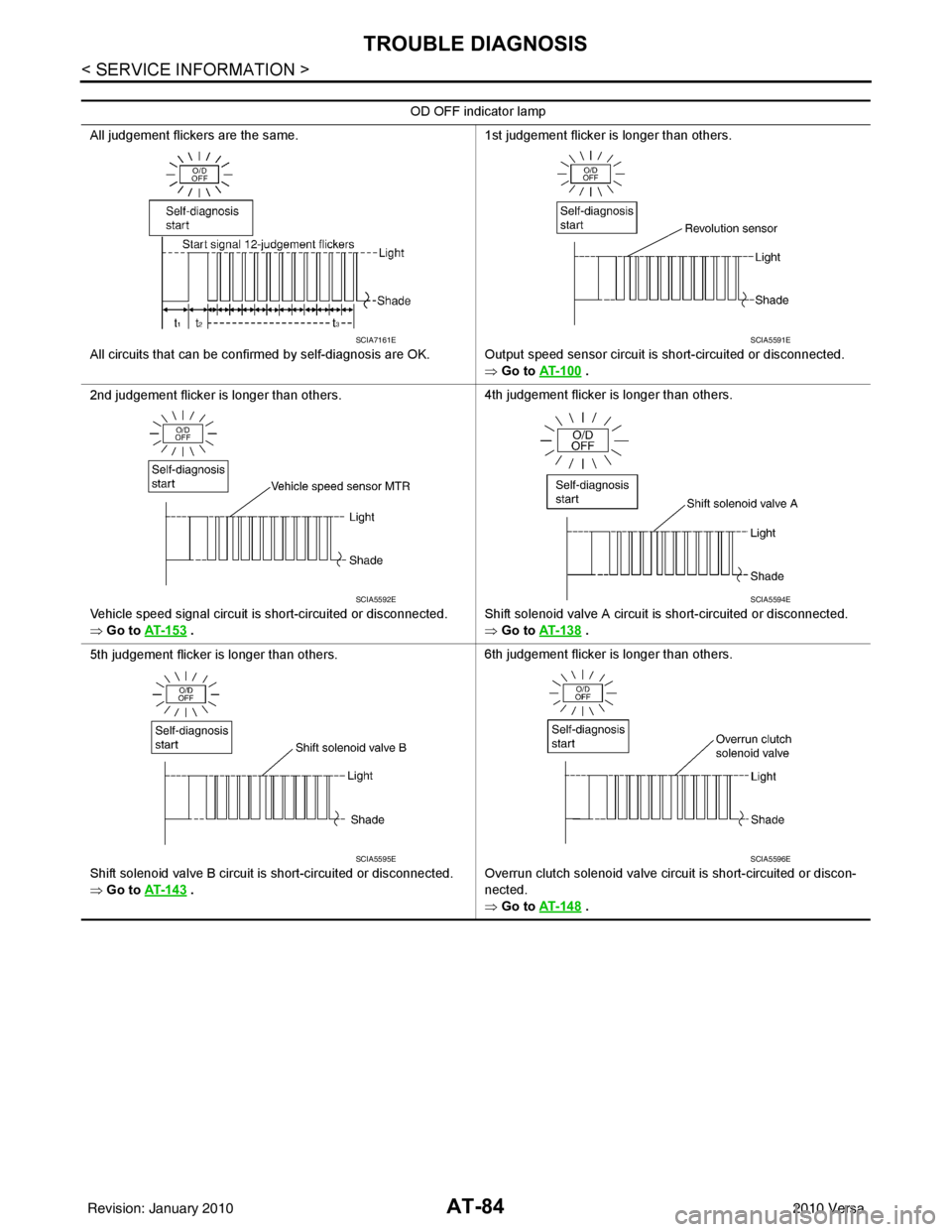

OD OFF indicator lamp

All judgement flickers are the same.

All circuits that can be confirmed by self-diagnosis are OK. 1st judgement flicker is longer than others.

Output speed sensor circuit is short-circuited or disconnected.

⇒ Go to

AT- 1 0 0

.

2nd judgement flicker is longer than others.

Vehicle speed signal circuit is short-circuited or disconnected.

⇒ Go to AT- 1 5 3

. 4th judgement flicker is longer than others.

Shift solenoid valve A circuit is short-circuited or disconnected.

⇒ Go to

AT- 1 3 8 .

5th judgement flicker is longer than others.

Shift solenoid valve B circuit is short-circuited or disconnected.

⇒ Go to AT- 1 4 3

. 6th judgement flicker is longer than others.

Overrun clutch solenoid valve circuit is short-circuited or discon-

nected.

⇒ Go to

AT- 1 4 8

.

SCIA7161ESCIA5591E

SCIA5592ESCIA5594E

SCIA5595ESCIA5596E

Revision: January 20102010 Versa

Page 117 of 3745

AT-100

< SERVICE INFORMATION >

P0720 OUTPUT SPEED SENSOR

P0720 OUTPUT SPEED SENSOR

DescriptionINFOID:0000000005397275

The output speed sensor detects the revolution of the idler gear parking pawl lock gear and emits a pulse sig-

nal. The pulse signal is sent to the TCM which converts it into vehicle speed.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005397276

Remarks: Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000005397277

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0720 OUTPUT SPEED SENSOR ” with CONSULT-III or 1st judgement flicker

without CONSULT-III is detected when TCM does not re ceive the proper voltage signal from the sensor.

Possible CauseINFOID:0000000005397278

• Harness or connector

(The sensor circuit is open or shorted.)

• Output speed sensor

DTC Confirmation ProcedureINFOID:0000000005397279

CAUTION:

• Always drive vehicle at a safe speed.

• Be careful not to rev engine into the red zone on the tachometer.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Drive vehicle and check for an increase of “VHCL/S SE-MTR” value. If the check result is NG, go to AT-102, "

Diagnosis Procedure" .

If the check result is OK, go to following step.

4. Select “DATA MONITOR” mode fo r “TRANSMISSION” with CONSULT-III.

5. Touch “START”.

6. Start engine and maintain the following conditions for at least 5 consecutive seconds.

VEHICLE SPEED: 30 km/h (19 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehicle uphill (increased engine load) will help maintain the driving

conditions required for this test.

If the check result is NG, go to AT-102, "

Diagnosis Procedure" .

If the check result is OK, go to following step.

7. Maintain the following conditions for at least 5 consecutive seconds. ENGINE SPEED: 3,500 rpm or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehicle uphill (increased engine load) will help maintain the driving

conditions required for this test.

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

Item name Condition Display value

VHCL/S SE-A/T During driving Approximately matches the speedometer reading.

Revision: January 20102010 Versa

Page 118 of 3745

P0720 OUTPUT SPEED SENSORAT-101

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

2. Drive vehicle under the following conditions for more than 5 seconds. Selector lever posi tion: “D” position

Vehicle speed: 30 km/h (19 MPH) or more

Throttle position: greater than 1.0/8 of the full throttle position

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-102, "

Diagnosis Procedure" .

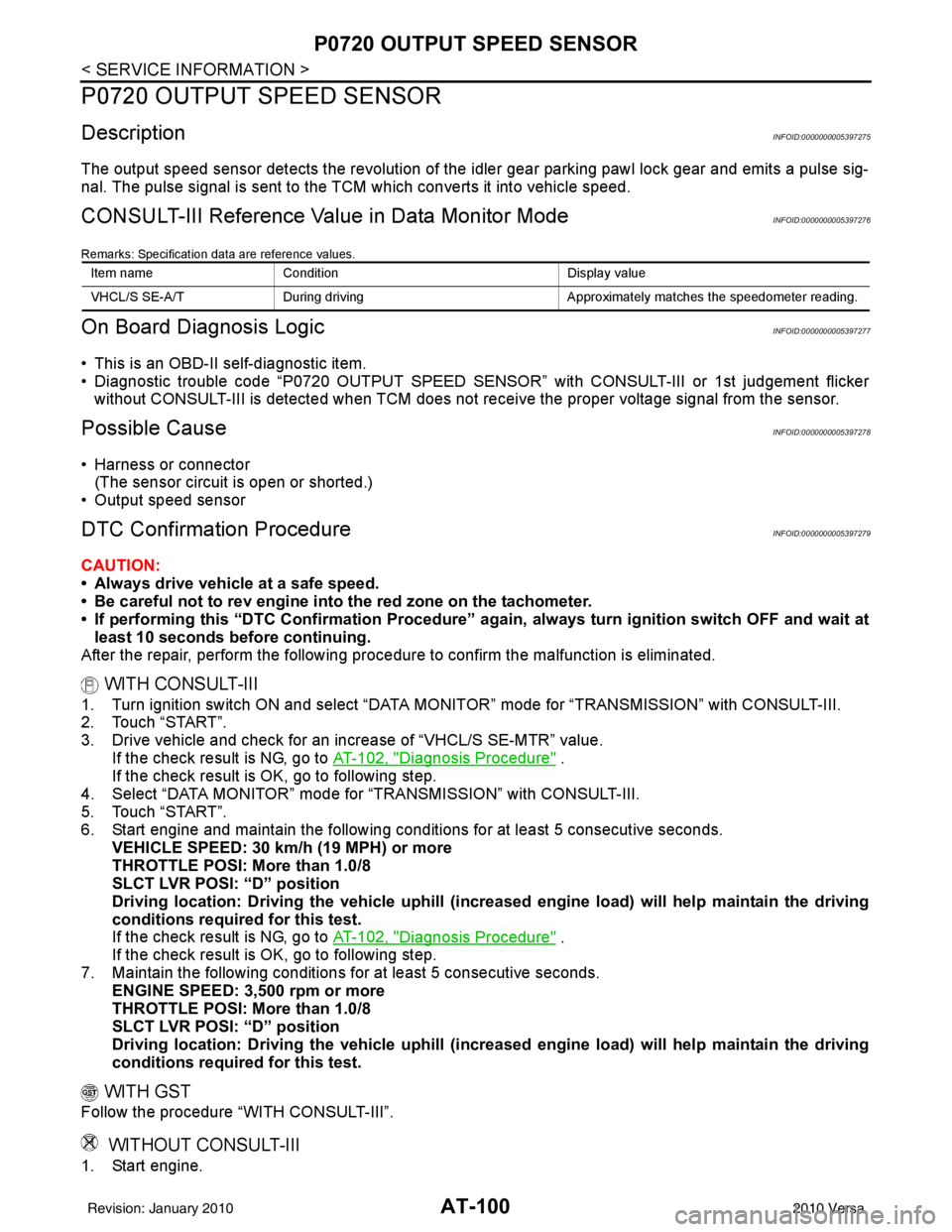

Wiring Diagram - AT - VSSA/TINFOID:0000000005397280

ABDWA0213GB

Revision: January 20102010 Versa

Page 119 of 3745

AT-102

< SERVICE INFORMATION >

P0720 OUTPUT SPEED SENSOR

TCM TERMINALS AND REFERENCE VALUES

Refer to AT-75, "TCM Terminal and Reference Value".

Diagnosis ProcedureINFOID:0000000005397281

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Start engine.

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “VHCL/S SE-A/T” while driving. Check the value changes according to driving speed.

OK or NG

OK >> GO TO 8.

NG >> GO TO 2.

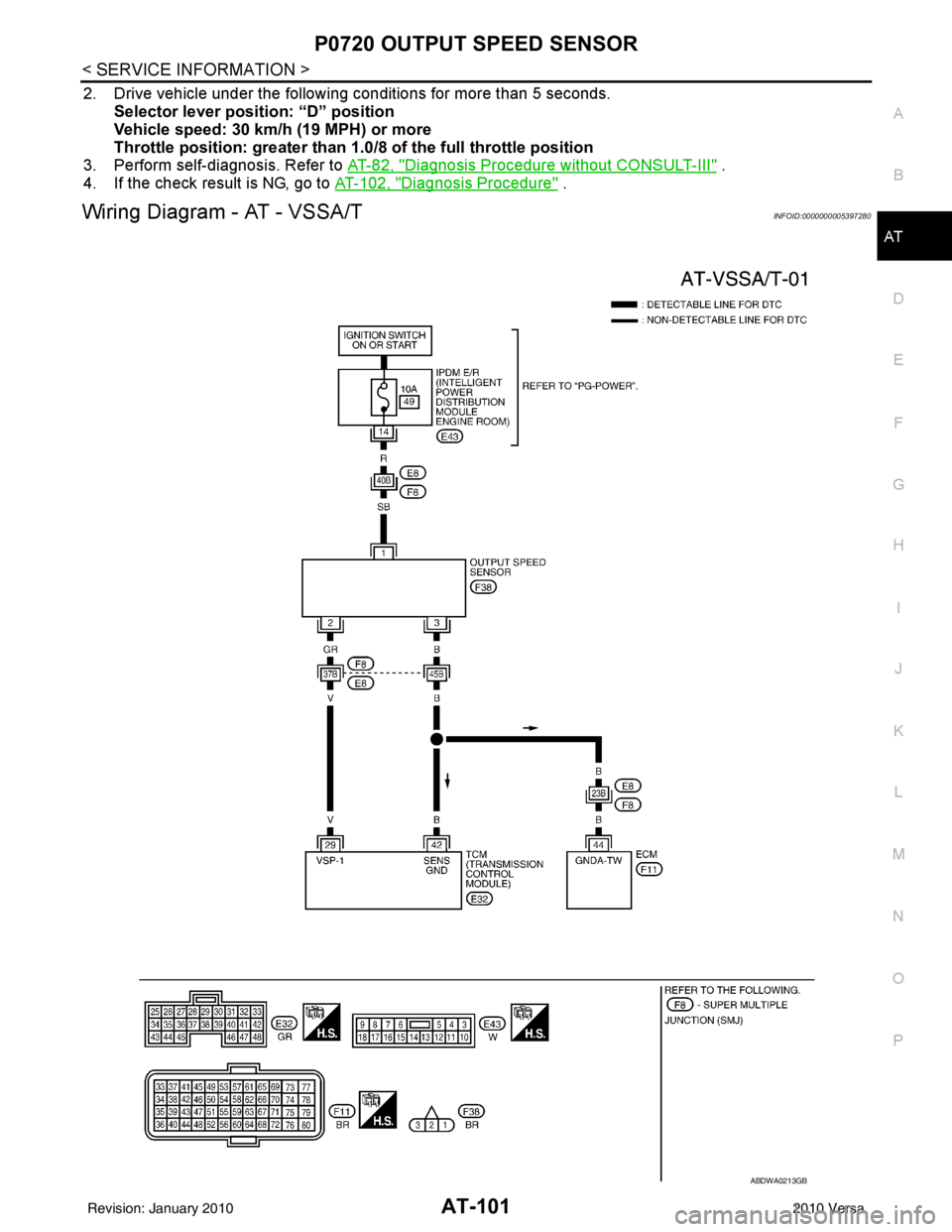

2. CHECK OUTPUT SPEED SENSOR

With CONSULT-III

1. Start engine.

2. Check power supply to output speed sensor by voltage between TCM connector terminals. Refer to AT-

168, "Wiring Diagram - AT - MAIN" and AT-101, "Wiring Diagram - AT - VSSA/T" .

3. If OK, check the pulse when vehicle cruises.

OK or NG

OK >> GO TO 8.

NG >> GO TO 3.

3. CHECK POWER AND SENSOR GROUND

1. Turn ignition switch OFF.

2. Disconnect the output speed sensor harness connector.

3. Turn ignition switch ON. (Do not start engine.)

Item Connector TerminalJudgement standard

(Approx.)

TCM E31, E32 10 - 42

Battery voltage

19 - 42

Item Condition

Output speed sen-

sor When driving at 20 km/h (12 MPH), use the CONSULT-III

pulse frequency measuring function.*1

CAUTION:

Connect the diagnosis

data link cable to the data link

connector.

*1: A circuit tester cannot be used to test this item.

Item Connector Terminal Condition Judgement stan-

dard (Approx.)

TCM E32 29When driving at 20

km/h (12 MPH) 150 Hz

AWDIA0641GB

Revision: January 20102010 Versa

Page 120 of 3745

P0720 OUTPUT SPEED SENSORAT-103

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

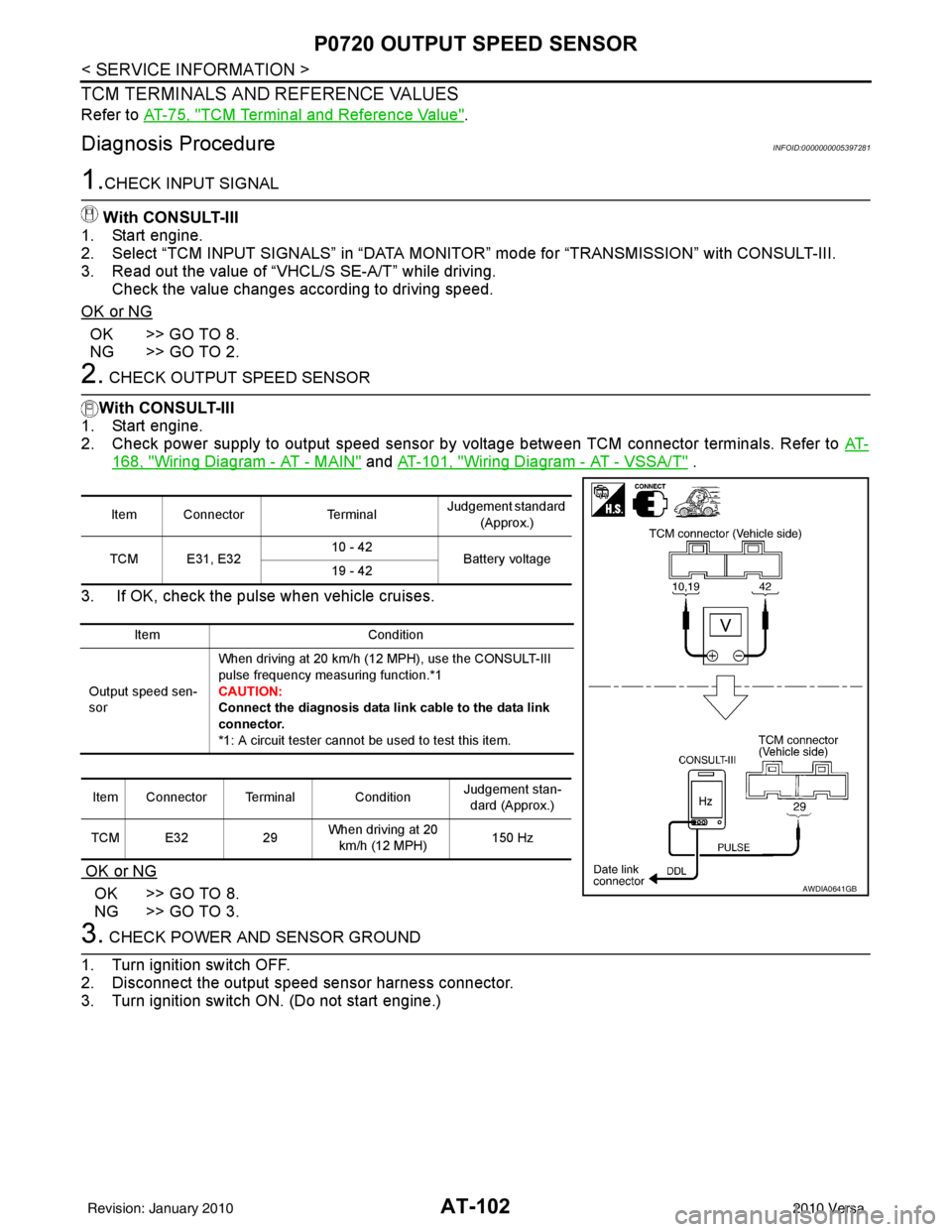

4. Check voltage between output speed sensor harness connector terminals.

5. Check voltage between output speed sensor harness connector terminal and ground.

6. If OK, check harness for short to ground and short to power.

7. Reinstall any part removed.

OK or NG

OK >> GO TO 4.

NG - 1 >> Battery voltage is not supplied between terminals 1 and 3, terminals 1 and ground: GO TO 6.

NG - 2 >> Battery voltage is not supplied between terminals 1 and 3 only: GO TO 7.

4. CHECK HARNESS BETWEEN TCM AND OUTPUT SPEED SENSOR

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and output speed sensor harness connector.

3. Check continuity between TCM connector (A) terminal and out- put speed sensor harness connector (B) terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, re-check TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

6. CHECK HARNESS BETWEEN TCM AND OUTPUT SPEED SENSOR (POWER)

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and output speed sensor harness connector.

Item Connector Terminal Judgement standard

(Approx.)

Output speed sen- sor F38

1 - 3Battery voltage

JSDIA1504ZZ

Item Connector Terminal Judgement standard

(Approx.)

Output speed sen- sor F38

1 - ground Battery voltage

JSDIA1505ZZ

Item Connector Terminal Continuity

TCM E3229

Ye s

Output speed sensor F382

JSDIA1506ZZ

Revision: January 20102010 Versa

Page 121 of 3745

AT-104

< SERVICE INFORMATION >

P0720 OUTPUT SPEED SENSOR

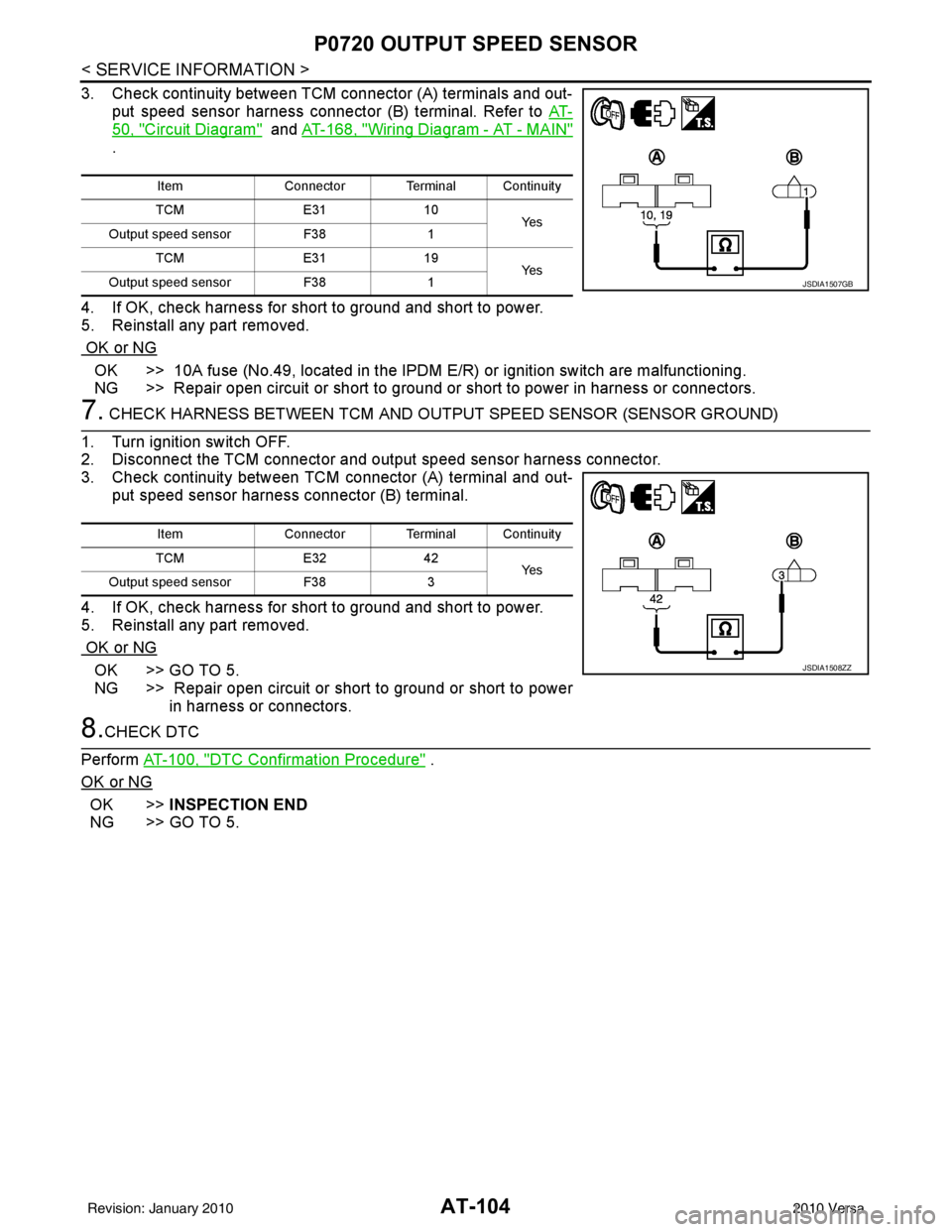

3. Check continuity between TCM connector (A) terminals and out-put speed sensor harness connector (B) terminal. Refer to AT-

50, "Circuit Diagram" and AT-168, "Wiring Diagram - AT - MAIN"

.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> 10A fuse (No.49, located in the IPDM E/R) or ignition switch are malfunctioning.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

7. CHECK HARNESS BETWEEN TCM AND OUTPUT SPEED SENSOR (SENSOR GROUND)

1. Turn ignition switch OFF.

2. Disconnect the TCM connector and output speed sensor harness connector.

3. Check continuity between TCM connector (A) terminal and out-

put speed sensor harness connector (B) terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK DTC

Perform AT-100, "

DTC Confirmation Procedure" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

Item Connector Terminal Continuity

TCM E3110

Ye s

Output speed sensor F381

TCM E3119

Ye s

Output speed sensor F381

JSDIA1507GB

Item Connector Terminal Continuity

TCM E3242

Ye s

Output speed sensor F383

JSDIA1508ZZ

Revision: January 20102010 Versa

Page 126 of 3745

P0731 1GR INCORRECT RATIOAT-109

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

P0731 1GR INCORRECT RATIO

DescriptionINFOID:0000000005397289

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis malfunction.

• This malfunction is detected when the A/T does not shif t into first gear position as instructed by the TCM.

This is not caused by electrical malfunction (circuit s open or shorted) but by mechanical malfunction such as

control valve sticking, improper solenoid valve operation, etc.

On Board Diagnosis LogicINFOID:0000000005397290

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0731 1GR INCORRECT RATIO” with CONSULT-III is detected when A/T cannot

be shifted to the 1GR position even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from output speed sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is higher than the position (1st) supposed by TCM, the slip ratio will be more than

normal. In case the ratio exceeds the specif ied value, TCM judges this diagnosis malfunction.

This malfunction will be caused when either shift solenoid valve A is stuck open or shift solenoid valve B is

stuck open.

• Gear positions supposed by TCM are as follows: In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve A stuck open: 2*, 2, 3 and 3 positions

In case of gear position with shift solenoid valve B stuck open: 4*, 3, 3 and 4 positions to each gear position

above

*: “P0731 1GR INCORRECT RATIO” is detected.

Possible CauseINFOID:0000000005397291

• Shift solenoid valve A

• Shift solenoid valve B

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000005397292

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive the vehicle to decrease the vo ltage (warm up the fluid) or stop engine to increase the

voltage (cool down the fluid).

4. Select “1ST GR FNCTN P0731” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

Gear position 1234

Shift solenoid valve A ON (Closed)OFF (Open)OFF (Open)ON (Closed)

Shift solenoid valve B ON (Closed)ON (Closed) OFF (Open)OFF (Open)

Revision: January 20102010 Versa