NISSAN TIIDA 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 291 of 3745

AT-274

< SERVICE INFORMATION >

DISASSEMBLY

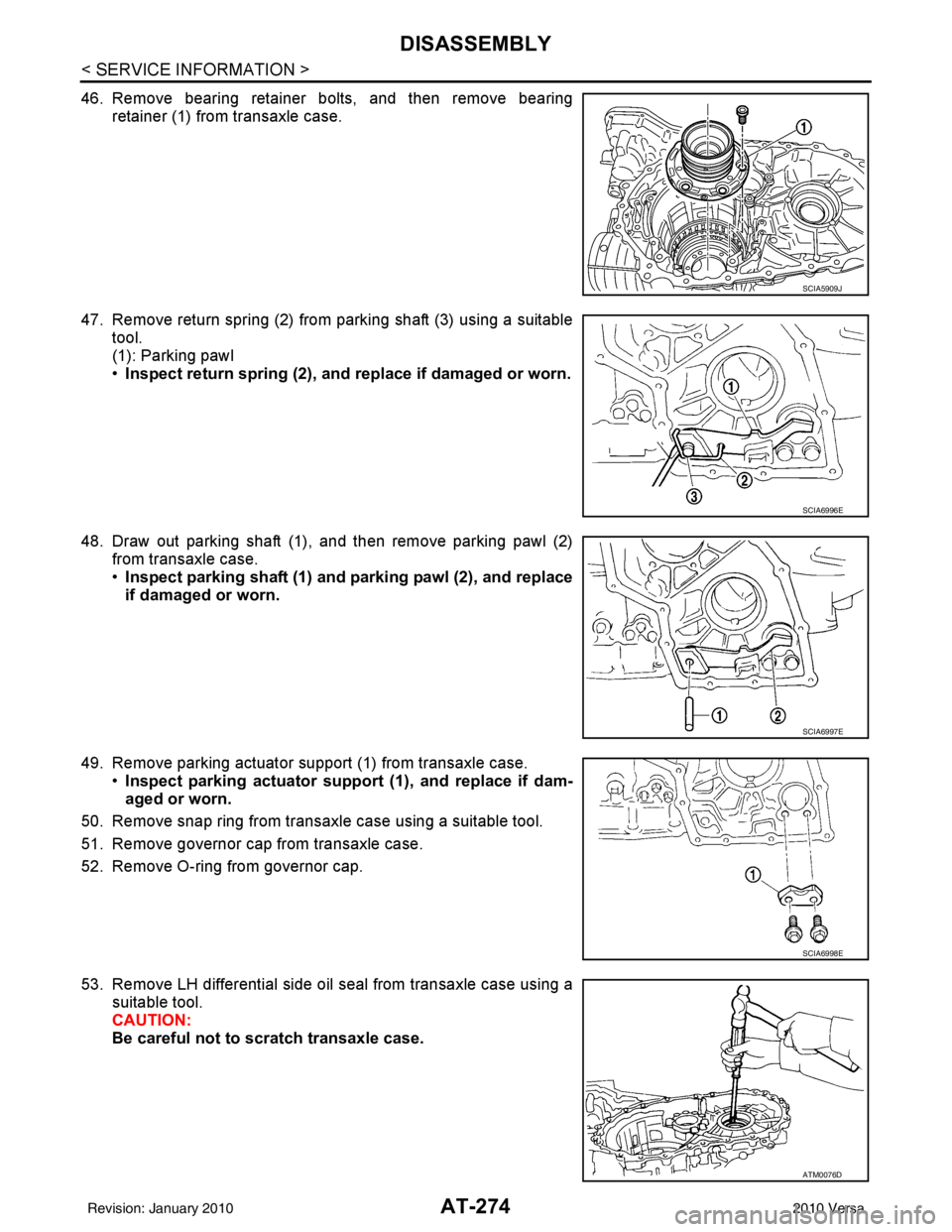

46. Remove bearing retainer bolts, and then remove bearingretainer (1) from transaxle case.

47. Remove return spring (2) from parking shaft (3) using a suitable tool.

(1): Parking pawl

•Inspect return spring (2), and replace if damaged or worn.

48. Draw out parking shaft (1), and then remove parking pawl (2) from transaxle case.

•Inspect parking shaft (1) and parking pawl (2), and replace

if damaged or worn.

49. Remove parking actuator support (1) from transaxle case. •Inspect parking actuator support (1), and replace if dam-

aged or worn.

50. Remove snap ring from transaxle case using a suitable tool.

51. Remove governor cap from transaxle case.

52. Remove O-ring from governor cap.

53. Remove LH differential side oil seal from transaxle case using a suitable tool.

CAUTION:

Be careful not to scratch transaxle case.

SCIA5909J

SCIA6996E

SCIA6997E

SCIA6998E

ATM0076D

Revision: January 20102010 Versa

Page 292 of 3745

REPAIR FOR COMPONENT PARTSAT-275

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

REPAIR FOR COMPONENT PARTS

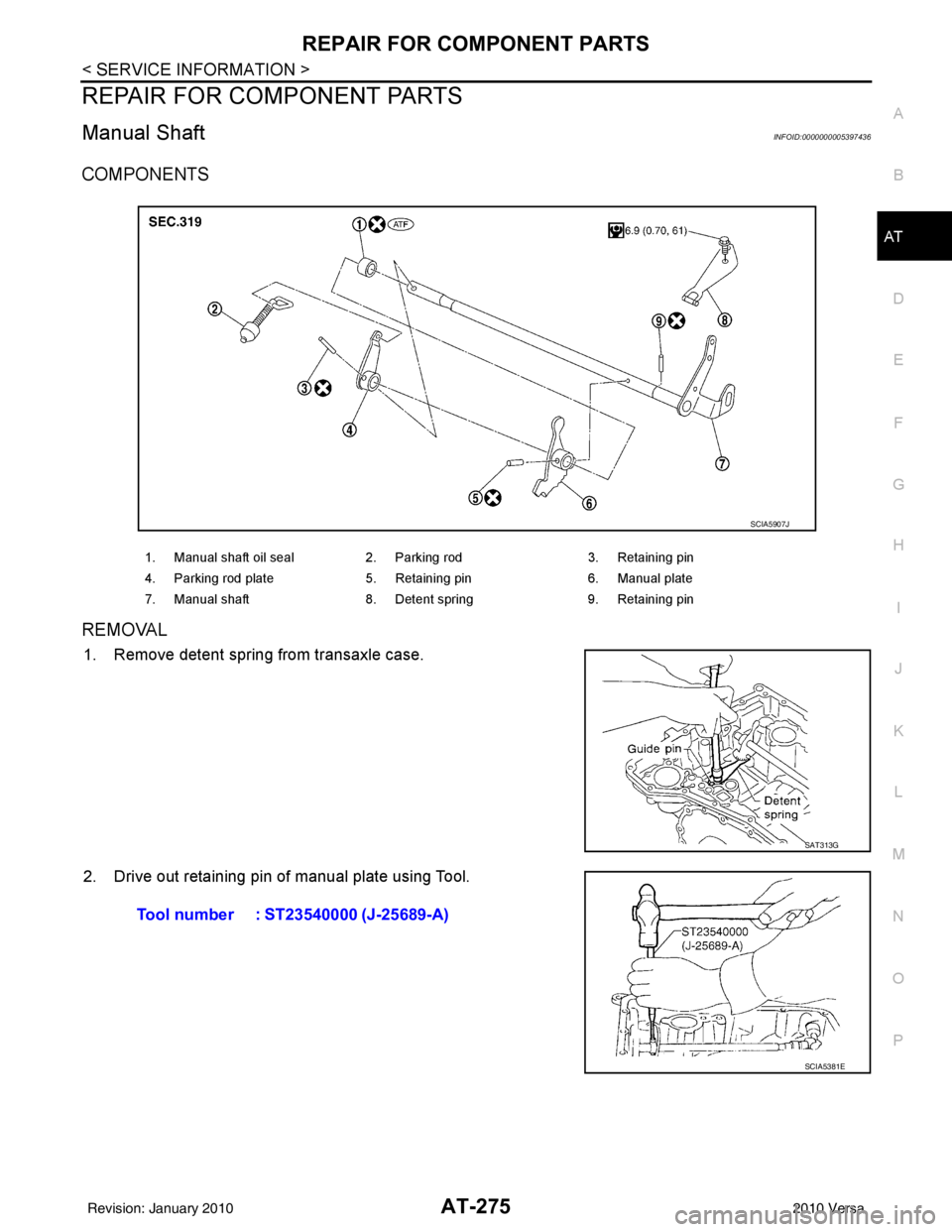

Manual ShaftINFOID:0000000005397436

COMPONENTS

REMOVAL

1. Remove detent spring from transaxle case.

2. Drive out retaining pin of manual plate using Tool.

1. Manual shaft oil seal 2. Parking rod 3. Retaining pin

4. Parking rod plate 5. Retaining pin 6. Manual plate

7. Manual shaft 8. Detent spring 9. Retaining pin

SCIA5907J

SAT313G

Tool number : ST23540000 (J-25689-A)

SCIA5381E

Revision: January 20102010 Versa

Page 293 of 3745

AT-276

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

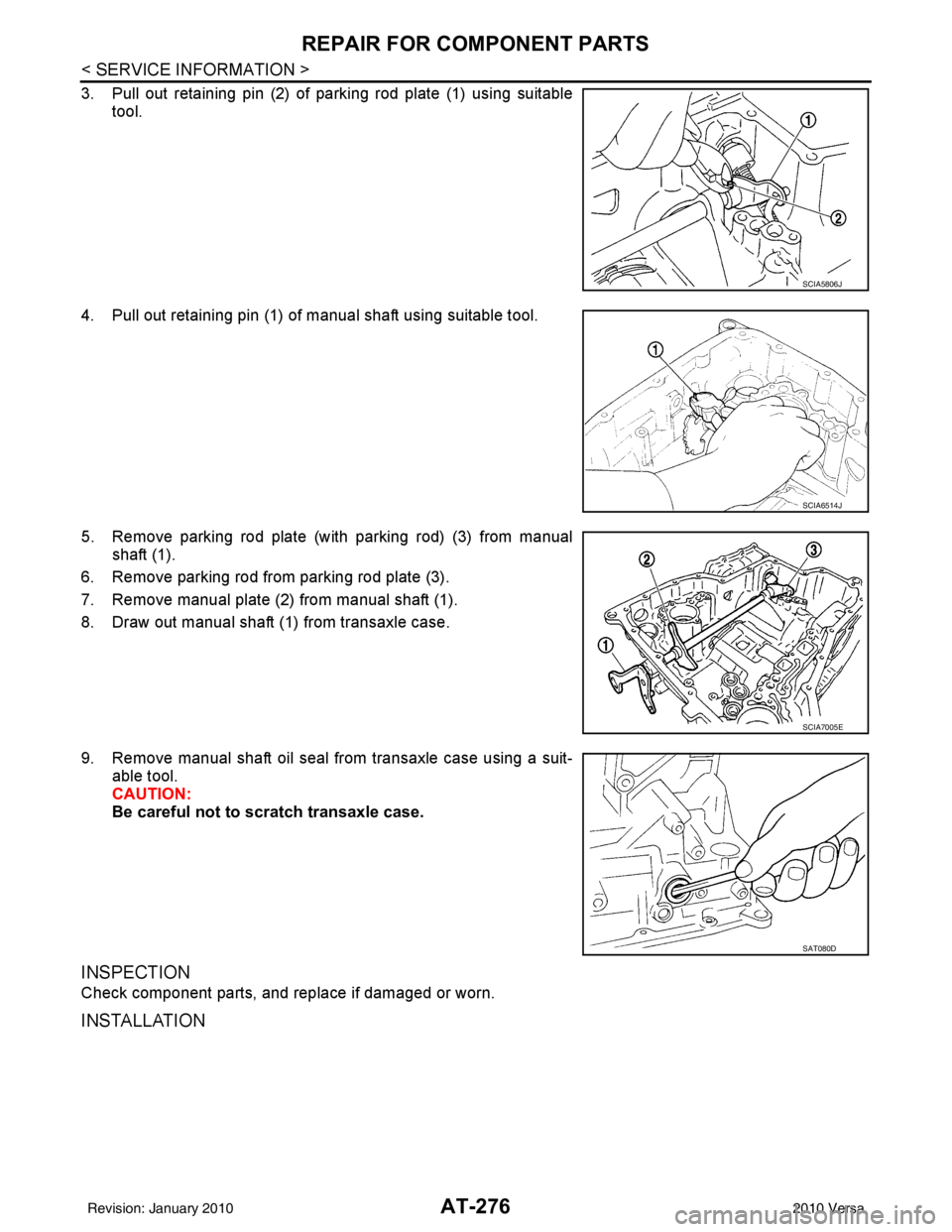

3. Pull out retaining pin (2) of parking rod plate (1) using suitabletool.

4. Pull out retaining pin (1) of manual shaft using suitable tool.

5. Remove parking rod plate (with parking rod) (3) from manual shaft (1).

6. Remove parking rod from parking rod plate (3).

7. Remove manual plate (2) from manual shaft (1).

8. Draw out manual shaft (1) from transaxle case.

9. Remove manual shaft oil seal from transaxle case using a suit- able tool.

CAUTION:

Be careful not to scratch transaxle case.

INSPECTION

Check component parts, and replace if damaged or worn.

INSTALLATION

SCIA5806J

SCIA6514J

SCIA7005E

SAT080D

Revision: January 20102010 Versa

Page 294 of 3745

REPAIR FOR COMPONENT PARTSAT-277

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

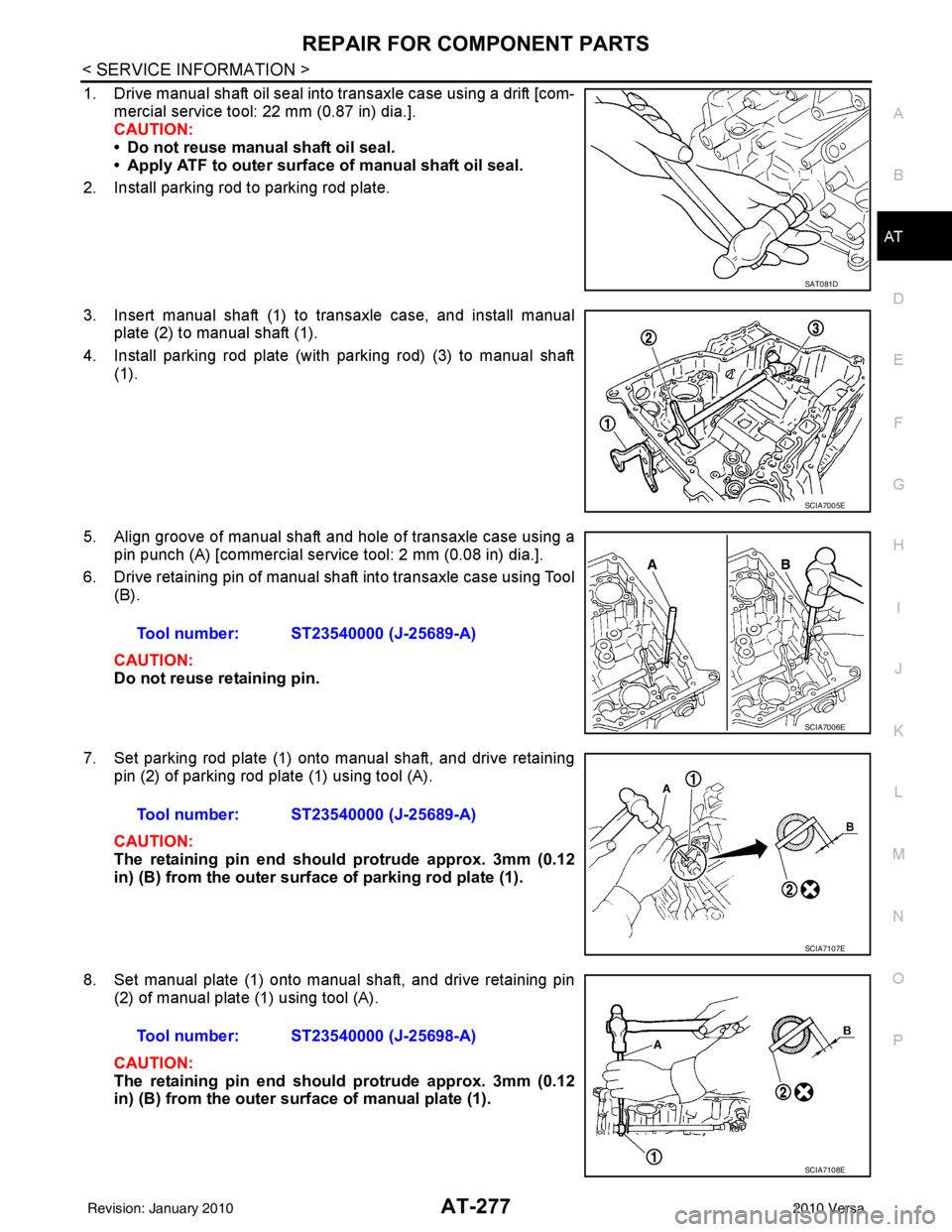

1. Drive manual shaft oil seal into transaxle case using a drift [com- mercial service tool: 22 mm (0.87 in) dia.].

CAUTION:

• Do not reuse manual shaft oil seal.

• Apply ATF to outer surface of manual shaft oil seal.

2. Install parking rod to parking rod plate.

3. Insert manual shaft (1) to transaxle case, and install manual plate (2) to manual shaft (1).

4. Install parking rod plate (with parking rod) (3) to manual shaft (1).

5. Align groove of manual shaft and hole of transaxle case using a pin punch (A) [commercial service tool: 2 mm (0.08 in) dia.].

6. Drive retaining pin of manual shaft into transaxle case using Tool (B).

CAUTION:

Do not reuse retaining pin.

7. Set parking rod plate (1) onto manual shaft, and drive retaining pin (2) of parking rod plate (1) using tool (A).

CAUTION:

The retaining pin end should protrude approx. 3mm (0.12

in) (B) from the outer surface of parking rod plate (1).

8. Set manual plate (1) onto manual shaft, and drive retaining pin (2) of manual plate (1) using tool (A).

CAUTION:

The retaining pin end should protrude approx. 3mm (0.12

in) (B) from the outer surface of manual plate (1).

SAT081D

SCIA7005E

Tool number: ST23540000 (J-25689-A)

SCIA7006E

Tool number: ST23540000 (J-25689-A)

SCIA7107E

Tool number: ST23540000 (J-25698-A)

SCIA7108E

Revision: January 20102010 Versa

Page 295 of 3745

AT-278

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

9. Install detent spring on transaxle case.

10. Tighten detent spring bolt to the specified torque. Refer to AT-

275, "Manual Shaft".

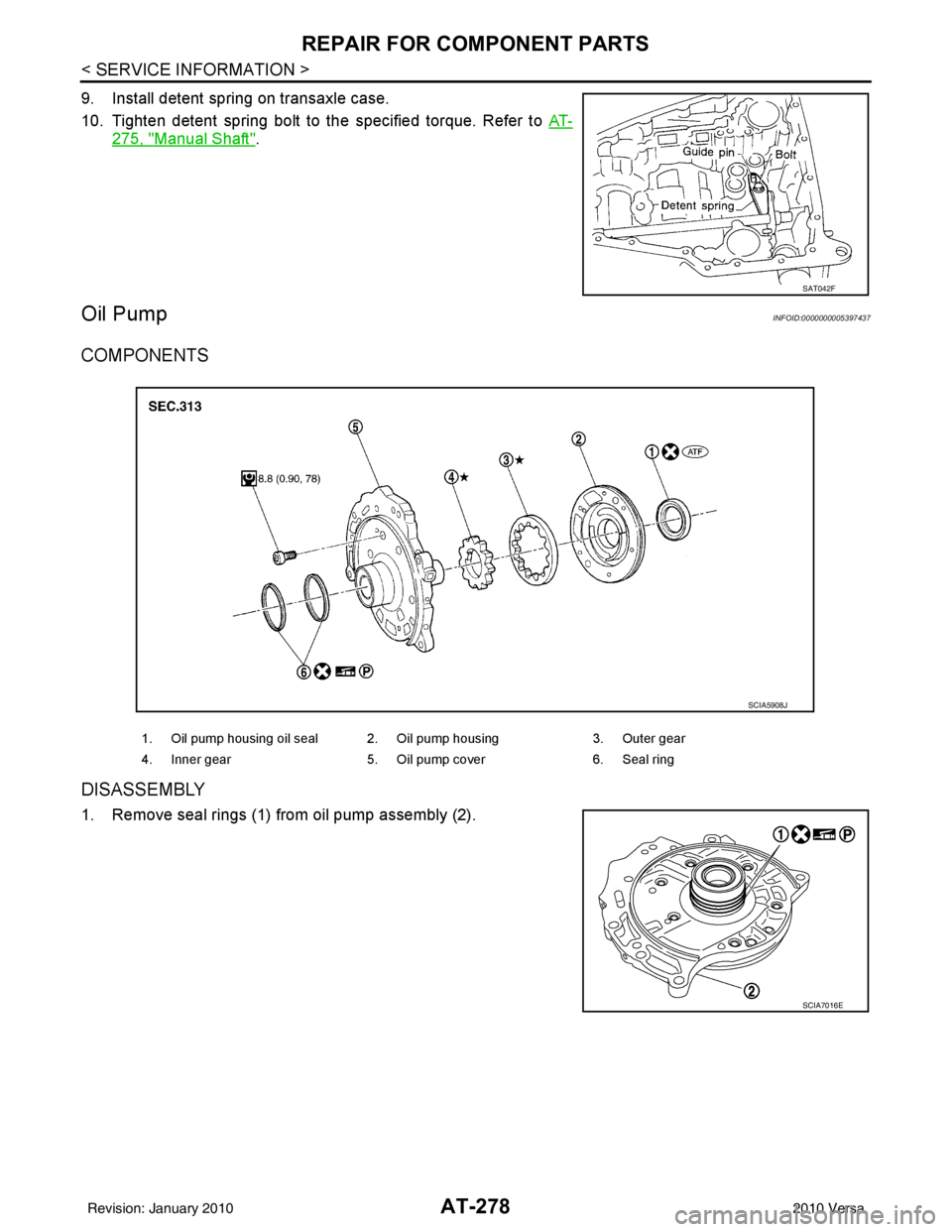

Oil PumpINFOID:0000000005397437

COMPONENTS

DISASSEMBLY

1. Remove seal rings (1) from oil pump assembly (2).

SAT042F

1. Oil pump housing oil seal 2. Oil pump housing 3. Outer gear

4. Inner gear 5. Oil pump cover6. Seal ring

SCIA5908J

SCIA7016E

Revision: January 20102010 Versa

Page 296 of 3745

REPAIR FOR COMPONENT PARTSAT-279

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

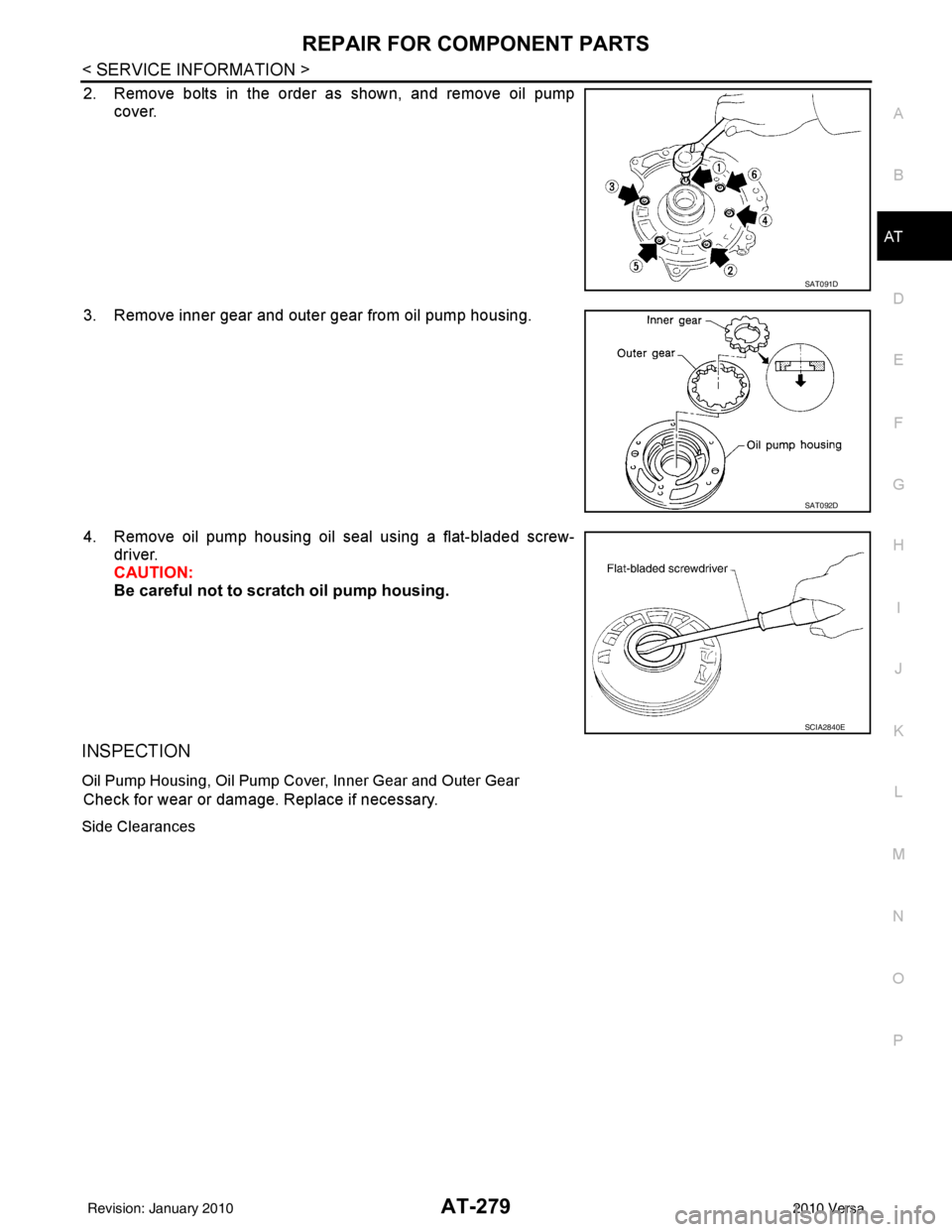

2. Remove bolts in the order as shown, and remove oil pump cover.

3. Remove inner gear and outer gear from oil pump housing.

4. Remove oil pump housing oil seal using a flat-bladed screw- driver.

CAUTION:

Be careful not to scratch oil pump housing.

INSPECTION

Oil Pump Housing, Oil Pump Co ver, Inner Gear and Outer Gear

Check for wear or damage. Replace if necessary.

Side Clearances

SAT091D

SAT092D

SCIA2840E

Revision: January 20102010 Versa

Page 297 of 3745

AT-280

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

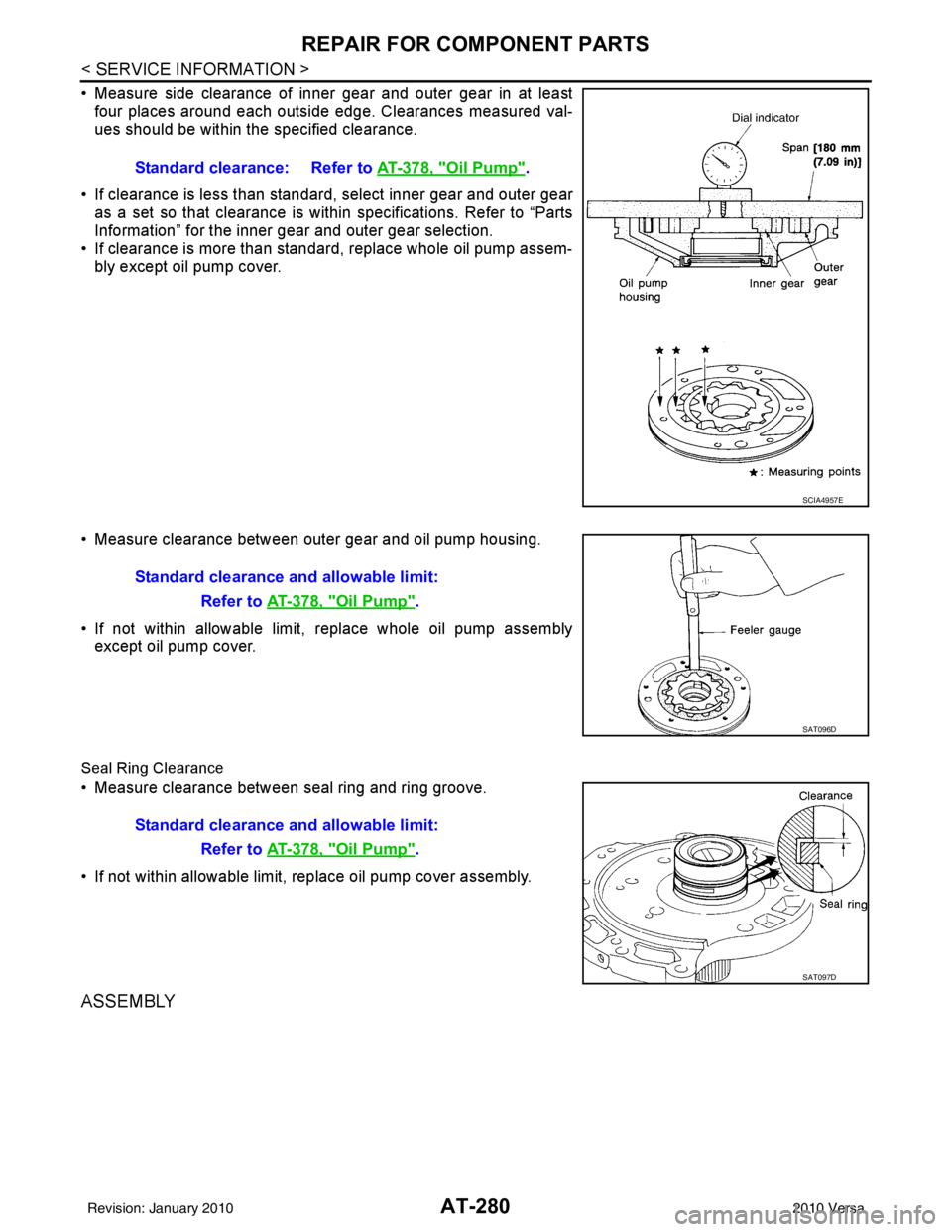

• Measure side clearance of inner gear and outer gear in at leastfour places around each outside edge. Clearances measured val-

ues should be within the specified clearance.

• If clearance is less than standard, select inner gear and outer gear as a set so that clearance is within specifications. Refer to “Parts

Information” for the inner gear and outer gear selection.

• If clearance is more than standard, replace whole oil pump assem- bly except oil pump cover.

• Measure clearance between outer gear and oil pump housing.

• If not within allowable limit, replace whole oil pump assembly except oil pump cover.

Seal Ring Clearance

• Measure clearance between seal ring and ring groove.

• If not within allowable limit, replace oil pump cover assembly.

ASSEMBLY

Standard clearance: Refer to AT-378, "Oil Pump".

SCIA4957E

Standard clearance and allowable limit:

Refer to AT-378, "

Oil Pump".

SAT096D

Standard clearance and allowable limit:

Refer to AT-378, "

Oil Pump".

SAT097D

Revision: January 20102010 Versa

Page 298 of 3745

REPAIR FOR COMPONENT PARTSAT-281

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

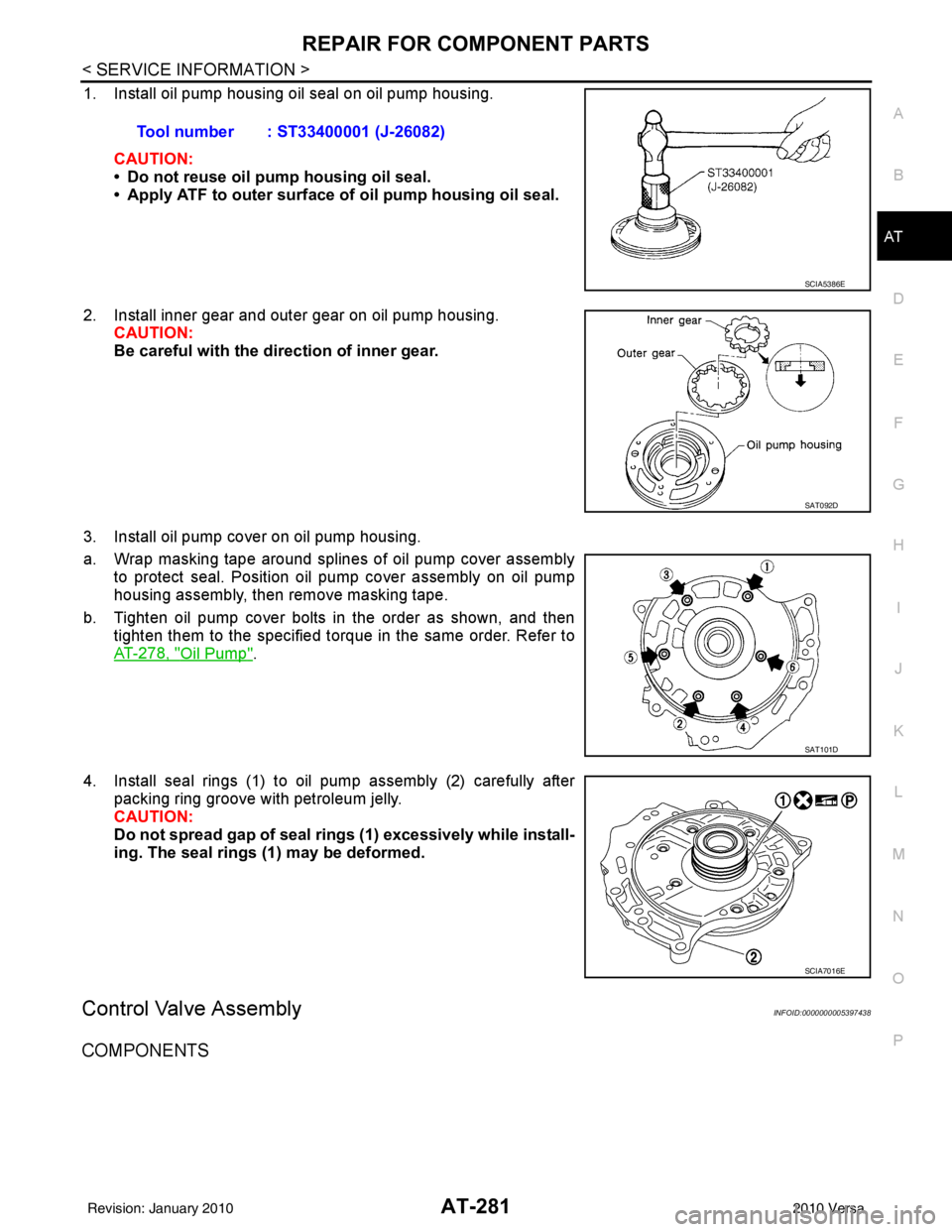

1. Install oil pump housing oil seal on oil pump housing.

CAUTION:

• Do not reuse oil pump housing oil seal.

• Apply ATF to outer surface of oil pump housing oil seal.

2. Install inner gear and outer gear on oil pump housing. CAUTION:

Be careful with the di rection of inner gear.

3. Install oil pump cover on oil pump housing.

a. Wrap masking tape around splines of oil pump cover assembly to protect seal. Position oil pump cover assembly on oil pump

housing assembly, then remove masking tape.

b. Tighten oil pump cover bolts in the order as shown, and then tighten them to the specified torque in the same order. Refer to

AT-278, "

Oil Pump".

4. Install seal rings (1) to oil pump assembly (2) carefully after packing ring groove with petroleum jelly.

CAUTION:

Do not spread gap of seal ri ngs (1) excessively while install-

ing. The seal rings (1) may be deformed.

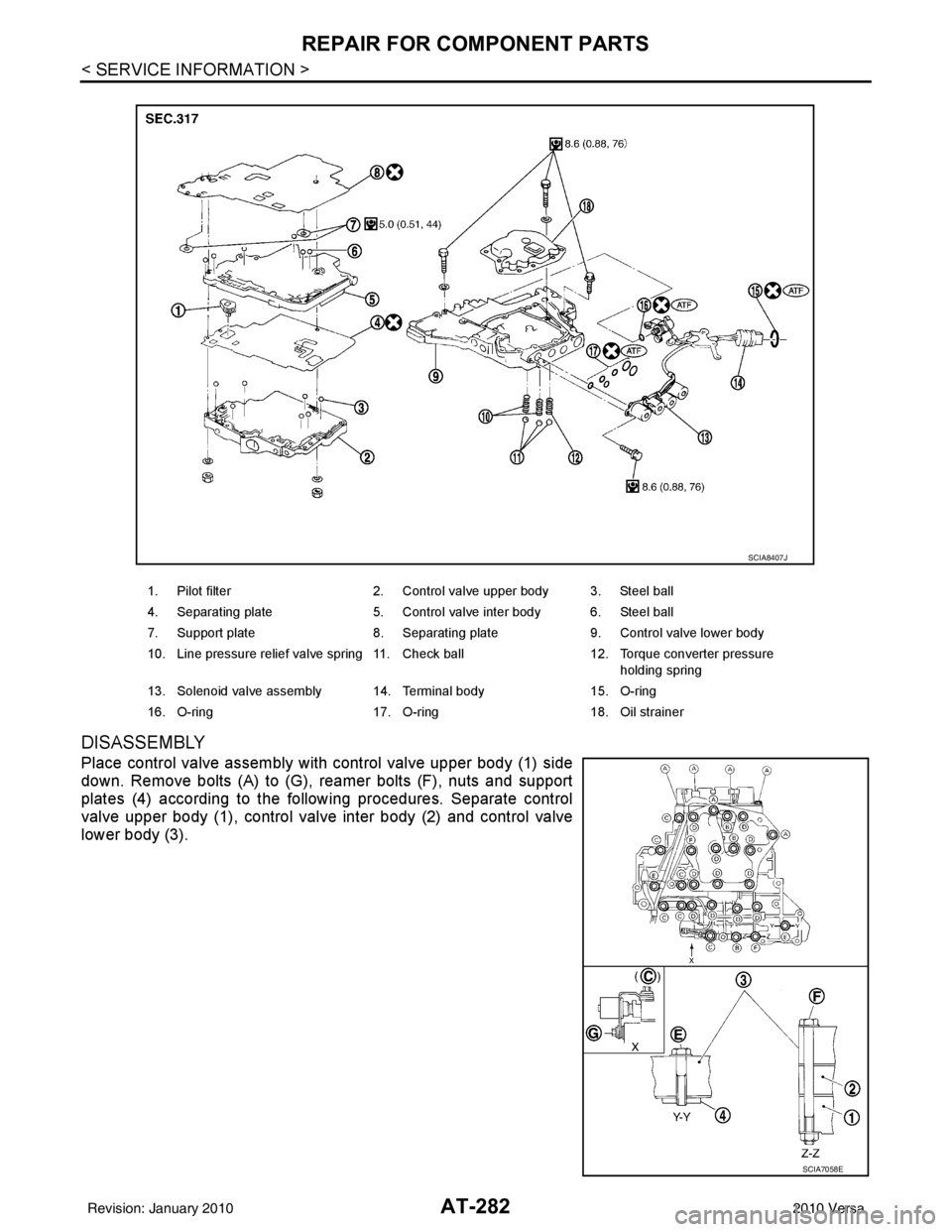

Control Valve AssemblyINFOID:0000000005397438

COMPONENTS

Tool number : ST33400001 (J-26082)

SCIA5386E

SAT092D

SAT101D

SCIA7016E

Revision: January 20102010 Versa

Page 299 of 3745

AT-282

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

DISASSEMBLY

Place control valve assembly with control valve upper body (1) side

down. Remove bolts (A) to (G), reamer bolts (F), nuts and support

plates (4) according to the following procedures. Separate control

valve upper body (1), control valve inter body (2) and control valve

lower body (3).

1. Pilot filter2. Control valve upper body 3. Steel ball

4. Separating plate 5. Control valve inter body 6. Steel ball

7. Support plate 8. Separating plate9. Control valve lower body

10. Line pressure relief valve spring 11. Check ball 12. Torque converter pressure

holding spring

13. Solenoid valve assembly 14. Terminal body 15. O-ring

16. O-ring 17. O-ring18. Oil strainer

SCIA8407J

SCIA7058E

Revision: January 20102010 Versa

Page 300 of 3745

REPAIR FOR COMPONENT PARTSAT-283

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

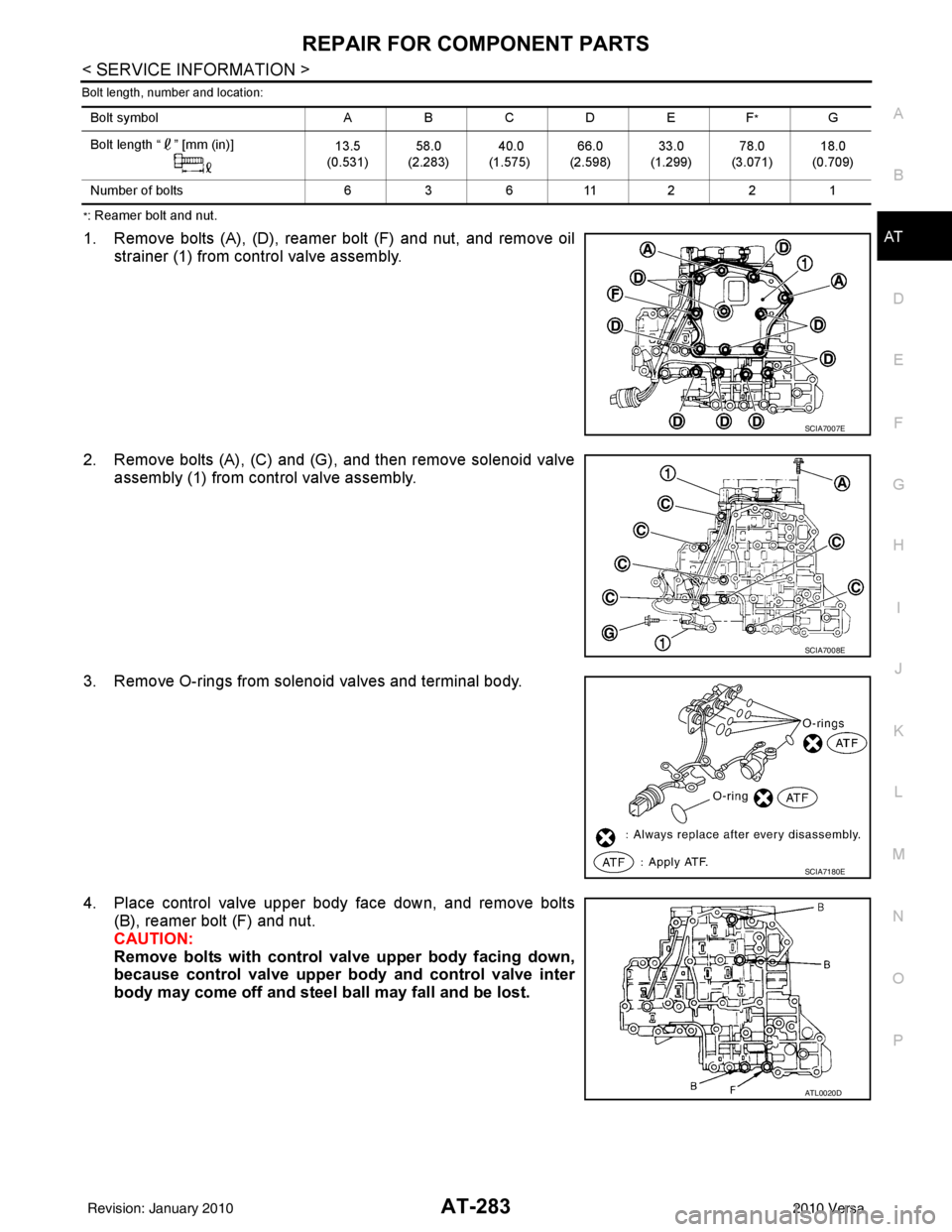

Bolt length, number and location:

*: Reamer bolt and nut.

1. Remove bolts (A), (D), reamer bolt (F) and nut, and remove oil strainer (1) from control valve assembly.

2. Remove bolts (A), (C) and (G), and then remove solenoid valve assembly (1) from control valve assembly.

3. Remove O-rings from solenoid valves and terminal body.

4. Place control valve upper body face down, and remove bolts (B), reamer bolt (F) and nut.

CAUTION:

Remove bolts with control val ve upper body facing down,

because control valve upper body and control valve inter

body may come off and steel ball may fall and be lost.

Bolt symbol ABC D EF*G

Bolt length “ ” [mm (in)] 13.5

(0.531) 58.0

(2.283) 40.0

(1.575) 66.0

(2.598) 33.0

(1.299) 78.0

(3.071) 18.0

(0.709)

Number of bolts 63 611 221

SCIA7007E

SCIA7008E

SCIA7180E

ATL0020D

Revision: January 20102010 Versa