NISSAN TIIDA 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3521 of 3745

REAR SUSPENSION ASSEMBLYRSU-7

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

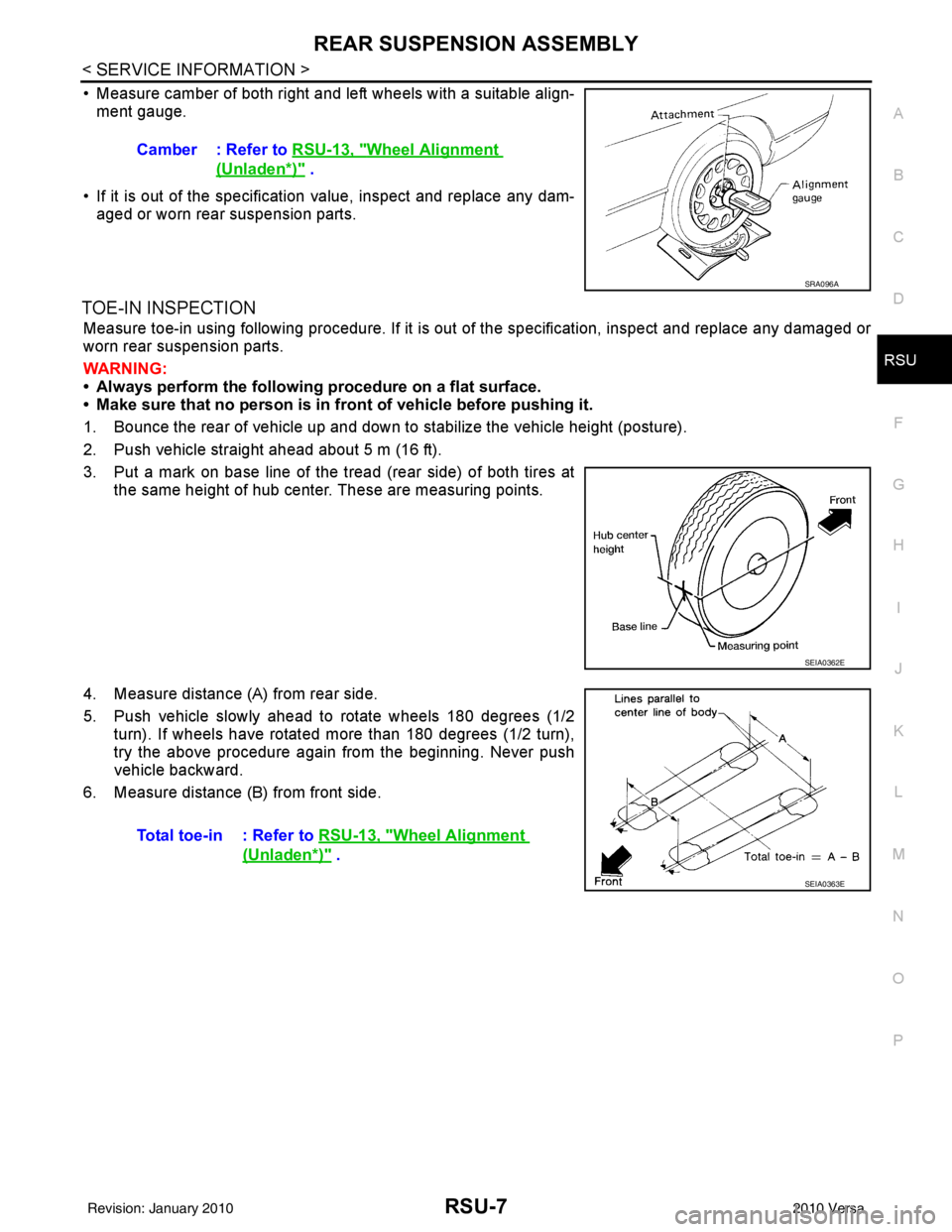

• Measure camber of both right and left wheels with a suitable align- ment gauge.

• If it is out of the specificati on value, inspect and replace any dam-

aged or worn rear suspension parts.

TOE-IN INSPECTION

Measure toe-in using following procedure. If it is out of the specification, inspect and replace any damaged or

worn rear suspension parts.

WARNING:

• Always perform the following procedure on a flat surface.

• Make sure that no person is in fron t of vehicle before pushing it.

1. Bounce the rear of vehicle up and down to stabilize the vehicle height (posture).

2. Push vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires at the same height of hub center. These are measuring points.

4. Measure distance (A) from rear side.

5. Push vehicle slowly ahead to rotate wheels 180 degrees (1/2 turn). If wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance (B) from front side. Camber : Refer to

RSU-13, "

Wheel Alignment

(Unladen*)" .

SRA096A

SEIA0362E

Total toe-in : Refer to RSU-13, "Wheel Alignment

(Unladen*)" .

SEIA0363E

Revision: January 20102010 Versa

Page 3522 of 3745

RSU-8

< SERVICE INFORMATION >

REAR SUSPENSION ASSEMBLY

Component

INFOID:0000000005397079

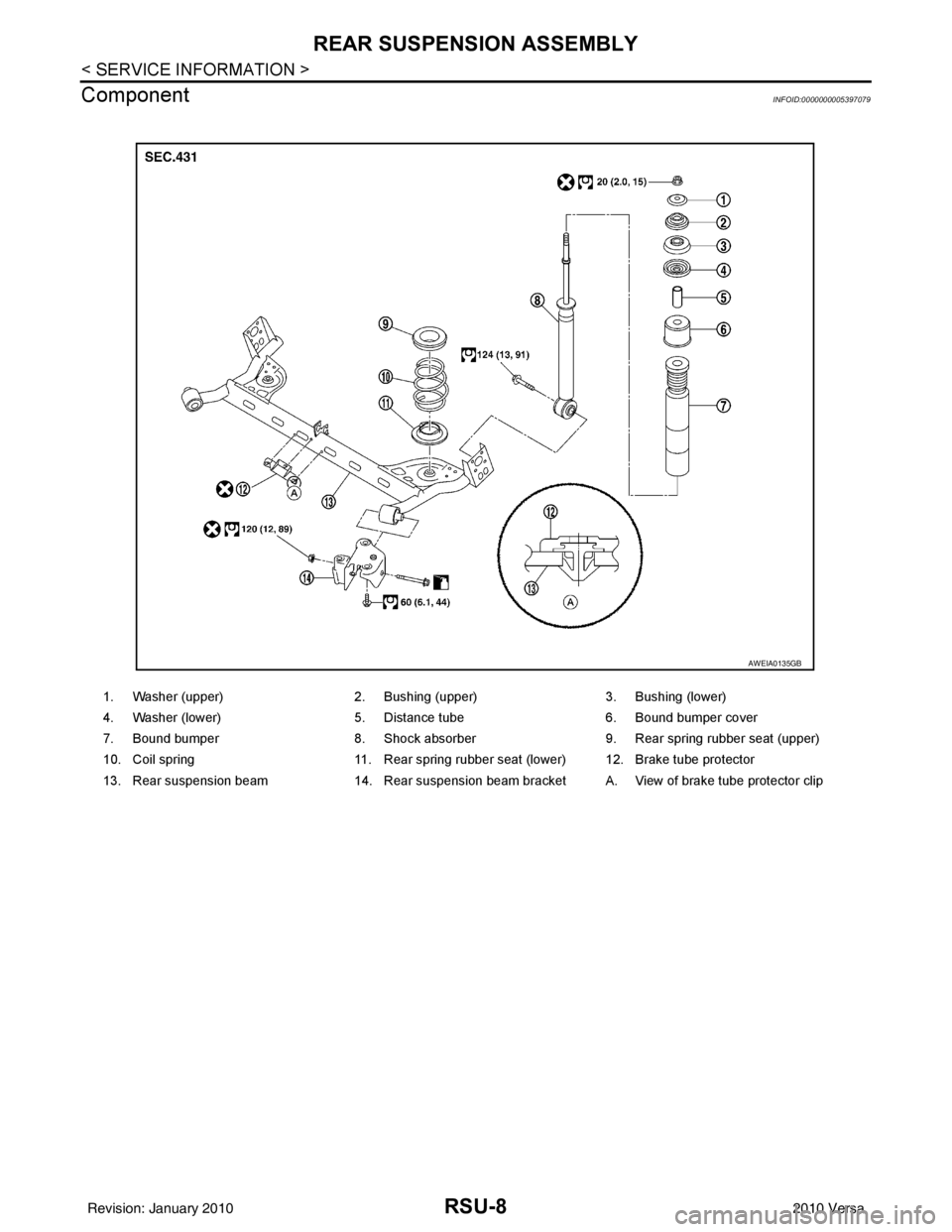

1. Washer (upper) 2. Bushing (upper)3. Bushing (lower)

4. Washer (lower) 5. Distance tube6. Bound bumper cover

7. Bound bumper 8. Shock absorber 9. Rear spring rubber seat (upper)

10. Coil spring 11. Rear spring rubber seat (lower) 12. Brake tube protector

13. Rear suspension beam 14. Rear suspension beam bracket A. View of brake tube protector clip

AWEIA0135GB

Revision: January 20102010 Versa

Page 3523 of 3745

SHOCK ABSORBERRSU-9

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SHOCK ABSORBER

Removal and InstallationINFOID:0000000005397080

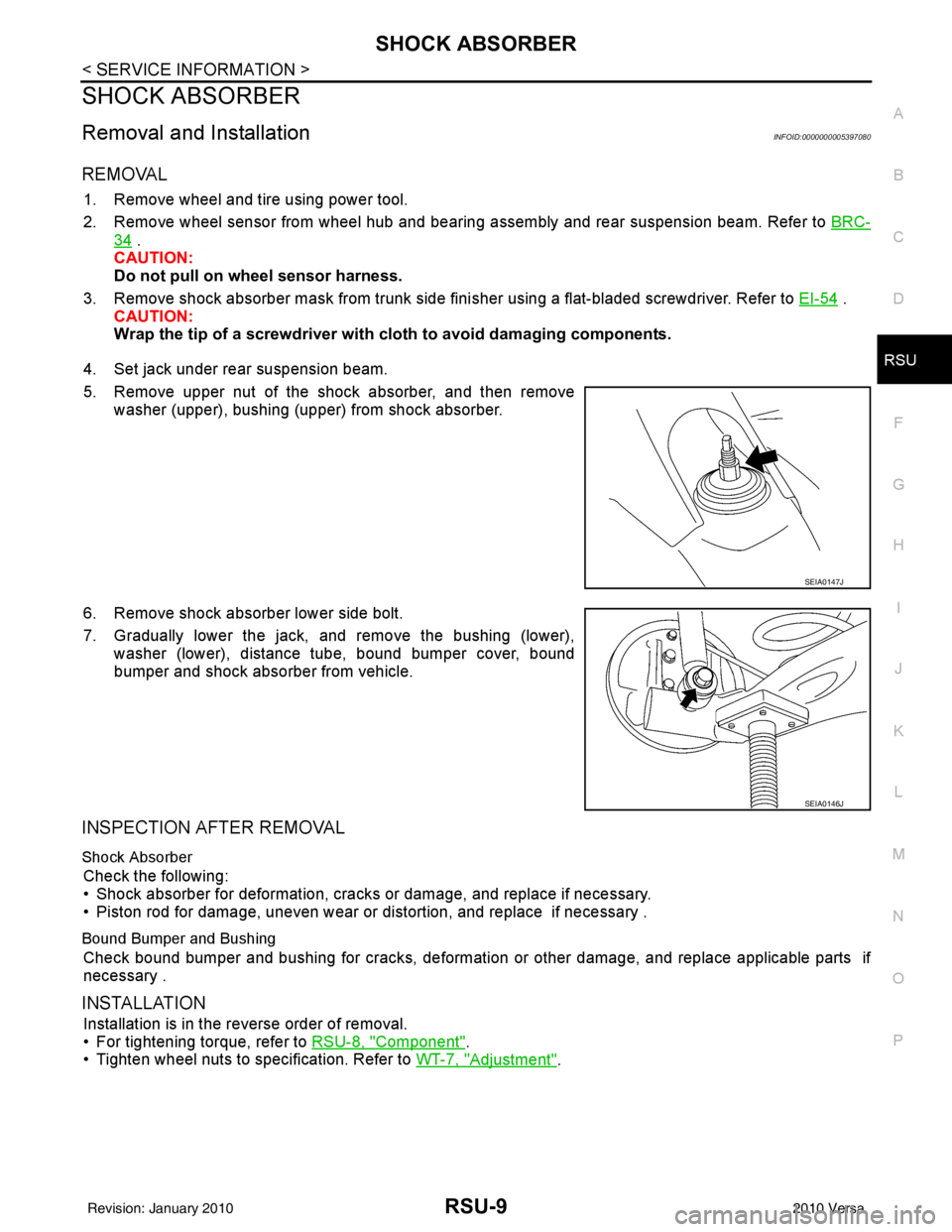

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly and rear suspension beam. Refer to BRC-

34 .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove shock absorber mask from trunk side fini sher using a flat-bladed screwdriver. Refer to EI-54

.

CAUTION:

Wrap the tip of a screwdriver with cl oth to avoid damaging components.

4. Set jack under rear suspension beam.

5. Remove upper nut of the shock absorber, and then remove washer (upper), bushing (upper) from shock absorber.

6. Remove shock absorber lower side bolt.

7. Gradually lower the jack, and remove the bushing (lower), washer (lower), distance tube, bound bumper cover, bound

bumper and shock absorber from vehicle.

INSPECTION AFTER REMOVAL

Shock Absorber

Check the following:

• Shock absorber for deformation, cracks or damage, and replace if necessary.

• Piston rod for damage, uneven wear or distortion, and replace if necessary .

Bound Bumper and Bushing

Check bound bumper and bushing for cracks, deformation or other damage, and replace applicable parts if

necessary .

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, "

Component".

• Tighten wheel nuts to specification. Refer to WT-7, "

Adjustment".

SEIA0147J

SEIA0146J

Revision: January 20102010 Versa

Page 3524 of 3745

RSU-10

< SERVICE INFORMATION >

SHOCK ABSORBER

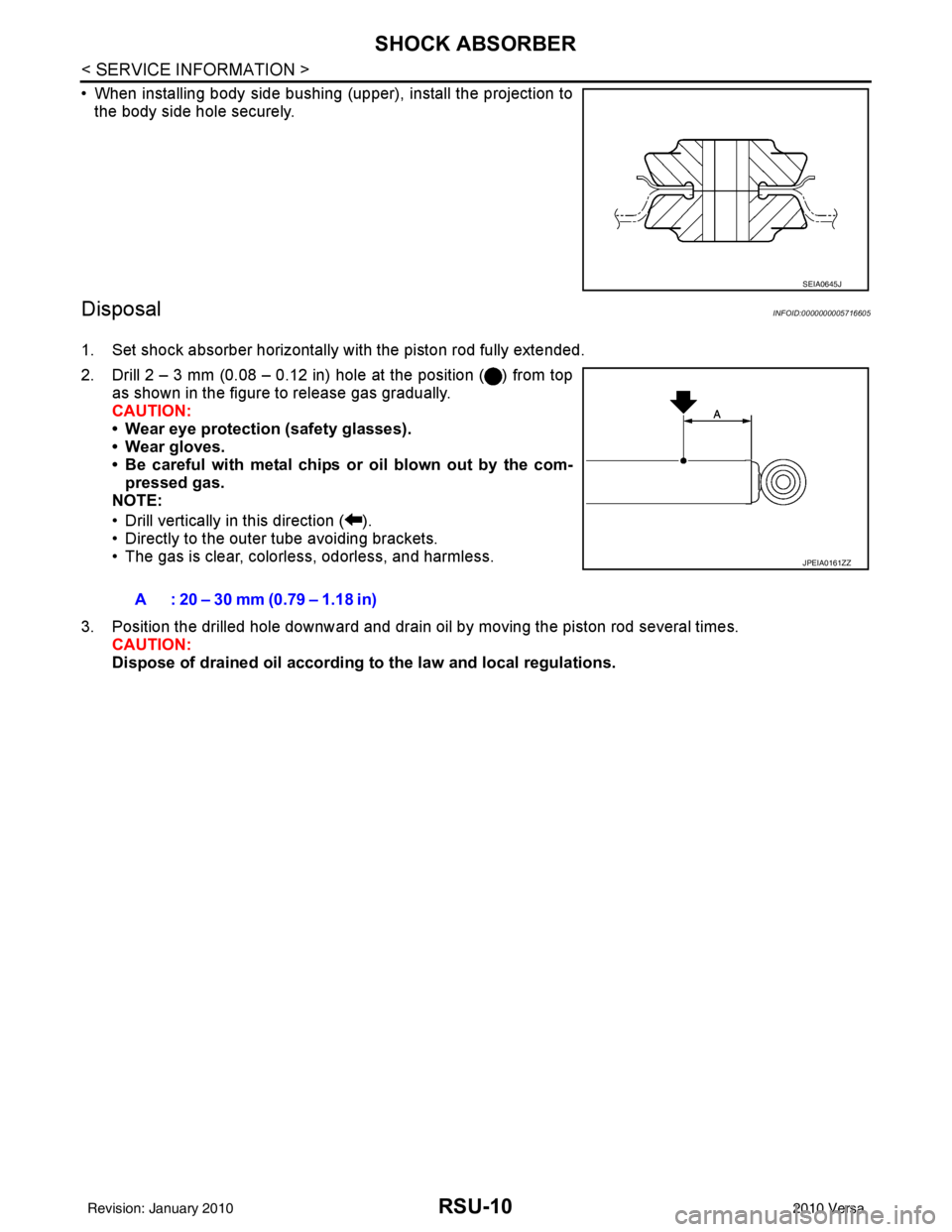

• When installing body side bushing (upper), install the projection tothe body side hole securely.

DisposalINFOID:0000000005716605

1. Set shock absorber horizontally with the piston rod fully extended.

2. Drill 2 – 3 mm (0.08 – 0.12 in) hole at the position ( ) from top as shown in the figure to release gas gradually.

CAUTION:

• Wear eye protection (safety glasses).

• Wear gloves.

• Be careful with metal chips or oil blown out by the com-pressed gas.

NOTE:

• Drill vertically in this direction ( ).

• Directly to the outer tube avoiding brackets.

• The gas is clear, colorless, odorless, and harmless.

3. Position the drilled hole downward and drain oil by moving the piston rod several times. CAUTION:

Dispose of drained oil according to the law and local regulations.

SEIA0645J

A : 20 – 30 mm (0.79 – 1.18 in)

JPEIA0161ZZ

Revision: January 20102010 Versa

Page 3525 of 3745

COIL SPRINGRSU-11

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

COIL SPRING

Removal and InstallationINFOID:0000000005397081

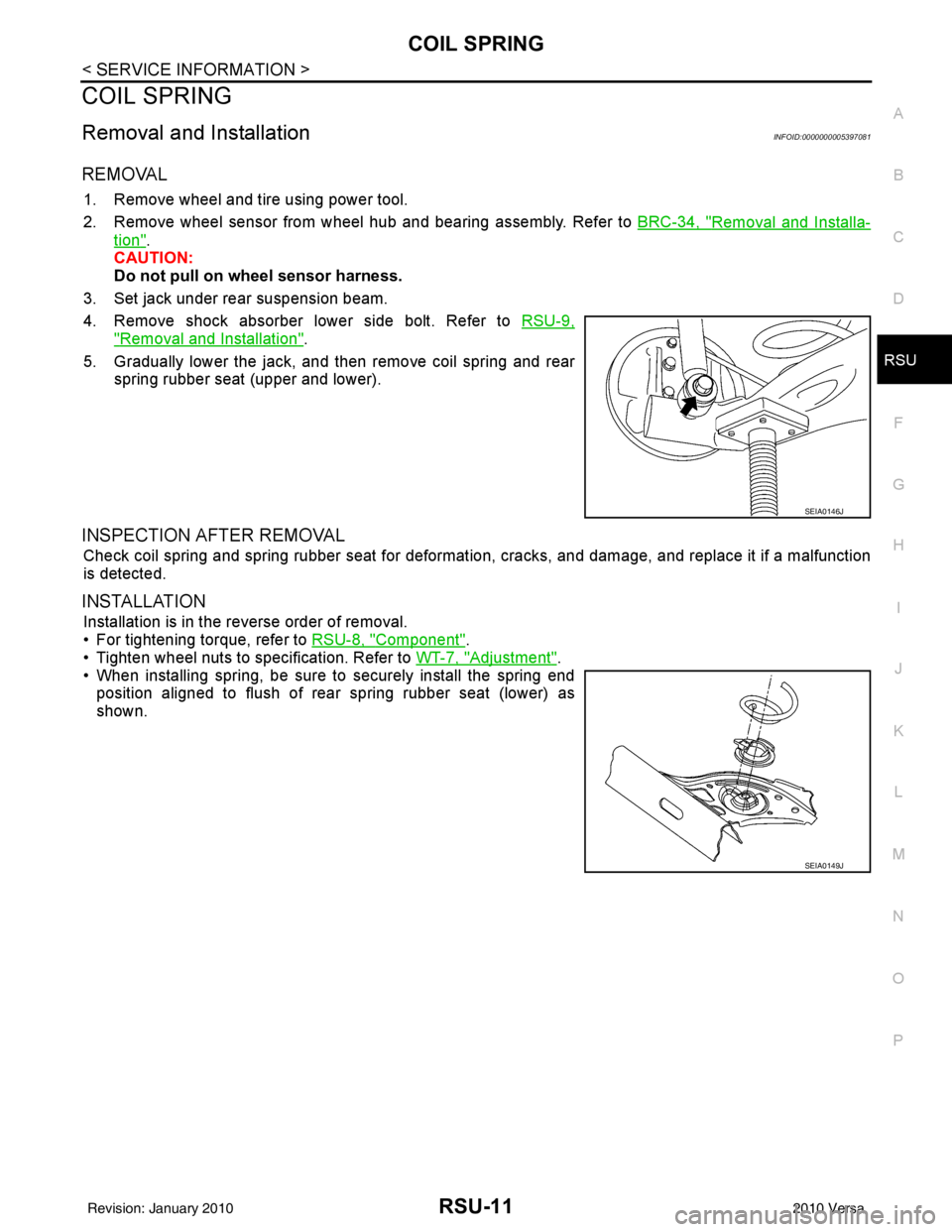

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove wheel sensor from wheel hub and bearing assembly. Refer to BRC-34, "

Removal and Installa-

tion".

CAUTION:

Do not pull on wheel sensor harness.

3. Set jack under rear suspension beam.

4. Remove shock absorber lower side bolt. Refer to RSU-9,

"Removal and Installation".

5. Gradually lower the jack, and then remove coil spring and rear spring rubber seat (upper and lower).

INSPECTION AFTER REMOVAL

Check coil spring and spring rubber seat for deformation, cracks, and damage, and replace it if a malfunction

is detected.

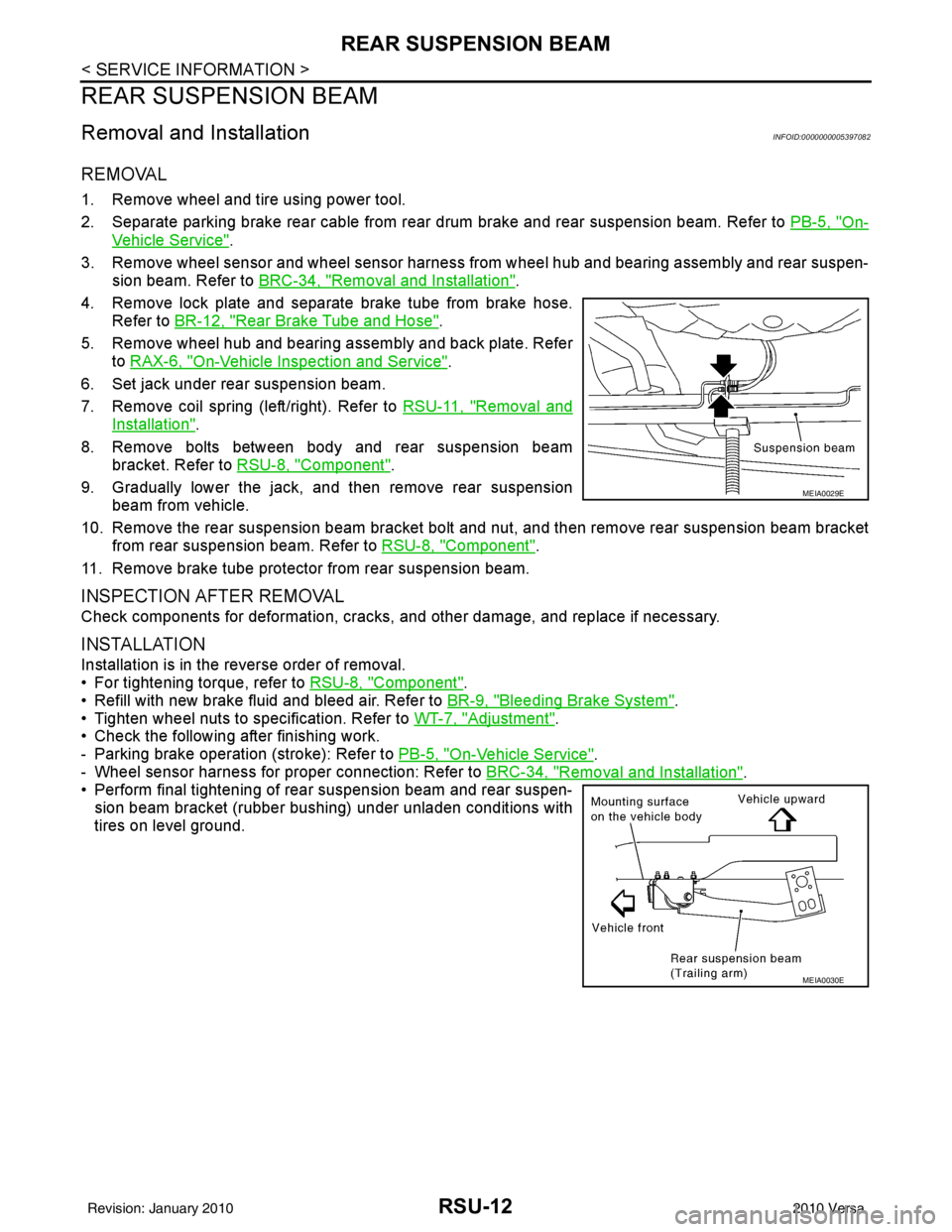

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, "

Component".

• Tighten wheel nuts to specification. Refer to WT-7, "

Adjustment".

• When installing spring, be sure to securely install the spring end position aligned to flush of rear spring rubber seat (lower) as

shown.

SEIA0146J

SEIA0149J

Revision: January 20102010 Versa

Page 3526 of 3745

RSU-12

< SERVICE INFORMATION >

REAR SUSPENSION BEAM

REAR SUSPENSION BEAM

Removal and InstallationINFOID:0000000005397082

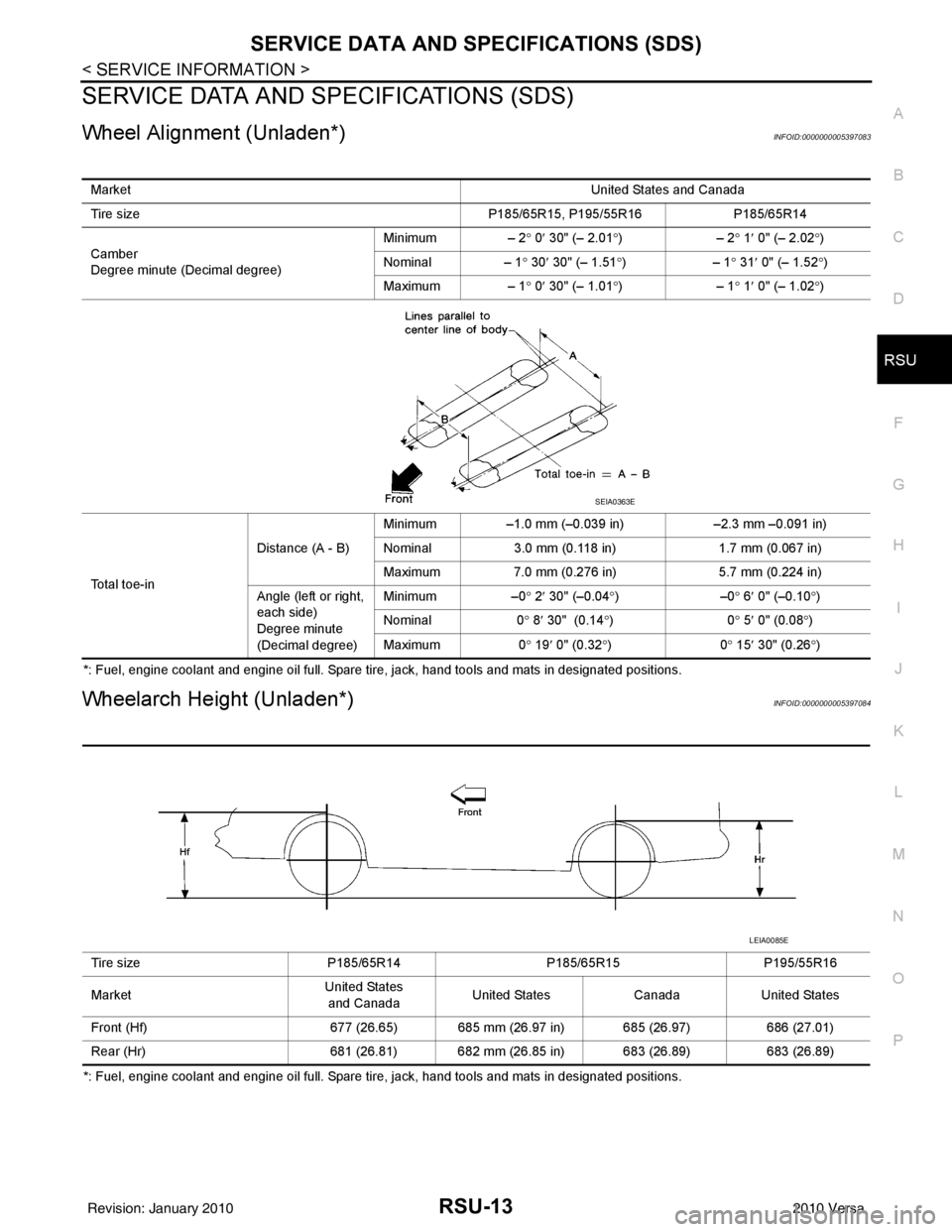

REMOVAL

1. Remove wheel and tire using power tool.

2. Separate parking brake rear cable from rear drum brake and rear suspension beam. Refer to PB-5, "

On-

Vehicle Service".

3. Remove wheel sensor and wheel sensor harness from wheel hub and bearing assembly and rear suspen-

sion beam. Refer to BRC-34, "

Removal and Installation".

4. Remove lock plate and separate brake tube from brake hose. Refer to BR-12, "

Rear Brake Tube and Hose".

5. Remove wheel hub and bearing assembly and back plate. Refer to RAX-6, "

On-Vehicle Inspection and Service".

6. Set jack under rear suspension beam.

7. Remove coil spring (left/right). Refer to RSU-11, "

Removal and

Installation".

8. Remove bolts between body and rear suspension beam bracket. Refer to RSU-8, "

Component".

9. Gradually lower the jack, and then remove rear suspension beam from vehicle.

10. Remove the rear suspension beam bracket bolt and nut, and then remove rear suspension beam bracket

from rear suspension beam. Refer to RSU-8, "

Component".

11. Remove brake tube protector from rear suspension beam.

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage, and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• For tightening torque, refer to RSU-8, "

Component".

• Refill with new brake fluid and bleed air. Refer to BR-9, "

Bleeding Brake System".

• Tighten wheel nuts to specification. Refer to WT-7, "

Adjustment".

• Check the following after finishing work.

- Parking brake operation (stroke): Refer to PB-5, "

On-Vehicle Service".

- Wheel sensor harness for proper connection: Refer to BRC-34, "

Removal and Installation".

• Perform final tightening of rear suspension beam and rear suspen-

sion beam bracket (rubber bushing) under unladen conditions with

tires on level ground.

MEIA0029E

MEIA0030E

Revision: January 20102010 Versa

Page 3527 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)RSU-13

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Alignment (Unladen*)INFOID:0000000005397083

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Wheelarch Height (Unladen*)INFOID:0000000005397084

*: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions. Market

United States and Canada

Tire size P185/65R15, P195/55R16 P185/65R14

Camber

Degree minute (Decimal degree) Minimum

– 2° 0′ 30" (– 2.01 °)– 2° 1 ′ 0" (– 2.02 °)

Nominal – 1° 30 ′ 30" (– 1.51 °)– 1° 31 ′ 0" (– 1.52 °)

Maximum – 1° 0′ 30" (– 1.01 °)– 1° 1 ′ 0" (– 1.02 °)

To t a l t o e - i n Distance (A - B)

Minimum

–1.0 mm (–0.039 in) –2.3 mm –0.091 in)

Nominal 3.0 mm (0.118 in) 1.7 mm (0.067 in)

Maximum 7.0 mm (0.276 in) 5.7 mm (0.224 in)

Angle (left or right,

each side)

Degree minute

(Decimal degree) Minimum

–0° 2 ′ 30" (–0.04 °)– 0° 6 ′ 0" (–0.10 °)

Nominal 0° 8 ′ 30" (0.14 °)0 ° 5 ′ 0" (0.08 °)

Maximum 0° 19 ′ 0" (0.32 °)0 ° 15 ′ 30" (0.26 °)

SEIA0363E

Tire size P185/65R14P185/65R15P195/55R16

Market United States

and Canada United States

CanadaUnited States

Front (Hf) 677 (26.65) 685 mm (26.97 in) 685 (26.97) 686 (27.01)

Rear (Hr) 681 (26.81) 682 mm (26.85 in) 683 (26.89) 683 (26.89)

LEIA0085E

Revision: January 20102010 Versa

Page 3528 of 3745

SB-1

RESTRAINTS

C

DE

F

G

I

J

K L

M

SECTION SB

A

B

SB

N

O P

CONTENTS

SEAT BELTS

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Seat Belt Service ...............................3

ON-VEHICLE REPAIR ..................................4

SEAT BELTS .....................................................4

Removal and Installation of Front Seat Belt ........ .....4

Removal and Installation of Rear Seat Belt ..............6

Seat Belt Inspection ............................................. .....8

LATCH (LOWER ANCHORS AND TETHER

FOR CHILDREN) SYSTEM ...............................

11

Removal and Installation .........................................11

TOP TETHER STRAP CHILD RESTRAINT .....12

Removal and Installation .........................................12

Revision: January 20102010 Versa

Page 3529 of 3745

SB-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005714399

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005396884

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3530 of 3745

PRECAUTIONSSB-3

< PRECAUTION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Seat Belt ServiceINFOID:0000000005396885

CAUTION:

• Before removing the front seat belt pre-tensioner assembly, turn the ignition switch off, disconnect

the both battery cables and wait at least 3 minutes.

• After replacing or reinstalling front seat belt pre-tensioner assembly, or reconnecting front seat belt

pre-tensioner connector, check th e system function. Refer to SRS-19, "

SRS Operation Check".

• Do not disassemble buckle or seat belt assembly.

• Do not reuse seat belt anchor bolts after removal. Replace with new ones.

• Replace anchor bolts if th ey are deformed or worn out.

• Never oil tongue and buckle.

• If any component of seat belt assembly is questio nable, do not repair. Replace the whole seat belt

assembly.

• If webbing is cut, frayed, or damaged, replace seat belt assembly.

• When replacing seat belt assembly, u se a genuine NISSAN seat belt assembly.

AFTER A COLLISION

WARNING:

• Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

• NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an acci dent. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or im proper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly (including anchor bolts) if:

• The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and buckles show no damage and continue to operate properly).

• The seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide).

• The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage or distortion and repair as necessary before installing a new seat belt assembly.

• Anchor bolts are deformed or worn out.

• The seat belt pre-tensioner should be replaced even if t he seat belts are not in use during the collision in

which the air bags are deployed.

Revision: January 20102010 Versa