Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3256 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-72

< SERVICE INFORMATION >[RS6F94R]

TRANSAXLE ASSEMBLY

25. Remove mainshaft rear bearing outer race from transaxle case,

using a suitable tool.

26. Remove mainshaft rear bearing adjusting shim from NISSAN TIIDA 2010 Service Repair Manual MT-72

< SERVICE INFORMATION >[RS6F94R]

TRANSAXLE ASSEMBLY

25. Remove mainshaft rear bearing outer race from transaxle case,

using a suitable tool.

26. Remove mainshaft rear bearing adjusting shim from](/img/5/57397/w960_57397-3255.png)

MT-72

< SERVICE INFORMATION >[RS6F94R]

TRANSAXLE ASSEMBLY

25. Remove mainshaft rear bearing outer race from transaxle case,

using a suitable tool.

26. Remove mainshaft rear bearing adjusting shim from transaxle case.

27. Remove snap ring (1) and oil channel (2) from transaxle case.

28. Remove input shaft oil seal (1) from clutch housing, using a suit- able tool.

CAUTION:

Never damage clutch housing.

29. Remove mainshaft front bearing outer race (1) from clutch hous- ing, using Tool (A) and a suitable tool (B).

30. Remove oil channel (2) from clutch housing.

PCIB1706E

PCIB1708E

PCIB1714E

Tool number : KV381054S0 (J-34286)

JPDIC0107ZZ

Revision: January 20102010 Versa

Page 3258 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-74

< SERVICE INFORMATION >[RS6F94R]

TRANSAXLE ASSEMBLY

4. Install two way connector (1) to clutch housing.

5. Install bushings (1) so that they becomes even to clutch housing

edge surface, using a NISSAN TIIDA 2010 Service Repair Manual MT-74

< SERVICE INFORMATION >[RS6F94R]

TRANSAXLE ASSEMBLY

4. Install two way connector (1) to clutch housing.

5. Install bushings (1) so that they becomes even to clutch housing

edge surface, using a](/img/5/57397/w960_57397-3257.png)

MT-74

< SERVICE INFORMATION >[RS6F94R]

TRANSAXLE ASSEMBLY

4. Install two way connector (1) to clutch housing.

5. Install bushings (1) so that they becomes even to clutch housing

edge surface, using a suitable tool (A).

6. Install oil channel to clutch housing. CAUTION:

Never reuse oil channel.

7. Install mainshaft front bearing outer race to clutch housing, using Tool (A).

CAUTION:

Replace mainshaft front bearing outer race and mainshaft

front bearing inner race as a set.

8. Install input shaft oil seal (1) to clutch housing, using Tool (A).

9. Install snap ring (1) and oil channel (2) to transaxle case. CAUTION:

• Select and install snap ring that has the same thickness

as previous one.

• Replace transaxle assembly when replacing transaxle case.

10. Install mainshaft rear bearing adjusting shim to transaxle case. CAUTION:

Select mainshaft rear bearin g adjusting shim according to

the following procedures when replacing mainshaft adjust-

ing shim, 6th main gear, 5th main gear, or 4th main gear.

• Replace mainshaft adjusting shim.

PCIB1720E

JPDIC0108ZZ

Tool number : KV38100200 ( — )

PCIB1724E

Tool number : ST33220000 ( — )

PCIB1721E

PCIB1729E

Revision: January 20102010 Versa

Page 3265 of 3745

![NISSAN TIIDA 2010 Service Repair Manual INPUT SHAFT AND GEARSMT-81

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

5. Remove snap ring (1) using suitable tool.

6. Remove spacer, 5th baulk ring, 5th input gear (2), and spa NISSAN TIIDA 2010 Service Repair Manual INPUT SHAFT AND GEARSMT-81

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

5. Remove snap ring (1) using suitable tool.

6. Remove spacer, 5th baulk ring, 5th input gear (2), and spa](/img/5/57397/w960_57397-3264.png)

INPUT SHAFT AND GEARSMT-81

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

5. Remove snap ring (1) using suitable tool.

6. Remove spacer, 5th baulk ring, 5th input gear (2), and spacer.

7. Remove snap ring (1) using suitable tool.

8. Remove spacer, 4th input gear (2), 4th baulk ring, and 3rd-4th synchronizer hub assembly (3).

9. Remove insert keys and 3rd-4th coupling sleeve from 3rd-4th synchronizer hub.

10. Remove snap ring (1).

11. Remove spacer, 3rd baulk ring, 3rd input gear (2).

12. Set a suitable puller to input shaft front bearing (1), and then remove input shaft front bearing.

INSPECTION AFTER DISASSEMBLY

Input shaft and gear

Check the following items and replace if necessary.

PCIB1754E

PCIB1753E

PCIB1752E

PCIB1751E

Revision: January 20102010 Versa

Page 3267 of 3745

![NISSAN TIIDA 2010 Service Repair Manual INPUT SHAFT AND GEARSMT-83

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

• Replace 5th-6th coupling sleeve and 5th-6th synchronizer hub as a set.

• Be careful to install 3rd- NISSAN TIIDA 2010 Service Repair Manual INPUT SHAFT AND GEARSMT-83

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

• Replace 5th-6th coupling sleeve and 5th-6th synchronizer hub as a set.

• Be careful to install 3rd-](/img/5/57397/w960_57397-3266.png)

INPUT SHAFT AND GEARSMT-83

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

• Replace 5th-6th coupling sleeve and 5th-6th synchronizer hub as a set.

• Be careful to install 3rd-4th synchronizer hub according to the

specified direction.

• Be careful to install 5th-6th synchronizer hub according to the

specified direction.

• Install input shaft front bearing (1) using a suitable drift (A).

• Install input shaft rear bearing (1) using a suitable drift (A) and the Tool (B).

• Apply gear oil to 3rd baulk ring, 4th baulk ring, 5th baulk ring, and 6th baulk ring.

A : 3rd input gear side

B : 4th input gear side

PCIB1748E

A : 5th input gear side

B : 6th input gear side

PCIB1749E

JPDIC0112ZZ

Tool number B: ST36720030 ( — )

JPDIC0113ZZ

Revision: January 20102010 Versa

Page 3270 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MT-86

< SERVICE INFORMATION >[RS6F94R]

MAINSHAFT AND GEARS

5. Remove 1st main gear (1), 1st-2nd synchronizer hub assembly

(2) , 2nd main gear (3), and 3rd main gear (4) according to the

following proc NISSAN TIIDA 2010 Service Repair Manual MT-86

< SERVICE INFORMATION >[RS6F94R]

MAINSHAFT AND GEARS

5. Remove 1st main gear (1), 1st-2nd synchronizer hub assembly

(2) , 2nd main gear (3), and 3rd main gear (4) according to the

following proc](/img/5/57397/w960_57397-3269.png)

MT-86

< SERVICE INFORMATION >[RS6F94R]

MAINSHAFT AND GEARS

5. Remove 1st main gear (1), 1st-2nd synchronizer hub assembly

(2) , 2nd main gear (3), and 3rd main gear (4) according to the

following procedures.

a. Set a suitable tool to 1st main gear.

b. Remove 3rd main gear, busing, 2nd main gear, 2nd inner baulk ring, 2nd synchronizer cone, 2nd outer baulk ring, 1st-2nd syn-

chronizer hub assembly, 1st outer baulk ring, 1st synchronizer

cone, 1st inner baulk ring, and 1st main gear using the Tool (A).

c. Remove insert keys and 1st-2nd coupling sleeve from 1st-2nd synchronizer hub.

6. Remove mainshaft front bearing inner race (1) according to the following procedures.

a. Set a suitable puller to mainshaft front bearing inner race.

b. Remove mainshaft front bearing inner race using the Tool (A).

INSPECTION AFTER DISASSEMBLY

Mainshaft and Gear

Check the following items and replace if necessary.

• Damage, peeling, bend, uneven wear, and distortion of shaft.

• Excessive wear, damage, and peeling of gear.

Synchronizer

• Synchronizer hub and coupling sleeve Check the following items and replace if necessary.

- Breakage, damage, and unusual wear on contact surface of cou-

pling sleeve, synchronizer hub, and insert key.

- Coupling sleeve and synchronizer hub move smoothly.

• Baulk ring Tool number A: ST33052000 ( — )

Tool number A: ST33052000 ( — )

PCIB1742E

PCIB1741E

PCIB1775E

SCIA1753J

Revision: January 20102010 Versa

Page 3271 of 3745

![NISSAN TIIDA 2010 Service Repair Manual MAINSHAFT AND GEARSMT-87

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

Check contact surface of baulk ring cam and insert key for exces-

sive wear, uneven wear, bend, and damage. NISSAN TIIDA 2010 Service Repair Manual MAINSHAFT AND GEARSMT-87

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

Check contact surface of baulk ring cam and insert key for exces-

sive wear, uneven wear, bend, and damage.](/img/5/57397/w960_57397-3270.png)

MAINSHAFT AND GEARSMT-87

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

Check contact surface of baulk ring cam and insert key for exces-

sive wear, uneven wear, bend, and damage. Replace if necessary.

Bearing

Check bearing for damage and unsmooth rotation. Replace if neces-

sary.

CAUTION:

• Replace mainshaft front bearing outer race and mainshaft front bearing inner race as a set.

• Replace mainshaft rear bearin g inner race and mainshaft rear

bearing outer race as a set.

ASSEMBLY

CAUTION:

• Select mainshaft rear bearing adjusting shim acco rding to the following procedures when replacing

mainshaft adjusting shim, 6th main gear , 5th main gear, or 4th main gear.

- Replace mainshaft adjusting shim.

• If new mainshaft adjusting shim is thinner than previous one, offset the thickness difference by

selecting thicker mainshaft r ear bearing adjusting shim.

• If new mainshaft adjusting shim is thicker th an previous one, offset the thickness difference by

selecting thinner mainshaft rear bearing adjusting shim.

- Replace 6th main gear, 5th main gear, or 4th main gear.

• Measure the thickness of the main gear used before and the new main gear

• Increase the thickness of the mainsh aft rear bearing adjusting shim, if the difference is smaller than

0.025 mm (0.0010 in).

• Replace transaxle assembly when replacing mainshaft.

1. Install mainshaft front bearing inner race (1) using the Tool (A).

CAUTION:

Replace mainshaft front bearing outer race and mainshaft

front bearing inner race as a set.

2. Apply gear oil to 1st inner baulk ring, 1st synchronizer cone, 1st outer baulk ring, 2nd inner baulk ring, 2nd synchronizer cone,

and 2nd outer baulk ring.

CAUTION:

• Replace 1st inner baulk ring, 1st synchronizer cone, and

1st outer baulk ring as a set.

• Replace 2nd inner baulk ring, 2nd synchronize r cone, and 2nd outer baulk ring as a set.

3. Install insert keys and 1st-2nd coupling sleeve to 1st-2nd synchronizer hub. CAUTION:

Replace 1st-2nd synchroni zer hub and 1st-2nd coupling sleeve as a set.

SCIA0608J

SPD715

Tool number A: ST36720030 ( — )

PCIB1733E

Revision: January 20102010 Versa

Page 3280 of 3745

MTC-1

AIR CONDITIONER

C

DE

F

G H

I

K L

M

SECTION MTC

A

B

MTC

N

O P

CONTENTS

MANUAL AIR CONDITIONER

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Working with HFC-134a (R-134a) ......4

General Refrigerant Precaution ................................4

Oil Precaution ............................................................5

Precaution for Refrigerant Connection ......................5

Precaution for Service of Compressor ................ ......7

Precaution for Service Equipment ....................... ......8

Precaution for Leak Detection Dye ...........................9

PREPARATION ..................................................11

HFC-134a (R-134a) Service Tool and Equipment ....11

Commercial Service Tool ........................................14

REFRIGERATION SYSTEM ..............................15

Refrigerant Cycle ................................................ ....15

Refrigerant System Protection ................................15

Component Part Location ................................... ....16

OIL ......................................................................17

Maintenance of Oil Quantity in Compressor ....... ....17

AIR CONDITIONER CONTROL .........................19

Control Operation ................................................ ....19

Discharge Air Flow ..................................................20

System Description .................................................20

TROUBLE DIAGNOSIS .....................................22

CONSULT-III Function (BCM) ............................. ....22

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ......................................................

23

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

23

Schematic ...............................................................26

Wiring Diagram - Heater - .......................................27

Wiring Diagram - A/C,M - .................................... ....28

Operational Check ...................................................31

Mode Door ...............................................................32

Air Mix Door .............................................................33

Intake Door ..............................................................34

Front Blower Motor Circuit .......................................34

Magnet Clutch Circuit (If Equipped) ..................... ....38

Insufficient Cooling ..................................................46

Insufficient Heating ..................................................53

Noise .......................................................................54

CONTROLLER ..................................................56

Removal and Installation .........................................56

Disassembly and Assembly .....................................57

THERMO CONTROL AMPLIFIER ....................58

Removal and Installation .........................................58

A/C UNIT ASSEMBLY ......................................59

Removal and Installation .........................................59

Disassembly and Assembly .....................................61

BLOWER MOTOR ............................................63

Removal and Installation .........................................63

INTAKE DOOR ..................................................64

Intake Door Cable Adjustment .................................64

AIR MIX DOOR .................................................65

Air Mix Door Cable Adjustment ...............................65

MODE DOOR ....................................................66

Mode Door Cable Adjustment .................................66

BLOWER FAN RESISTOR ...............................67

Removal and Installation .........................................67

HEATER CORE .................................................68

Removal and Installation .........................................68

AIR CONDITIONER FILTER .............................69

Removal and Installation .........................................69

Revision: January 20102010 Versa

Page 3282 of 3745

PRECAUTIONSMTC-3

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006022079

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005396473

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3289 of 3745

MTC-10

< SERVICE INFORMATION >

PRECAUTIONS

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bot tle (1/4 ounce /7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in CFC-12 (R-12) A/C s ystem or CFC-12 (R-12) leak detector dye in HFC-

134a (R-134a) A/C syst em or A/C system damage may result.

• The fluorescent properties of the dye will remain for over three (3) years unless a compressor malfunction

occurs.

IDENTIFICATION LABEL FOR VEHICLE

Vehicles with factory installed fluorescent dye have an identification label on the front underside of the hood.

NOTE:

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Revision: January 20102010 Versa

Page 3304 of 3745

TROUBLE DIAGNOSISMTC-25

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

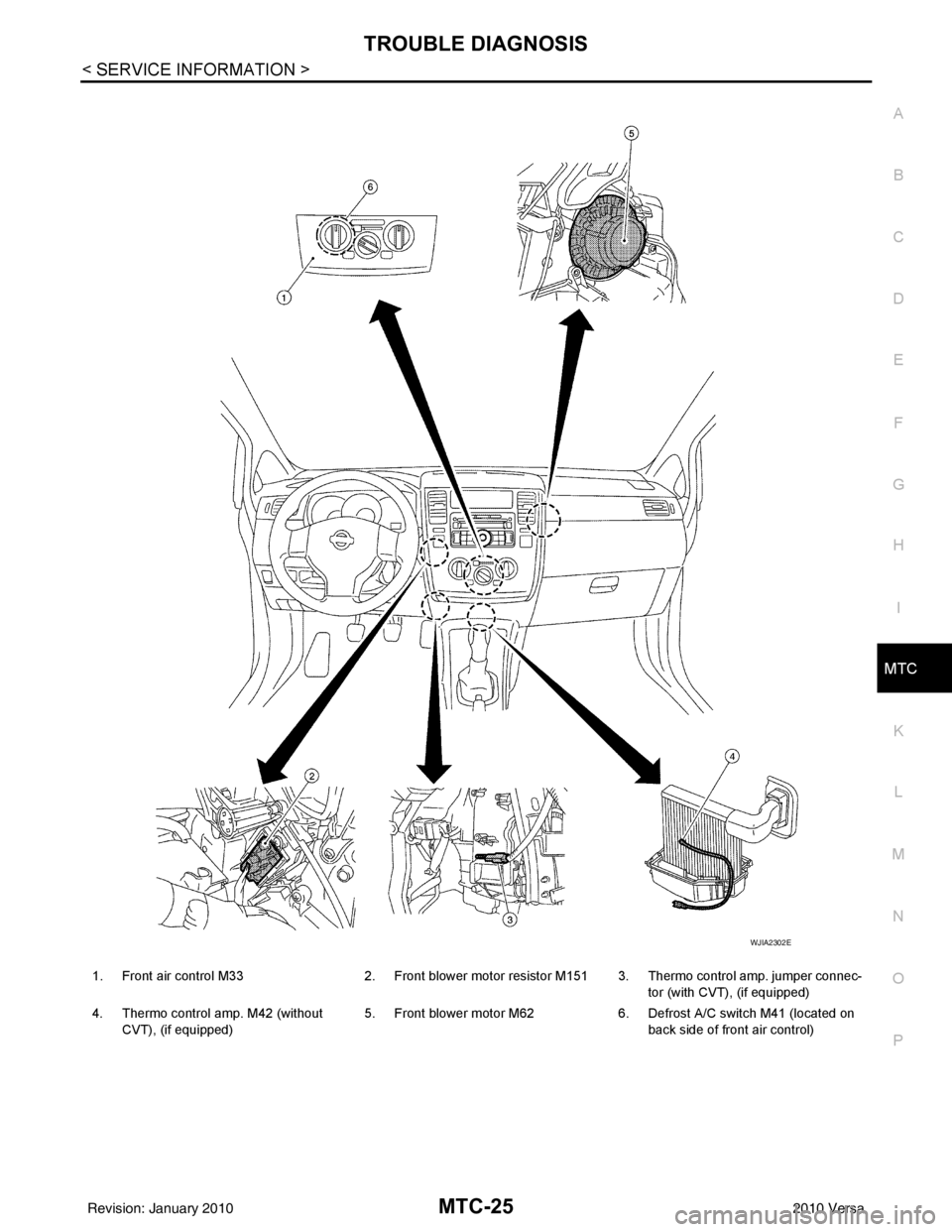

1. Front air control M33 2. Front blower motor resistor M151 3. Thermo control amp. jumper connec-

tor (with CVT), (if equipped)

4. Thermo control amp. M42 (without CVT), (if equipped) 5. Front blower motor M62

6. Defrost A/C switch M41 (located on

back side of front air control)

WJIA2302E

Revision: January 20102010 Versa