Brake system NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1 of 3787

-1

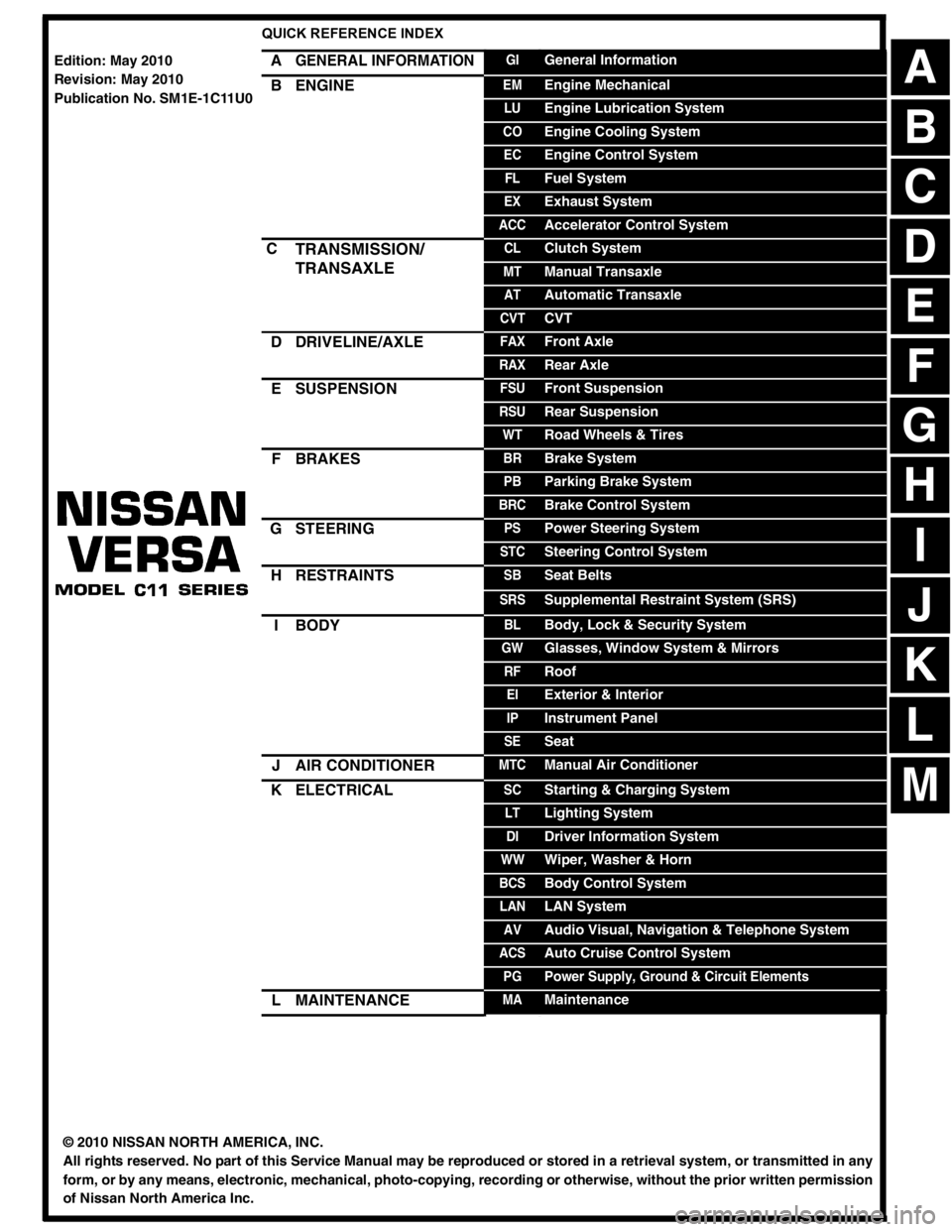

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: May 2010

Revision: May 2010

Publication No. SM1E-1C11U0

B

D

© 2010 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 11 of 3787

QUICK REFERENCE INDEX: VERSA

2011

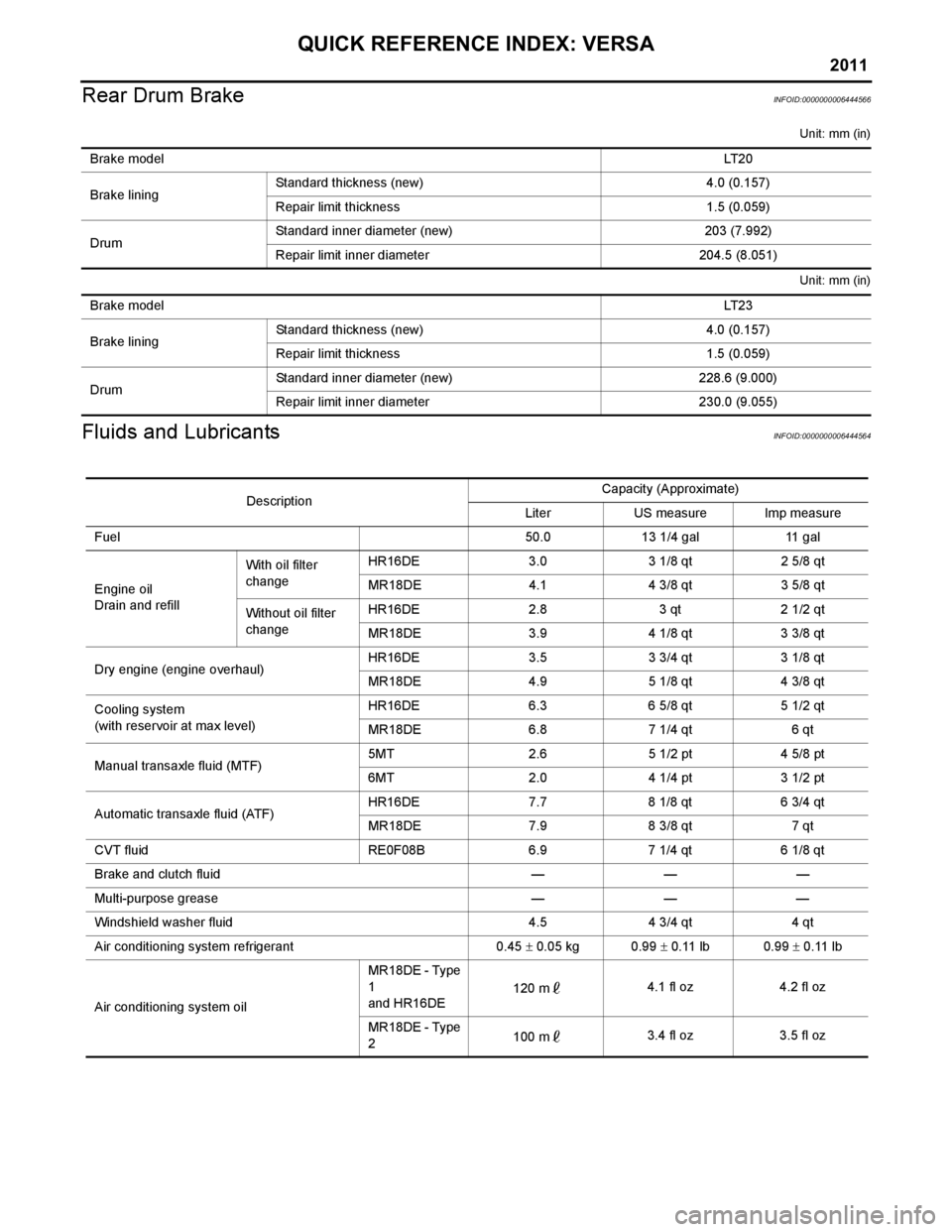

Rear Drum BrakeINFOID:0000000006444566

Unit: mm (in)

Unit: mm (in)

Fluids and LubricantsINFOID:0000000006444564

Brake modelLT 2 0

Brake lining Standard thickness (new)

4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

203 (7.992)

Repair limit inner diameter 204.5 (8.051)

Brake model LT 2 3

Brake lining Standard thickness

(new) 4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

228.6 (9.000)

Repair limit inner diameter 230.0 (9.055)

DescriptionCapacity (Approximate)

Liter US measure Imp measure

Fuel 50.013 1/4 gal 11 gal

Engine oil

Drain and refill With oil filter

change

HR16DE

3.03 1/8 qt 2 5/8 qt

MR18DE 4.14 3/8 qt 3 5/8 qt

Without oil filter

change HR16DE

2.83 qt2 1/2 qt

MR18DE 3.94 1/8 qt 3 3/8 qt

Dry engine (engine overhaul) HR16DE

3.53 3/4 qt 3 1/8 qt

MR18DE 4.95 1/8 qt 4 3/8 qt

Cooling system

(with reservoir at max level) HR16DE

6.36 5/8 qt 5 1/2 qt

MR18DE 6.87 1/4 qt 6 qt

Manual transaxle fluid (MTF) 5MT

2.65 1/2 pt 4 5/8 pt

6MT 2.04 1/4 pt 3 1/2 pt

Automatic transaxle fluid (ATF) HR16DE

7.78 1/8 qt 6 3/4 qt

MR18DE 7.98 3/8 qt 7 qt

CVT fluid RE0F08B6.97 1/4 qt 6 1/8 qt

Brake and clutch fluid —— —

Multi-purpose grease —— —

Windshield washer fluid 4.54 3/4 qt 4 qt

Air conditioning system refrigerant 0.45 ± 0.05 kg 0.99 ± 0.11 lb 0.99 ± 0.11 lb

Air conditioning system oil MR18DE - Type

1

and HR16DE

120 m

4.1 fl oz

4.2 fl oz

MR18DE - Type

2 100 m

3.4 fl oz

3.5 fl oz

Page 18 of 3787

AT-1

TRANSMISSION/TRANSAXLE

DE

F

G H

I

J

K L

M

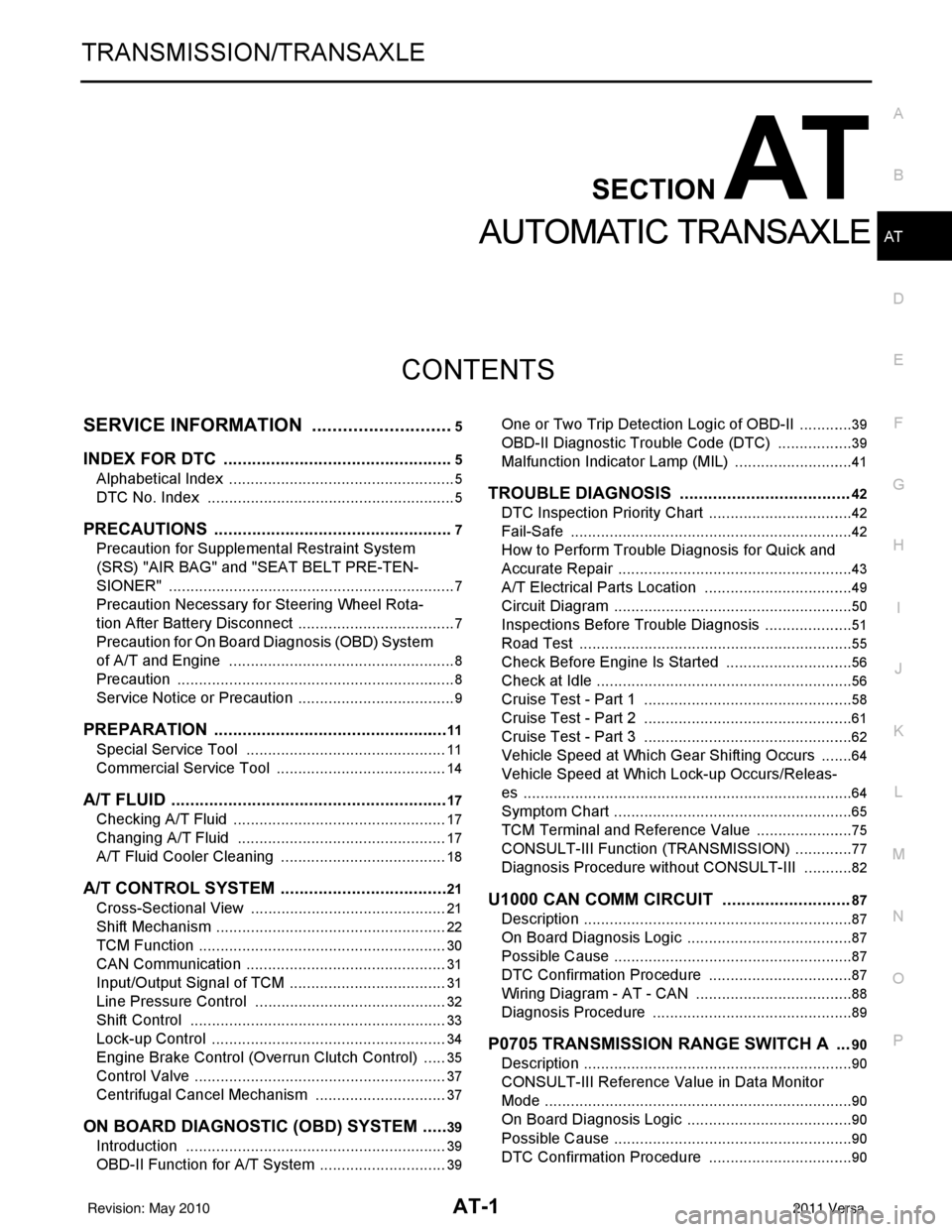

SECTION AT

A

B

AT

N

O P

CONTENTS

AUTOMATIC TRANSAXLE

SERVICE INFORMATION .. ..........................5

INDEX FOR DTC ............................................ .....5

Alphabetical Index ............................................... ......5

DTC No. Index ..........................................................5

PRECAUTIONS ...................................................7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

7

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

7

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine .....................................................

8

Precaution .................................................................8

Service Notice or Precaution .....................................9

PREPARATION ..................................................11

Special Service Tool ........................................... ....11

Commercial Service Tool ........................................14

A/T FLUID ...........................................................17

Checking A/T Fluid ..................................................17

Changing A/T Fluid .................................................17

A/T Fluid Cooler Cleaning .......................................18

A/T CONTROL SYSTEM ....................................21

Cross-Sectional View ..............................................21

Shift Mechanism .................................................. ....22

TCM Function ..........................................................30

CAN Communication ...............................................31

Input/Output Signal of TCM .....................................31

Line Pressure Control .............................................32

Shift Control ........................................................ ....33

Lock-up Control .......................................................34

Engine Brake Control (Overrun Clutch Control) ......35

Control Valve ....................................................... ....37

Centrifugal Cancel Mechanism ...............................37

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......39

Introduction ......................................................... ....39

OBD-II Function for A/T System ..............................39

One or Two Trip Detection Logic of OBD-II ......... ....39

OBD-II Diagnostic Trouble Code (DTC) ..................39

Malfunction Indicator Lamp (MIL) ............................41

TROUBLE DIAGNOSIS ....................................42

DTC Inspection Priority Chart ..................................42

Fail-Safe ..................................................................42

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

43

A/T Electrical Parts Location ...................................49

Circuit Diagram ........................................................50

Inspections Before Trouble Diagnosis .....................51

Road Test ................................................................55

Check Before Engine Is Started ..............................56

Check at Idle ............................................................56

Cruise Test - Part 1 .................................................58

Cruise Test - Part 2 .................................................61

Cruise Test - Part 3 .................................................62

Vehicle Speed at Which Gear Shifting Occurs ........64

Vehicle Speed at Which Lock-up Occurs/Releas-

es .............................................................................

64

Symptom Chart ........................................................65

TCM Terminal and Reference Value .......................75

CONSULT-III Function (TRANSMISSION) .......... ....77

Diagnosis Procedure without CONSULT-III ............82

U1000 CAN COMM CIRCUIT ...........................87

Description ........................................................... ....87

On Board Diagnosis Logic .......................................87

Possible Cause ........................................................87

DTC Confirmation Procedure ..................................87

Wiring Diagram - AT - CAN .....................................88

Diagnosis Procedure ...............................................89

P0705 TRANSMISSION RANGE SWITCH A ...90

Description ...............................................................90

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ....

90

On Board Diagnosis Logic .......................................90

Possible Cause ........................................................90

DTC Confirmation Procedure ..................................90

Revision: May 2010 2011 Versa

Page 20 of 3787

AT-3

DE

F

G H

I

J

K L

M A

B

AT

N

O

P

N

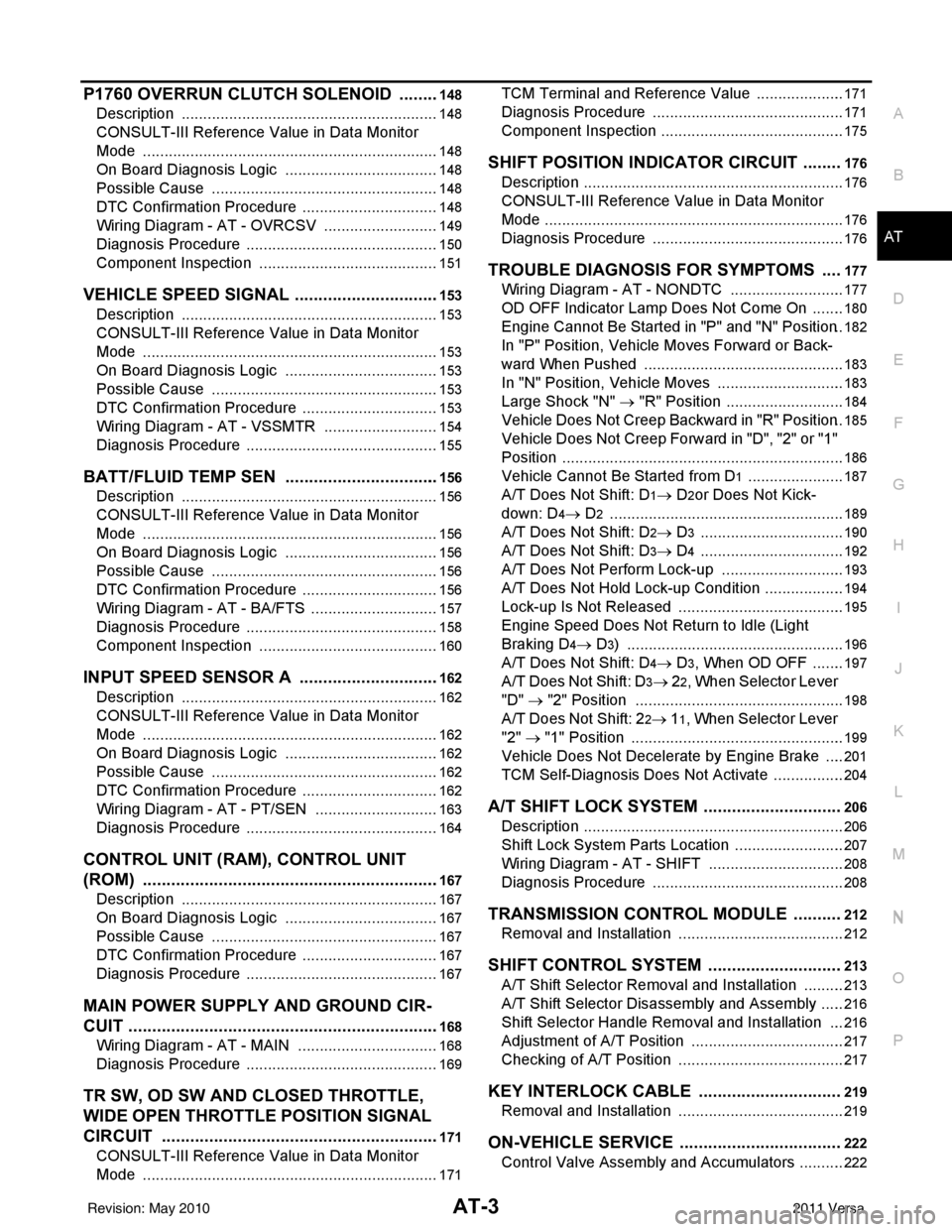

P1760 OVERRUN CLUTCH

SOLENOID .........148

Description .......................................................... ..148

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

148

On Board Diagnosis Logic ....................................148

Possible Cause .....................................................148

DTC Confirmation Procedure ................................148

Wiring Diagram - AT - OVRCSV ...........................149

Diagnosis Procedure .............................................150

Component Inspection ..........................................151

VEHICLE SPEED SIGNAL ...............................153

Description .......................................................... ..153

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

153

On Board Diagnosis Logic ....................................153

Possible Cause .....................................................153

DTC Confirmation Procedure ................................153

Wiring Diagram - AT - VSSMTR ...........................154

Diagnosis Procedure ........................................... ..155

BATT/FLUID TEMP SEN .................................156

Description .......................................................... ..156

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

156

On Board Diagnosis Logic ....................................156

Possible Cause .....................................................156

DTC Confirmation Procedure ................................156

Wiring Diagram - AT - BA/FTS ..............................157

Diagnosis Procedure .............................................158

Component Inspection ..........................................160

INPUT SPEED SENSOR A ..............................162

Description .......................................................... ..162

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

162

On Board Diagnosis Logic ....................................162

Possible Cause .....................................................162

DTC Confirmation Procedure ................................162

Wiring Diagram - AT - PT/SEN .............................163

Diagnosis Procedure .............................................164

CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...............................................................

167

Description .......................................................... ..167

On Board Diagnosis Logic ....................................167

Possible Cause .....................................................167

DTC Confirmation Procedure ................................167

Diagnosis Procedure .............................................167

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................

168

Wiring Diagram - AT - MAIN ............................... ..168

Diagnosis Procedure .............................................169

TR SW, OD SW AND CLOSED THROTTLE,

WIDE OPEN THROTTLE POSITION SIGNAL

CIRCUIT ......................................................... ..

171

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

171

TCM Terminal and Reference Value .....................171

Diagnosis Procedure ........................................... ..171

Component Inspection ...........................................175

SHIFT POSITION INDICATOR CIRCUIT ........176

Description .............................................................176

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

176

Diagnosis Procedure .............................................176

TROUBLE DIAGNOSIS FOR SYMPTOMS ....177

Wiring Diagram - AT - NONDTC ...........................177

OD OFF Indicator Lamp Does Not Come On ........180

Engine Cannot Be Started in "P" and "N" Position ..182

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

183

In "N" Position, Vehicle Moves ..............................183

Large Shock "N" → "R" Position .......................... ..184

Vehicle Does Not Creep Backward in "R" Position ..185

Vehicle Does Not Creep Forward in "D", "2" or "1"

Position ................................................................ ..

186

Vehicle Cannot Be Started from D1 .......................187

A/T Does Not Shift: D1→ D2or Does Not Kick-

down: D

4→ D2 ..................................................... ..189

A/T Does Not Shift: D2→ D3 ................................ ..190

A/T Does Not Shift: D3→ D4 ................................ ..192

A/T Does Not Perform Lock-up ........................... ..193

A/T Does Not Hold Lock-up Condition ...................194

Lock-up Is Not Released .......................................195

Engine Speed Does Not Return to Idle (Light

Braking D

4→ D3) ................................................. ..196

A/T Does Not Shift: D4→ D3, When OD OFF ...... ..197

A/T Does Not Shift: D3→ 22, When Selector Lever

"D" → "2" Position ............................................... ..

198

A/T Does Not Shift: 22→ 11, When Selector Lever

"2" → "1" Position ................................................ ..

199

Vehicle Does Not Decelerate by Engine Brake ... ..201

TCM Self-Diagnosis Does Not Activate .................204

A/T SHIFT LOCK SYSTEM .............................206

Description .............................................................206

Shift Lock System Parts Location ..........................207

Wiring Diagram - AT - SHIFT ................................208

Diagnosis Procedure .............................................208

TRANSMISSION CONTROL MODULE ..........212

Removal and Installation .......................................212

SHIFT CONTROL SYSTEM ............................213

A/T Shift Selector Removal and Installation ........ ..213

A/T Shift Selector Disassembly and Assembly ......216

Shift Selector Handle Removal and Installation ....216

Adjustment of A/T Position ....................................217

Checking of A/T Position .......................................217

KEY INTERLOCK CABLE ..............................219

Removal and Installation .......................................219

ON-VEHICLE SERVICE ..................................222

Control Valve Assembly and Accumulators ...........222

Revision: May 2010 2011 Versa

Page 38 of 3787

A/T CONTROL SYSTEMAT-21

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

A/T CONTROL SYSTEM

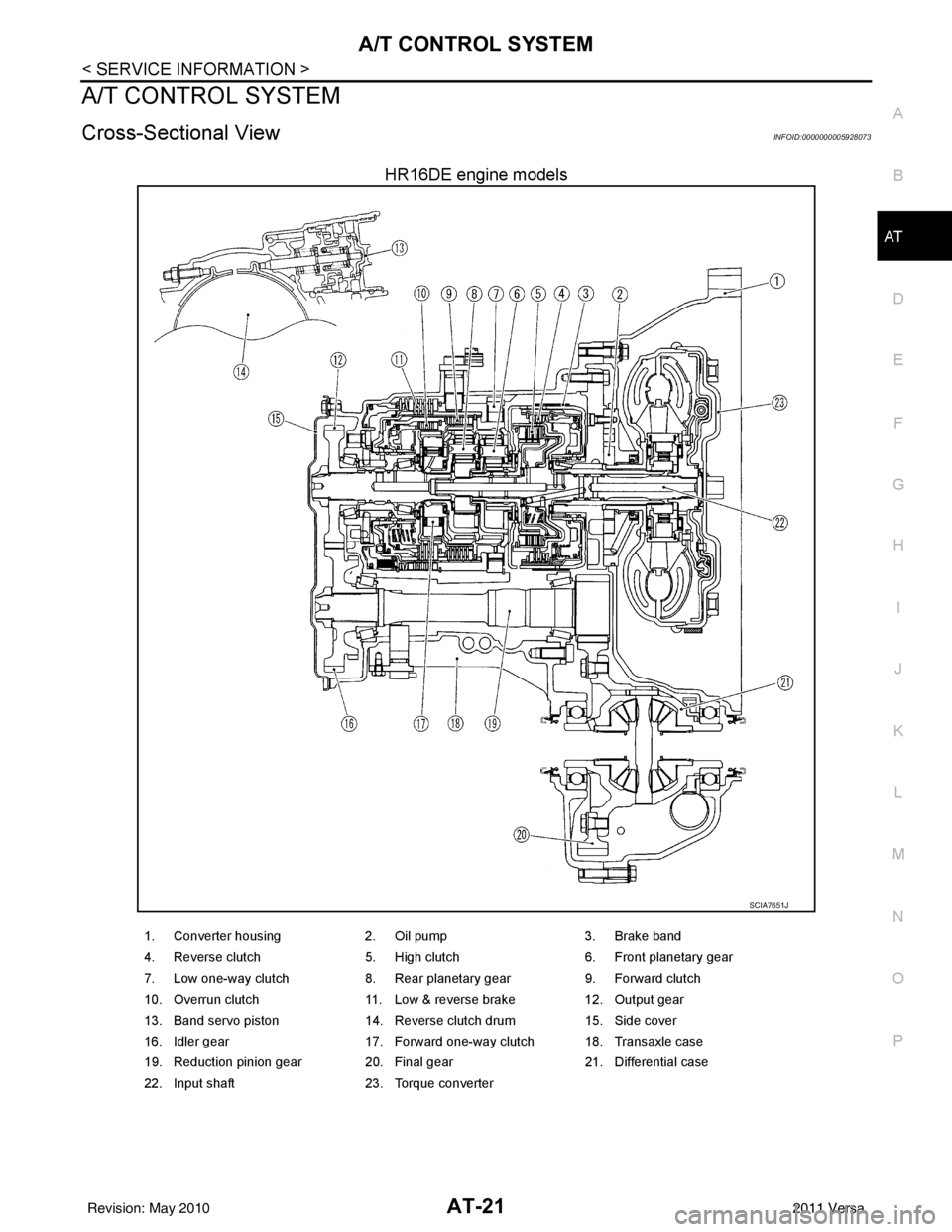

Cross-Sectional ViewINFOID:0000000005928073

HR16DE engine models

SCIA7651J

1. Converter housing 2. Oil pump3. Brake band

4. Reverse clutch 5. High clutch6. Front planetary gear

7. Low one-way clutch 8. Rear planetary gear9. Forward clutch

10. Overrun clutch 11. Low & reverse brake12. Output gear

13. Band servo piston 14. Reverse clutch drum15. Side cover

16. Idler gear 17. Forward one-way clutch 18. Transaxle case

19. Reduction pinion gear 20. Final gear 21. Differential case

22. Input shaft 23. Torque converter

Revision: May 2010 2011 Versa

Page 39 of 3787

AT-22

< SERVICE INFORMATION >

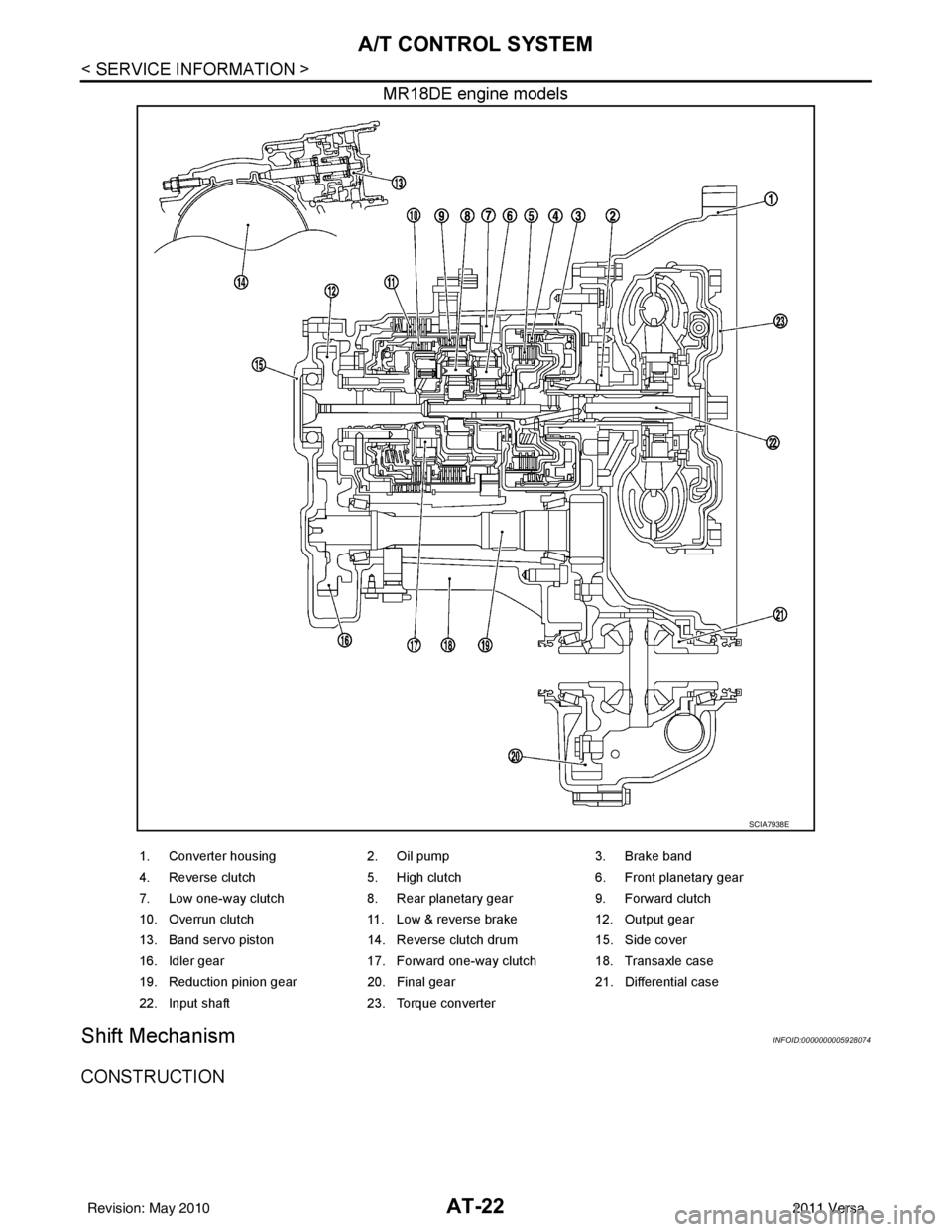

A/T CONTROL SYSTEM

MR18DE engine models

Shift MechanismINFOID:0000000005928074

CONSTRUCTION

SCIA7938E

1. Converter housing2. Oil pump3. Brake band

4. Reverse clutch 5. High clutch6. Front planetary gear

7. Low one-way clutch 8. Rear planetary gear9. Forward clutch

10. Overrun clutch 11. Low & reverse brake12. Output gear

13. Band servo piston 14. Reverse clutch drum15. Side cover

16. Idler gear 17. Forward one-way clutch 18. Transaxle case

19. Reduction pinion gear 20. Final gear21. Differential case

22. Input shaft 23. Torque converter

Revision: May 2010 2011 Versa

Page 40 of 3787

A/T CONTROL SYSTEMAT-23

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

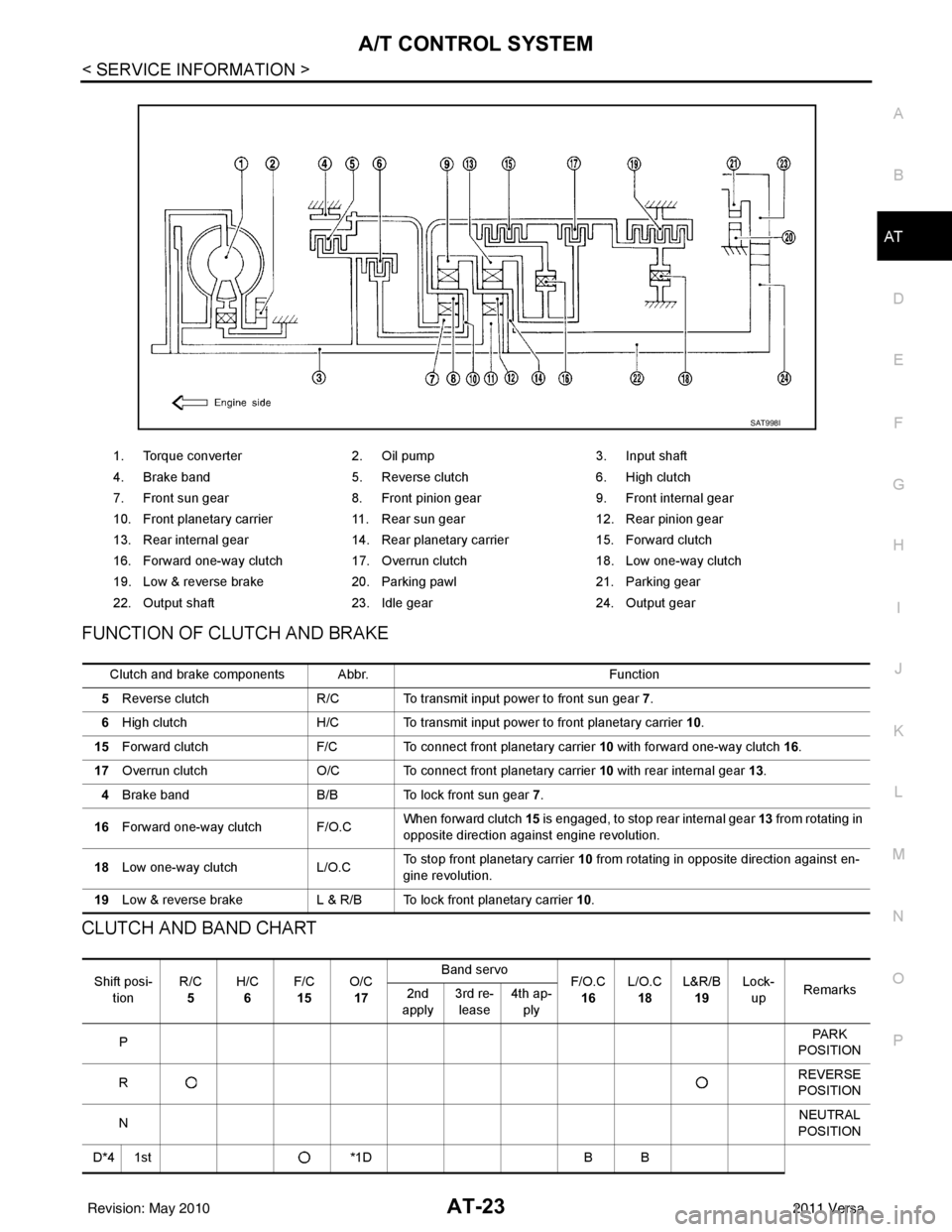

FUNCTION OF CLUTCH AND BRAKE

CLUTCH AND BAND CHART

1. Torque converter 2. Oil pump 3. Input shaft

4. Brake band 5. Reverse clutch 6. High clutch

7. Front sun gear 8. Front pinion gear 9. Front internal gear

10. Front planetary carrier 11. Rear sun gear 12. Rear pinion gear

13. Rear internal gear 14. Rear planetary carrier 15. Forward clutch

16. Forward one-way clutch 17. Overrun clutch 18. Low one-way clutch

19. Low & reverse brake 20. Parking pawl 21. Parking gear

22. Output shaft 23. Idle gear 24. Output gear

SAT998I

Clutch and brake components Abbr. Function

5 Reverse clutch R/C To transmit input power to front sun gear 7 .

6 High clutch H/C To transmit input power to front planetary carrier 10.

15 Forward clutch F/C To connect front planetary carrier 10 with forward one-way clutch 16.

17 Overrun clutch O/C To connect front planetary carrier 10 with rear internal gear 13 .

4 Brake band B/B To lock front sun gear 7.

16 Forward one-way clutch F/O.C When forward clutch 15

is engaged, to stop rear internal gear 13 from rotating in

opposite direction against engine revolution.

18 Low one-way clutch L/O.CTo stop front planetary carrier

10 from rotating in opposite direction against en-

gine revolution.

19 Low & reverse brake L & R/B To lock front planetary carrier 10.

Shift posi-

tion R/C

5 H/C

6 F/C

15 O/C

17 Band servo

F/O.C

16 L/O.C

18 L&R/B

19 Lock-

up Remarks

2nd

apply 3rd re-

lease 4th ap-

ply

P PA R K

POSITION

R REVERSE

POSITION

N NEUTRAL

POSITION

D*4 1st *1DB B

Revision: May 2010 2011 Versa

Page 41 of 3787

AT-24

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

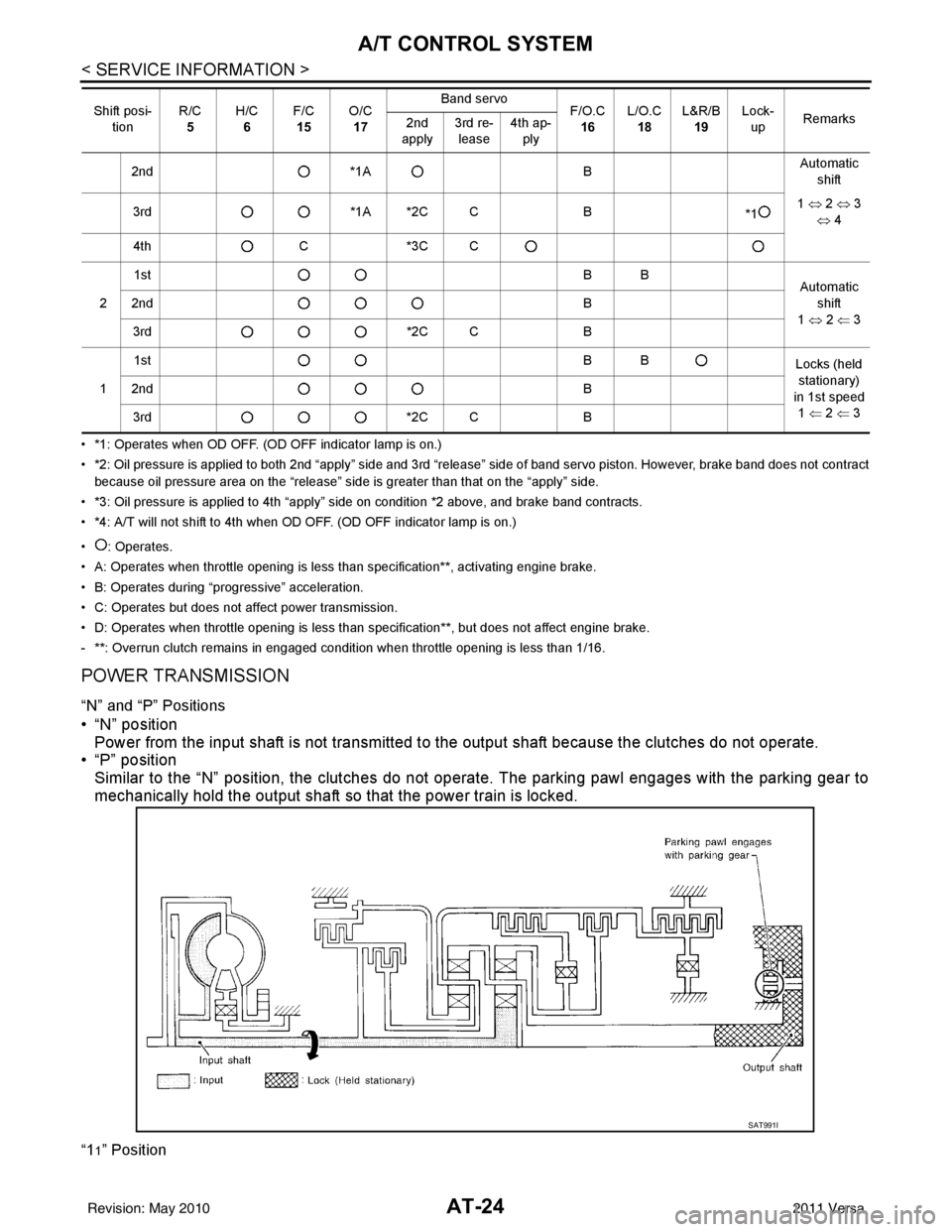

• *1: Operates when OD OFF. (OD OFF indicator lamp is on.)

• *2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not contract

because oil pressure area on the “release” side is greater than that on the “apply” side.

• *3: Oil pressure is applied to 4th “apply” side on condition *2 above, and brake band contracts.

• *4: A/T will not shift to 4th when OD OFF. (OD OFF indicator lamp is on.)

• : Operates.

• A: Operates when throttle opening is less than specification**, activating engine brake.

• B: Operates during “pro gressive” acceleration.

• C: Operates but does not affect power transmission.

• D: Operates when throttle opening is less than specification**, but does not affect engine brake.

- **: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

POWER TRANSMISSION

“N” and “P” Positions

• “N” position Power from the input shaft is not transmitted to the output shaft because the clutches do not operate.

• “P” position

Similar to the “N” position, the clutches do not operate. The parking pawl engages with the parking gear to

mechanically hold the output shaft so that the power train is locked.

“11” Position

2nd *1A BAutomatic

shift

3rd *1A *2C C B

*11

⇔ 2 ⇔ 3

⇔ 4

4th C*3C C

2 1st

BB

Automatic

shift

1 ⇔ 2 ⇐ 3

2nd

B

3rd *2C CB

1 1st

BB

Locks (held

stationary)

in 1st speed 1 ⇐ 2 ⇐ 3

2nd

B

3rd *2C CB

Shift posi-

tion R/C

5 H/C

6 F/C

15 O/C

17 Band servo

F/O.C

16 L/O.C

18 L&R/B

19 Lock-

up Remarks

2nd

apply 3rd re-

lease 4th ap-

ply

SAT991I

Revision: May 2010 2011 Versa

Page 42 of 3787

A/T CONTROL SYSTEMAT-25

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

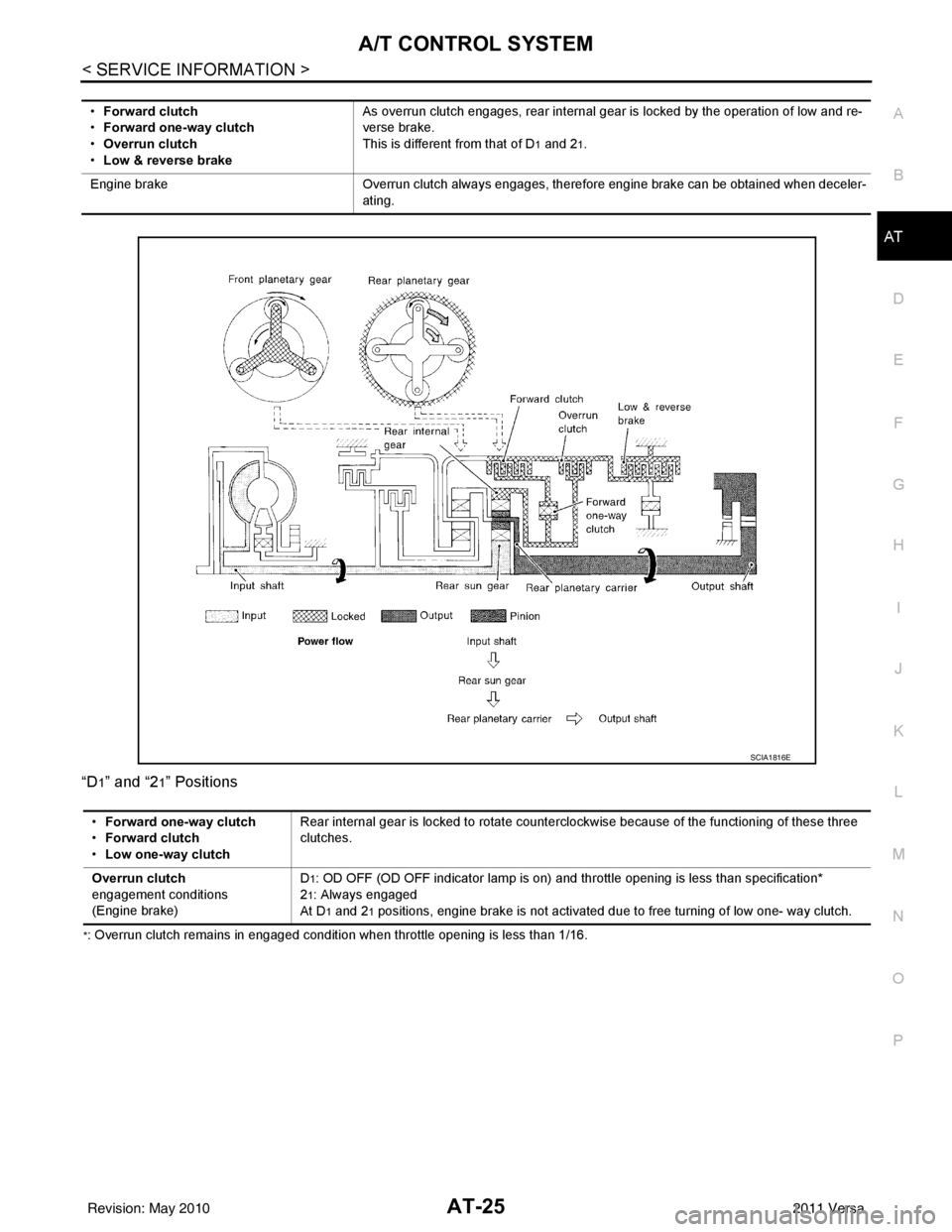

“D

1” and “21” Positions

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16. •

Forward clutch

• Forward one-way clutch

• Overrun clutch

• Low & reverse brake As overrun clutch engages, rear internal gear is locked by the operation of low and re-

verse brake.

This is different from that of D

1 and 21.

Engine brake Overrun clutch always engages, therefore engine brake can be obtained when deceler-

ating.

SCIA1816E

• Forward one-way clutch

• Forward clutch

• Low one-way clutch Rear internal gear is locked to rotate counterclockwise because of the functioning of these three

clutches.

Overrun clutch

engagement conditions

(Engine brake) D

1: OD OFF (OD OFF indicator lamp is on) and th

rottle opening is less than specification*

2

1: Always engaged

At D

1 and 21 positions, engine brake is not activated due to free turning of low one- way clutch.

Revision: May 2010 2011 Versa

Page 43 of 3787

AT-26

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

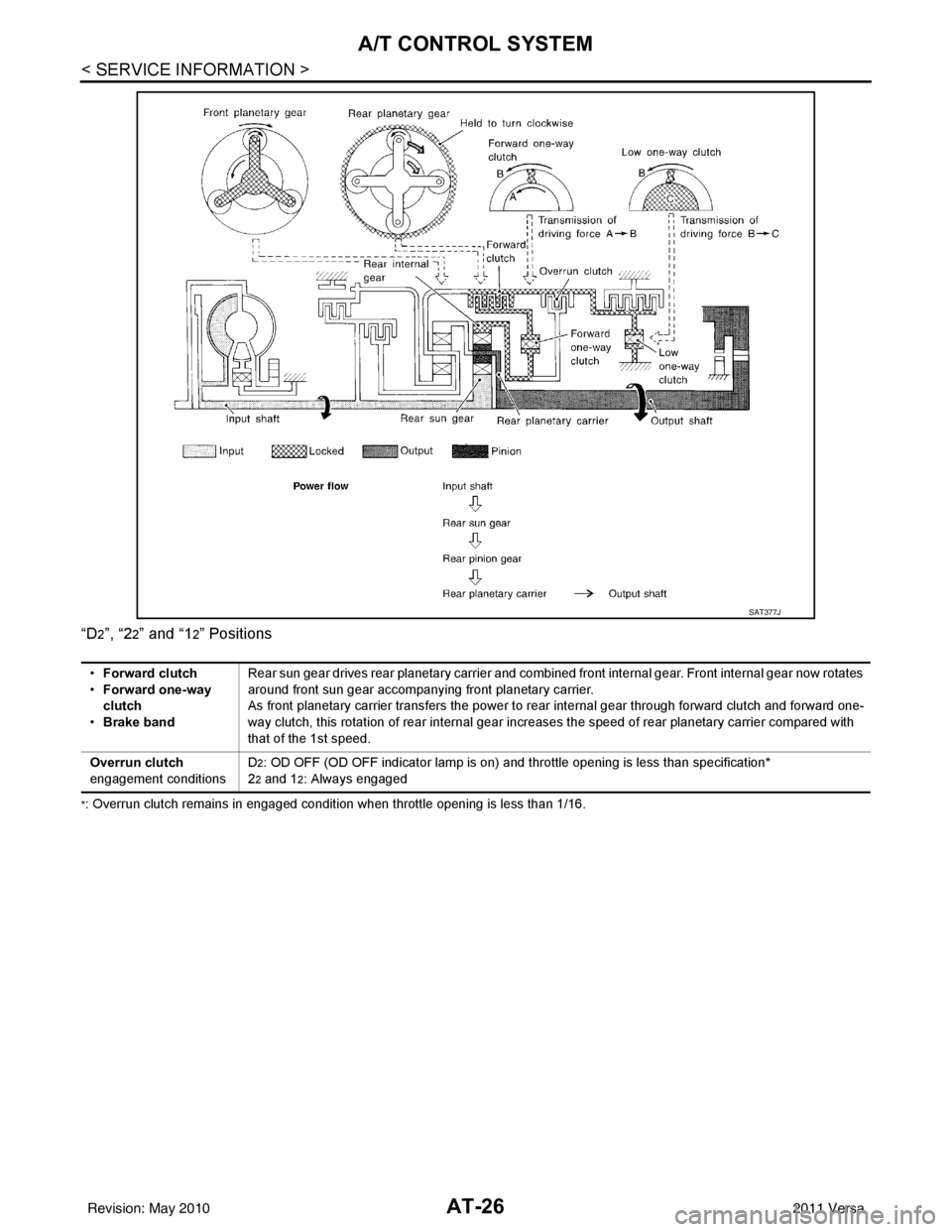

“D2”, “22” and “12” Positions

*: Overrun clutch remains in engaged condition when throttle opening is less than 1/16.

SAT377J

•Forward clutch

• Forward one-way

clutch

• Brake band Rear sun gear drives rear planetary carrier and combined front internal gear. Front internal gear now rotates

around front sun gear accompanying front planetary carrier.

As front planetary carrier transfers the power to rear internal gear through forward clutch and forward one-

way clutch, this rotation of rear internal gear increases the speed of rear planetary carrier compared with

that of the 1st speed.

Overrun clutch

engagement conditions D

2: OD OFF (OD OFF indicator lamp is on) and throttle opening is less than specification*

2

2 and 12: Always engaged

Revision: May 2010 2011 Versa