ECU NISSAN TITAN 2018 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2018, Model line: TITAN, Model: NISSAN TITAN 2018Pages: 650, PDF Size: 7.54 MB

Page 548 of 650

secondary latch keeps the hood from

opening when the primary latch is re-

leased.

When driving in areas using road salt or

other corrosive materials, check lubrica-

tion frequently.

Lights*:Clean the headlights on a regular

basis. Make sure that the headlights, stop

lights, tail lights, turn signal lights, and other

lights are all operating properly and in-

stalled securely. Also check headlight aim.

Road wheel nuts (lug nuts)*: When check-

ing the tires, make sure no wheel nuts are

missing, and check for any loose wheel

nuts. Tighten if necessary.

Tire rotation*: Tires should be rotated ev-

ery 5,000 miles (8,000 km).

Tires*: Check the pressure with a gauge

of ten and always prior to long distance

trips. If necessary, adjust the pressure in all

tires, including the spare, to the pressure

specified. Check carefully for damage, cuts

or excessive wear.

Tire Pressure Monitoring System (TPMS)

transmitter components: Replace the

TPMS transmitter grommet seal, valve core

and cap when the tires are replaced due to

wear or age. Wheel alignment and balance:

If the ve-

hicle should pull to either side while driving

on a straight and level road, or if you detect

uneven or abnormal tire wear, there may

be a need for wheel alignment. If the steer-

ing wheel or seat vibrates at normal high-

way speeds, wheel balancing may be

needed.

For additional information regarding tires,

refer to “Important Tire Safety Information”

(US) or “Tire Safety Information” (Canada) in

the Warranty Information Booklet.

Windshield: Clean the windshield on a

regular basis. Check the windshield at least

every six months for cracks or other dam-

age. Have a damaged windshield repaired

by a qualified repair facility.

Windshield wiper blades*: Check for

cracks or wear if they do not wipe properly.

Inside the vehicle

The maintenance items listed here should

be checked on a regular basis, such as

when performing scheduled maintenance,

cleaning the vehicle, etc.

Accelerator pedal: Check the pedal for

smooth operation and make sure the pedal does not bind or require uneven ef-

fort. Keep the floor mat away from the

pedal.

Automatic transmission P (Park) posi-

tion mechanism:

On a fairly steep hill

check that your vehicle is held securely

with the shif t lever in the P (Park) position

without applying any brakes.

Brake pedal: Check the pedal for smooth

operation. If the brake pedal suddenly goes

down further than normal, the pedal feels

spongy or the vehicle seems to take longer

to stop, have your vehicle checked imme-

diately. It is recommended that you visit a

NISSAN dealer for this service.

Brakes: Check that the brakes do not pull

the vehicle to one side when applied.

Parking brake: Check the parking brake

operation regularly. The vehicle should be

securely held on a fairly steep hill with only

the parking brake applied. If the parking

brake needs adjustment, it is recom-

mended that you visit a NISSAN dealer for

this service.

Seats: Check seat position controls such

as seat adjusters, seatback recliner, etc., to

ensure they operate smoothly and all

latches lock securely in every position.

Maintenance and schedules9-3

Page 549 of 650

Check that the head restraints/headrests

move up and down smoothly and the locks

(if so equipped) hold securely in all latched

positions.

Seat belts:Check that all parts of the seat

belt system (for example, buckles, anchors,

adjusters and retractors) operate properly

and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying,

wear or damage.

Steering wheel: Check for changes in the

steering system, such as excessive free-

play, hard steering or strange noises.

Warning lights and chimes: Make sure all

warning lights and chimes are operating

properly.

Windshield wiper and washer*: Check

that the wipers and washer operate prop-

erly and that the wipers do not streak.

Windshield defroster: Check that the air

comes out of the defroster outlets properly

and in sufficient quantity when operating

the heater or air conditioner.

Under the hood and vehicle

The maintenance items listed here should

be checked periodically (for example, each

time you check the engine oil or refuel). Battery* (for serviceable batteries):

Check the fluid level in each cell. The fluid

should be at the bottom of the filler open-

ing. Vehicles operated in high tempera-

tures or under severe conditions require

frequent checks of the battery fluid level.

NOTE:

Care should be taken to avoid situations

that can lead to potential battery dis-

charge and potential no-start conditions

such as:

1. Installation or extended use of elec-

tronic accessories that consume bat-

tery power when the engine is not

running (Phone chargers, GPS, DVD

players, etc.).

2. Vehicle is not driven regularly and/or

only driven short distances.

In these cases, the battery may need to

be charged to maintain battery health.

Brake fluid level*: Make sure that the brake

fluid level is between the MIN and MAX lines

on the reservoir.

Engine coolant level*: Check the coolant

level when the engine is cold. Engine drive belts*:

Make sure the drive

belts are not frayed, worn, cracked or oily.

Engine oil level*: Check the level af ter

parking the vehicle on a level surface with

the engine off. Wait more than 10 minutes

for the oil to drain back into the oil pan.

Exhaust system: Visually inspect the ex-

haust pipes, muffler and hangers for leaks,

cracks, deterioration and damage. Tighten

connections or replace parts as necessary.

For additional information, refer to “Exhaust

gas (carbon monoxide)” in the “Starting and

driving” section of this manual.

Fluid leaks: Check under the vehicle for

fuel, oil, water or other fluid leaks af ter the

vehicle has been parked for a while. Water

dripping from the air conditioner af ter use

is normal. If you should notice any leaks or if

fuel fumes are evident, check for the cause

and have it corrected immediately.

Power steering fluid level* and lines:

Check the level when the fluid is cold, with

the engine off. Check the lines for proper

attachment, leaks, cracks, etc.

9-4Maintenance and schedules

Page 567 of 650

10 Technical and consumer information

Recommended fluids/lubricants and

capacities...................................... 10-2

Fuel recommendation ....................... 10-4

Engine oil and oil filter

recommendations (for gas engine only) .....10-7

Air conditioner system refrigerant and

oil recommendations .......................10-8

Specifications .................................. 10-9

Engine ...................................... 10-9

Wheels and tires ............................ 10-10

Dimensions and weights ....................10-11

When traveling or registering in another

country ........................................ 10-17

Vehicle identification .......................... 10-17

Vehicle Identification Number (VIN)

plate ....................................... 10-17

Vehicle identification number

(chassis number) ........................... 10-17

Engine serial number ....................... 10-18

F.M.V.S.S./C.M.V.S.S. certification label ........10-18

Emission control information label .........10-19

Tire and Loading Information label .........10-20

Air conditioner specification label ...........10-20

Installing front license plate ....................10-21Vehicle loading information

...................10-22

Terms ...................................... 10-22

Vehicle load capacity ....................... 10-23

Securing the load ........................... 10-24

Utili-track® channel system

(if so equipped) ............................. 10-25

Loading tips ................................ 10-33

Truck-camper loading information ............10-34

Crew cab models ........................... 10-34

King Cab® models .......................... 10-34

Special Body vehicles ....................... 10-34

Location for center of gravity ...............10-34

Vehicle load weight capacity ...............10-35

Measurement of weights ...................10-35

Towing a trailer ................................ 10-36

Maximum load

limits ....................... 10-36

Towing load/specification ..................10-40

Towing safety .............................. 10-45

Flat towing for 2-Wheel Drive (2WD)

vehicle (if so equipped) .....................10-61

Flat towing for 4-Wheel Drive (4WD)

vehicle (if so equipped) .....................10-61

Snowplow .................................... 10-61

Uniform tire quality grading ....................10-62

Page 591 of 650

Steps for determining correct

load limit

1. Locate the statement “The com-bined weight of occupants and

cargo should never exceed XXX

lbs. or XXX kg” on your vehicle’s

Tire and Loading Information la-

bel.

2. Determine the combined weight of the driver and passengers

that will be riding in your vehicle.

3. Subtract the combined weight of the driver and passengers

from XXX lbs. or XXX kg.

4. The resulting figure equals the available amount of cargo and

luggage load capacity. For ex-

ample, if the XXX amount equals

1,400 lbs. and there will be five

150 lbs. passengers in your ve-

hicle, the amount of available

cargo and luggage load capac-

ity is 650 lbs. (1,400-750 (5 X 150) =

650 lbs.) or (640-340 (5 X 70) =

300 kg.) 5. Determine the combined weight

of luggage and cargo being

loaded on the vehicle. That

weight may not safely exceed

the available cargo and luggage

load capacity calculated in

step 4.

6. If your vehicle will be towing a trailer, load from your trailer will

be transferred to your vehicle.

Consult this manual to deter-

mine how this reduces the avail-

able cargo and luggage load ca-

pacity of your vehicle.

Before driving a loaded vehicle, con-

firm that you do not exceed the

GVWR or the GAWR for your vehicle.

For additional information, refer to

“Measurement of weights” in this

section.

Also check tires for proper inflation

pressures. For additional informa-

tion, refer to “Tire and Loading Infor-

mation label” in the “Do-it-yourself ”

section of this manual.

SECURING THE LOAD

For your convenience, tie down hooks are

placed at each corner of the truck box.

These may be used to help secure cargo

loaded into the truck box.

WARNING

∙ Properly secure all cargo with ropes or straps to help prevent it from sliding

or shif ting. Do not place cargo higher

than the seatbacks. In a sudden stop

or collision, unsecured cargo could

cause personal injury.

LTI0102

10-24Technical and consumer information

Page 592 of 650

∙ Do not load your vehicle any heavierthan the GVWR or the maximum front

and rear GAWRs. If you do, parts of

your vehicle can break, tire damage

could occur, or it can change the way

your vehicle handles. This could result

in loss of control and cause personal

injury.

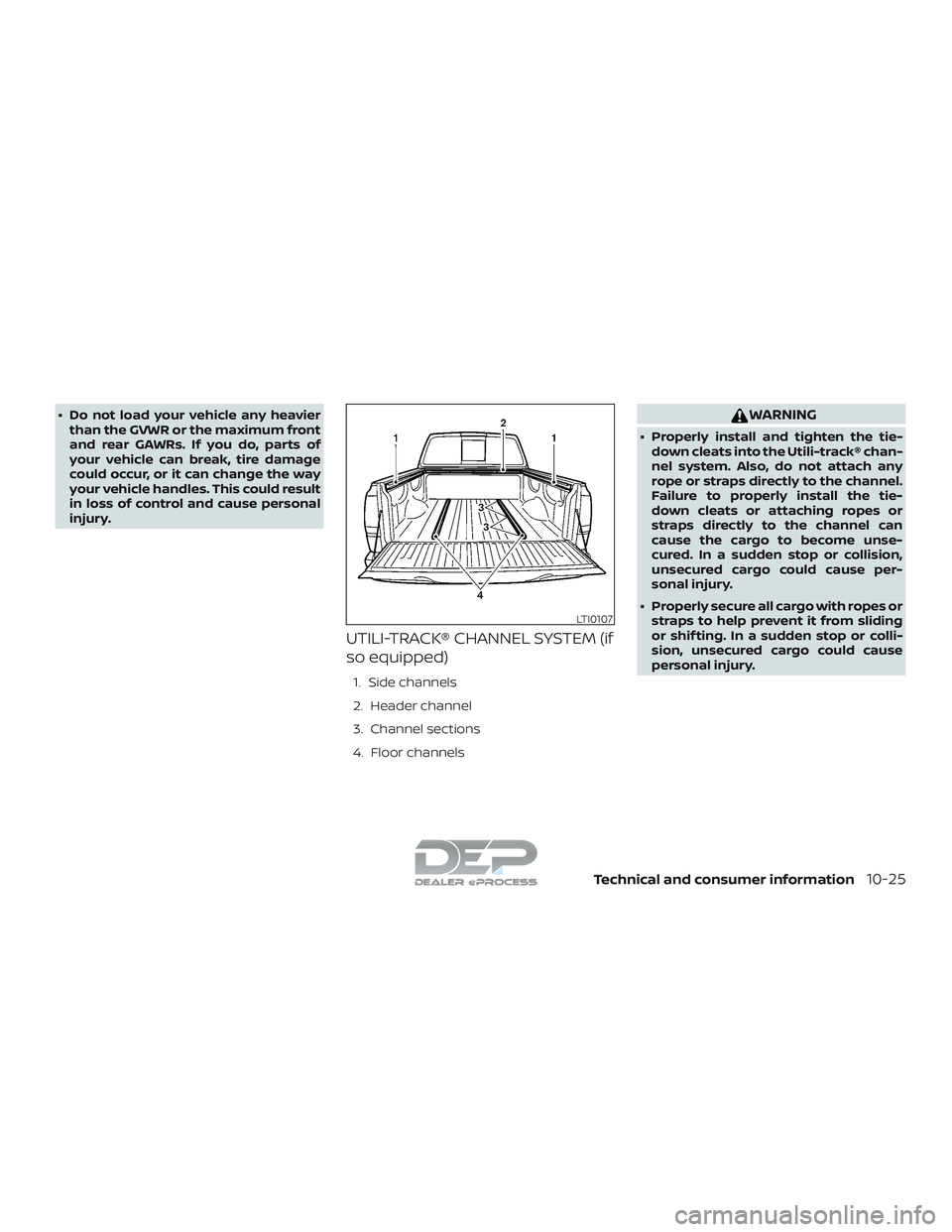

UTILI-TRACK® CHANNEL SYSTEM (if

so equipped)

1. Side channels

2. Header channel

3. Channel sections

4. Floor channels

WARNING

∙ Properly install and tighten the tie-down cleats into the Utili-track® chan-

nel system. Also, do not attach any

rope or straps directly to the channel.

Failure to properly install the tie-

down cleats or attaching ropes or

straps directly to the channel can

cause the cargo to become unse-

cured. In a sudden stop or collision,

unsecured cargo could cause per-

sonal injury.

∙ Properly secure all cargo with ropes or straps to help prevent it from sliding

or shif ting. In a sudden stop or colli-

sion, unsecured cargo could cause

personal injury.

LTI0107

Technical and consumer information10-25

Page 593 of 650

NOTE:

If the bed liner storage bins (if so

equipped) are installed on the vehicle,

use type B cleats (if so equipped) in the

side channel locations. The use of type A

cleats (if so equipped) in the side channel

locations with the bed liner storage bins

installed will interfere with bed liner

storage bin lid operation. For additional

information on bed liner storage bins, re-

fer to “Storage” in the “Instruments and

controls” section of this manual.

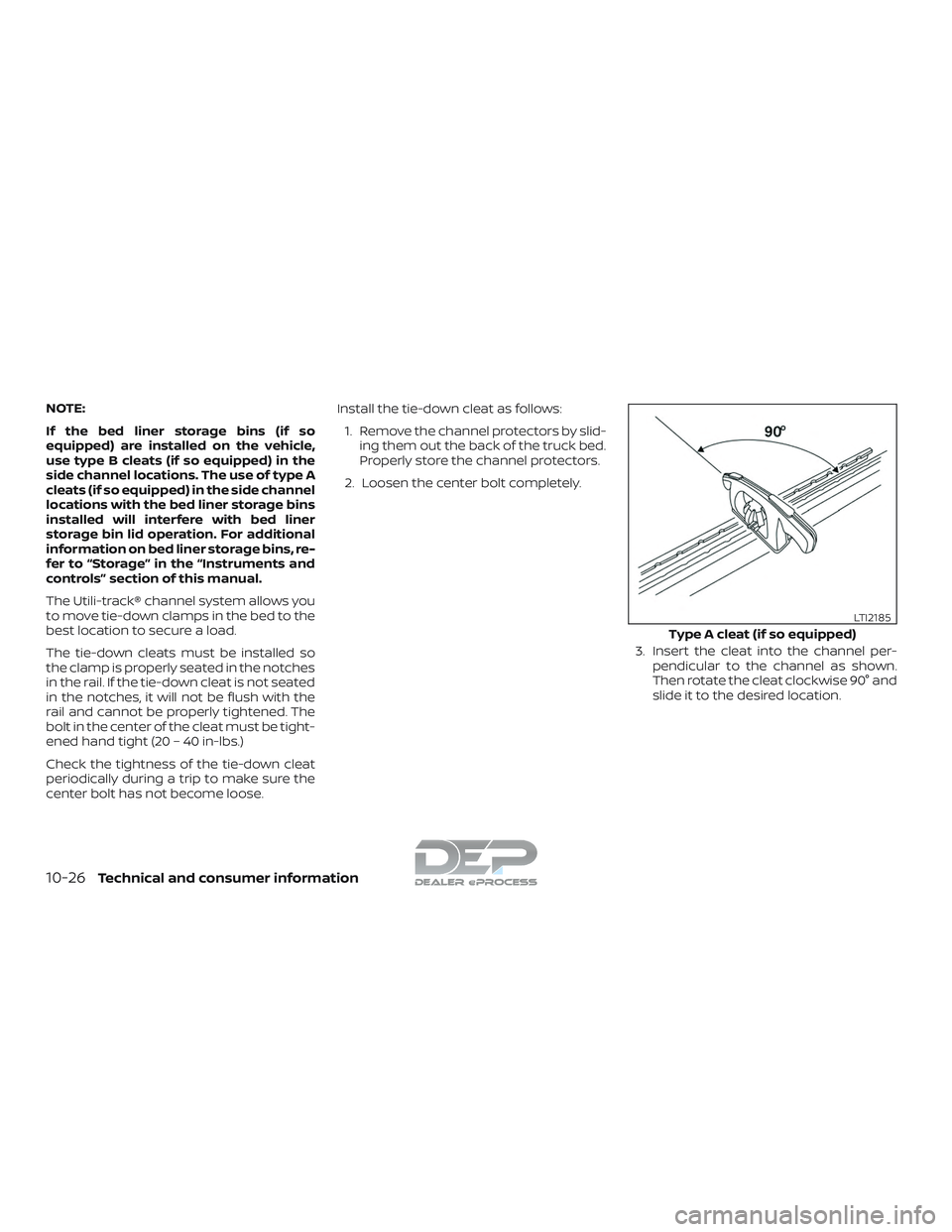

The Utili-track® channel system allows you

to move tie-down clamps in the bed to the

best location to secure a load.

The tie-down cleats must be installed so

the clamp is properly seated in the notches

in the rail. If the tie-down cleat is not seated

in the notches, it will not be flush with the

rail and cannot be properly tightened. The

bolt in the center of the cleat must be tight-

ened hand tight (20 – 40 in-lbs.)

Check the tightness of the tie-down cleat

periodically during a trip to make sure the

center bolt has not become loose.Install the tie-down cleat as follows:

1. Remove the channel protectors by slid- ing them out the back of the truck bed.

Properly store the channel protectors.

2. Loosen the center bolt completely.

3. Insert the cleat into the channel per-pendicular to the channel as shown.

Then rotate the cleat clockwise 90° and

slide it to the desired location.

Type A cleat (if so equipped)

LTI2185

10-26Technical and consumer information

Page 600 of 650

WARNING

Do not install accessories over the gap

between the front and rear side chan-

nels. Doing this could affect the rear

structure in certain rear impacts, which

could result in serious injury.

LOADING TIPS

∙ The GVW must not exceed GVWRor GAWR as specified on the

F.M.V.S.S./C.M.V.S.S. certification

label. ∙ Do not load the front and rear

axle to the GAWR. Doing so will

exceed the GVWR.

WARNING

∙ Properly secure all cargo with ropes or straps to help prevent

it from sliding or shif ting. Do not

place cargo higher than the

seatbacks. In a sudden stop or

collision, unsecured cargo could

cause personal injury. ∙ Do not load your vehicle any

heavier than the GVWR or the

maximum front and rear

GAWRs. If you do, parts of your

vehicle can break, tire damage

could occur, or it can change the

way your vehicle handles. This

could result in loss of control

and cause personal injury.

∙ Overloading not only can shorten the life of your vehicle

and the tire, but can also cause

unsafe vehicle handling and

longer braking distances. This

may cause a premature tire fail-

ure which could result in a seri-

ous accident and personal in-

jury. Failures caused by

overloading are not covered by

the vehicle’s warranty.

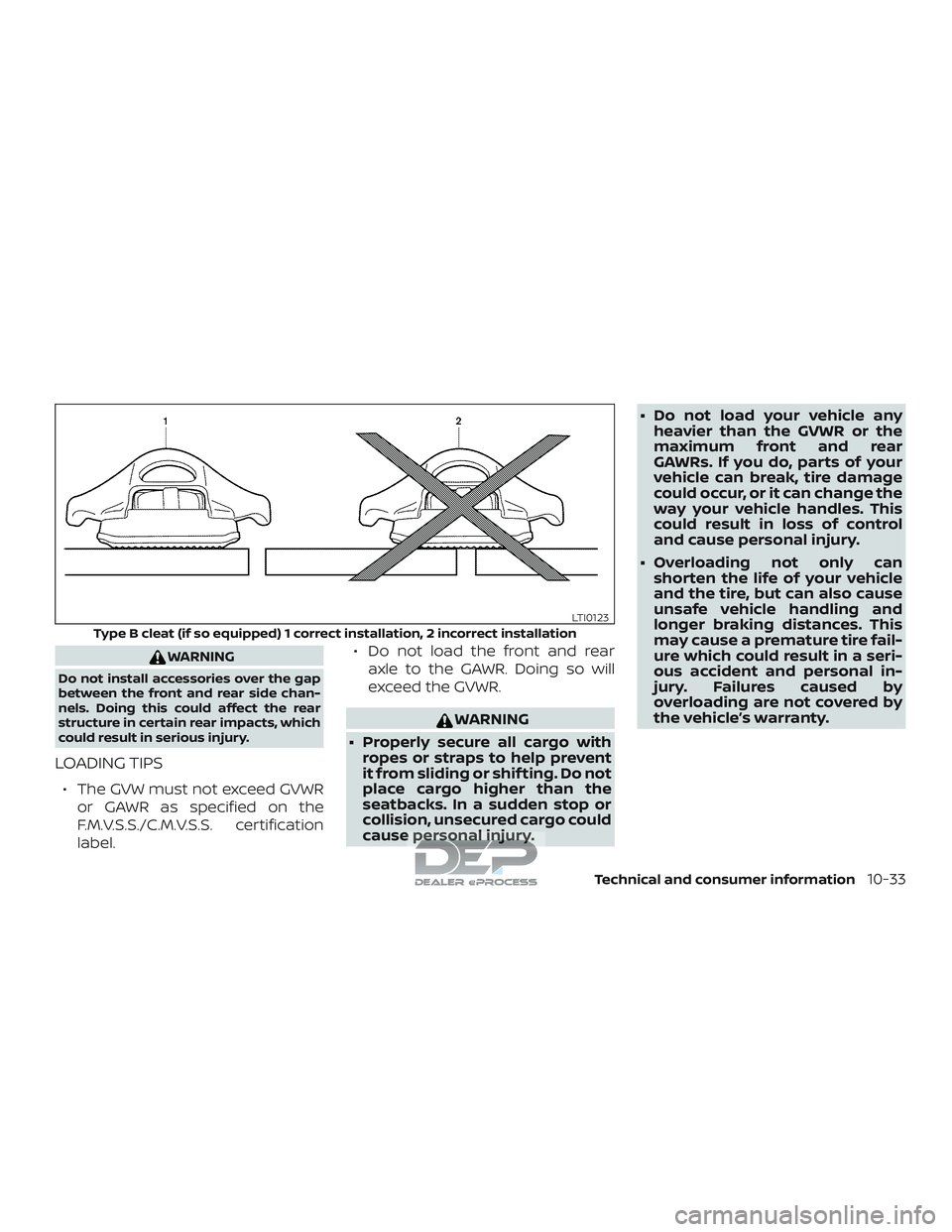

Type B cleat (if so equipped) 1 correct installation, 2 incorrect installation

LTI0123

Technical and consumer information10-33

Page 602 of 650

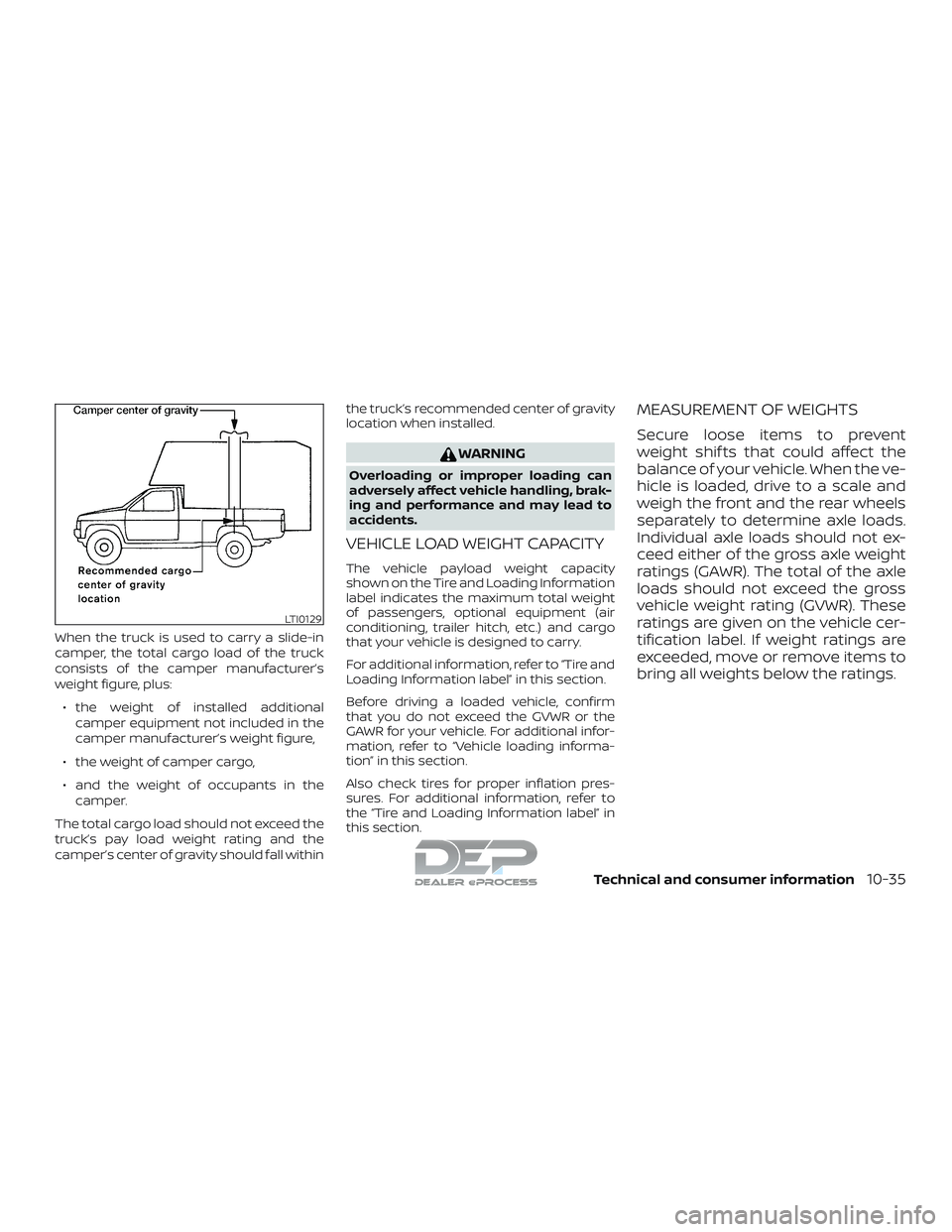

When the truck is used to carry a slide-in

camper, the total cargo load of the truck

consists of the camper manufacturer’s

weight figure, plus:∙ the weight of installed additional camper equipment not included in the

camper manufacturer’s weight figure,

∙ the weight of camper cargo,

∙ and the weight of occupants in the camper.

The total cargo load should not exceed the

truck’s pay load weight rating and the

camper’s center of gravity should fall within the truck’s recommended center of gravity

location when installed.

WARNING

Overloading or improper loading can

adversely affect vehicle handling, brak-

ing and performance and may lead to

accidents.

VEHICLE LOAD WEIGHT CAPACITY

The vehicle payload weight capacity

shown on the Tire and Loading Information

label indicates the maximum total weight

of passengers, optional equipment (air

conditioning, trailer hitch, etc.) and cargo

that your vehicle is designed to carry.

For additional information, refer to “Tire and

Loading Information label” in this section.

Before driving a loaded vehicle, confirm

that you do not exceed the GVWR or the

GAWR for your vehicle. For additional infor-

mation, refer to “Vehicle loading informa-

tion” in this section.

Also check tires for proper inflation pres-

sures. For additional information, refer to

the “Tire and Loading Information label” in

this section.

MEASUREMENT OF WEIGHTS

Secure loose items to prevent

weight shif ts that could affect the

balance of your vehicle. When the ve-

hicle is loaded, drive to a scale and

weigh the front and the rear wheels

separately to determine axle loads.

Individual axle loads should not ex-

ceed either of the gross axle weight

ratings (GAWR). The total of the axle

loads should not exceed the gross

vehicle weight rating (GVWR). These

ratings are given on the vehicle cer-

tification label. If weight ratings are

exceeded, move or remove items to

bring all weights below the ratings.

LTI0129

Technical and consumer information10-35

Page 612 of 650

TOWING SAFETY

Trailer hitch

Your vehicle may be equipped with an op-

tional trailer tow package. The trailer tow

package includes a receiver-type frame

mounted hitch. This hitch is rated for the

maximum towing capacity of this vehicle

when the proper towing equipment is

used. Choose a proper ball mount and

hitch ball that is rated for the trailer to be

towed. Genuine NISSAN ball mounts and

hitch balls are available at a NISSAN dealer.

If your vehicle is not equipped with the op-

tional trailer tow package, check the tow-

ing capacity of your bumper hitch or

receiver-type frame mounted hitch.

Choose a proper hitch for your vehicle and

trailer. A Genuine NISSAN trailer hitch is

available at a NISSAN dealer. Make sure the

trailer hitch is securely attached to the ve-

hicle to help avoid personal injury or prop-

erty damage due to sway caused by cross-

winds, rough road surfaces or passing

trucks.A hitch used for towing 5th wheel and

gooseneck trailers can also be installed on

your vehicle. Contact a professional sup-

plier of towing equipment to purchase and

have a 5th wheel or gooseneck hitch in-

stalled.

WARNING

Trailer hitch components have specific

weight ratings. Your vehicle may be ca-

pable of towing a trailer heavier than

the weight rating of the hitch compo-

nents. Never exceed the weight rating

of the hitch components. Doing so can

cause serious personal injury or prop-

erty damage.

Hitch ball

Choose a hitch ball of the proper size and

weight rating for your trailer:

∙ The required hitch ball size is stamped on most trailer couplers. Most hitch

balls also have the size printed on the

top of the ball.

∙ Choose the proper class hitch ball based on the trailer weight. ∙ The diameter of the threaded shank of

the hitch ball must be matched to the

ball mount hole diameter. The hitch ball

shank should be no more than 1/16”

smaller than the hole in the ball mount.

∙ The threaded shank of the hitch ball must be long enough to be properly

secured to the ball mount. There should

be at least 2 threads showing beyond

the lock washer and nut.

Ball mount

The hitch ball is attached to the ball mount

and the ball mount is inserted into the

hitch receiver. Choose a proper class ball

mount based on the trailer weight. Addi-

tionally, the ball mount should be chosen to

keep the trailer tongue level with the

ground.

Technical and consumer information10-45

Page 615 of 650

Weight Rating or the rear axle weight to

exceed the Rear Gross Axle Weight rating.

For additional information, refer to “Maxi-

mum load limits” in this section.

The weight of the trailer should not exceed

the maximum towing capacity for the ve-

hicle. For additional information, refer to

“Towing Load/Specification” chart in this

section.

Make sure the trailer design allows for the

correct vehicle to trailer clearances before

purchasing a 5th wheel trailer.

WARNING

∙ The hitch should not be attached to oraffect the operation of the impact-

absorbing bumper.

∙ Do not use axle-mounted hitches.

∙ Do not modif y the vehicle exhaust system, brake system, etc. to install a

trailer hitch.

∙ To reduce the possibility of additional damage if your vehicle is struck from

the rear, where practical, remove the

receiver when not in use. ∙ Regularly check that all trailer hitch

mounting bolts are securely

mounted.

∙ When towing with the hitch ball mounted to the rear bumper, do not

make sharp turns. The trailer may

contact the bumper and cause dam-

age to the bumper or trailer.

∙ When towing a 5th wheel trailer, do not make sharp turns while driving or

backing. The trailer may contact the

vehicle and cause damage to both the

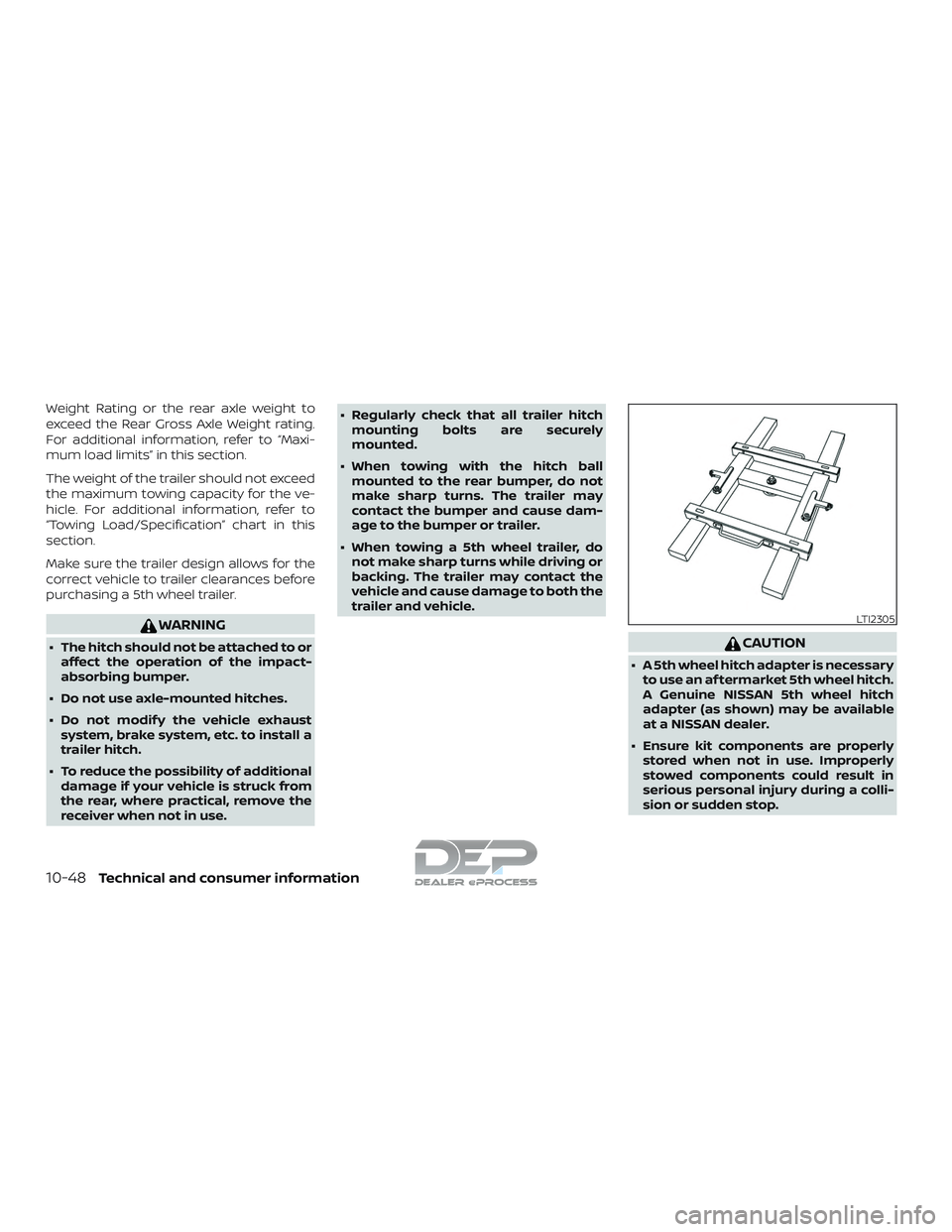

trailer and vehicle.CAUTION

∙ A 5th wheel hitch adapter is necessaryto use an af termarket 5th wheel hitch.

A Genuine NISSAN 5th wheel hitch

adapter (as shown) may be available

at a NISSAN dealer.

∙ Ensure kit components are properly stored when not in use. Improperly

stowed components could result in

serious personal injury during a colli-

sion or sudden stop.

LTI2305

10-48Technical and consumer information